HONDA CIVIC 2003 7.G Workshop Manual

Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 681 of 1139

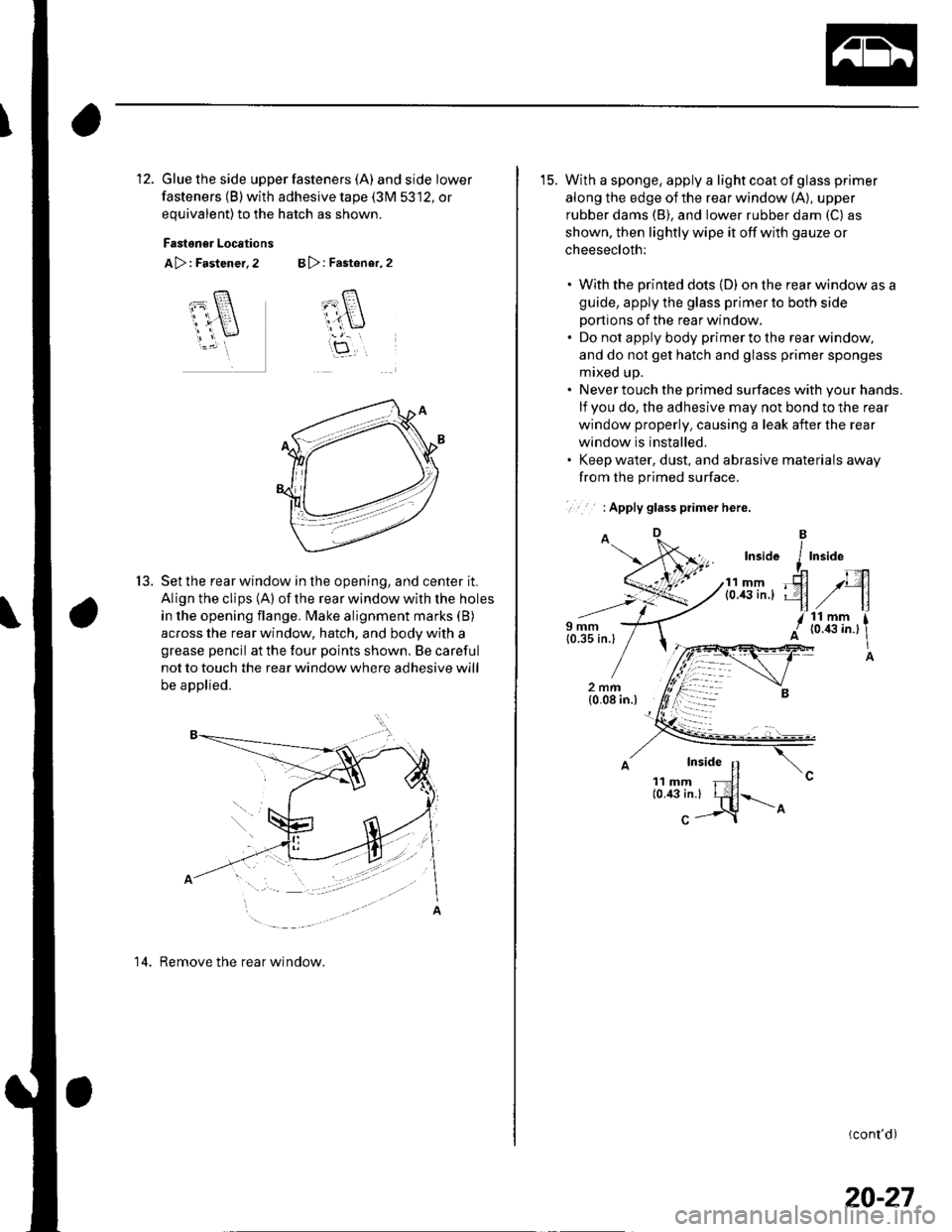

12. Glue the side upper fasteners (A) andsidelower

fasteners (B) with adhesive tape (3M 5312, or

equivalent)to the hatch as shown.

Fastoner Locations

A>: Fastener, 2 B >: Fastener, 2

T-8.

cl

ar\

itf,

t5.Set the rear window in the opening, and center it.

Align the clips (A) of the rear window with the holes

in the opening flange. Make alignment marks (B)

across the rear window, hatch, and body with a

grease pencil at the four points shown. Be careful

not to touch the rear window where adhesive will

be applied.

14. Remove the rear window.

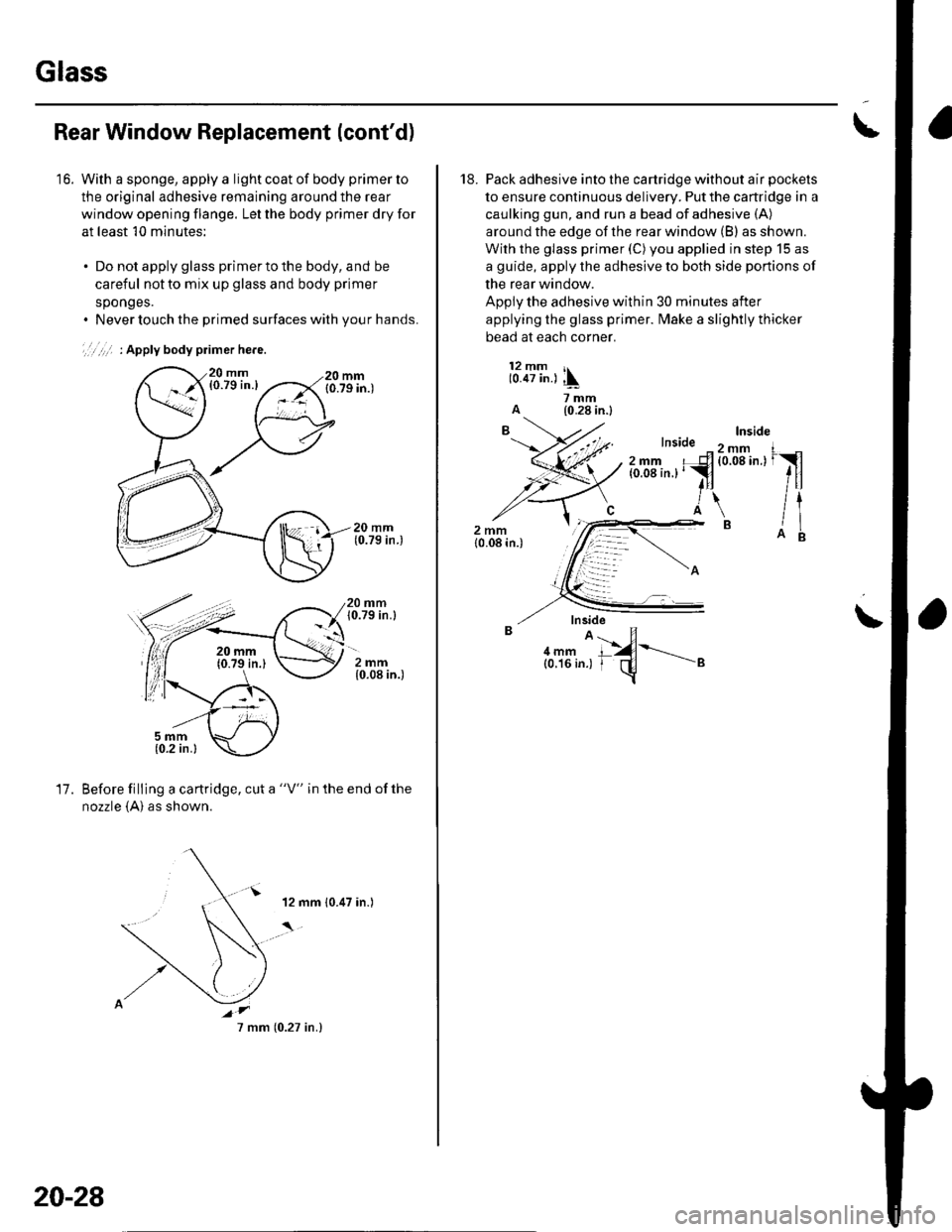

15. With a sponge, apply a light coat of glass primer

along the edge of the rear window (A), upper

rubber dams (B), and lower rubber dam (C) as

shown, then lightly wipe it off with gauze or

cheesecloth:

. With the printed dots (D) on the rear window as a

guide, apply the glass primer to both side

portions of the rear window.. Do not apply body primer to the rear window,

and do not get hatch and glass primer sponges

mixed up.. Never touch the primed surfaces with your hands.

lf you do, the adhesive may not bond to the rear

window properly. causing a leak after the rear

window is installed.. Keep water, dust, and abrasive materials away

from the primed surface.

.. : Apply glass piimer here.

(cont'd)

20-27

Page 682 of 1139

Glass

16.

Rear Window Replacement (cont'd)

With a sponge, apply a light coat of body primer to

the original adhesive remaining around the rear

window opening flange. Let the body primer dry for

at least 10 minutes;

. Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.. Never touch the primed surfaces with your hands.

',,,,,' : Apply body primer he.e.

20 mm10.79 in.l

2mm{0.08 in.)

17.Before filling a cartridge, cut a "V" in the end ofthe

nozzle {A} as shown.

20-28

7 mm (0.27 in.)

I

18. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive (A)

around the edge of the rear window (B) as shown.

With the glass primer (C) you applied in step 15 as

a guide, apply the adhesive to both side portions of

the rear window.

Apply the adhesive within 30 minutes after

applying the glass primer. fMake a slightly thicker

bead at each corner.

12 mm r,10.47 in.) ,\

ii'-A (0.28 in.l

\

aru'.1{-----"

Page 683 of 1139

19. Use suction cups to hold the rear window over the

opening. align it with the alignment marks you

made in step '13, and set it down on the adhesive.

Lightly push on the rear window until its edges are

fully seated on the adhesive all the way around. Do

not open or close the doors until the adhesive is dry.

20. Scrape or wipe the excess adhesive off with a putty

knife or towel. To remove adhesive from a painted

surface or the rear window, use a soft shop towel

dampened with alcohol.

21. Let the adhesive dry for at least 'l hour,thenspray

water over the rear window and check for leaks.

Mark the leaking areas, let the rear window dry,

then seal with sealant. Let the vehicle stand for at

least 4 hours after rear window installation, lf the

vehicle has to be used within the first 4 hours, it

must be driven slowly.

22. Reinstallall remaining removed parts.

NOTE: Advise the customer not to do the following

things for 2 to 3 days:

. Slam the doors with all the windows rolled up.. Twist the body excessively (such as when going

in and out of driveways at an angle or driving

over rough, uneven roads).

Ouarter Glass Replacement

NOTE:. Put on gloves to protect your hands.. Wear eye protection while cufting the glass adhesive

with piano wire,. Use seat covers to avoid damaging any surfaces.

1. Remove the C-pillar trim (see page 20-51).

lf necessary, remove the rear side trim panel (see

page 20-51 ) and B-pillar upper trim (see page 20-

50).

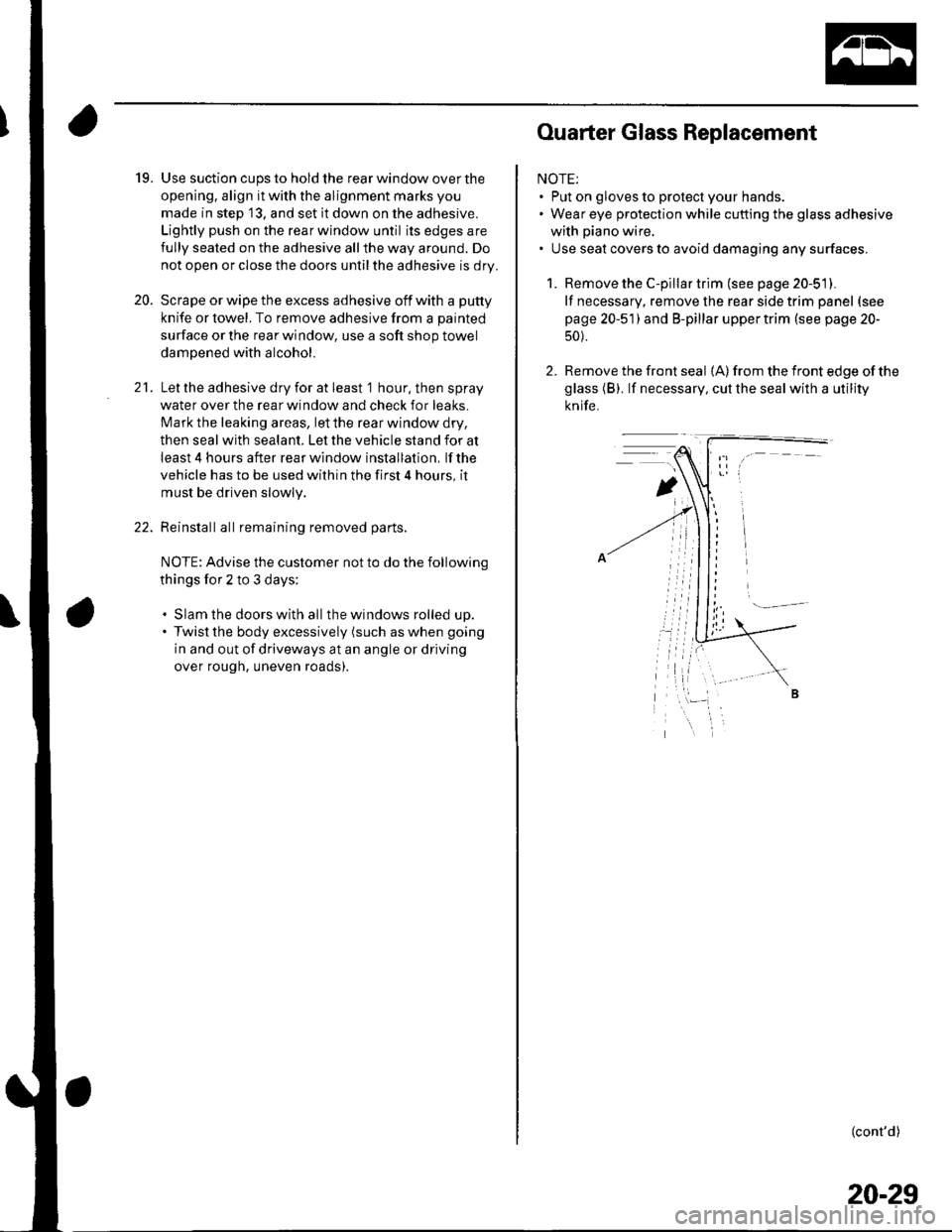

2. Remove the front seal {A) from the front edge of the

glass (B). lf necessary, cut the seal with a utility

knife.

(cont'd)

20-29

Page 684 of 1139

Glass

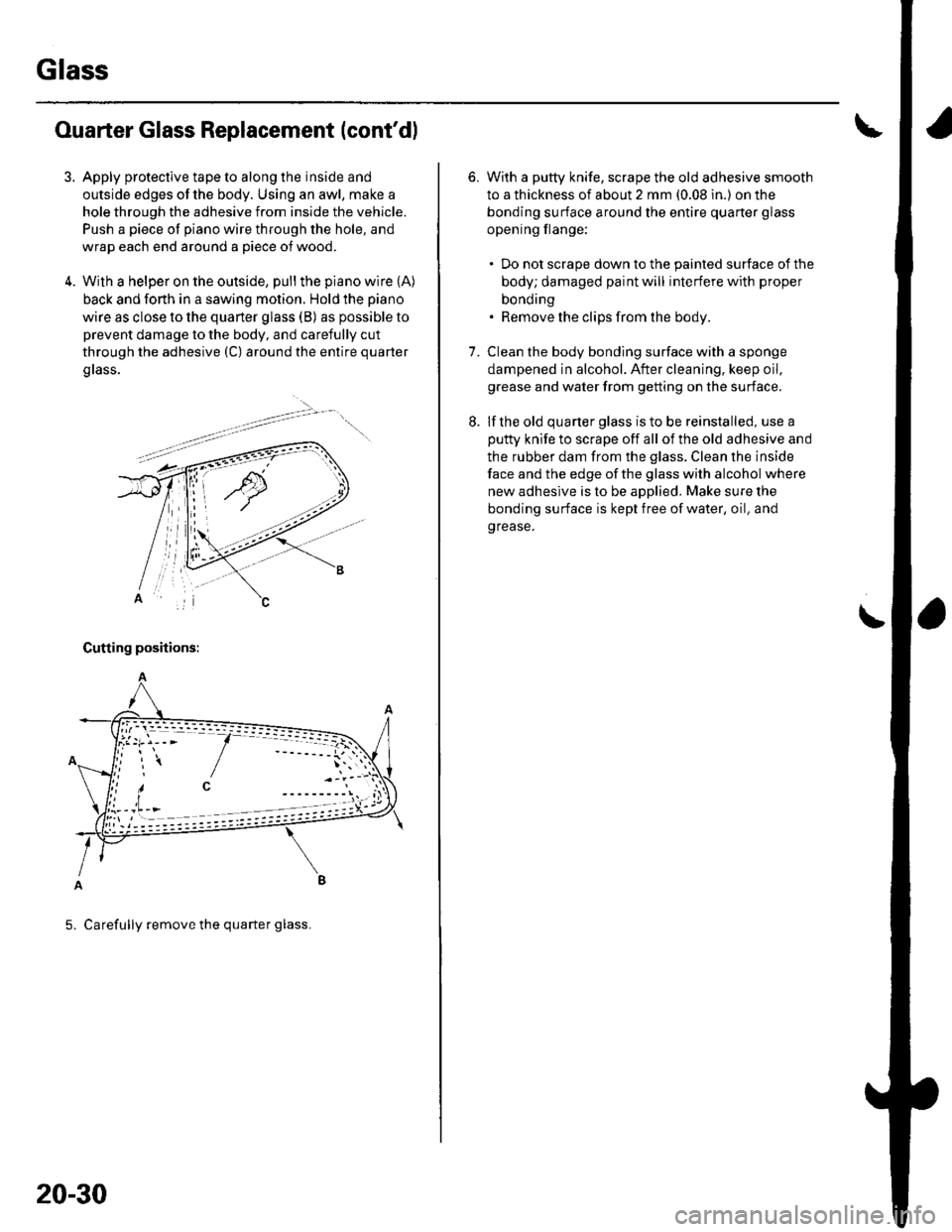

3.

Ouarter Glass Replacement (cont'dl

Apply protective tape to along the inside and

outside edges of the body. Using an awl, make a

hole through the adhesive from inside the vehicle.

Push a piece of piano wire through the hole, and

wrap each end around a piece of wood.

With a helper on the outside, pull the piano wire (A)

back and forth in a sawing motion. Hold the piano

wire as close to the quarter glass (B) as possible to

prevent damage to the body, and carefully cut

through the adhesive (C) around the entire quarter

grass.

Cutting positions:

5. Carefully remove the quarter glass.

20-30

6.With a putty knife, scrape the old adhesive smooth

to a thickness of about 2 mm (0.08 in.) on the

bonding surface around the entire quaner glass

opening flange:

. Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding. Remove the clips from the body.

Clean the body bonding surface with a sponge

dampened in alcohol. After cleaning. keep oil,

grease and water from getting on the surface.

lf the old quarter glass is to be reinstalled, use a

putty knife to scrape off all of the old adhesive and

the rubber dam from the glass. Clean the inside

face and the edge of the glass with alcohol where

new adhesive is to be applied. Make sure the

bonding su rface is kept free of water, oil, and

grease.

7.

Page 685 of 1139

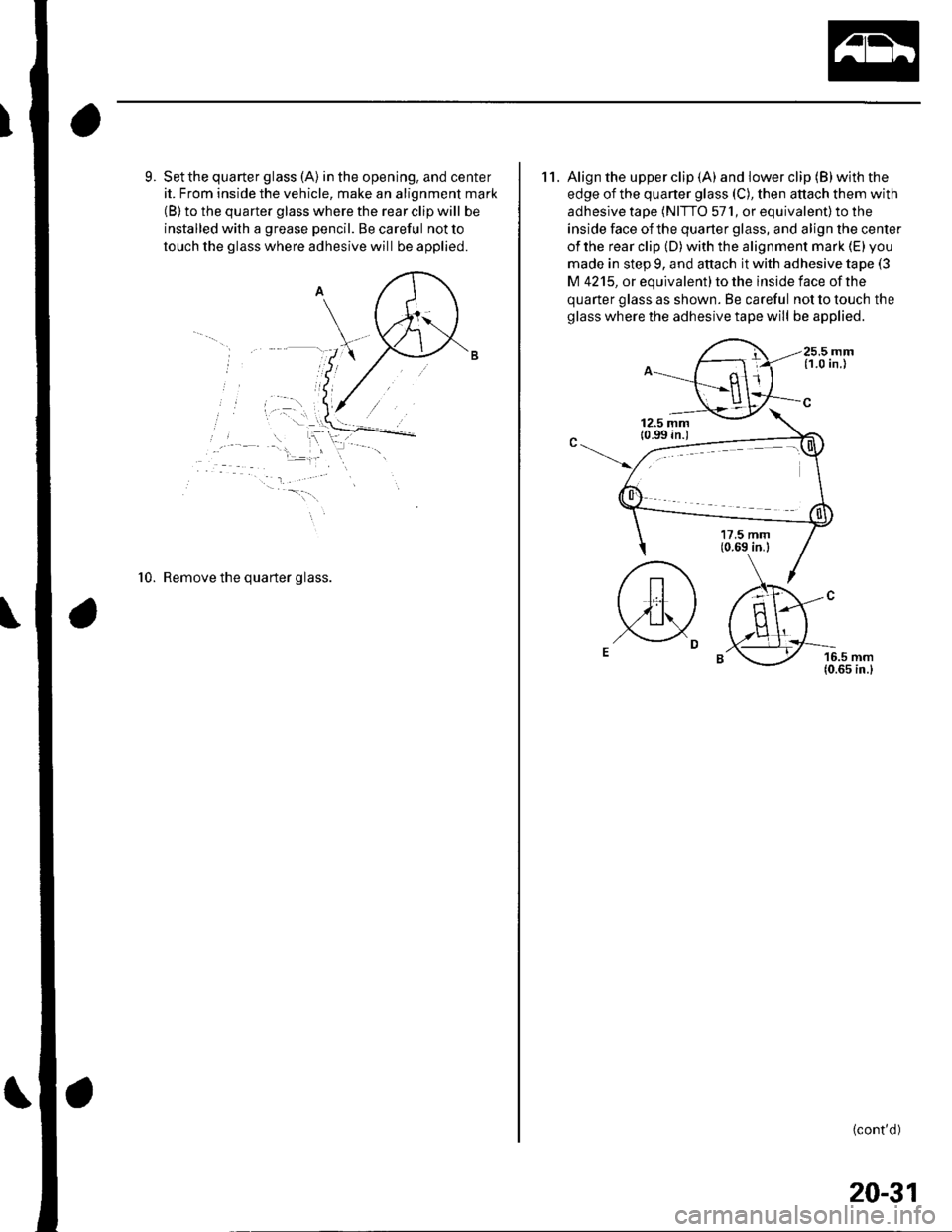

9. Set the quarter glass (A) in the opening, and center

it. From inside the vehicle, make an alignment mark(B) to the quarter glass where the rear clip will be

installed with a grease pencil. Be careful not to

louch the glass where adhesive will be applied.

10. Remove the quarter glass.

1 1. Align the upper clip {A) and lower clip (B) with the

edge of the quarter glass (C), then anach them with

adhesive tape (NITTO 571, or equivalent) to the

inside face of the quarter glass, and align the center

of the rear clip (D) with the alignment mark (E) you

made in step 9, and attach it with adhesive tape (3

M 4215, or equivalent) to the inside face of the

quarter glass as shown. Be careful not to touch the

glass where the adhesive tape will be applied.

25.5 mm{1.0 in.)

(cont'd)

20-31

Page 686 of 1139

Glass

Ouarter Glass Replacement (cont'dl

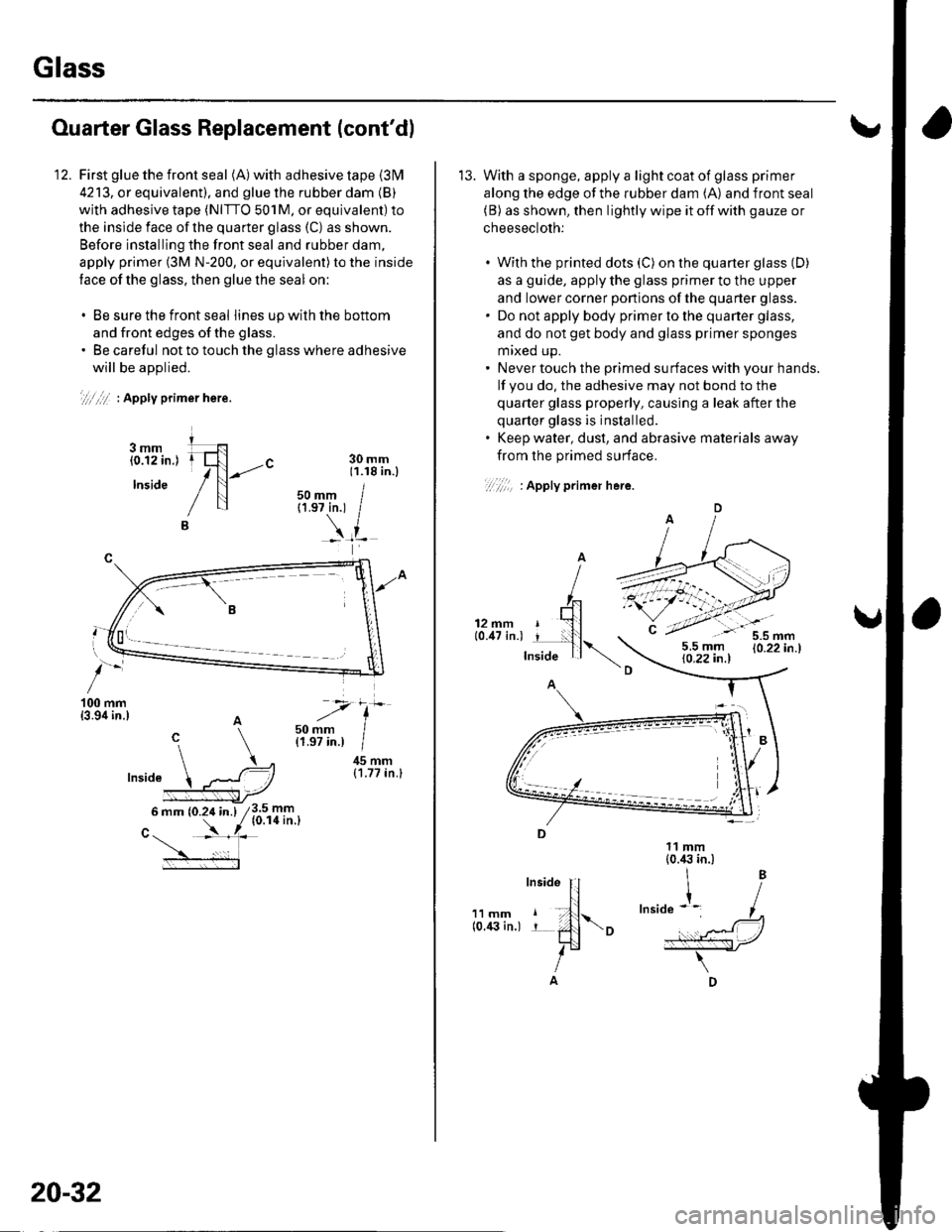

First glue the front seal (A) with adhesive tape {31\4

4213, or equivalent). and glue the rubber dam (B)

with adhesive tape (NITTO 501M, or equivalent) to

the inslde face of the quarter glass (C) as shown.

Before installing the front seal and rubber dam,

apply primer (3M N-200, or equivalent)to the inside

tace of the glass. then glue the seal on:

. Be sure the front seal lines upwiththe bottom

and front edges of the glass.. Be careful not to touch the glass where adhesive

will be aoolied.

.,1.,,/:/ | Apply prlJner hete.

-"-c

i--l

'100 mm{3.9i1in.)

45 mm{1.77 in.}

3.5 mm{0.r4 in.l

30 mm11.18 in.l

50 mm I{1.97in.1 /

6 mm (0.24 in.)

nLv--

20-32

'13. With a sponge, apply a light coat of glass primer

along the edge of the rubber dam (A) and front seal(B) as shown, then lightly wipe it off with gauze or

cheesecloth:

With the printed dots (C) on the quarter glass (D)

as a guide, apply the glass primer to the upper

and lower corner ponions of the quarter glass.

Do not apply body primer to the quaner glass,

and do not get body and glass primer sponges

mrxed up.

Never touch the primed surfaces with your hands.

lf you do, the adhesive may not bond to the

quarter glass properly, causing a leak after the

quarter glass is inslalled.

Keep water, dust, and abrasive materials away

from the primed surface.

11 mmlo.i(} in.)

Page 687 of 1139

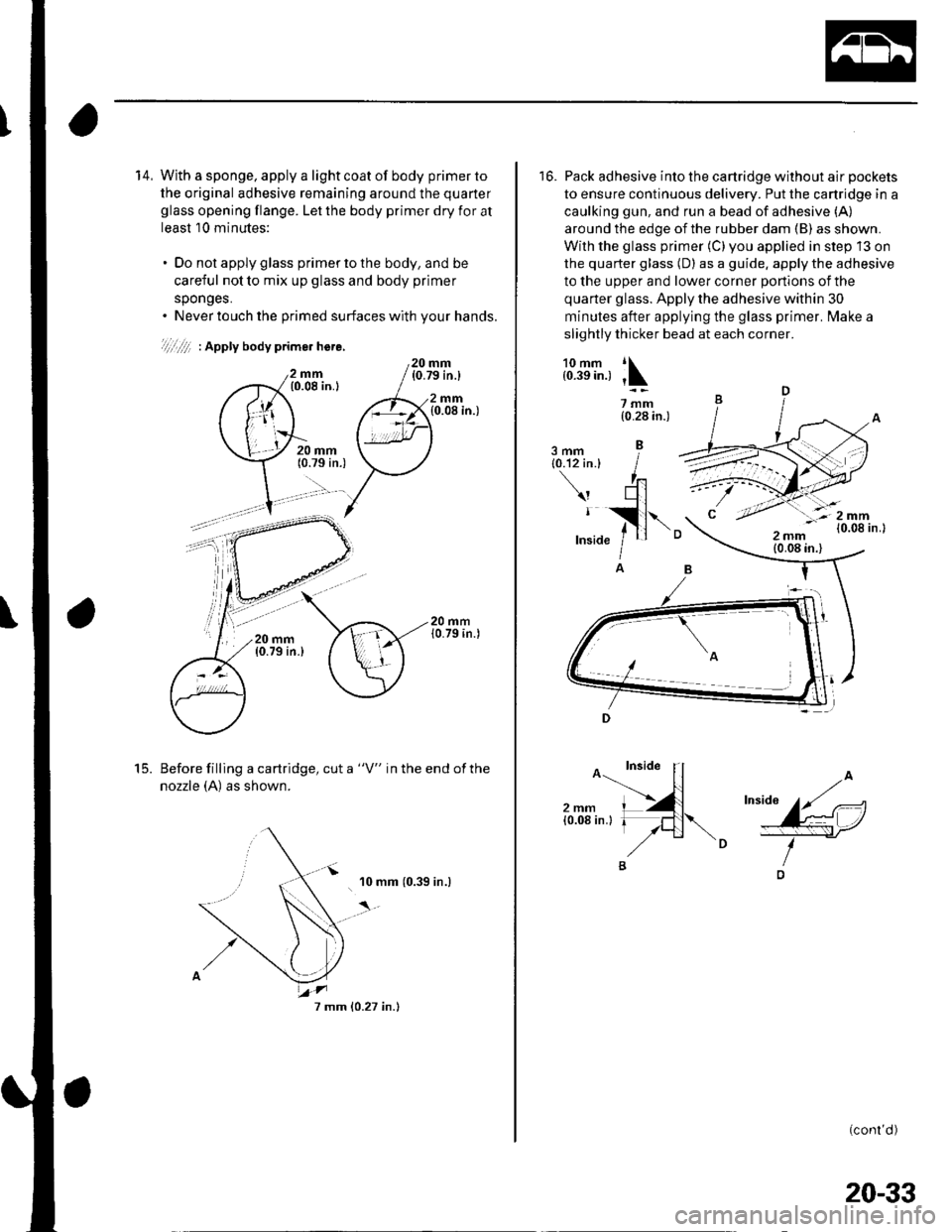

14, With a sponge. apply a light coat of body primer to

the original adhesive remaining around the quarter

glass opening flange. Let the body primer dry for at

least 10 minutes:

. Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.. Never touch the primed surfaces with your hands.

)'/ii ,/ii. I Apply bodv prime. here,

mm(0.08 in.l

20 mm(0.79 in.)

2mm{0.08 in.)

Before filling a cartridge, cut a "V" in the end ofthe

nozzle (A) as shown.

'10 mm (0.39 in.)

20 mm{0.79 in.)

t5.

7 mm 10.27 in.)

20-33

16. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive (A)

around the edge of the rubber dam (B) as shown.

With the glass primer (C)you applied in step 13 on

the quarter glass (D) as a guide. apply the adhesive

to the upper and lower corner portions of the

quarter glass. Apply the adhesive within 30

minutes after applying the glass primer. lvlake a

slightly thicker bead at each corner.

l.:J611, ;\

7mm{0.28 in.)

3mm{0.'12 in.}

I

IA

(conl'd )

Page 688 of 1139

Glass

Ouarter Glass Replacement (cont'd)

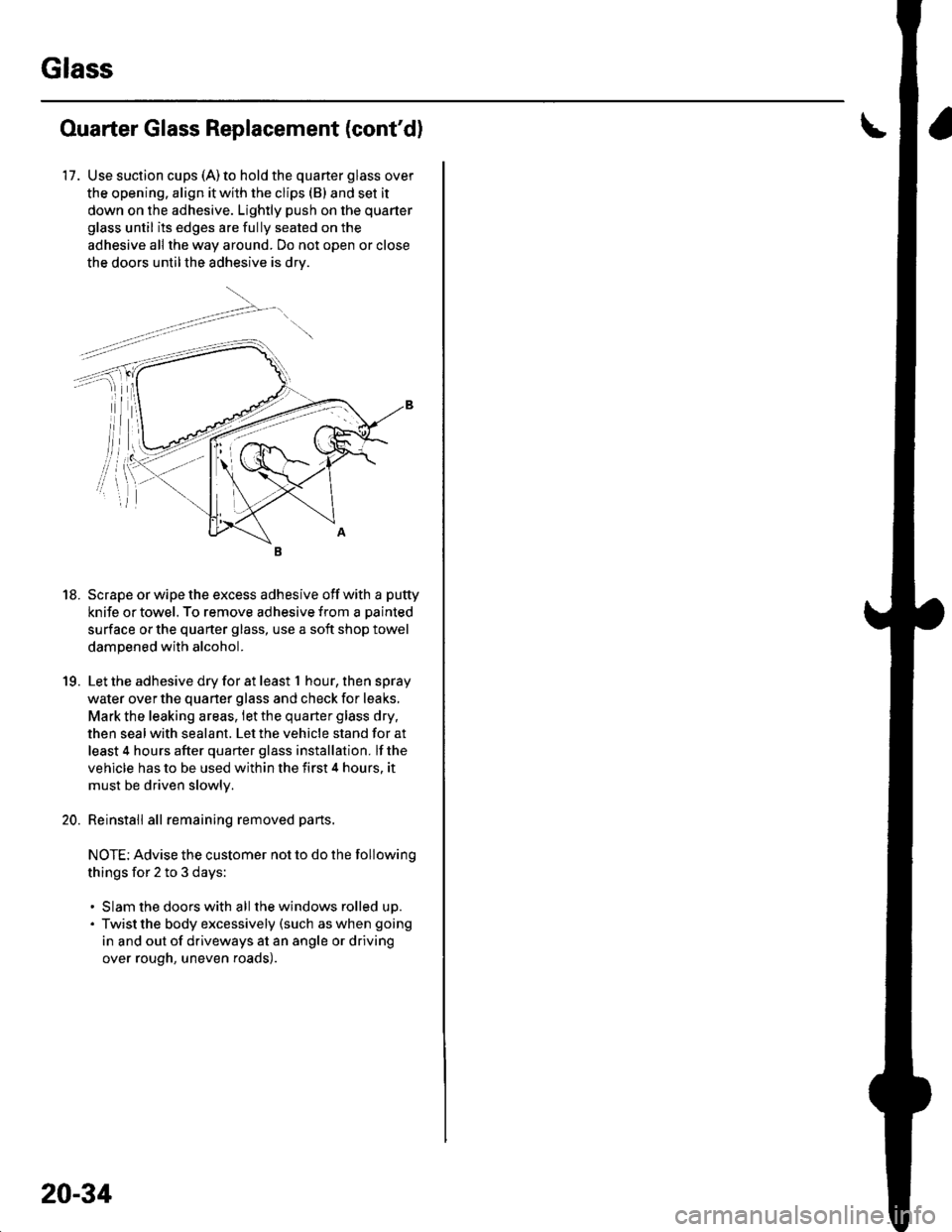

17. Use suction cups (A)to hold the quarter glass over

the opening. align it with the clips (B) and set it

down on the adhesive. Lightly push on the quarter

glass until its edges are fully seated on the

adhesive all the way around. Do not open or close

the doors untilthe adhesive is drv.

18. Scrape or wipe the excess adhesive off with a putty

knife or towel. To remove adhesive from a painted

surface or the quarter glass, use a soft shop towel

dampened with alcohol.

19. Let the adhesive dry for at least t hour,thenspray

water over the quarter glass and check for leaks,

Mark the leaking areas, let the quarter glass dry,

then seal with sealant. Let the vehicle stand for at

least 4 hours after quarter glass installation. lf the

vehicle has to be used within the first 4 hours. it

must be driven slowlv.

20. Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the following

things for 2 to 3 days:

. Slam the doors with all the windows rolled up.. Twist the body excessively (such as when going

in and out of driveways at an angle or driving

over rough, uneven roads).

20-34

Page 689 of 1139

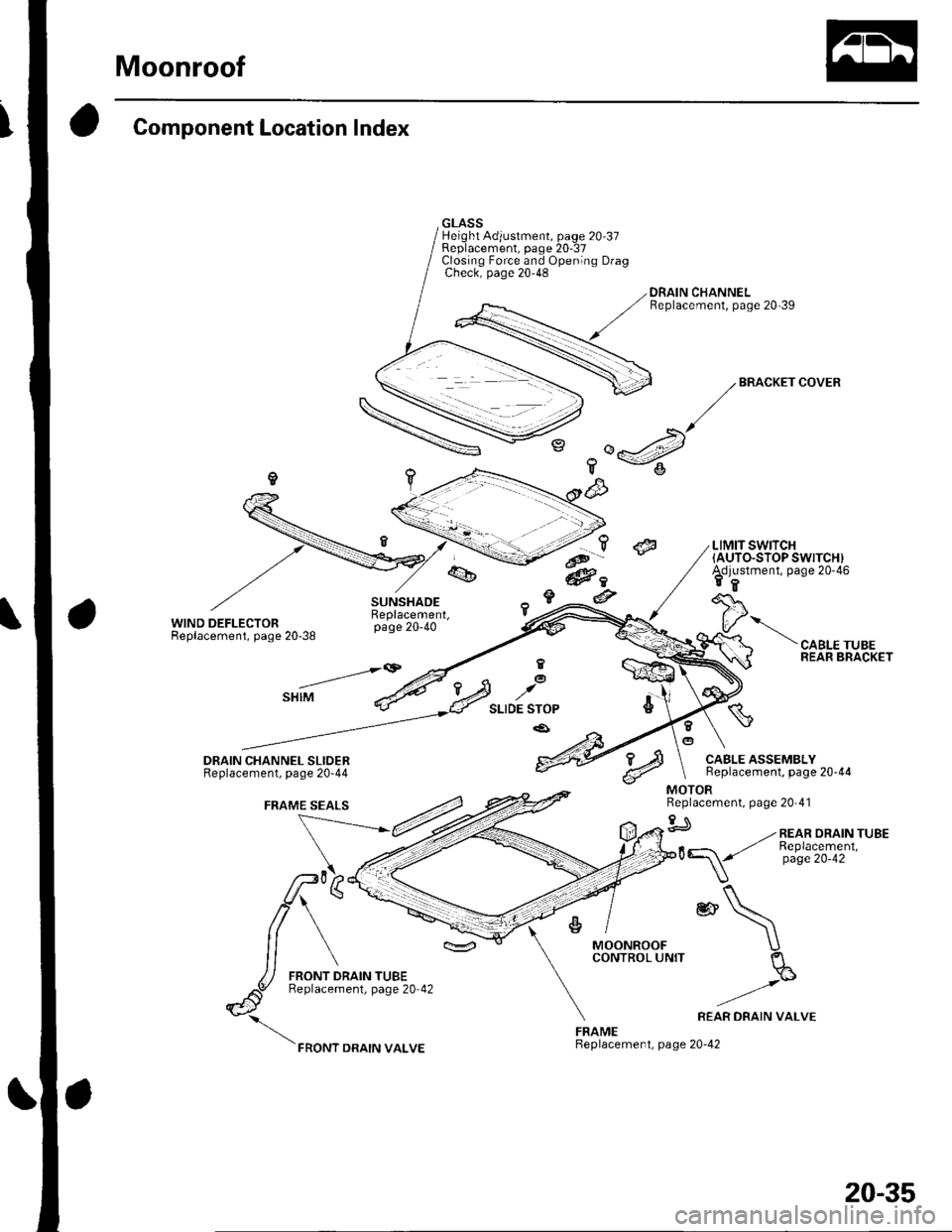

Moonroof

Component Location Index

WIND DEFLECTORReplacement, page 20-38

GLASSHeight Adjustment, page 20 37Replacement, paqe 20-37Closino Force and Ooenino DraoCheck; page 20-48 "

DRAIN CHANNELReplacement, page 20-39

,5

?a<&,

@

..t'- ?.@-@c

_a

@

/,BR^CKEI

COVER

LIMIT SWITCH(AUTO.STOP SWITCH)Adjustment, page 20-46ER

I

CABLE TUBEREAR BRACKETE@

E STOP

.a'

MOONROOFCONTROL UNIT

FRAMEReplacement, page 20-42

CABLE ASSEMBLYBeplacement, page 20-44

*\

)REAR DRAIN VAI-VE

_-""-\q

Replacement, page 20'41

gJ -.- REAR DRA'N TUBE

20-35

Page 690 of 1139

Moonroof

Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check for

Water leaks'1. Check for a clogged drain tube.

2. Check for a gap between the glass weatherstrip and the roof

panel.

3. Check for a defective or an improperly installed glass

weatherstrip or drain channel.

4. Check for a gap between the drain seal and the roof panel.

G lass height

adJustment

Wind nolse1. Check for excessive clearance between the glass weatherstrip

and the root panel.

Glass height

adjustment

Deflector noise1. Check for a imDrooer clearance between deflector seal and

roof panel.

2, Check for a insufficient deflector extension.

3. Check for a deformed deflector.

Motor noise1. Check for a loose motor.

2. Check for a worn gear or bearing.

3. Check for a deformed cable assembly.

Check closing force

Glass does not move,

but motor turns

1. Check for a defective gear or inner cable.

2. Check for foreign matter stuck between the guide rail and the

slide r.

3. Check for a loose inner cable.

4. l\,4ake sure the cable assembly is attached properly.

Glass does not move

and motor does nol

turn (glass can be

moved with

moonroof wrench)

1. Check for a blown fuse.

2. Check for a faulty moonroof switch.

3. Check the limit switch.

4. Check for a run down battery.

5. Check for a defective motor.

6. Check for a faulty relay.

20-36