HONDA CIVIC 2003 7.G Workshop Manual

CIVIC 2003 7.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/5744/w960_5744-0.png

HONDA CIVIC 2003 7.G Workshop Manual

Trending: starter, OBD port, wiper fluid, headlight bulb, Power steering, power mirrors, rear view mirror

Page 761 of 1139

2.

5.

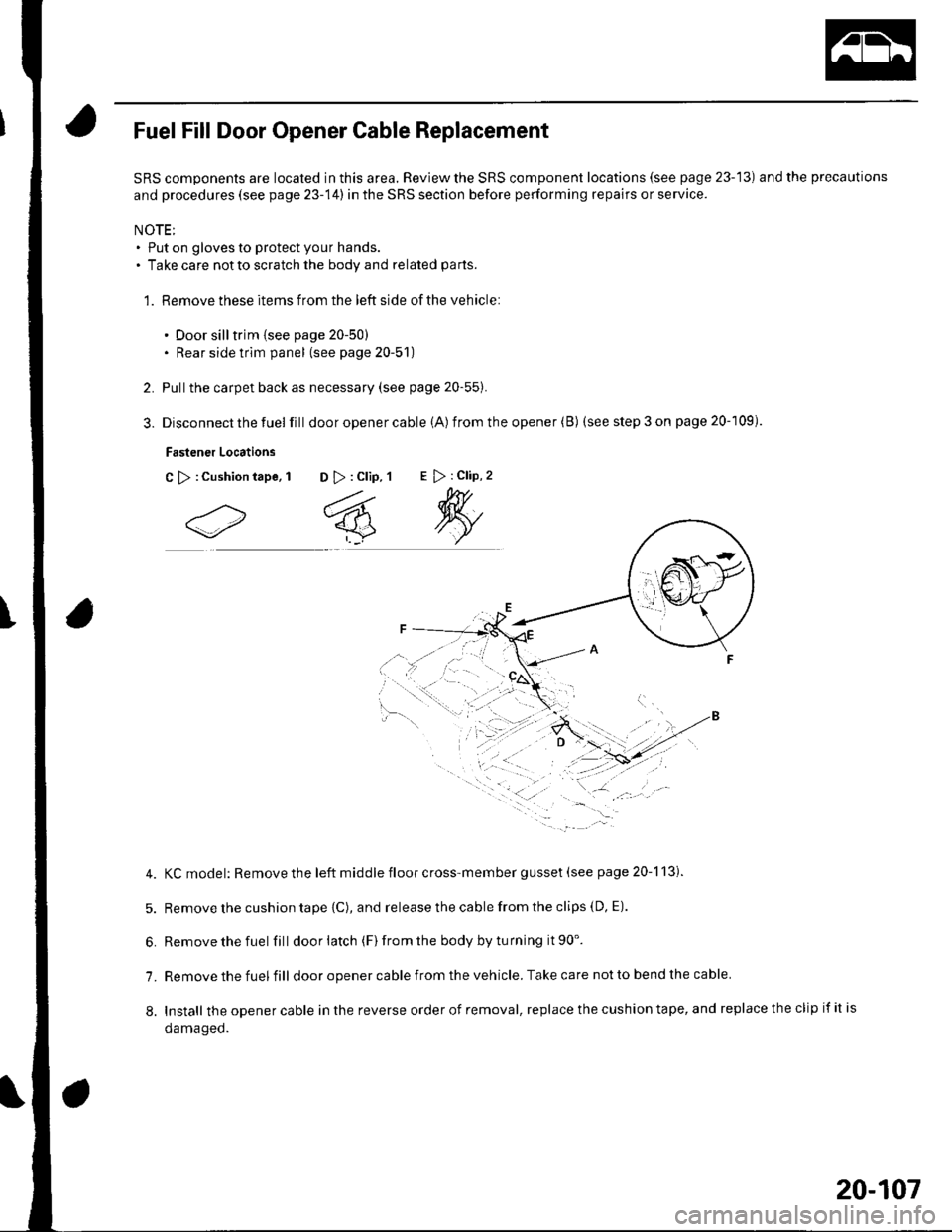

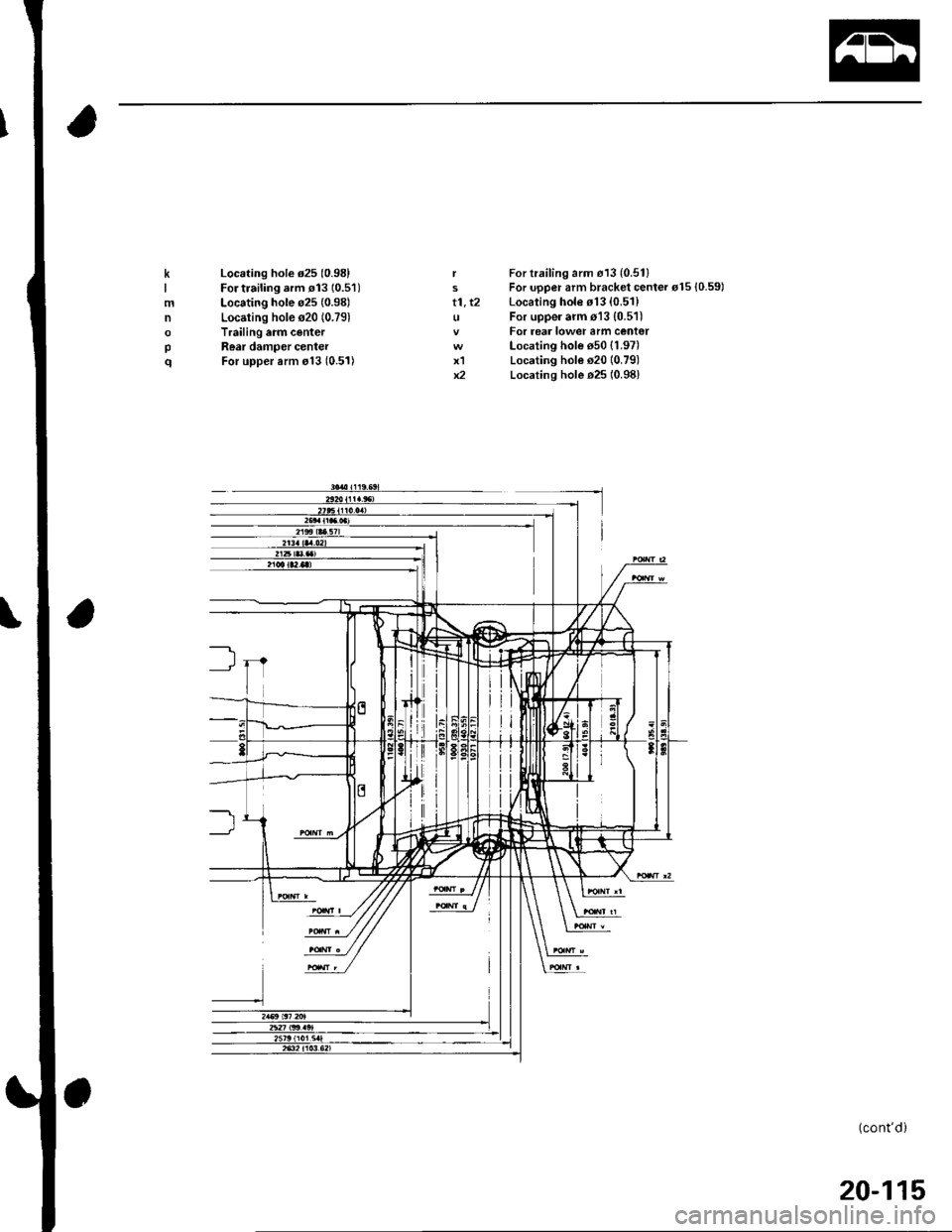

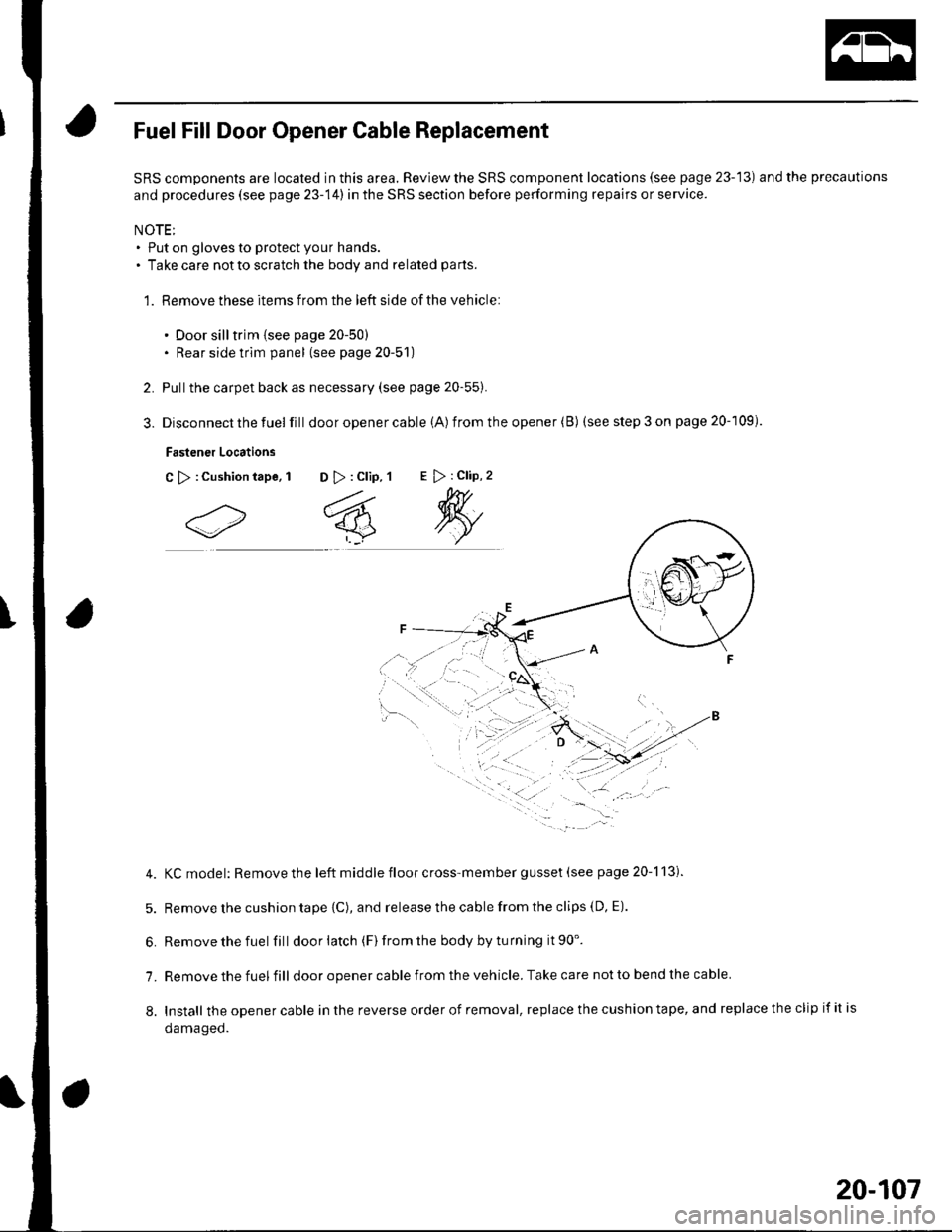

Fuel Fill Door Opener Cable Replacement

SRS components are located in this area. Review the SRS component locations (see page 23-13) and the precautions

and procedures (see page 23-14) in the SRS section before performing repairs or service.

NOTE;. Put on gloves to protect your hands.. Take care notto scratch the body and related parts.

1. Remove these items from the left side of the vehicle:

. Door silltrim {see page 20-50). Rear side trim panel (see page 20-51)

Pullthe carpet back as necessary (see page 20-55).

Disconnect the fuel fill door opener cable (A) from the opener (B) (see step 3 on page 20-109).

Fastener Locations

C >:Cushiontape, 1 D >: Clip, 1E > : Clip, 2

4. KCmodel: Removethe left middle floor cross-member gusset (see page 20-113).

5. Remove the cushion tape {C), and release the cable from the clips (D, E).

6. Removethefuel fill doorlatch (F)fromthe bodybyturning it90'.

7. Remove the fuel fill door opener cable from the vehicle. Take care not to bend the cable

8. Install theopenercableinthereverseorderofremoval,replacethecushiontape,andreplacetheclipifitis

oamageo.

20-107

Page 762 of 1139

Openers

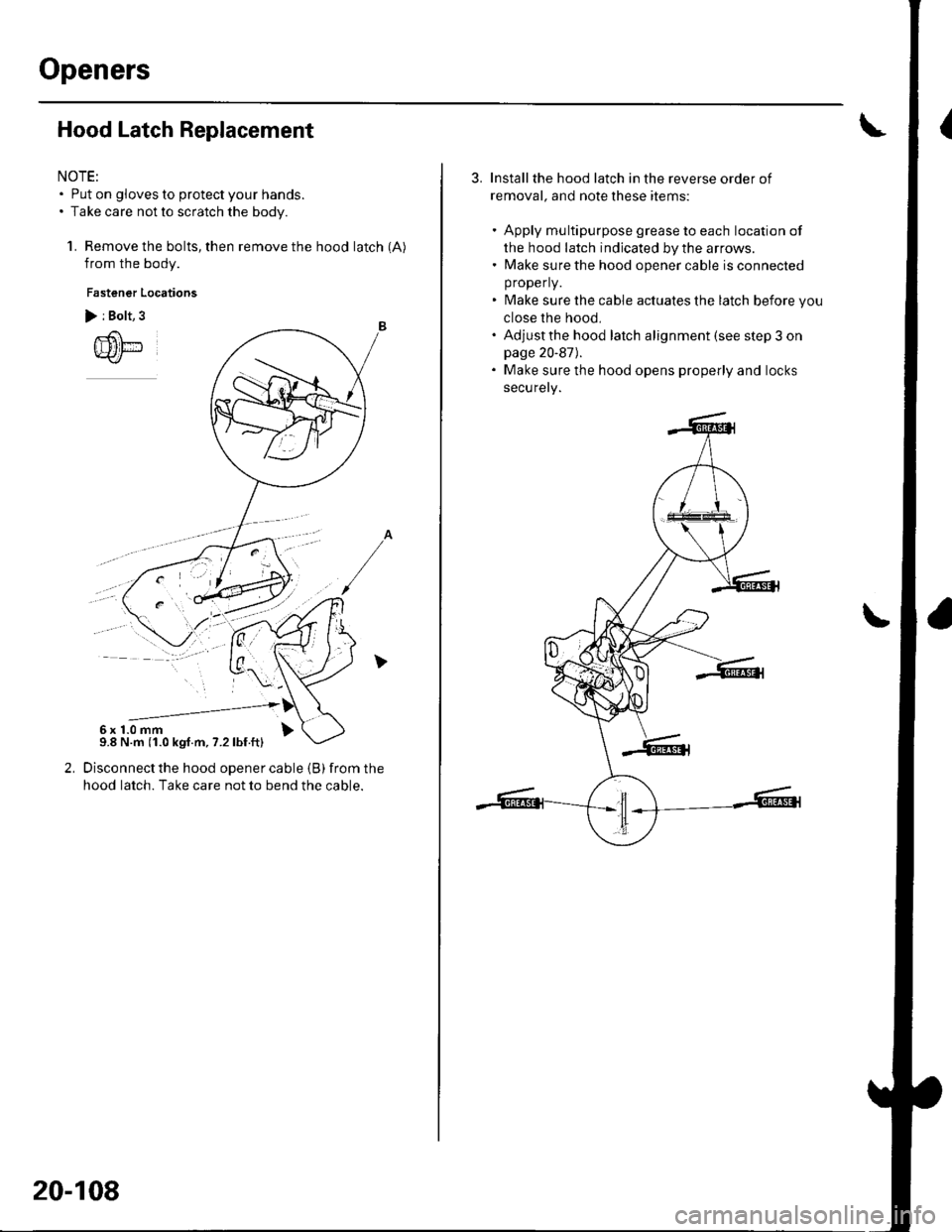

Hood Latch Replacement

NOTE:. Put on gloves to protect your hands.. Take care not to scratch the body.

1. Remove the bolts, then remove the hood latch (A)

from the body.

Fastener Locations

> i Bolt, 3

Disconnect the hood opener cable (B) from the

hood latch. Take care not to bend the cable.

--------------'6x1.0mm9.8 N.m (1.0 kgf.m, 7.2lbf.ft)

20-108

Installthe hood latch in the reverse order of

removal, and note these items:

. Apply multipurpose grease to each location of

the hood latch indicated by the arrows.. Make sure the hood opener cable is connected

properly.

. Make sure the cable actuates the latch before you

close the hood,. Adjustthe hood latch alignment (see step 3 onpage 20-87).. Make sure the hood opens properly and locks

securely.

Page 763 of 1139

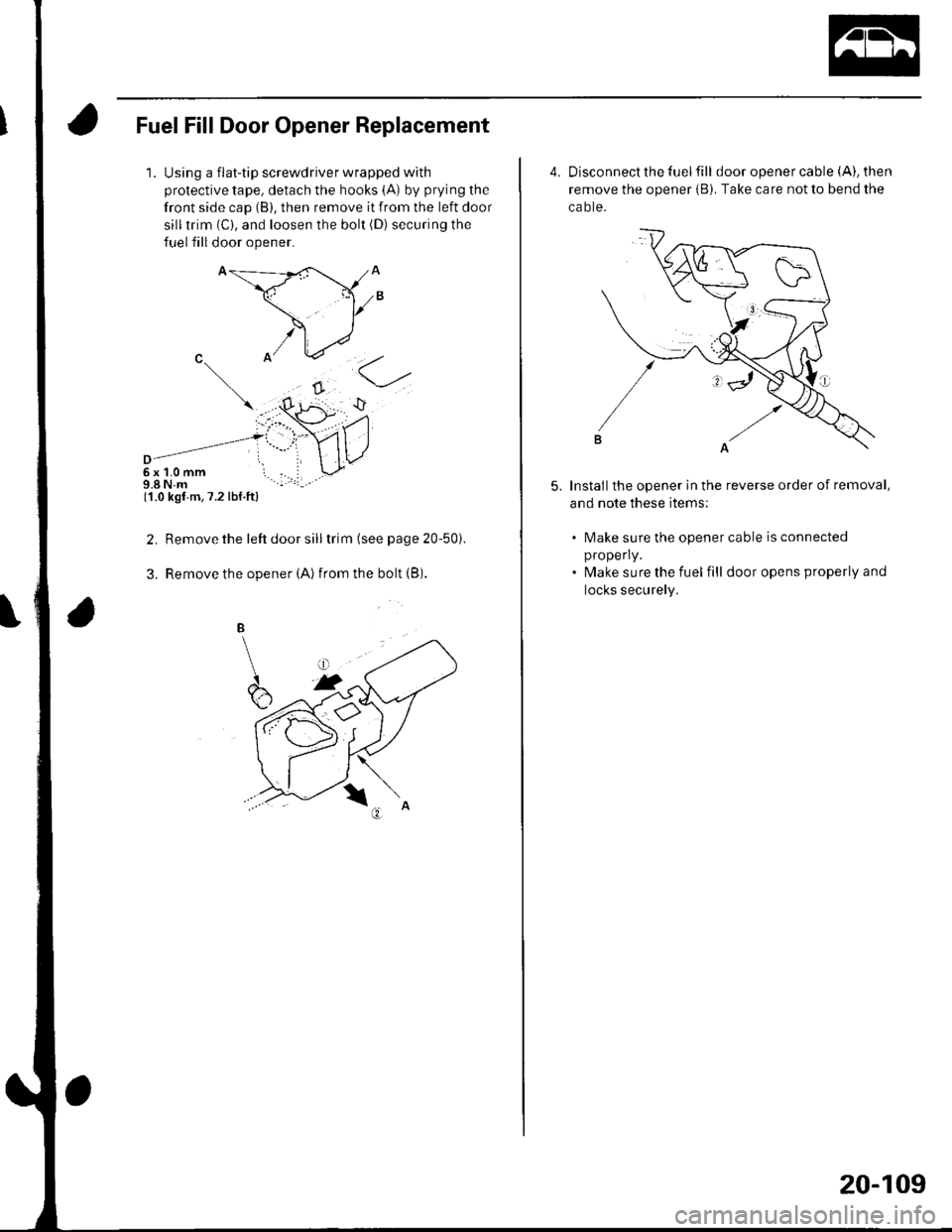

Fuel Fill Door Opener Replacement

1.Using a flat-tip screwdriver wrapped with

protective tape, detach the hooks (A) by prying the

front side cap (B), then remove it from the left door

silltrim (C), and loosen the bolt (D) securing the

fuel fill door opener.

6x1.0mm9.8 N.m11.0 kgf m,7.2 lbf.ft)

Remove the left door sill trim (see page 20-50i.

Remove the opener (Alfrom the bolt {B).

2.

3.

4. Disconnect the fuel fill door opener cable (A), then

remove the opener iB). Take care not to bend the

ca o te.

Installthe opener in the reverse order of removal,

and note these items:

5.

lMake sure the opener cable is connected

properly.

lvlake sure the fuel fill door opens properly and

locks securely.

20-109

Page 764 of 1139

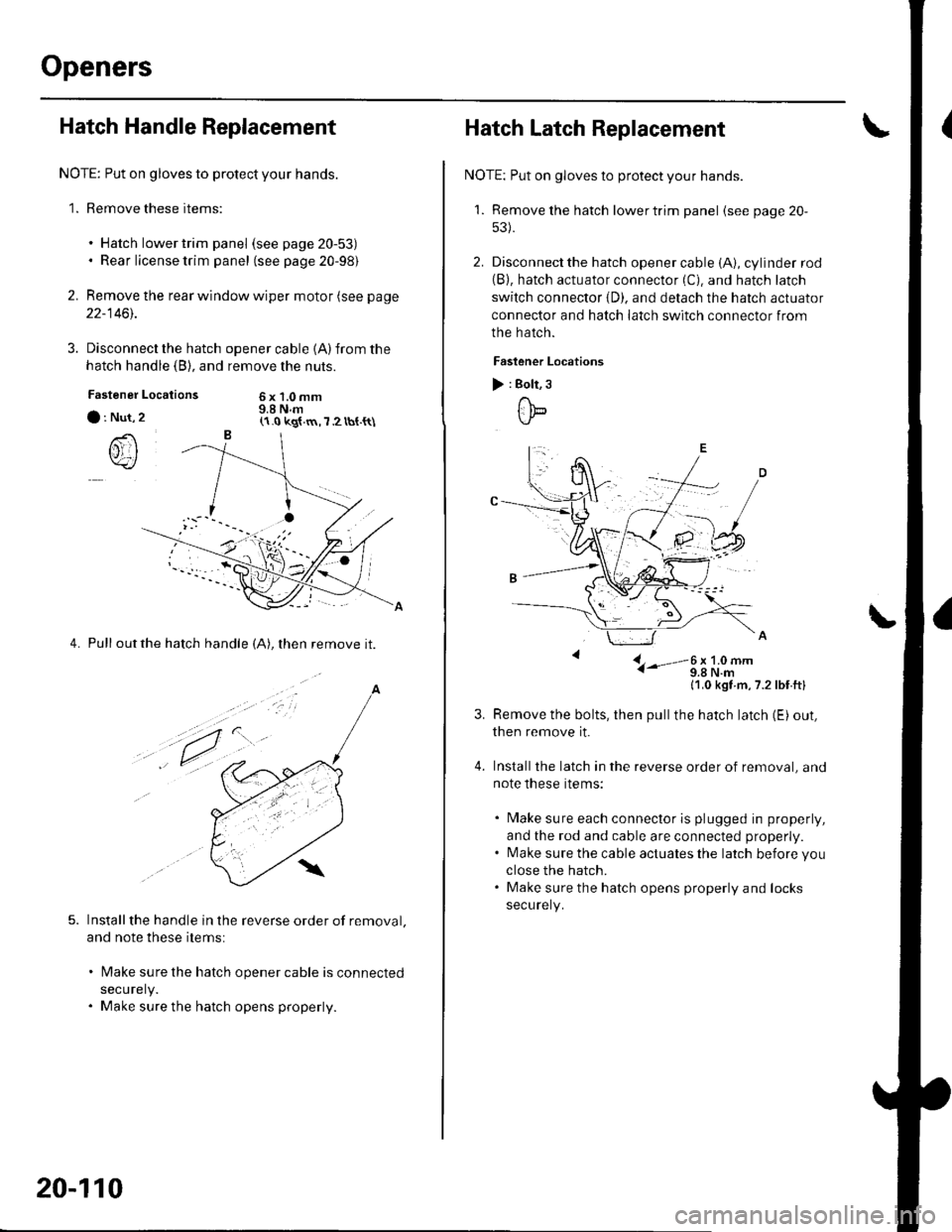

Openers

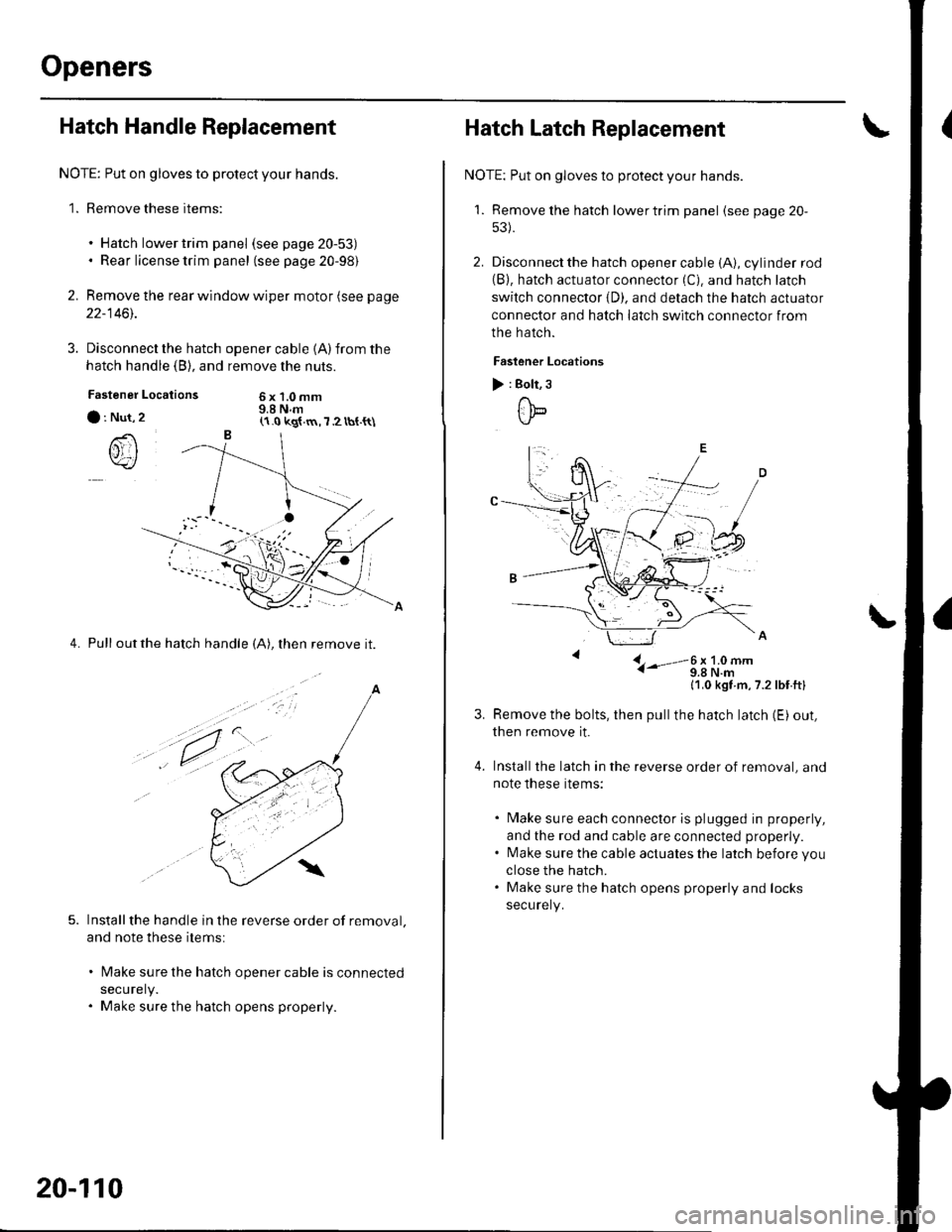

Hatch Handle Replacement

NOTE: Put on gloves to protect your hands.

1. Remove these items:

. Hatch lower trim panel (see page 20-53). Rear license trim panel (see page 20-98)

2. Remove the rear window wiper motor (see page

22-1461.

3. Disconnect the hatch

hatch handle (B), and

Locations

opener cable 1A)from the

remove the nuts.

6x1.0mm9.8 N.mFastener

a : Nut,

()rI

4. Pull outthe hatch handle (A), then remove it.

Installthe handle in the reverse order of removal.

and note these items:

lMake sure the hatch opener cable is connected

securely.

Make sure the hatch opens properly.

(1.0 kg{.m,7 2 tbt.{t\

a

,t.

20-110

Hatch Latch Replacement

NOTE: Put on gloves to protect your hands.

'1. Remove the hatch lowertrim panel (see page 20-

53).

2. Disconnect the hatch opener cable (A), cylinder rod(B). hatch actuator connector (C). and hatch latch

switch connector {D). and detach the hatch actuator

connector and hatch latch switch connector from

the hatch.

Faslener Locations

) : Bolt, 3

ttb

L- i-'-3;li9#-

11,0 kgt m,7.2lbf ftl

Remove the bolts, then pullthe hatch latch (E) out,

then remove it.

Installthe latch in the reverse order of removal, and

note these items:

. Make sure each connector is plugged in properly,

and the rod and cable are connected properly.. l\4ake sure the cable actuates the latch before you

close the hatch.. Make sure the hatch opens properly and locks

securely.

Page 765 of 1139

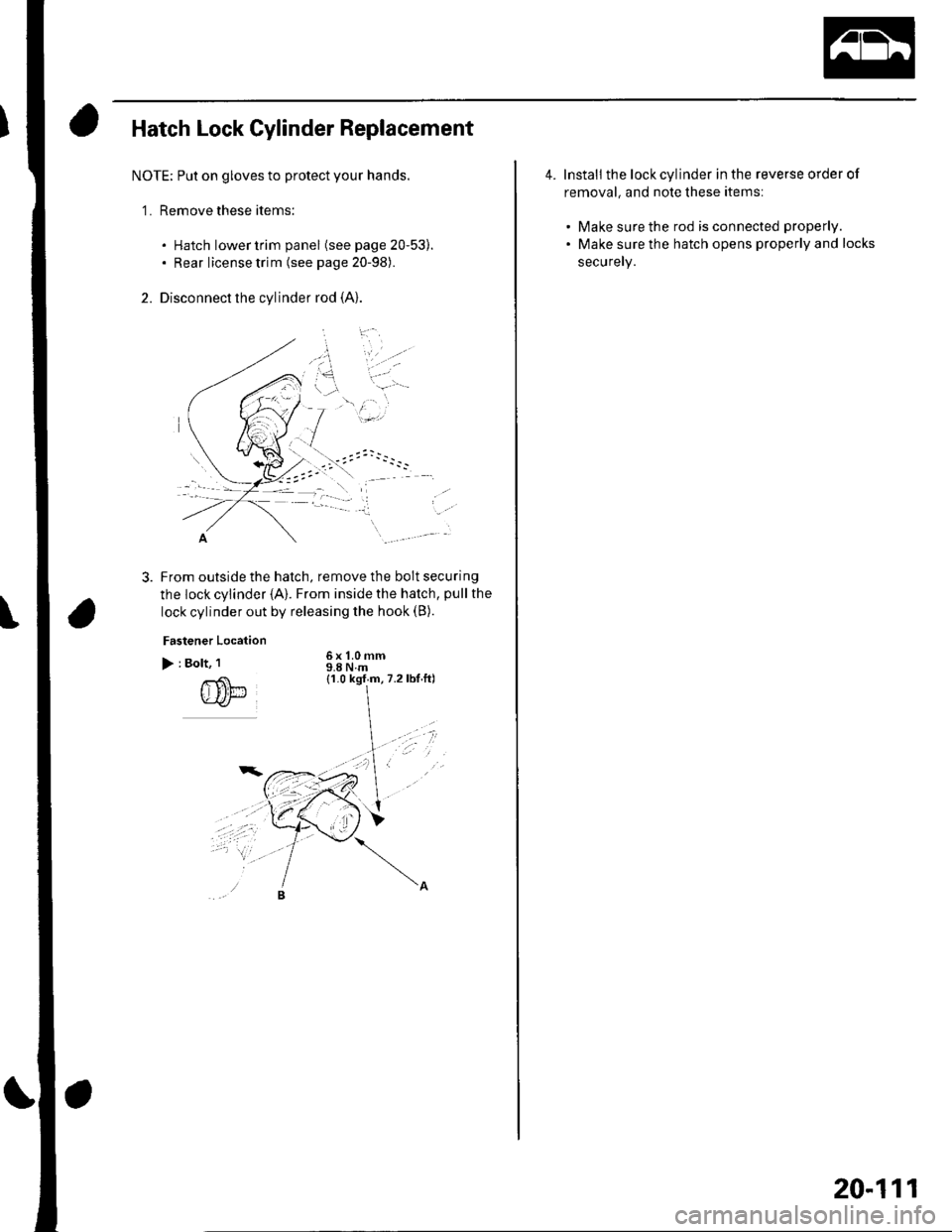

Hatch Lock Cylinder Replacement

NOTE; Put on gloves to protect your hands.

'1. Remove these items:

. Hatch lower trim panel (see page 20-53).. Rear license trim (see page 20-98).

2. Disconnect the cylinder rod (A)

-..

From outside the hatch, remove the bolt securing

the lock cylinder {A}. From inside the hatch, pull the

lock cylinder out by releasing the hook (B).

Fastener Location

> : Bolt, 1

rS'l-.u-ar

6x 1.0 mm9.8Nm(1.0 kgf m,7.2lbt.ftl

*/t

4. Install the lock cylinder in the reverse order of

removal, and note these items:

. Make sure the rod is connected properly.

. Make sure the hatch opens properly and locks

securely.

20-111

Page 766 of 1139

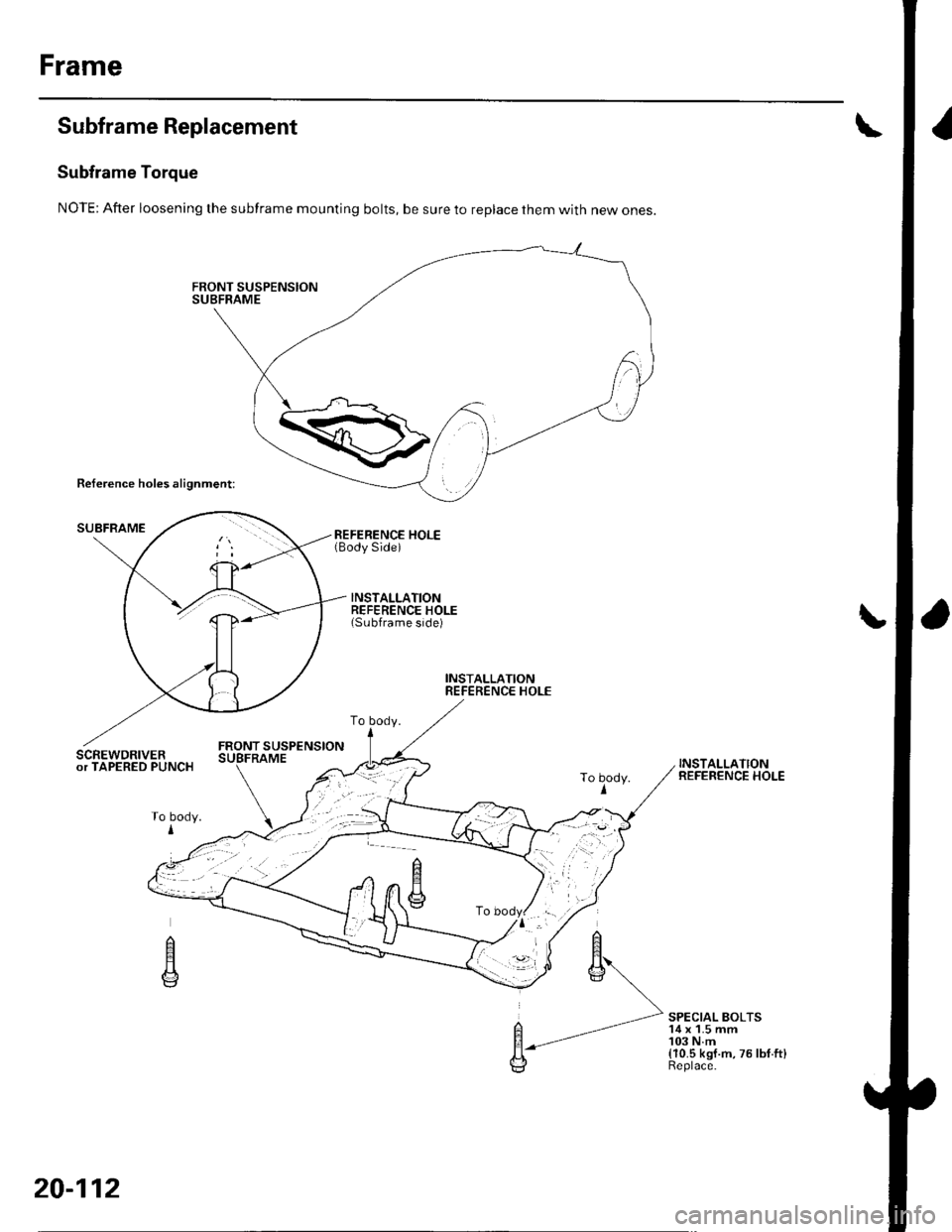

Frame

Subframe Replacement

Subframe Torque

NOTE: After loosening the subframe mounting bolts, be sure to replace them with new ones.

Reference holes alignment:

SUBFRAMEREFERENCE HOLE(Body Side)

INSTALLATIONREFERENCE HOLE(Subframe side)

INSTALLATIONREFERENCE HOLE

FRONT SUSPENSIONSCREWDRIVERor TAPERED PUNCHINSTALLATIONREFERENCE HOLE

SPECIAL BOLTS'14 x 1.5 mm103 N.m(10.5 kgf.m,75lbf.ft)Replace.

To body.

To body.I

n

E

20-112

Page 767 of 1139

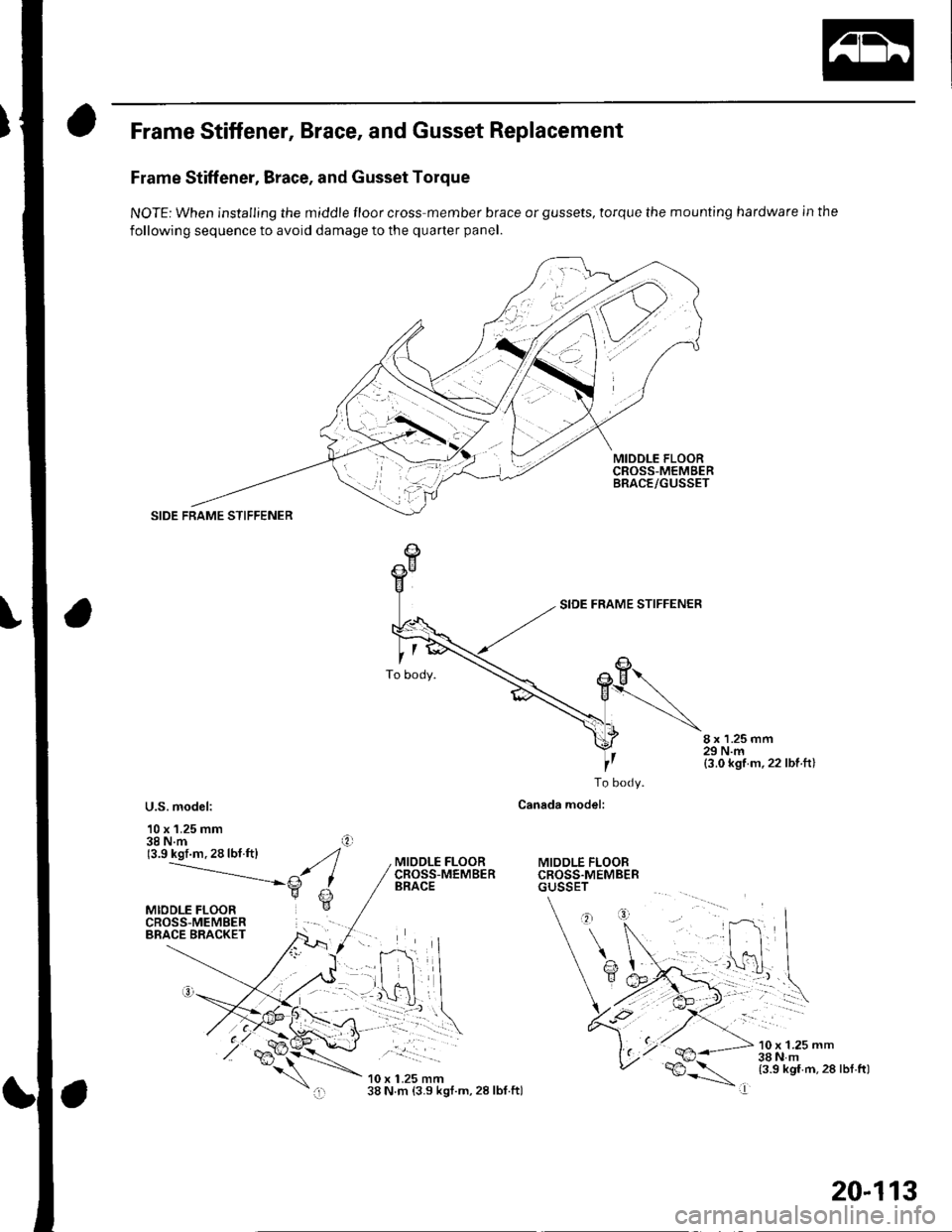

Frame Stiffener, Brace, and Gusset Replacement

Frame Stiffener, Brace, and Gusset Torque

NOTE: When installing the middle floor cross member brace or gussets, torque the mounting hardware in the

following sequence to avoid damage to the quarter panel.

MIDDLE FLOORCROSS-MEMgERBRACE/GUSSET

SIDE FRAME STIFFENER

8 x 1.25 mm29 N.m(3.0 kgf m,22 lbf ft)

U.S. model:

10 x 1.25 mm38 N.m(3.9 kgf.m.28lbf.ftl

To body.

Canada model:

MIDDLE FLOORCROSS.MEMBERGUSSET

MIODLE FLOORCROSS-MEMBERBRACE

.. __!:::-- | -

10 x 1.25 mm38 N m (3.9 kgt.m, 28 lbf.ftl

10 x 1.25 mm38Nm(3.9 kgf.m,28 lbl.ftl

I

20-113

Page 768 of 1139

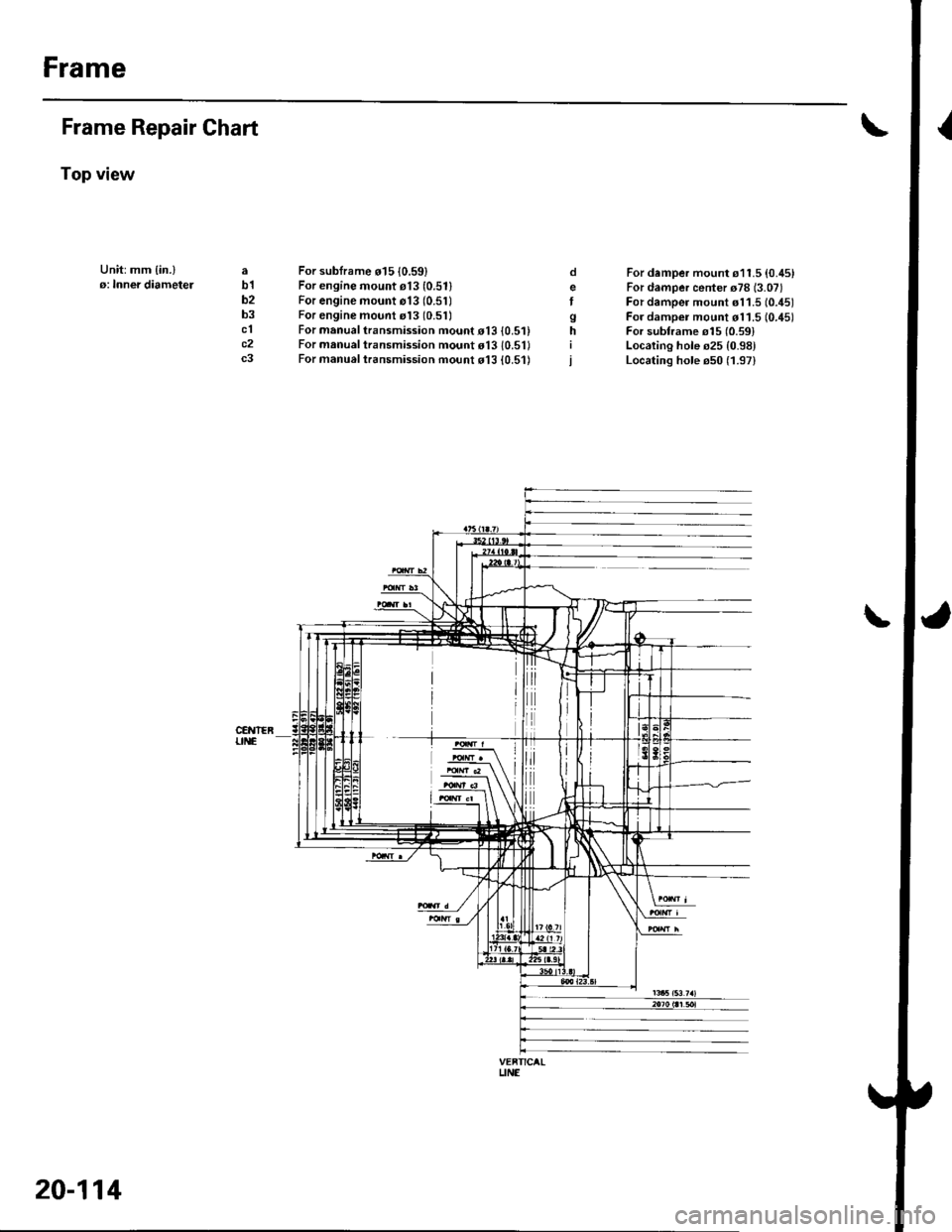

Frame

Frame Repair Chart

Top view

Unit:mm {in.}o: Inner diametelab1b2b3clc2c3

For sublrame o15 10.59)For engine mount e13 (0.511

For engine mount o13 (0.51)For engine mount rl3 (0.51)

For manual transmission mouot o13 {0.5'For manual transmission mount o13 10.5'For manual t.ansmission mo!nt d13 {0.51)

o

Igh

For damper mount s11.5 {0.45}For damper center o78 (3.07)

For damper mount s11.5 (0.451

For dampei mount d11.5 10.45)For subframe o15 {0.591Localing hole s25 {0.98}Locating hole e50 (1.97)

\

VEFTICALUNE

20-114

Page 769 of 1139

t1, t2

x1x2

K

mn

pq

Locating hole d25 (0.981

For trailing.rm rl3 10.51)Locating hole o25 (0.981

Locating hole s20 (0.79)

Trailing arm centerRear damper centerFor upper arm o13 (0.51)

For trailing arm d13 (0.511

For upper arm bracket center rl5 {0.59)Locating hole s13 (0.51)

For uppe. arm o13 {0.511For rear lower arm cent€rLocating hole s50 (1.97)

Locating hole s20 (0.79)

Locating hole o25 (0.981

(cont'd)

20-115

Page 770 of 1139

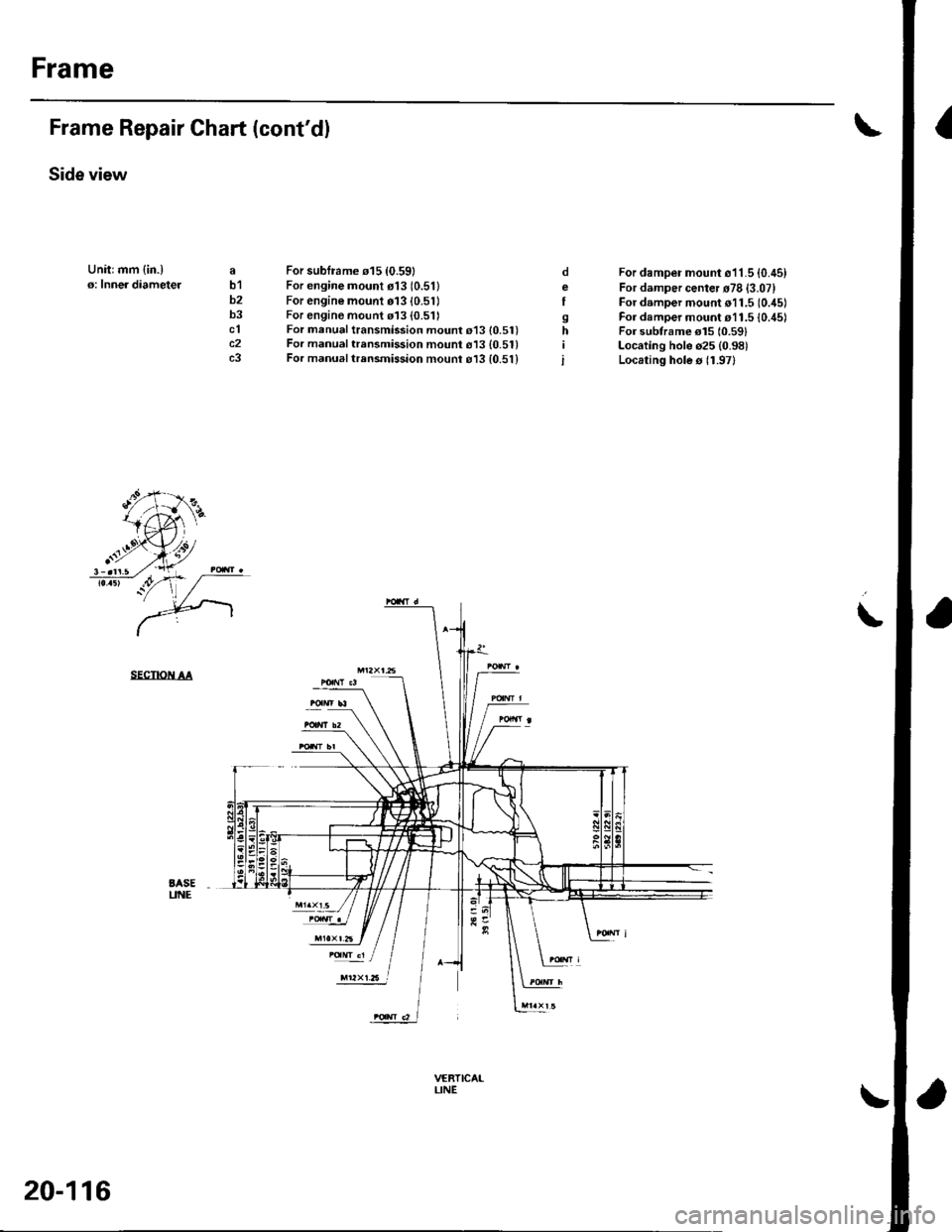

Frame

IFrame Repair Chart (cont'dl

Side view

Unitrmm {in.)o: Inner diameteJab1b2b3clc2c3

For subframe 015 {0.59}For engine mount o13 (0.511

For engine mount 01310.51)For engine mount 113 (0.511For manual transmission mount 013 {0.51)For manual trensmission mount 613 {0.51}For manual trrnsmission mounr o13 {0.51}

For damper mount o11.5 {0.45)For damper center r78 {3.07}For damper mount o11.5 (0.45)

For damper mount r11.5 {0./t5lFor subtrame el5 10.591Locating hole o25 (0.98)

Locating hole s 11.97)

oeI

sh

i

\

SECTIOiI AA

BASEUNE

trr2xt.6 l

VERTICAILINE

20-116

Trending: indicator relay, vtc strainer, egr valve, p1505, Wiring, Shock absorber, RECIRCULATION