Gear HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 718 of 1395

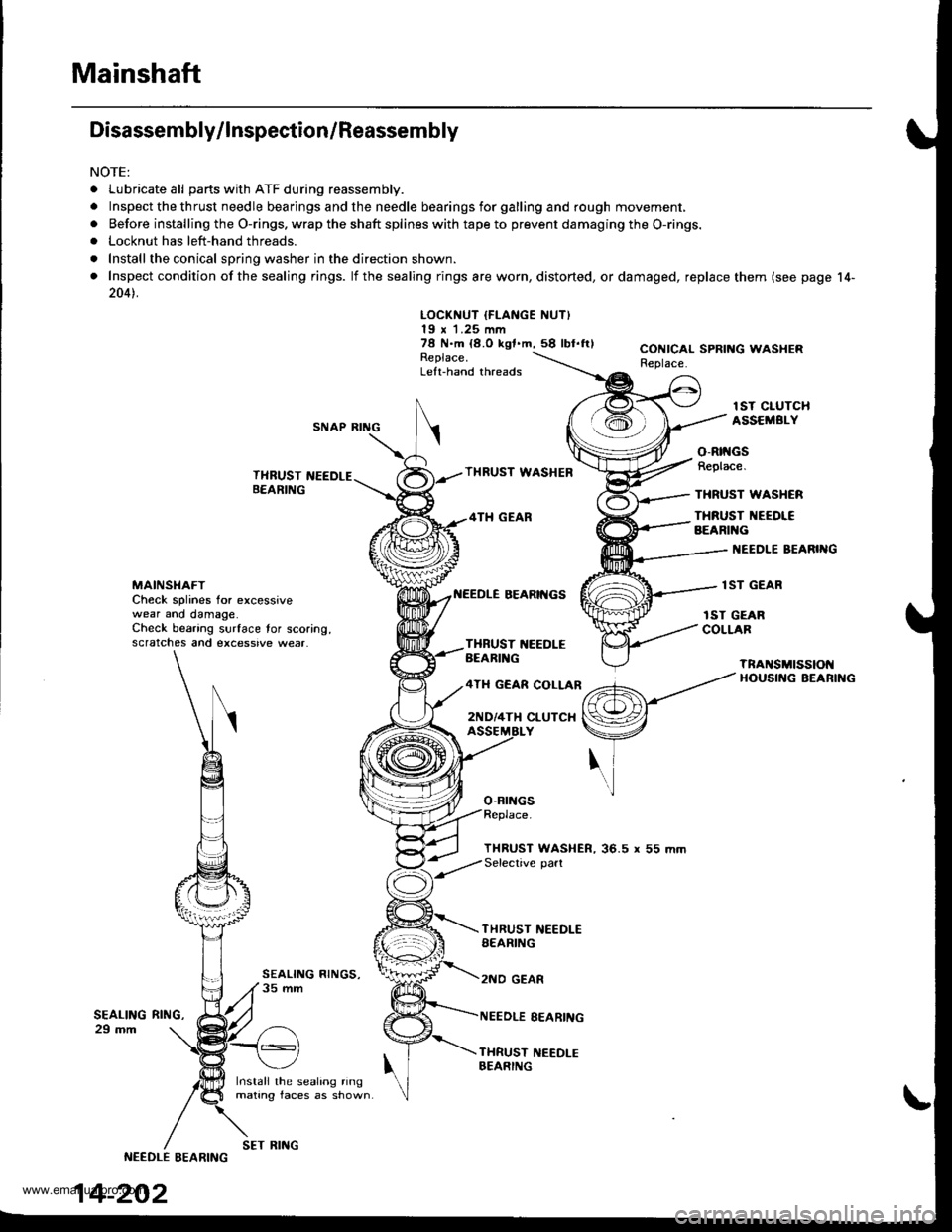

Mainshaft

Disassembly/lnspection/Reassembly

NOTE:

. Lubricate all parts with ATF during reassembly.

.Inspectthethrustneedlebearingsandtheneedlebearingsforgallingandroughmov\

ement,

. Before installing the O-rings. wrap the shaft splines with tape to prevent damaging the O-rings.. Locknut has left-hand threads.

. Install the conical spring washer in the direction shown.

. Inspect condition of the sealing rings. lf the sealing rings are worn, distorted, ordamaged, replace them (see page 14-

2041.

LOCKNUT IFLANGE NUT)19 x 1.25 mm78 N.m {8.O kgf.m,58 lbl.ftlReplace.Left-hand threads

CONICAL SPRING WASHERReplace.

lST CIUTCHASSEMBI.YSNAP RING

THRUST NEEDLEB€ARING

Install the sealing ringmating faces as shown

THRUST WASHEB

4TH GEAR

BEARII{GS

o-Brr{Gs

o-Rtt{GsReplace.

THRUST WASHCR

THRUST NEEOI€BEARIl{G

I{EEDLE BEARIIIG

lST GEARMAINSI{AFTCheck splines for excessivewear ano damage.Check bearing surface tor scoring,scratches and excessive wear.

rST GEARCOLLARTXBUST 1{EEDLEBEARIl{G

4TH GEAR COLLAR

2ND/4TH CLUTCX

TnANSMtSSIOt{HOUSII{G BEARII{G

THRUST WASHER, 36.5 r 55 mmSelective part

SEALING29 mm

THRUST NEEDLESEARING

2NO GEAR

NEEDLE EEARING

THRUST NEEDI-EBEARING

RltrlG,

NEEDLE EEARING

14-202

SET RING

www.emanualpro.com

Page 719 of 1395

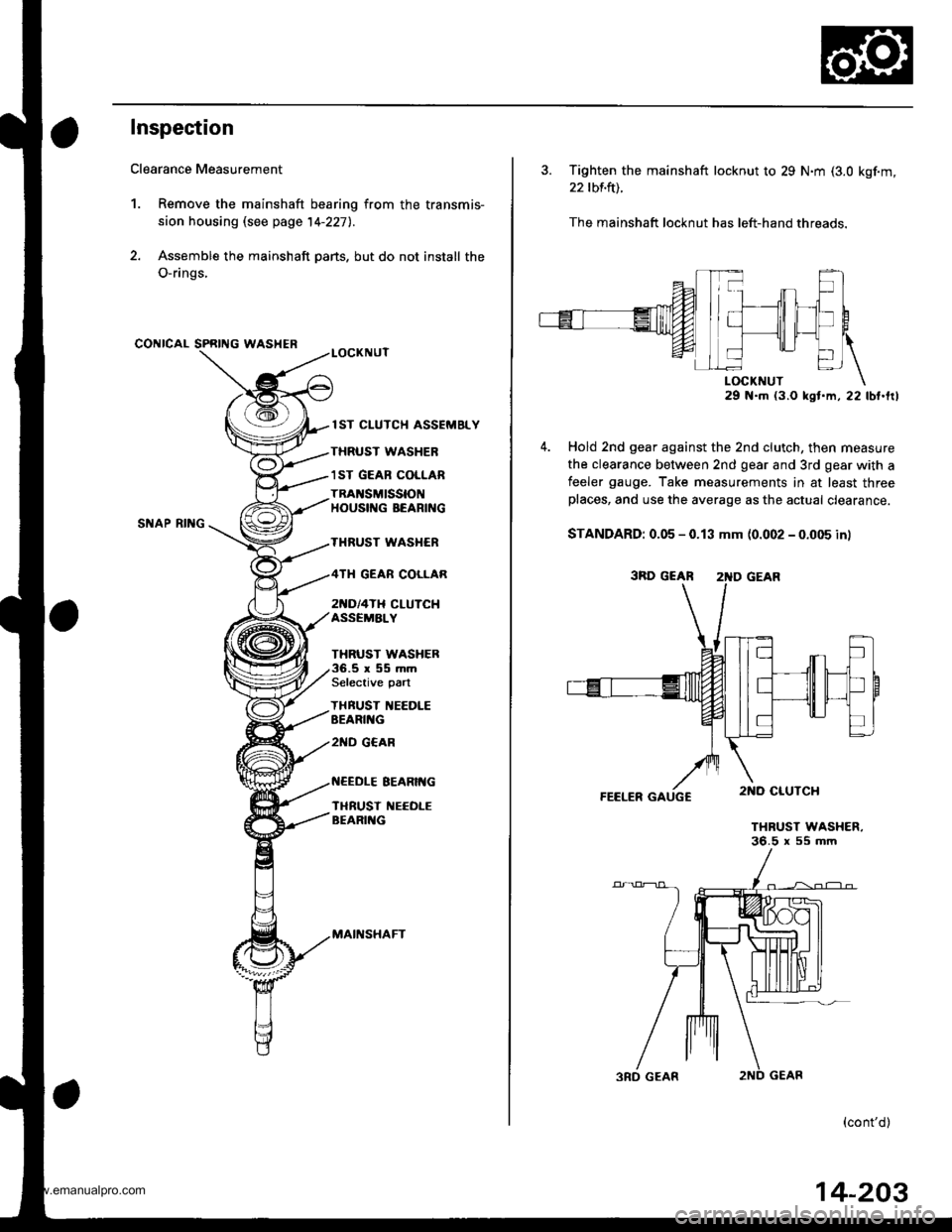

Inspection

Clearance Measurement

1. Remove the mainshaft bearing from the transmis-

sion housing lsee page 14-227l..

2. Assemble the mainshaft parts, but do not install the

O-rings,

CONICAL SPRING WASHER

SNAP RII{G

lST CLUTCH ASSEMELY

THRUST WASHER

1ST GEAB COLLAR

TRAI{SMISSIONHOUSIf{G BEARING

THRUST WASI{ER

2[{D/4TH CLUTCHASSEMALY

GEAR COLLAR

THRUST WASHER.5r55mmSelective part

THBUST IIEEDLEEEARII{G

2ND G€AR

EEARIt{G

TI{RUST NEEOLEBEARII{G

MAII{SHAFT

3. Tighten the mainshaft locknut to 29 N.m (3.0 kgf.m,

22 tbf.ft).

The mainshaft locknut has left-hand threads.

29 N.m (3.O kst.m, 22 lbt.frl

Hold 2nd gear against the 2nd clutch, then measure

the clearance between 2nd gear and 3rd gear with a

feeler gauge. Take measurements in at least threeplaces, and use the average as the actual clearance.

STANDARD: 0.05 - 0.13 mm (0.002 - 0.005 in)

FEELER GAUGC

THRUST WASHER.36.5 x 55 mm

(cont'd)

3RD GEAR 2'{D GEAR

14-203

www.emanualpro.com

Page 721 of 1395

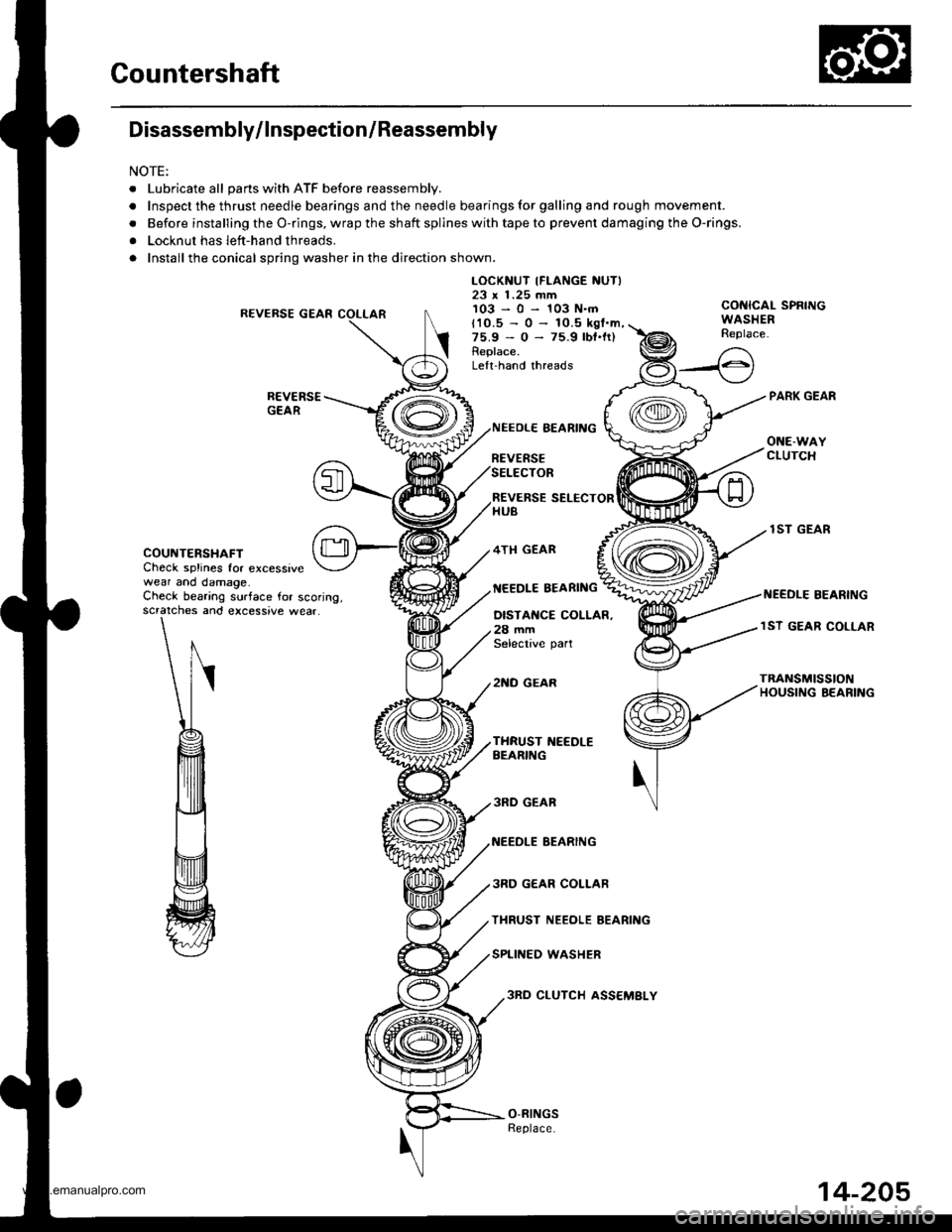

Countershaft

Disassembly/lnspection/Reassembly

NOTE:

. Lubricate all pans with ATF before reassembly.

.Inspectthethrustneedlebearingsandtheneedlebearingsforgallingandroughmov\

ement.

. Before installing the O-rings, wrap the shaft spllnes with tape to prevent damaging the O-rings.

. Locknut has left-hand threads.

. Install the conical spring washer in the direction shown.

R€VERSE GEAR

LOCKNUT IFLANGE NUTI23 x 1.25 mm103-0-103N.mCONICAL SPRINGWASHERReplace.t10.5 - 0 -

75.9 - 0 -

Replace.

10.5 kgl.m,75.9 lbt.lr)

Lelt.hand threads

COUNTERSHAFTCheck splines for excessivewear and damage.

REVERSE SELECTORHUB

4TH GEAR

NEEDLE EEARING

NEEOLE BEARING

REVERSESELECTOR

OISTANCE COLLAR.28 mmSelective part

2NO GEAR

lST GEAR

I{EEDLE BEARINGCheck bearing surface for scoring,scratches and excessive wear.lST GEAR COLLAR

TRANSn SSTONHOUSI G BEARING

3RD GEAR

NEEDLE BEARING

3RD GEAR COLLAR

THRUST NEEOLE BEARING

SPLINED WASHER

3RO CLUTCH ASS€MBLY

14-205

www.emanualpro.com

Page 722 of 1395

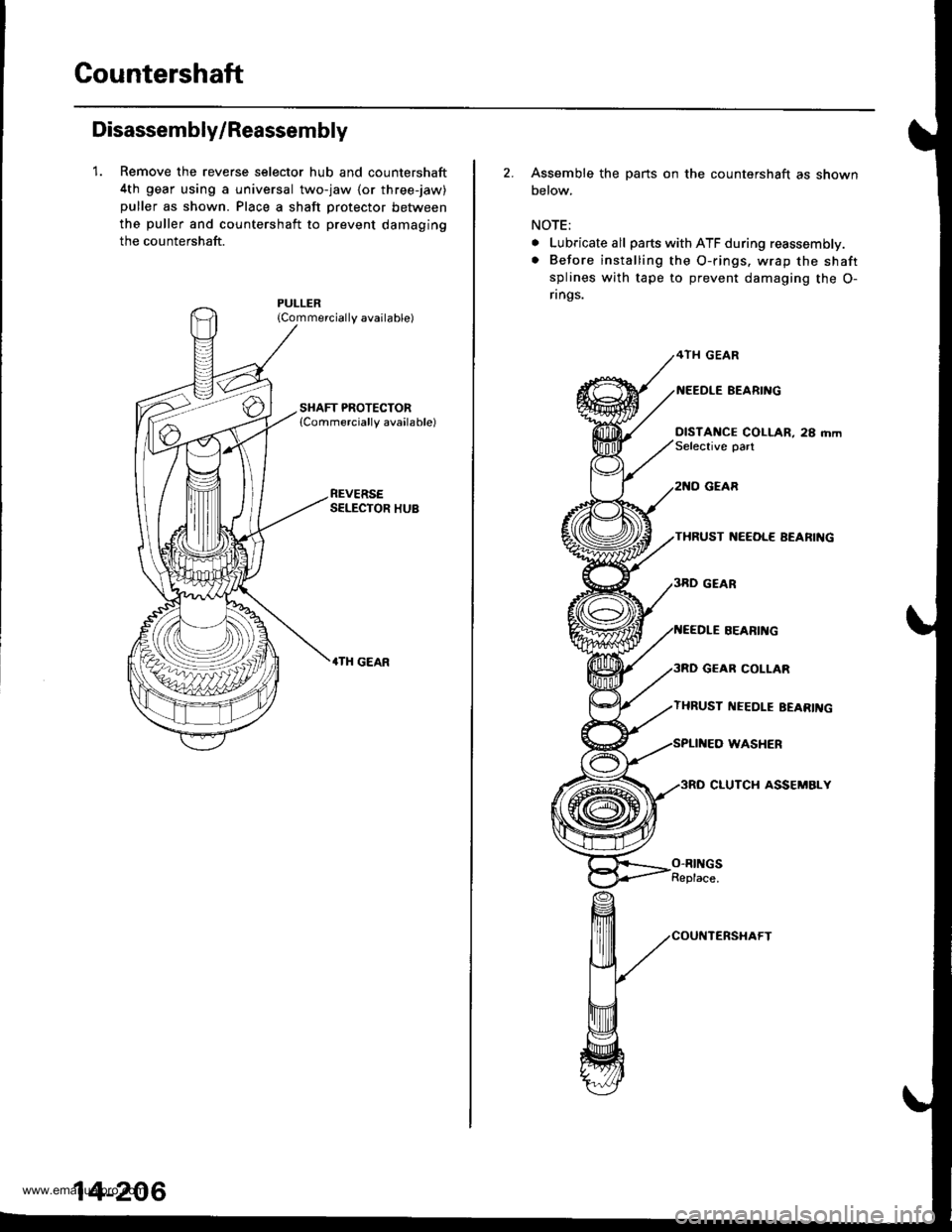

Gountershaft

Disassembly/Reassembly

1. Remove the reverse selector hub and countershaft

4th gear using a universal two-jaw lor three-jaw)

puller as shown. Place a shaft protector between

the puller and countershaft to prevent damaging

the countershaft.

{Commercially available)

REVERSESELECTOR HUB

.TH GEAR

14-206

2. Assemble the parts on the countershaft as shown

below.

NOTE;

. Lubricate all parts with ATF during reassembly.

. Before installing the O-rings. wrap the shaft

splines with tape to prevent damaging the O-

rings.

4TH GEAR

BEARI'{G

DISTANCE COLLAR, 28 mmSelective oart

GEAR

THRUST ]{EEOL€ AEARIIIG

GEAR COLLAR

THRUST I{EEDLE EEARII{G

WASHER

3RO CLUTCH ASSEMBLY

SEARII{G

O-RINGSReplace.

www.emanualpro.com

Page 723 of 1395

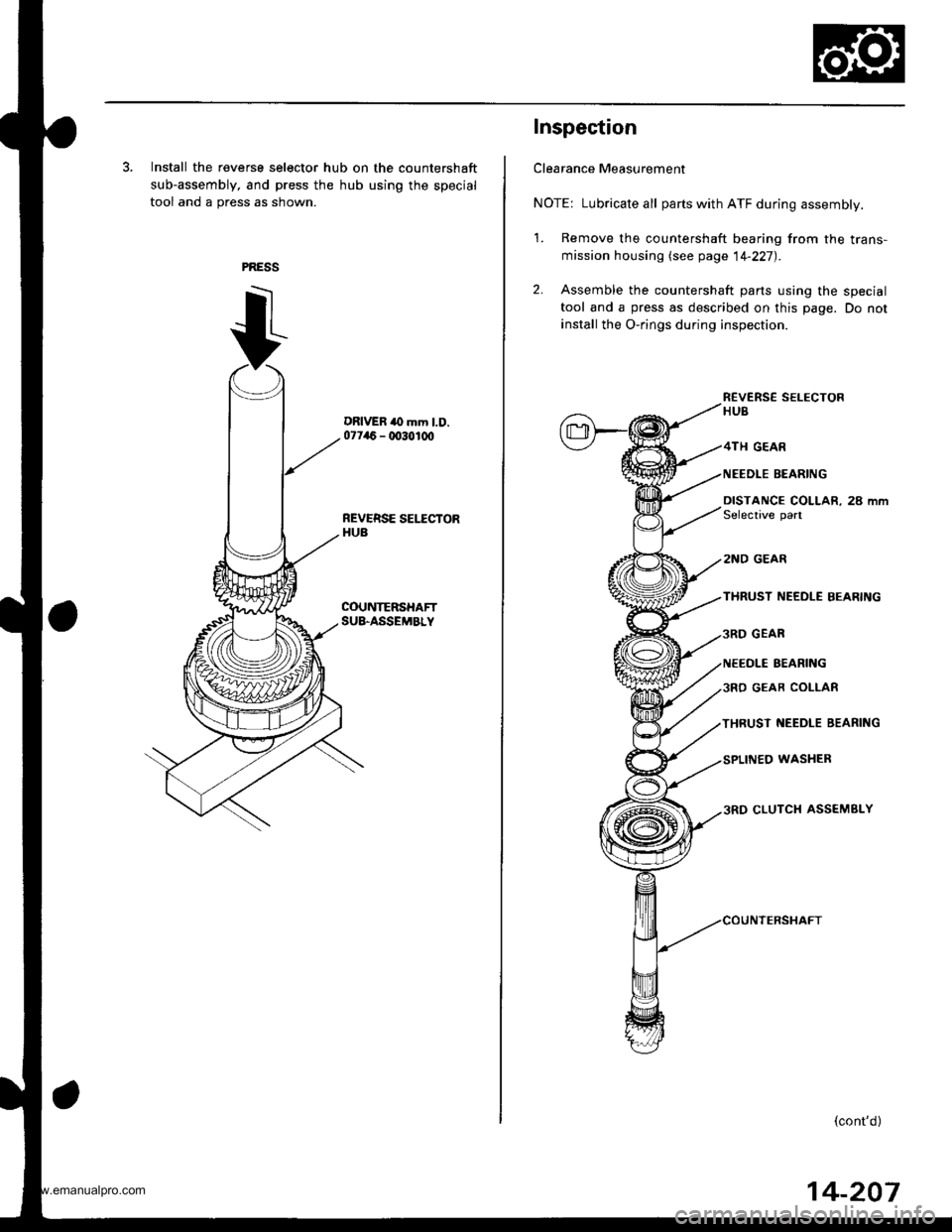

3. Install the reverse selector hub on the countershaft

sub-assembly, and press the hub using the special

tool and a press as shown.

DRIVER to mm l.D.07746 - 0030100

REVERSE SEI.ICTORHUB

COUNTERSHAFTSU&ASSEMBLY

Inspection

Clearance Measurement

NOTE: Lubricate all parts with ATF during assembly.

1. Remove the countershaft bearing from the trans-

mission housing lsee page 14-227).

2. Assemble the countershaft parts using the special

tool and a press as described on this page. Do not

install the O-rings during inspection.

R€VERS€ SELECTORHUB

GEAR

NEEDLE BEARING

DISTANCE COLLAR, 28 mmSelective part

2NO GEAR

THRUST NEEDLE BEARING

GEAR

NEEOLE BEARING

GEAR COLIAR

THRUST NEEDLE BEARING

WASHER

CLUTCH ASSEMBLY

(cont'd)

14-207

www.emanualpro.com

Page 724 of 1395

Countershaft

Inspection (cont'd)

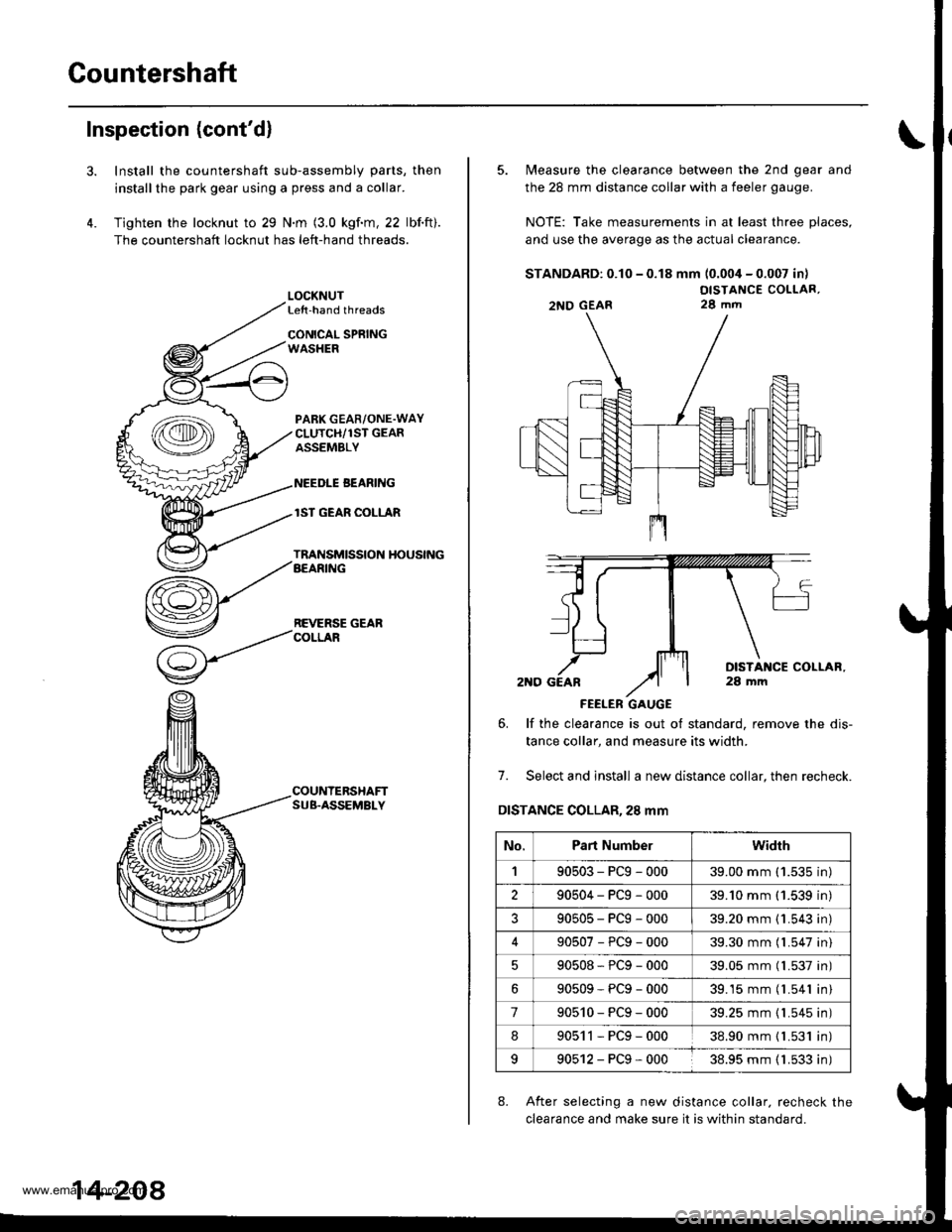

3.

4.

Install the countershaft sub-assembly parts, then

installthe park gear using a press and a collar.

Tighten the locknut to 29 N.m (3.0 kgf.m, 22 lbf.ft).

The countershaft locknut has left-hand threads.

LOCKNUTLe{t-hand threads

CONICAL SPRINGWASHER

PABK GEAR/ONE.WAYCLUTCH/1ST GEARASSEMBLY

NEEDLE BEANING

lST GEAR COLLAR

TRANSMISSION HOUSINGAEARING

REVERSE GEARCOLLAR

COUNTERSHAFTSUB.ASSEMBLY

14-208

5. Measure the clearance between the 2nd gear and

the 28 mm distance collar with a feeler gauge.

NOTE: Take measurements in at least three places,

and use the average as the actual clearance.

STANDARD: 0.10 - 0.18 mm (0.004 - 0.007 in)

OISTANCE COLLAR,28 mm

FEELER GAUGE

6. lf the clearance is out ot standard, remove the dis-

tance collar, and measure its width.

7. Select and install a new distance collar, then recheck.

DISTANCE COLLAR,28 mm

8. After selecting a new distance collar. recheck the

clearance and make sure it is within standard.

2NO GEAR

No.Part Numberwidrh

190503-PCg-00039.00 mm ('1.535 in)

290504-PCg-00039.'10 mm (1.539 in)

?90505-PCg-00039.20 mm {1.543 in)

90507-PCg-00039.30 mm (l.547 in)

90508*PCg-00039.05 mm (l.537 in)

90509-PCg-00039.15 mm (l.541 in)

790510-PCg-00039.25 mm {1.545 in)

890511-PCg-00038.90 mm { L531 in)

990512-PCg-00038.95 mm ( 1.533 in)

www.emanualpro.com

Page 725 of 1395

One-way Glutch

Disassembly/lnspection/Reassem bly

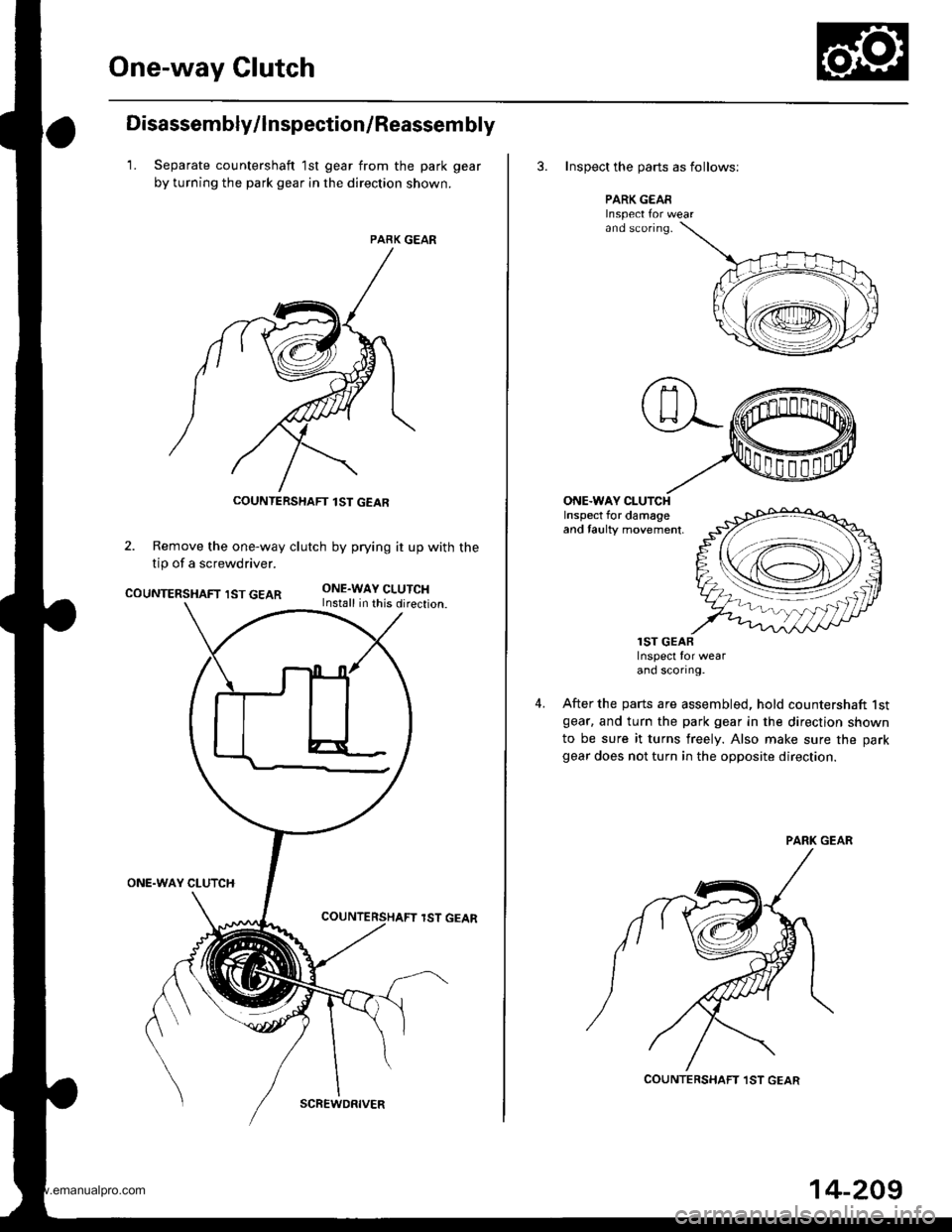

1. Separate countershaft 1st gear from the park gear

by turning the park gear in the direction shown.

PARK GEAR

2. Remove the one-way clutch by prying it up with the

tip of a screwdriver.

COUNTERSHAFT IST GEARONE.WAY CLUTCHInstall in this direction.

ONE.WAY CLUTCH

lST GEAR

COUNTERSHAFT lST GEAR

SCREWDRIVER

14-209

3. Inspect the oarts as follows;

PARK GEARInspect Ior wearand sconng.

ONE.WAY CLUTCHInspect for damageand taulty movement,

4.

lST GEARInspect for wearand scortng.

After the parts are assembled, hold countershaft lstgear. and turn the park gear in the direction shown

to be sure it turns freely. Also make sure the park

gear does not turn in the opposite direction.

COUNTERSHAFT ,IST GEAR

www.emanualpro.com

Page 738 of 1395

Differential

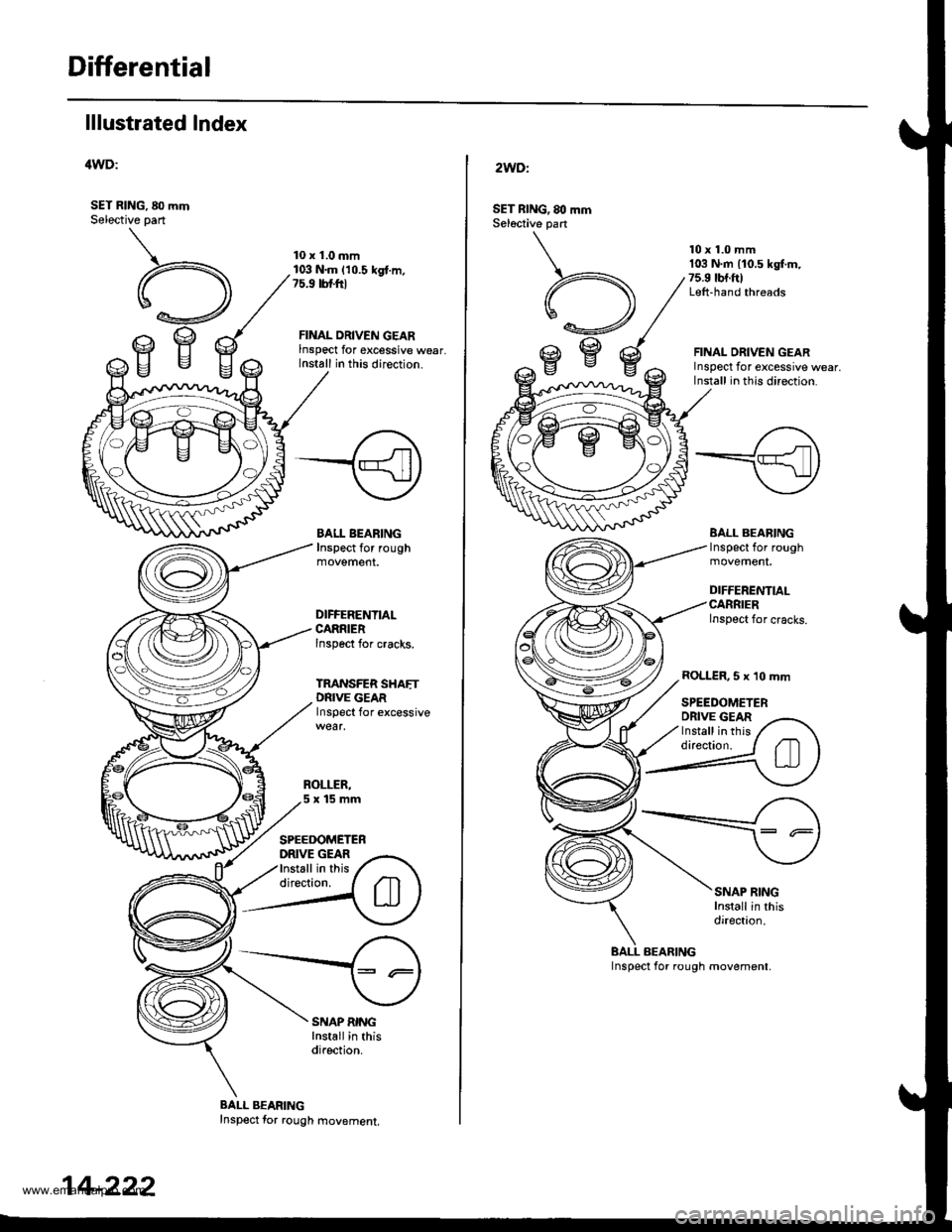

lllustrated Index

'lWD:

SET RING, 80 mmSelective part

10 x 1.0 mm103 N.m (10.5 kgt.m,?5.9 tbtftl

FINAL ORIVEN GEARlnspect for excessive wear,Install in this direction.

BALL BEARINGInspect for rough

DIFFERENTIAI.CARRIERlnspect for cracks.

TRANSFER SHAETDNlvE GEARInspect for excessive

SPEEDOMETERDRIVE GEARInstall in thisdirection.

SNAP RINGInstall in thisdirection.

BALL BEARINGInspect for rough movement,

14-222

2WDl

SET nlNG, 80 mmSel6ctive part

A,U

,gBc

10 x 1.0 mm103 N.m {10.5 kg[.m,75.9 tbt.ftlLeft-hand threads

FINAL ORIVEN GEARInspect for excessive wear,Install in thls direction.

BALL BEABINGInspect for rough

DIFFERENTIAI.CARRIERInspect for cracks.

ROLLER,5 x 10 mm

SPEEDOMETERDRIVE GEARInstall in thisdirection.

SNAP RINGInstall in thisdirection.

BALL BEARING

www.emanualpro.com

Page 739 of 1395

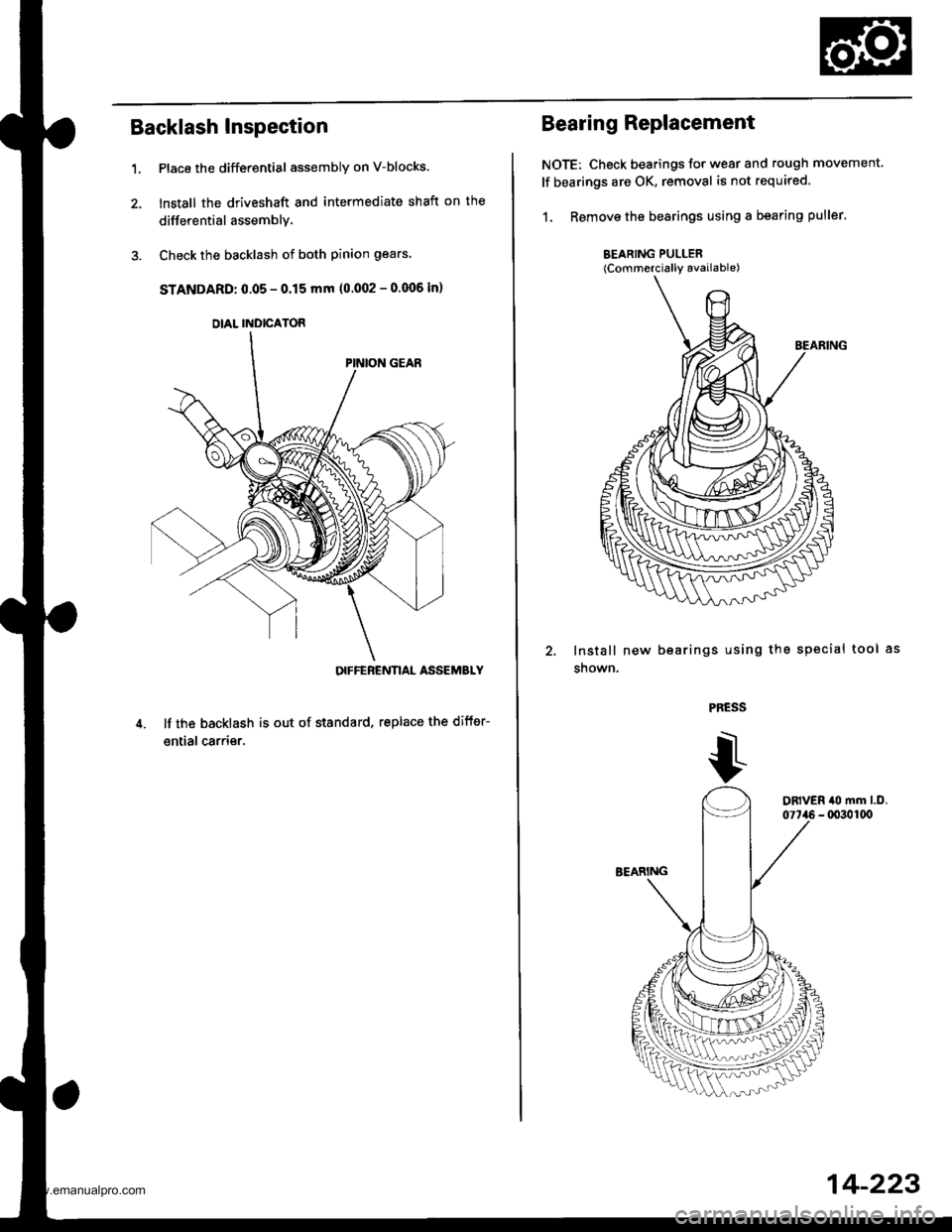

Backlash Inspection

Place the differential assembly on V-blocks.

lnstall the driveshaft and intermediate shaft on the

differential assemblY.

Check the backlash of both pinion gears.

STANDARD: 0.05 - 0.15 mm (0.002 - 0.006 in)

OIFFEBENNAL ASSEMBLY

It the backlash is out of standard, replace the difter-

ential carrier.

1.

DIAL INDICATOR

Bearing Replacement

NOTE: Check bearings for wear and rough movement.

lf bearings are OK, removal is not required.

1. Remove the bearings using a bearing puller.

BEARING PULLER(Commercially available)

lnstall new

snown.

bearings using the sPecial tool

PRESS

14-223

www.emanualpro.com

Page 740 of 1395

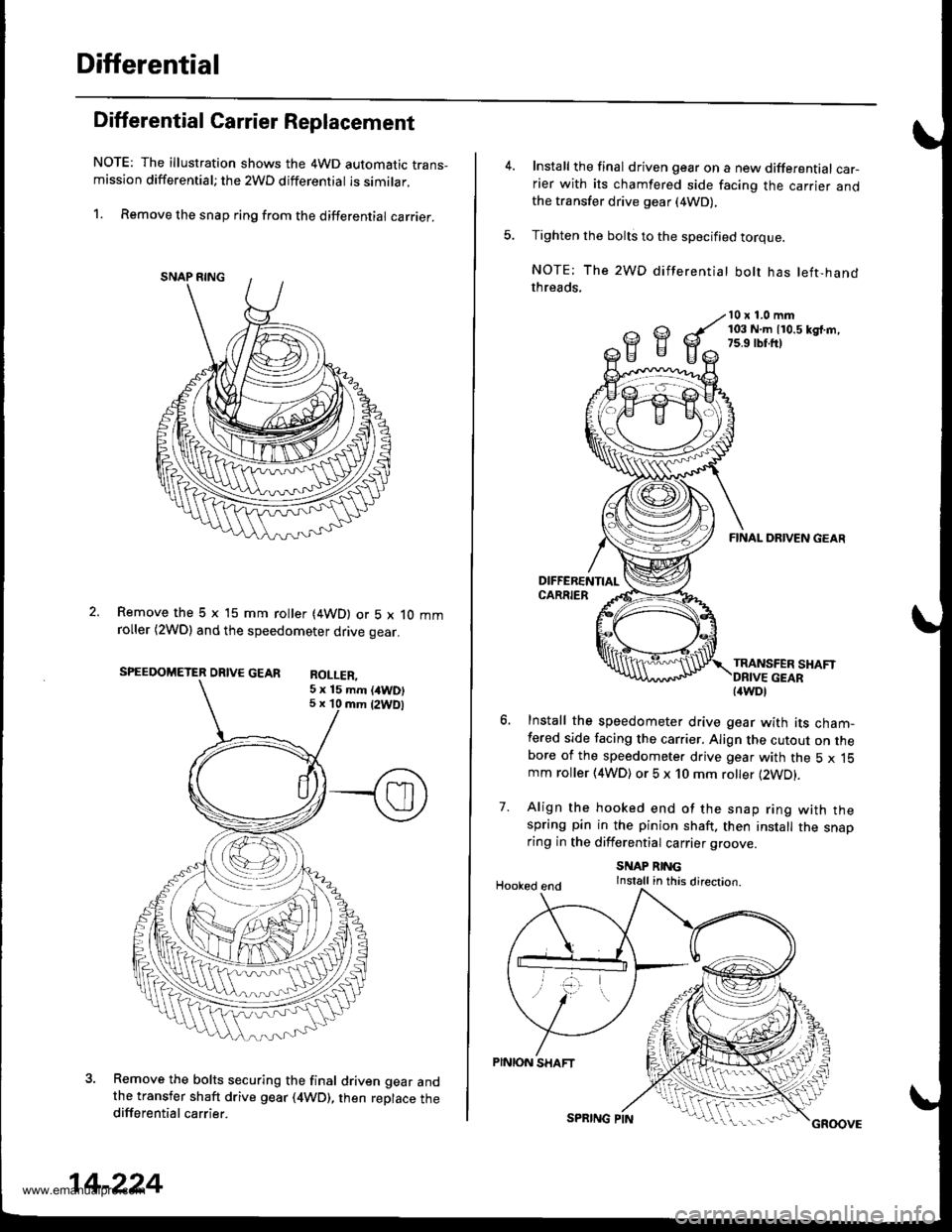

Differential

Differential Carrier Replacement

NOTE: The illustration shows the 4WD automatic trans-mission differential; the 2WD differential is similar.

1. Remove the snap ring from the differential carrier.

Remove the 5 x 15 mm roller (4WD) or 5 x 10 mmroller (2WDl and the speedometer drive gear.

SPEEDOMETER DRIVE GEAR RoI I FP

Remove the bolts securing the final driven gear andthe transfer shaft drive gear (4WD), then replace thedifferential carrier.

5 x 15 mm (/tWD)5 x 10 mm {2WDl

14-224

SPRING PINGROOVE

Install the final driven gear on a new differential car-rier with its chamfered side facing the carrier andthe transfer drive gear (4WD),

Tighten the bolts to the specified torque.

NOTE: The 2WD differentiat bolt has left-handthreads,

10 x 1.0 mm103 N.m 110.5 kd.m,7s.9 rbr.ft)

7.

FINAL DRIVEN GEAR

TRANSFER SHAFT

Install the speedometer drive gear with its cham-fered side facing the carrier. Align the cutout on thebore of the speedometer drive gear with the 5 x 15mm roller (4WD) or 5 x 10 mm roller (2WD).

Align the hooked end of the snap ring with thespring pin in the pinion shaft. then install the snaoring in the differential carrier groove

SNAP RINGInstall in this direction.Hooked end

PINION SHAFT

{4WDl

www.emanualpro.com