Back HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 517 of 1395

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 518 of 1395

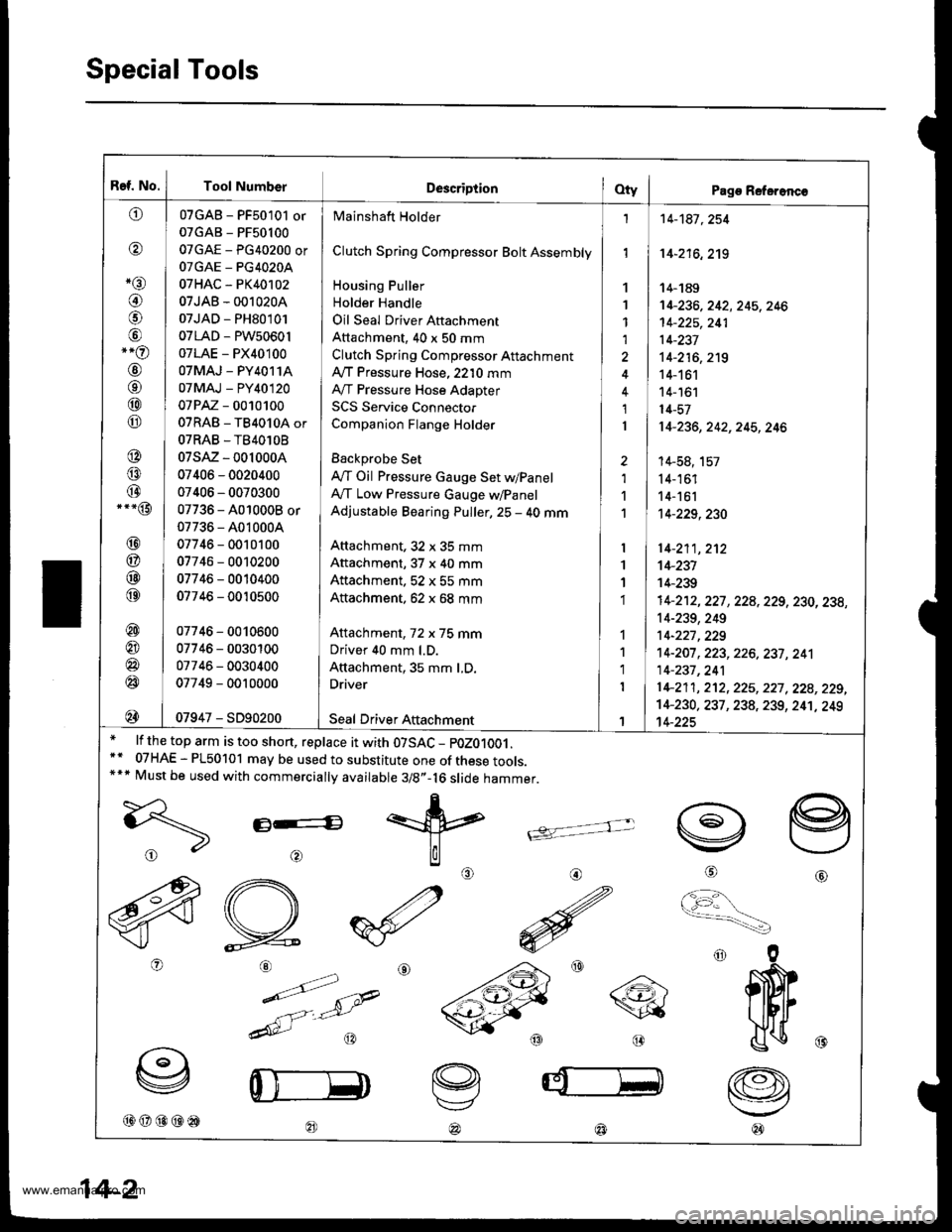

Ref. No.

^tl)

@

*rar

@

@

,-o

@

o

@

@

@

@

@.--@

@

@

@

@

@

@

@

@

@

Tool NumberDescriptionOty I Pago Referonc€

Mainshaft Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Holder Handle

Oil Seal Driver Aftachment

Attachment, 40 x 50 mm

Clutch Spring Compressor Attachment

Ay'T Pressure Hose, 2210 mm

IVT Pressure Hose Adapter

SCS Service Connector

Companion Flange Holder

Backprobe Set

lVT Oil Pressure Gauge Set w/Panel

A,/T Low Pressure Gauge w/Panel

Adjustable Bearing Puller, 25 - 40 mm

Anachment, 32 x 35 mm

Attachment, 37 x 40 mm

Attachment. 52 x 55 mm

Attachment. 62 x 68 mm

Attachment, 72 x 75 mm

Driver 40 mm l.D.

Attachment, 35 mm LD.

Driver

07GAB - PF50101 or

07GAB - PF50100

07GAE - PG40200 or

OTGAE _ PG4O2OA

07HAC - PK40102

07JAB - 001020A

07JAD - PH80101

07LAD - PW50601

07LAE - PX40100

OTMAJ - PY4O114

07MAJ - PY40120

07 PAZ - 0010100

07RAB - TB4010A or

07RAB.TB40lOB

07sAz - 001000A

07406 - 0020400

07406 - 0070300

07736 - 4010008 or

07736 - A010004

07746 - 0010100

07746 - 0010200

07746 - 0010400

07746 - 0010500

07746 - 0010600

07746 - 0030100

07746 - 0030400

07749 - 0010000

07947 - SD90200Seal Driver Aftachment

1

1

1

1,l

1

I

2

1'l

1

I

1

1

1

1

1

1

I

1

14-181 , 254

14-216,219

14-189't4-236,242,245,246

't 4-225, 241

14-237

14-216,2't9

14-161

14- 161

14-57

14-236,242,245,246

14-58, 157

14-161

14-161'14-229,230

14-211, 2't2

14-231

14-239

14-212, 227 , 228,229, 230, 238,

14-239, 249

14-221 ,229't 4-207 , 223,226, 237 , 241

14-237,241

1 +21 1, 2't2, 225, 227, 228, 229,

14-230, 237 , 238, 239, 24't, 249't4-225

lf the top arm is too short, replace it with 07SAC - pOZ01OO1.

07HAE - PL50101 may be used to substitute one of these tools.Must be used with commercially available 3/8"-16 slide hammer.

E----G

@@@@@

@

tvj

'

@@@)

14-2

www.emanualpro.com

Page 519 of 1395

Description

General Operation

The Automatic transmission is a 3-element torque converter and triple-shaft electronically controlled unit which provides 4

speeds forward and 1 reverse speed The unit is positioned in line with the engine'

There are two tvoes of automatic transmission on CR-V; the four-wheel drive (4WD) model ('97 - 00)' and the front-wheel

drive (2WD) model ('98 - 00).

Toroue Converter, G€ars, and Clutches

The torque converter consists of a pump. turbine. and stator assembly in a single unit. The torque converter is connected to

the engine crankshatt. These parts turn together as a unit as the engine turns. Around the outside of the torque converter is

a ring gear which meshes with the starter pinion when the engine is started. The torque converter assembly serves as a fly-

wheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts: the mainshaft. the countershaft, and the sub-shaft. The mainshaft is in line with

the engine crankshaft. The mainshaft includes the 1st, 2nd. and 4th clutches, and gears lor 3rd,2nd,4th. reverse and 1st

(3rd gear is integral with the mainshaft, while reverse gear is integral with the 4th gear). The countershaft includes the 3rd

clutch and gears for 3rd,2nd, 4th, reverse, 1st, and park. Reverse and 4th gears can be locked to the countershaft at its cen-

ter, providing 4th gear or reverse, depending on which way the selector is moved. The sub-shaft includes the lst-hold

clutch and gears for lst and 4th.

The gears on the mainshaft are in constant mesh with those on the countershaft and sub-shaft. When certain combinations

of gears are engaged by the ctutches, power is transmitted from the mainshaft to the countershaft to provide E, D!, tr, tr,

and E position ('97 - 98 models). and E. E, E, and E position ('99 - 00 models)'

Electlonic Control

The electronic controt system consists of the Powenrain Control Module (PCM), sensors, a linear solenoid, and four

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions. The PCM is

located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the servo body, and

the lock up valve body. They are bolted to the torque converter housing. The main valve body contains the manual valve,

the 1-2 shift valve, the 2nd orifice control valve. the CPB {Clutch Pressure Back-up) valve, the modulator valve, the servo

control valve. the relief valve, and ATF pump gears. The secondary valve body contains the 2-3 shift valve, the 3-4 shift

valve, the 3,4 orifice control valve. the 4th exhaust valve and the CPC (Clutch Pressure Control) valve. The regulator valve

bodv contains the pressure regulator valve, the torque converter check valve, the cooler relief valve, and the lock-up con-

trol valve. The servo body contains the servo valve which is integrated with the reverse shift tork, and the accumulators

The lock-up valve body contains the lock-up shift valve and the lock-up timing valve. The linear solenoid and the shift con-

trol solenoid valve Ay'B are bolted to the outside of the transmission housing, and the lock-up control solenoid valve Ay'B is

bolted to the outside of the torque converter housing. Fluid trom the regulator passes through the manual valve to the

various control valves. The clutches receive fluid from their respective feed pipes or internal hydraulic circuit

ShiftControl Mechanism

input from various sensors located throughout the vehicle determines which shift control solenoid valve the PCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear. The shift control solenoid valves A and B are

controlled by the PCM.

Lock-up Mechanism

tn E! position (,97 - 98 modets) and in E position ('99 - O0 models), in 3rd and 4th, and in Del position in 3rd ('97 - 98

models) and in El position with Over,Drive (O/D) is OFF (by pressing rhe O/D switchl in 3rd ('99 - 00 models), pressurized

fluid is drained from the back of the torque converter through a fluid passage, causing the lock-up piston to be held

against the torque converter cover, As this takes place, the mainshaft rotates at the same speed as the engine crankshaft.

Together with hydraulic control, the PcM optimizes the timing of the lock-up mechanism The lock-up valves control the

range of lock-up according to lock-up control solenoid valves A and B, and the linear solenoid. When lock-up control

solenoid valves A and B activate, the modulator pressure changes. The lock-up control solenoid valves A and B and the

linear solenoid are controlled by the PCM.

{cont'd)

14-3

www.emanualpro.com

Page 520 of 1395

Description

General Operation (cont'dl

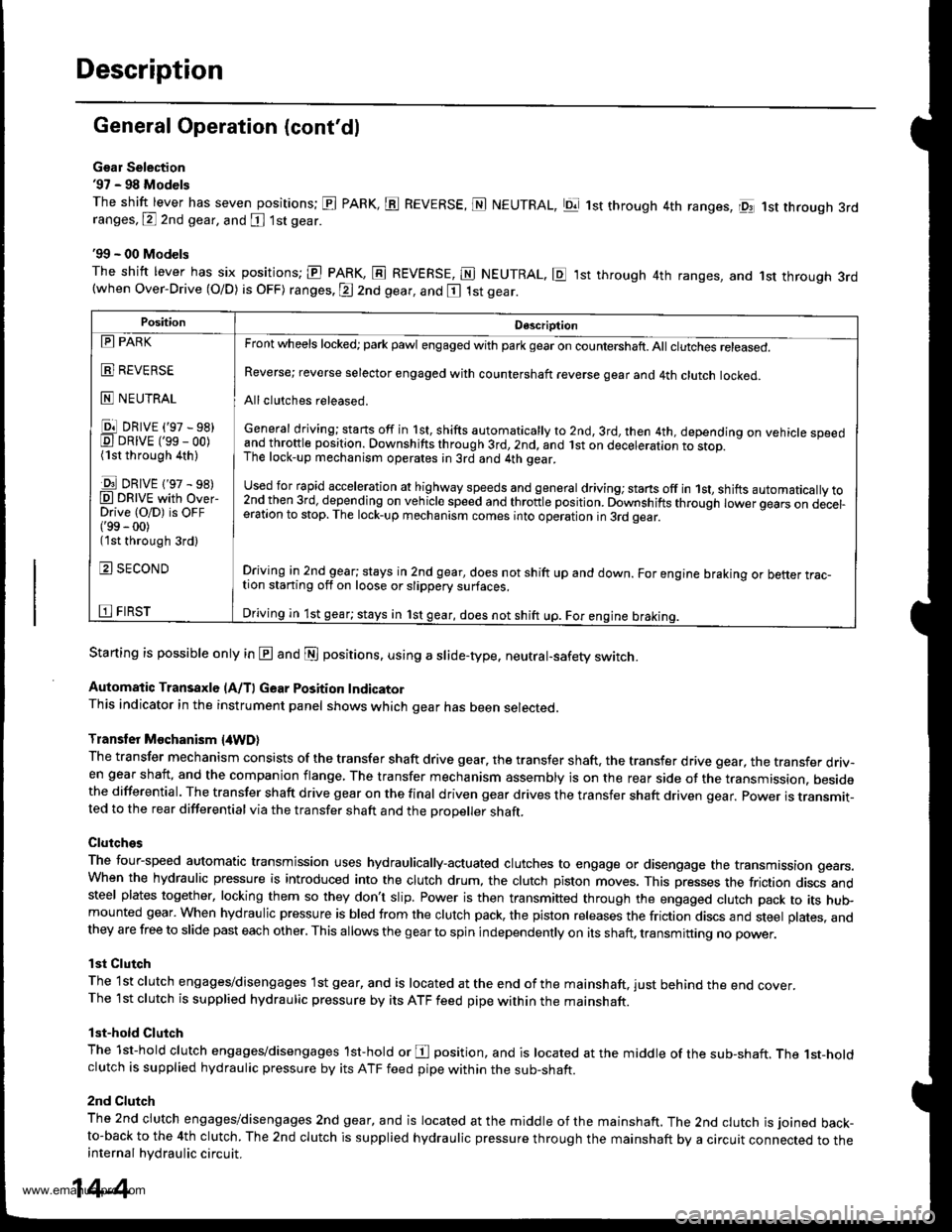

Gsar Selection'97 - 98 Models

The shift lever has seven positions; El PARK, ts REVERSE, N NEUTRAL, Ell 1st through 4th ranges, lpq 1st th.ough 3rdranges, P 2nd gear, and [ 1st gear

'99 - 00 Models

The shitt lever has six positions; El PARK, E REVERSE, E NEUTRAL. E ,lst through 4th ranges, and 1st through 3rd(when Over-Drive (O/D) is OFF) ranges. @ 2nd gear, and E 1st gear.

Starting is possible only in @ and @ positions. using a slide-type. neutral-safety switch.

Automatic Transaxle (A/T) Gear Position IndicatorThis indicator in the instrument panel shows which gear has been selected.

Transler Mochanism {4WD}

The transfer mechanism consists of the transfer shaft drive gear. the transfer shaft. the transfer drive gear, the transfer driv-en gear shaft, and the companion flange, The transfer mechanism assembly is on the rear side ot the transmission. besidethe differential. The transfer shaft drive gear on the final driven gear drives the transfer shaft driven qear. power is transmit-ted to the rear differential via the transfer shaft and the Drooeller shaft.

Clutches

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission gears.When the hydraulic pressure is introduced into the clutch drum, the clutch piston moves. This presses the friction discs andsteel plates together, locking them so they don't slip. Power is then transmifted through the engaged clutch pack to its hu$mounted gear. When hydraulic pressure is bled from the clutch pack, the piston releases the friction discs and steel plates, andthey are free to slide past each other. This allows the gearto spin independently on its shaft, transmitting no power.

lst Clutch

The 1st clutch engages/disengages lst gear, and is located at the end ofthe mainshaft, just behind the end cover.The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

lst-hold Clutch

The 1st-hold clutch engages/disengages 1st-hold or E position, and is located at the middle of the sub-shaft. The 1st-holdclutch is supplied hydraulic pressure by its ATF feed pipe within the sub-shaft.

2nd Clutch

The znd ciutch engages/disengages 2nd gear, and is located at the middle of the mainshaft. The 2nd clutch is joined back-to-back to the 4th clutch. The 2nd clutch is supplied hydraulic pressure through the mainshaft by a circuit connected to theinternal hydraulic circuit.

PositionDescription

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

Allclutches released.

General driving; starts off in 1st, shifts automatically to 2nd, 3rd, then 4th, depending on vehicle speedand throftle position. Downshifts through 3rd,2nd, and lst on deceleration to stop.The lock-up mechanism operates;n 3rd and 4th gear.

used for rapid €cceleration at highway speeds and general driving; stans off in 1st, shifts automatically to2nd_then 3rd, dejending on vehicle speed and throttle position. Downshifts through lower gears on decel-eration to stop. The lock-up mechanism comes into operation in 3rd gear.

Driving in 2nd_gear; stays in 2nd gear, does not shift up and down. For engine braking or better trac_tion starting off on loose or slippery surfaces.

Driving in 1st gear; stays in 1st gear, does not shift up. For engine braking.

tll PARK

t!!l l|EvEn>E

E NEUTRAL

Ell DRrvE ('97 - sB)E DRrvE ('ss - oo)(1st through 4th )

E DRrvE {'97 - s8)O DRTVE with over-Drive (O/D) is OFF('99 - 00)(1st through 3rd)

E SECOND

E FIRST

14-4

www.emanualpro.com

Page 521 of 1395

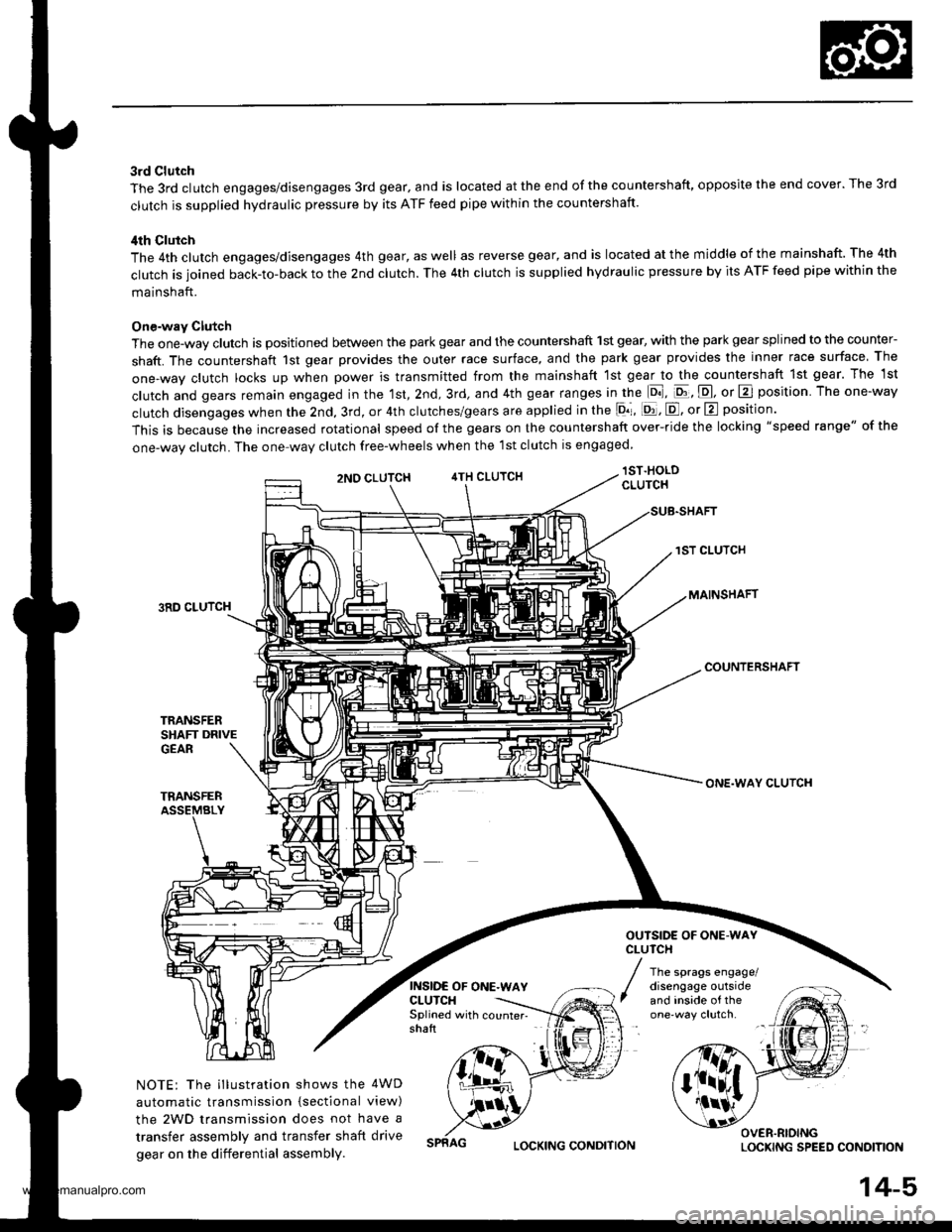

3rd Clutch

The 3rd clutch engages/disengages 3rd gear, and is located at the end of the countershaft, opposite the end cover. The 3rd

clutch is supplied hydraulic pressure by its ATF feed pipe within the countershaft.

ilth Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the middle of the mainshaft. The 4th

clutch is joined back-to-back to the 2nd clutch. The 4th clutch is supplied hydraulic pressure by its ATF feed pipe within the

mainshaft.

One-way Clutch

The one-way clutch is positioned between the park gear and the countershaft 1st gear, with the park gear splined to the counter-

shaft. The countershaft 1st gear provides the outer race surface, and the park gear provides the inner race surface The

one,way clutch locks up when power is transmitted from the mainshaft lst gear to the countershaft 1st gear. The 1st

clutch and gears remain engaged in the 1st, 2nd, 3rd, and 4th gear ranges in the lo], pt, E, or E position The one-way

clutch disengages when the 2nd, 3rd, or 4th clutches/gears are applied in the lor, [d, E, or E position'

This is because the increased rotational speed of the gears on the countershaft over-ride the locking "speed range" of the

one-wav clutch. The one-wav clutch free-wheels when the lst clutch is engaged

lST.HOLDCLUTCH

1ST CLUTCH

MAINSHAFT3RD CLUTCH

COUNTERSHAFT

TRANSFERSHAFT DRIVEGEAR

TRANSFERASSEMBLY

NOTE: The illustration shows the 4WD

automatic transmission {sectional view)

the 2WD transmission does not have a

transfer assembly and transfer shaft drive

gear on the differential assembly.

2NO CLUTCH4TH CLUTCH

INSIDE OF ONE.WAYCLUTCH

ONE.WAY CLUTCH

OUTSIDE OF ONE.WAYCLUTCH

The sprags engage/disengage outsideand inside of theSplined with counter- -

shaft

OVER.RIOINGLOCKING SPEED CONOITIONLOCKING CONDITION

14-5,

www.emanualpro.com

Page 555 of 1395

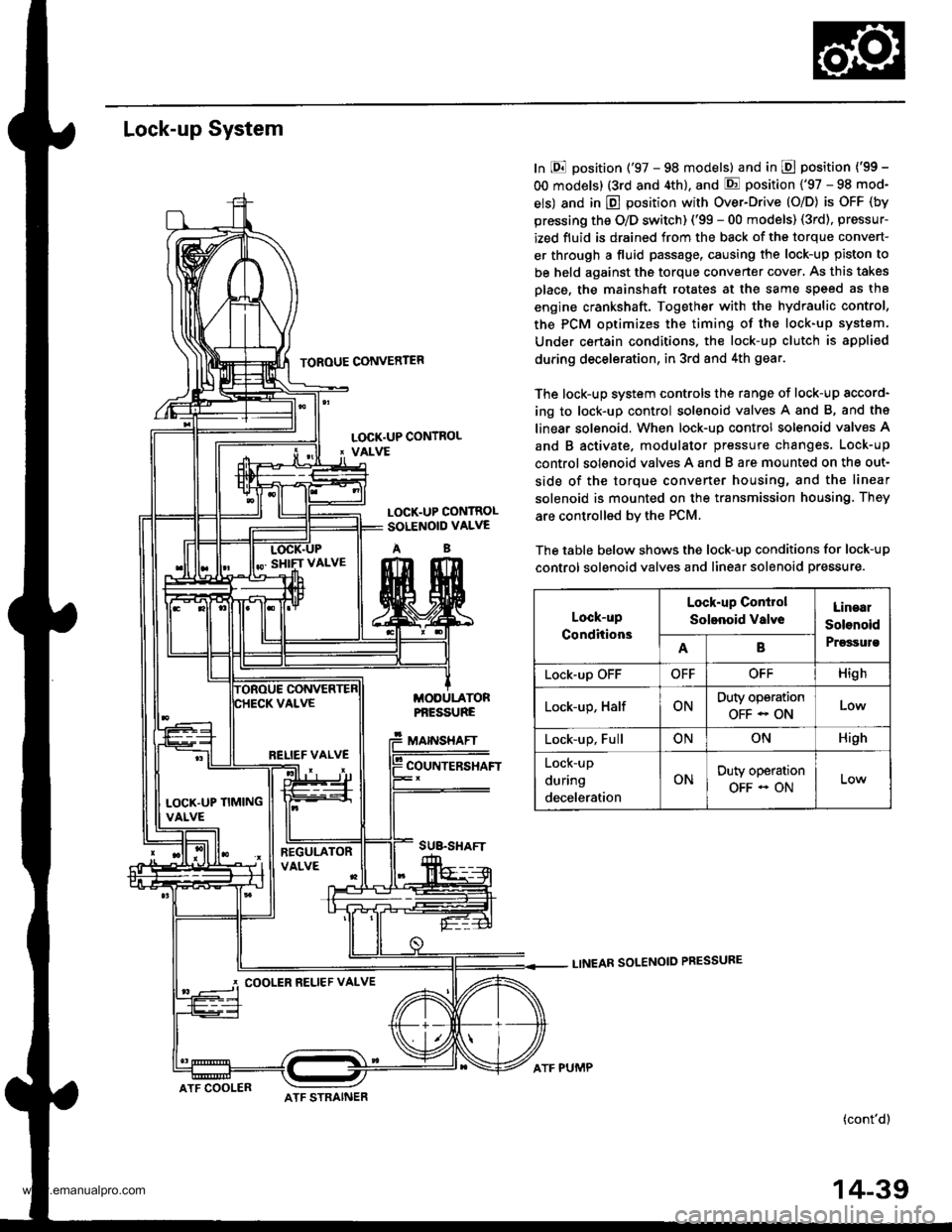

Lock-up System

TOROUE CONVERTER

In E position ('97 - 98 models) and in E position ('99 -

OO models) (3rd and 4th), and E position ('97 - 98 mod-

els) and in E position with Over-Drive (O/D) is OFF (by

pressing the O/D switch) ('99 - 00 models) (3rd), pressur-

ized fluid is drained from the back of the torque convert-

er through a fluid passage, causing the lock-up piston to

be held against the torque converter cover, As this takes

Dlace, the mainshaft rotates at the same speed as th8

engine crankshaft. Together with the hydraulic control,

the PCM optimizes the timing of the lock-up system.

Under certain condltions. the lock-up clutch is appli€d

during deceleration, in 3rd and 4th gear.

The lock-up system controls the range of lock-up sccord-

ing to lock-up control solenoid valves A and B, and ths

linear solenoid. When lock-up control solenoid valves A

and B activate. modulator pressure changes. Lock-up

control solenoid valves A and B are mounted on the out-

side of the torque converter housing, and the linear

solenoid is mounted on the transmission housing. They

are controlled bv the PCM.

The table below shows the lock-up conditions for lock-up

control solenoid valves and linear solenoid pressure.

LINEAR SOLENOID PRESSURE

(cont'd)

LOCK.UP CONTROL' VALVE

LOCK.UP CONTROLSOLENOID VALVE

AB

MODULATORPf,ESSURE

MAINSHAFT

COUNTERSHAFT

SUB.SHAFT

Lock-up

Conditions

Lock-up Conirol

Solenoid valveLinaal

Solenoid

PrgssulsAB

Lock-up OFFOFFOFFHigh

Lock-up, HalfONDuty operation

OFF - ONLow

Lock-up, FullONONHigh

Lock-up

during

deceleration

ONDuty operation

OFF - ON

RELIEF VALVE

LOCK'UP TIMINGVALVE

COOLER RELIEF VALVE

ATF COOLERATF STRAINER

ATF PUMP

14-39

www.emanualpro.com

Page 558 of 1395

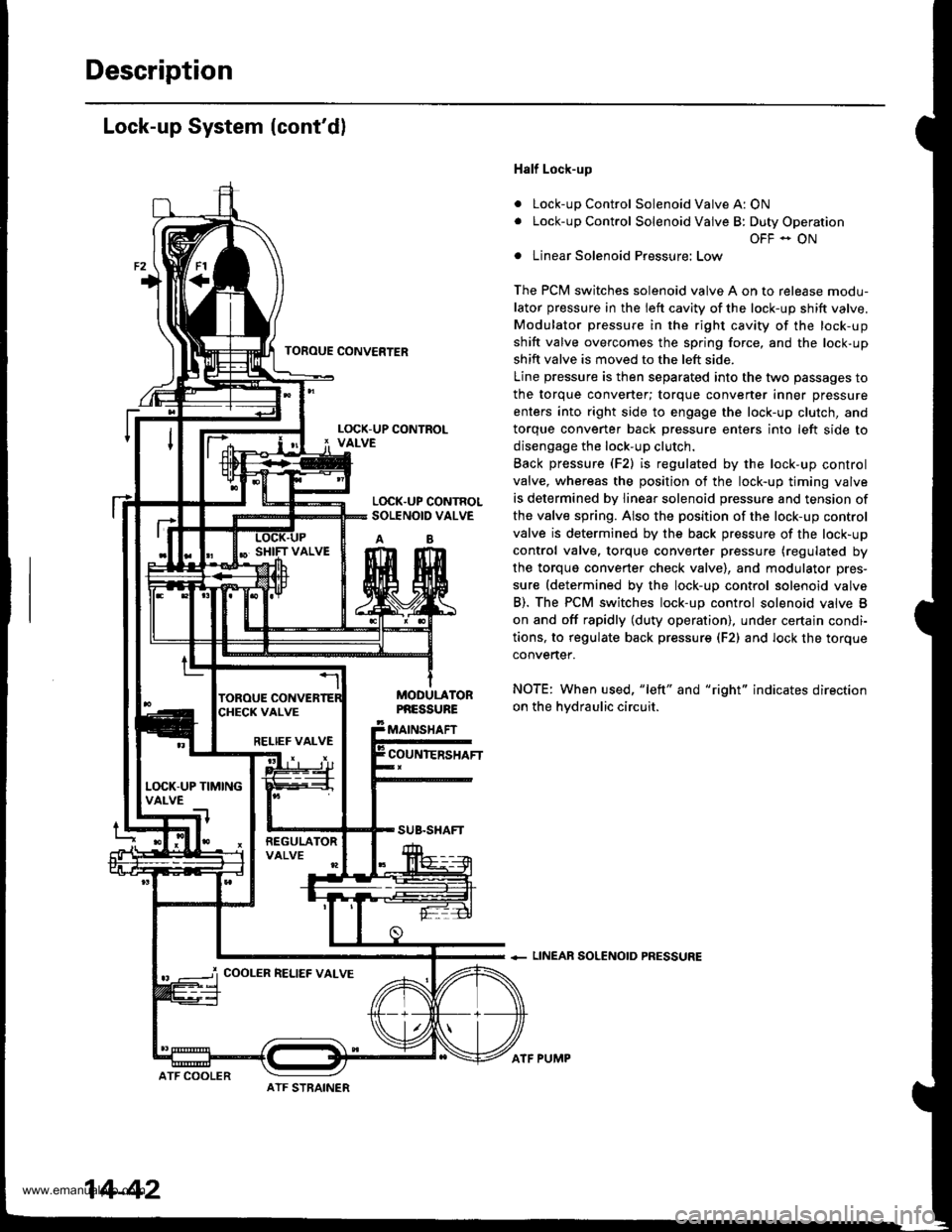

Description

Lock-up System (cont'dl

a

a

Half Lock-up

Lock-up Control Solenoid Valve A: ON

Lock-up Control Solenoid Valve B: Duty Operation

OFF - ON

Linear Solenoid Pressure: Low

The PCM switches solenoid valve A on to release modu-

lator pressure in the left cavity of the lock-up shift valve.

Modulator pressure in the right cavity of the lock-up

shift valve overcomes the spring force, and the lock-up

shift valve is moved to the left side.

Line pressure is then separated into the two passages to

the torque converter; torque converter inner pressure

enters into right side to engage the lock-up clutch, and

torque convener back Dressure enters into left side to

disengage the lock-up clutch.

Back pressure (F2) is regulated by the lock-up control

valve, whereas the position of the lock-up timing valve

is determined by linear solenoid pressure and tension of

the valve spring. Also the position of the lock-up control

valve is determined by the back pressure of the lock-up

control valve. torque converter pressure (regulated by

the torque converter check valve), and modulator pres-

sure (determined by the lock-up control solenoid valve

B). The PCM switches lock-up control solenoid valve B

on and off rapidly (duty operation), under certajn condi-

tions, to regulate back pressur€ (F2) and lock the torque

convertef.

NOTE: When used, "left" and "right" indicates direction

on the hvdraulic circuit.

+ LINEAR SOLENOID PRESSURE

TOFOUE CONVERTER

L(rcK.UP CONTROLSOLENOID VALVE

AB

MODULATORPNESSURE

MAINSHAFT

COUNIERSHAFTRELIEF VALVE

L(rcK-UP TIMINGVALVE

COOLER RELIEF VALVE

ATF STRAINER

14-42

ATF COOLER

ATF PUMP

www.emanualpro.com

Page 559 of 1395

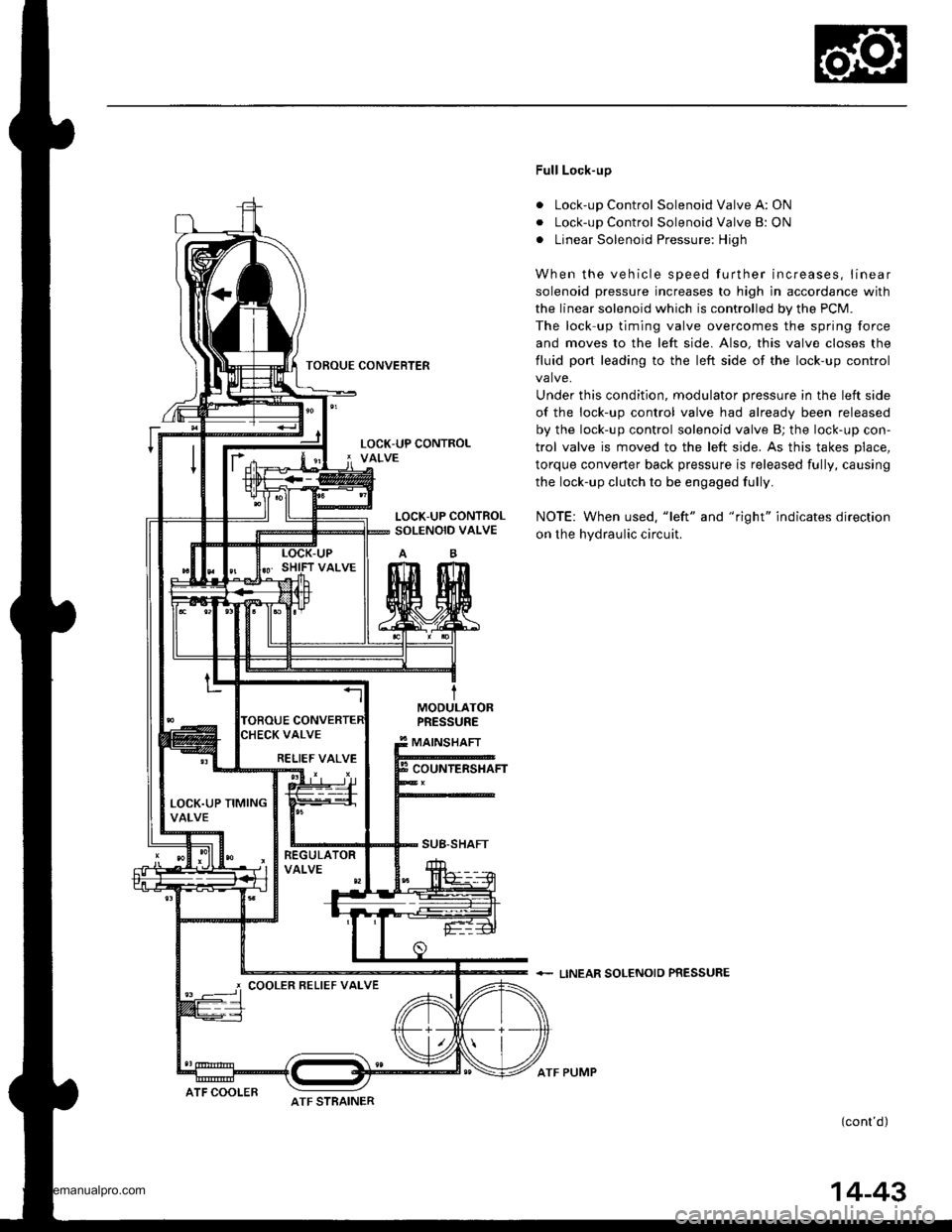

TOROUE CONVEFTER

Full Lock-up

. Lock-up Control Solenoid Valve A: ON

. Lock-up Control Solenoid Valve B: ON

. Linear Solenoid Pressure: High

When the vehicle speed further increases, linear

solenoid pressure increases to high in accordance with

the linear solenoid which is controlled by the PCM.

The lock up timing valve overcomes the spring force

and moves to the left side. Also, this valve closes the

fluid port leading to the left side of the lock-up control

valve.

Under this condition, modulator pressure in the left side

of the lock-up control valve had already been released

by the lock-up control solenoid valve B; the lock-up con-

trol valve is moved to the left side. As this takes place,

torque converter back pressure is released fully, causing

the lock-up clutch to be engaged fully.

NOTE: When used. "left" and "right" indicates direction

on the hydraulic circuit.

+ LINEAR SOLENOIO PRESSURE

(cont'd)

LOCK-UP CONTROLSOLENOID VALVE

MODULATORPRESSURE

MAINSHAFT

COUNTERSHAFT

SUB-SHAFT

RELIEF VALVE

LOCK.UP TIMINGVALVE

COOLER BELIEF VALVE

ATF STRAINERATF COOLER

ATF PUMP

14-43

www.emanualpro.com

Page 565 of 1395

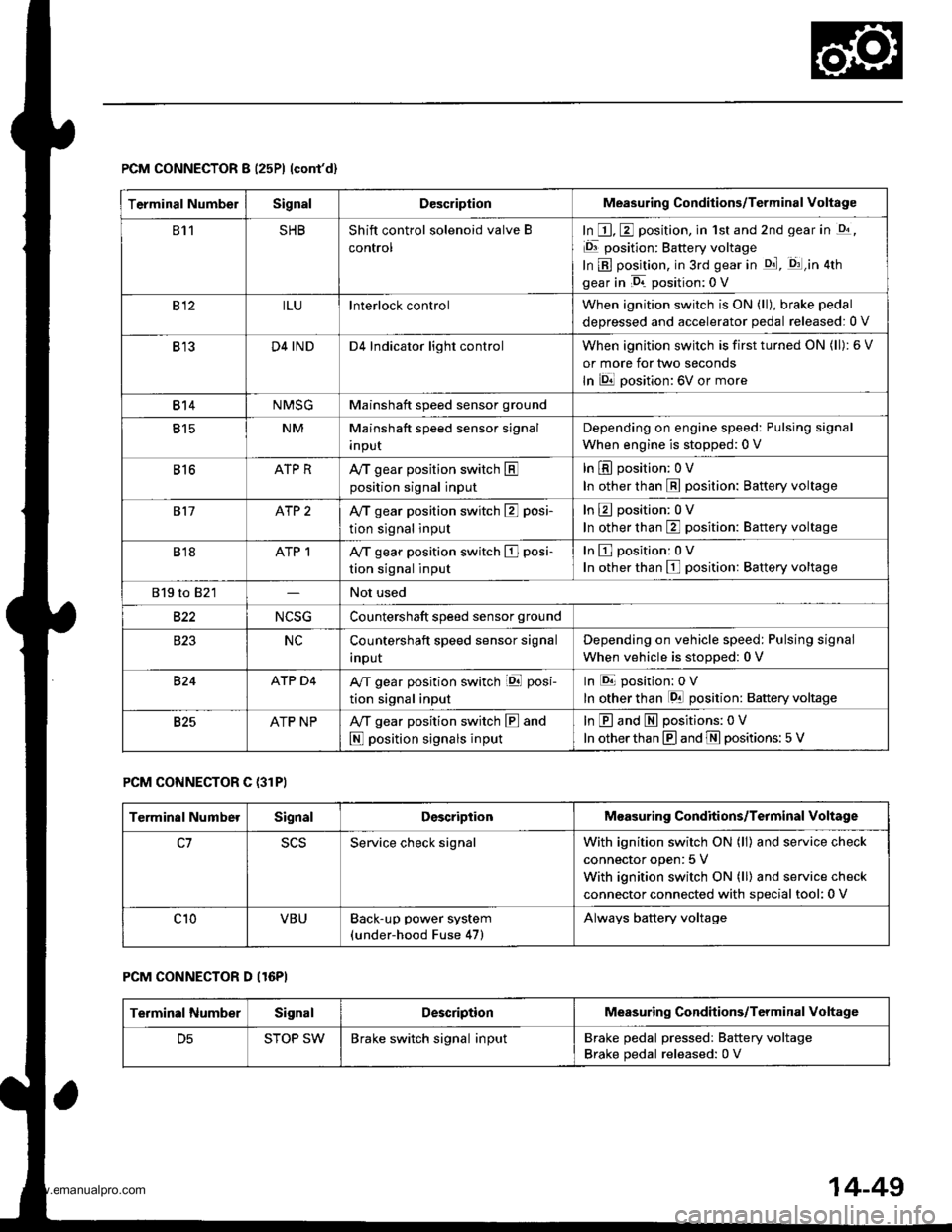

PCM CONNECTOR B (25P) lcont'd)

PCM CONNECTOR C {31PI

PCM CONNECTOR D II6PI

Terminal NumbelSignalDescriptionMeasuring Conditions/Terminal voltage

811SHBShift control solenoid valve B

control

In E, E position, in 1st and 2nd gear in -q,

Er position: Battery voltage

In B position, in 3rd gear in qd, q:l,in atn

gear in D. position: 0 V

812ILUlnterlock controlWhen ignition switch is ON (ll), brake pedal

deDressed and accelerator oedal released:0 V

B13D4 INDD4 Indicator light controlWhen ignition switch is first turned ON (ll): 6 V

or more for tlvo seconds

In lDll position: 6V or more

814NMSGMainshaft speed sensor ground

815NMMainshaft speed sensor signal

InpuI

Depending on engine speed: Pulsing signal

When engine is stopped: 0 V

816ATP RAy'T gear position switch Eposition signal input

In E position; OV

In other than E position: Battery voltage

817ATP 2Ay'T gear position switch E posi-

tion signal input

InEposition:0V

In other than E position: Battery voltage

B18ATP 1A/T gear position switch El posi-

tion signal input

InEposition:0V

In other than E position: Battery voltage

819 to 821Not used

B�22NCSGCountershaft speed sensor ground

NCCountershaft speed sensor signal

Inpur

Depending on vehicle speed: Pulsing signal

when vehicle is stooped: 0 V

824ATP D4A/T gear position switch iql posi-

tion signal input

In E position: 0V

In other than lgal position: Baftery voltage

825ATP NPAy'T gear position switch E and

N position signals input

In E and E positions: 0V

In otherthan @ and ffi positions:5 V

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

SCSService check signalWith ignition switch ON (ll) and service check

connector open: 5 V

With ignition switch ON (ll) and service check

connector connected with special tool: 0 V

c10VBUBack-up power system(under-hood Fuse 47)

Always battery voltage

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

STOP SWBrake switch signal inputBrake pedal pressedr Battery voltage

Brake pedal released: 0 V

14-49

www.emanualpro.com

Page 570 of 1395

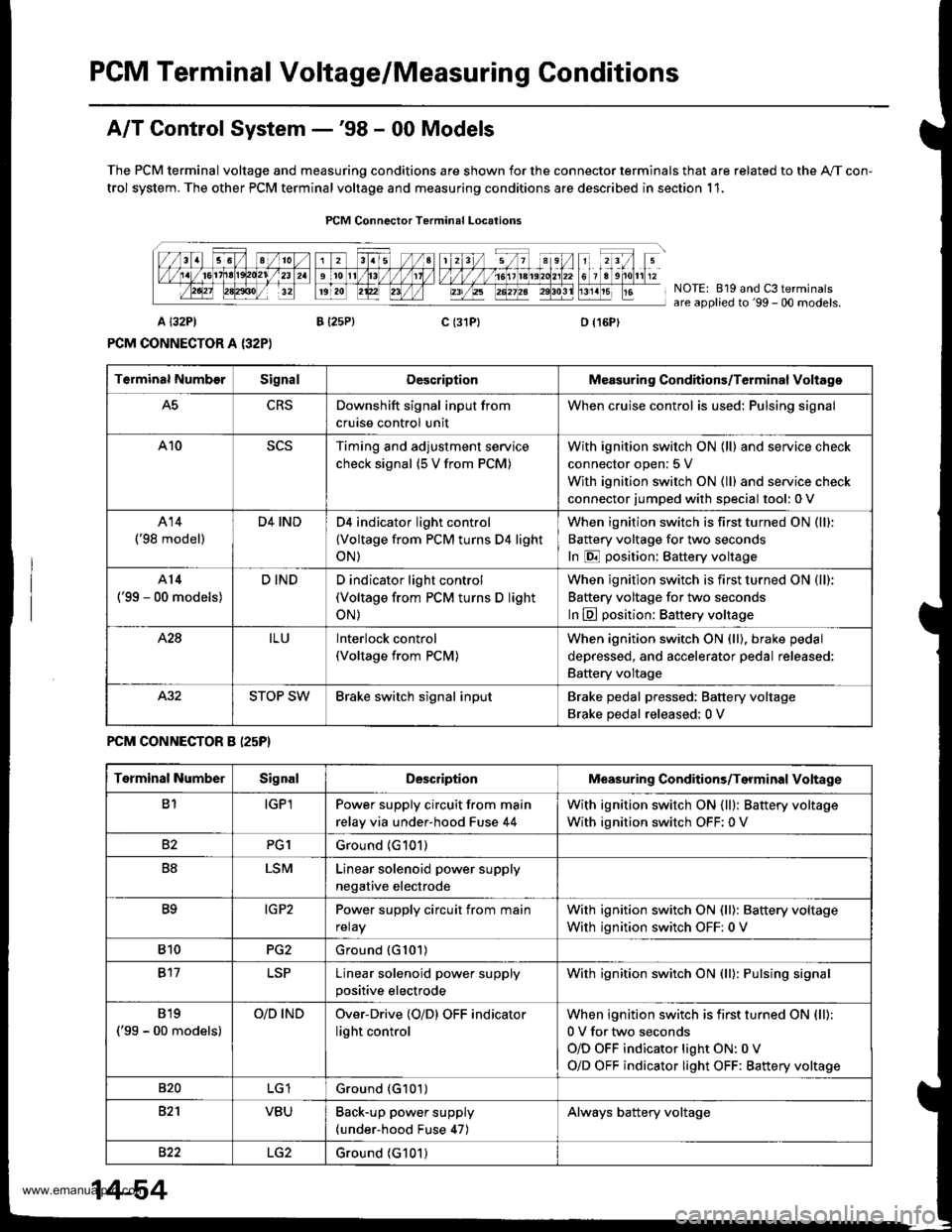

PCM Terminal Voltage/Measuring Conditions

A/T Control System -'98 - 00 Models

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A"/T con-

trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

FCM Connector Terminal Localions

NOTE: 819 and C3 terminalsare applied to'99 - 00 models.

o (16Pt

T6rminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

A5CRSDownshift signal input from

cruise control unit

When cruise control is used; Pulsing signal

A10scsTiming and adjustment service

check signal (5 V from PCM)

With ignition switch ON (ll) and service check

connector open:5 V

With ignition switch ON (ll) and service check

connector jumped with special tool: 0 V

A14('98 model)

D4 INDD4 indicator light control

{Voltage from PCM turns D4 light

oN)

When ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Battery voltage

A14

('99 - 00 models)

D INDD indicator light control(Voltage from PCM turns D light

oN)

When ignition switch is first turned ON (ll):

Baftery voltage for two seconds

ln E position: Battery voltage

428ILUInterlock control(Voltage from PCM)

When ignition switch ON {ll), brake pedal

depressed, and accelerator pedal released:

Battery voltage

A.32STOP SWBrake switch signal inputBrake pedal pressed; Battery voltage

Brake pedal released: 0 V

FCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

B1IGPlPower supply circuit from main

relay via under-hood Fuse 44

With ignition switch ON {ll): Battery voltage

With ignition switch OFF: 0 V

82PG1Ground (G101)

B8LSMLinear solenoid power supply

negative electrode

IG P2Power supply circuit from main

relay

With ignition switch ON (ll): Baftery voltage

With ignition switch OFF: 0 V

810PG2Ground (G101)

B17Linear solenoid power supply

positive electrode

With ignition switch ON (ll): Pulsing signal

819

('99 - 00 models)

O/D INDOver-Drive (O/D) OFF indicator

light control

When ignition switch is first turned ON (ll):

0 V for two seconds

O/D OFF indicator light ON:0 V

O/D OFF indicator light OFF: Battery voltage

s20Ground (G101)

B�21VBUBack-up power supply(under-hood Fuse 47)

Always battery voltage

B�22LG2Ground (G101)

14-54

www.emanualpro.com