Tension HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 846 of 1395

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 847 of 1395

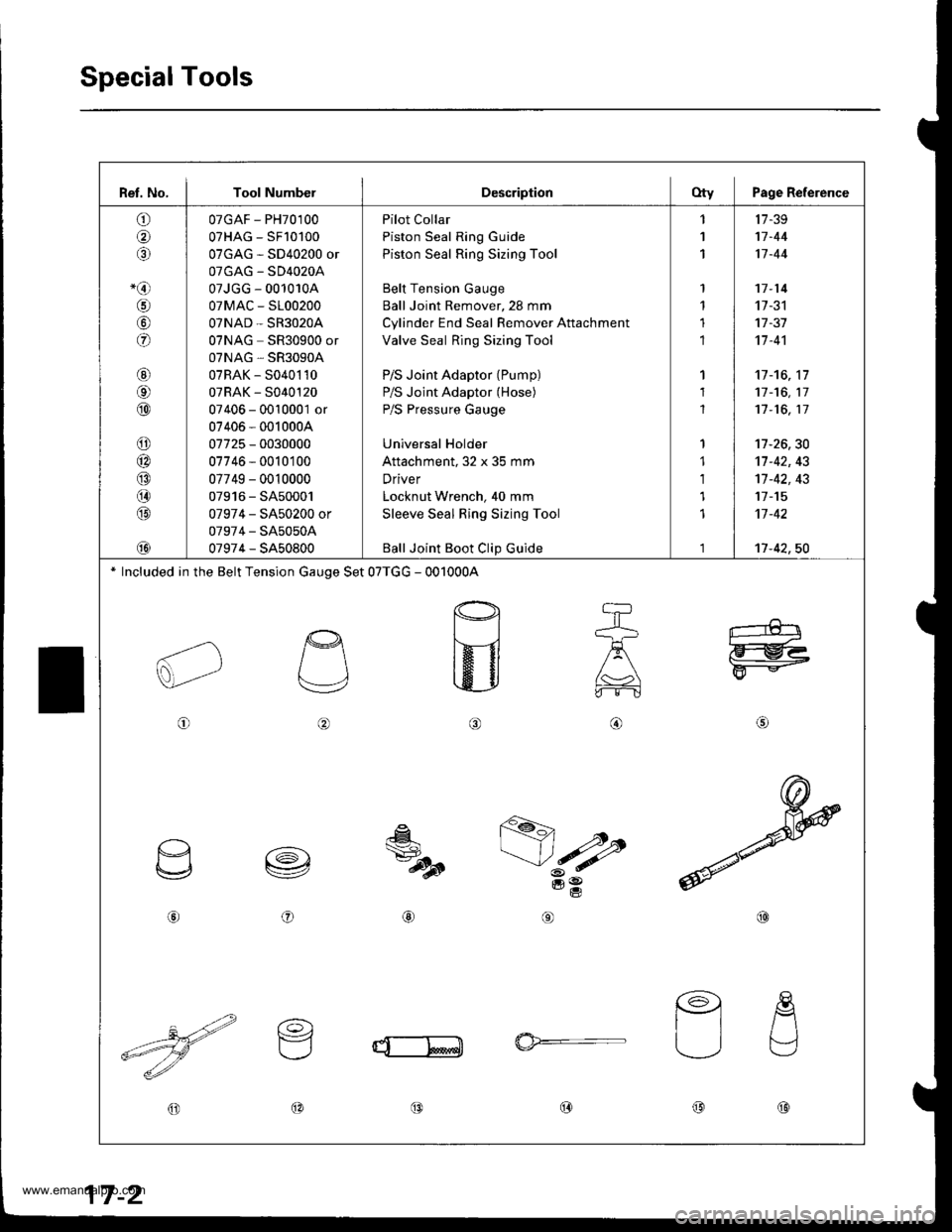

Ret. No, I Tool NumbelDescriptionfty Page Reference

o

o

-@

€r

o

@rol

@

o

@

@(}

@

@

07GAF - PH70100

07HAG - SF10100

07GAG - SD40200 or

OTGAG - SD4O2OA

07JGG - 001010A

07MAC - S100200

OTNAD _ SR3O2OA

07NAG SR30900 or

07NAG , SR3OgOA

07RAK - 50401 10

07RAK - 5040120

07406 - 0010001 or

07406 - 0010004

07725 - 0030000

07746 - 0010100

07749 - 0010000

07916 - SA50001

07974 - SA50200 or

07974 - SA5050A

07974 - SA50800

Pilot Collar

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover,23 mm

Cylinder End Seal Remover Attachment

Valve Seal Ring Sizing Tool

P/S Joint Adaptor (Pump)

P/S Joint Adaptor (Hose)

P/S Pressure Gauge

Universal Holder

Attachment, 32 x 35 mm

Driver

Locknut Wrench, 40 mm

Sleeve Seal Ring Sizing Tool

Ball Joint Boot Clip Guide

'l

1

1

1

1

1

1

1

1

1

1

1

1,l

1

1

11-39

17-44

11-44

17 -14't]-31

17 -37't7 -4'l

17-'t6, 17

17-16, 17

11-16, 17

17-26,30't]-42, 43't1-42, 43

11-15't]-42

11-42, 50

* Included in the Belt Tension Gauge Set 07TGG - 001000,4

o@

\J

,/:\

I

o

,€l-

=tt

@@

aA)

l:I/\L----.--.--------_

@o(D(9@@

17-2

www.emanualpro.com

Page 852 of 1395

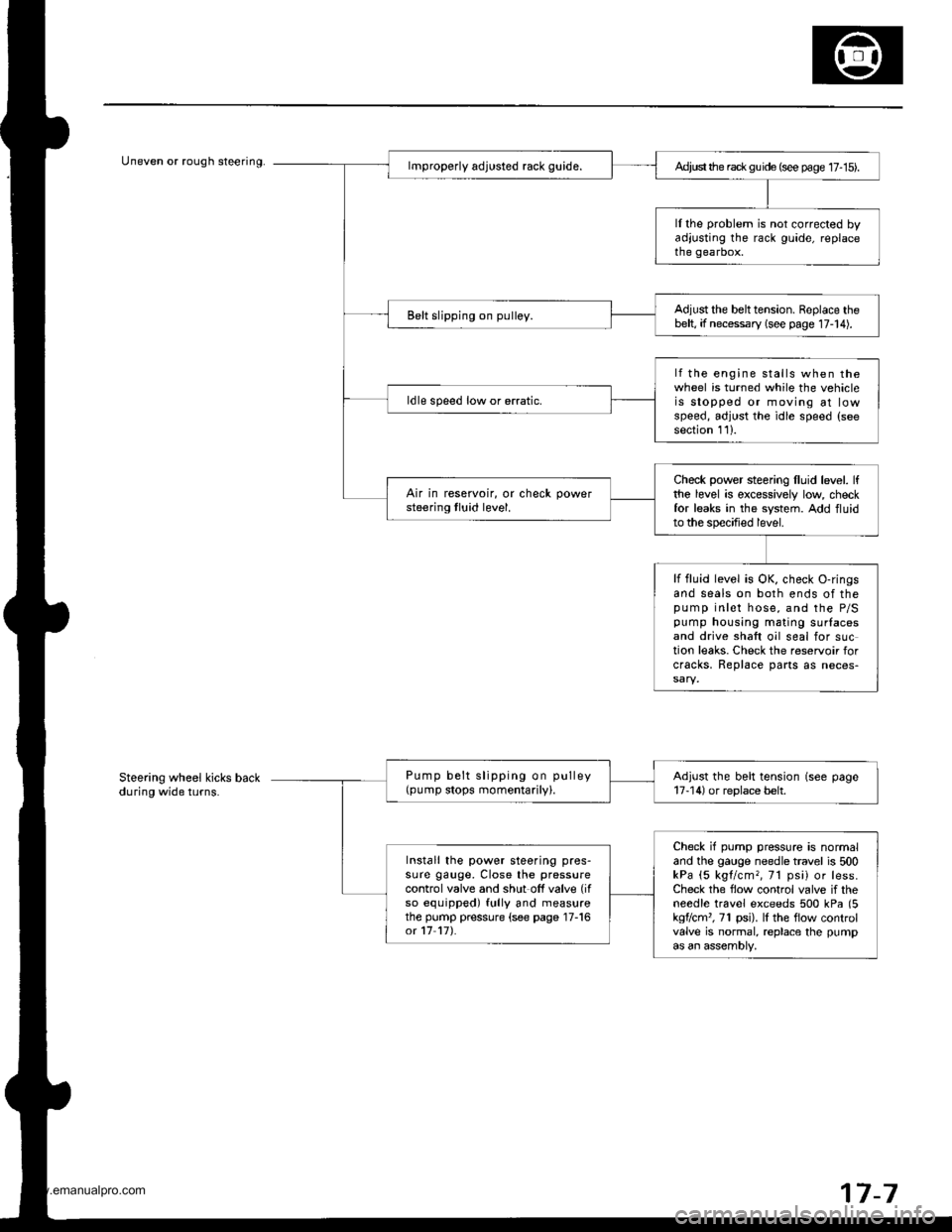

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com

Page 857 of 1395

Inspection and Adjustment

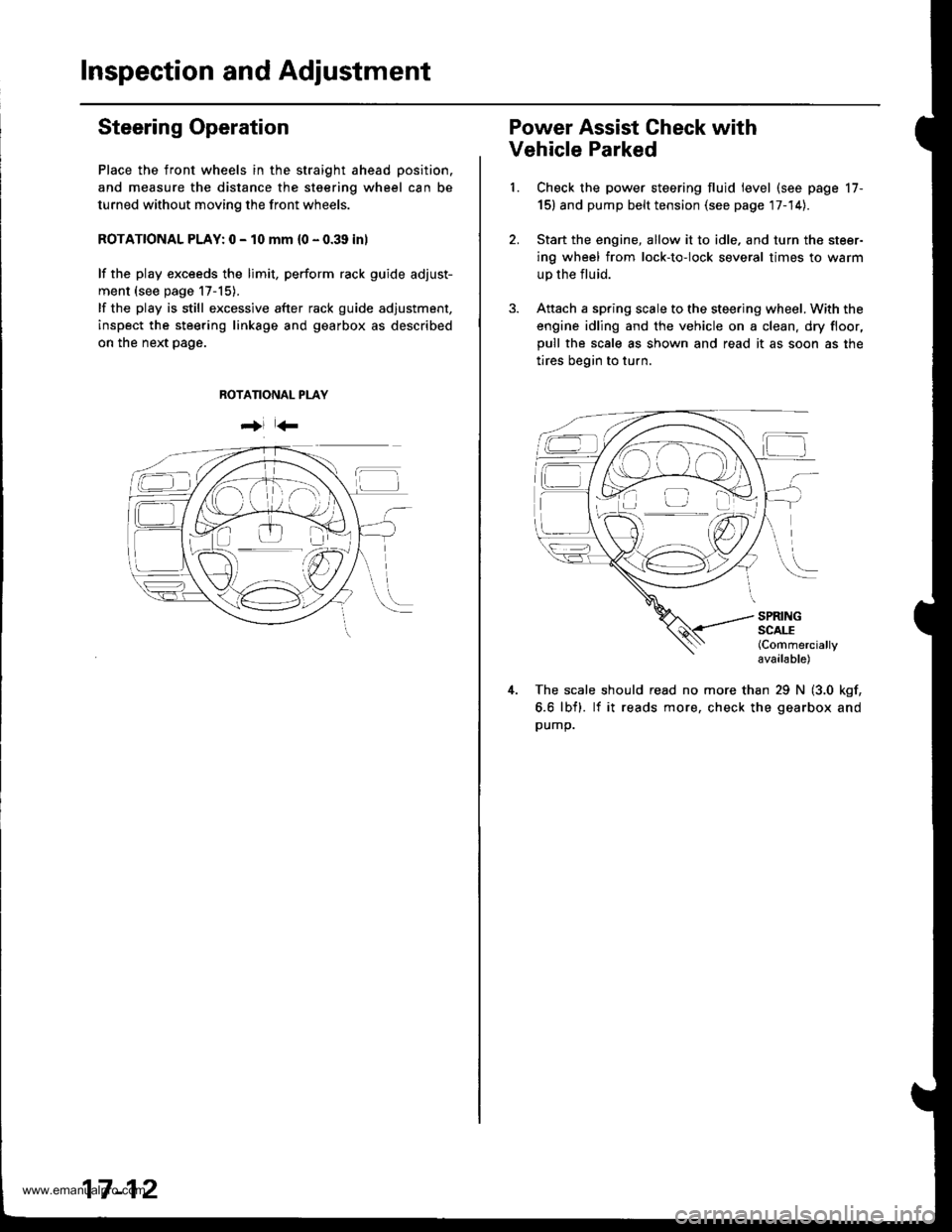

Steering Operation

Place the front wheels in the straight ahead position.

and measure the distance the steering wheel can be

turned without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.39 inl

lf the play exceeds the limit, perform rack guide adjust-

ment (see page 17-15).

lf the play is still excessive after rack guide adjustment,

inspect the steering linkage and gearbox as described

on the next page.

ROTANONAL PLAY

+i r

17-12

Power Assist Check with

Vehicle Parked

1. Check the power steering fluid level (see page 17-

15) and pump belt tension (see page 17-14).

2. Start the engine, allow it to idle, and turn the steer-

ing wheel from lock-toiock several times to warm

up the fluid.

3. Aftach a spring scale to the steering wheel, With the

engine idling and the vehicle on a clean. dry floor,

pull the scale as shown and read it as soon as the

tires begin to turn.

SPRINGSCALE(Commercially

available)

The scale should read no more than 29 N (3.0 kgf,

6.6 lbfl. lf it reads more, check the gearbox and

oumo.

f::1-tE

www.emanualpro.com

Page 859 of 1395

Inspection and Adjustment

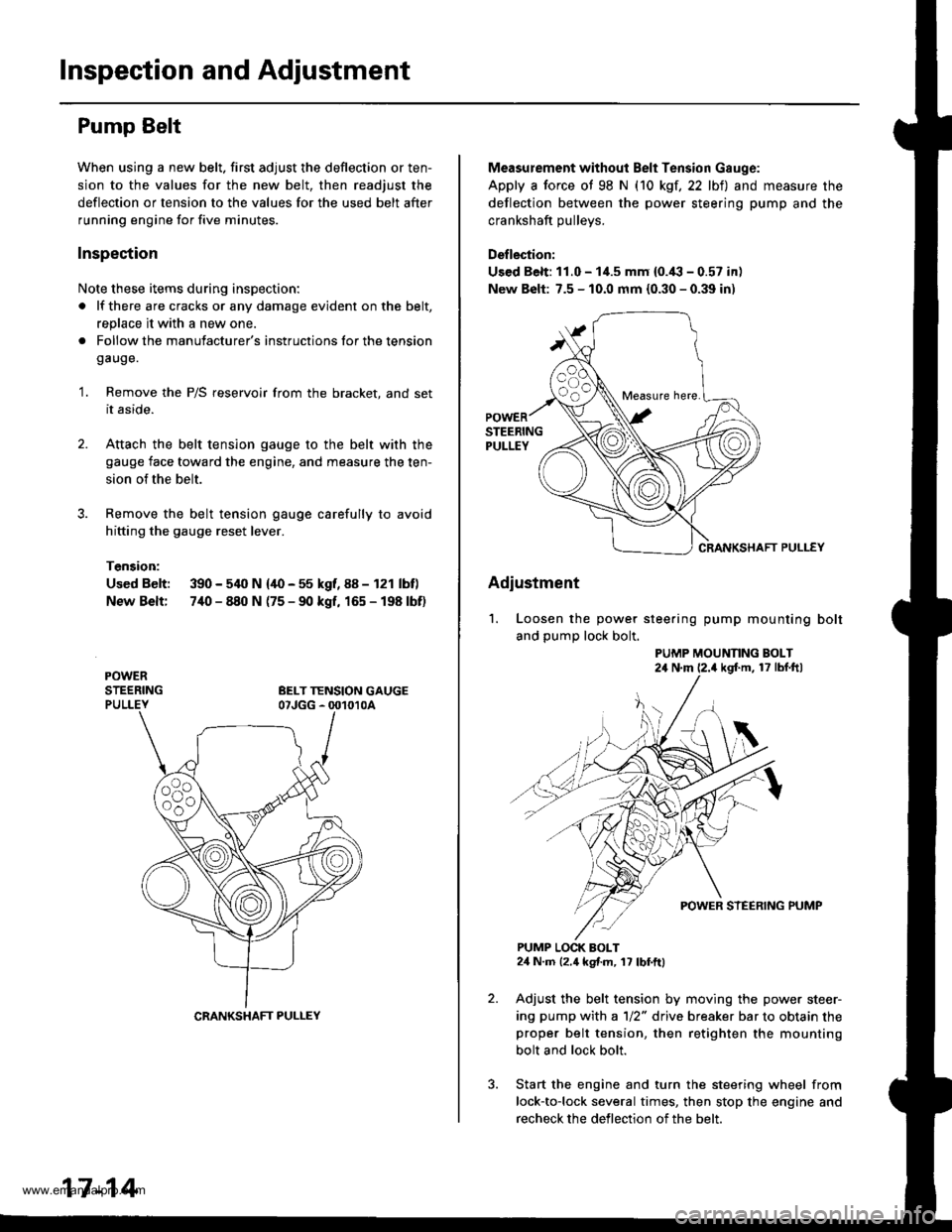

Pump Belt

When using a new belt. first adjust the deflection or ten-

sion to the values for the new belt, then readjust the

deflection or tension to the values for the used belt after

running engine for five minutes.

Inspection

Note these items during inspection:

a lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions lor the tension

gauge.

'1. Remove the P/S reservoir from the bracket, and set

it aside.

2. Attach the belt tension gauge to the belt with the

gauge face toward the engine, and measure the ten-

sion of the belt.

Remove the belt tension gauge carefully to avoid

hitting the gauge reset lever.

Tension:

Used Belt: 390 - 540 N {40 - 55 kgf, 88 - 121 lbf)

New Belt: 7,[0 - 840 N (75 - 90 kgf, 165 - 198 lbf)

CRANKSHAFT PULLEY

17-14

Measurement without Belt Tension Gauge:

Apply a force ot 98 N (10 kgf,22 lbt) and measure the

deflection between the power steering pump and the

crankshaft oullevs.

Deflection:

Used Belt: 11.0 - 1i1.5 mm {0.'(l - 0.57 in)

New Belt: 7.5 - 10.0 mm {0.30 - 0.39 in)

CRANKSHAFT PULLEY

Adiustment

'1. Loosen the power steering pump mounting bolt

and pump lock bolt.

PUMP MOUNNNG BOLT24 N'm (2.4 kgf'm, 17 lbf ftl

PUMP LOCK BOLT24 N.m 12.4 kgf.m, 17 lbf.ftl

Adjust the belt tension by moving the power steer-

ing pump with a 1/2" drive breaker bar to obtain theproper belt tension, then retighten the mounting

bolt and lock bolt.

Start the engine and turn the steering wheel from

lock-to-lock several times, then stop the engine and

recheck the deflection of the belt.

Measure here.

www.emanualpro.com

Page 861 of 1395

lnspection and Adjustment

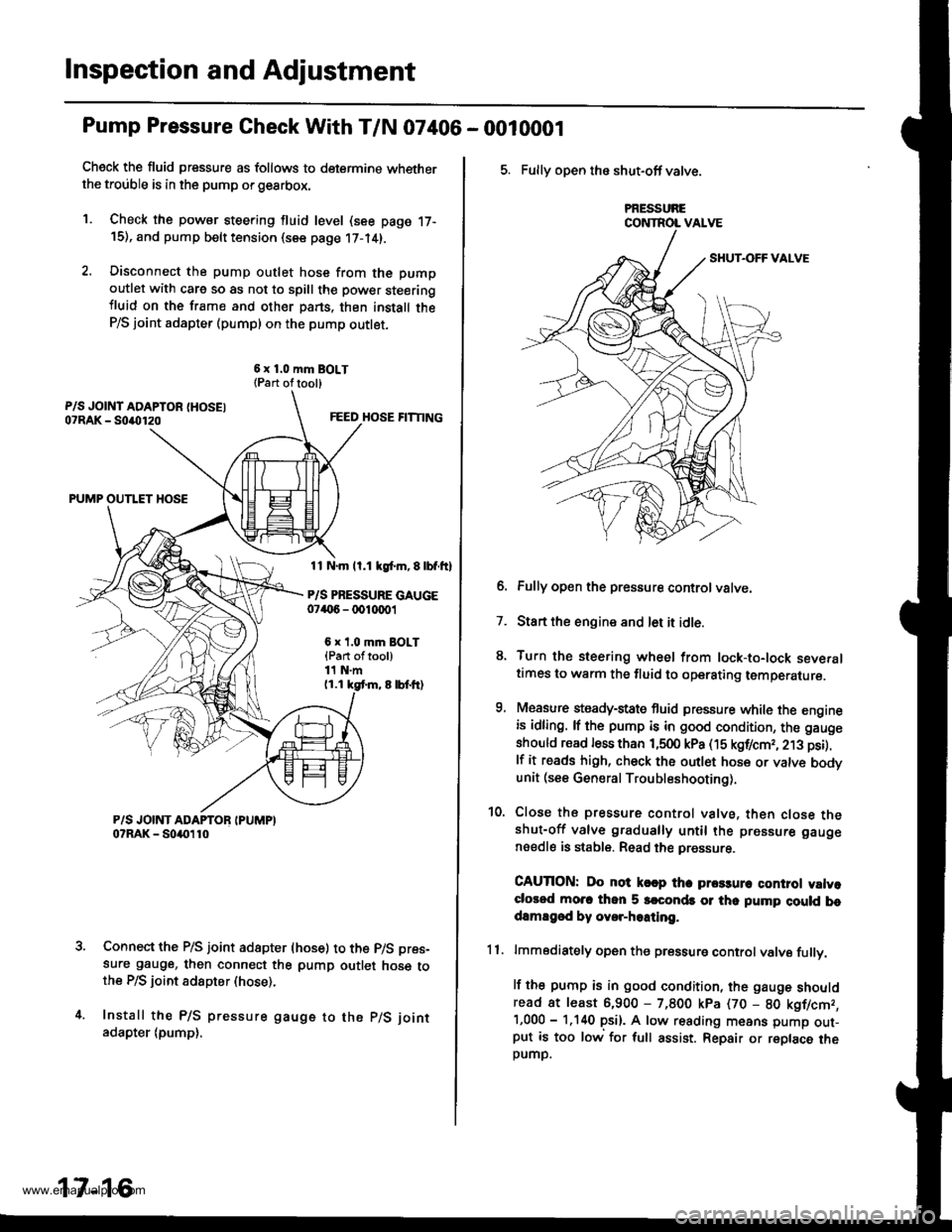

Pump Pressure Gheck With T/N 07406 - 0010001

Check the fluid pressure as follows to determine whetherthe trouble is in the pump orgearbox.

1. Check the powsr steering fluid level (see page 17-15), and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the pow€r steeringiluid on the frame and other pans. thon install theP/S joint adapter (pumpl on the pump outlet.

6 x 1.0 mm BOLT{Part oftool)

FEED HOSE FITTING

PUMP OUTLET HOSE

11 N.m ll.1 kgl.m, E lbf.ftl

P/S PRESSURE GAUGE07('6 - 0010001

6 x t.0 mm BOLT{Part oftool)11 N.m(1.1 kgt m, 8 lbf.tr)

Connect the P/S joint adapter (hose) to the p/S pres-

sure gauge, then connect the pump outlet hose tothe P/S ioint adspter (hose).

Install the P/S pressure gauge to the p/S joint

adapter (pump),

17-16

5. Fully open the shut-off valve.

PRESSURECONTROL VALVE

6. Fully open the pressure controlvatve.

7. Start the engine and let it idle.

8. Turn the steering wheel from lock-to-lock severaltimes to warm the fluid to operating temperature.

9, Measure steady-state fluid pressure while the engineis idling. lf the pump is in good condition, the gauge

should read less than 1,500 kPa (15 kgf/cmr, 213 psi).

lf it reads high, check the outlet hose or valve bodvunit (see General Troubleshooting).

10. Close the pressure control valve, then close theshut-off valve gradually until the pressure gauge

nsedle is stable. Read the pressure.

CAUTION: Do not k€ap tha prca3un control valvoclorod mo.c thon 5 srconds or thc pump cluld bodamEgod by ovor-hoating.

11. lmmodiately open the pressure controlvalve fullv.

lf the pump is in good condition, the gauge shouldread at least 6,900 - 7,800 kpa (70 - 80 kgflcmr,'1,000 - 1.140 psi). A low reading means pump out-put is too low for full assist. Repair or replace theDUMD.

www.emanualpro.com

Page 862 of 1395

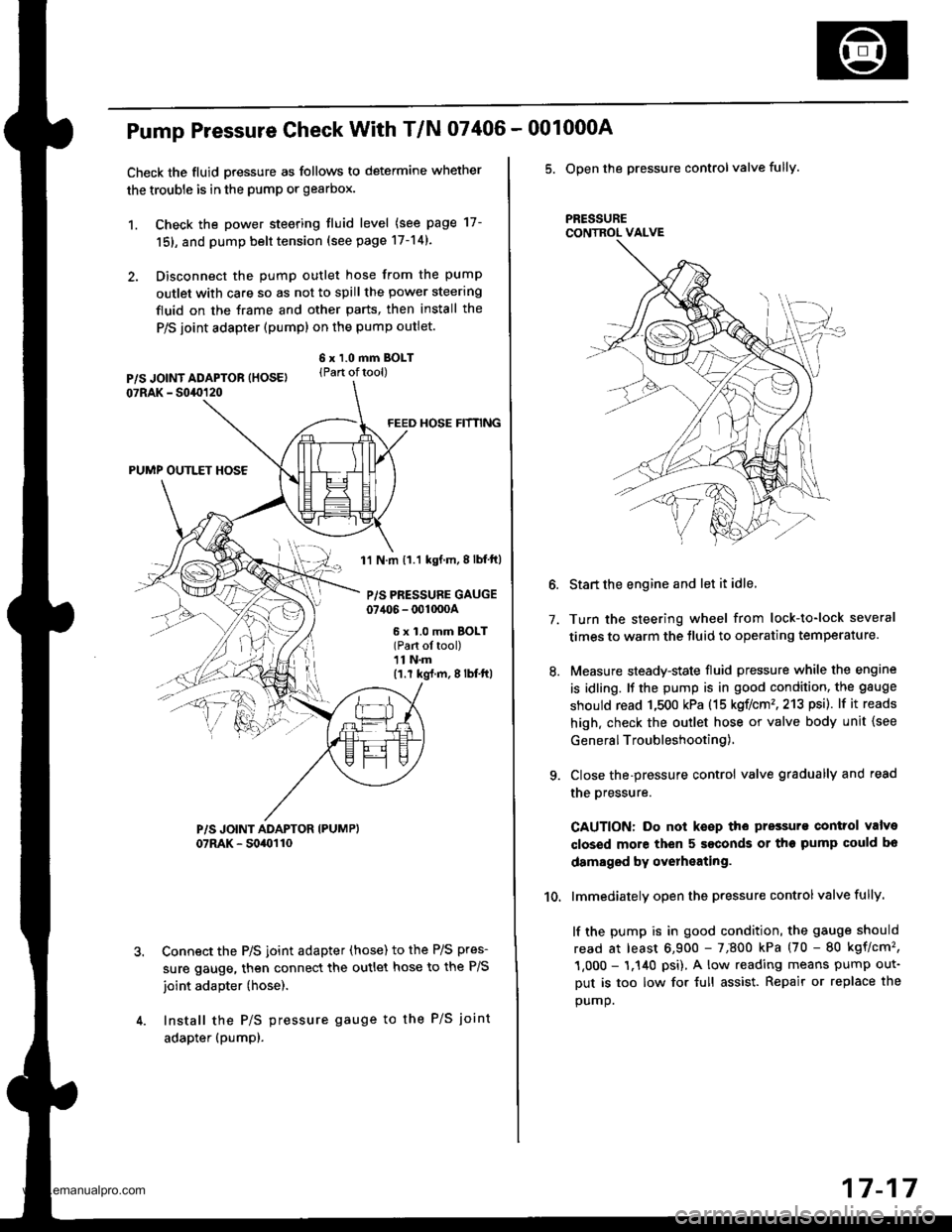

Pump Pressure Check With T/N 07406 -

Check the fluid pressure as follows to determine whether

the trouble is in the pump or gearbox.

1. Check the power steering tluid level (see page 17-

151, and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the power steering

fluid on the frame and other parts, then install the

P/S joint adapter (pump) on the pump outlet.

6 x 1.0 mm BOLT(Part oftool)

FEED HOSE HfNNG

PUMP OUTLET HOSE

1'l N.m 11.1 kgf.m,8lbf ft)

P/S PRESSURE GAUGE07406 - 001000A

6 x 1.0 mm BOLT(Part ol tool)11 N.m(1.r kg{.m,8lbf'ft|

Connect the P/S joint adapter (hose) to the P/S pres-

sure gauge, then connect the outlet hose to the P/S

joint adapter (hose).

Install the P/S pressure gauge to the P/S joint

adapter (pumpl.

001000A

5. Open the pressure controlvalve fully.

PRESSURECONTROL VALVE

7.

10.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the tluid to operating temperature.

Measure steady-state fluid pressure while the engine

is idling. It the pump is in good condition, the gauge

should read 1,500 kPa (15 koflcm'�,213 psi). lf it reads

high. check the outlet hose or valve body unit {see

General Troubleshooting),

Close the-pressure control valve gradually and read

the oressure.

CAUTION: Do not keep the pressurs control valve

closed more then 5 seconds or the pump could bo

damaged by overheating.

lmmediately open the pressure controlvalve fully.

lf the pump is in good condition, the gauge should

read at least 6,900 - 7;800 kPa (70 - 80 kgflcm'�,

1,000 - 1.140 psi), A low reading means pump out-

Dut is too low for {ull assist. Repair or replace the

oumo.

17-17

www.emanualpro.com

Page 882 of 1395

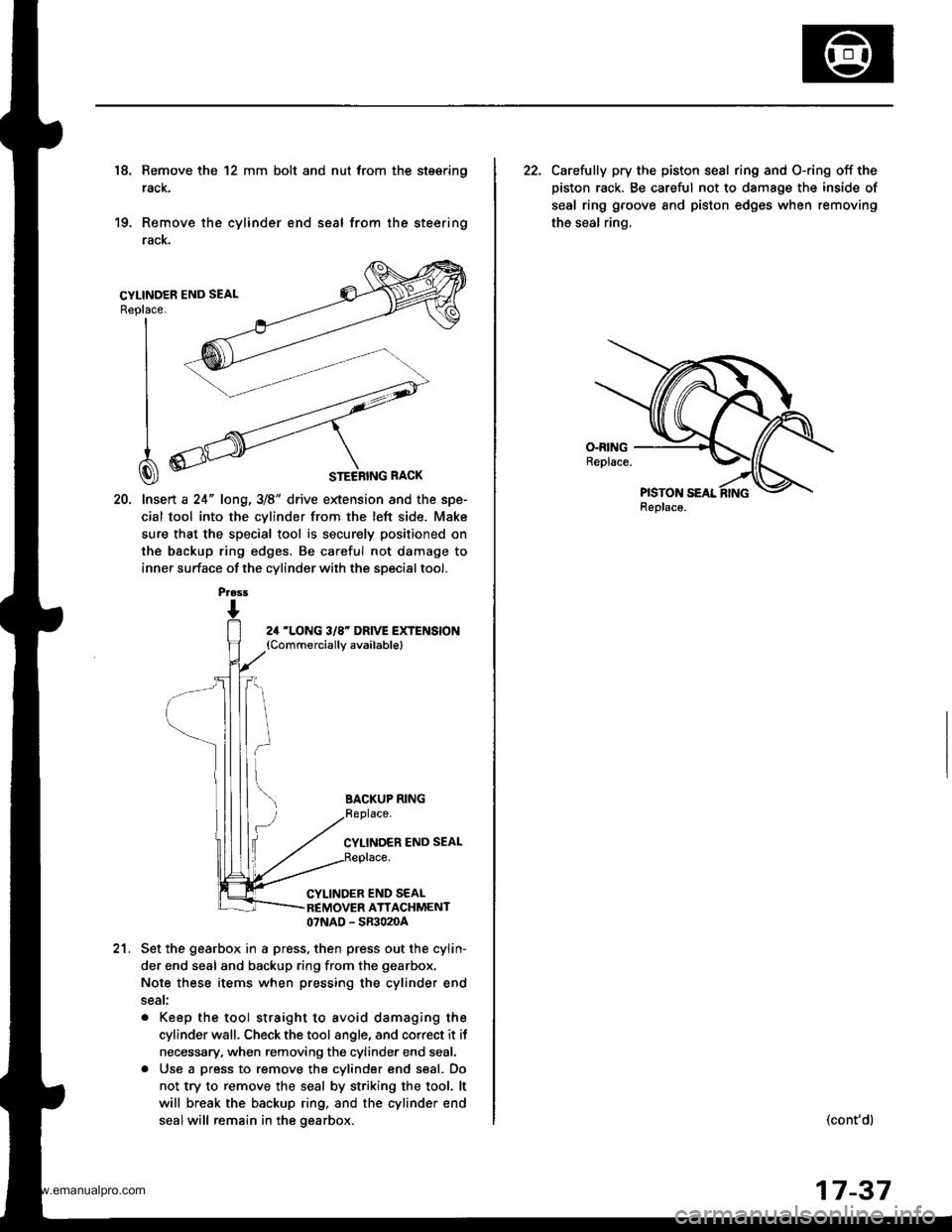

18. Remove the 12 mm bolt and nut trom the stsering

rack,

19. Remove the cylinder end seal from the steering

racK.

20. lnsert a 24" long,3/8" drive extension and the spe-

cial tool into the cvlinder from the left side. Make

sure that the special tool is securely positioned on

the backup ring edges. Be careful not damage to

inner surface of the cylinder with the special tool.

Replace.

I

I

I

CI

24 'LONG 3/8' DRIVE EXTENSION(Commerciallv available)

BACKUP RING

CYLINDER END SEAL

CYLINDER END SEALREMOVER ATTACHMENT07NAD - SR3020A

21.Set the gearbox in a press, then press out the cylin-

der end seal and backup ring from the gearbox.

Note these items when pressing the cylinder end

seat:

. Keep the tool straight to avoid damaging the

cylinder wall. Check the tool angle, and correct it if

necessary, when removing the cylinder end seal.

. Use a press to remove the cylinder end seal. Do

not try to remove the seal by striking the tool. lt

will break the backup ring, and the cylinder end

sealwill remain in the gearbox.

Prass

22. Carelully pry the piston sesl ring and O-ring off the

piston rack. Be careful not to damage the inside of

seal ring groove and piston edges when removing

the seal ring.

Replaco.

(cont'dl

17-37

www.emanualpro.com

Page 915 of 1395

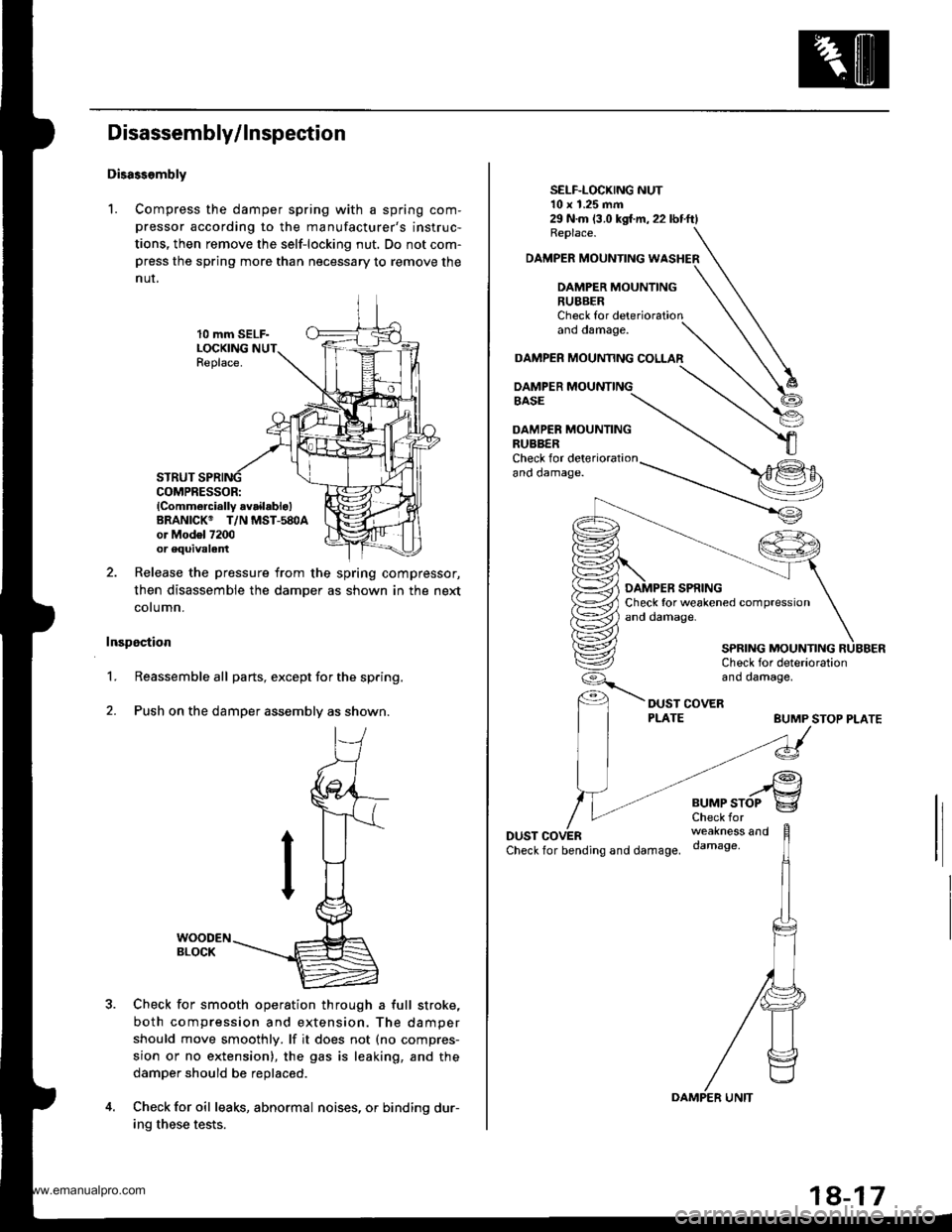

Disassembly/ Inspection

Disass.mbly

1. Compress the damper spring with a spring com-

pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut. Do not com-press the spring more than necessary to remove the

nur.

10 mm SELF-LOCKINGReplace.

STRUTCOMPRESSOR:lComm6rcially availablo)BRANICK@ T/N MST-580Aor Mod6l 7200or equivalent

Release the pressure from the spring compressor,

then disassemble the damper as shown in the next

cotumn.

Inspection

1.Reassemble all parts, except for the spring.

Push on the damper assembly as shown.

Check for smooth operation through a full stroke,

both compression and extension. The damper

should move smoothly. lf it does not (no compres-

sion or no extension), the gas is leaking, and the

damper should be replaced.

Check for oil leaks, abnormal noises, or binding dur-

ing these tests.

2.

29 N.m (3.0 kgl.m,22lbtftlReplace.

DAMPER MOUNTING WASHER

DAMPER MOUNTING

SELF-LOCKING NUT10 x 1.25 mm

RUBBERCheck forano oamage.

DAMPER MOUAMNG COLLAR

DAMPER MOUNTINGBASE

DAMPER MOUNTINGRUBBERCheck for det€riorationano oamage.

BUMP STOP PLATE

DUSTCheckfor bending and damage.

..rgBUMPSTOP g

weakness anddamage,

SPRING MOUNTING

www.emanualpro.com

Page 922 of 1395

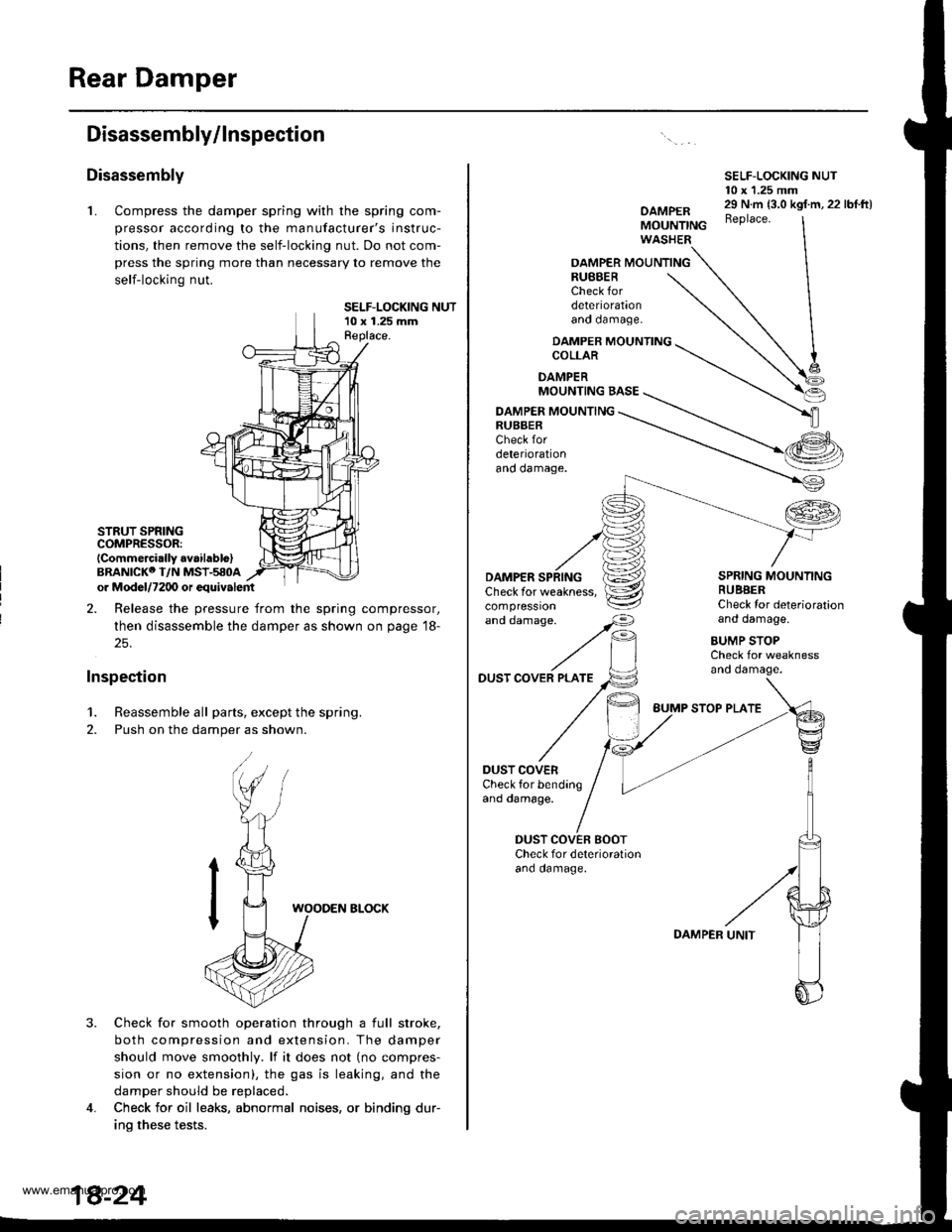

Rear Damper

Disassembly/lnspection

Disassembly

L Compress the damper spring with the spring com-

pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut. Do not com-

press the spring more than necessary to remove the

self-locking nut.

SELF-LOCKING NUT10 x 1.25 mmReplace.

STRUT SPRINGCOMPRESSOR:lCommercirlly avaihblo)BRANICKO I/N MSI-580Aor Mod6l/7200 or equivalent

2. Release the pressure from the spring compressor,

then disassemble the damper as shown on page 18-

25.

Inspection

1. Reassemble all parts, except the spring.

2. Push on the damper as shown.

3.

WOODEN ELOCK

Check for smooth operation through a full stroke,

both compression and extension. The damper

should move smoothly. lf it does not (no compres-

sion or no extension), the gas is leaking, and the

damper should be replaced.

Check for oil leaks, abnormal noises, or binding dur-

ino these tests.

4.

SELF-LOCKING NUT10 x 1.25 mm

OAMPERMOUNTINGWASHER

29 N.m {3.0 kgf.m, 22 lbf.ft)Beplace.

OAMPER MOUNTINGRUBBERCheck fordeteriorationano oamage.

DAMPER MOUNTINGCOLLAR

DAMPERMOUNTING BASE

DAMPER MOUNTINGRUBBERCheck fordeteriorationano oamage.

'"dd"^.s"'

//F,

DAMPERCheck for weakness,compressron

DUST COVER PLATE

DUST COVERCheck for bendingand damage.

SPRING MOUNTINGRUBBERCheck Ior deteriorationand damage.

BUMP STOPCheck for weaknessano oamage.

DUST COVEN BOOTCheck for deterioralionano oamage.

BUMP STOP PLATE

DAMPER

www.emanualpro.com