check engine HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 242 of 1139

Evaporative Emission (EVAPI Control

System

Refer to the System Diagram to see the functional

layout of the system.

EVAP Canister

The EVAP canister temporarily stores fuel vapor from

the fuel tank until it can be purged back into the engine

and burned.

EVAP Canister Purge Valve

When the engine coolant temperatu re is below 149'F(65'C), the ECM turns off the EVAP canister purge valve

which cuts vacuum to the EVAP canister.

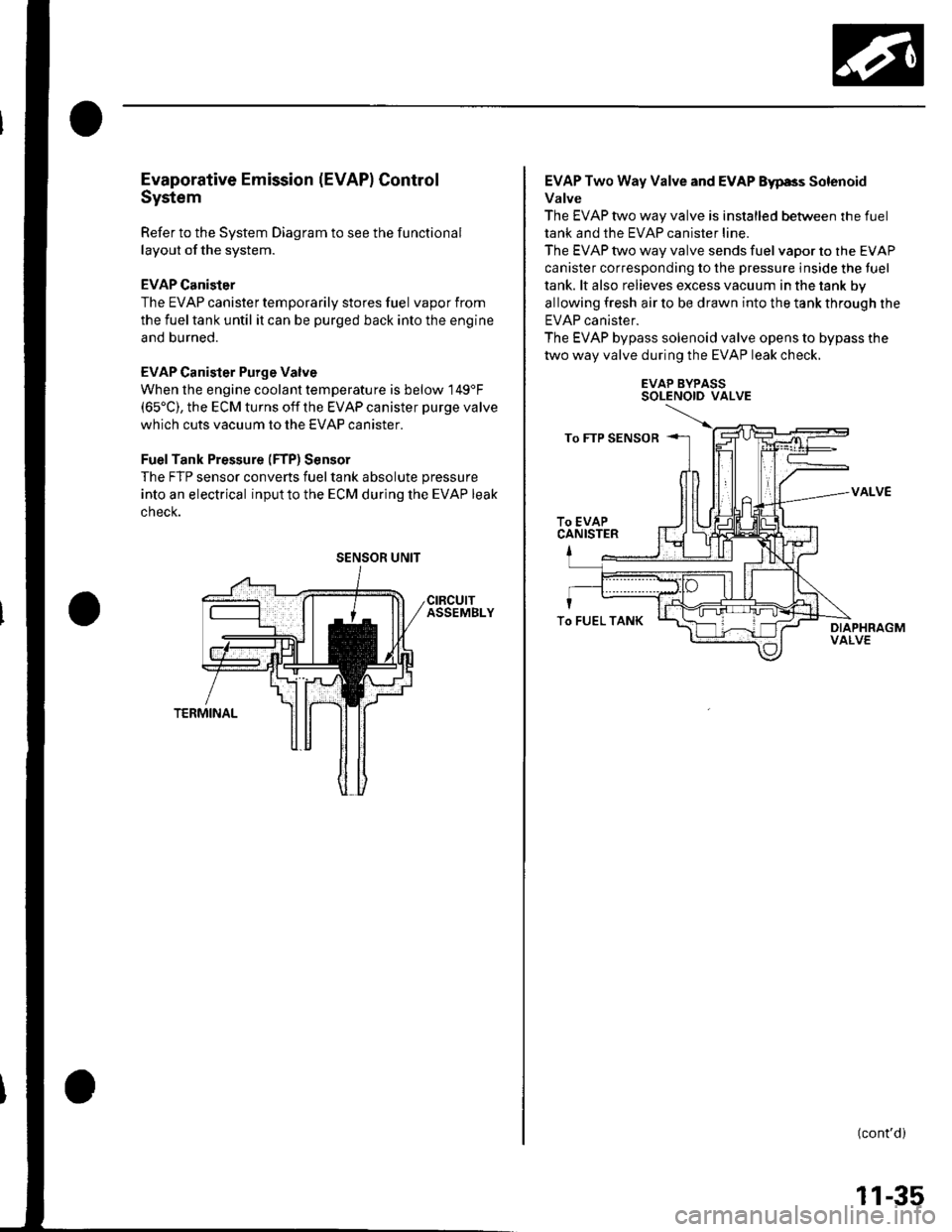

FuelTank Pressure (FTP) Sensor

The FTP sensor converts fueltank absolute pressure

into an electrical inputto the ECM during the EVAP leak

cnecK.

SENSOR UNIT

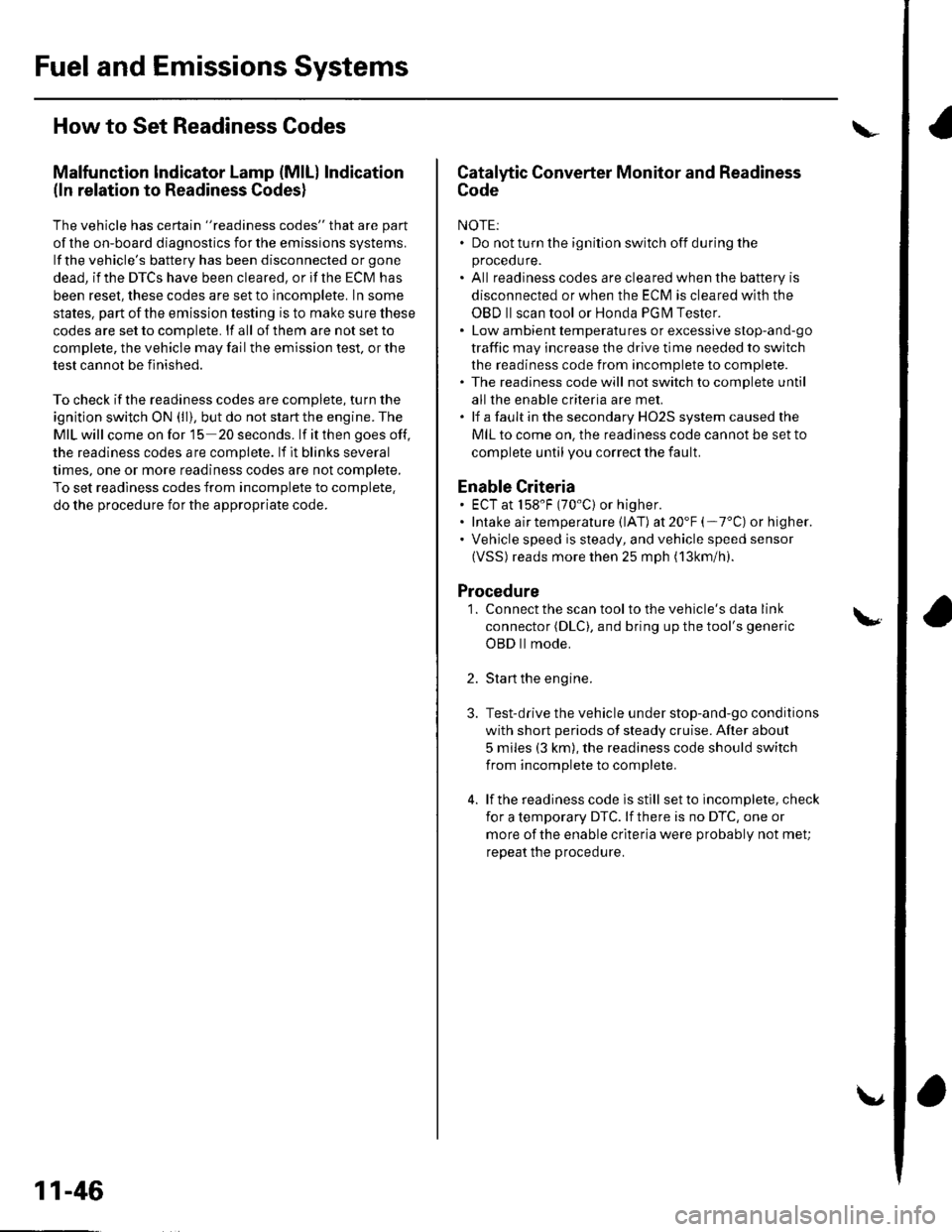

EVAP Two Way Valve and EVAP Eyp8s Solenoid

Valve

The EVAP two way valve is installed between the fuel

tank and the EVAP canister line.

The EVAP two way valve sends fuel vapor to the EVAP

canister corresponding to the pressure inside the tuel

tank. lt also relieves excess vacuum in the tank by

allowing fresh air to be drawn into the tank through the

EVAP canister.

The EVAP bypass solenoid valve opens to bypass the

two way valve during the EVAP leak check.

EVAP BYPASSSOLENOID VALVE

VALVE

(cont'd)

To FUEL TANK

11-35

Page 253 of 1139

Fuel and Emissions Systems

How to Set Readiness Codes

Malfunction lndicator Lamp (MlL) Indication

(ln relation to Readiness Codesl

The vehicle has certain "readiness codes" that are part

of the on-board diagnostics for the emissions systems.

lf the vehicle's battery has been disconnected or gone

dead, if the DTCS have been cleared, or if the ECM has

been reset, these codes are set to incomplete. In some

states, part of the emission testing is to make su re these

codes are set to complete. lf all of them are not set to

complete, the vehicle may fail the emission test, or the

test cannot be finished.

To check ifthe readiness codes are complete, turn the

ignition switch ON (ll), but do not start the engine. The

MIL will come on for 15 20 seconds. lf it then goes off,

the readiness codes are complete. lf it blinks several

times, one or more readiness codes are not complete.

To set readlness codes from incomplete to complete.

do the procedure for the appropriate code.

11-46

L

Catalytic Converter Monitor and Readiness

Code

NOTE:. Do not turn the ignition switch off during the

procedure.

. All readiness codes are cleared when the battery is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PG lvl Tester.. Low ambient temperatures or excessive slop-and-go

traffic may increase the drive time needed to switch

the readiness code from incomplete to complete.' The readiness code will not switch to com Dlete until

all the enable criteria are met.. lf a fault in the secondary HO2S system caused the

MIL to come on. the readiness code cannot be set to

comDlete until vou correct the fault.

Enable Criteria. ECT at 158"F (70'C) or higher.. Intake air temperature (lAT) at 20"F (-7'C) or higher.. Vehicle speed is steady, and vehicle speed sensor

(VSS) reads more then 25 mph (13km/h).

Procedure

1. Connect the scan tool to the vehicle's data link \

connector (DLCi, and bring up the tool's generic \"

OBD ll mode.

Start the engine.

Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. After about

5 miles (3 km), the readiness code should switch

from incomplete to complete.

lf the readiness code is still set to incomplete, check

for a temporary DTC. lf there is no DTC, one or

more of the enable crlteria were probably not met;

2.

3.

Page 254 of 1139

Evaporative Emissions (EVAP) Control

System Monitor and Readiness code

NOTE:

All readiness code are cleared when the batterV is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester.

The enable criteria must be repeated if the intake air

temperature (lAT) drops lower than 36'F (20"C) from

its value at engine $an up.

Enable Criteria

At engine start up, ECT and IAT are higher than 32'F(0"C) , but lower than 95'F (35"C).

At engine start up, the ECT and IAT are within 12'F(7'C) of each other.

Procedure

1. Connect the scan tool to the vehicle's data link

connector (DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine.

3. Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. After about

2.5 miles (1.6 km), the readiness code should

switch f rom incomplete to complete.

4. lf the readinesscode isstill setto incomplete, check

for a temporary DTC. lf there is no DTC, one or

more of the enable criteria were probably not met;

repeat the procedure.

Air Fuel Ratio (A/Fl Sensor Monitor and

Readiness Code

NOTE:. Do not turn the ignition switch off during the

orocedure.. All readiness codes are cleared when the baftery is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester.

Enable Criteria

ECT at 140'F (60"C) or higher.

Procedure

1. Connect the scan toolto the vehicle's data link

connector (DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine.

3. Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. During the

drive, decelerate (wirh the throttle fully closed) for

5 seconds. After about 3.5 miles (2.2 km). the

readiness code should switch from incomDlete to

complete.

4. lfthereadinesscodeisstill set to incomplete, check

for a temporary DTC. lfthere is no DTC, the enable

criteria was probably not meU repeat the procedure.

Air/Fuel Ratio (A/Fl Sensor Heater Monitor

Readiness Code

NOTE; All readiness codes are cleared when the battery

is disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester,

Procedure'1. Connect the scan tool to the vehicle's data link

connector {DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine, and let it idle for 1 minute. The

readiness code should switch from incomplete to

comDlete.

3. lf the readiness code is still set to incomplete, check

for a temporary DTC. lf there is no DTC, repeat theproceoure.

(cont'd)

11-47

Page 260 of 1139

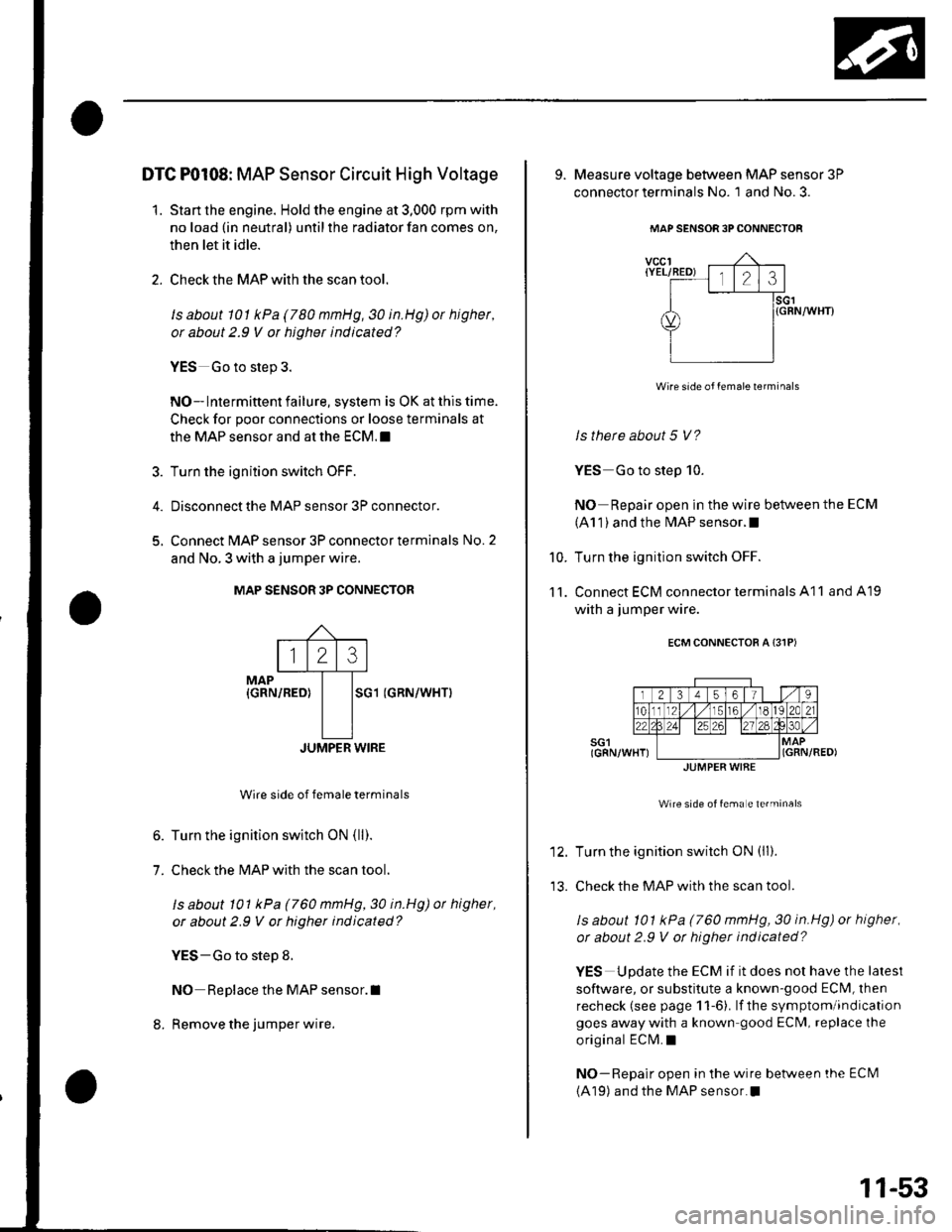

DTC P0108: MAP Sensor Circuit High Voltage

'1. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

2. Check the MAP with the scan tool.

le about 101 kPa (780 nmHg, 30 in.Hg) ot highet,

or about 2.9 V or higher indicated?

YES Go to step 3.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the MAP sensor and at the ECM.I

3. Turn the ignition switch OFF.

4. Disconnectthe MAP sensor 3P connector.

5, Connect MAP sensor 3P connector terminals No. 2

and No. 3 with a jumper wire.

MAP S€NSOR 3P CONNECTOR

MAP{GRN/REO}SG1 (GRN/WHTI

JUMPER WIRE

Wire side of female terminals

6. Turn the ignition switch ON (ll).

7. Check the MAP with the scan tool.

ls about 101 kPa (760 mmHg,30 in.Hg) ot higher,

or about 2.9 V or higher indicated?

YES-Go to step 8.

NO Replace the MAP sensor.I

8. Remove the jumper wire.

123

9. Measure voltage between MAP sensor 3P

connector terminals No. 1 and No. 3.

MAP SENSOR 3PCONNECTOF

vccl{YEL/RED) l,lo cll.l.rl

I lsct

d) l{GRN/wHrr

YIilll

Wire side of female lerminals

ls there about 5 V?

YES Go to step 10.

NO Repair open in the wire between the ECM

(A1 1 ) and the MAP sensor.I

Turn the ignition switch OFF.

Connect ECM connector terminals A11 and A19

with a jumper wire.

ECM CONNECTOR A {31PI

Wire side of fema e te.minals

Turn the ignition switch ON (ll).

Check the MAP with the scan tool.

ls about 101 kPa (760 mmHg, 30 in.Hg) or higher,

or about 2.9 V ot higher indicated?

YES Update the ECM if it does not have the lalest

software, or substitute a known-good ECM, lhen

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known good ECM, replace the

original ECM.I

NO-Repair open in the wire betlveen the ECI\il

(A19) and the MAP sensor.I

10.

11.

JUMPER WIAE

11-53

Page 261 of 1139

PGM-FI System

a

DTC Troubleshooting (cont'dl

DTC Pl128: MAP Sensor Signal Lower Than

Expected

1. Turn the ignition switch ON (ll).

2. Check the MAP with the scan tool.

ls 54.1 kPa(406mmHg, 16.0in.Hg), 1.6 V, or

higher indicated?

YES- Intermittent failure. system is OK at this

time.I

NO Replace the MAP sensor.l

11-54

\

\

DTC Pl129: MAP Sensor Signal Higher Than

Expected

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then Iet it idle.

2. Check the MAP with the scan toot.

ls 36.9 kPa (277 mmHg, 10.9 in.Hg), 1.1 V , or less

indicated?

YES- lntermittent failure, system is OK at this

time.l

NO Replace the MAP sensor.l

\

Page 262 of 1139

4.

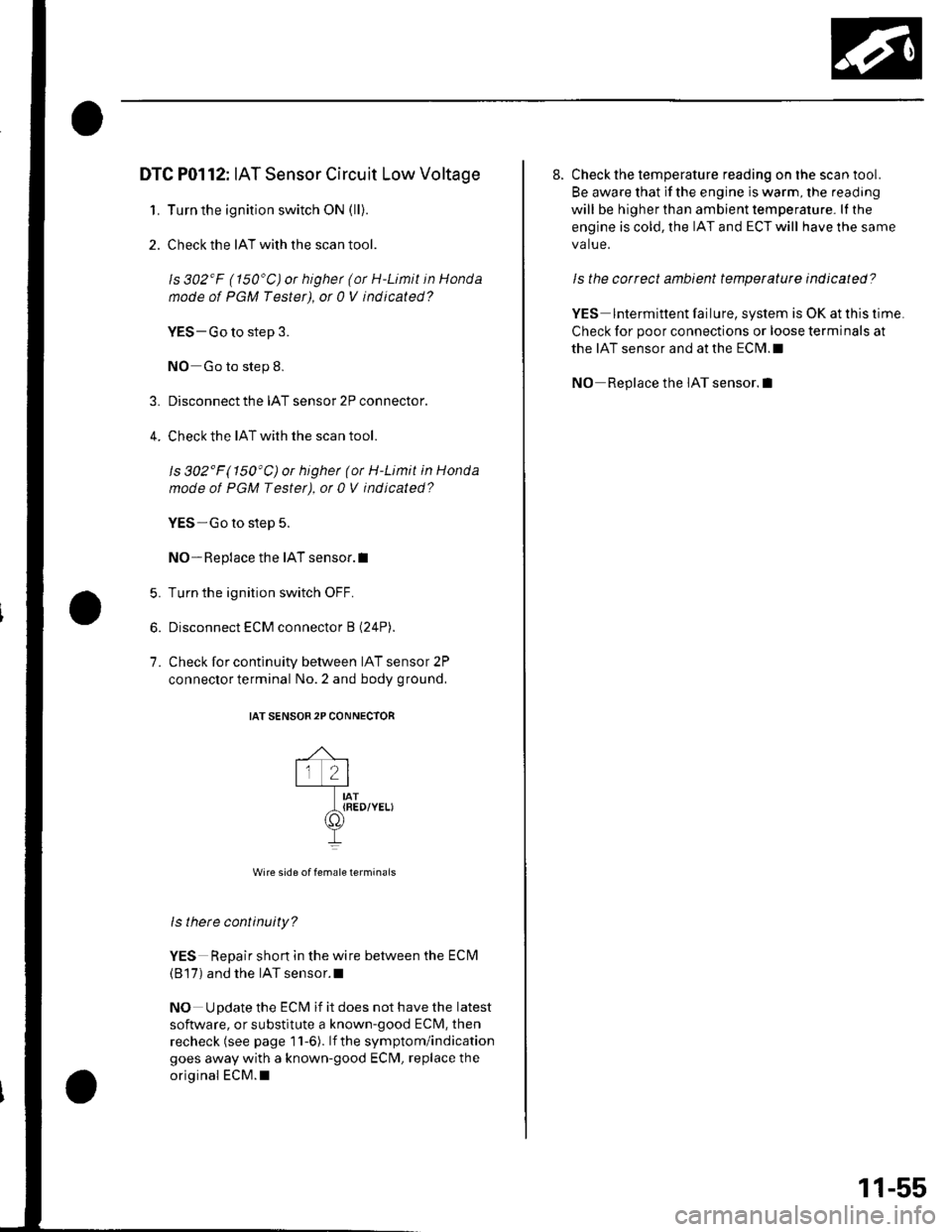

DTC P0112: IAT Sensor Circuit Low Voltage

1. Turn the ignition switch ON (ll).

2. Check the IAT with the scan tool.

ls 302'F (150'C) or highet (or H-Limit in Honda

node of PGM Tester), ot 0 V indicated?

VES-Go to step 3.

NO Go to step 8.

Disconnect the IAT sensor 2P connector.

Check the IAT with the scan tool.

ls 302'F(150'C)or higher (or H-Limit in Honda

mode of PGM Testet), ot 0 V indicated?

YES-Go to step 5.

NO- Replace the IAT sensor.I

Turn the ignition switch OFF.

Disconnect ECM connector B (24P).

Check for continuity between IAT sensor 2P

connector terminal No. 2 and body ground,

IAT SENSOR2P CONNECTOR

,^ ,lr 2lt-l-----Tr---IAT_t{RED/YELI

II

Wire side of female terminais

ls there continuity?

YES Repair shon in the wire between the ECM

(B'17) and the IAT sensor.l

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

5.

6.

7.

8. Check the temperature reading on the scan tool.

Be aware that if the engine is warm, the reading

will be higher than ambient temperature. lI the

engine is cold, the IAT and ECT will have the same

va lue.

ls the correct ambient temperature indicated?

YES lntermittent failure, system is OK at this time

Check for poor connections or loose terminals at

the IAT sensor and at the ECM.I

NO Replace the IAT sensor.l

11-55

Page 264 of 1139

DTC P0116: ECT Sensor Range/Performance

Problem

NOTE: lf DTC P0117 and/or P0118 are stored at the

same time as DTC P0116, troubleshoot those DTCS first,

then recheck for DTC P0116,

1. Stanthe engine. Hold the engine at 3,000 rpm with

no load {in neutral) until the radiator fan comes on,

then let it idle.

2. Check the ECT with the scan tool.

ls 176- 212'F (80 100"C)or0.5 0.8V

indicated?

YES Intermittent failure. system is OK at this time.

Check the thermostat and the cooling system.l

NO-Checkthe thermostat and the cooling system.

lf they are OK, replace the ECT sensor.l

11-57

Page 271 of 1139

PGM-FI System

aDTG Troubleshootang (cont'dl

DTC P0128: Cooling System Malfunction

NOTE; lf the DTCS listed below are stored at the same

time as DTC P0128. troubleshoot those DTCS first, thenrecheck for P0128.

P0107, P0108, P1128, P1129: N4anifold absolutepressure (MAP) sensor

P] I06, P1 107, P1 108: Barometric pressure (BARO)

sensor

P1259: VTEC system

P01 16, P01 17, P01 18: Engine coolant temperature (ECT)

sensor

P01 12, P01 13: Intake air temperature (lAT) sensor

P0500: Vehicle speed sensor {VSS)P0335, P0336: Crankshaft position (CKP) sensor

P0300: Random misfire

P0301, P0302, P0303, P0304: No. 1, No. 2, No.3 or No.4

cylinder misfire

P0505: ldle control system malfunction

P1519: ldle air control (lAC)valve

DTC P0128 can occasionally set when the hood is

opened while the engine is running.

1. Check the engine coolant level

Is the engine coolant level low?

VES Refill the engine coolant. lf necessary, repair

the coolant leakage.l

NO Go to step 2.

2. Turn the ignition switch ON (ll), and make sure the

A,/C is off.

11-64

\

3. Check the radiator fan.

Does the tadiator fan keep running?

YES Checkthe rad iato r fan circuit (see page 10-

14), the radiator fan switch circuit (Short) (see page

10-'16), and the radiator fan switch (see page 10-17).

Also, inspect the ECT and IAT circuits and terminal

connections. lf the circuits, the switch, and the

connections are OK, update the ECI\4 if it does not

have the latest software. or substitute a known-good ECM, then recheck (see page 1 1-6). lf the

symptom/indication goes away with a known-good

ECM, replace the original ECM.I

NO Replace the thermostat (see page 10-8).1

Page 272 of 1139

DTC P0134: Ay'F Sensor (Sensor 1) No Activity

Detected

1. Check the attachment state of the A,/F sensor(Sensor 1).

ls it slacked f rom the exhaust pipe?

YES- Reinstall the Ay'F sensor (Seneor 1) (see page

11-113).t

NO-Go to step 2.

2. Reset the ECM (see page 1 1-4).

3. Stan the engine. Hold the engine speed at

3,000rpm with no load (in neutral) until the radiator

fan comes on, then let it idle for 2 minute.

ls DTC PO134 indicated?

YES-Replace the Ay'F sensor {Seneor 1) (see page

11-113).t

NO - Intermittent failu re, sistem is OK at this time.

Check for poor connections or loose terminals at

the Ay'F sensor (Seneor 1 ) and the ECM.I

DTC P0137: Secondary HO2S (Sensor 2)

Circuit Low Voltage

1. Reset the ECM (see page I1-4)

2. Start the engine. Hold the engine at 3,000 rpm wilh

no load (in neutral) until the radiator fan comes on.

3. Check the secondary HO2S (Sensor 2) output

voltage at 3,000 rpm with the scan tool.

ls there 0.3 V or less?

YES Go to step 4.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the secondary HO2S (Sensor 2) and at the ECM.I

Turn the ignition switch OFF.

Disconnect the secondary HO2S (Sensor 2) 4P

connector.

Turn the ignition switch ON (ll).

Check the secondary HO2S (Sensor 2) output

voltage with the scan tool.

ls there 0.3 V or less?

YES Go to step 8.

NO Replace the secondary HO2S (Sensor 2).1

Turn the ignition switch OFF.

Disconnect ECM connector E (31P).

icont'd)

4.

5.

6.

7.

8.

9.

11-65

Page 273 of 1139

PGM-FISystem

aDTC Troubleshooting (cont'dl

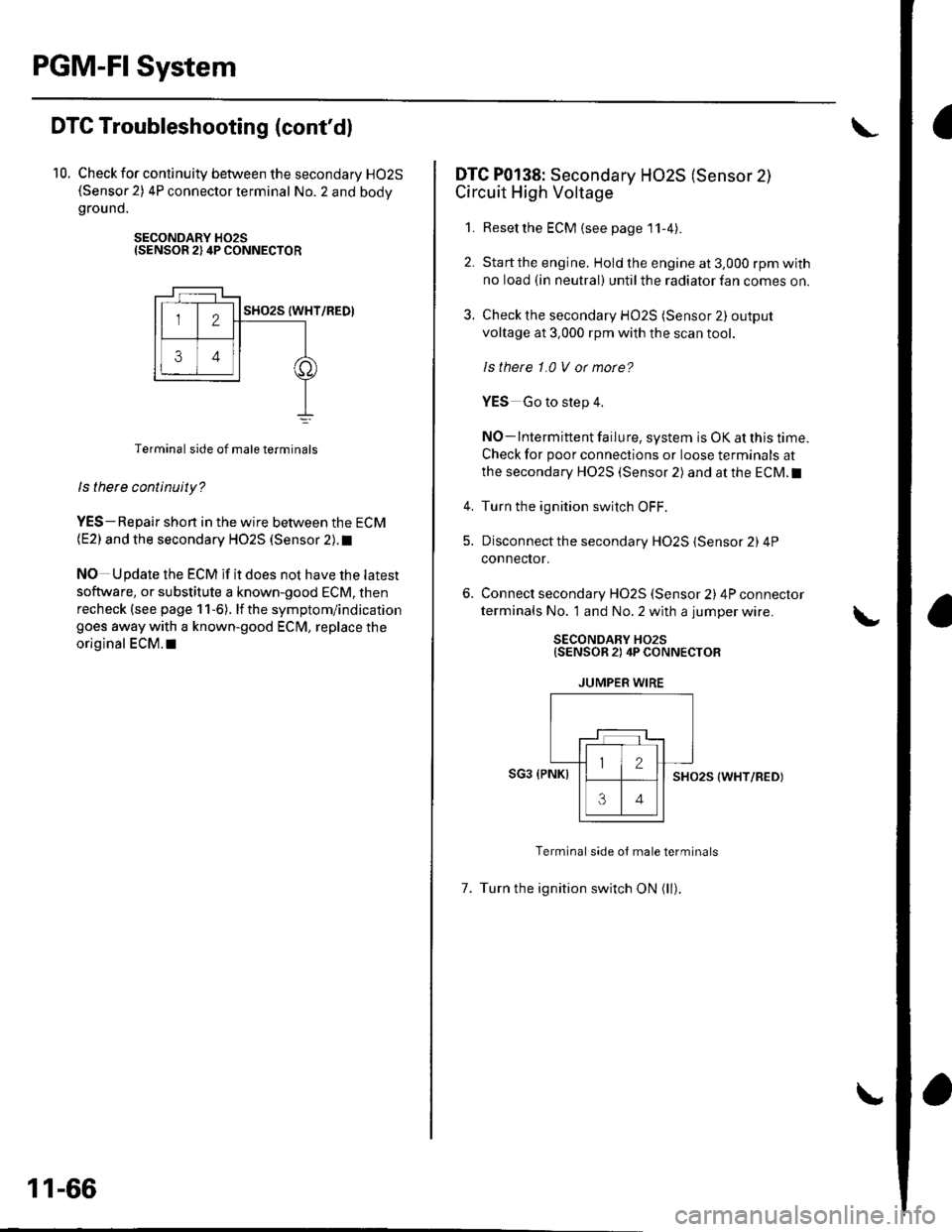

10. Check for continuity between the secondary HO2S(Sensor 2) 4P connector terminal No. 2 and bodygrou nd.

SECONDARY H02SISENSOR 2) 4P CONNECTOR

Terminal side of male terminals

ls there continuity?

YES-Repair shon in the wire between the ECM(E2) and the secondary HO2S (Sensor 2). t

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I|

11-66

DTC P0138: Secondary HO2S (Sensor 2)

Circuit High Voltage

1. Resetthe ECM {see page'11-4).

2. Startthe engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

3. Check the secondary HO2S (Sensor 2) output

voltage at 3,000 rpm with the scan tool.

ls thete 1.0 V or morc?

YES Go to step 4.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the secondary HO2S (Sensor 2) and at the ECM.I

4. Turn the ignition switch OFF.

5. Disconnect the secondary HO2S (Sensor 2) 4P

connector.

Connect secondary H02S (Sensor 2) 4P connector

terminals No. 1 and No. 2 with a jumper wire.

SECONDARY HO2S{SENSOR 2) 4P CONNECTOR

JUMPER WIRE

SG3 (PNKISHO25 (WHT/RED)

Terminal side oJ male terminals

7. Turn the ignition switch ON (ll).