ECU HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 497 of 1395

Transfer Assembly

Reassembly (cont'dl

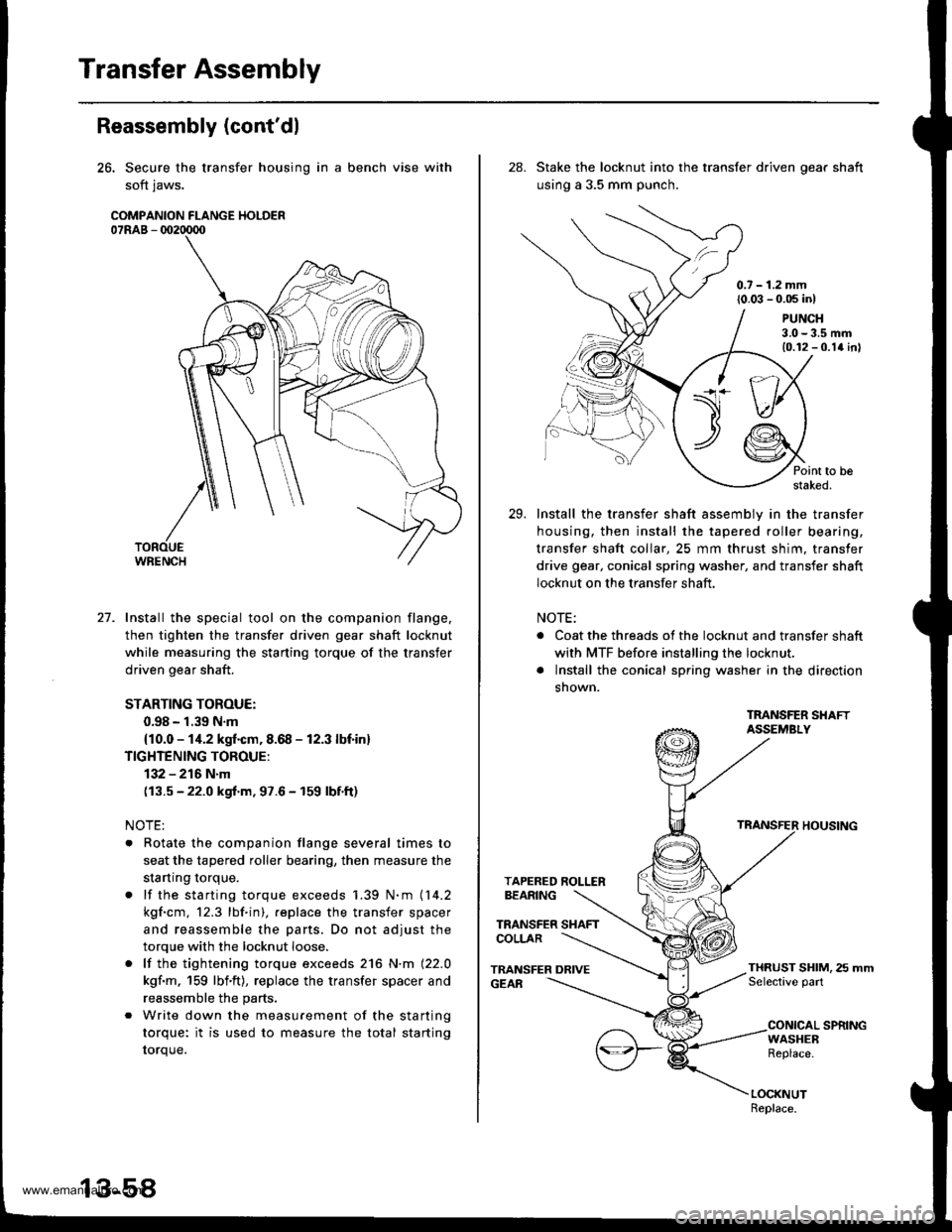

26. Secure the transfer housing in a bench vise with

soft jaws.

COMPANION FLANGE HOLDER07RAB - 002tD00

27. Install the special tool on the companion flange.

then tighten the transfer driven gear shaft locknut

while measuring the starting torque of the transfer

driven gear shaft.

STARTING TOROUE:

0.98 - 1.39 N.m

{10.0 - 1i1.2 kgf.cm, 8.68 - 12.3 lbf in}

TIGHTENING TOROUE:

132 - 216 N.m

(13.5 - 22.0 kgf.m, 97.6 - 159 lbf.ft)

NOTE:

. Rotate the companion flange several times to

seat the tapered roller bearing, then measure the

startrng torque.

. lf the starting torque exceeds 1.39 N.m (14.2

kgf.cm, 12.3 lbf.in), .eplace the transfer spacer

and reassemble the parts. Do not adjust the

torque with the locknut loose.

. lf the tightening torque exceeds 216 N.m (22.0

kgf.m, 159 lbf'ft), replace the transfer spacer and

reassemble the parts.

. Write down the measurement of the starting

torque: it is used to measure the total starting

torque.

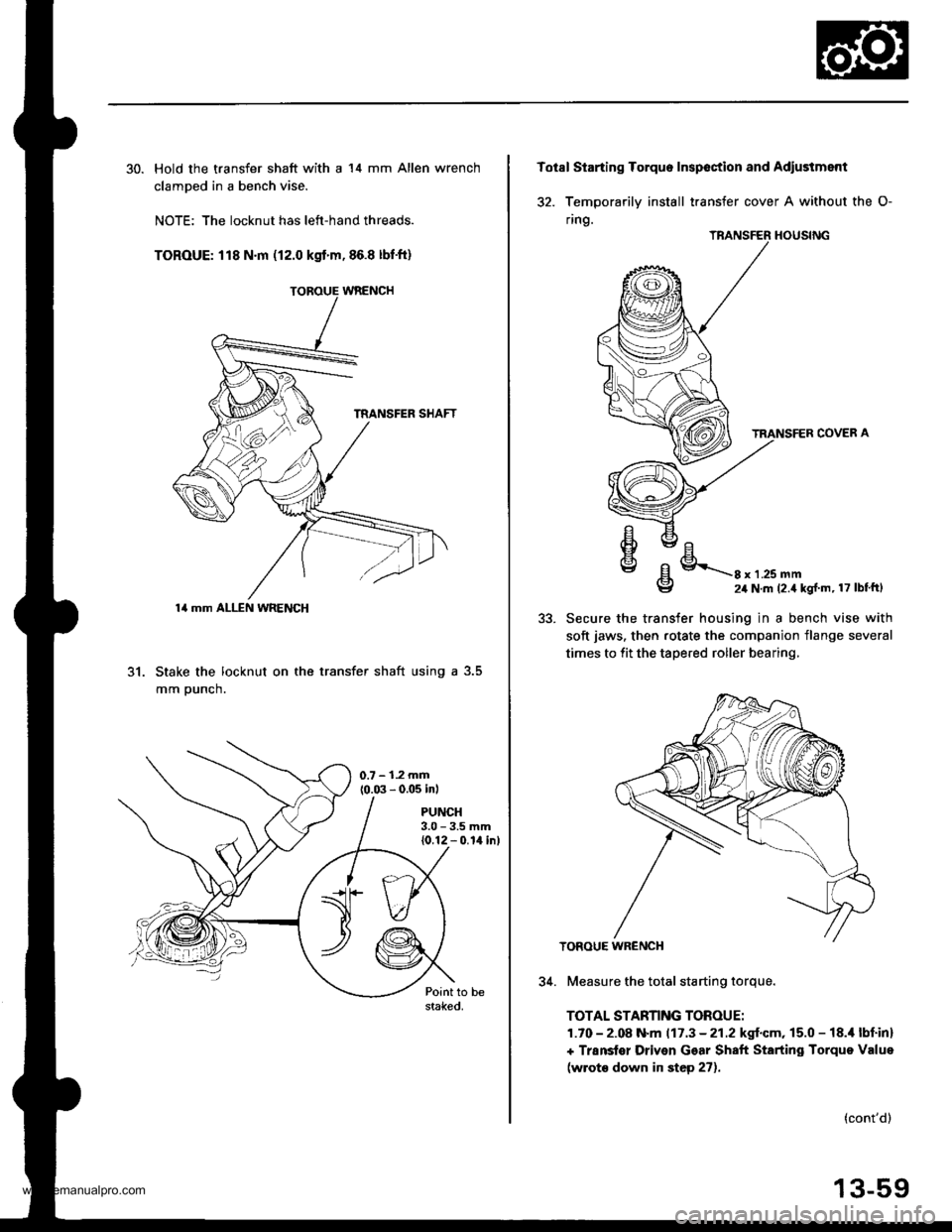

28. Stake the locknut into the transfer driven oear shaft

using a 3.5 mm punch.

0.7 - 1.2 mm(0.03 - 0.05 inl

Point to bestaked.

Install the transfer shaft assemblv in the transfer

housing, then install the tapered roller bearing,

transfer shaft collar, 25 mm thrust shim, transfer

drive gear, conical spring washer, and transfer shaft

locknut on the transfer shaft.

NOTE:

. Coat the threads of the locknut and transfer shaft

with MTF before installing the locknut.

. lnstall the conical spring washer in the direction

snown.

TMNSFER SHAFTASSEMBLY

TRANSFER HOUSING

TAPERED ROLLERBEARING

TRANSFER SHAFTCOLLAR

TRANSFER DRIVEGEAR

PUNCH3.0-3.5 mm10.12 - 0.1a inl

THRUST SHIM, 25 mmSelective part

CONICAL SPRINGWASHEBReplace.

LOCKNUTReplace.

29.

www.emanualpro.com

Page 498 of 1395

30. Hold the transfer shaft with a 14 mm Allen wrench

clamDed in a bench vise.

NOTE: The locknut has left-hand threads.

TOROUE: 118 N.m (12.0 kgt'm,86.8 lbf'ft)

31. Stake the locknut on the transfer shaft using a 3.5

mm Dunch.

PUNCH3.0 - 3.5 mm{0.12 - 0.14 inl

14 mm ALLEN WRENCH

Totsl Starting Torquo Inspoction and Adiustment

32. Temoorarilv install transfer cover A without the O-

ring.

TRANSFER HOUSING

TRANSFER COVER A

oEl

€lE/Ehvc/E\\g8 x 1 .25 mm24 N.m (2.4 kg{ m, 17 lbtftl

5t.Secure the transfer housing in a bench vise with

soft jaws. then rotate the companion flange several

times to fit the tapered roller bearing,

TOROUE WR€NCH

34. Measure the total starting torque.

TOTAL STARNNG TOROUE:

1.70 - 2.08 N.m 117.3 - 21.2 kgf.cm, 15.0 - 18.i1 lbf inl

+ Transter Driven Gear Shaft Starting Torque Value

(wrot€ down in step 27).

(cont'd)

13-59

www.emanualpro.com

Page 508 of 1395

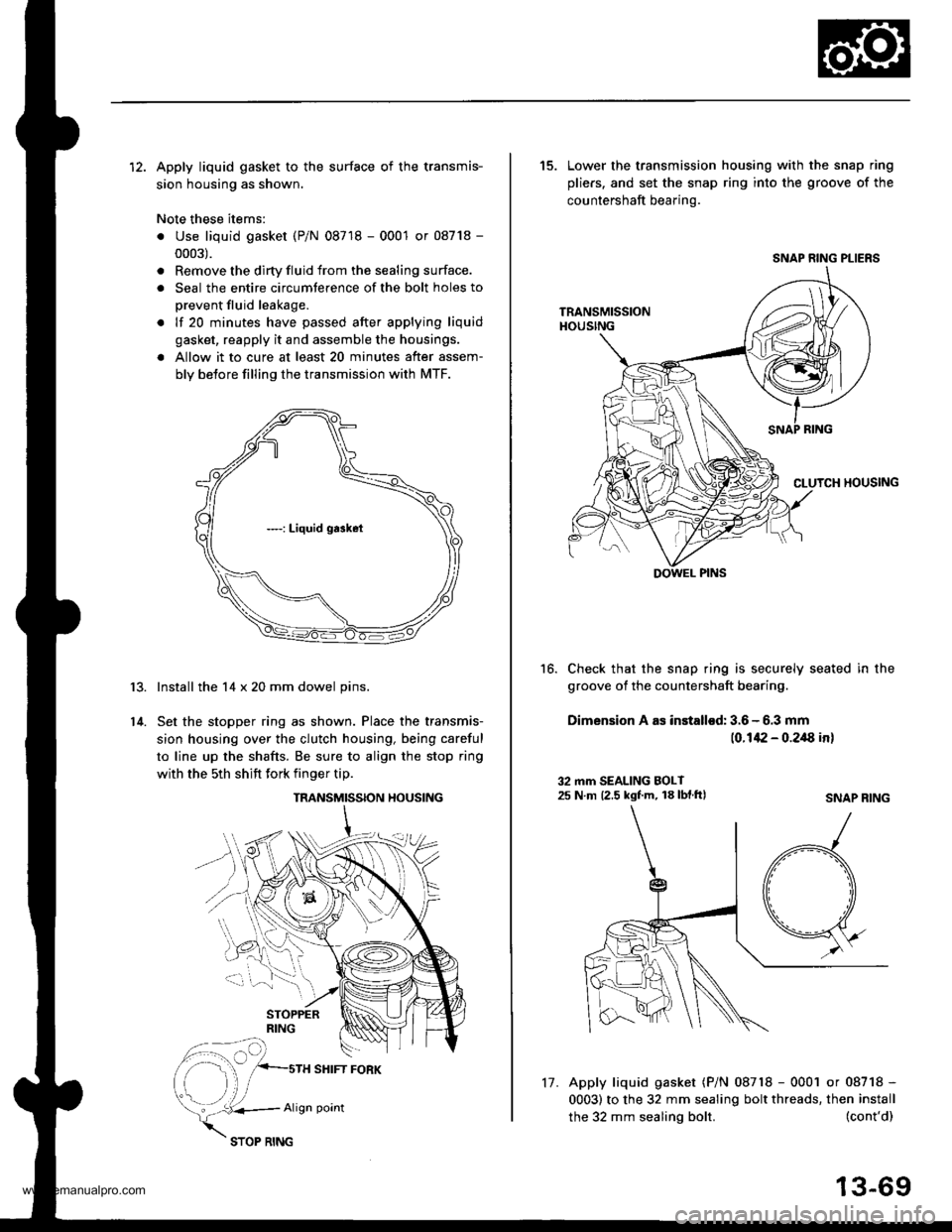

12. Apply liquid gasket to the surface of the transmis-

sion housing as shown.

Note these items:

. Use liquid gasket (P/N 08718 - 0001 or 08718 -

0003).

. Remove the dirty fluid from the sealing surface.

. Seal the entire circumterence of the bolt holes to

prevent fluid leakage.

. lf 20 minutes have passed after applying liquid

gasket, reapply it and assemble the housings.

a Allow it to cure at least 20 minutes after assem-

bly betore filling the transmission with MTF.

Install the 14 x 20 mm dowel pins.

Set the stopper ring as shown. Place the transmis-

sion housing over the clutch housing, being careful

to line up the shafts. Be sure to align the stop ring

with the 5th shift fork finger tip.

r3.

14.

TRANSMISSION HOUSING

SHIFT FORK

vk..*,

Align point

17.

the 32 mm sealing bolt.

15. Lower the transmission housing with the snap ring

pliers. and set the snap ring into the groove of the

countershaft bearing.

Check that the snap ring is securely seated in the

groove of the countershaft bearing.

Dimension A as installod: 3.6 - 6.3 mm

(0.142 - 0.2/8 in)

16.

32 mm SEALING BOLT25 N m 12.5 kgf.m, 18 lbf.ftlSNAP RING

(cont'd)

13-69

Apply liquid gasket (P/N 08718 - 0001 or 08718 -

0003) to the 32 mm sealing bolt threads, then install

SNAP RING PLIERS

DOWEL PINS

www.emanualpro.com

Page 651 of 1395

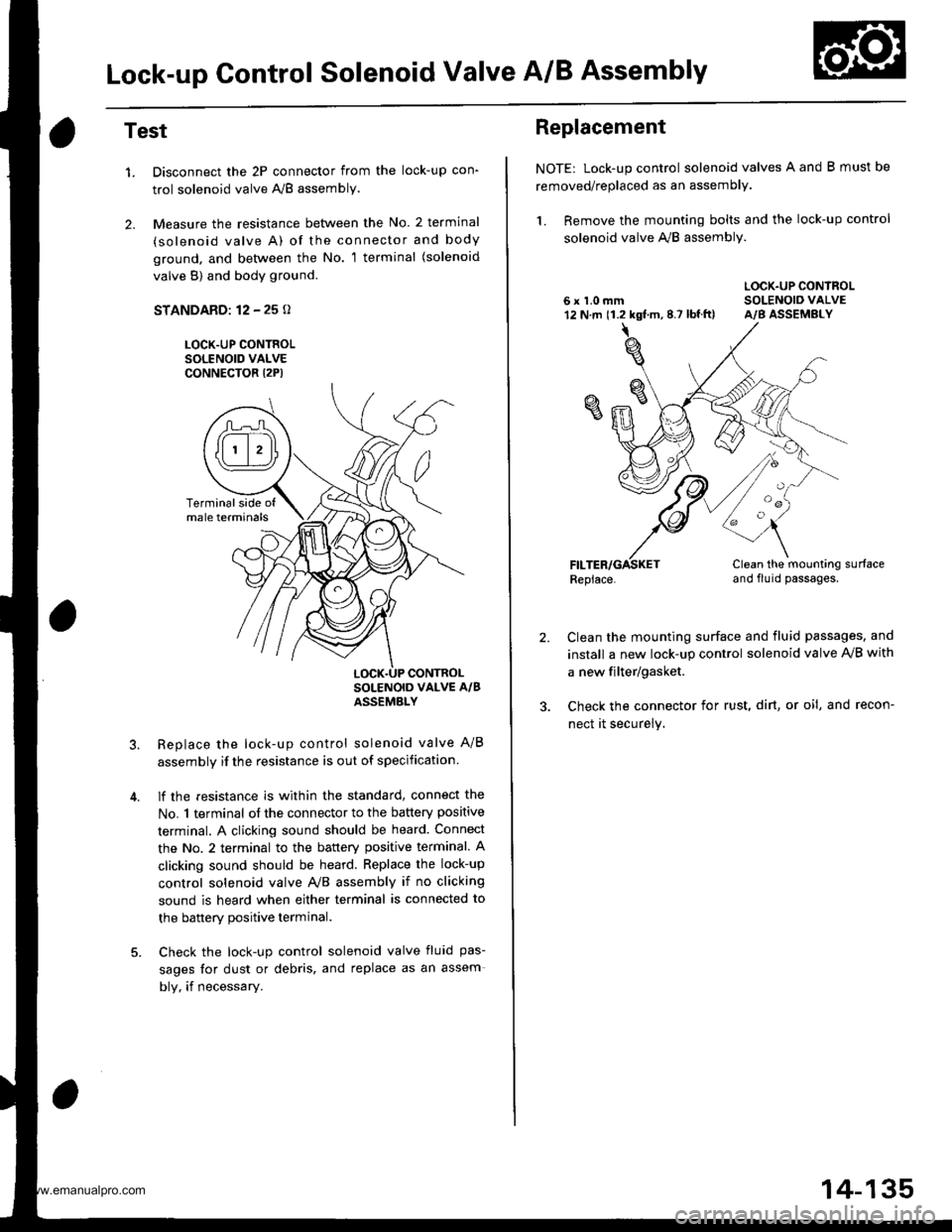

Lock-up Control Solenoid Valve A/B Assembly

Test

1.

2.

Disconnect the 2P connector from the lock-up con'

trol solenoid valve A'lB assembly.

Measure the resistance between the No. 2 terminal

(solenoid valve A) of the connector and body

ground. and bet\iveen the No. 1 terminal (solenoid

valve B) and body ground.

STANDARD: 12 - 25 o

LOCK-UP CONTROLSOLENOID VALVECONNECTOR I2P)

Replace the lock-up control solenoid valve A/B

assembly if the resistance is out of specification

lf the resistance is within the standard, connect the

No. 1 terminal of the connector to the battery positive

terminal. A clicking sound should be heard Connect

the No. 2 terminal to the battery positive terminal. A

clicking sound should be heard. Replace the lock-up

control solenoid valve Ay'B assembly if no clicking

sound is heard when either terminal is connected to

the banerv Dositive terminal.

Check the lock-up control solenoid valve fluid pas-

sages for dust or debris, and replace as an assem

bly, if necessary.

Terminalside ofmale terminals

LOCK.UP CONTROL

Replacement

NOTE: Lock-up control solenoid valves A and B must be

removed/replaced as an assembly.

1. Remove the mounting bolts and the lock-up control

solenoid valve A,,/B assembly.

LOCK.UP CONTROL6 x 1.0 mm SOLENOIO VALVE12 N.m 11.2 kgf.m,8.7 lbf.ft) A/B ASSEMBLY

Replace.Clean the mounting surfaceand flu id passages.

2.Clean the mounting surface and fluid passages, and

install a new lock-up control solenoid valve IVB with

a new filter/gasket.

Check the connector for rust, dirt, or oi!, and recon-

nect it securely.

oa

14-135

www.emanualpro.com

Page 652 of 1395

Shift Control Solenoid Valve A/B Assembly

Test

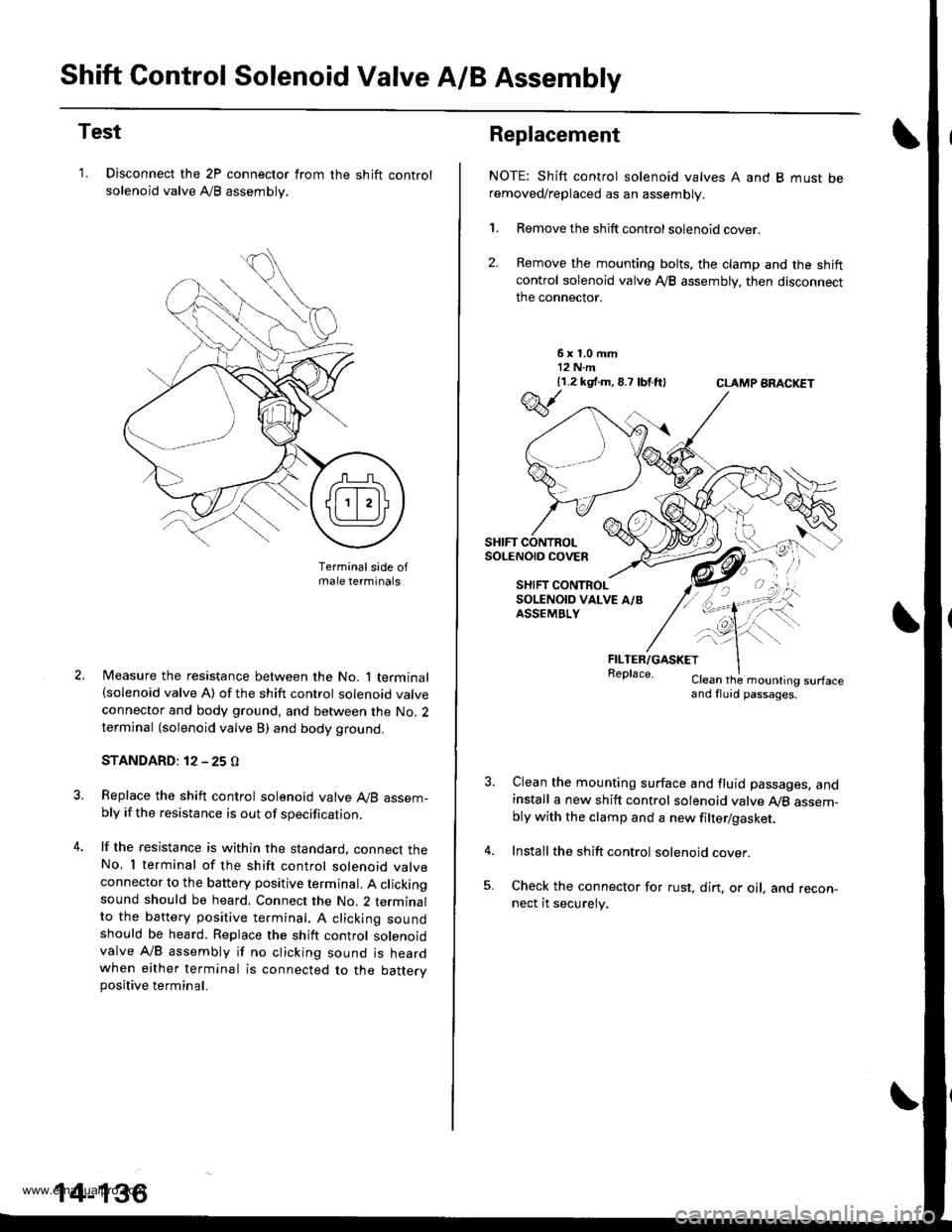

'1. Disconnect the 2P connector from

solenoid valve Ay'B assembly.

the shift control

Terminalsade ofmale terminals

Measure the resistance between the No. 1 terminal(solenoid valve A) of the shift control solenoid valve

connector and body ground, and between the No. 2terminal (solenoid valve B) and body ground.

STANDARD: 12 - 25 O

Replace the shift control solenoid valve A,/B assem-bly if the resistance is out of specification.

lf the resistance is within the standard. connect theNo, I terminal of the shift control solenoid valveconnector to the battery positive terminal. A clickingsound should be heard. Connect the No. 2 terminalto the battery positive te.minal. A clicking soundshould be heard. Replace the shift control solenoidvalve A/B assembly if no clicking sound is heardwhen either terminal is connected to the battervpositive terminal.

14-136

Replacement

NOTE: Shift control solenoid valves A and B must beremoved/replaced as an assembly.

1. Remove the shift control solenoid cover.

2. Remove the mounting bolts, the clamp and the shiftcontrol solenoid valve Ay'B assembly, then disconnect

the connector.

6x1.0mm12 N.m{1.2 k9 .m,8.7 lbtft}CLAMP ARACKET

FILTER/GASKETReplace.Clean the mounling surfaceand fluid passages.

Clean the mounting surface and fluid passages. andinstall a new shift control solenoid valve Ay'B assem-bly with the clamp and a new filter/gasket.

Install the shift control solenoid cover.

Check the connector for rust, dirt. or oil, and recon-nect it securely.

w

SHIFT CONTROLSoLENO|O COVEn

SHIFT CONTROLSOLENOID VALVE A/BASSEMBLY

\--

qK

-!t'">,,

www.emanualpro.com

Page 654 of 1395

Mai nshaft /Cou ntershaft

Linear Solenoid AssemblySpeed Sensors

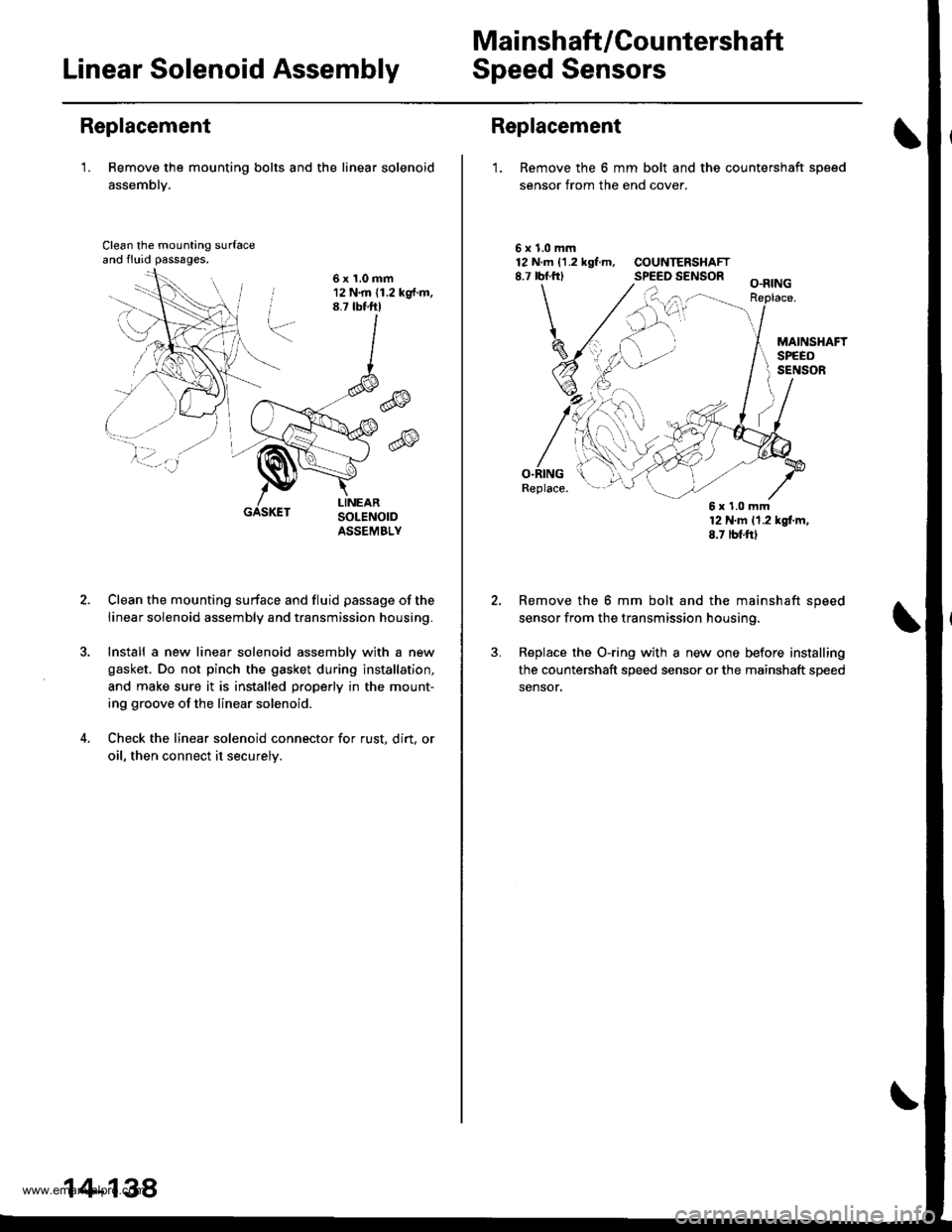

Replacement

'1. Remove the mounting bolts and the linear solenoid

assemblY.

Clean the mounting surfaceand fluid passages.

6x1.0mm12 N.m (1.2 kg{.m.8.7 tbtftl

@

@

GASKET

Clean the mounting surface and fluid passage of the

linear solenoid assembly and transmission housing.

Install a new linear solenoid assemblv with a new

gasket. Do not pinch the gasket during installation,

and make sure it is installed properly in the mount-

ing groove of the linear solenoid.

Check the linear solenoid connector for rust. dirt, or

oil, then connect it securelv.

14-138

Replacement

1. Remove the 6 mm bolt and the countershaft sDeed

sensor from the end cover.

\

5x1.0mm12 N.m 11.2 kgf.m, COUNTERSHAFT8.7 rbf.frl SPEED SENSOR

O.RINGReplace.

12 N'm 11.2 kgl.m,8.7 tbf.ftl

Remove the 6 mm bolt and the mainshaft speed

sensor from the transmission housing.

Replace the O-ring with a new one before installing

the countershaft speed sensor or the mainshaft speed

sensor,

6x1.0mm

www.emanualpro.com

Page 656 of 1395

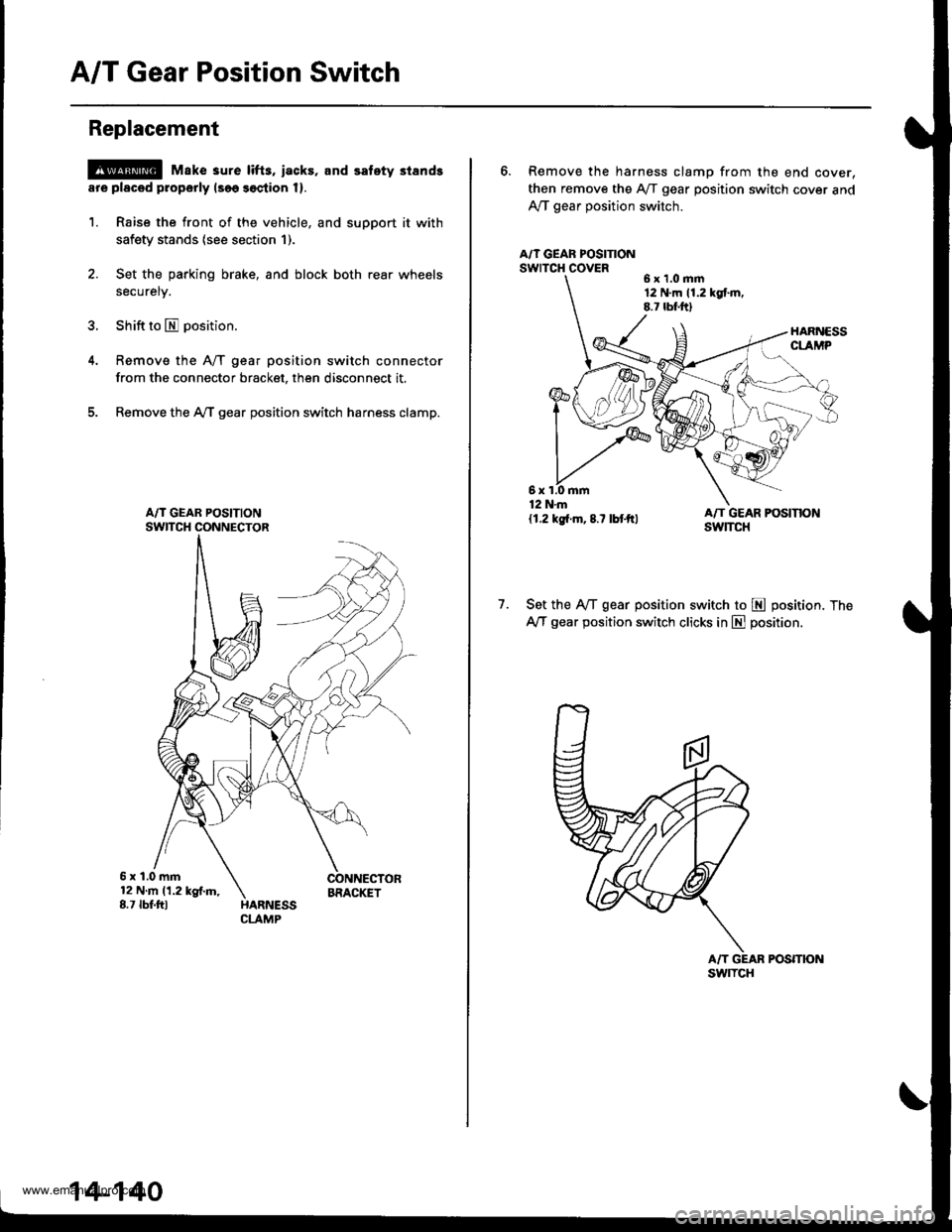

A/T Gear Position Switch

Replacement

@ Make 3ure lifts, iacks, and safety stands

ar€ placod properly lsoo soction 1).

1. Raise the front of the vehicle, and support it with

safety stands (see section 1).

2. Set the parking brake, and block both rear wheels

securely.

3. Shift to E position.

Remove the A/T gear position switch connector

from the connector bracket, then disconnect it.

Remove the AfI gear position switch harness clamp.

5x1.0mm12Nm11.2kgf.m,8.7 tbf.fttBRACIGT

14-140

6. Remove the harness clamp from the end cover,

then remove the Aff gear position switch cover and

Ay'T gear position switch.

A/T GEAF POSITIONswrTcH covER6x1.0mm12 N.m 11.2 kgt m.8.7 lbf.ftl

1.Set the IVT gear position switch to E position. The

AfI gear position switch clicks in E position.

POSmON

6x1.0mm12 N.m

{1.2 kg{.m,8.7 lbtftl

swlTcH

www.emanualpro.com

Page 664 of 1395

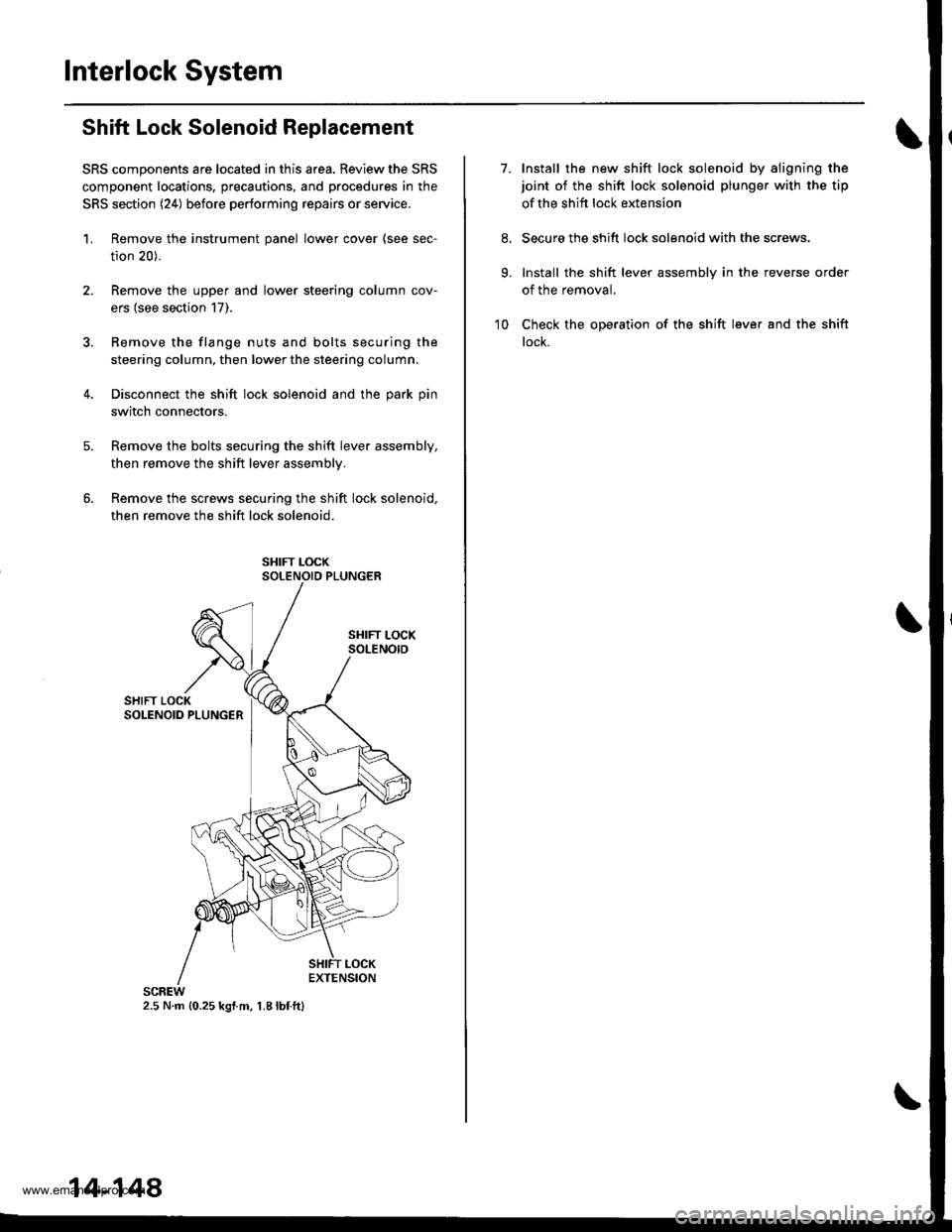

Interlock System

Shift Lock Solenoid Replacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

'L Remove the instrument panel lower cover (see sec-

tion 20).

2. Remove the upper and lower steering column cov-

ers (see section 17).

3. Bemove the flange nuts and bolts securing the

steering column, then lower the steering column.

4. Disconnect the shift lock solenoid and the park pin

switch connectors.

Remove the bolts securing the shift lever assembly,

then remove the shift lever assemblv.

Remove the screws securing the shift lock solenoid,

then remove the shift lock solenoid.

2.5 N.m {0.25 kgl.m, 1.8lbf.ft}

14-148

7.Install the new shift lock solenoid by aligning the

joint of the shift lock solenoid plunger with the tip

of the shift lock extension

Secure the shift lock solenoid with the screws,

Install the shift lever assembly in the reverse order

of the removal.

Check the operation of the shift lever and the shift

lock.

9.

10

www.emanualpro.com

Page 666 of 1395

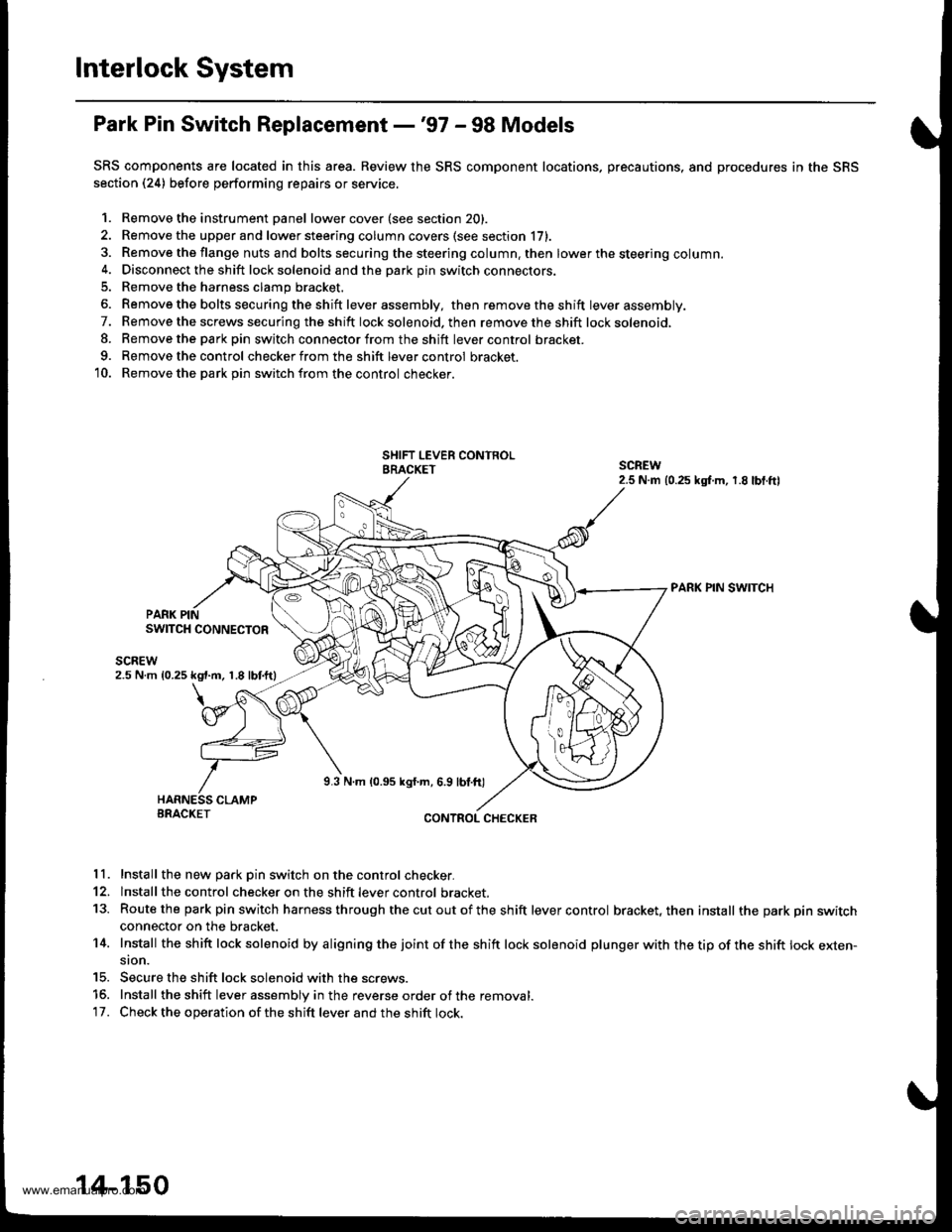

Interlock System

Park Pin Switch Replacement -'97 - 98 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

1. Remove the instrument Danel lower cover (see section 20).

2. Remove the upper and lower steering column covers (see section li,.

3. Remove the flange nuts and bolts securing the steering column. then lower the steering column.4. Disconnect the shift lock solenoid and the park pin switch connectors.

5. Remove the harness clamp bracket.

6. Remove the bolts secu ring the shift lever assembly, then removetheshift lever assembly.

7. Remove the screws securing the shift lock solenoid. then remove the shift lock solenoid,

8. Remove the parkpin switch connector from the shift lever control bracket.

9. Remove the control checker from the shift lever control bracket.

10. Remove the park Din switch from the control checker.

PARK PIN SWITCH

PARK PINSWITCH CONNECTOR

scnEw2.5 N m 10.25 kgt.m, 1.8 lbtftl

9.3 N.m 10.95 kgf.m, 6.9 lbl.ft)

BRACKETCONTROL CHECKER

11. Install the new Dark Din switch on the control checker.

12. lnstall the control checker on the shift lever control bracket.

13. Routethe park pin switch harness through thecutoutofthe shift lever control bracket, then install the park pin switchconnector on the bracket.

14. Install the sh ift lock solenoid by a ligning the joint of the sh ift lock solenoid plu nger with the tip of the shift lock exten-sion.

15. Secure the shift lock solenoid with the screws.

15. Install the shift lever assembly in the reverse order of the removal.'17. Check the operation of the shift lever and the shift lock.

14-150

www.emanualpro.com

Page 667 of 1395

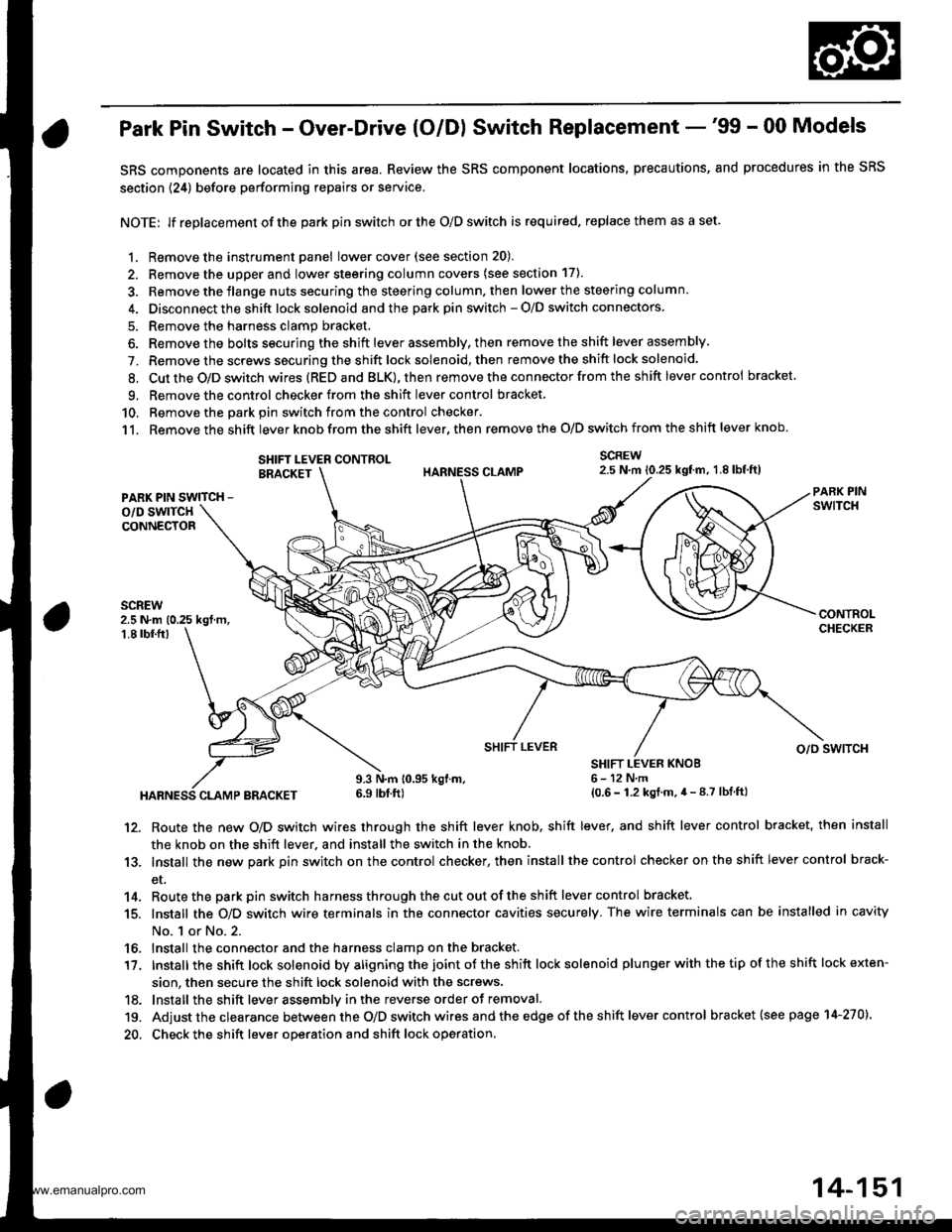

Park Pin Switch - Over-Drive (O/Dl Switch Replacement -'99 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24) before performing repairs or service.

NOTE: lf replacement of the park pin switch or the O/D switch is required. replace them as a set.

1. Remove the instrument panel lowercover(see section 20).

2. Remove the upper and lower steering column covers (see section 17).

3. Remove the flange nuts securing the steering column. then lower the steering column.

4. Disconnect the shift lock solenoid and the park pin switch - O/D switch connectors

5. Remove the harness clamp bracket.

6. Remove the bolts securing the shift lever assembly, then remove the shift lever assembly.

7. Remove the screws securing the shift lock solenoid, then remove the shift lock solenoid.

8. Cut the O/D switch wires (REDand BLK),then remove the con nector from the shift lever control bracket

9. Remove the control checker from theshift lever control bracket

10. Remove the oark oin switch from the control checker.

11. Remove the shift lever knob from the shift lever, then remove the O/D switch from the shift lever knob.

SCREW2.5 N.m 10.25 kgtm, 1.8lbf,ft)SHIFT LEVER CONTROLBRACKET

PARK PIN SWITCH -

o/D swlTcHCONNECTOR

2.5 N.m (0.25 kgt m,1.8 tbf.fr)

HABNESS CLAMP BRACKET

9.3 N.m 10.95 kgl.m.6.9 tbf ft)

SHIFT LEVER KNOB6-12N,m{0.6 - 1.2 kgt.m.4 - 8.7 lbf ftl

SHIFT LEVERo/o swlTcH

12. Route the new O/D switch wires through the shift lever knob, shift lever, and shift lever control bracket, then install

the knob on the shift lever, and install the switch in the knob.

13. Install the new park pin switch on the control checker, then install the control checker on the shift lever control brack-

et.

14. Routethe parkpin switch harnessthroughthecutoutoftheshift lever control bracket.

15. Install the O/D switch wire terminals in the connector cavities securely. The wire terminals can be installed in cavity

No. 1 or No.2.

16, Install the connector and the harness clamp on the bracket.

17. tnstall the shift lock solenoid by aligning the joint ot the shift lock solenoid plu nger with the tip of the shift lock exten-

sion, then secure the shift lock solenoid with the screws,

18. lnstall the shift lever assemblv inthe reverse order of removal.

19. Adjust the clearance between the O/D switch wires and the edge of the sh ift lever control bracket (see page 14-270).

20. Check the shift lever operation and shift lock operation.

14-151

www.emanualpro.com