spring HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 705 of 1395

1.Remove the transfer assembly from the torque con-

verter housing. (4WD)

Remove the mainshaft speed sensor from the trans-

mission housing.

Remove the transmission housing mounting bolts,

transmission hanger, and connector bracket.

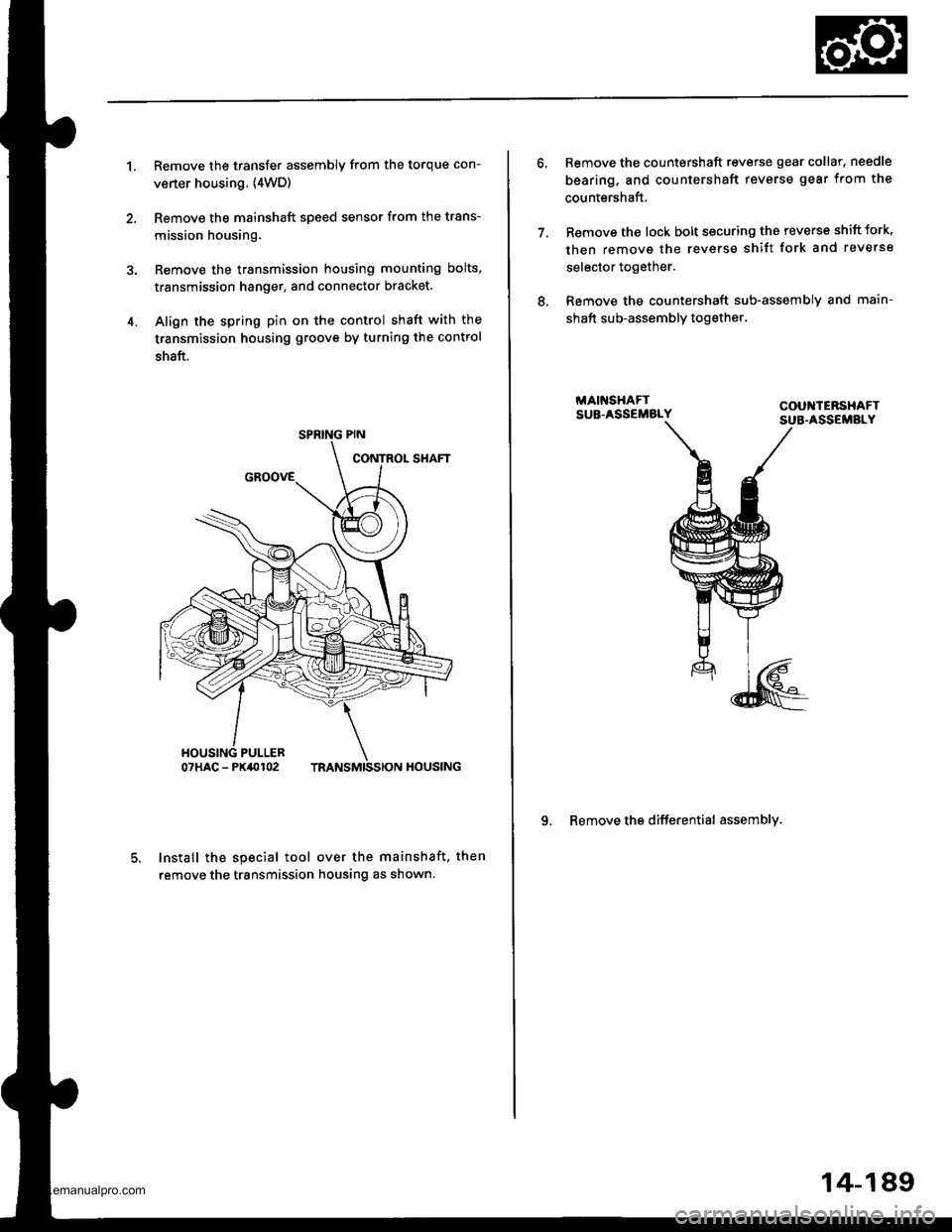

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

Install the special tool over the mainshaft. then

remove the transmission housing as shown.

4.

SPRING PIN

7.

Remove the countershaft reverse gear collar, needle

bearing, and countershaft revsrse gear from the

countershaft,

Remove the lock bolt securing tho reverse shift fork,

then remove the reverse shift fork and reverse

selector together.

Remove the countershaft sub-assemblv and main-

shaft sub-assembly together,

9. Remove the differential assembly.

8.

14-189

www.emanualpro.com

Page 707 of 1395

1.Remove the control lever mounting bolt trom the

torque converter side of the torque converter hous-

ing. (4WD)

Remove the ATF feed pipes from the servo body,

secondary valve body, lock-up valve body, and main

valve body.

For '97 - 98 models:

Remove the two bolts securing the ATF strainer and

servo detent base, then remove the strainer and the

base.

For'99 - 00 models;

Remove the ATF strainer {one bolt).

4. For'97 - 98 models:

Remove the seven bolts securing the servo body,

then remove the servo body and separator plate'

For'99 - 00 models:

Remove the eight bolts securing the servo body,

then remove the servo body and separator plate'

5. Bemove the three bolts securing the secondary

valve body, then remove the secondary valve body'

stop shaft bracket, and separator plate.

6. Remove the eight bolts securing the ATF lubrication

plate and lock-up valve body, then remove the ATF

lubrication plate, lock-up valve body' and separator

plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body'

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

houslng.

10. Remove the detent arm and detent arm shaft from

the main valve body.

11. Remove the five bolts securing the main valve

body, then remove the main valve body.

When removing the main valve body, do not let the

eight check balls fall out.

12. Remove the ATF pump driven gear shaft, then

remove the ATF PumP gears.

13. Remove the main separator plate with two dowel

prns.

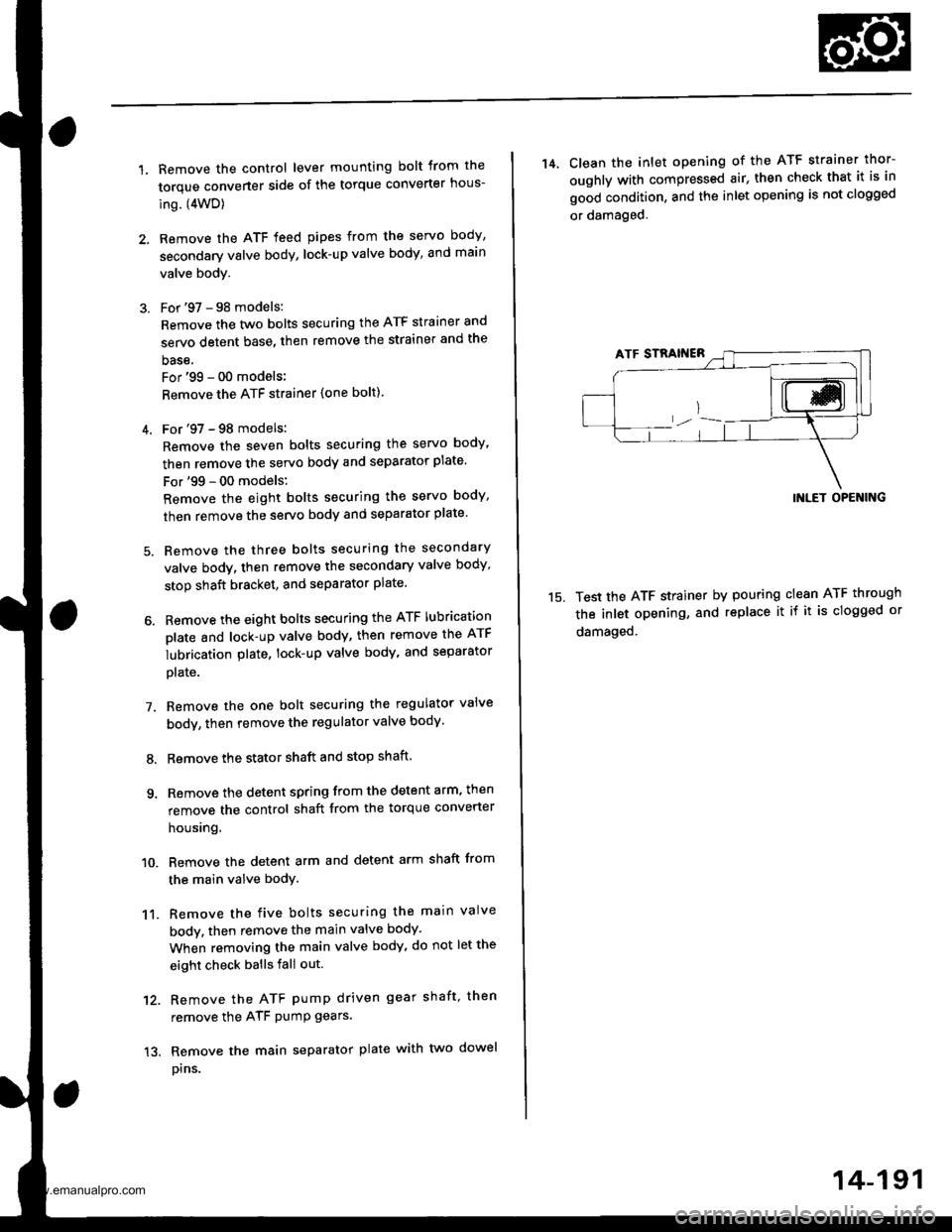

14, Clean the inlet opening of the ATF strainer thor-

oughly with compressed air, then check that it is in

good condition, and the inlet opening is not clogged

or damaged.

15.

INLET OPENING

Test the ATF strainer by pouring clean ATF through

the inlet opening, and replace it if it is clogged or

damaged.

14-191

www.emanualpro.com

Page 709 of 1395

Valve

Assembly

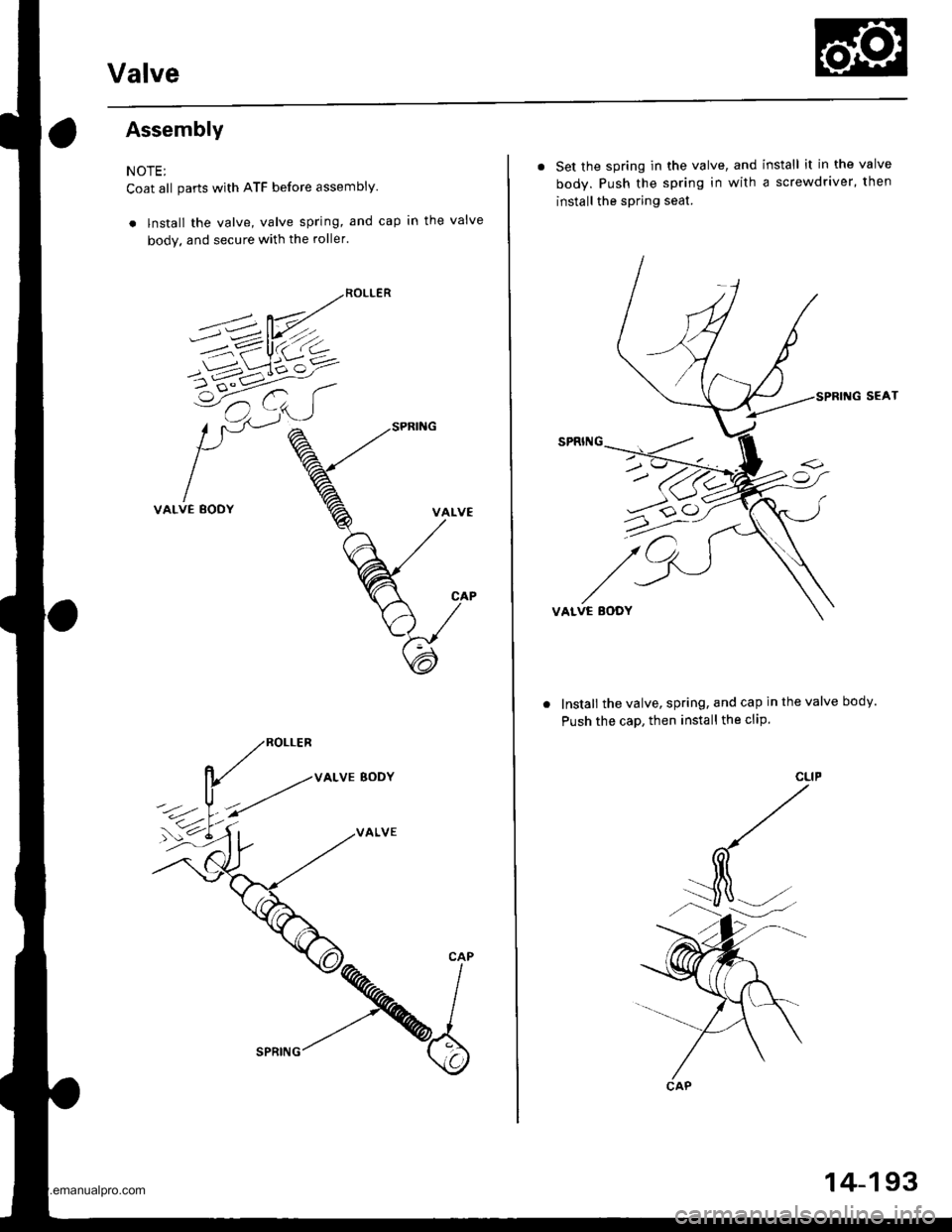

NOTE;

Coat all parts with ATF before assembly.

. lnstall the valve, valve spring, and cap in the valve

body. and secure with the roller.

VALVE BODY

VALVE

. Set the spring in the valve, and install it in the valve

body. Push the spring in with a screwdriver, then

install the spring seat.

SEAT

VALVE EODY

Install the valve, spring, and cap in the valve body.

Push the caD, then install the cliP.

u>o

CAP

14-193

www.emanualpro.com

Page 710 of 1395

Valve Gaps

Description

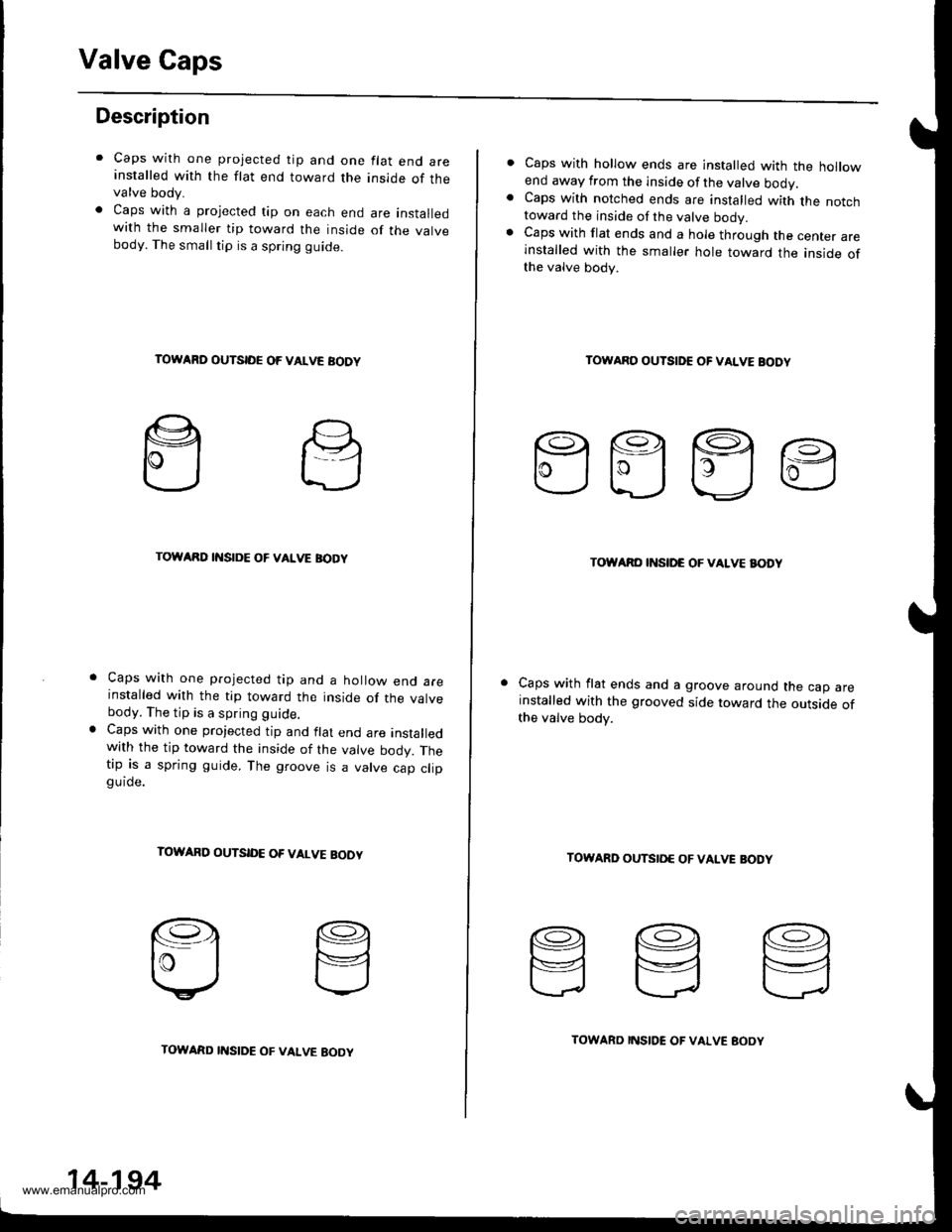

Caps with one projected tip and one flat end areinstalled with the flat end toward the inside of thevalve body.

Caps with a projected tip on each end are installedwith the smaller tip toward the inside of the valvebody. The small tip is a spring guide.

TOWARD OUTSIDE OF VALVE AODY

TOWARD INSIDE OF VALVE BODY

Caps with one projected tip and a hollow end areinstalled with the tip toward the inside of the valvebody. The tip is a spring guide.

Caps with one projected tip and flat end are installedwith the tip toward the inside of the valve bodv. Thetip is a spring guide. The groove is a valve cao cliogu ide.

TOWARD OUTSID€ OF VALVE BOOY

14-194

TOWARD I'{SIDE OF VALVE EOOYTOWARD INSIDE OF VALVE BOOY

Caps with hollow ends are installed with the hollowend away from the inside of the valve ooov.Caps with notched ends are installed with the notchtoward the inside of the valve bodv.Caps with flat ends and a hole through the center areinstalled with the smaller hole toward the inside ofthe valve body.

TOWARO OUTSIDE OF VALVE BODY

EEEE

TOWARO INSII'C OF VALVE BODY

Caps with flat ends and a groove around the cap areinstalled with the grooved side toward the outside ofthe valve body.

TOWARD OUTSIO€ OF VAIVE BODY

www.emanualpro.com

Page 712 of 1395

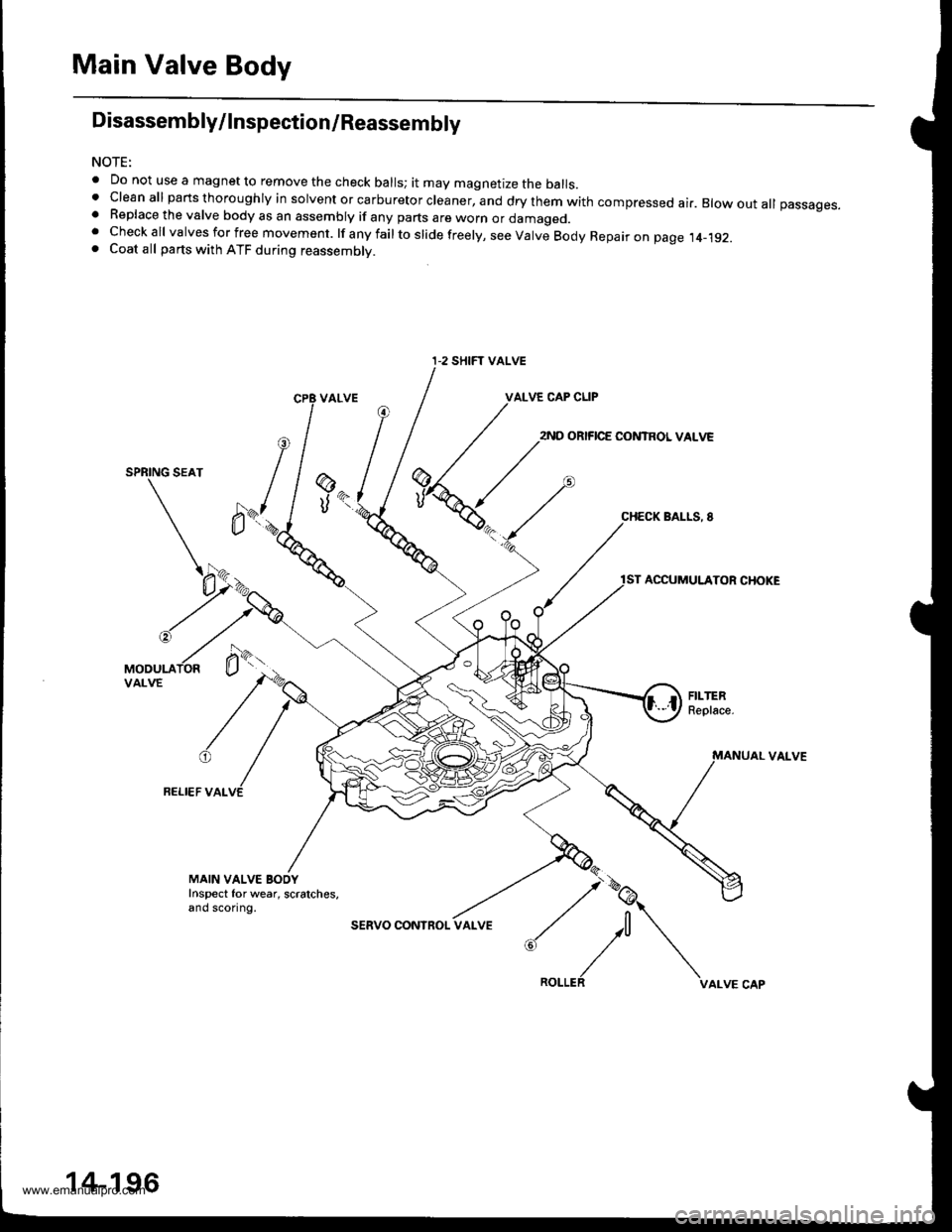

Main Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. Do not use a magnet to remove the check balls; it may magnetize the balls.t clean all parts thoroughly in solvent or carburetor cleaner, and dry them with compressed ai.. Blow out all passages.. Replace the valve body as an assembly if any parts are worn or damageo.. Checkall valvesforfree movement. lfanyfailtoslidefreely,seeValveBodyRepaironpage.t4_192.. Coat all parts with ATF during reassembly.

VALVE CAP CLIP

2ND ORIFICE CONTROL VALVE

SPRING SEAT

BALLS, 8

ACCUMULATOR CHOKE

VAI-VE

FELI€F VALVE

@

UK

MAIN VALVE BOOYInspect for wear, scratches,and sconng.

sERVO CONInOL

:,/\^._.^,

I-2 SHIFT VALVE

14-196

www.emanualpro.com

Page 713 of 1395

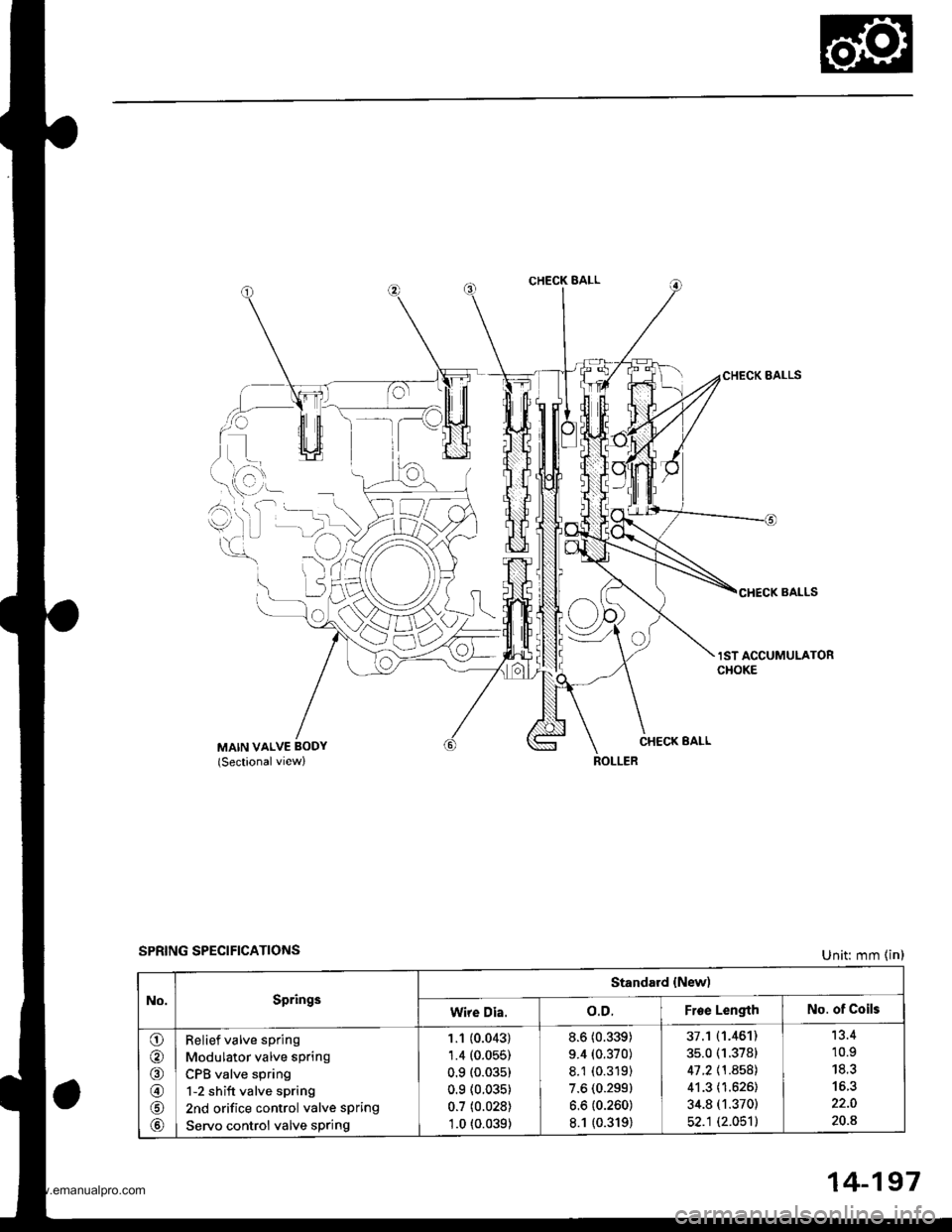

CHECK BALL

i)L)

lo

CHECK BALLS

lST ACCUMULATORCHOKE

CHECK EALLMAIN VALVE BODY(Sectionalview)

SPRING SPECIFICATIONSUnit: mm (in)

No.Springs

Standard {New)

Wire Dia.o.D.Froe LengthNo. of Coils

o

@

@

@

Relief valve spring

Modulator valve spring

CPB valve spring

1-2 shift valve spring

2nd orifice control valve spring

Servo control valve sPring

1.1 (0.043)

1.4 (0.055)

0.9 (0.03s)

0.9 (0.035)

0.7 (0.028)

1.0 t0.039)

8.6 (0.339)

9.4 (0.370)

8.1 (0.319)

7.6 (0.299)

6.6 (0.260)

8.1 {0.319)

37.1 (1.461)

35.0 (1.3781

41 .2 \1 .8581

41.3 (1.626)

34.8 (1.370)

52.1 (2.051)

'13.4

10.9

20.8

14-197

www.emanualpro.com

Page 714 of 1395

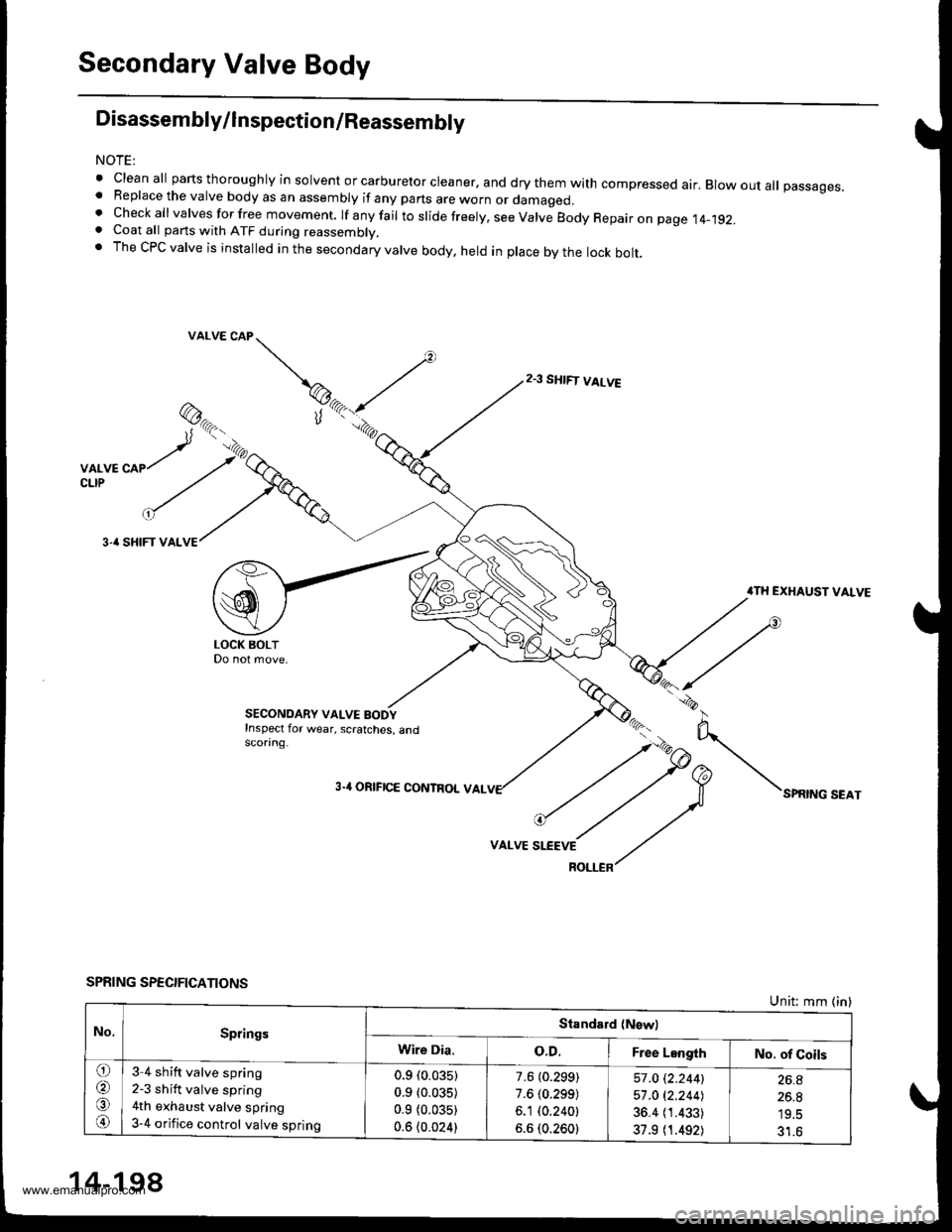

Secondary Valve Body

Disassembly/lnspection/Reassembly

NOTE:

' clean all parts thoroughly in solvent or carburetor cleaner. and dry them with compressed air. Blow out aU passages,. Replace the valve body as an assembly if any parts are worn or damaged.t check all valves for free movement. rf anyfair to sride freery. see varve Body Repair on page 14-192.. Coat all parts with ATF during reassembly.. The CPC valve is installed in the secondary valve body, held in place by the lock bolt.

@,.-.t'tr.,

,rr'^'//u

"/ ./

3-' SHIFT VALVE

VALVE CAP

SPRING SPEC!FICATIONS

2.3 SHIFT VALVE

VALVE SLEEVE

ROLLER

ilTH EXHAUST VALVE

N"*,"o"*,

Unit: mm (in)

t*-1

SECONOARY VALVE BODYInspect for wear, scratches, andscorang.

3.4 ORIFICE CONTROL VAL

No.SpringsStandald {Nswl

Wire Dia.o.D.Free LengthNo. of Coils

o

@

o

@

3 4 shift valve spring

2-3 shift valve spring

4th exhaust valve spring

3-4 orifice control valve spring

0.9 (0.035)

0.9 (0.035)

0.9 {0.035)

0.6 {0.024}

7.6 (0.299)

7.6 (0.299)

6.1 (0.240t

6.6 (0.2601

57 .O i.2.2441

57 .O 12.244J

36.4 (1.433)

37.9 (1.492)

26.A

26.8

19.5

31.6

14-198

www.emanualpro.com

Page 715 of 1395

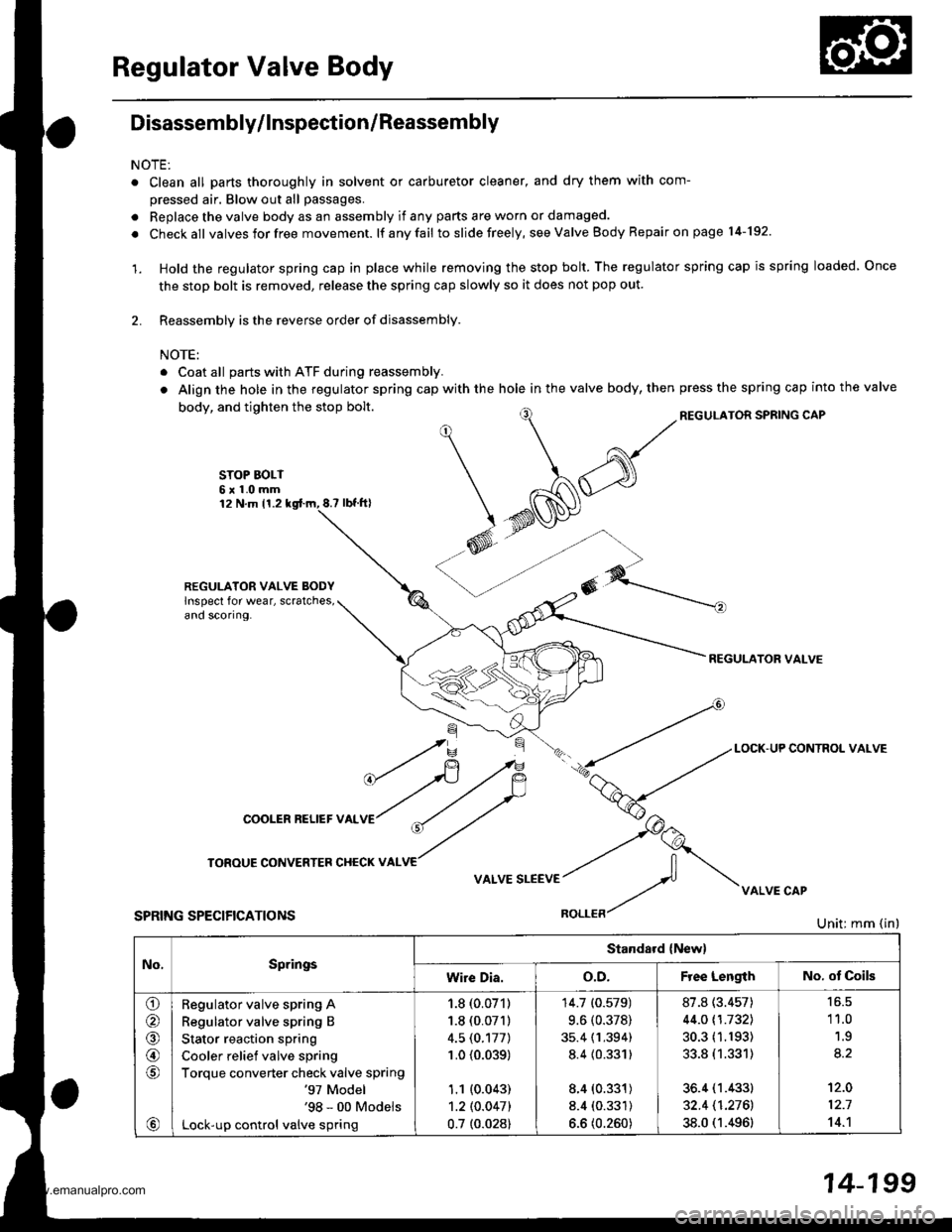

Regulator Valve Body

Disassembly/lnspection/Reassembly

NOTE:

o Clean all parts thoroughly in solvent or carburetor cleaner, and dry them with com-

pressed air. Blow out all passages.

. Replace the valve body as an assembly if any parts are worn or damaged.

. Checkall valvesforfree movement. lf anyfail toslidefreely, see Valve Body Repair on page l4-192.

'1. Hold the regulator spring cap in place while removing the stop bolt. The regulator spring cap is spring loaded Once

the stop bolt is removed, release the spring cap slowly so it does not pop out.

2. Reassembly is the reverse order of disassembly.

NOTE:

. Coat all parts with ATF during reassembly.

. Align the hole in the regulator spring cap with the hole in the valve body, thenpress the spring cap into the valve

REGULATOR SPSING CAPbody, and tighten the stop bolt.

STOP BOLT6x1.0mm12 N.m 11.28.? tbt.fil

REGULATOR VALVE BODYlnspect for wear, scratches,ano scoflng.

REGULATOR VALVE

No,SpringsStandard {New}

wire Dia.o.D.F ee LengthNo. ot Coils

o

@

@,6

a,

Regulator valve spring A

Regulator valve spring B

Stator reaction spring

Cooler relief valve spring

Torque converter check valve spring'97 Model'98 - 00 Models

Lock-up control valve spring

1.8 (0.071)

1.8 (0.071)

4.5 (0.177)

1.0 {0.039)

1.1 (0.043)

1.2lO.O47l

0.7 t0.028)

14.7 (0.579)

9.6 (0.378)

35.4 (1.394)

8.4 {0.331)

8.4 (0.331)

8.4 (0.331)

6.6 (0.260)

87.8 (3.457)

44.0 t1.7321

30.3 (1.193)

33.8 (1.331)

36.4 (1.433)

32.4 11.2761

38.0 (1.496)

'11.0

1.9

't2.0

12.7

14.'l

14-199

www.emanualpro.com

Page 716 of 1395

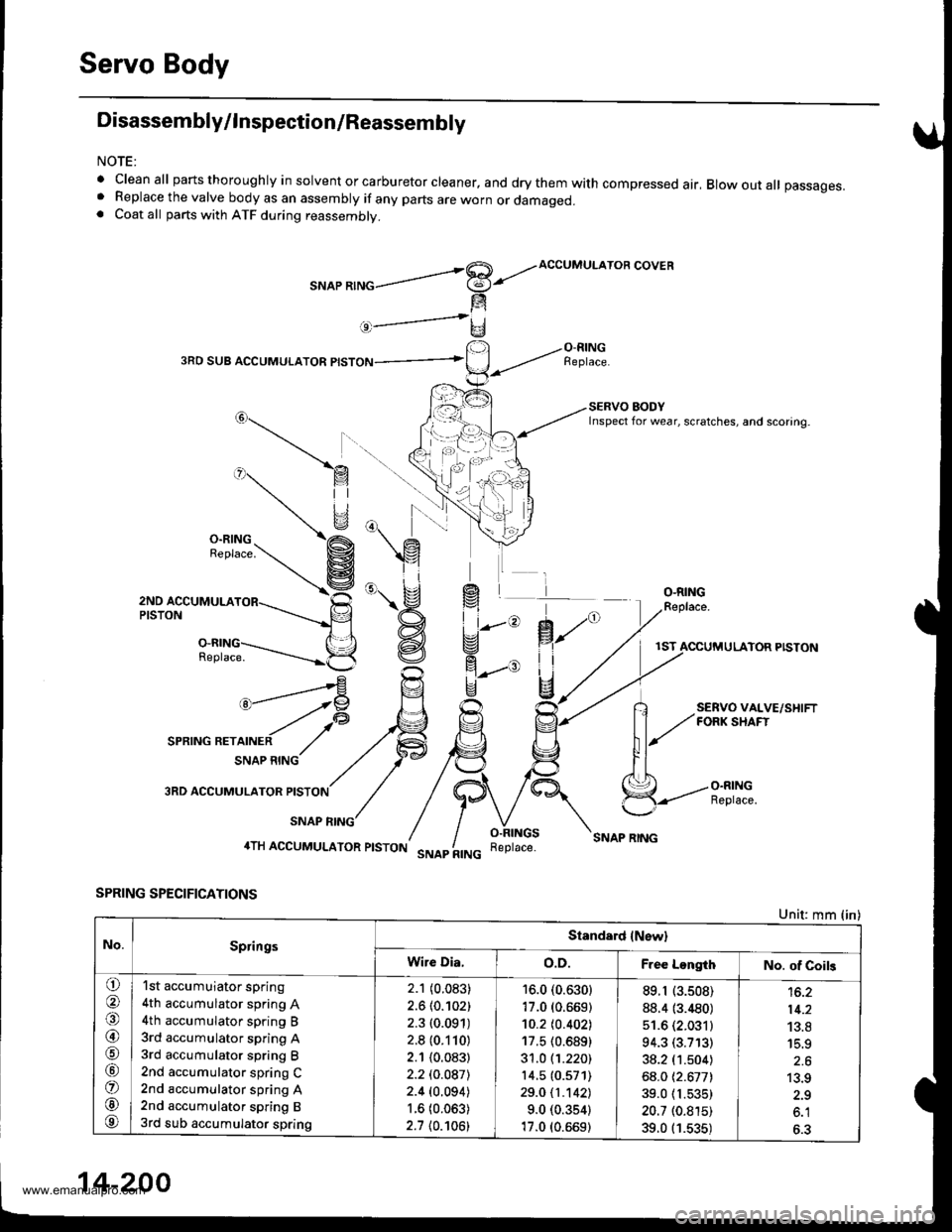

Servo Body

Disassembly/lnspection/Reassembly

NOTE:

' cleanall parts thoro ugh ly in solvent or ca rbu retor clea ner, a nd dry them with compressed air, Blow out all passages.. Replace the valve body as an assembly if any parts are worn or damaged.. Coat all parts with ATF during reassembly.

ACCUMULATOR COVER

3RO SUB ACCUMULATOR

O-RINGFeplace.

SERVOFORK S

fi,

il

g

1ST ACCUMULATOR PISTON

Replace.

RVO VAL\IRK SHAFT

O.RING

VE/SHIFT

3RD ACCUMULATOR

SPRING SPECIFICATIONS

\_)

SNAP RING

SNAP RING

Unit: mm {in)

@"- -tP

-.t l@SPR|NG RETATNER ,/

No.SpringsStandard lNewl

Wire Dia,o.D.Free LongthNo. of Coil3

o

@J6

@.A

\o,

o

@

@

1st accumuiator spring

4th accumulator spring A

4th accumulator spring B

3rd accumulator spring A

3rd accumulator spring B

2nd accumulator spring C2nd accumulator spring A2nd accumulator spring B

3rd sub accumulator spring

2.1 (0.083)

2.6 {0.102)

2.3 (0.091)

2.8 (0.110)

2.1 (0.083)

2.2 (0.087l-

2.4 (0.094)

r.6 (0.063)

2.7 {0.106)

16.0 (0.6301

17.0 (0.669)'t0.2 t0.402]�

17.5 (0.689)

31.0 (1.220)

14.5 {0.571)

29.0 11.1421

9.0 (0.354)

17.0 (0.669)

89.r (3.508)

88.4 (3.480)

51.6 (2.031)

94.3 (3.713)

38.2 (1.504)

68.0 {2.677)

39.0 fi.535)

20.7 (0.815)

39.0 (1.535)

14.2

13.8

15.9

2.6

13.9

2.9

o.l

6.3

14-200

www.emanualpro.com

Page 717 of 1395

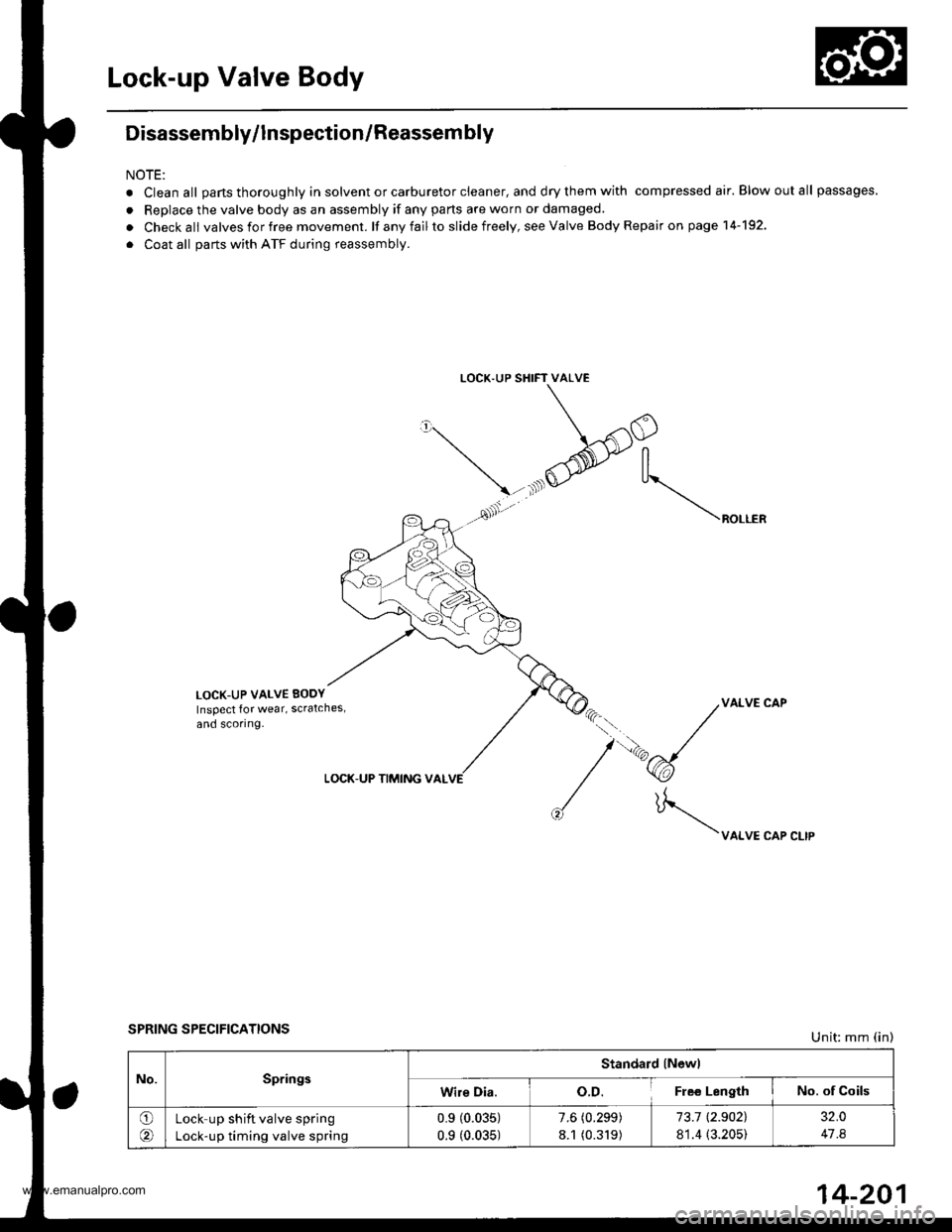

Lock-up Valve Body

Disassembly/lnspection/Reassem bly

NOTE:

. Clean all parts thoroughly in solvent or carburetor cleaner, and dry them with compressed air. Blow out all passages.

. Replace the valve body as an assembly if any parts are worn or damaged.

. Checkall valvesforfree movement. lf anyfailto slide freely, seeValve Body Repairon page 14-192.

. Coat all parts with ATF during reassembly.

LOCK.UP SHIFT VALVE

\/'

\-.xlO

@-tr

, ^ ,As'. \"o...*

LOCK-UP VALVE EODY

Inspect lor wear, scratches,

and scoring.

VALVE CAP

\uo.*"or".,,

LOCK-UP TIMING VAL

SPRING SPECIFICATIONSUnit: mm (in)

No.SpringsStandard lNewl

Wire Dia.o.D.Fle€ LengthNo. of Coils

O(Lock up shift valve spring

Lock-up timing valve spring

0.9 (0.035)

0.9 (0.035)

7.6 (0.299)

8.1 (0.319)

73.1 t2.902),

81.4 (3.205)

32.0

47 .8

14-201

www.emanualpro.com