Meter HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 61 of 1395

I

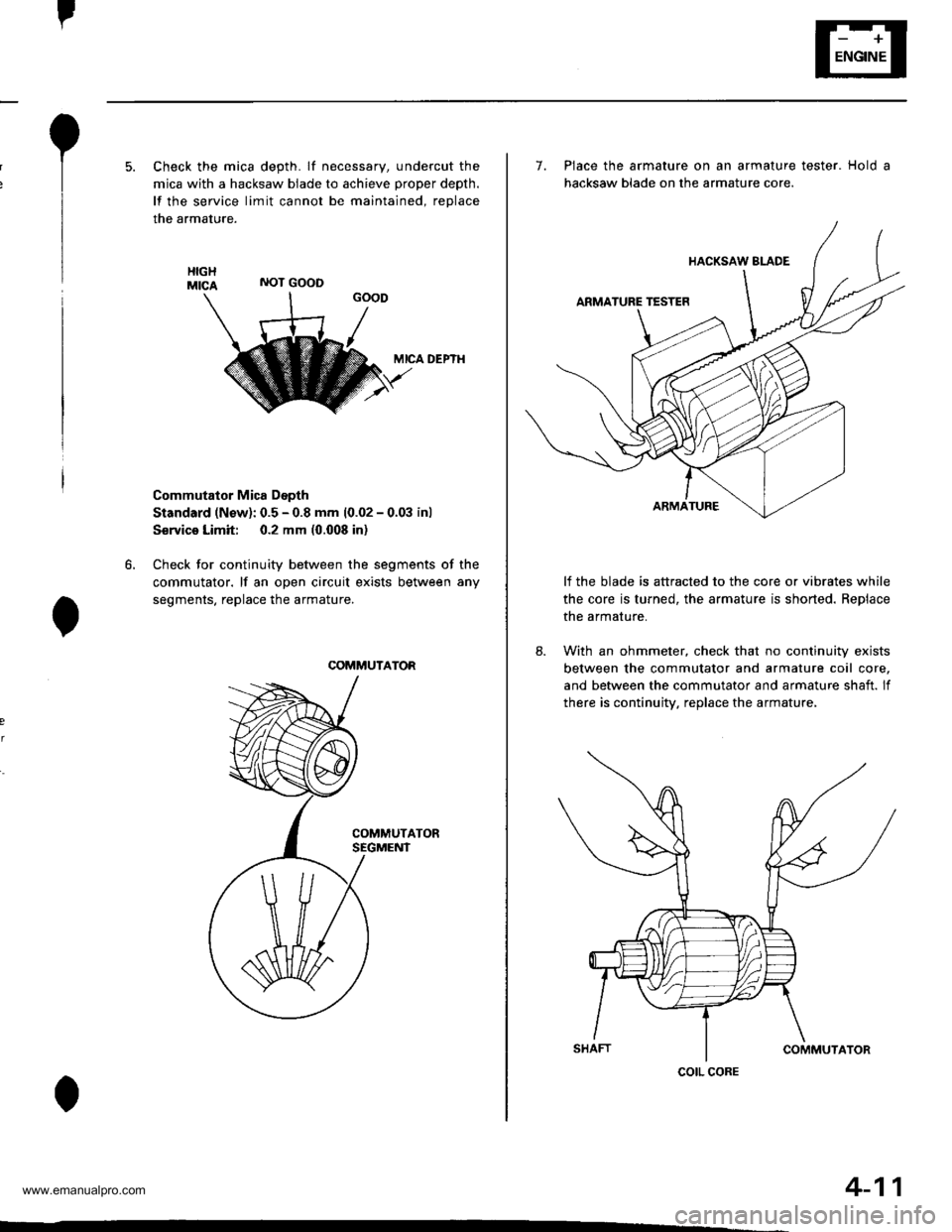

NOT GOOD

5. Check the mica depth. lf necessary, undercut the

mica with a hacksaw blade to achieve proper depth.

lf the service limit cannot be maintained, reDlace

the armature.

MICA DEPTI{

Commutator Mica Depth

Standard (Nsw): 0.5 - 0.8 mm 10.02 - 0.03 inl

Servico Limit: 0.2 mm (0.008 in)

Check for continuity between the segments of the

commutator. lf an open circuit exists between any

segments. replace the armature.

6.

COMMUTATOR

4-11

7. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

lf the blade is attracted to the core or vibrates while

the core is turned. the armature is shorted. Replace

the armature.

8. With an ohmmeter, check that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. lf

there is continuity. replace the armature,

cotL coRE

www.emanualpro.com

Page 64 of 1395

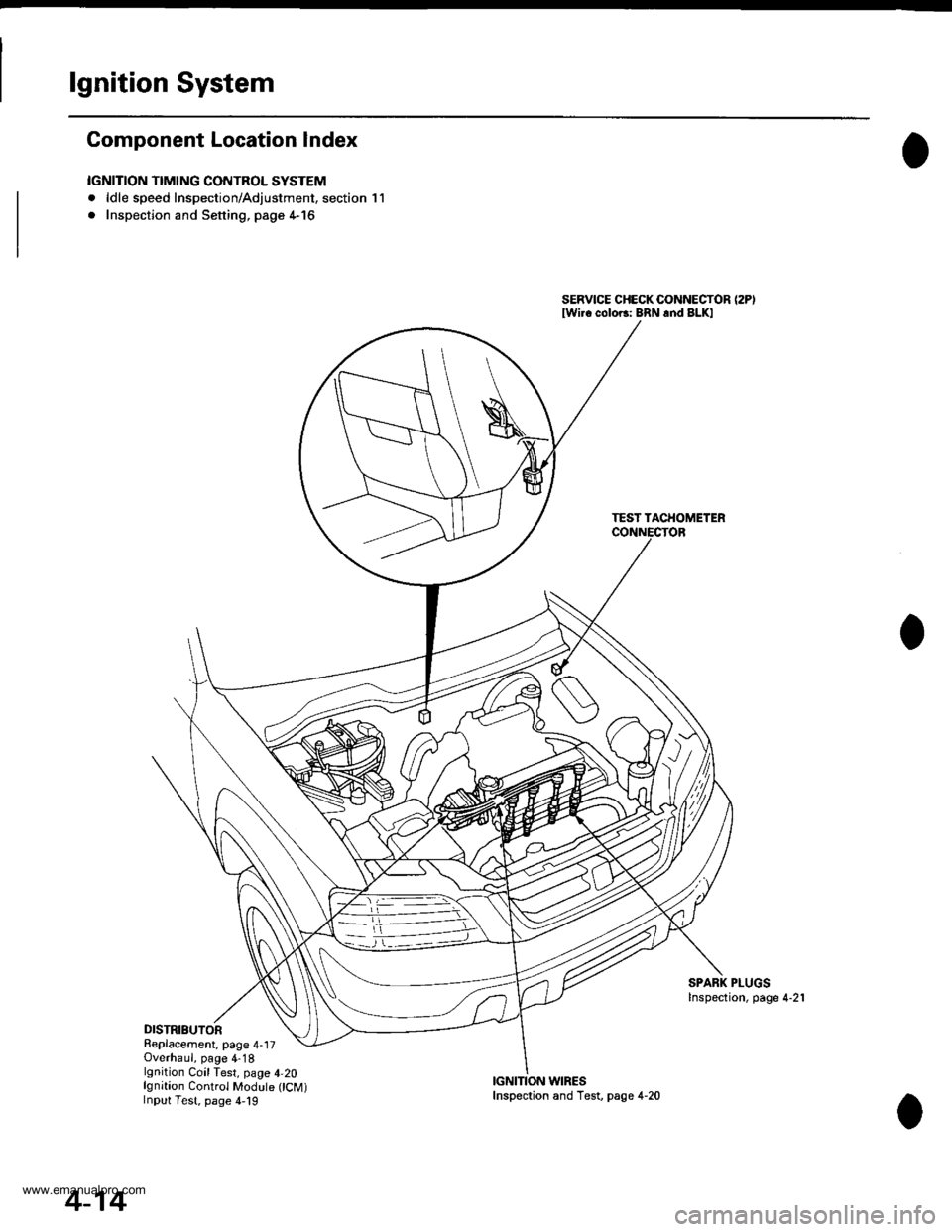

lgnition System

Component Location Index

IGNITION TIMING CONTROL SYSTEM

. ldle speed Inspection/Adjustment, section 11

. Inspection and Sening. page 4-16

DISTRIBUTORReplacement, page 4-17Overhaul, page 4-18lgnition CoilTest, page 4,20lgnition Control Module CM)Input Test, page 4,19

SERVICE CHECK CONNECTOR (2P)

lwi.c colo6: BRN rnd BLKI

TEST TACHOMETER

SPARK PLUGSInspection, page 4-21

WIRES

4-14

Inspection and Test, page 4-20

www.emanualpro.com

Page 65 of 1395

![HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

Circuit Diagram

IGNIT ONSW TCHUNDEF,DASHFUSEi RELAY BOX

6 l;;l Eci,.pcMi{Hr6-(-\9--*.--EII

Vil

IGN TIONW]BES

SPARKPLUGS

I l: 99 - 00 modelsGt01

4-15

UNDEF.HOOD FUSE/RELAY 8OX

f l-- r

TDC Top de HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

Circuit Diagram

IGNIT ONSW TCHUNDEF,DASHFUSEi RELAY BOX

6 l;;l Eci,.pcMi{Hr6-(-\9--*.--EII

Vil

IGN TIONW]BES

SPARKPLUGS

I l: 99 - 00 modelsGt01

4-15

UNDEF.HOOD FUSE/RELAY 8OX

f l-- r

TDC Top de](/img/13/5778/w960_5778-64.png)

Circuit Diagram

IGNIT ONSW TCHUNDEF,DASHFUSEi RELAY BOX

6 l;;l Eci,.pcMi{Hr6-(-\9-'-'*'.--EII

V'il

IGN TIONW]BES

SPARKPLUGS

I l: '99 - 00 modelsGt01

4-15

UNDEF.HOOD FUSE/RELAY 8OX

f l-- r

TDC Top dead cenlerCKP Cran[shan poslionCYP Cylnder posrlon

TDC/CKP/CYP SENSOR

BLK/YEL

l^IGNITIONcotL

IGN]TION CONTROLMODULE (CM)

/ Has buil-if \I no|se l

i l' i--, -BLUll

ifrI BLU BLU I

ll/' i

| | resrI TACHOMETER

I I

tott"to*

LTTCHoMEIEB j'97 -'98 models

IJltfi--cMFcr,r

I

www.emanualpro.com

Page 69 of 1395

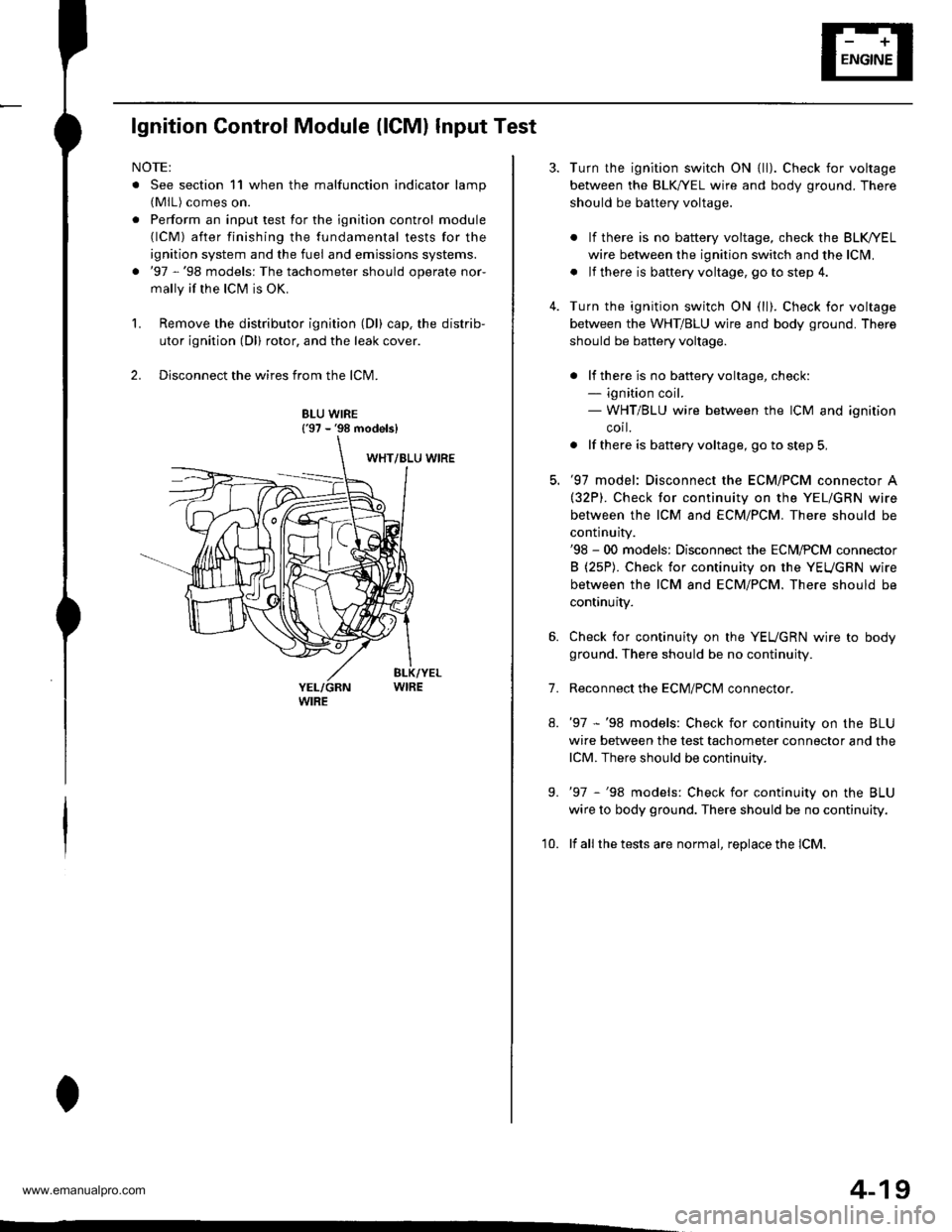

lgnition Control Module (lCMl Input Test

NOTE:

. See section 11 when the malfunction indicator lamp(MlL) comes on.

. Perform an input test for the ignition control module(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems.

. '97 -'98 models: The tachometer should operate nor-

mally if the ICM is OK.

L Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor, and the leak cover.

2. Disconnect the wires from the lCM.

8LU WIRE{'97 - '98 models}

4-19

7.

Turn the ignition switch ON {ll). Check for voltage

between the BLK,^/EL wire and body ground. There

should be battery voltage.

. lf there is no battery voltage, check the BLK/rEL

wire betlveen the ignition switch and the lclvl.

. lf there is baftery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the WHT/BLU wire and body ground. There

should be battery voltage.

. lf there is no batteryvoltage, check:- ignition coil.- WHT/BLU wire between the ICM and ignition

corl.

. lf there is battery voltage, go to step 5,

'97 model: Disconnect the ECM/PCM connector A(32P). Check for continuity on the YEL/GRN wire

between the ICM and ECM/PCM. There should be

continuity.'98 - 00 models: Disconnect the ECM,PCM connector

B (25P). Check for continuity on the YEUGRN wire

between the ICM and ECM/PCM. There should be

continuity.

Check for continuity on the YEUGRN wire to body

ground. There should be no continuity.

Reconnect the ECM/PClvl connector.

'97 -'98 models: Check for continuity on the BLU

wire between the test tachometer connector and the

lCM. There should be continuity.

'97 -'98 models: Check for continuity on the BLU

wire to body ground. There should be no continuity.

lf all the tests are normal, replace the lCM.

9.

'10.

www.emanualpro.com

Page 70 of 1395

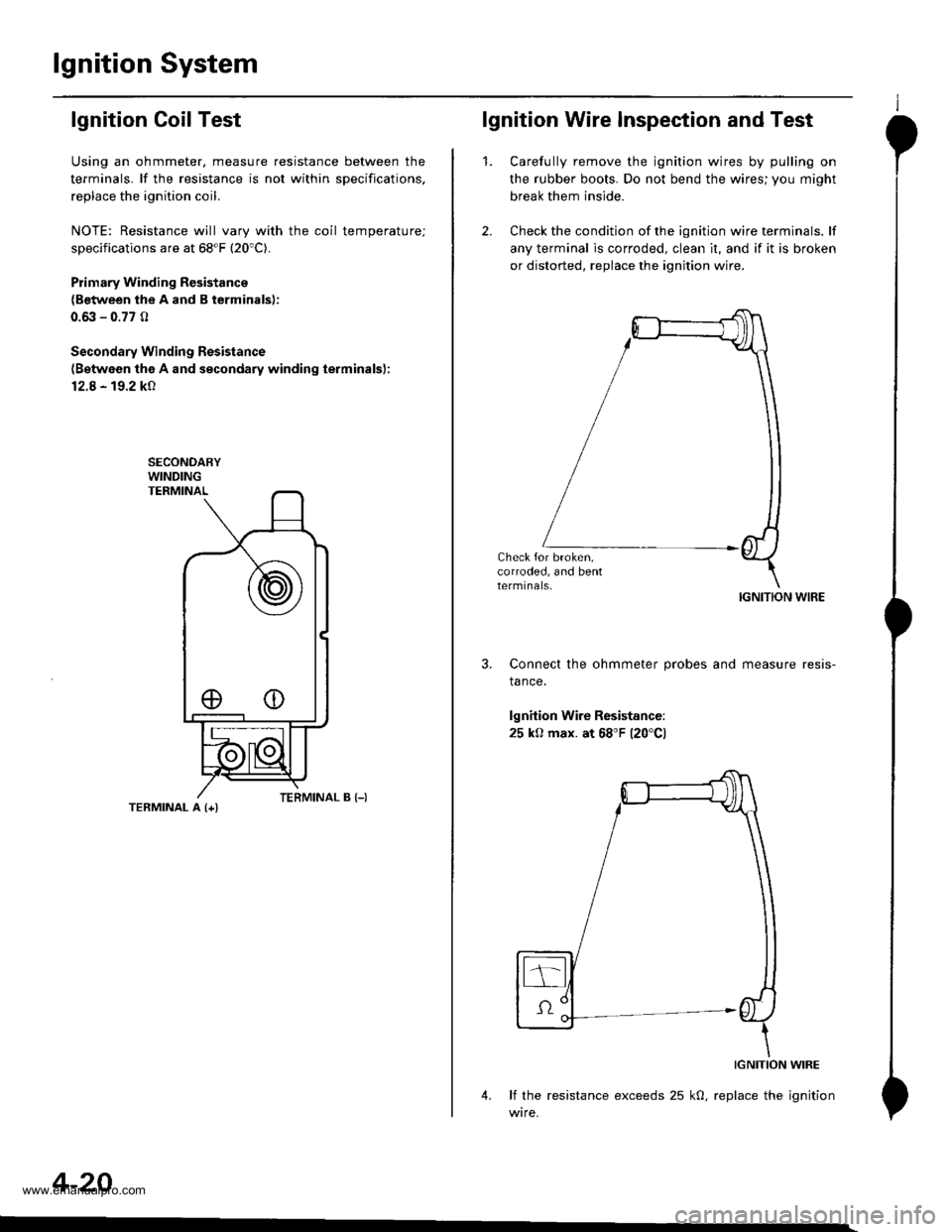

lgnition System

lgnition Coil Test

Using an ohmmeter, measure resistance between the

terminals. lf the resistance is not within sDecifications,

replace the ignition coil.

NOTE: Resistance will vary with the coil temperature;

specifications are at 68"F (20'C).

Plimary Winding Resistance

{Between the A and B terminals):

0.6it - 0.77 0

Secondary Winding Resistance

{Between the A and secondary winding terminals):

12.8 - 19.2 kO

TERMINAL A {+l

4-20

eo

lgnition Wire Inspection and Test

1.Carefully remove the ignition wires by pulling on

the rubber boots. Do not bend the wires; you might

break them inside.

Check the condition of the ignition wire terminals. lf

any terminal is corroded, clean it, and if it is broken

or distorted, replace the ignition wire.

IGNITION WIRE

Connect the ohmmeter probes and measure resis-

tance.

lgnition Wire Resistance:

25 kO max. at 68'F 120'Cl

IGNITION WIRE

4. lf the resistance exceeds 25 kO, replace the ignition

wire.

www.emanualpro.com

Page 76 of 1395

Charging System

Troubleshooting (cont'dl

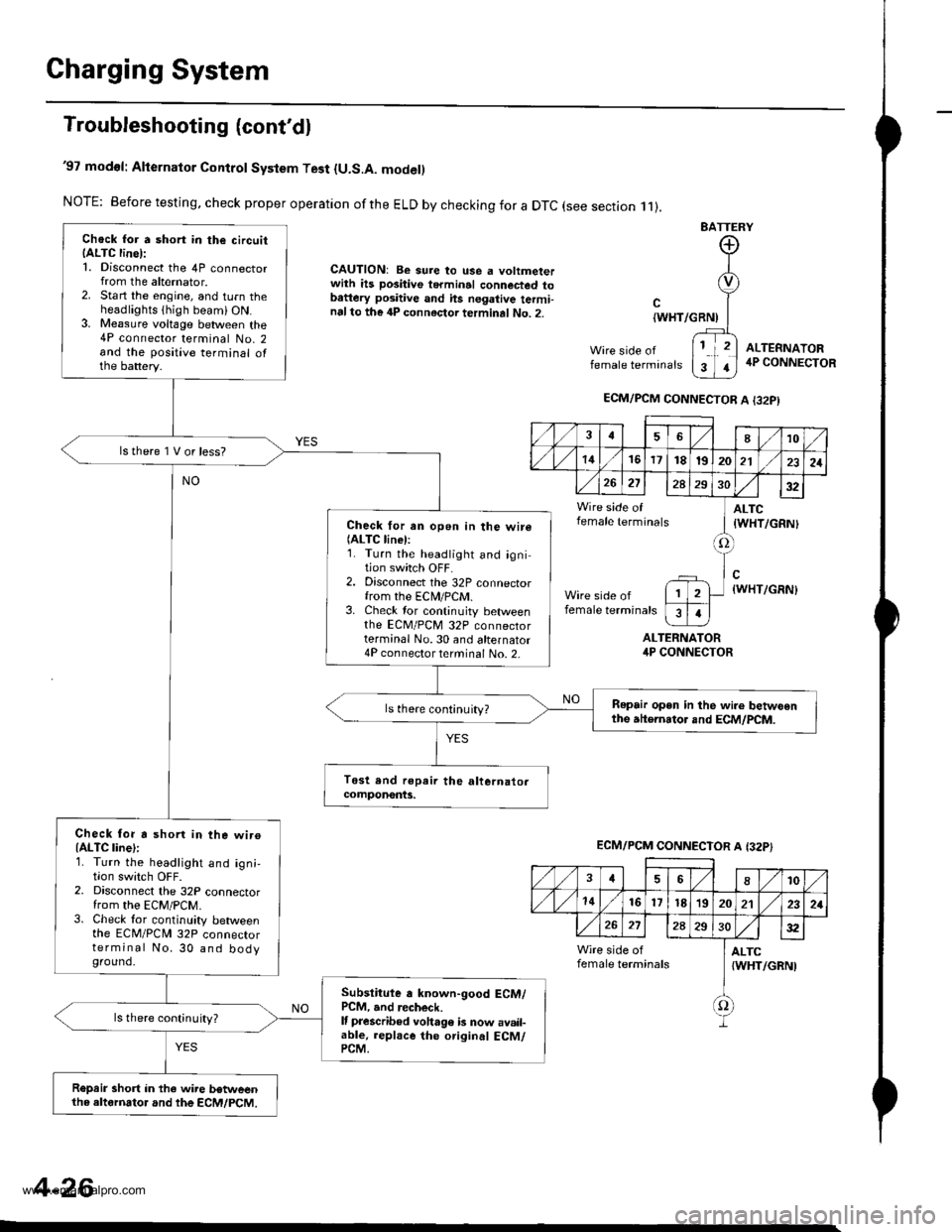

'97 modol: Alternator Control System Test {U.S.A. model)

NOTE: Before testing, check proper operation ofthe ELD by checking for a DTC (see section .11).

CAUTION: Be sure to use a voltmeterwith ils positive terminal connected tobattery positive and hs negative termi-nalto the 4P connector terminal No. 2.

BATTERY

Wire side offemale terminals

{WHT/GRNI

ALTERNATORirP CONNECTOR

ALTEFNATOR4P CONNECTOR

Chock for a short in the circuitIALTC line):1. Disconnect the 4P connectorfrom the alternator.2. Start the engine, and turn theheadlights thigh beami ON.3. Me8sure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

lstherelVorless?

Check for an open in the wire(ALTC linel:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectorfrom the ECN4/PCM.3. Check tor continuity betweenthe EcM/PcM 32P connectorterminal No.30 and alternator4P connector terminal No. 2-

Repair open in the wi.e betwoenthe atternator and ECM/PCM.ls there continuity?

Check for a shorl in the wiroIALTC line):1. Turn the headlight and ign;,I|on swrtcn UFF2. Disconnect the 32P connectorfrom the EcM/PcM.3. Check tor continuity betweenthe ECM/PCN4 32P connectorterminal No. 30 and bodyground.

Subslitute a known-good ECM/PCM, and recheck.It prescribed voha96 b now avail-able, replace the original ECM/PCM.

ls there continuity?

R€prir short in the wire betweenthe altornator and the ECM/PCM.

ECM/PCM CONNECTOR A I32PI

,/1./1810

./ l./t4161718t9202121

26272A293032

Wire side of ] ALTCfemale terminals I tWHT/cRNl

tlWHT/GRN)

female terminals

I

1

ECM/PCM CONNECTOR A {32P}

,/ ,/46810

,/1,/1416l7t8'1920212321

272A2S30:t2

Wire side of I ALTCfemale terminals {WHT/GRNI

f)

4-26

www.emanualpro.com

Page 78 of 1395

Gharging System

Troubleshooting (cont'd)

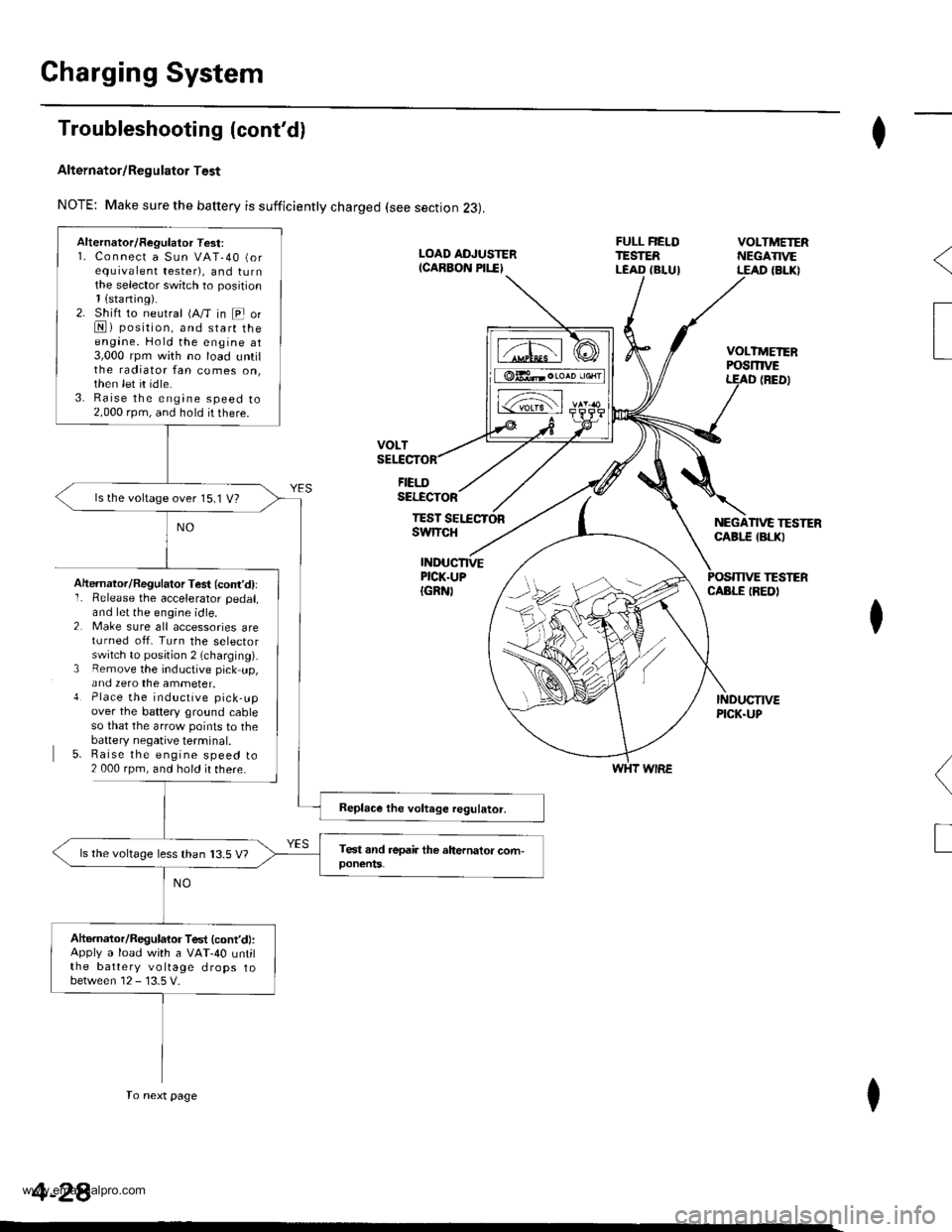

Alternator/Regulator Test

NOTE: Make sure the battery is sufficiently charged (see section 23).

FIELDSELECTOR

TESTswtTcH

I

VOLTMEIERPOSmVEt

NEGATIVE TESTERCABI.E {BLKI

(BED)

TESTERINDUCTIVEPICK.UP{GRN)CABLE IREDIAhernator/Regulator Test (cont'd)lI� Release the accelerator pedal,and let the engine idle.2 Make sure all accessories areturned off. Turn the selectorswitch to posjtion 2 (charging).3 Remove the inductive pick up,and zero the ammeter.{ Place the inductive pick-upover the battery ground cableso that the arrow points to thebaftery negative terminal.5. Raise the engine speed to2 000 rpm, and hold ir there.

I

(

T

I

WHT WIRE

Alternator/Regulator Test:1. Connect a Sun VAT-40 (orequrvalent tester), and turnthe selector switch to position1{sraning).2. Shift to neutral (A/T in E orN) position, and start theengane. Hold the engine at3,000 rpm with no load untilthe radiator fan comes on,then let it idle.3. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

ls the voltage less than 13.5 V?

Altarnator/Regulator Test (cont'd:Apply a load with a VAT-40 untilthe battery voltage drops tobetween 12 - 13.5 V.

To next page

4-28

www.emanualpro.com

Page 82 of 1395

Charging System

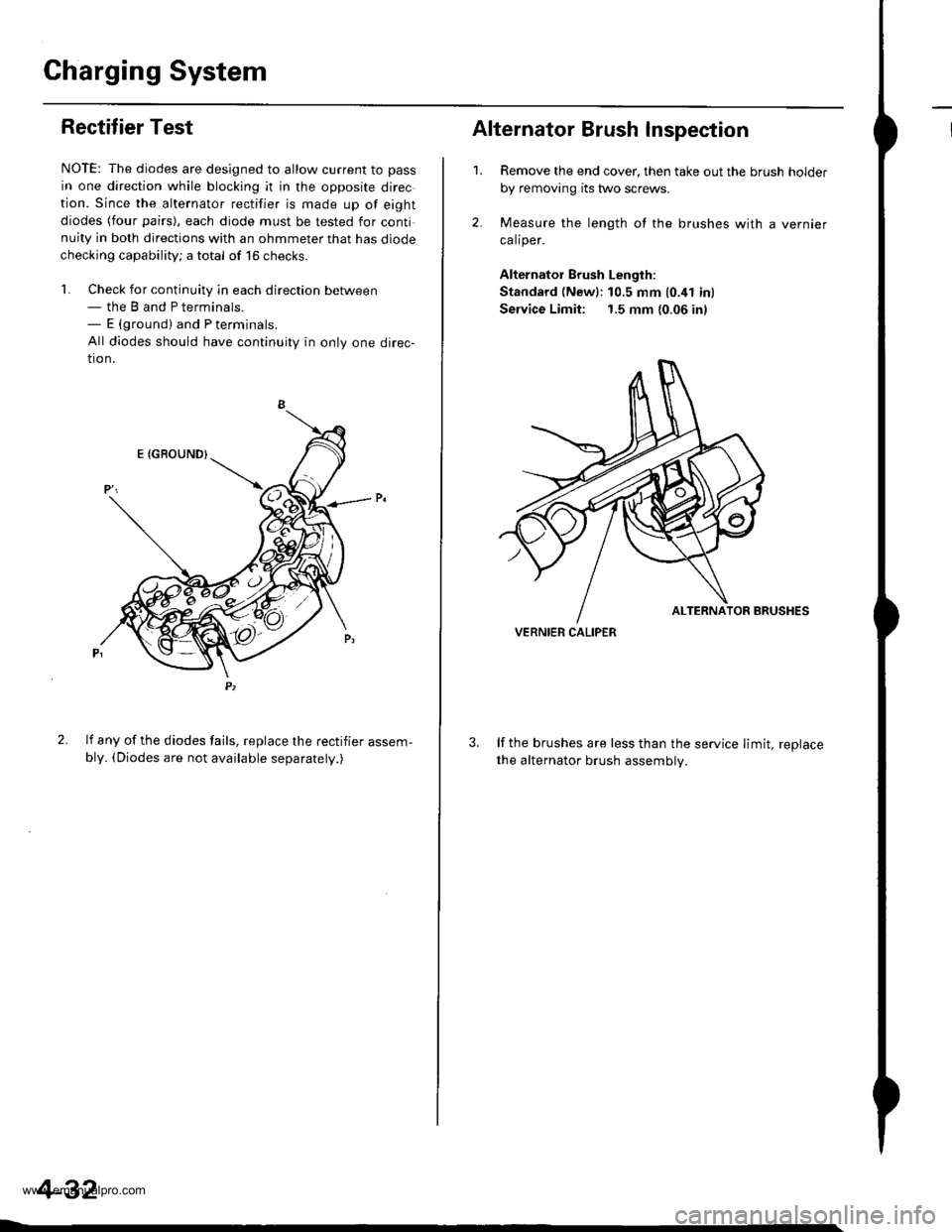

IRectifier Test

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc

tion. Since the alternator rectifier is made up of eight

diodes (four pairs), each diode must be tested for continuity in both directions with an ohmmeter that has diode

checking capability; a total of 16 checks.

'l. Check for continuity in each direction between- the B and P terminals.- E (ground) and P terminals.

All diodes should have continuity in only one direc-

tion.

2. lf any of the diodes fails, replace the rectifier assem-

bly. (Diodes are not available separatelv.)

4-32

1.

Alternator Brush Inspection

2.

Remove the end cover, then take out the brush holder

by removing its two screws.

Measure the length of the brushes with a vernier

calrper.

Alternator Brush Length:

Standard (Newl:10.5 mm 10.41 inl

Service Limit: 1.5 mm {0.06 in)

lf the brushes are less than the service limit, replace

the alternator brush assemblv.

VERNIER CALIPER

www.emanualpro.com

Page 118 of 1395

Valve Seals

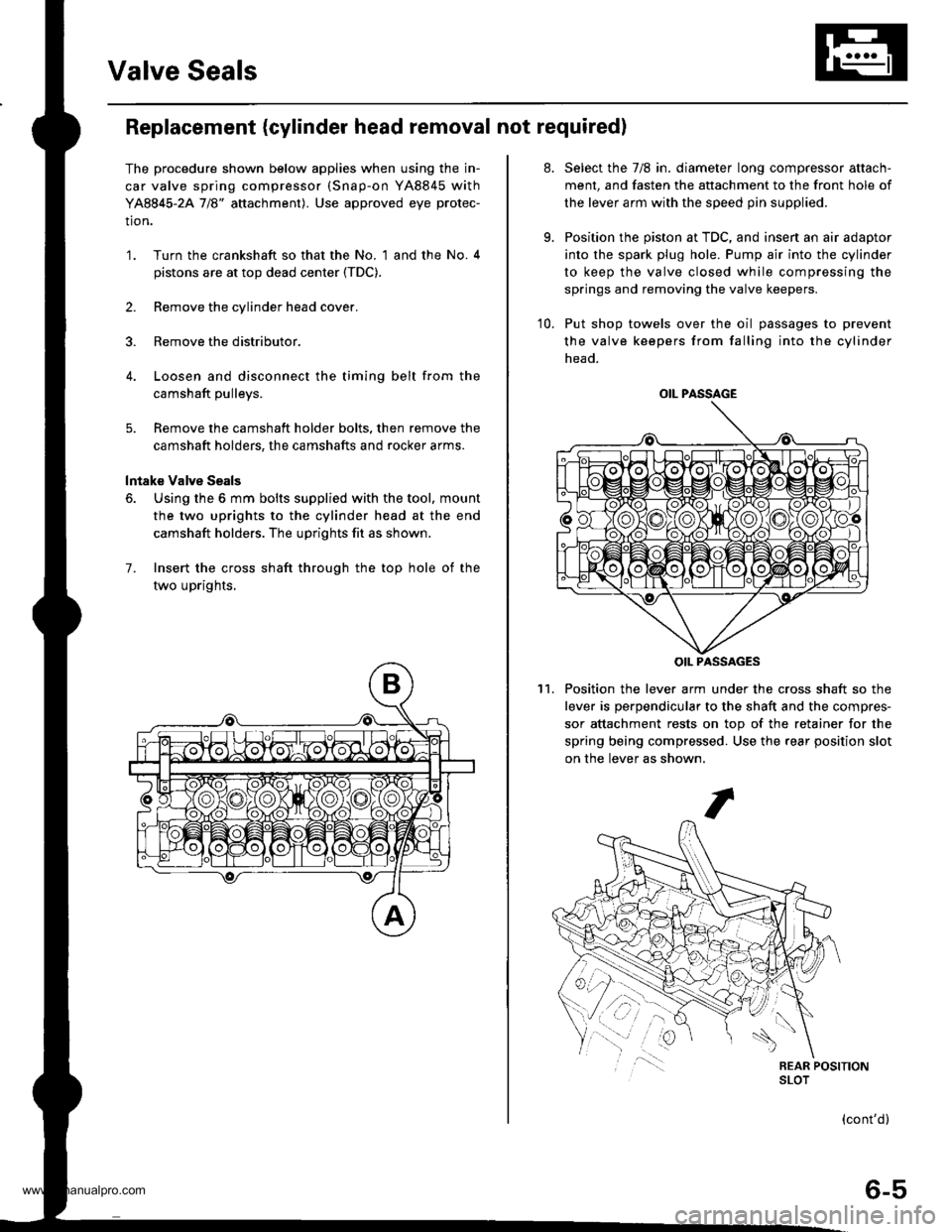

Replacement (cylinder head removal not required)

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

YA8845-2A 7/8" auachment). Use approved eye protec-

tion.

1. Turn the crankshaft so that the No. 1 and the No. 4

pistons are at top dead center (TDC).

2. Remove the cylinder head cover.

3. Remove the distributor.

4. Loosen and disconnect the timing belt from the

camshaft pulleys.

5. Remove the camshaft holder bolts. then remove the

camshaft holders, the camshafts and rocker arms.

lntake Valve Seals

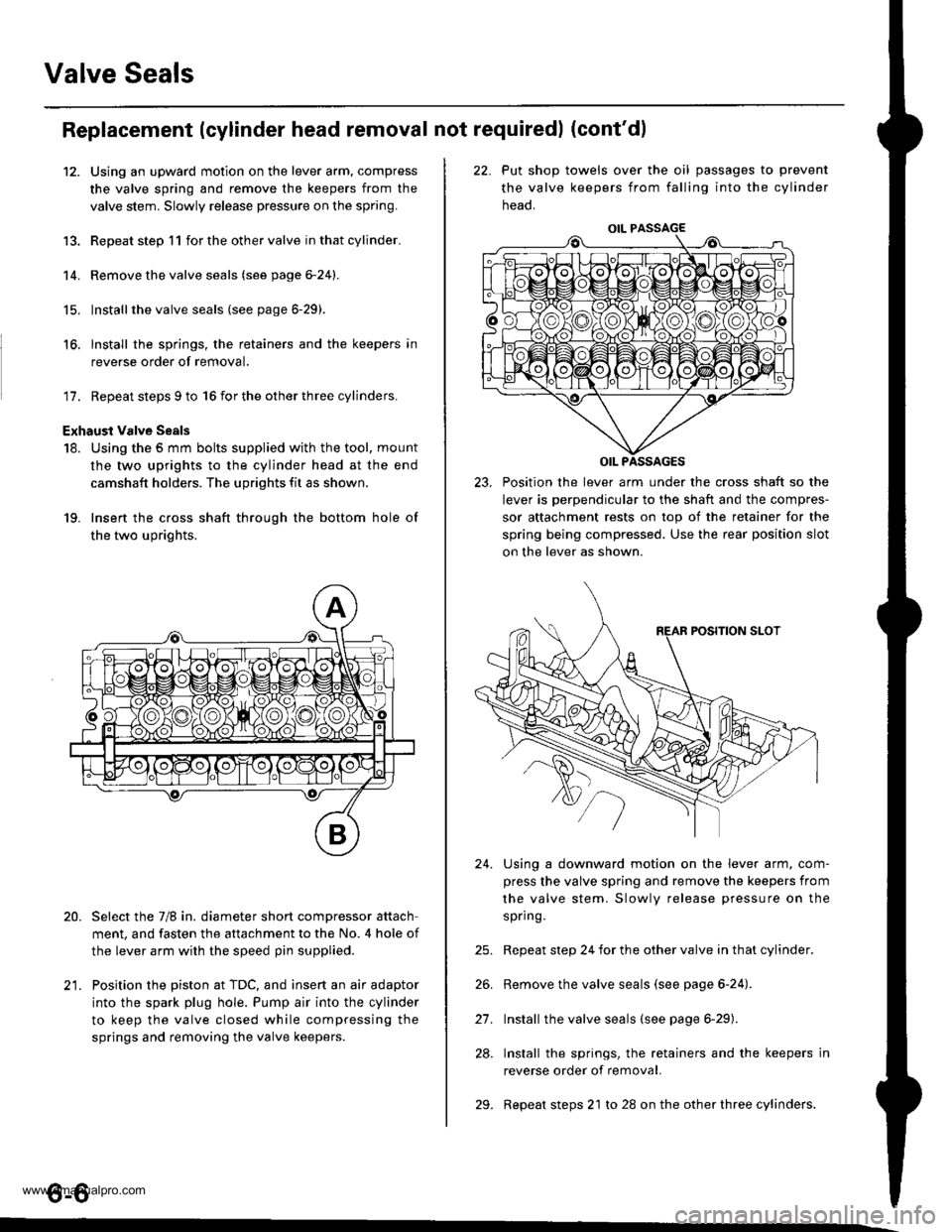

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the top hole of the

two uprights,

at.

9.

Select the 7/8 in. diameter long compressor attach-

ment, and fasten the attachment to the front hole of

the lever arm with the speed pin supplied.

Position the piston at TDC, and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing the

springs and removing the valve keepers.

10. Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

head.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown,

't1.

OIL PASSAGE

OIL PASSAGES

(cont'd)

6-5

www.emanualpro.com

Page 119 of 1395

Valve Seals

12.

Replacement (cylinder head removal not requiredl (cont'dl

Using an upward motion on the lever arm, compress

the valve spring and remove the keepers from the

valve stem. Slowly release pressure on the spring.

Repeat step 11 for the other valve in that cylinder.

Remove the valve seals (see page 6-24).

Installthe valve seals (see page 6-29).

lnstall the springs, the retainers and the keepers in

reverse order of removal.

'17. Repeat steps 9 to 16 for the other three cylinders.

Exhaust valve Seals

18. Using the 5 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

19. Insert the cross shaft through the bottom hole of

the two uprights.

Select the 7/8 in. diameter short compressor attach

ment, and fasten the attachment to the No. 4 hole of

the lever arm with the speed pin supplied.

Position the piston at TDC, and insert an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing the

springs and removing the valve keepers.

13.

14.

15.

16.

20.

t1

22. Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

neao.

23. Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown.

Using a downward motion on the lever arm, com-

press the valve spring and remove the keepers from

the valve stem. Slowly release pressure on the

spring.

Repeat step 24 for the other valve in that cylinder.

Remove the valve seals (see page 6-24).

Install the valve seals (see page 6-29).

Install the springs, the retainers and the keepers in

reverse order of removal.

Repeat steps 21 to 28 on the other three cylinders.

24.

21.

28.

29.

o-o

www.emanualpro.com