Meter HONDA CR-V 1997 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 740 of 1395

Differential

Differential Carrier Replacement

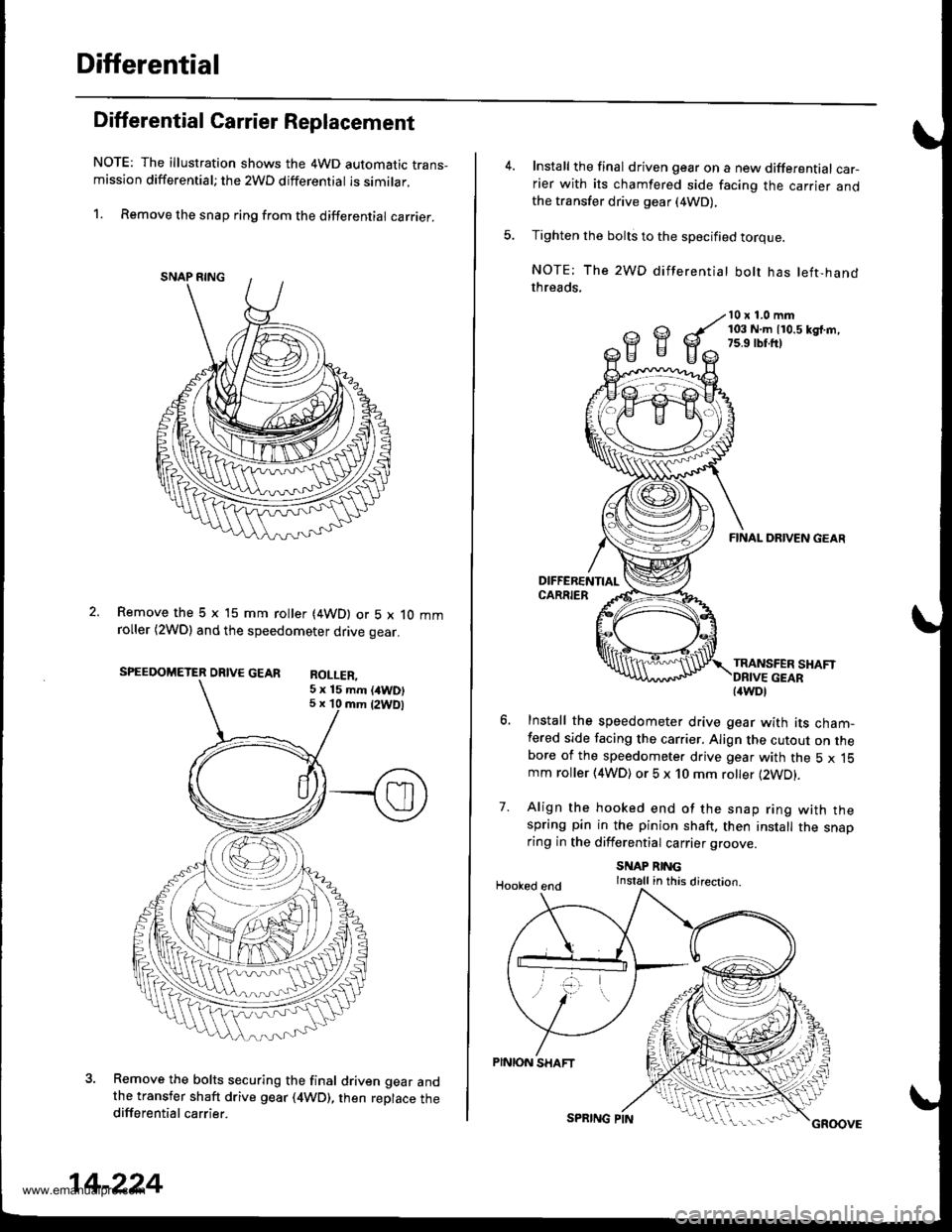

NOTE: The illustration shows the 4WD automatic trans-mission differential; the 2WD differential is similar.

1. Remove the snap ring from the differential carrier.

Remove the 5 x 15 mm roller (4WD) or 5 x 10 mmroller (2WDl and the speedometer drive gear.

SPEEDOMETER DRIVE GEAR RoI I FP

Remove the bolts securing the final driven gear andthe transfer shaft drive gear (4WD), then replace thedifferential carrier.

5 x 15 mm (/tWD)5 x 10 mm {2WDl

14-224

SPRING PINGROOVE

Install the final driven gear on a new differential car-rier with its chamfered side facing the carrier andthe transfer drive gear (4WD),

Tighten the bolts to the specified torque.

NOTE: The 2WD differentiat bolt has left-handthreads,

10 x 1.0 mm103 N.m 110.5 kd.m,7s.9 rbr.ft)

7.

FINAL DRIVEN GEAR

TRANSFER SHAFT

Install the speedometer drive gear with its cham-fered side facing the carrier. Align the cutout on thebore of the speedometer drive gear with the 5 x 15mm roller (4WD) or 5 x 10 mm roller (2WD).

Align the hooked end of the snap ring with thespring pin in the pinion shaft. then install the snaoring in the differential carrier groove

SNAP RINGInstall in this direction.Hooked end

PINION SHAFT

{4WDl

www.emanualpro.com

Page 860 of 1395

Rack Guide Adjustment

1.

6.

7.

5.

4.

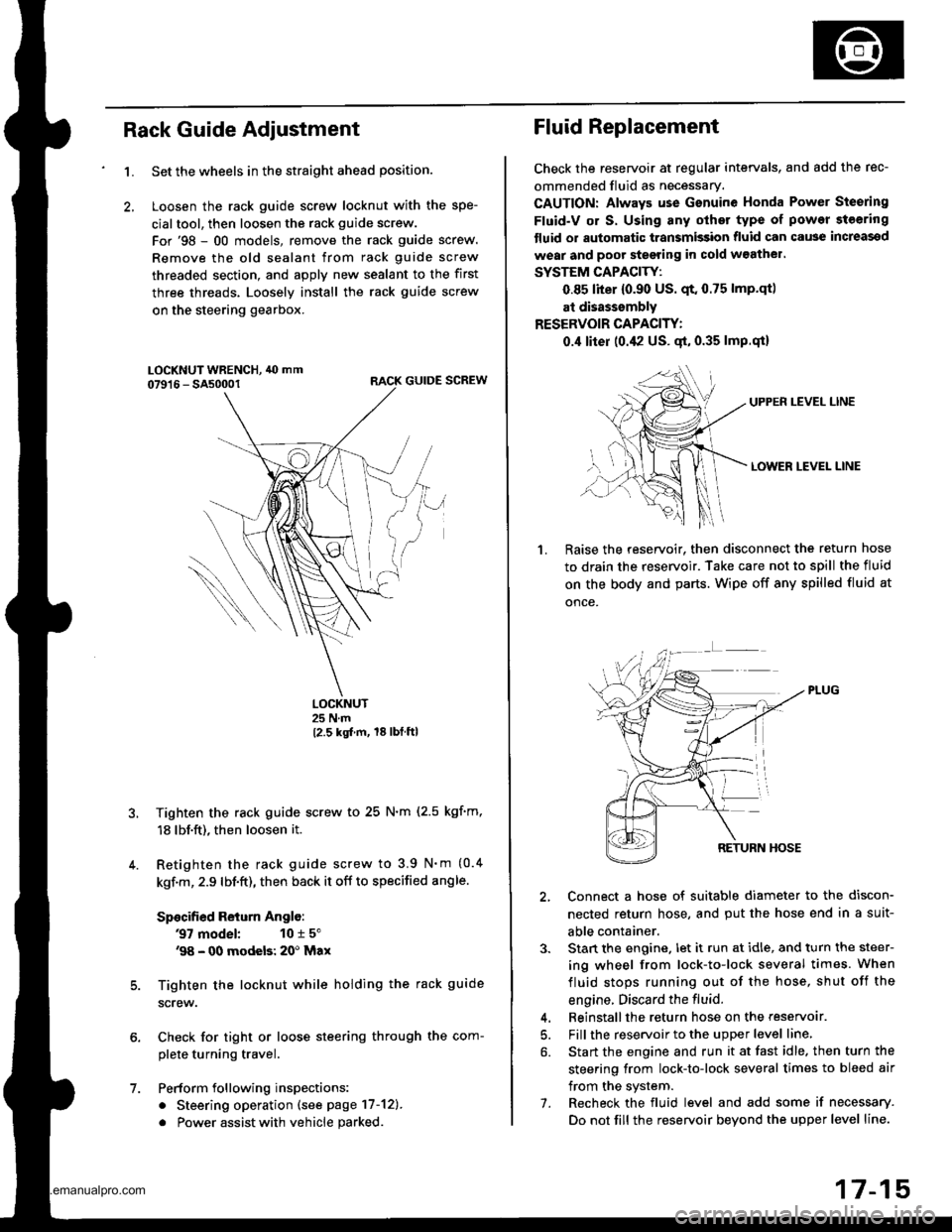

Set the wheels in the straight ahead position.

Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

For'98 - 00 models, remove the rack guide screw.

Remove the old sealant from rack guide screw

threaded section, and apply new sealant to the first

three threads. Loosely install the rack guide screw

on the steering gearbox.

RACK GUIDE SCREW

LOCKNUT25 N.m

12.5 kgt m, 18lbtftl

Tighten the rack guide screw to 25 N.m (2.5 kgf'm,

18 lbf.ft), then loosen it.

Retighten the rack guide screw to 3.9 N'm (0.4

kgf.m, 2.9 lbf.ft), then back it off to specified angle.

Specified Return Anglo:

37 model: 10 r 5"'98 - 00 modeb: 20' Max

Tighten the locknut while holding the rack guide

screw.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-12).

. Power assist with vehicle parked

Fluid Replacement

Check the reseryoir at regular intervals, and add the rec-

ommended fluid as necessary.

CAUTION: Always use Gsnuine Honda Power Steering

Fluid-V or S. Using any other type of power steering

tluid or automatic transmission fluid can cause increassd

wear and poor steering in cold w3athel.

SYSTEM CAPACITY:

0.85 liter {0.90 US. qt. 0.75 lmp.qtl

at disasssmbly

RESERVOIR CAPACITY:

0.,1 liter (0.42 US. gt, 0.35 lmp.qi)

UPPEN LEVEL LINE

LOWER LEVEL LINE

1.Raise the reservoir. then disconnect the return hose

to drain the reservoir. Take care not to spill the fluid

on the body and parts. Wipe off any spilled fluid at

once.

2, Connect a hose of suitable diameter to the discon-

nected return hose, and put the hose end in a suit-

able container.

3. Stan the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

4. Beinstallthe return hose on the reservoar.

5. Fill the reservoir to the upper level line,

6. Start the engine and run it at fast idle. then turn the

steering from lock-to-lock several times to bleed air

from the system.

7. Recheck the fluid level and add some if necessary.

Do not fill the reservoir beyond the upper level line.

www.emanualpro.com

Page 881 of 1395

Power Steering Gearbox

Disassembly {cont'd}

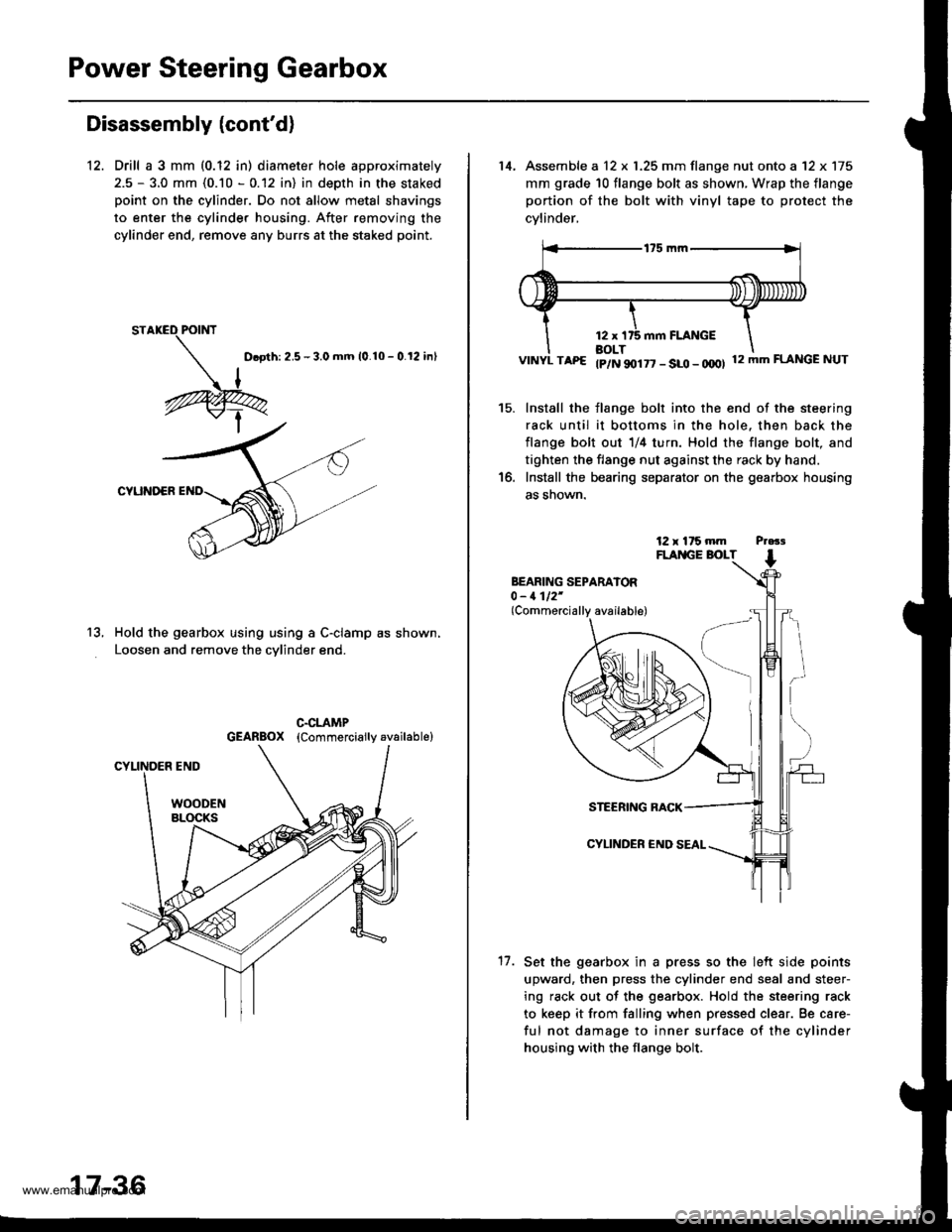

12. Drill a 3 mm (0.12 in) diameter hole approximately

2.5 - 3.0 mm (0.10 - 0.12 in) in depth in the staked

point on the cylinder. Do not allow metal shavings

to enter the cylinder housing. After removing the

cylinder end, remove any burrs at the staked point.

D.oth: 2.5 - 3.0 mm 10.10 - 0.12 inl

CYUNOER

Hold the gearbox using using a C-clamp as shown,

Loosen and remove the cvlinder end.

13.

17-36

14, Assemble a 12 x 1.25 mm flange nut onto a '12 x 175

mm grade 10 flange bolt as shown, Wrap the flange

portion of the bolt with vinyl tape to protect the

cvlinder,

VINYL TAP€ tp/N 90177 - SLO - OOOI 12mmFLANGENUT

Install the flange bolt into the end of the steering

rack until it bottoms in the hole. then back the

flange bolt out 1/4 turn. Hold the flange bolt, and

tighten the flange nut against the rack by hand.

Install the bearing separator on the gearbox housing

as snown.

15.

BEARING SEPARATOR0 - 1112'(Commercially available)

17.

STEERING RACK

CYLINDER €ND

Set the gearbox in a press so the lelt side points

upward, then press the cylinder end seal and steer-

ing rack out of the gearbox. Hold the steering rack

to keep it from falling when pressed clear. Be care-

ful not damage to inner surface of the cylinder

housing with the flange bolt.

www.emanualpro.com

Page 886 of 1395

Valve Body Unh Roa$embly

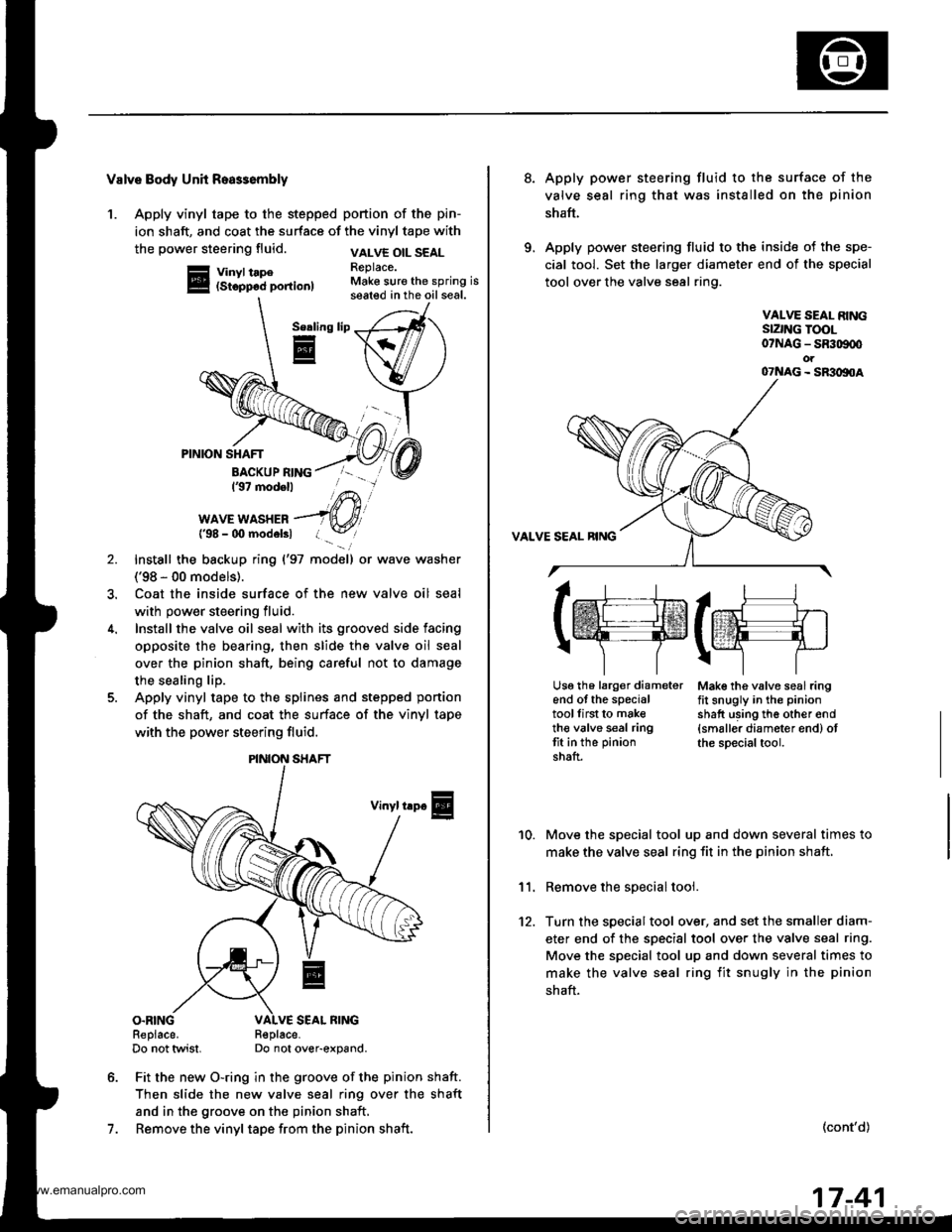

1. Apply vinyl tape to the stepped portion of the pin-

ion shaft, and coat the surface of the vinyl tape with

the power steering fluid.

Vinyl tape(Stopp6d portion)

VALVE OIL SEALReplace.Make sure the spring isseated in the oil seal.

Serling

E

7.

PINION SHAFT

BACKUP RING137 modell

WAVE WASHER{'98 - 00 modelsl

Install the backup ring {'97 model) or wave washer

('98 - 00 models).

Coat the inside surface of the new valve oil seal

with power steering fluid.

Install the valve oil seal with its grooved side facing

opposite the bearing, then slide the valve oil seal

over the pinion shaft, being careful not to damage

the sealing lip.

Apply vinyl tape to the splines and stepped ponion

of the shaft, and coat the surface of the vinyl tape

with the power steering fluid.

Vinyl trp€

O.RINGReplace.Do not twist.R€place-Do not over-expand.

Fit the new O-ring in the groove of the pinion shaft.

Then slide the new valve seal ring over the shaft

and in the groove on the pinion shaft,

Remove the vinyl tape from the pinion shaft.

\/

PINION SHAFT

8.Apply power steering fluid to the surface of the

valve seal ring that was installed on the pinion

shaft.

Apply power steering fluid to the inside of the spe-

cial tool. Set the larger diameter end of the special

tool over the valve seal ring.

VALVE SEAL RINGSIZNG TOOL07NAG - SR309q'ot07NAG - SR3oltoA

Mak€ the valve seal ringfit snugly in the pinion

shatt using th6 other end{smaller diameter end) otthe special tool.

10.

11.

12.

Move the special tool up and down several times to

make the valve seal ring fit in the pinion shaft,

Remove the soecial tool.

Turn the special tool over, and set the smaller diam-

eter end of the specisl tool over the valve seal ring.

Move the special tool up and down several times to

make the valve seal ring fit snugly in the pinion

shaft.

(cont'd)

lrr.rj1

tffifrE-rr.]

r\-''] 7

Usg th6 larg€r diameterend of the specialtoollirst to maketh€ valve seal ringtit in the pinion

shaft.

17-41

www.emanualpro.com

Page 887 of 1395

Power Steering Gearbox

13.

Reassembly (cont'd)

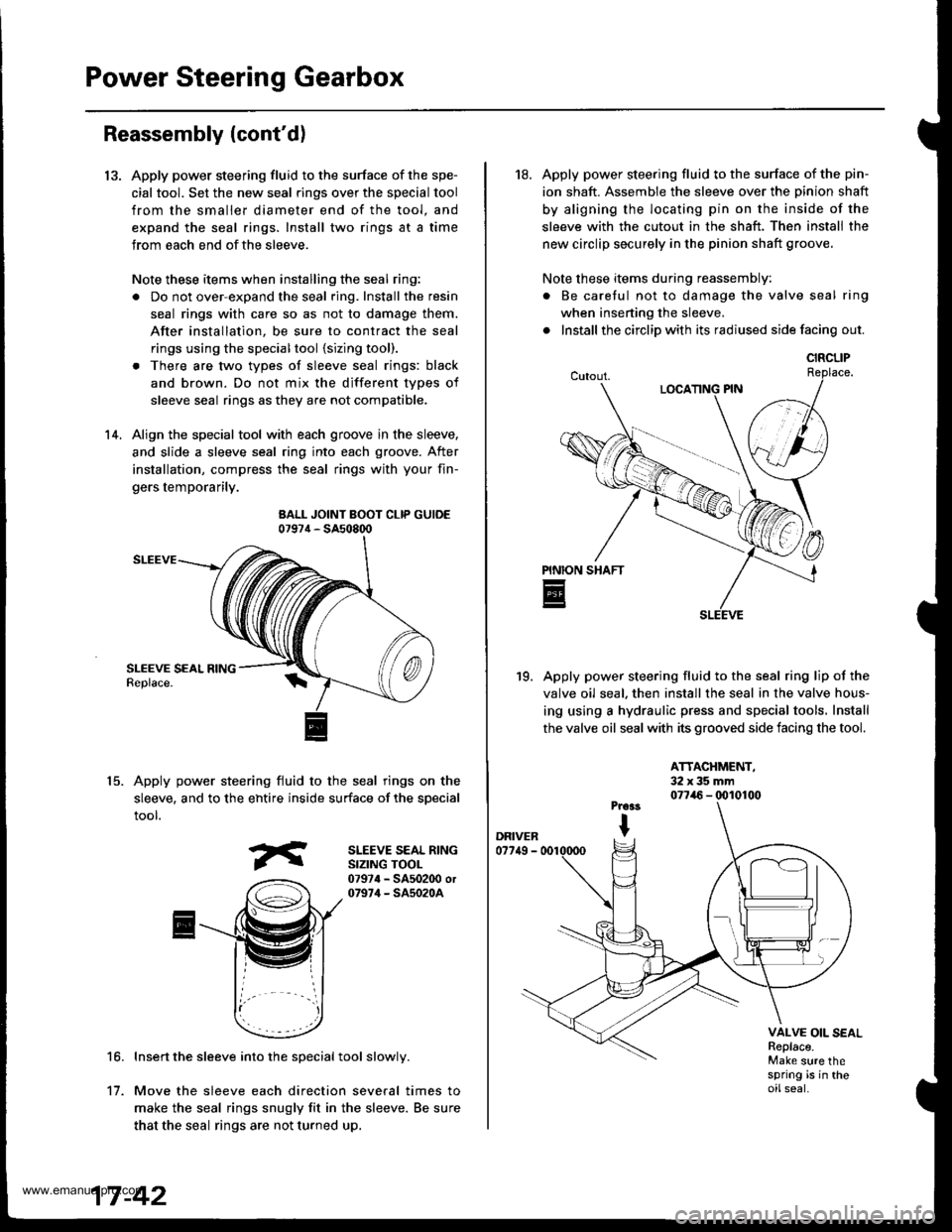

Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool. and

expand the seal rings. Install two rings at a time

Jrom each end ofthe sleeve.

Note these items when installing the seal ring:

. Do not over-expand the seal ring. Install the resin

seal rings with care so as not to damage them.

After installation, be sure to contract the seal

rings using the specialtool {sizing tool).

. There are two types of sleeve seal rings: black

and brown. Do not mix the different types of

sleeve seal rings as they are not compatible.

Align the special tool with each groove in the sleeve,

and slide a sleeve seal ring into each groove. After

installation, compress the seal rings with your fin-

gers temporarily.

BALL JOINT BOOT CLIP GUIDE07974 - SA508q)

SLEEVE

Apply power steering fluid to the seal rings on the

sleeve, and to the ehtire inside surface of the special

tool.

14.

15.

SLEEVE SEAL RINGSIZING TOOL07974 - SA502O0 or07974 - SA5020A

16.Insert the sleeve into the special tool slowly.

Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve. Be sure

that the seal rings are not turned up,

't1.

18. Apply power steering fluid to the surface of the pin-

ion shaft. Assemble the sleeve over the Dinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove.

Note these items during reassembly:

. Be caretul not to damage the valve seal ring

when inserting the sleeve.

. Install the circlip with its radiused side facing out.

Apply power steering fluid to the seal ring lip of the

valve oil seal. then install the seal in the valve hous-

ing using a hydraulic press and special tools. Install

the valve oil seal with its grooved side facing the tool.

19.

ATTACHMENT,32x35mm077i16 - (x)10100

VALVE OIL SEALReplace.Make sure thespring is in theoilseal.

CIRCLIP

www.emanualpro.com

Page 891 of 1395

Power Steering Gearbox

Reassembly (cont'dl

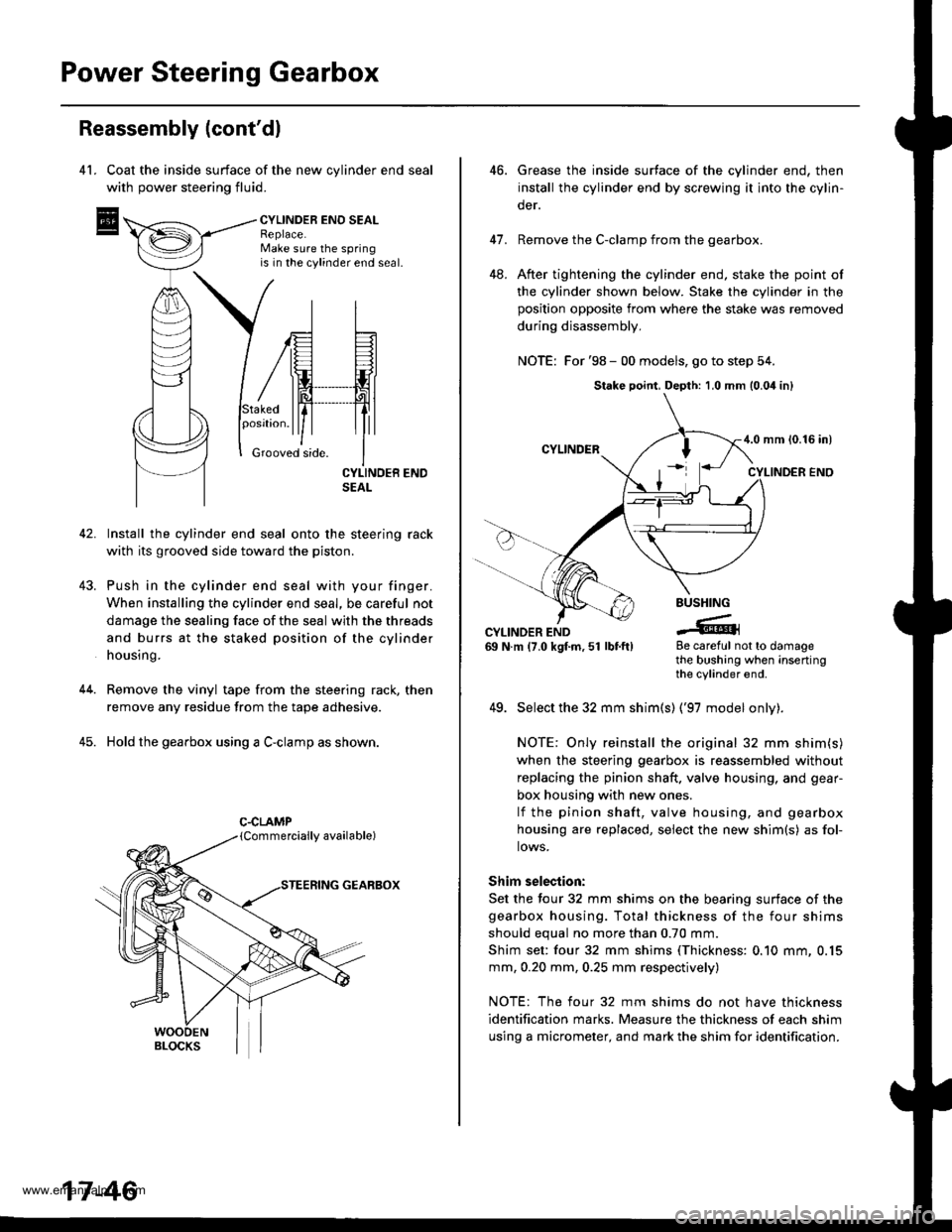

4l. Coat the inside surface of the new cvlinder end seal

with power steering fluid.

CYLINDEB ENO SEALReplace.Make sure the springis in the cylinder end seal.

43.

Stakedposrtron.

Grooved side.

42. Install the cylinder end seal onto the steering rack

with its grooved side toward the piston.

Push in the cylinder end seal with your finger.

When installing the cylinder end seal, be careful not

damage the sealing face of the seal with the threads

and burrs at the staked position of the cylinder

housing.

Remove the vinyl tape from the steering rack, then

remove any residue from the tape adhesive.

Hold the gearbox using a C-clamp as shown.

GEARBOX

44.

45.

C.CLAMP

17-46

46.Grease the inside surtace of the cylinder end, then

install the cylinder end by screwing it into the cylin-

der.

Remove the C-clamp from the gearbox.

After tightening the cylinder end, stake the point of

the cylinder shown below. Stake the cylinder in the

position opposite from where the stake was removed

during disassembly,

NOTE: For '98 - 00 models, go to step 54.

41.

48.

BUSHING

-tGCYLINDER END69 N.m (7.0 kgf.m,51 lbtft)8e careful not to damagethe bushing when insertingthe cylinder end.

49. Select the 32 mm shim(s) ('97 model onlv).

NOTE: Only reinstall the original 32 mm shim(s)

when the steering gearbox is reassembled without

replacing the pinion shaft. valve housing, and gear-

box housing with new ones.

lf the pinion shaft, valve housing, and gearbox

housing are replaced, select the new shim{s) as fol-

lows.

Shim selection:

Set the four 32 mm shims on the bearing surface of the

gearbox housing. Total thickness of the four shims

should equal no more than 0.70 mm.

Shim set: four 32 mm shims (Thickness: 0.10 mm, 0.15

mm, 0.20 mm, 0.25 mm respectively)

NOTE: The four 32 mm shims do not have thickness

identification marks. Measure the thickness of each shim

using a micrometer, and mark the shim for identification.

Stake point, Depth: 1,0 mm (0.04 inl

4.0 mm {0.16 in)

www.emanualpro.com

Page 941 of 1395

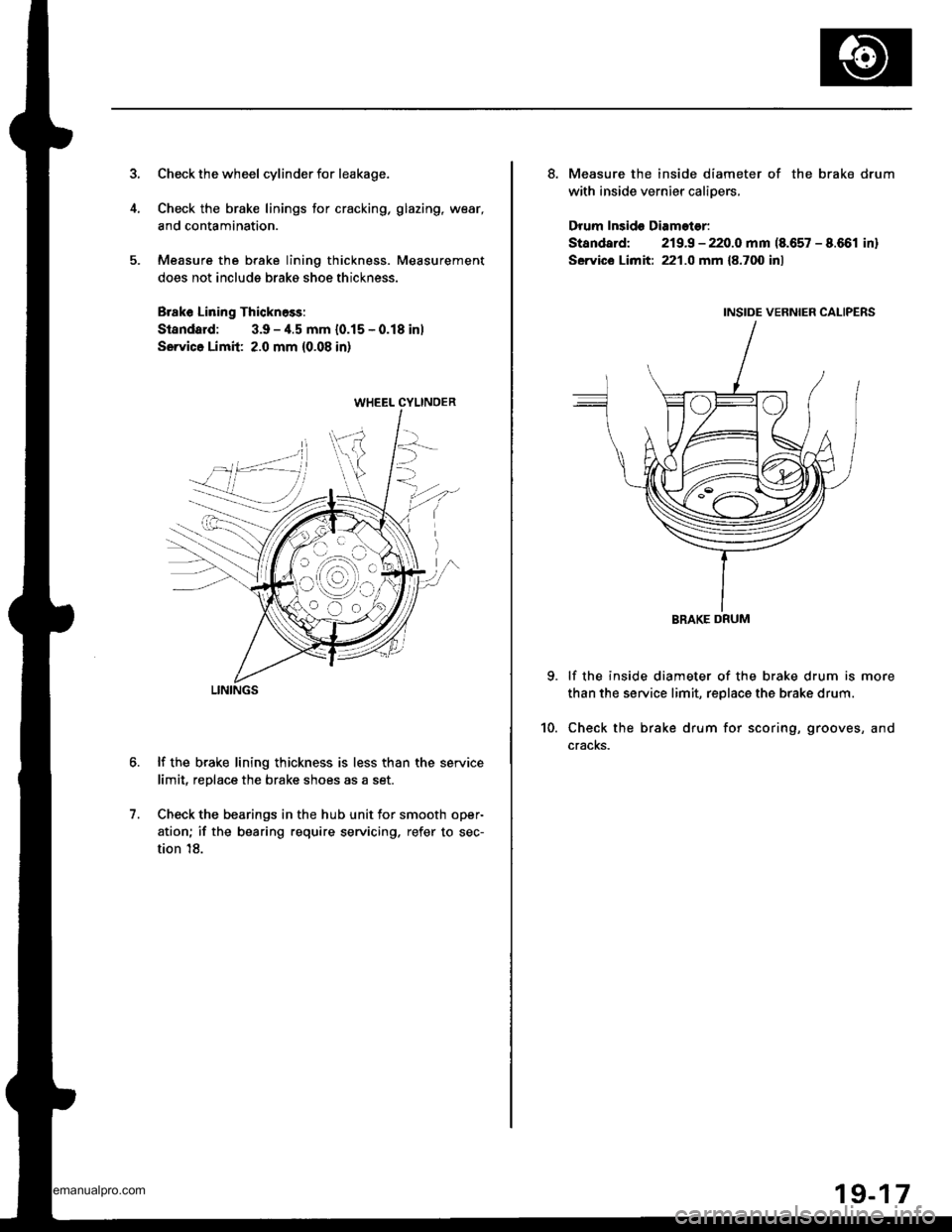

Check the wheel cylinder for leakage.

Check the brake linings for cracking, glazing, wear,

and contamination.

Measure the brake lining thickness. Measurement

does not include brako shoe thickness.

Brake Lining Thicknoss:

Standard: 3.9 -,1.5 mm {0.15 - 0.18 inl

Sorvice Limil: 2.0 mm {0.08 in}

lf the brake lining thickness is less than the service

limit, replace the brake shoes as a set.

Check the bearings in the hub unit for smooth oper-

ation; if the bearing require servicing. refer to sec-

tion 18.

7.

WHEEL CYLINOER

LININGS

8. Measure the inside diameter of the brake drum

with inside vernier calioers,

Drum Insido Diamoter:

Standard: 219.9 - 220.0 mm (8.657 - 8.661 in)

Service Limit: 221.0 mm {8.700 inl

lf the inside diameter of the brake drum is more

than the service limit, replaca the brake drum.

Check the brake drum for scoring, grooves, and

cracKs.

10.

BRAKE DRUM

19-17

www.emanualpro.com

Page 950 of 1395

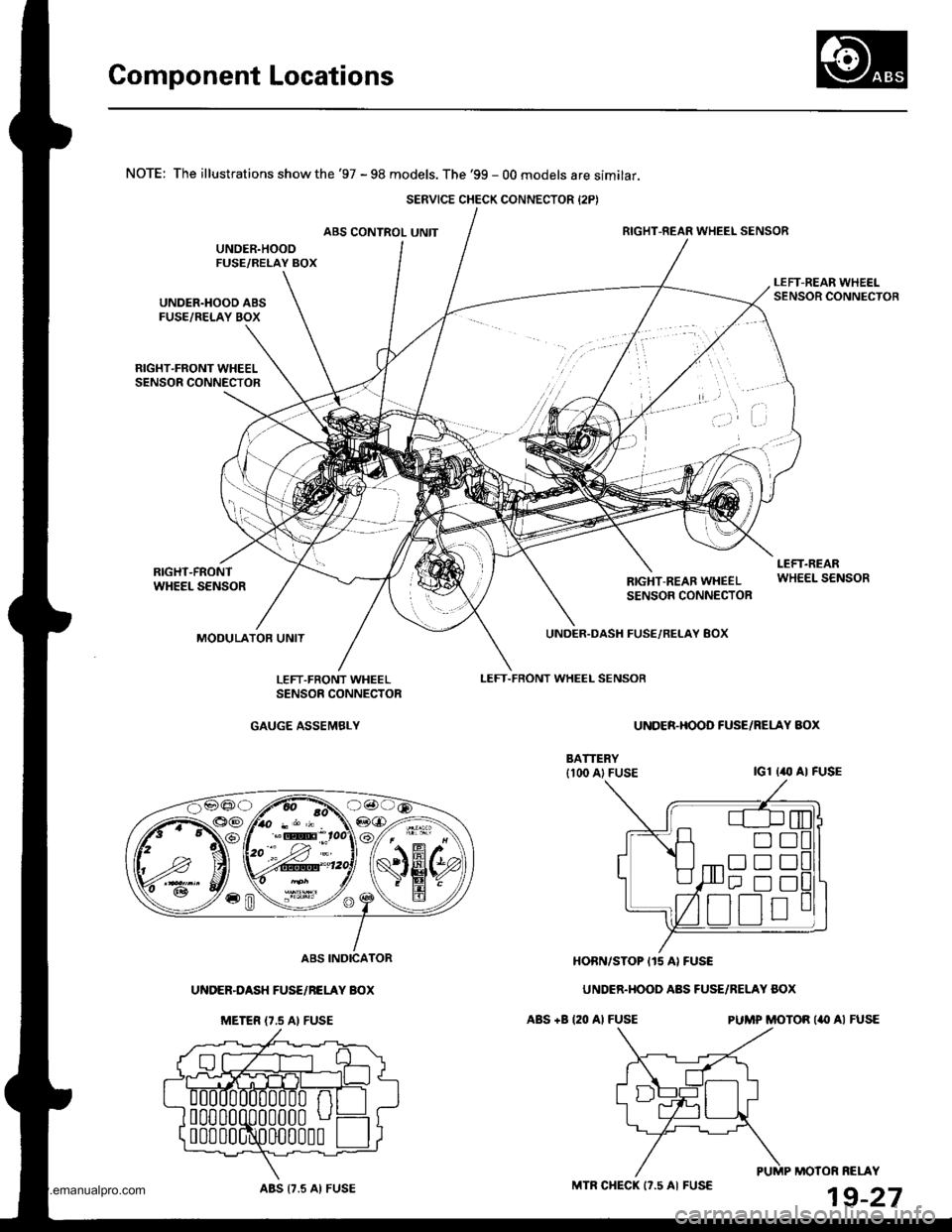

Component Locations

NOTE: The illustrations show the '97 - 98 models. The '99 - 00 models are similar.

ABS CONTROL UNITRIGHT-REAR WHEEL SENSOR

UNDER.HOOD ABSFUSE/RELAY BOX

RIGHT.FRONT WHEELSENSOR CONNECTOR

RIGHT-FRONTWHEEL SENSORRIGHT-REAB WHEELSENSOR CONNECTOR

MODULATOR UNIT

LEFT.FRONT WHEEL SENSOB

UNDER.DASH FUSE,/RELAY 8OX

UNDER.HOOO FUSE/RELAY AOX

IGl I(, AI FUSE

ABS +B 120 Al FUSEPUMP MOTOR ('II AI FUSE

HOBN/STOP I15 AI FUSE

UNDER.HOOD ABS FUSE/RELAY BOX

LEFT.FRONT WHEELSENSOE CONNECTOR

GAUGE ASSEMBLY

ABS INDICATOR

UNDER-DASH FUSE/NELAY BOX

METER {7.5 AI FUSE

MOTOR RELAY

19-27

SERVICE CHECK CONNECTOR {2PI

D!

trtrtr

[r D!

ABS {7.5 AI FUSEMTR CHECK 17.5 AI FUSE

www.emanualpro.com

Page 964 of 1395

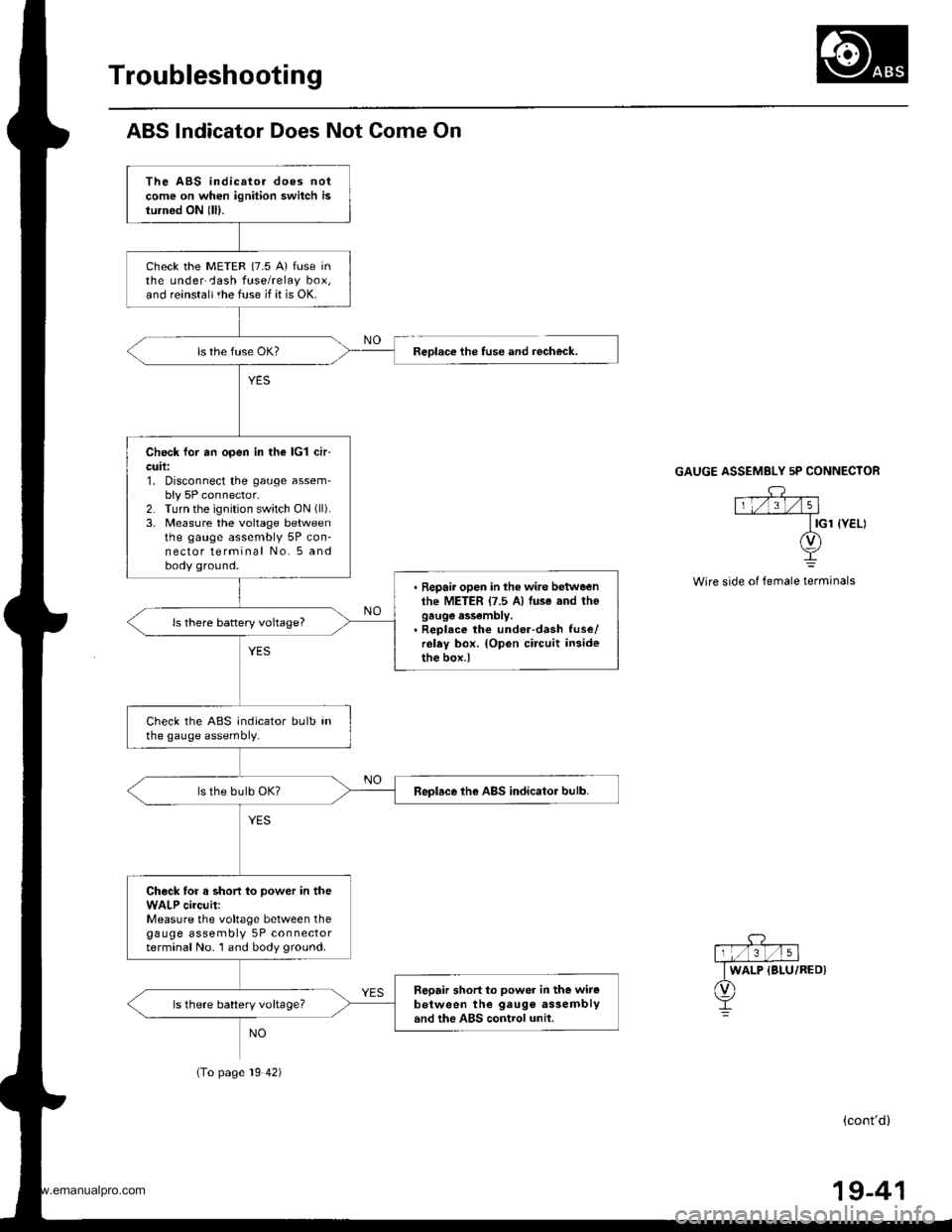

Troubleshooting

ABS lndicator Does Not Come On

The ABS indicator does notcome on when ignition switch isturnod ON lll).

check the METER {7.5 A} fuse inthe underCash fuse/relay box,and reinstaltthe fuse if it is OK.

Check for an open in the lcl ch-cuil:1. Disconnect the gauge assem-bly 5P connector.2. Turn the ignition switch ON (ll).

3. Measure the voltage betweenthe gauge assembly 5P con-nector terminal No. 5 andbody ground.

. Repair open in the wire betweenlhe METER {7.5 A) luse and thogauge assembly.. Reolece the under-dash fuse/relay box. (Opon circuit insidethe box.)

ls there battery voltage?

Check the ABS indicator bulb inthe gauge assembly.

Replace the ABS indicator bulb.

Check for a short to power in theWALP circuit:Measure the voltage between thegauge assembly 5P connectorterminal No. 1 and body ground.

Sepair short to power in the witeb€tween the gaug€ assemblyand the ABS control unil.ls there battery voltageT

Reolace the tuse and recheck.

(To page 19 42)

GAUGE ASSEMBLY 5P CONNECTOR

Wire side of female terminals

(cont'd)

19-41

www.emanualpro.com

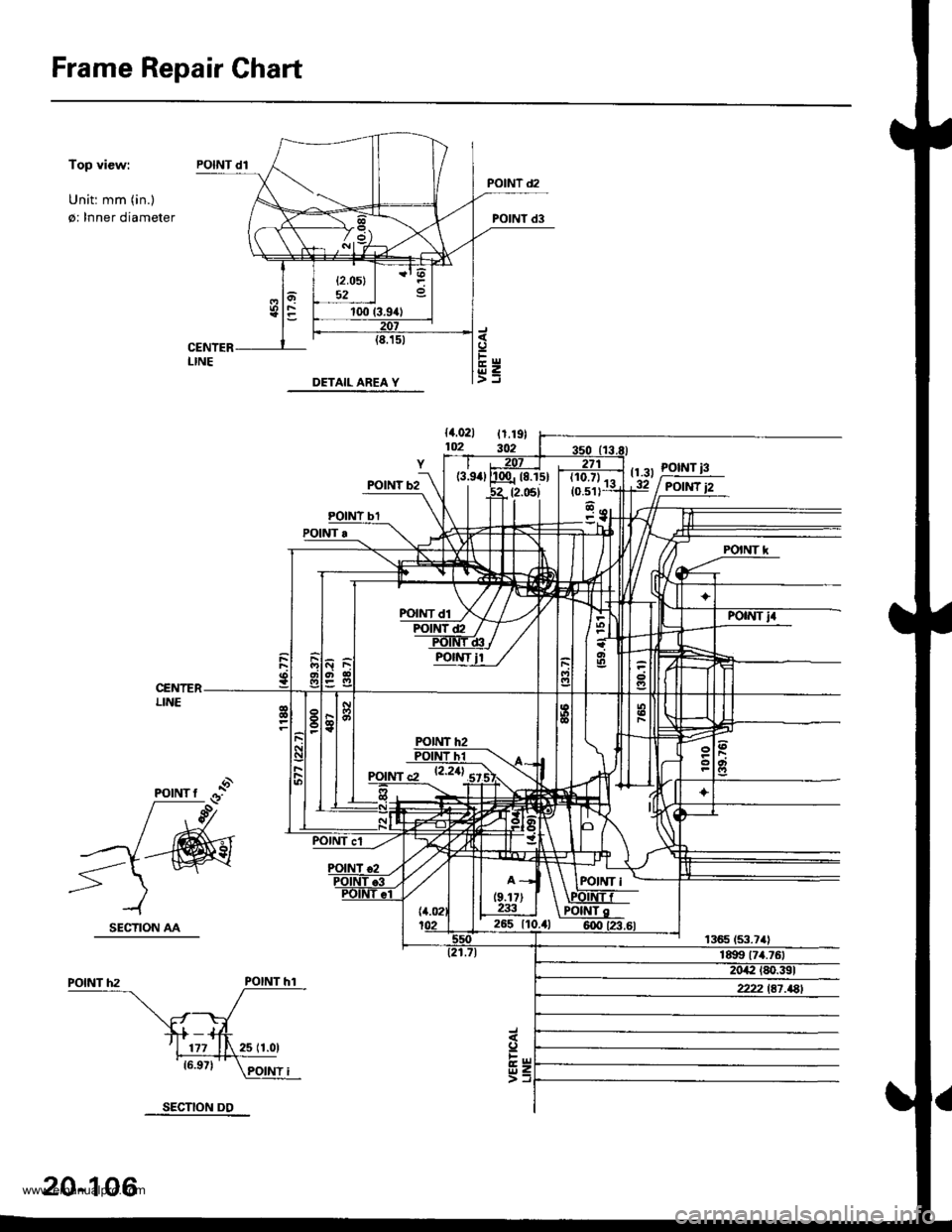

Page 1086 of 1395

Frame Repair Chart

Top view:

Unit: mm (in.)

0: Inner diameter

{4.021 t1.19}lm 302

tr.rr !9$IPOtt{T

POINT'

POINT hl

20-106

SECTION DD

www.emanualpro.com