HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 51 of 1395

Engine Electrical

Speciaf Tools ............. 4-2

Starting System

Component Location Index ............ 4-3

Circuit Diagram ................................ 4-4

Starter Test ........... 4-5

Starter Solenoid Test ...................... 4'5

Starter Replacement ....................... 4-7

Field Winding Test ........................... 4-7

Starter Overhaul ............................,. 4-8

Brush Inspection ...........................,., 4-9

Overrunning Glutch Inspection ...... 4-9

Armature lnspection and Test ........4-10

Brush Holder Test ............................ 4-12

Starter Reassemb|y ......................... 4-1 2

Perf ormance Test ............................. 4- 1 3

lgnition System

Component Location Index ............ 4-14

Circuit Diagram ................................ 4-15

lgnition Timing Inspection and

Setting .......................................... 4-16

Distributor Replacement ........,........ 4-17

Distributor Overhaul .............,,......... 4-18

lgnition Control Module (lCM) Input

Test ..............................,................ 4-19

fgnition Coil Test .............................. 4-2O

lgnition Wire Inspection and

Test ............................................... 4-20

Spark Plug Inspection ..................... 4-21

-+

ENGINE

Charging System

Component Location Index ............ 4-22

Circuit Diagram ....................,........... 4-23

Troubleshooting .............................. 4-24

Alternator Replacement ..........,....... 4-30

Alternator Overhaul .......,,................ 4-31

Rectifier Test .........4-32

Alternator Brush Inspection ........... 4-32

Rotor Slip Ring Test ........................ 4-33

Stator Test ............. 4-33

Alternator Belt Inspection and

Adiustment ........4-34

Gruise Control

Component Location Index .,,,........ 4-36

Circuit Diagram ................................ 4-37

Control Unit Input Test ................... 4-38

Main Switch Test/Replacement ..... 4-40

Set/Resume Switch Test/

Replacement .......................,........ 4'40

Actuator Test ....,,., 4-41

Actuator Replacement ...............,.... 4-42

Actuator Cable Adiustment ............ 4-43

Clutch Switch Test .......................... 4-43

Brake Switch Test .................. .......... 4-44

Actuator Solenoid Test .............. ...,. 4-44

Actuator Disassembly ..................... 4-45

www.emanualpro.com

Page 52 of 1395

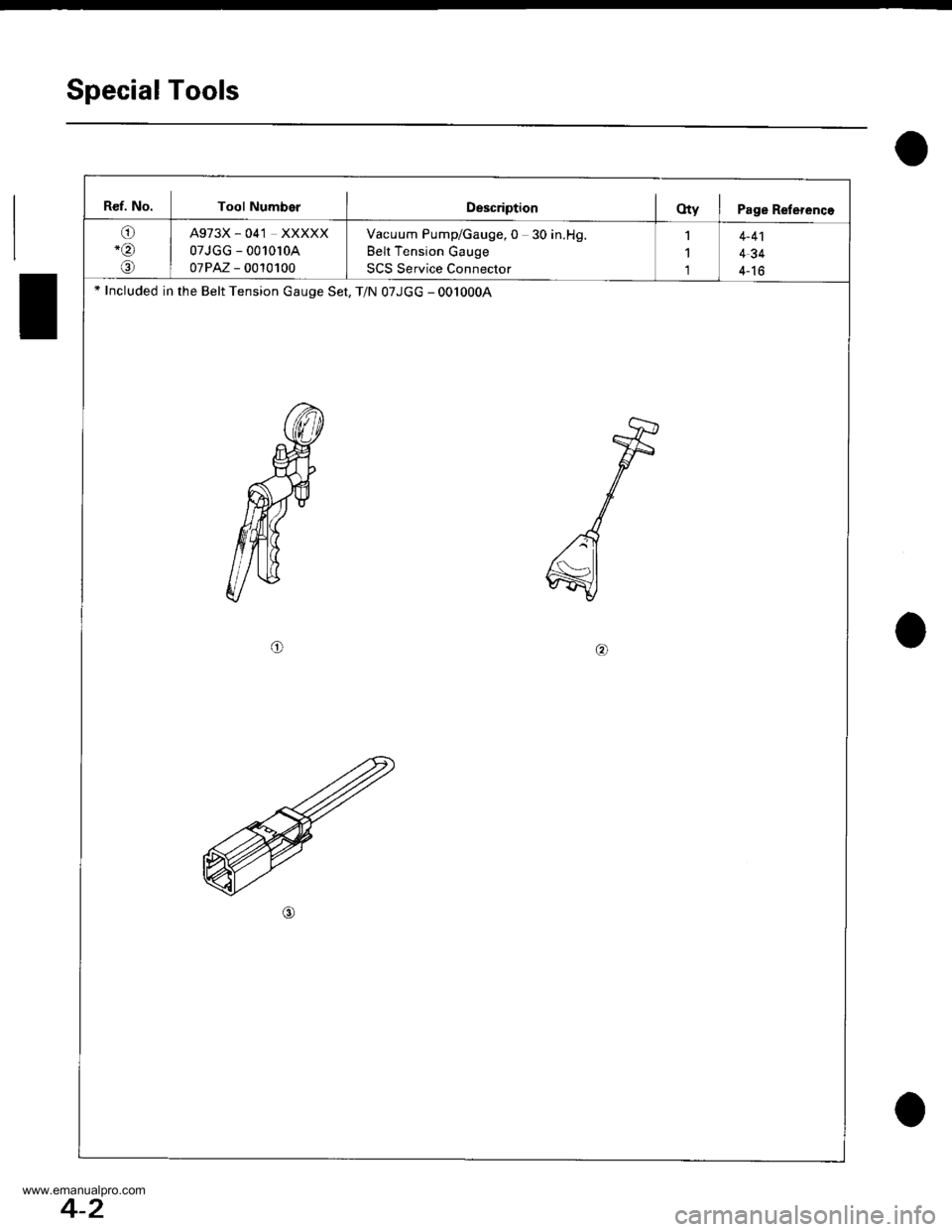

Special Tools

Ref. No.Tool NumberDescriptionOty I Page Reference

o-o

o

A973X - 041 XXXXX

07JGG - 001010A

07PAZ - 0010100

Vacuum Pump/Gauge, 0 30 in.Hg.

Belt Tension Gauge

SCS Service Connector

4-41

434

4-16* Included in the Belt Tension Gauge Set, T/N 07JGG - 0010004

o@

o

4-2

www.emanualpro.com

Page 53 of 1395

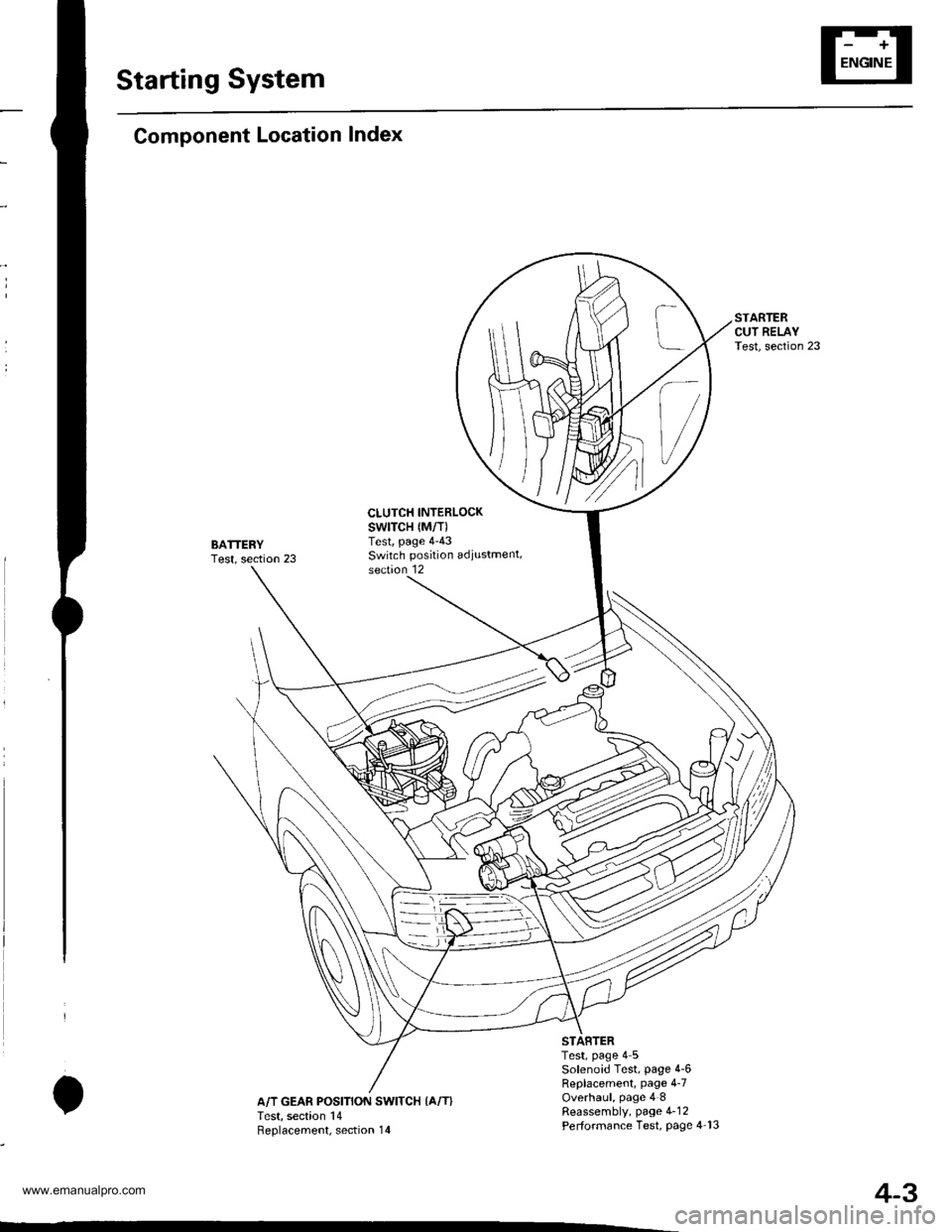

Starting System

Component Location Index

BATTERYTest, section 23

CLUTCH INTERLOCKswtTcH {M/T)Test, page 4-43Switch position adiustment,section 12

IA/T GEAR POSITION SWITCH {A/T}Test, section 14Reolacement. section 14

Test, page 4 5Solenoid Test, page 4-6Replacement, page 4-7Overhaul, page 4 8Reassembly, page 4-12Performance Test, Page 4-13

4-3

www.emanualpro.com

Page 54 of 1395

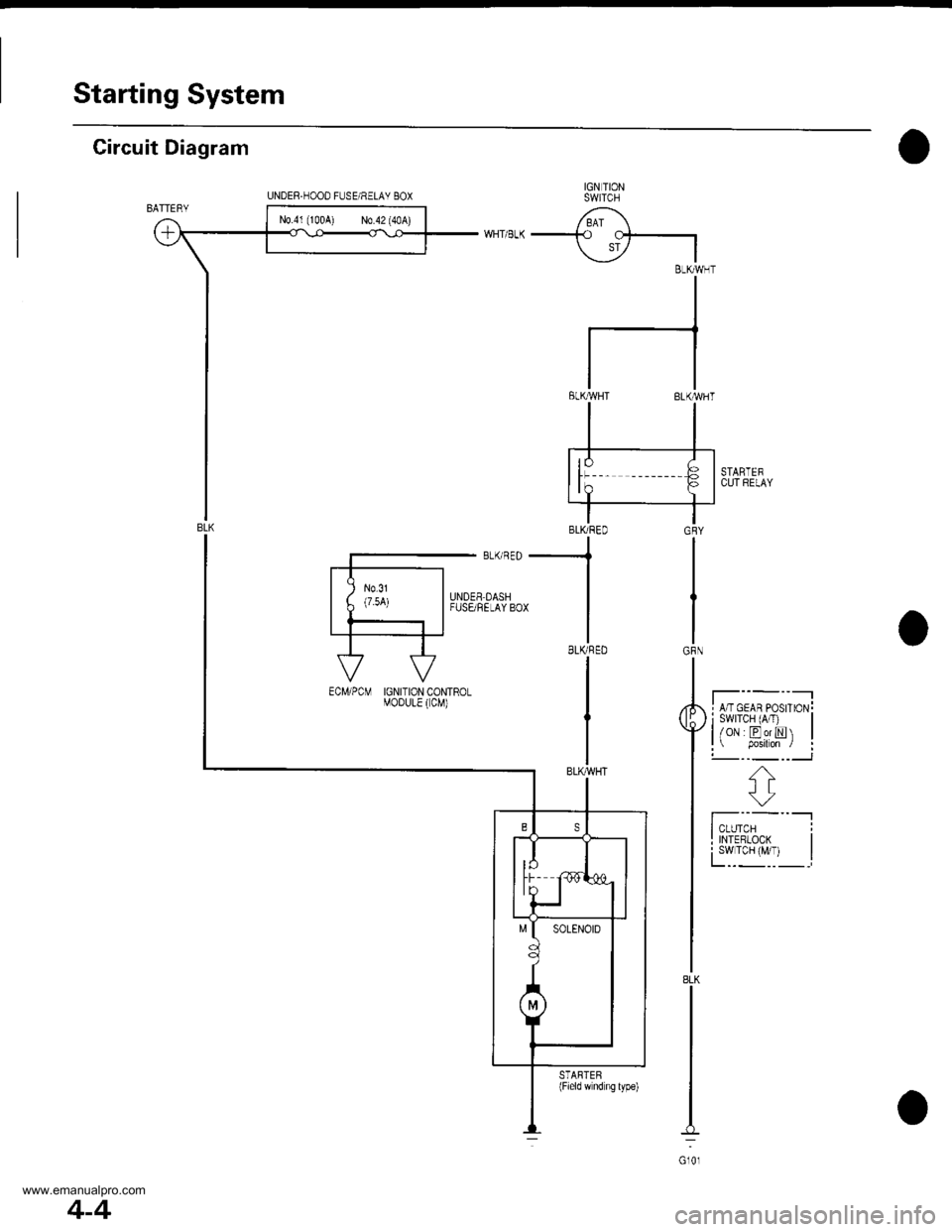

Starting System

Circuit Diagram

IGN TIONSWITCH

/ BAI \-+o cf-.|

\i7 IBLKMHT

II

I

tl

tlELKMHT BLK'WHT

STARTEFCUl RELAY

I A/T GEAR PosrroN!i swrTcH (A/T) |l/oN EorN |l p.siton / :!-- -_ --___J

f';--"-lI TNTERLooK I

fYl""yl, I

GRY

IGRN

8LK

Gl0l

UNDER.HOOD FUSE/RELAY 8OX

N0.41 (100A) N0.42 (40A)

-.1

BLKRED

I

IGNITION CONTROLMOoULE ( CM)

STARTEB(Field wnd ng lype)

4-4

www.emanualpro.com

Page 55 of 1395

Starting System

Starter Test

NOTE: The air temperature must be between 59 and'100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described.

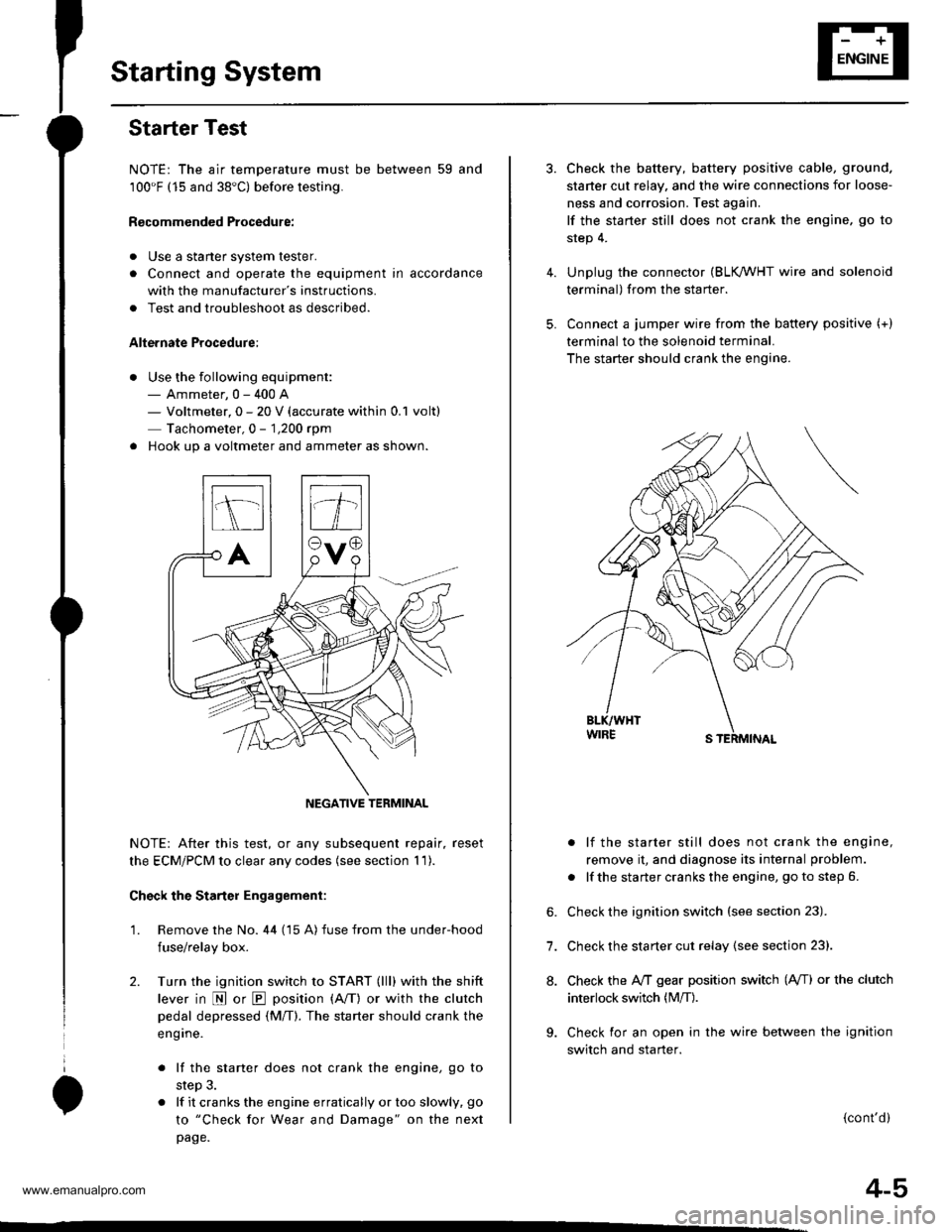

Alte.nate Procedure:

. Use the following equipment:- Ammeter, 0 - 400 A- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

Tachometer,0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section 1 1).

Check the Starter Engagement:

'1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box.

2. Turn the ignition switch to START (lll) with the shift

lever in E or E position (A/T) or with the clutch

pedal depressed {M/T). The starter should crank the

eng ine.

. lf the starter does not crank the engine, go to

step 3.

. lf it cranks the engine erratically or too slowly, go

to "Check for Wear and Damage" on the next

page.

NEGATIVE TERMINAL

4.

5.

6.

7.

8.

Check the battery, battery positive cable, ground.

staner cut relay, and the wire connections for loose-

ness and corrosion. Test again.

lf the staner still does not crank the engine, go to

step 4.

Unplug the connector (BLK /VHT wire and solenoid

terminal) from the starter.

Connect a jumper wire from the baftery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem.

. lf the starter cranks the engine, go to step 6.

Check the ignition switch (see section 23).

Check the starter cut relay {see section 23}.

Check the IVT gear position switch (A/T) or the clutch

interlock switch (M[).

Check for an open in the wire between the ignition

switch and starter.

(cont'd)

4-5

www.emanualpro.com

Page 56 of 1395

Starting System

Starter Test (cont'dl

Check lor Wear and D8mage

The starter should crank the engine smoothly and

steadily. lf the staner engages, but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter ring gear or flywheel ring gear for

oamage.

Check the drive gear overrunning clutch for binding or

slipping when the armature is rotated with the drive

gear held. lf damaged, replace the gears.

Check Cranking Voltage and Current Draw

Cranking voltage should be no less than 8.7 volts on Ay'T

models, and 8.0 volts on M/T moders.

Current draw should be no more than 230 amperes on

A,/T models, and 200 amperes on M/T models.

lf cranking voltage is too low, or current draw too high,

check for:

. dead or low battery.

a open circuit in starter armature commutator seg,

ments.

. starter armature dragging.

. shorted armature winding.

. excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm.

lf speed is too low, check for:

a loose baftery or starter terminals.

. excesslvely worn staner brushes

. open circuit in commutator segments.

. dirty or damaged helical splines or drive gear.

a defective drive gear overrunning clutch.

Check Starter Disengagement

With the shift lever in @ or @ position (A,iT) or with the

clutch pedal depressed {M/T). turn the ignition switch to

START (lll). and release to ON (ll).

The starter drive gear should disengage from the torque

converter ring gear or flywheel ring gear when you

release the key.

lf the drive gear hangs up on the torque converter ring

gear or flywheel ring gear, check for

. solenoid plunger and switch malfunction.

. dirty drive gear assembly or damaged overrunning

clutch.

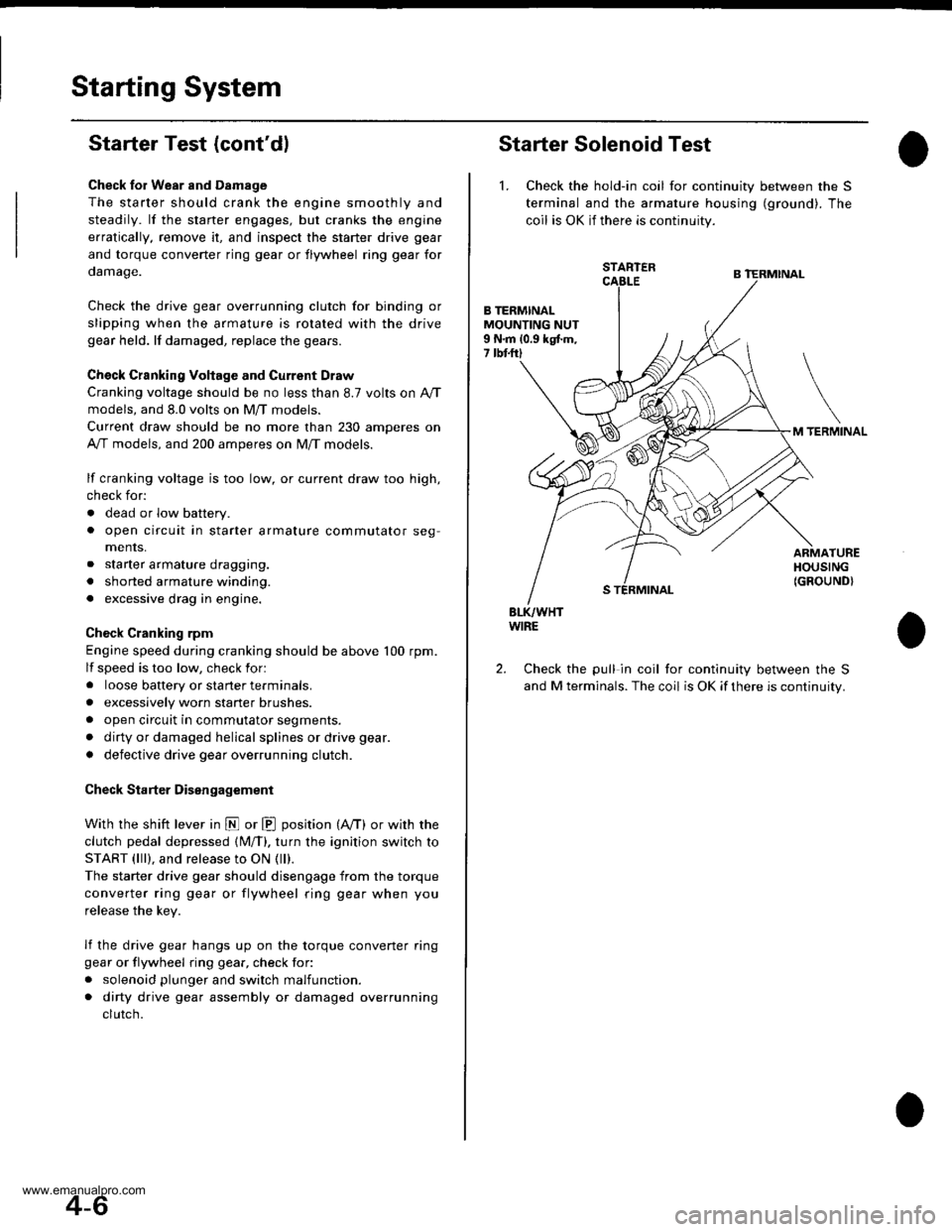

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and lhe armature housing (ground). The

coil is OK if there is continuity.

STARTER

B TERMINALMOUNTING NUT9 N.m 10.9 kgtm,7 tbtftl

TERMINAL

ARMATUREHOUSING(GROUND}

BLK/WHTWIRE

Check the pull in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

2.

4-6

www.emanualpro.com

Page 57 of 1395

RE

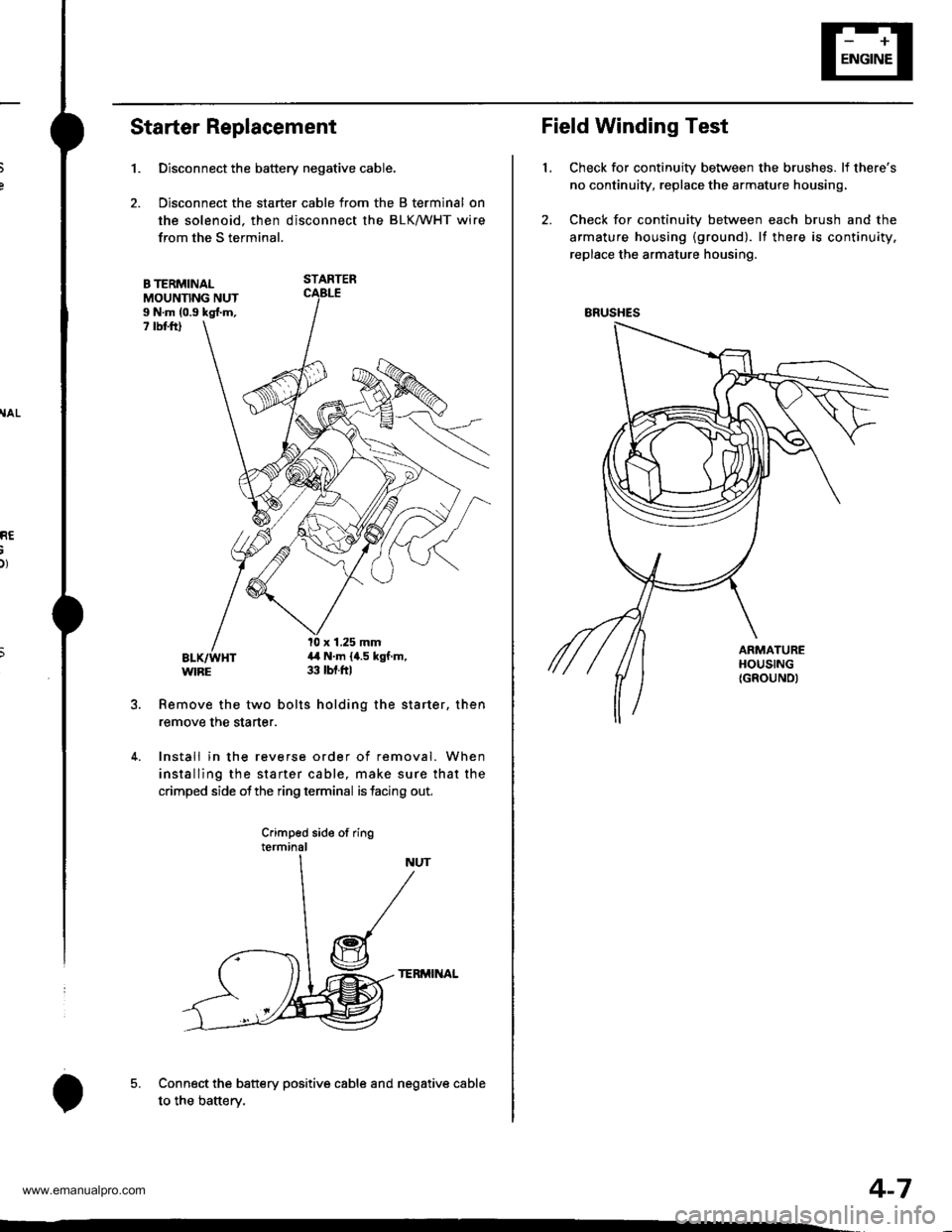

Starter Replacement

1.

B TERMINALMOUNNNG NUTI N.m (0.9 kgl.m,7 rbt ftl

Remove the two bolts holding the starter. then

remove the starter.

4. Install in the reverse order of removal. When

installing the starter cable, make sure that the

crimped side ofthe ring terminal is facing out,

Crimped side of ringterminal

TERMINAL

Connect the battery positive cable and negative cable

to the batterv.

Disconnect the battery negative cable.

Disconnect the starter cable from the B terminal on

the solenoid. then disconnect the BLK/WHT wire

from the S terminal.

STARTER

l0 x 1.25 mm4,1 N.m {4.5 kgf.m,33 tbt.ftl

5.

o

Field Winding Test

Check for continuity between the brushes. lf there's

no continuity, replace the armature housing,

Check for continuity between each brush and the

armature housing {ground). lf there is continuity.

replace the armature housing.

t.

ERUSHES

4-7

www.emanualpro.com

Page 58 of 1395

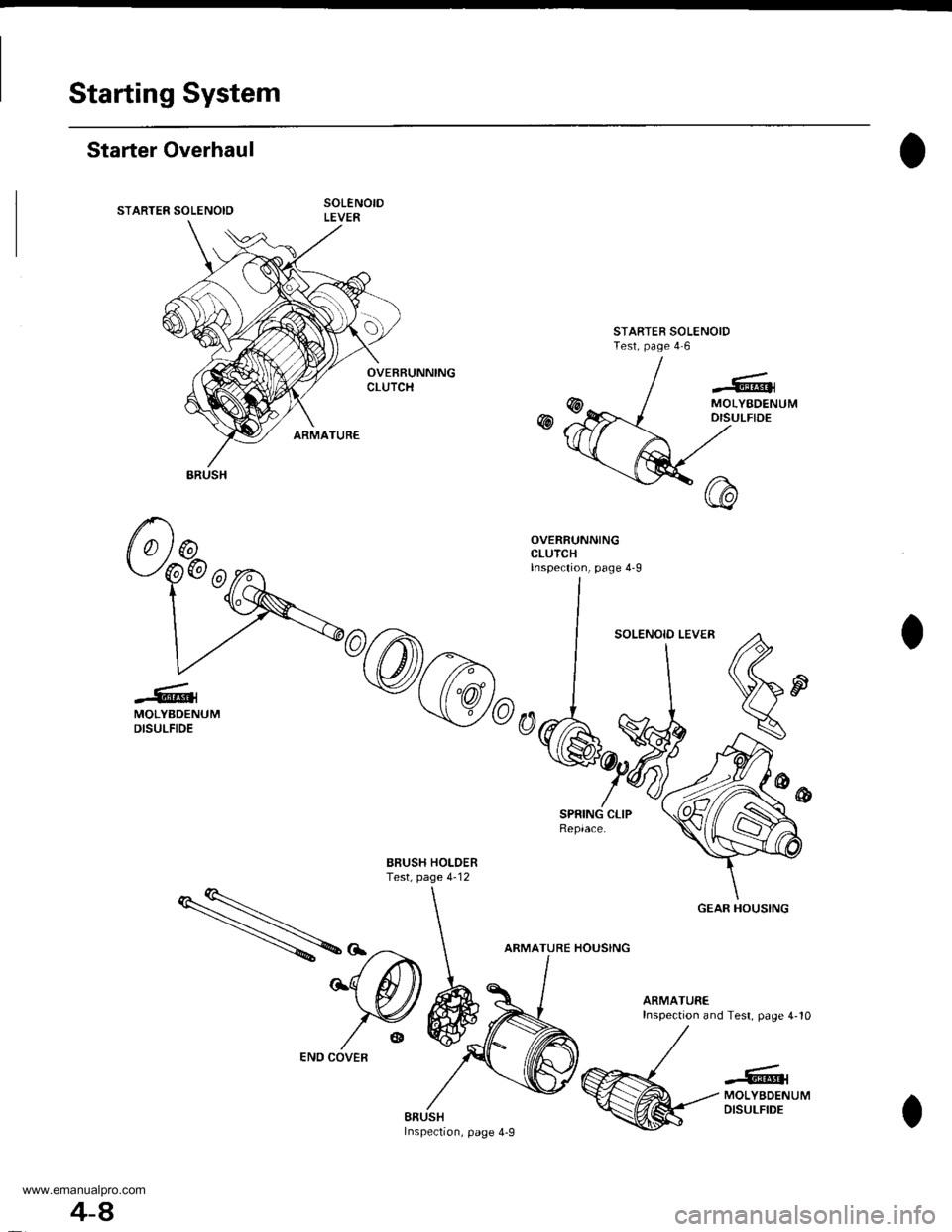

Starting System

Starter Overhaul

STARTER SOLENOID

STARTER SOLENOIDTest, page 4 6

OVEBRUNNINGCLUTCH

w

-6^lMOLYBDENUMDISULFIDE

SPRING CLIPReplace.

BBUSH HOLDERTest, page 4-12

ARMATURE HOUSING

ARMATUREInspection and Test. page 4-10

..'...:|@{MOLYBDENUMDISULFIDEBAUSHInsPeclon, page 4-9

ARUSH

GEAR HOUSING

4-A

END COVER

www.emanualpro.com

Page 59 of 1395

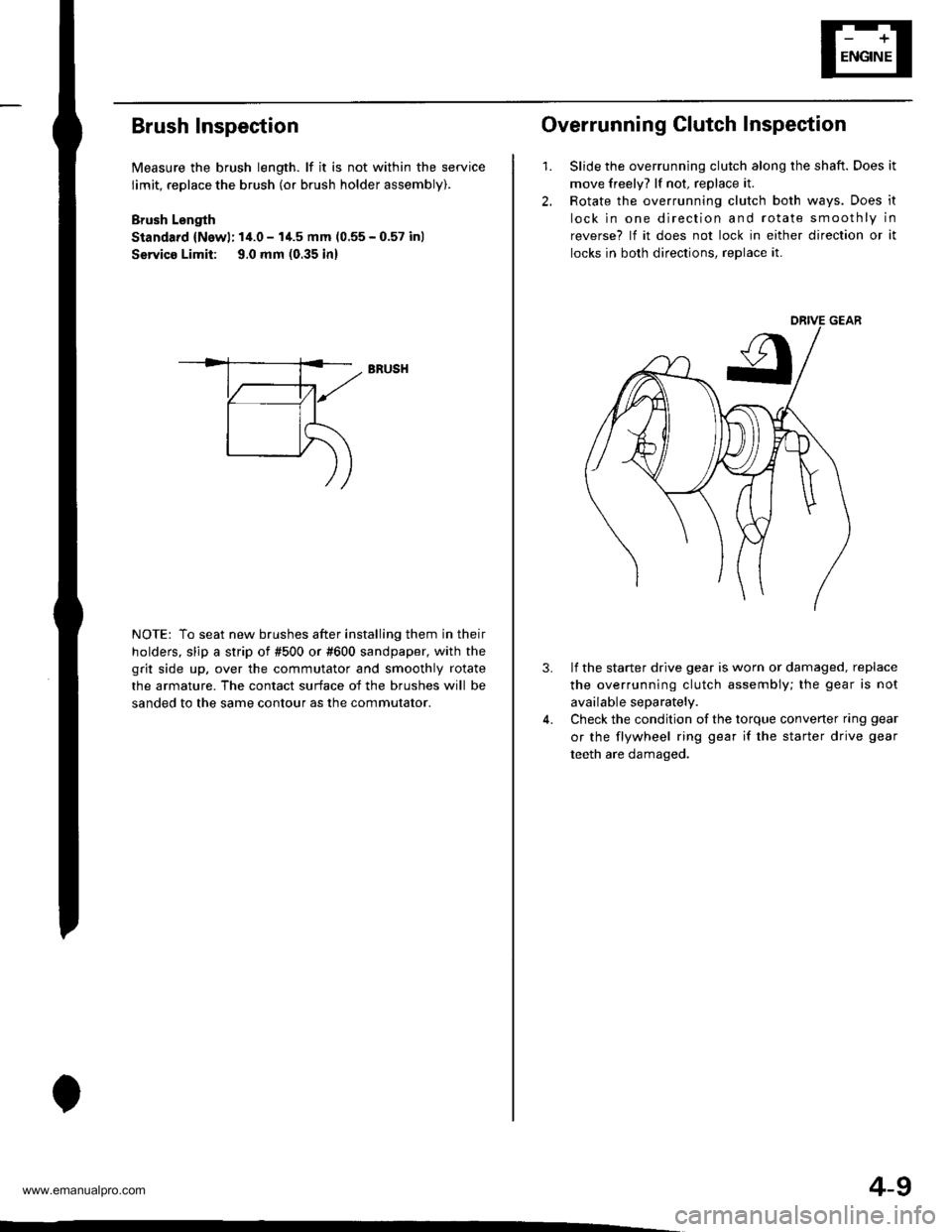

Brush Inspection

Measure the brush length. lf it is not within the service

limit, replace the brush (or brush holder assembly).

Brush Lsngth

Standard {Newl: 14.0 - I'1.5 mm (0.55 - 0.57 inl

Servico Limit: 9.0 mm (0.35 in)

NOTE: To seat new brushes after installing them in their

holders. slip a strip of #500 or #600 sandpaper, with the

grit side up, over the commutator and smoothly rotate

the armature. The contact surface of the brushes will be

sanded to the same contour as the commutator.

BRUSH

4-9

2.

1.

Overrunning Clutch Inspection

Slide the overrunning clutch along the shaft. Does it

move freely? lf not, replace it.

Rotate the overrunning clutch both ways. Does it

lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, reDlace it.

3.lf the starter drive gear is worn or damaged, replace

the overrunning clutch assembly; the gear is not

available separately.

Check the condition of the torque converter ring gear

or the flywheel ring gear if the starter drive gear

teeth are damaged.

www.emanualpro.com

Page 60 of 1395

Starting System

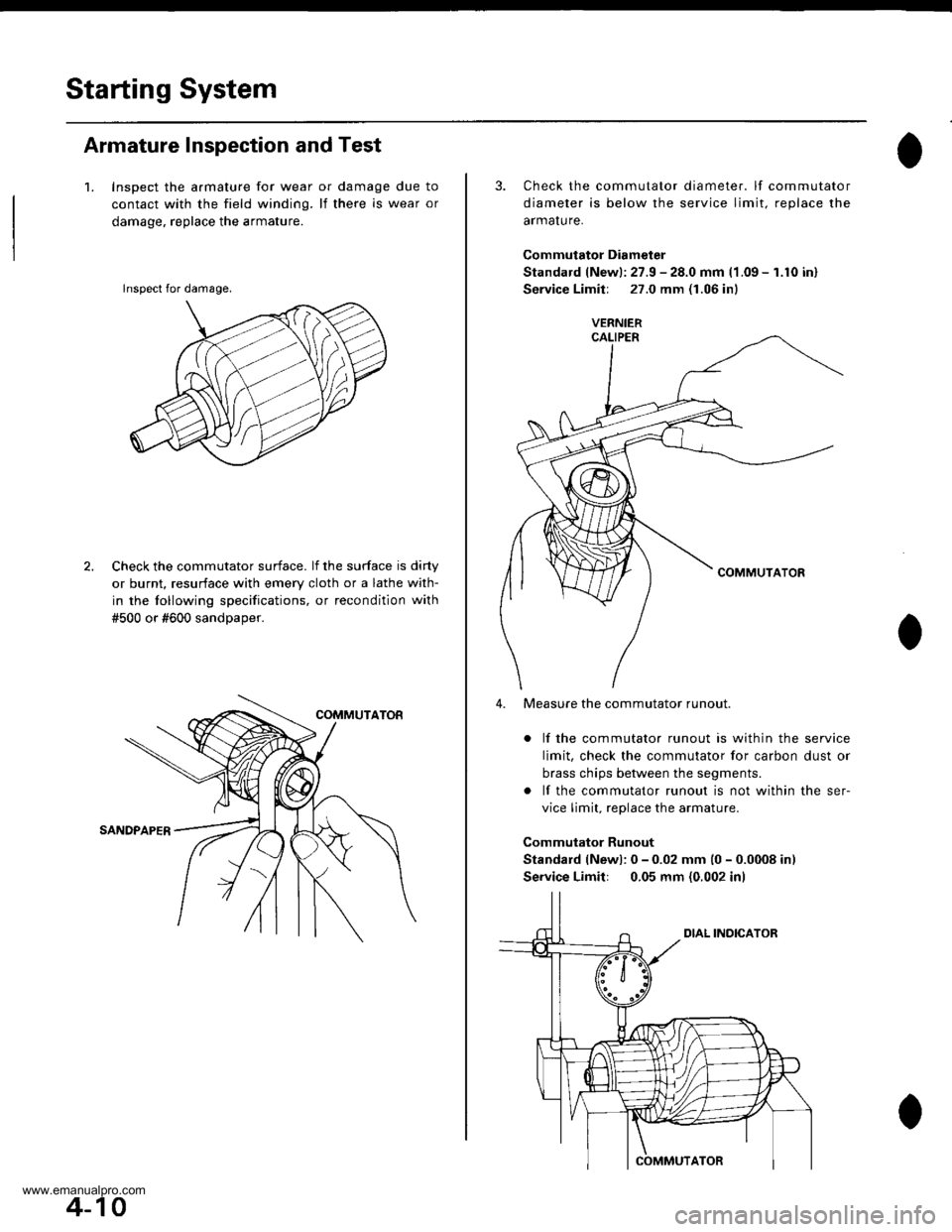

Armature Inspection and Test

1. Inspect the armature for wear or damage due to

contact with the field winding. lf there is wear or

damage. replace the armature.

Check the commutator surface. lf the surface is dirty

or burnt, resurface with emery cloth or a lathe with-

in the tollowing specifications, or recondition with

#500 or #600 sandDaoer.

lnspect for damage.

4-10

3. Check the commutator diameter. lf commutator

diameter is below the service limit, reolace the

armalure.

Commutator Diameter

Standard (Newl: 27.9 - 28.0 mm (1.09 - 1.10 in)

Service Limilr 27.0 mm (1.06 inl

lf the commutator runout is within the service

limit, check the commutator for carbon dust or

brass chips between the segments.

lf the commutator runout is not within the ser-

vice limit, replace the armature.

Commutator Runout

Standard (Newl: 0 - 0.02 mm (0 - 0.0008 in)

Service Limit: 0.05 mm {0,002 inl

4. Measure the commutator runout.

www.emanualpro.com