ECU HONDA CR-V 1998 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 752 of 1395

Transfer Assembly

Disassembly (cont'd)

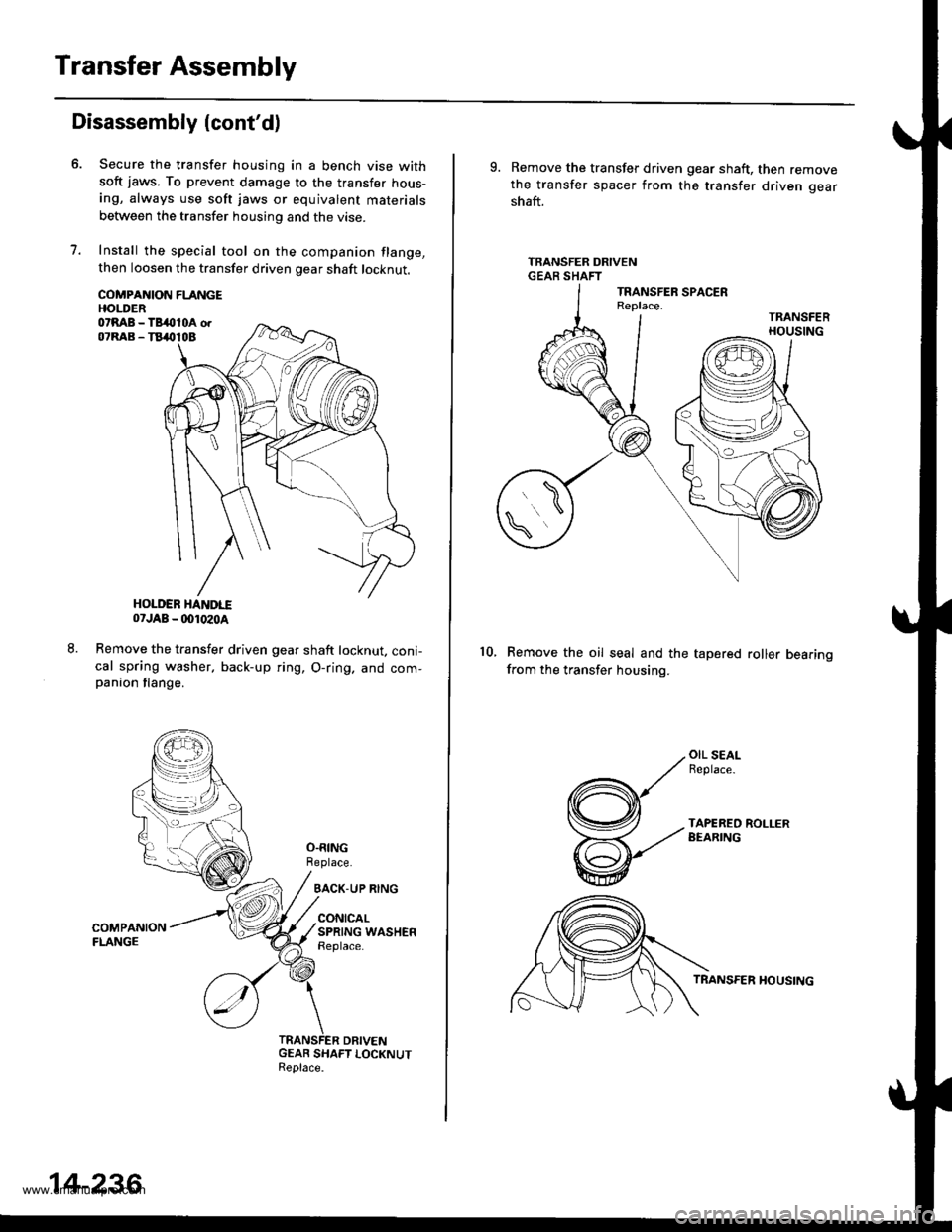

7.

Secure the transfer housing in a bench vise withsoft iaws. To prevent damage to the transfer hous-ing, always use soft jaws or equivalent materials

between the transfer housing and the vise.

Install the special tool on the companion flange,then loosen the transfer driven gear shaft locknut.

COMPANION FLANGEHOI.DER07RAB - TB4lll0A orOTRAB - TB&TOB

HOLDER HAITDI..E07JAB _ (x)1020a

Remove the transfer driven gear shaft locknut, coni-cal spring washer, back-up ring, O-ring. and com-panion flange.

O.RINGReplace.

BACK-UP RING

CONICALSPRING WASHENReplace.

GEAR SHAFT LOCKNUTReplace.

14-236

9. Remove the transfer driven gear shaft, then removethe transfer spacer from the transfer driven gear

shaft.

TRANSFER DRIVENGEAR SHAFT

Remove the oil seal and the tapered roller bearingfrom the transfer housing.

10.

OIL SEALFeplace-

TAPEREO ROLLERBEARING

TRANSFER HOUSING

www.emanualpro.com

Page 758 of 1395

Transfer Assembly

Reassembly (cont'd)

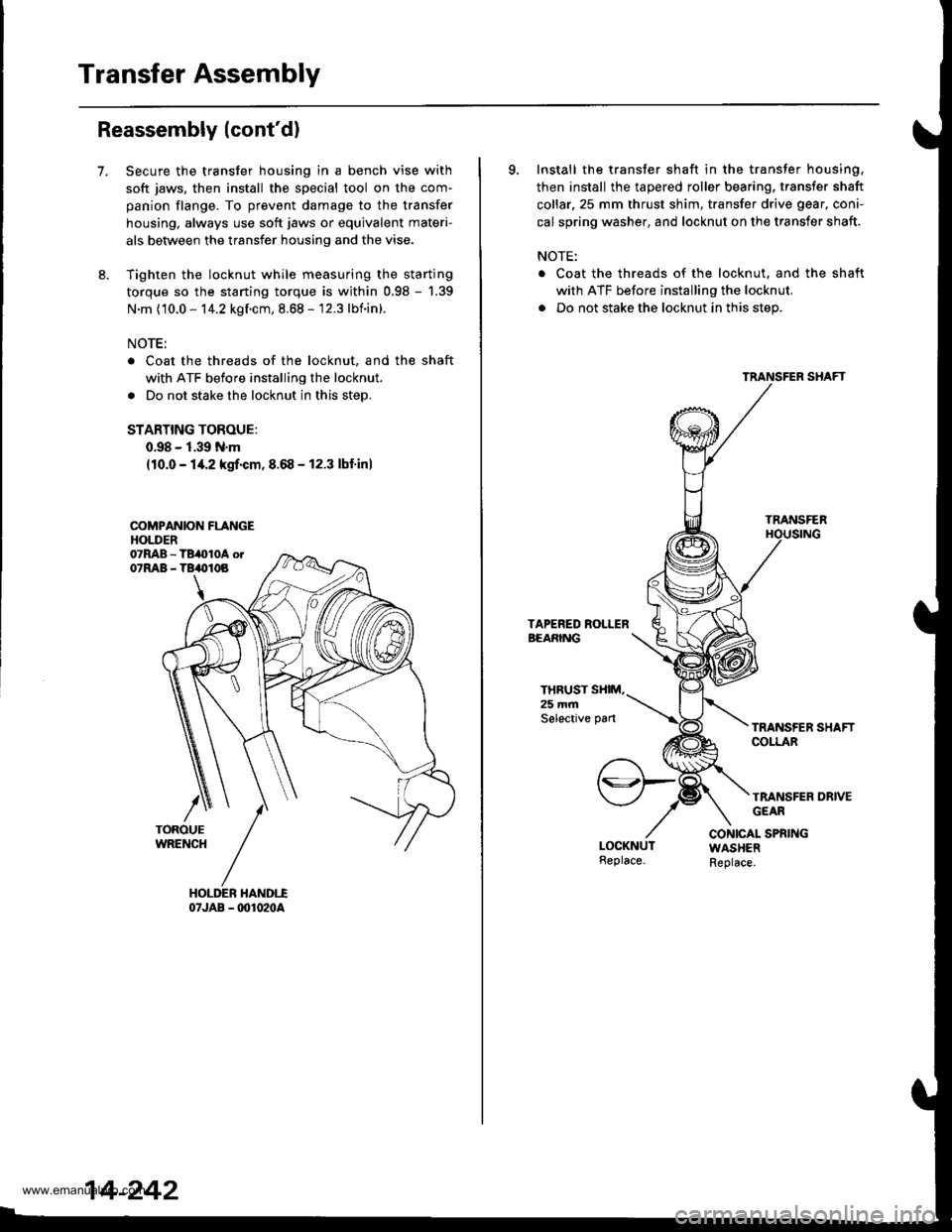

7.Secure the transfer housing in a bench vise with

soft jaws, then install the special tool on the com-

panion flange. To prevent damage to the transfer

housing, always use soft jaws or equivalent materi-

als between the transfer housing and the vise.

Tighten the locknut while measuring the starting

torque so the starting torque is within 0.98 - '1.39

N.m (10.0 - 14.2 kgf.cm, 8.68 - 12.3 lbnin).

NOTE:

Coat the threads of the locknut, and the shaft

with ATF before installing the locknut.

Do not stake the locknut in this step.

STARTING TOROUE:

0.98 - 1.39 N.m

{10.0 - 14.2 kgrf.cm,8.68 - 12.3 lbf'inl

COMPANION FLANGEHOLDER

07JAB - @1020A

14-242

9. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar.25 mm thrust shim, transfer drive gear, coni-

cal spring washer, and locknut on the transfer shaft.

NOTE:

. Coat the threads of the locknut. and the shaft

with ATF before installing the locknut.

. Do not stake the locknut in this step.

TRANSFER

THRUST SXIM,25 mmSelective pan

TRANSFER DRIVEGEAR

CONICAL SPRINGWASHERReplace.

www.emanualpro.com

Page 759 of 1395

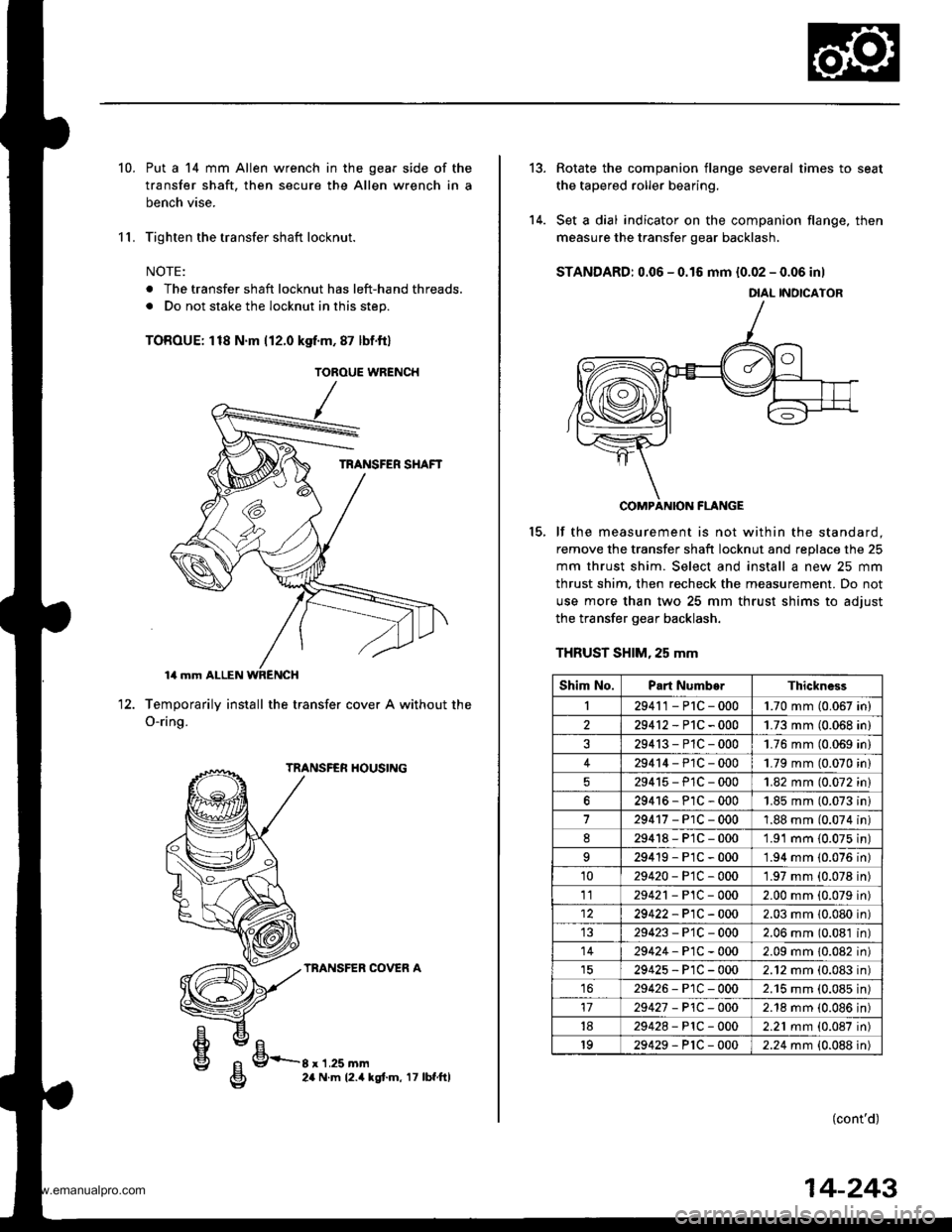

10.

11.

Put a 14 mm Allen wrench in the gear side of the

transfer shaft, then secure the Allen wrench in a

bench vise.

Tighten the transfer shaft locknut.

NOTE:

. The transfer shaft locknut has left-hand threads.

. Do not stake the locknut in this step.

TOROUE: 118 N'm 112.0 kgf.m, 87 lbf.ftl

Temporarily install the transfer cover A without

O-ring.

TRANSFER HOUSING

TRANSFER COVER A

the12.

g/FrE24 N.m 12.4 kgt.m, 17 lbf.ftl

TOROUE WRENCH

tt el

g 9-r'r.ru--g 24 N.m 12.4 |

14-243

13.

14.

Rotate the companion flange several times to seat

the tapered roller bearing.

Set a dial indicator on the companion flange, then

measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm {0.02 - 0.06 inl

COMPANION FLANGE

lf the measurement is not within the standard.

remove the transfer shaft locknut and replace the 25

mm thrust shim. Select and install a new 25 mm

thrust shim. then recheck the measurement. Do not

use more than two 25 mm thrust shims to adiust

the transfer gear backlash.

THRUST SHIM, 25 mm

(cont'd)

15.

DIAL INOICATOR

Shim No.Part NumborThickness

I29411-P1C-0001.70 mm (0.067 in)

229412-P1C-0001.73 mm (0.068 in)

29413-P1C-0001.76 mm (0.069 in)

429414-P1C-0001.79 mm (0.070 in)

29415-PlC-0001.82 mm (0.072 in)

629416-P1C-0001.85 mm (0.073 ini

729417-PlC-0001.88 mm (0.074 in)

d29418-P1C-0001.91 mm {0.075 in)

29419-P1C-0001.94 mm (0.076 in)

1029420-PtC-0001.97 mm (0.078 in)

1129421 - P1C - 0002.00 mm (0.079 in)

29422-P1C-0002.03 mm 10.080 in)

29423-P'1C-0002.06 mm (0.081 in)

1429424-P1C-0002.09 mm 10.082 in)

29425-P1C-0002.12 mm (0.083 in)

1629426-P1C-0002.'15 mm (0.085 in)

1729427 - P1C -O002.18 mm (0.086 in)

1829428-PlC-0002.21 mm (0.087 in)

1929429-P1C-0002.24 mm {0.088 in)

www.emanualpro.com

Page 761 of 1395

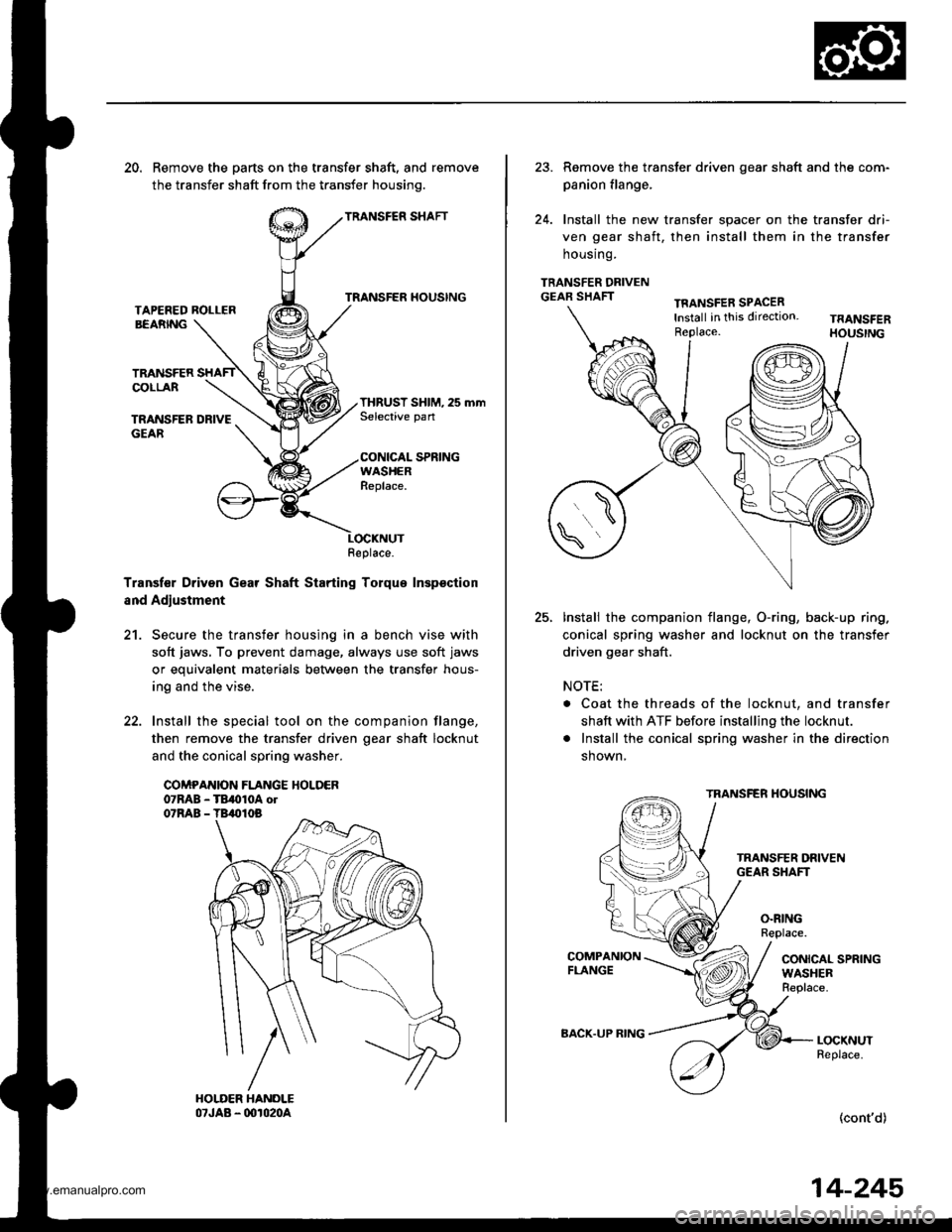

20. Remove the parts on the transfer shaft, and remove

the transfer shaft from the transfer housinq.

TRANSFER SHAFT

TRANSFER HOUSINGTAPEFED ROLLERBEARNG

TRANSFERCOLLAR

TRANSFER DRIVEGEAR

THRUST SHIM, 25 mmSelective pan

CONICAL SPRINGWASHERReplace.

Transf€r Driven Gear Shaft Starting Torque Inspsction

and Adjustment

21. Secure the transfer housing in a bench vise with

soft jaws, To prevent damage, always use soft jaws

or equivalent materials between the transfer hous-

ing and the vise.

22. Install the special tool on the companion flange,

then remove the transfer driven oear shaft locknut

and the conical spring washer.

COMPANION FLANGE HOLDER07RAB - TB,010A ol07RAB - TB,010B

Replace.

23. Remove the transter driven gear shaft and the com-

panion flange,

24. Install the new transfer spacer on the transfer dri-

ven gear shaft, then install them in the transfer

housrng.

TRANSFER DRIVENGEAR SHAFTTFANSFER SPACERlnstall in this direction.Replace.

25.Install the companion flange, O-ring, back-up ring.

conical spring washer and locknut on the transfer

driven gear shaft.

NOTE:

. Coat the threads of the locknut, and transfer

shaft with ATF before installing the locknut.

. Install the conical spring washer in the direction

shown,

TRANSFER HOUSING

O.RINGReplace.

CONICAL SPRINGWASHERReplace.

LOCKNUTReplace.

(cont'd)

BACK.UP RING

14-245

www.emanualpro.com

Page 762 of 1395

Transfer Assembly

Reassembly (cont'd)

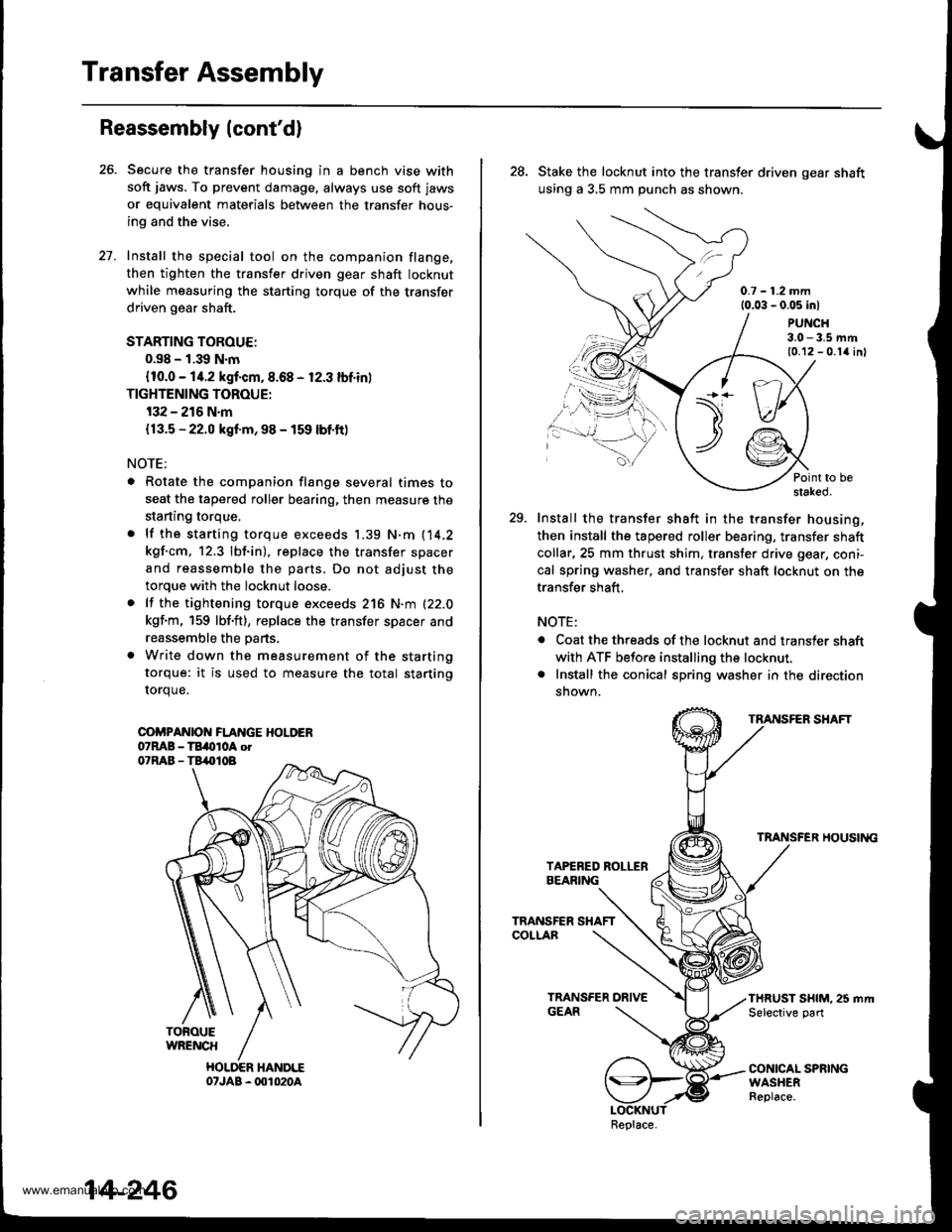

Secure the transfer housing in a bench vise with

soft jaws. To prevent damage, always use soft jaws

or equivalent materials between the transfer hous-

ing and the vise.

Install the special tool on the companion flange,

then tighten the transfer driven gear shaft locknut

while measuring the starting torque of the transfer

driven gear shaft.

STARTING TOROUE:

0.s8 - 1.39 N.m

{10.0 - 14.2 kgf.cm,8.68 - 12.3 lbf.in)

TIGHTENING TOROUE:

132 - 216 N.m

{13.5 - 22.0 kgf.m, 98 - 159 lbf.ft)

NOTE;

. Rotate the companion flange several times to

seat the tapered roller bearing, then measure the

starting torque,

. lf the starting torque exceeds 1.39 N.m (14,2

kgf.cm, 12.3 lbf.in), replace the transfer spacer

and reassemble the parts. Do not adjust the

torque with the locknut loose.

. lf the tightening torque exceeds 216 N.m (22.0

kgf.m, 159 lbf'ft), replace the transfer spacer and

reassemble the parts.

. Write down the measurement of the starting

torque: it is used to measure the total starting

rorque.

COi'PANIOI{ FLANGE HOLDER07MB - TBi(tloA otO'RAB - TB,.|}IOB

TOFOUEWRENCH

HOLDER HANDLE07JAB - 001020A

27.

14-246

28. Stake the locknut into the transfer driven gear shaft

using a 3,5 mm punch as shown.

0.7 - 1.2 mm{0.03 - 0.05 inl

PUNCH3.0 - 3.5 mm10.12 - 0.1{ inl

Point to bestaked.

29. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar,25 mm thrust shim, transter drive gear, coni-

cal spring washer, and transfer shaft locknut on the

transfer shaft,

NOTE:

. Coat the threads of the locknut and transler shaft

with ATF before installing the locknut.. Install the conical spring washer in the direction

snown.

TRANSFER SHAFT

TRANSFER HOUSII{G

THRUST SHIM. 25 mrt|Selective part

CONICAL SPRINGWASHERReplace.

\t)t--/./

.,.-,.,\

Replace.

www.emanualpro.com

Page 763 of 1395

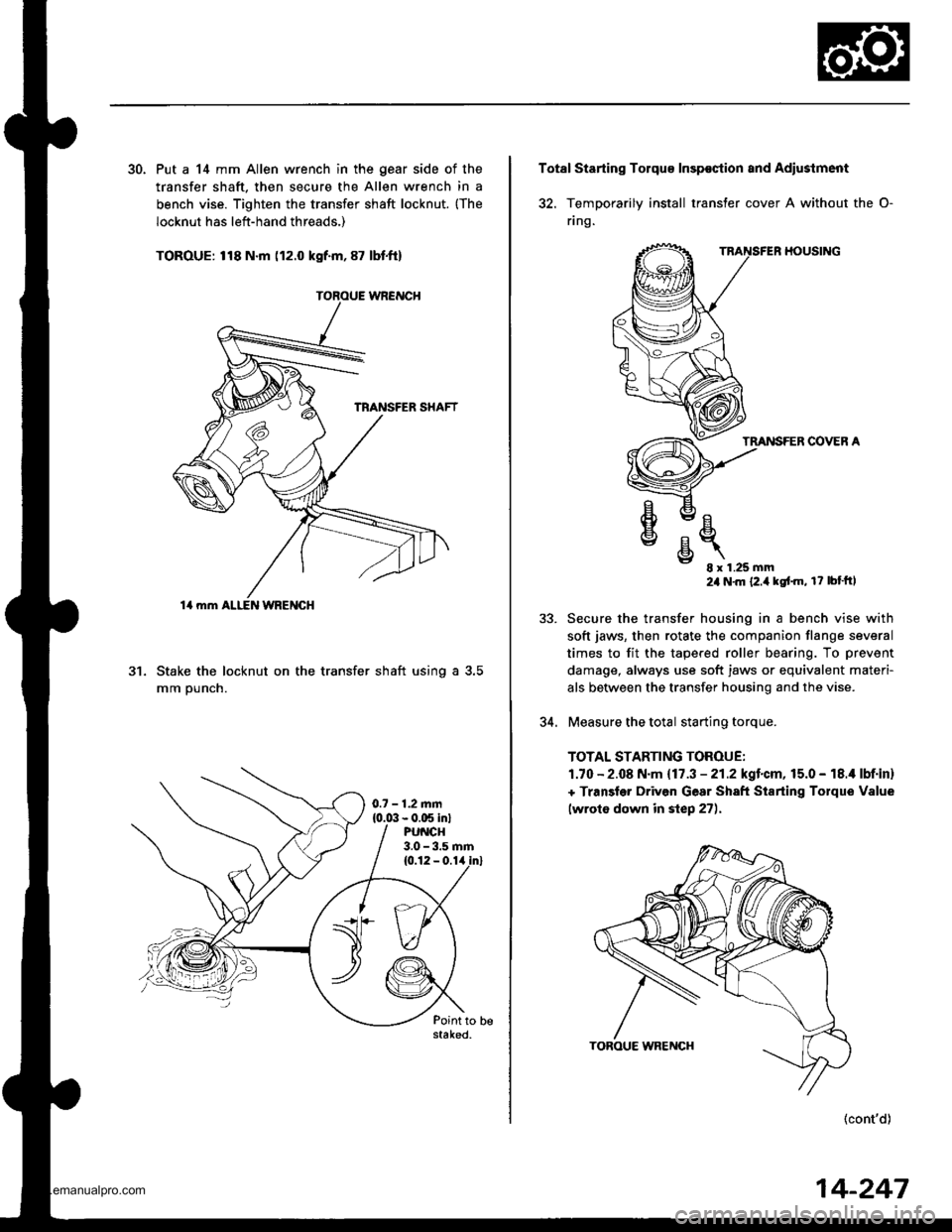

30. Put a 14 mm Allen wrench in the gear side of the

transfer shaft. then secure the Allen wrench in a

bench vise. Tighten the transfer shaft locknut. {The

locknut has left-hand threads,)

TOROUE: 118 N.m (12.0 kgf.m, 87 lbt.ft)

Stake the locknut on the transfer shaft using a 3.5

mm ounch.

al

14 mm ALI-EN WRENGH

0.7 - 1.2.nm{0.0:1- 0.C5 in}PU CH3.0 - 3.5 rnm

Total Starting Tolqu€ Insp€ction and Adiustment

32. TemDorarilv install transter cover A without the O-

flng.

HOUSING

TMNSFER COVER A

e

€

v

E- 8x1.25mm24 N'm {2.i1kgt'm, r? bt'ftl

Secure the transfer housing in a bench vise with

soft jaws, then rotate the companion flange several

times to fit the tapered roller bearing. To prevent

damage, always use soft jaws or equivalent materi-

als betlveen the transfer housing and the vise.

Measure the total starting torque.

TOTAL STARTING TOROUE:

1.70 - 2.08 N.m {17.3 - 21.2kgl.cm,15.0 - 18.i1 lbf.in}

+ Transler Driven Gear Sh8ft Starting Torque Value

lwroto down in step 27).

(cont'd)

5J.

34.

14-247

www.emanualpro.com

Page 777 of 1395

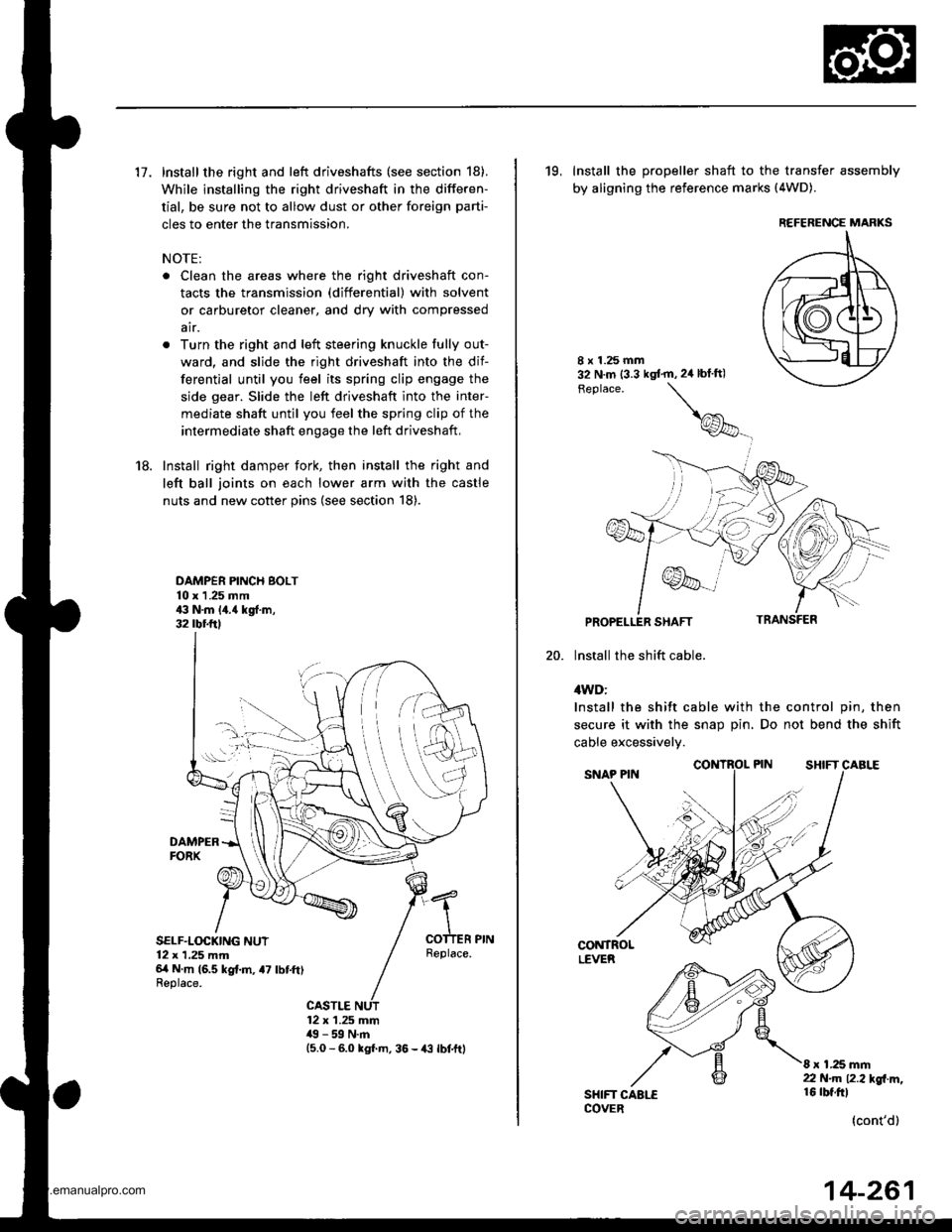

17. Install the right and left driveshafts (see section 18).

While installing the right driveshaft in the differen-

tial, be sure not to allow dust or other foreign parti-

cles to enter the transmission.

NOTE:

. Clean the areas where the right driveshaft con-

tacts the transmission (differential) with solvent

or carburetor cleaner, and dry with compressed

air.

. Turn the right and left steering knuckle fully out-

ward, and slide the right driveshaft into the dif-

ferential until you feel its spring clip engage the

side gear. Slide the left driveshaft into the inter-

mediate shaft until you feel the spring clip of the

intermediate shaft engage the left driveshaft,

18. Install right damper fork, then install the right and

left ball joints on each lower arm with the castle

nuts and new cotter pins (see section 18).

DAMPER PINCH BOLT10 x 1 .25 mm43 N.m 14.{ kgf.m,32 rbr.ftl

DAMPERFORX

SELF.LOCKING NUT12 x 1,25 mm6/t N m (6.5 kg{.m, a7 lbtft)Replace.

Replace.

CASTLE12 x 1.25 mm49 - 59 N.m15.0 - 6.0 kgl m, 36 - {3 lbtftl

19, Install the propeller shaft to the transfer assembly

by aligning the reference marks (4WD).

20.

8 x 1.25 mm32 N.m (3.3 kgt'm,2ir blft)

Feplace.

\

@_

PROPELLER SHAFT

lnstall the shift cable.

4WD:

Install the shift cable with the control pin, then

secure it with the snap Din. Do not bend the shift

cable excessivelv.

CONTROLLEVER

SHIFT CAALECOVER

8 x 1.25 mm22 N.m 12.2l'gl m,16 rbt.ftl

(cont'd)

REFERENCE MARKS

14-261

www.emanualpro.com

Page 780 of 1395

Transmission

Cooler Flushing

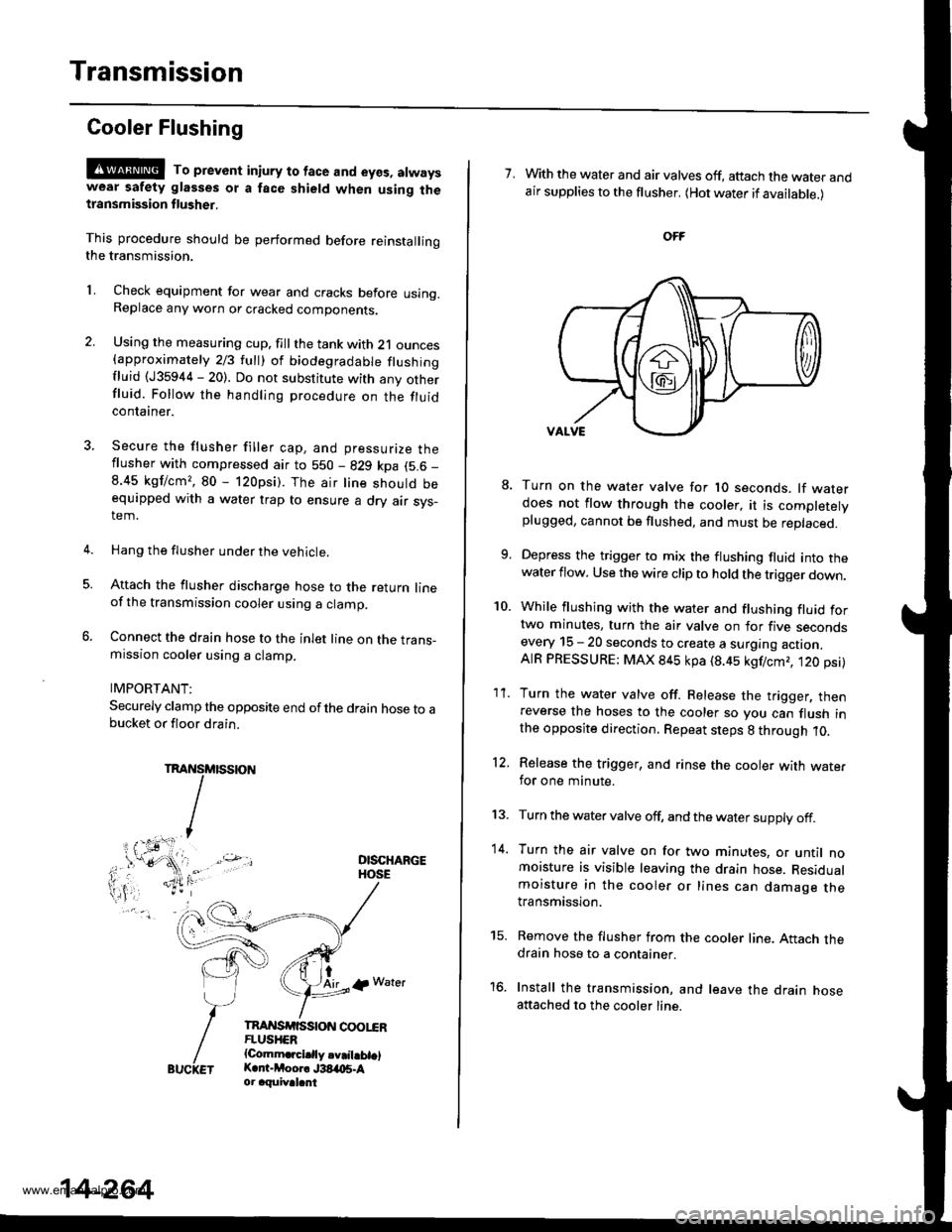

@@ To prevent in;ury to face and eyos, atwayswear safety glasses ot a face shield when using thetlansmission flusher.

This procedure should be performed before reinstallingthe transmission.

2.

LCheck equipment for wear and cracks before using.Replace any worn or cracked components.

Using the measuring cup. fill the tank with 21 ounces{approximately 213 lull) ol biodegradable flushingfluid (J35944 - 20). Do not substitute with any otherfluid. Follow the handling procedure on the fluidcontaaner.

Secure the flusher filler cap, and pressurize theflusher with compressed air to 550 - 829 kpa (5.6 _

8.45 kgf/cm,, 80 - 120psi). The air line should beequipped with a water trap to ensure a dry air sys-tem.

Hang the flusher under the vehicle.

Attach the flusher discharge hose to the return lineof the transmission cooler using a clamp.

Connect the drain hose to the inlet line on the trans-mission cooler using a clamp.

IMPORTANT:

Securely clamp the opposite end ofthe drain hose to abucket or floor drain.

DISCHARGEHOSE

tAirlp Water

TnAI{SrfiSStoN coot"€RFLUSHER{Comm.rcidly.v.il.bt.lK.r -Moor. J38,t{15.Aor aquival.nt

5.

14-264

7. With the water and air valves off, attach the water andair supplies to the flusher. (Hot water if available.)

10.

8.

1'�I.

Turn on the water valve for 1O seconds. lf waterdoes not flow through the cooler, it is completelyplugged, cannot be flushed, and must be replaced.

Depress the trigger to mix the flushing fluid into thewater flow. Use the wire clip to hold the trigger down.

While flushing with the water and flushing fluid fortwo minutes, turn the air valve on for five secondsevery 15 - 20 seconds to create a surging action.AIR PRESSURE: MAX 845 kpa (8.45 kgf/cmr, t20 psi)

Turn the water valve off. Release the trigger, thenreverse the hoses to the cooler so you can flush inthe opposite direction. Repeat steps 8 through 10.

Release the trigger, and rinse the cooler with wate.for one minute.

Turn the water valve off, and the water supply off.

Turn the air valve on for two minutes, or until nomoisture is visible leaving the drain hose. Residualmoisture in the cooler or lines can damage thetransmission.

Remove the flusher from the cooler line. Attach thedrain hose to a container.

Install the transmission, and leave the drain hoseattached to the cooler line.

12.

13.

14.

to.

www.emanualpro.com

Page 782 of 1395

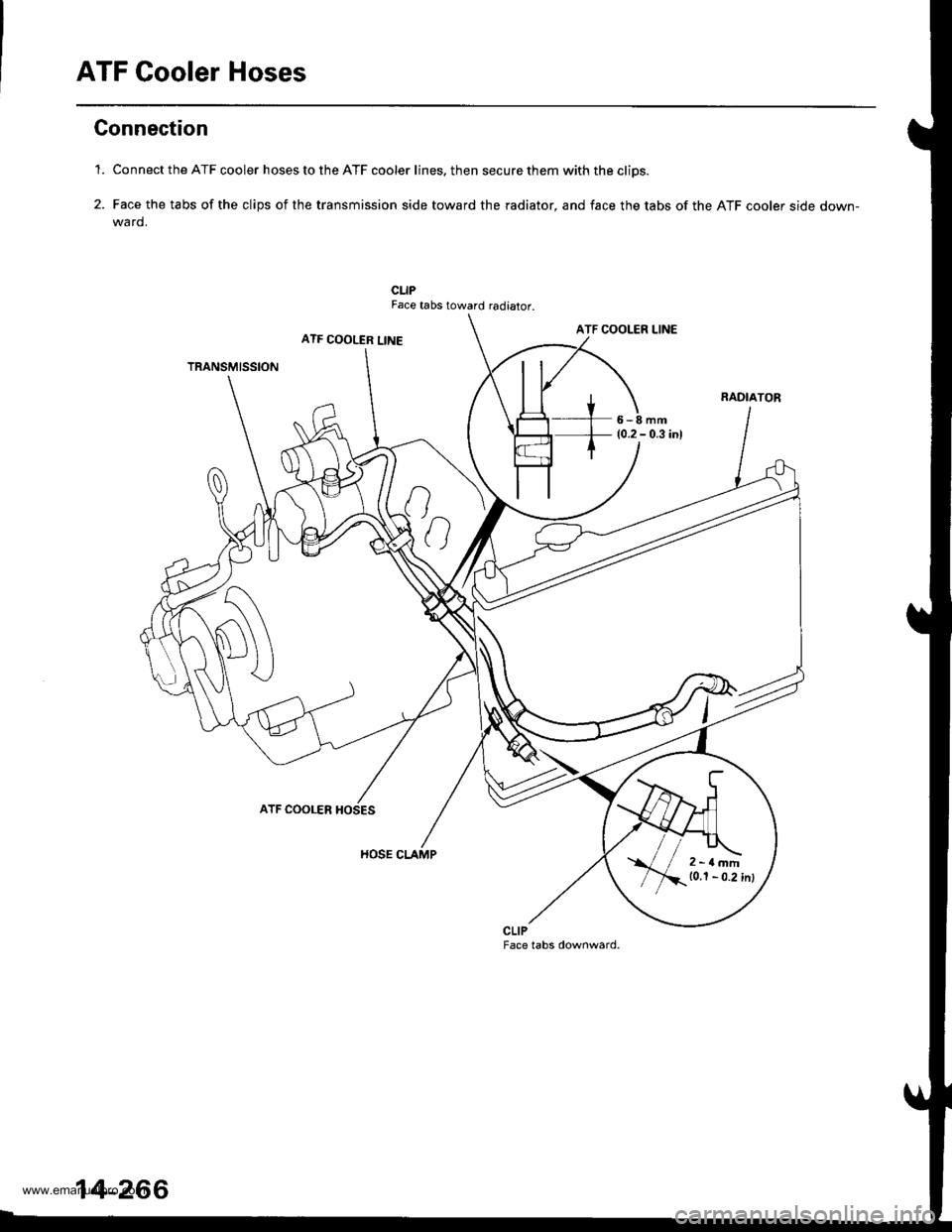

ATF Cooler Hoses

Gonnection

'1. Connect the ATF cooler hoses to the ATF cooler lines. then secure them with the cliDs.

2. Face the tabs of the clips of the transmission side toward the radiator, and face the tabs of the ATF cooler side down-wa rd.

CLIPFace tabs toward radiator.

ATF COOLER LINEATF COOLER LINE

TRANSMISSION

6-8mm(0.2 - 0.3 inl

ATF COOLER

HOSE CLAMP

CLIPFace tabs downward.

2-rlmm10.1 - 0.2 inl

14-266

www.emanualpro.com

Page 783 of 1395

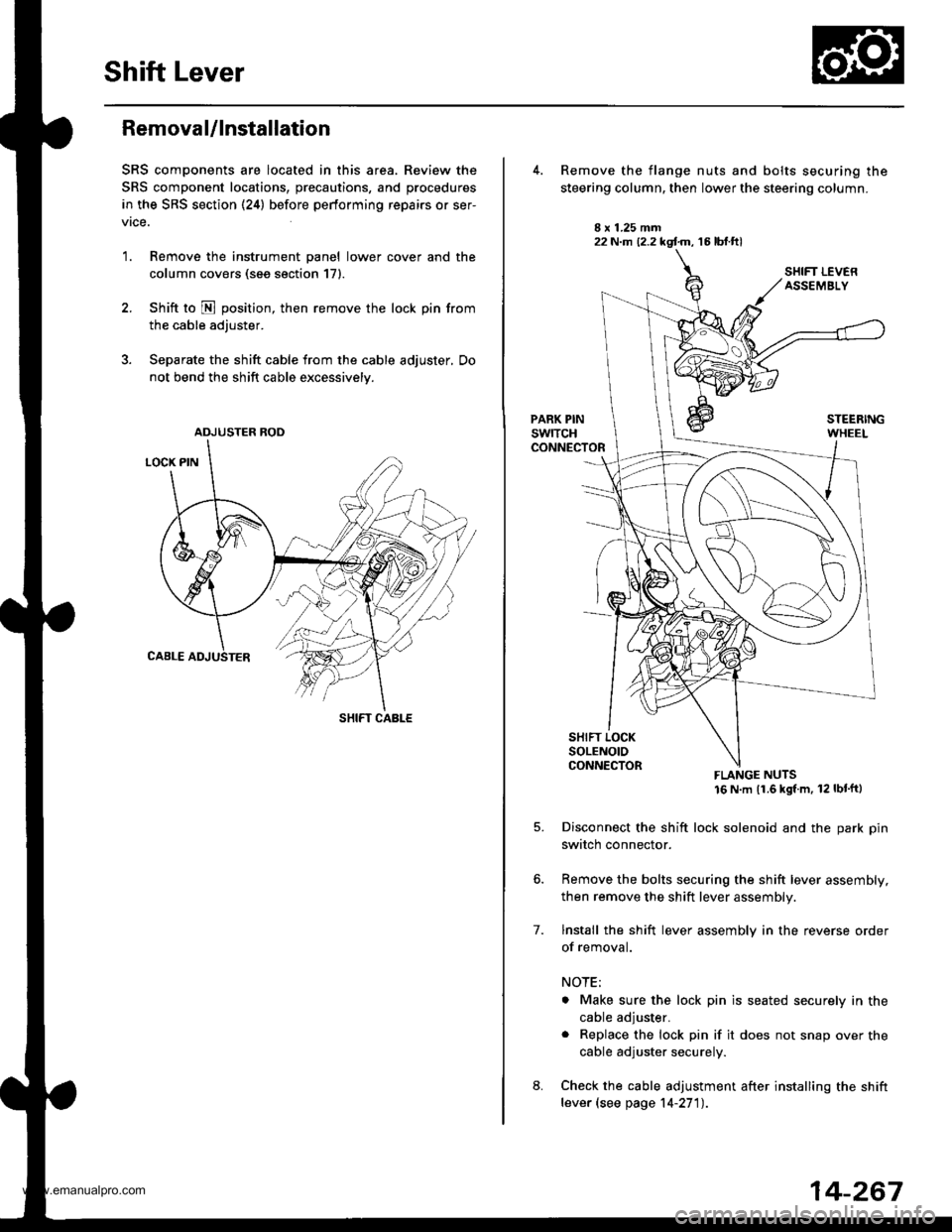

Shift Lever

Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vrce.

1. Remove the instrument panel lower cover and the

column covers (see section 171.

2. Shift to N position, then remove the lock pin from

the cable adjuster.

3. Separate the shift cable from the cable adjuster, Do

not bend the shift cable excessively.

ADJUSTER ROD

SHIFT CABLE

22 N.m (2.2 kgf.m, 16 lbt.ftl

7.

Remove the flange nuts and bolts securing the

steering column, then lower the steering column.

FLANGE NUTS16 N m (1.6 kgl m, 12 lbt'ftl

Disconnect the shift lock solenoid and the park pin

switch connector.

Remove the bolts securing the shift lever assembly,

then remove the shift lever assembly.

lnstall the shift lever assembly in the reverse order

of removal.

NOTE;

. Make sure the lock pin is seated securely in the

cable adjuster.

. Replace the lock pin if it does not snap over the

cable adjuster securely.

Check the cable adjustment after installing the shift

lever (see page 14-27'l).

14-267

www.emanualpro.com