spring HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 799 of 1395

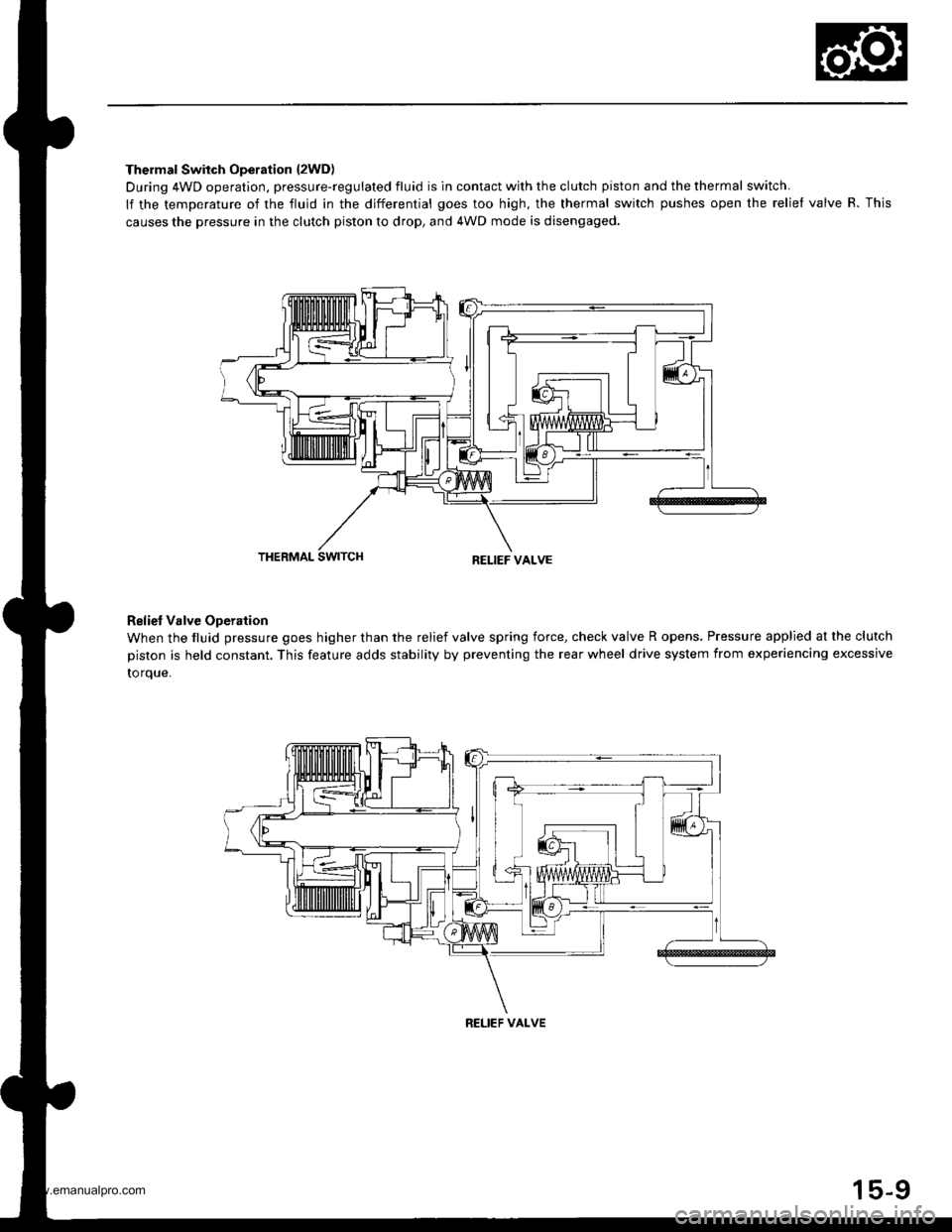

Thermal Switch Operation l2WD)

During 4WD operation, pressure-regulated fluid is in contact with the clutch piston and the thermal switch.

lf the temperature of the fluid in the differential goes too high, the thermal switch pushes open the relief valve R. This

causes the pressure in the clutch piston to drop, and 4WD mode is disengaged.

THERMAL SWITCHRELIEF VALVE

Reliet Valve Operation

When the fluid pressure goes higher than the relief valve spring force, check valve R opens. Pressure applied at the clutch

piston is held constant. This feature adds stability by preventing the rear wheel drive system from experiencing excessive

to rque.

RELIEF VALVE

15-9

www.emanualpro.com

Page 811 of 1395

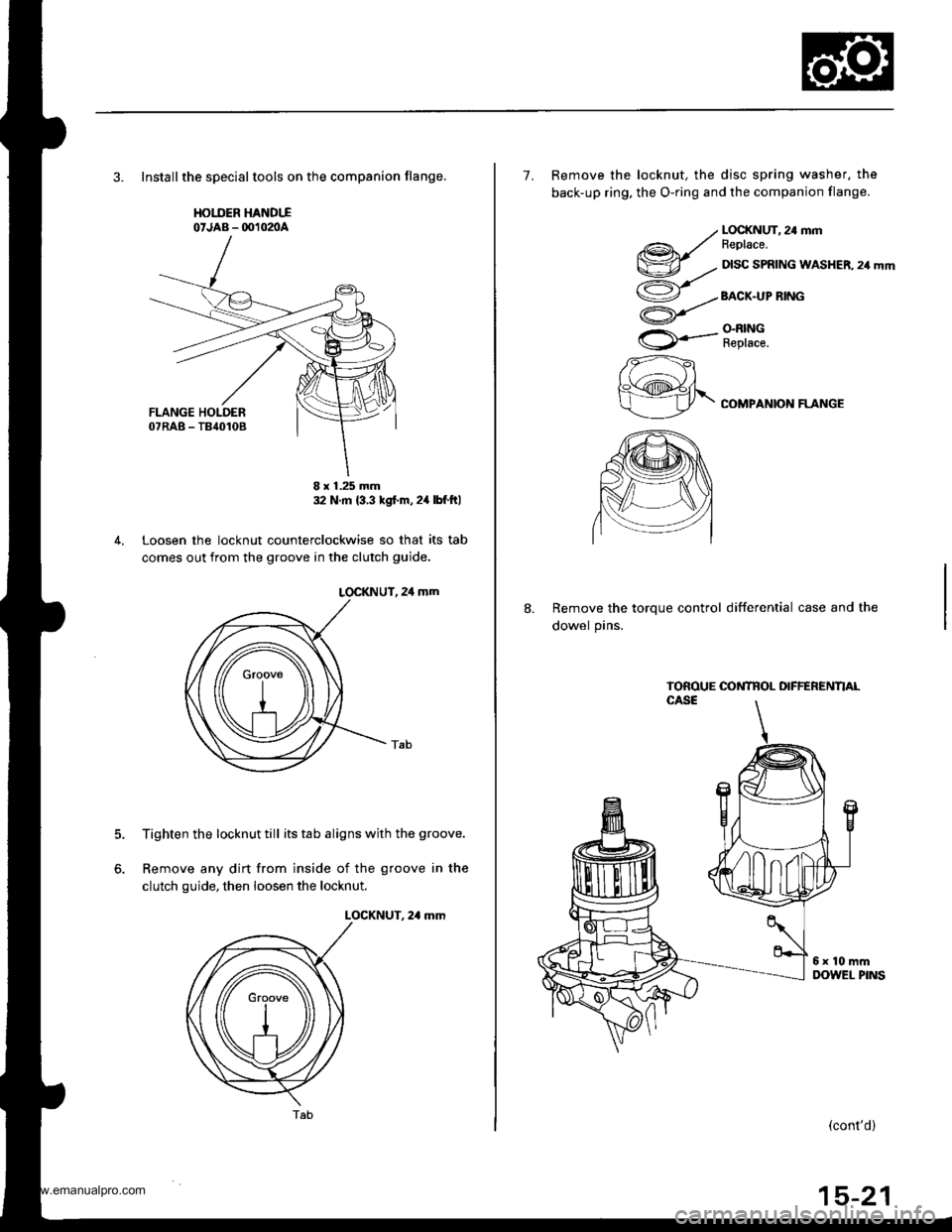

3. Installthe speclaltools on the companion flange,

HOIIIER HANDTIo'JAB - OO102nA

32 N m {3 3 tgt m,24lbf ftl

Loosen the locknut counterclockwise so that its tab

comes out from the groove in the clutch guide.

LOCKNUT, 24 mm

Tighten the locknut till its tab aligns with the groove.

Remove any dirt from inside of the groove in the

clutch guide, then loosen the locknut.

LOCKNUT. 2,1 mm

5.

6.

8 x 1.25 mm

Tab(cont'd)

7. Remove the locknut, the disc spring washer, the

back-up ring, the O-ring and the companion flange.

@r/v-.,.

ao/

U

rA*..-

zzft

h\@fr\

LOCKNUT, 24 mmFeplace.

DISC SPRING WASHER, 24 mm

BACX.UP RING

O.N|NGReplace.

COMPANION FLANGE

8.Remove the torque control differential case and the

dowel pins.

www.emanualpro.com

Page 814 of 1395

Rear Differential Assembly

Reassembly (cont'dl

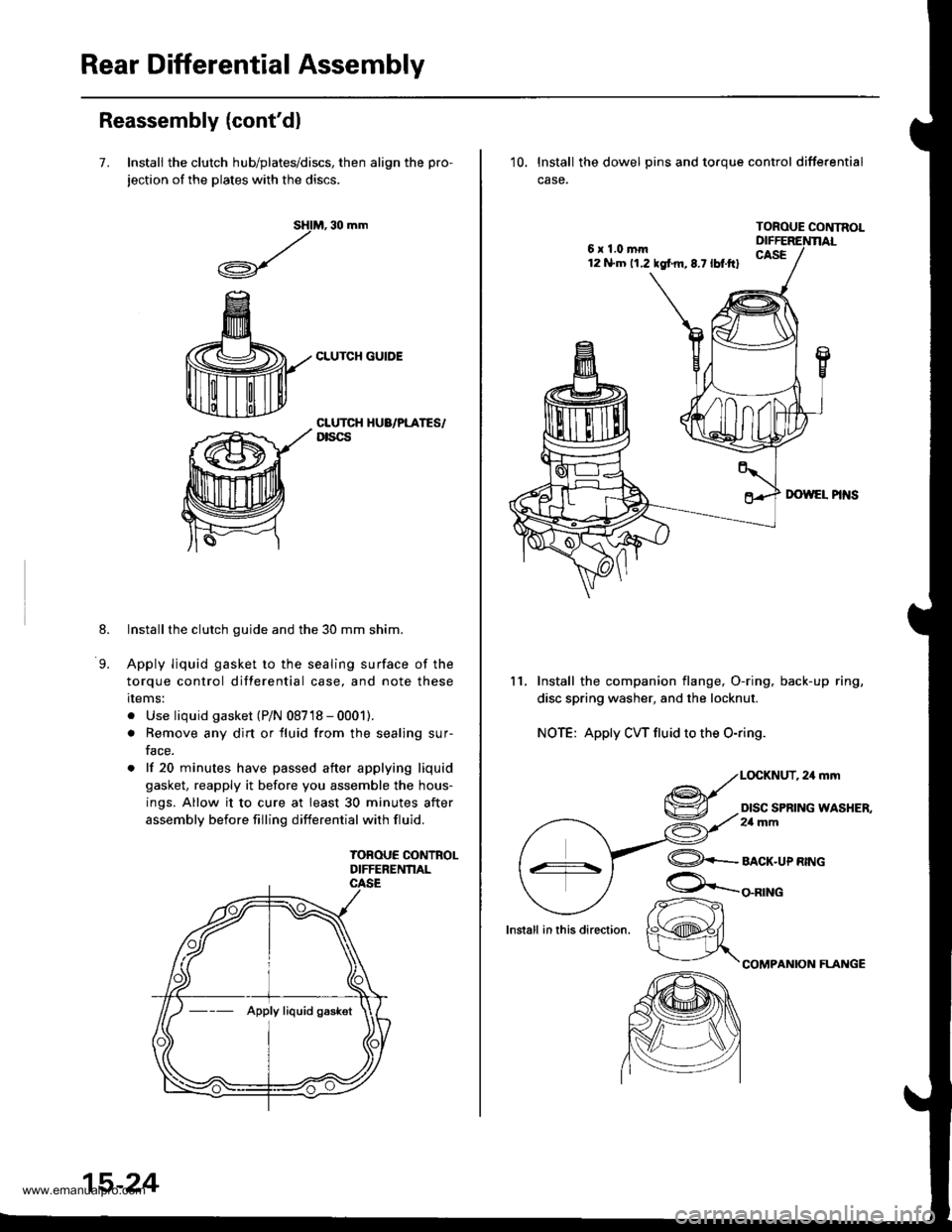

7. Install the clutch hub/plates/discs, then align the pro-

jection of the plates with the discs.

M, 30 mm

CLUTCH GUIDE

sHl

,/

.A-\,/r\-7

8.

9.

CLUTCH HUA/PLATES/Dtscs

Installthe clutch guide and the 30 mm shim.

Apply liquid gasket to the sealing surface of the

torque control differential case, and note these

rlems:

. Use liquid gasket (P/N 08718 - 0001).

. Remove any dirt or fluid from the sealing sur-

face.

. lf 20 minutes have passed after applying liquid

gasket, reapply it before you assemble the hous-

ings. Allow it to cure at least 30 minutes after

assembly before filling differential with fluid.

TOBOUE CONTROLDIFFERENNAL

--- Apply liquid gaskot

15-24

6x1.0mm12 N.m 11.2 tgf m,8.7lbt.ftl

10. lnstall the dowel pins and toroue control differential

case.

TOROUE CONTNOL

11. Install the companion flange, O-ring, back-up ring,

disc spring washer, and the locknut.

NOTE: Apply CW fluid to the O-ring.

,24mm

DISC SPRING WASHER,2a mm

lnstall in this direction.

@+-_alcr-upnwc

COMPANION FLAI{GE

/r-

K@#/

www.emanualpro.com

Page 857 of 1395

Inspection and Adjustment

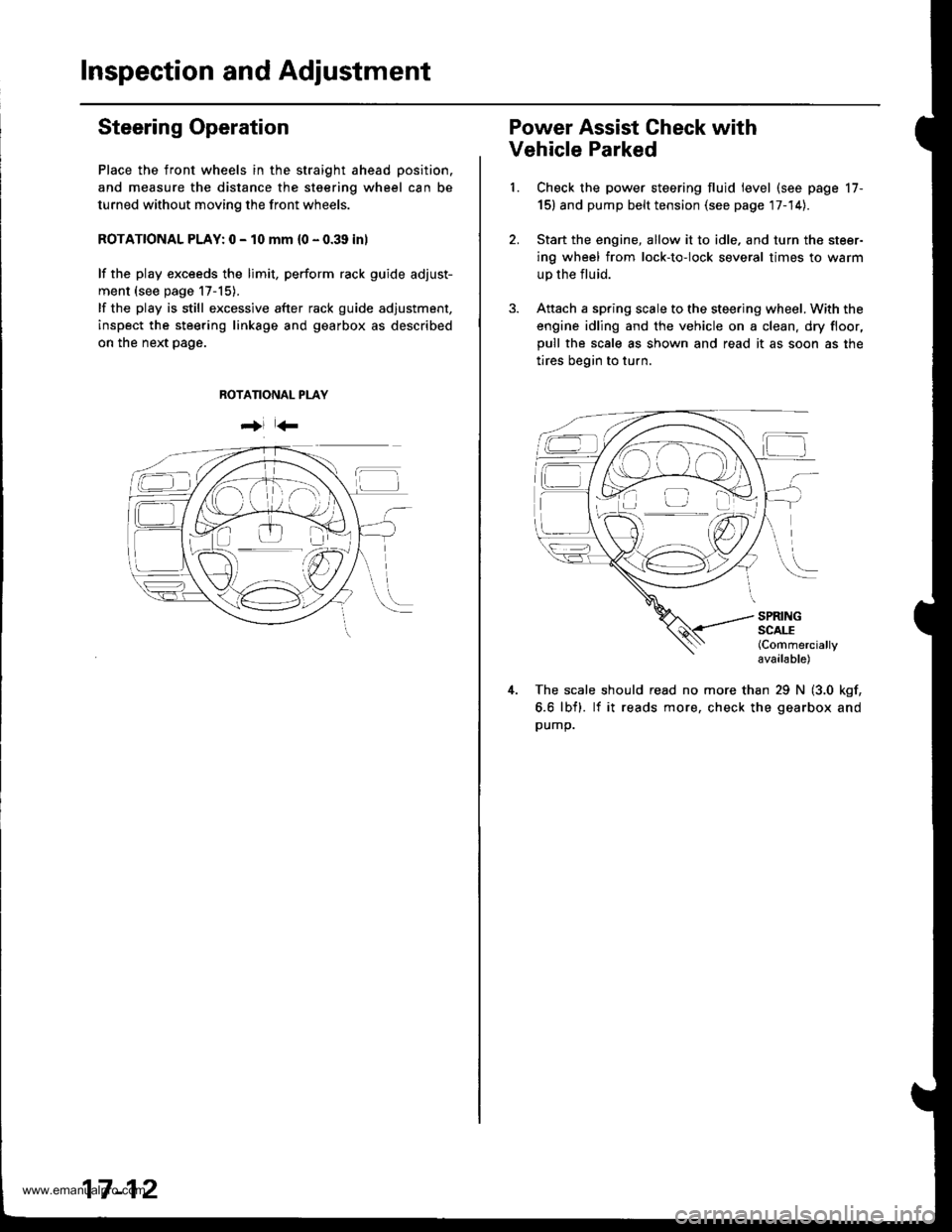

Steering Operation

Place the front wheels in the straight ahead position.

and measure the distance the steering wheel can be

turned without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.39 inl

lf the play exceeds the limit, perform rack guide adjust-

ment (see page 17-15).

lf the play is still excessive after rack guide adjustment,

inspect the steering linkage and gearbox as described

on the next page.

ROTANONAL PLAY

+i r

17-12

Power Assist Check with

Vehicle Parked

1. Check the power steering fluid level (see page 17-

15) and pump belt tension (see page 17-14).

2. Start the engine, allow it to idle, and turn the steer-

ing wheel from lock-toiock several times to warm

up the fluid.

3. Aftach a spring scale to the steering wheel, With the

engine idling and the vehicle on a clean. dry floor,

pull the scale as shown and read it as soon as the

tires begin to turn.

SPRINGSCALE(Commercially

available)

The scale should read no more than 29 N (3.0 kgf,

6.6 lbfl. lf it reads more, check the gearbox and

oumo.

f::1-tE

www.emanualpro.com

Page 867 of 1395

Steering Column

Inspection (cont'dl

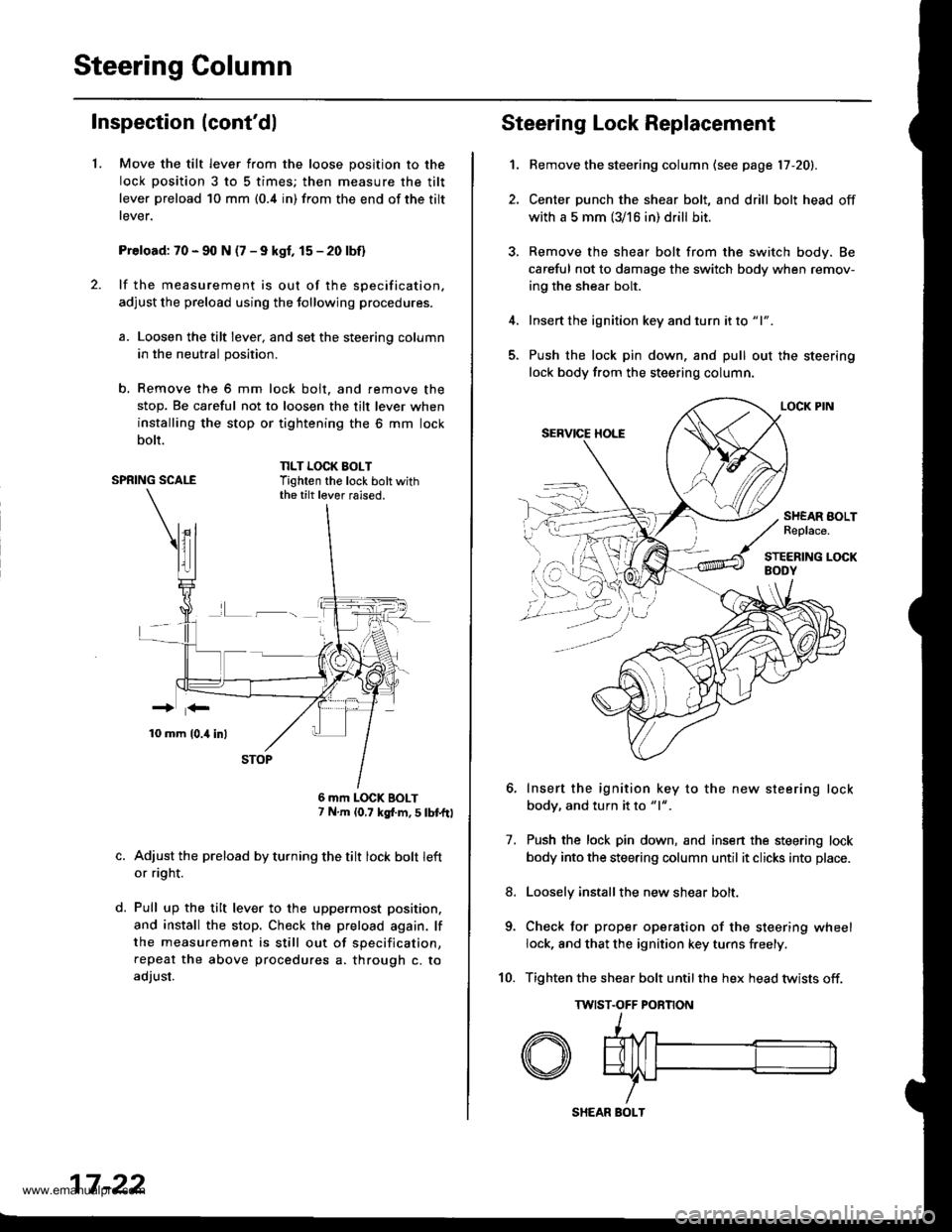

1.Move the tilt lever from the loose position to the

lock position 3 to 5 times; then measure the tilt

lever preload 10 mm (0.4 in) from the end of the tilt

rever.

Preload: 70 - 90 N (7 - 9 kgf, 15 - 20 lbf)

lf the measurement is out of the specification.

adjust the preload using the tollowing procedures.

a. Loosen the tilt lever, and set the steering column

in the neutral position.

b, Remove the 6 mm lock bolt. and remove the

stop. Be careful not to loosen the tilt lever when

installing the stop or tightening the 6 mm lock

bolt.

SPRING SCALENLT LOCK BOLTTighten the lock bolt withthe tilt lever raised.

L-_

d.

6 mm LOCK BOLT7 N.m (0,7 kgf.m, S tbtftl

Adjust the preload by turning the tilt lock bolt left

or ri9ht.

Pull up the tilt lever to the uppermost position.

and install the stop. Check the preload again. lf

the measurement is still out of specification,

repeat the above procedures a. through c. to

adjust.

17 -22

SHEAR BOLT

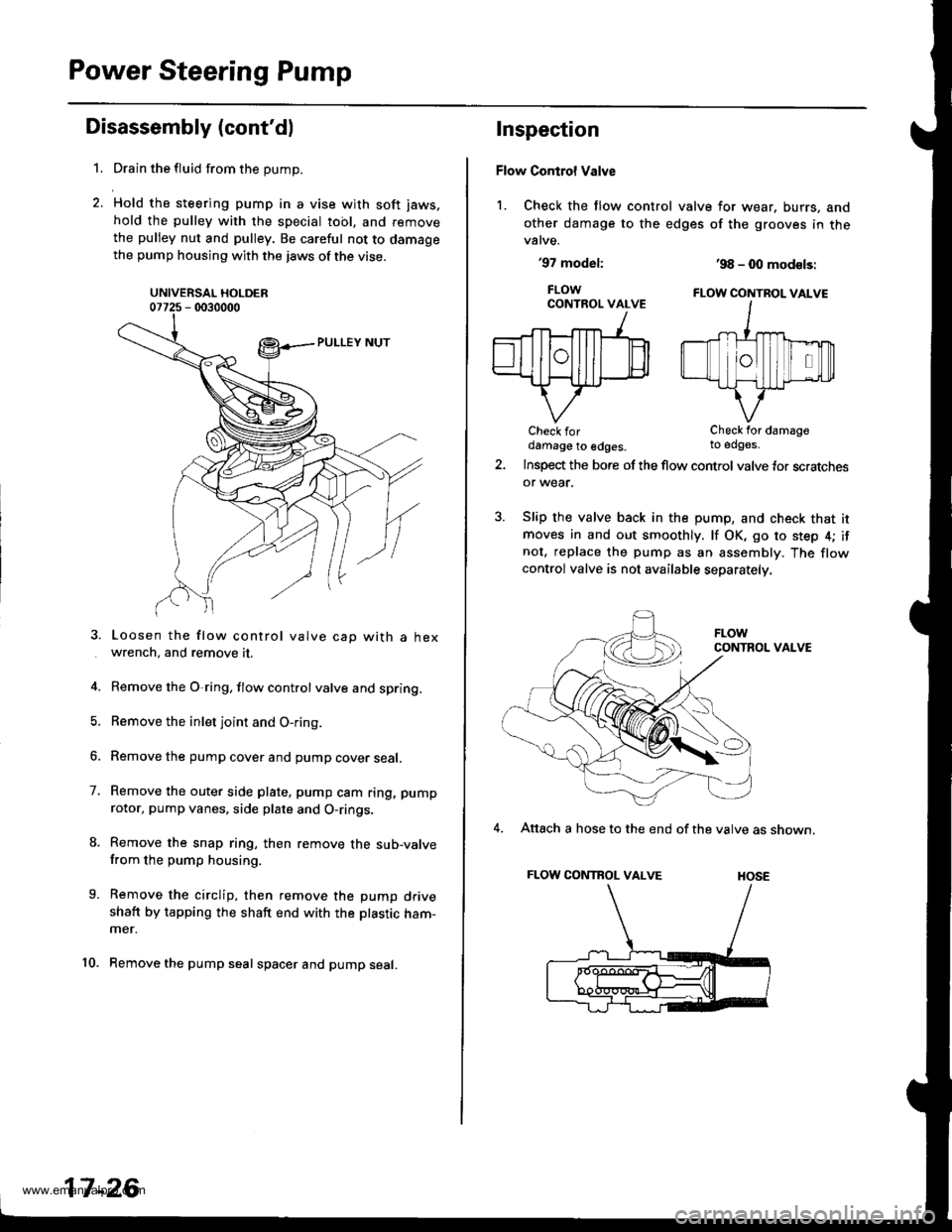

Steering Lock Replacement

1.

7.

Bemove the steering column (see page 17 -20).

Center punch the shear bolt, and drill bolt head off

with a 5 mm (3/16 in) drill bit.

Remove the shear bolt from the switch body. Be

careful not to damage the switch body when remov-

ing the shear bolt.

Insert the ignition key and turn it to "1".

Push the lock pin down, and pull out the steering

lock body from the steering column.

Insert the ignition key to the new steering lock

body, and turn it to "1".

Push the lock pin down, and insen the steering lock

body into the steering column until it clicks into place.

Loosely installthe new shear bolt.

Check tor proper operation of the steering wheel

lock, and that the ignition key turns freely.

Tighten the shear bolt untilthe hex head twists off.

TWIST.OFF PORNON

8.

10.

SHEAR BOLTReplace.

www.emanualpro.com

Page 871 of 1395

Power Steering Pump

Disassembly (cont'dl

1.

7.

9.

10.

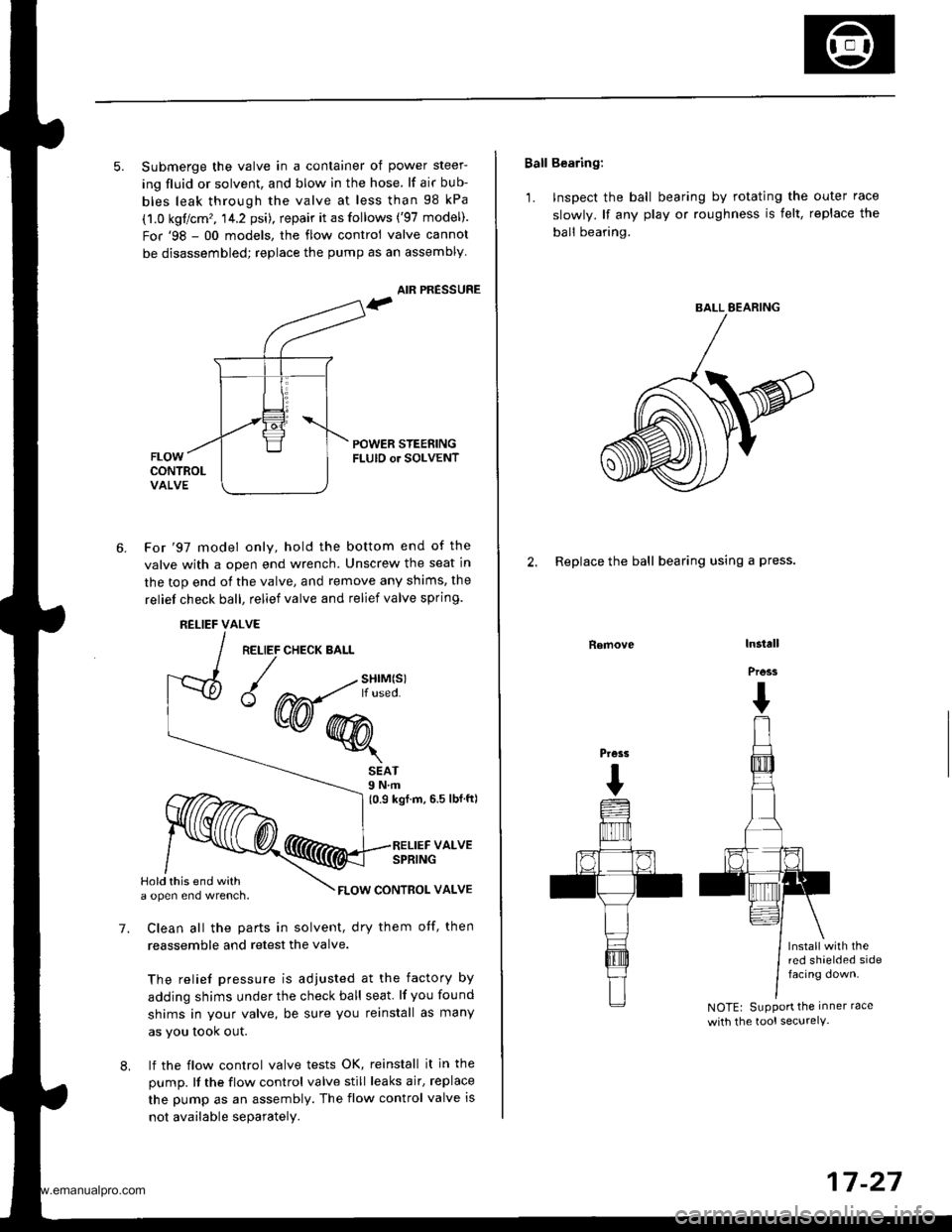

Drain the fluid from the pump.

Hold the steering pump in a vise with soft jaws.

hold the pulley with the special tool, and remove

the pulley nut and pulley. Be careful not to damagethe pump housing with the jaws of the vise.

UNIVERSAL HOLDER07725 - 0030000

Loosen the flow control valve cap with a hexwrench, and remove it.

Remove the O,ring, flow control valve and spring.

Remove the inlet joint and O-ring.

Remove the pump cover and pump cover seal.

Remove the outer side plate, pump cam ring, pump

rotor, pump vanes, side plate and O-rings.

Remove the snap ring, then remove the sub-valvefrom the pump housing.

Remove the circlip, then remove the pump driveshaft by tapping the shaft end with the ptastic ham-mer.

Remove the pump seal spacer and pump seal.

17-26

Inspection

Flow Control Valve

1. Check the flow control valve for wear, burrs, and

other damage to the edges of the grooves in thevalve.

'97 model:

FLOWCONTROL VALVE

Check fordamage to edges.

'98 - 0O mod€ls:

FLOW CONTBOL VALVE

Check for damageto edges.

Insp€d the bore of the flow control valve tor scratchesor wear.

Slip the valve back in the pump, and check that itmoves in and out smoothly. lf OK, go to step 4; ifnot, replace the pump as an assembly. The flowcontrolvalve is not available separately.

CONTROL VALVE

4. Attach a hose to the end of the valve as shown.

FLOW CONTROL VALVE HOSE

www.emanualpro.com

Page 872 of 1395

5. Submerge the valve in a container of power steer-

ing fluid or solvent, and blow in the hose. lf air bub-

bles leak through the valve at less than 98 kPa

(1.0 kgflcm'�, 14.2 psi), repair it as follows ('97 model).

For'98 - 00 models, the flow control valve cannot

be disassembled; replace the pump as an assembly

AIR PRESSURE

POWER STEENINGFLUID or SOLVENT

6.For'97 model only, hold the bottom end of the

valve with a open end wrench. Unscrew the seat in

the top end of the valve, and remove any shims, the

reliel check ball, relief valve and relief valve spring.

RELIEFALVE

RELIEF CHECK BALL

{w@r

7.

SEAT9 N.m(0.9 kgf.m, 6.5 lbfft)

RELIEF VALVESPRING

FLOW CONTBOL VALVE

Clean all the parts in solvent, dry them otf, then

reassemble and retest the valve.

The relief pressure is adjusted at the factory by

adding shims under the check ball seat lf you found

shims in your valve, be sure you reinstall as many

as you took out.

lf the flow control valve tests OK, reinstall it in the

pump. It the flow control valve still leaks air, replace

the pump as an assembly. The flow control valve is

not available separately.

8,

Hold this end witha open eno wrencn.

Ball Bearing:

'1. Inspect the ball bearing by rotating the outer race

slowly. lf any play or roughness is felt, replace the

ball bearing.

2. Replace the ball bearing using a press.

Removelnstall

Press

I

Press

I

lnstall with thered shaelded sidefacing down.

NOTEr SuPPort the inner race

with the tool securelY-

BALL EEARING

17-27

www.emanualpro.com

Page 874 of 1395

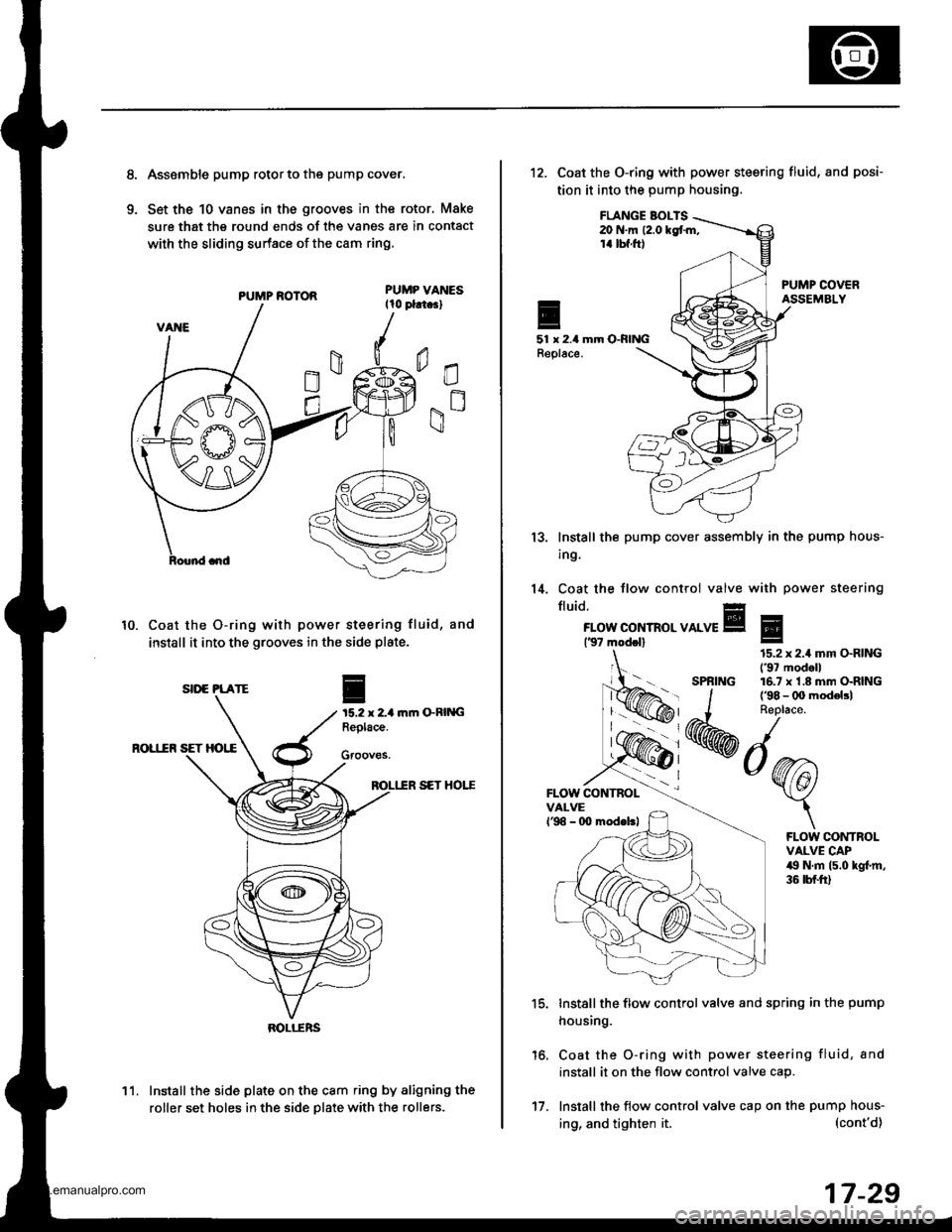

8.

9.

Asssmble pump rotor to the pump cover,

Set the 10 vanes in the grooves in the rotor, Make

sure that the round ends of the vanes are in contact

with the sliding surface of the cam ring.

PUMP ROTOR

Coat the O-ring with power steering fluid, and

install it into the grooves in the side plate.

ftm GRING

ROL1IR SET HOI,E

SET HOTT

Install the side plate on the cam ring by aligning the

roller set holes in the side Dlate with the rollers.

10.

I

15.2 x 2-1Replace.

Gfooves.

SII'E PLATE

BOLI-ERS

11.

17.

ing, and tighten it.

12. Coat the O-ring with power steering fluid,

tion it into the pump housing.

and posi-

FLANGE BOI-TS20 N.m (2.0 kgt m,14 tbf.ft)

51 x 2.4 mm O-RINGReplace.

13.

14.

lnstall the

ing.

Coat the

fluid.

pump cover assembly in the pump hous-

tlow control valve with power steering

FLOW CONTROL VALVE137 modol)

FLOW CONTBOLVALVEl'98 - 0O modeltl

'15.

16.

Install the flow control valve and spring in the pump

housing.

Coat the O-ring with power steering fluid, and

install it on the flow control valve cap.

Install the flow control valve cap on the pump hous-

Eg

SPRING

15.2 x 2.4 mm O.RING('97 modell16.7 x'1.8 mm O-RING

FLOW CONTROLVALVE CAP49 N.m (5.0 kgl.m,36 tbf.ft)

(cont'd)

17-29

www.emanualpro.com

Page 880 of 1395

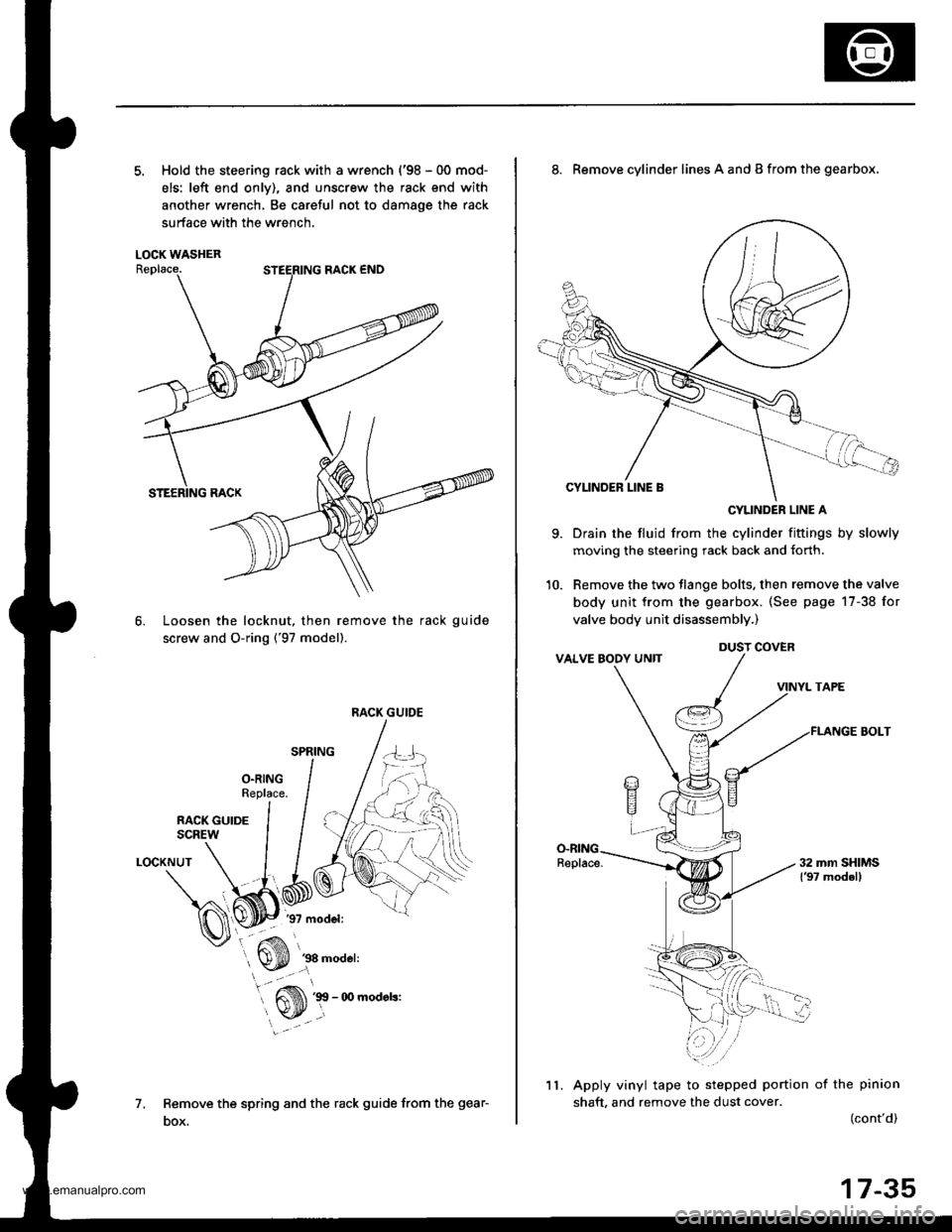

5. Hold the steering rack with a wrench {'98 - 00 mod-

els: left end onlv), and unscrew the rack end with

another wrench, Be careful not to damage the rack

surface with the wrench,

LOCK WASHER

Loosen the locknut, then remove the rack guide

screw and O-ring ('97 model).

6.

1.

LOCKNUT

Remove the spring and the rack guide from the gear-

DOX.

RACK GUIDE

9.

8. Remove cylinder lines A and B from the gearbox,

CYLINDER LINE A

Drain the fluid from the cylinder fittings by slowly

moving the steering rack back and {orth.

Remove the two tlange bolts, then remove the valve

body unit from the gearbox. (See page 17-38 for

valve body unit disassembly.)

VINYL TAPE

FLANGE BOLT

Apply vinyl tape to stepped portion of the pinion

shaft, and remove the dust cover.(cont'd)

DUST COVER

11.

17-35

www.emanualpro.com

Page 886 of 1395

Valve Body Unh Roa$embly

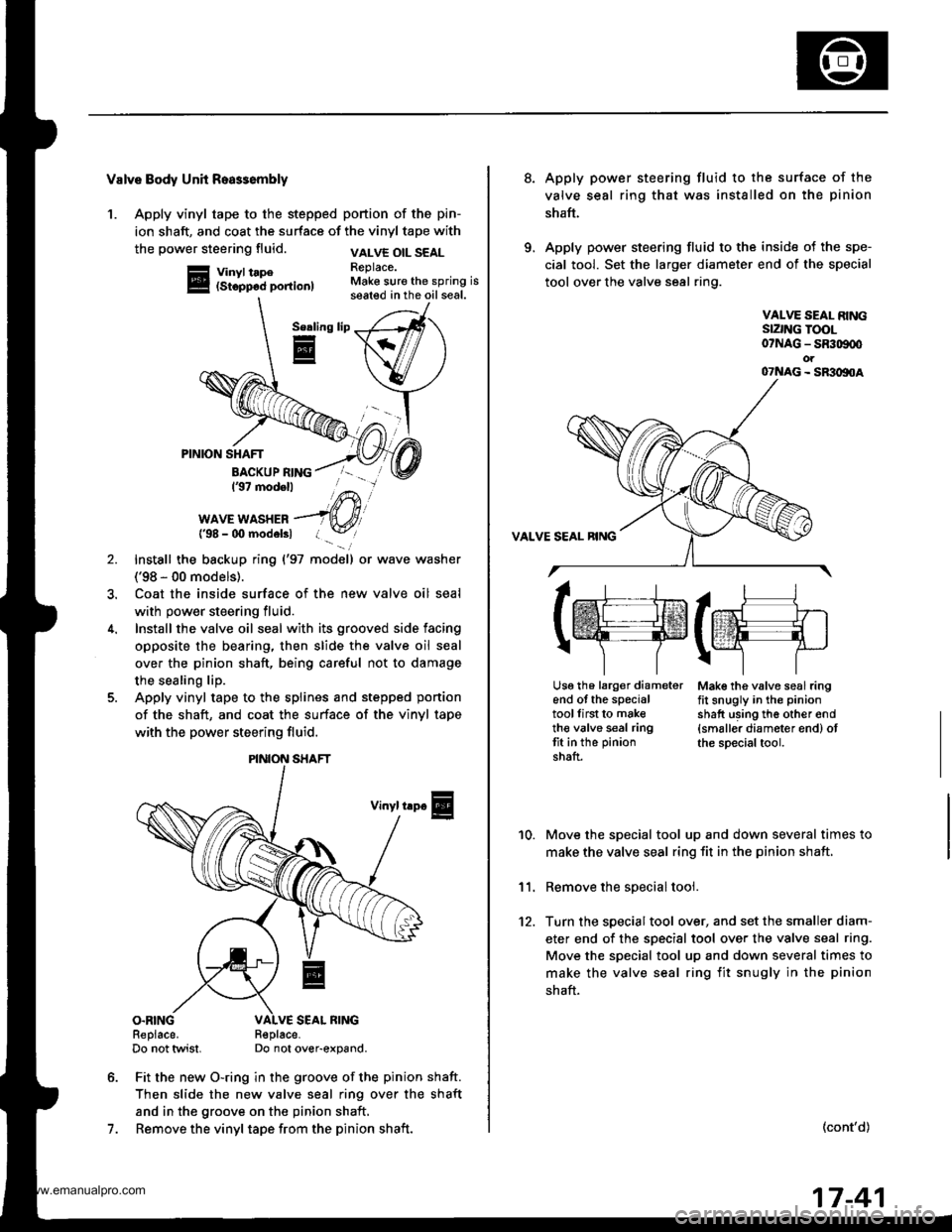

1. Apply vinyl tape to the stepped portion of the pin-

ion shaft, and coat the surface of the vinyl tape with

the power steering fluid.

Vinyl tape(Stopp6d portion)

VALVE OIL SEALReplace.Make sure the spring isseated in the oil seal.

Serling

E

7.

PINION SHAFT

BACKUP RING137 modell

WAVE WASHER{'98 - 00 modelsl

Install the backup ring {'97 model) or wave washer

('98 - 00 models).

Coat the inside surface of the new valve oil seal

with power steering fluid.

Install the valve oil seal with its grooved side facing

opposite the bearing, then slide the valve oil seal

over the pinion shaft, being careful not to damage

the sealing lip.

Apply vinyl tape to the splines and stepped ponion

of the shaft, and coat the surface of the vinyl tape

with the power steering fluid.

Vinyl trp€

O.RINGReplace.Do not twist.R€place-Do not over-expand.

Fit the new O-ring in the groove of the pinion shaft.

Then slide the new valve seal ring over the shaft

and in the groove on the pinion shaft,

Remove the vinyl tape from the pinion shaft.

\/

PINION SHAFT

8.Apply power steering fluid to the surface of the

valve seal ring that was installed on the pinion

shaft.

Apply power steering fluid to the inside of the spe-

cial tool. Set the larger diameter end of the special

tool over the valve seal ring.

VALVE SEAL RINGSIZNG TOOL07NAG - SR309q'ot07NAG - SR3oltoA

Mak€ the valve seal ringfit snugly in the pinion

shatt using th6 other end{smaller diameter end) otthe special tool.

10.

11.

12.

Move the special tool up and down several times to

make the valve seal ring fit in the pinion shaft,

Remove the soecial tool.

Turn the special tool over, and set the smaller diam-

eter end of the specisl tool over the valve seal ring.

Move the special tool up and down several times to

make the valve seal ring fit snugly in the pinion

shaft.

(cont'd)

lrr.rj1

tffifrE-rr.]

r\-''] 7

Usg th6 larg€r diameterend of the specialtoollirst to maketh€ valve seal ringtit in the pinion

shaft.

17-41

www.emanualpro.com