spring HONDA CR-V 1998 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 503 of 1395

Mainshaft Thrust Clearance

Adjustment

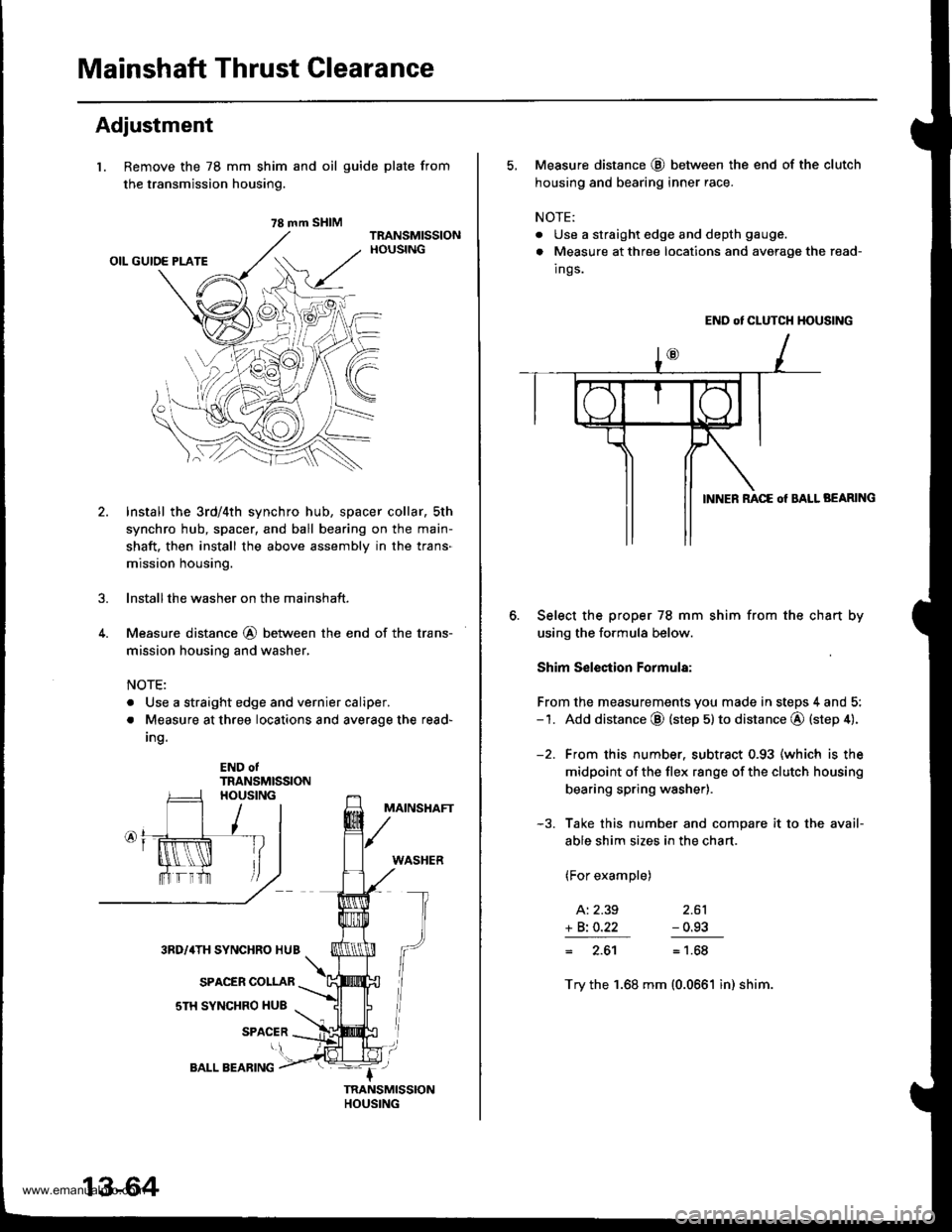

l. Remove the 78 mm shim

the transmission housing.

4.

and oil guide plate from

Install the 3rd/4th synchro hub, spacer collar, sth

synchro hub, spacer, and ball bearing on the main-

shaft. then install the above assembly in the trans-

mission housing.

lnstallthe washer on the mainshaft.

Measure distance @ between the end of the trans-

mission housing and washer,

NOTE:

. Use a straight edge and vernier caliper.

. Measure at three locations and average the read-

Ing.

END otTRANSMISSION

MAINSHAFT

WASHER

3RD/4TH SYNCHRO HUB

SPACER COLLAR

sTH SYNCHRO HUB

SPACER

78 mm SHIM

13-64

BALL BEARING

5, Measure distance @ between the end of the clutch

housing and bearing inner race.

NOTE:

. Use a straight edge and depth gauge.

. Measure at three locations and avorage the read-

Ings.

END ot CLUTCH HOUSING

BEARING

Select the proper 78 mm shim from the chan by

using the formula below.

Shim S€lection Formula:

From the measurements you made in steps 4 and 5:-1. Add distance @ (step 5) to distance @ (step 4).

-2. From this number. subtract 0.93 (which is the

midpoint of the flex range of the clutch housing

bearing spring washer).

-3. Take this number and compare it to the avail-

able shim sizes in the chart.

(For example)

A: 2.39 2.61

+ Bi O.22 - 0.93

= 2.61= 1.68

Try the 1.68 mm (0.0661 in) shim.

www.emanualpro.com

Page 504 of 1395

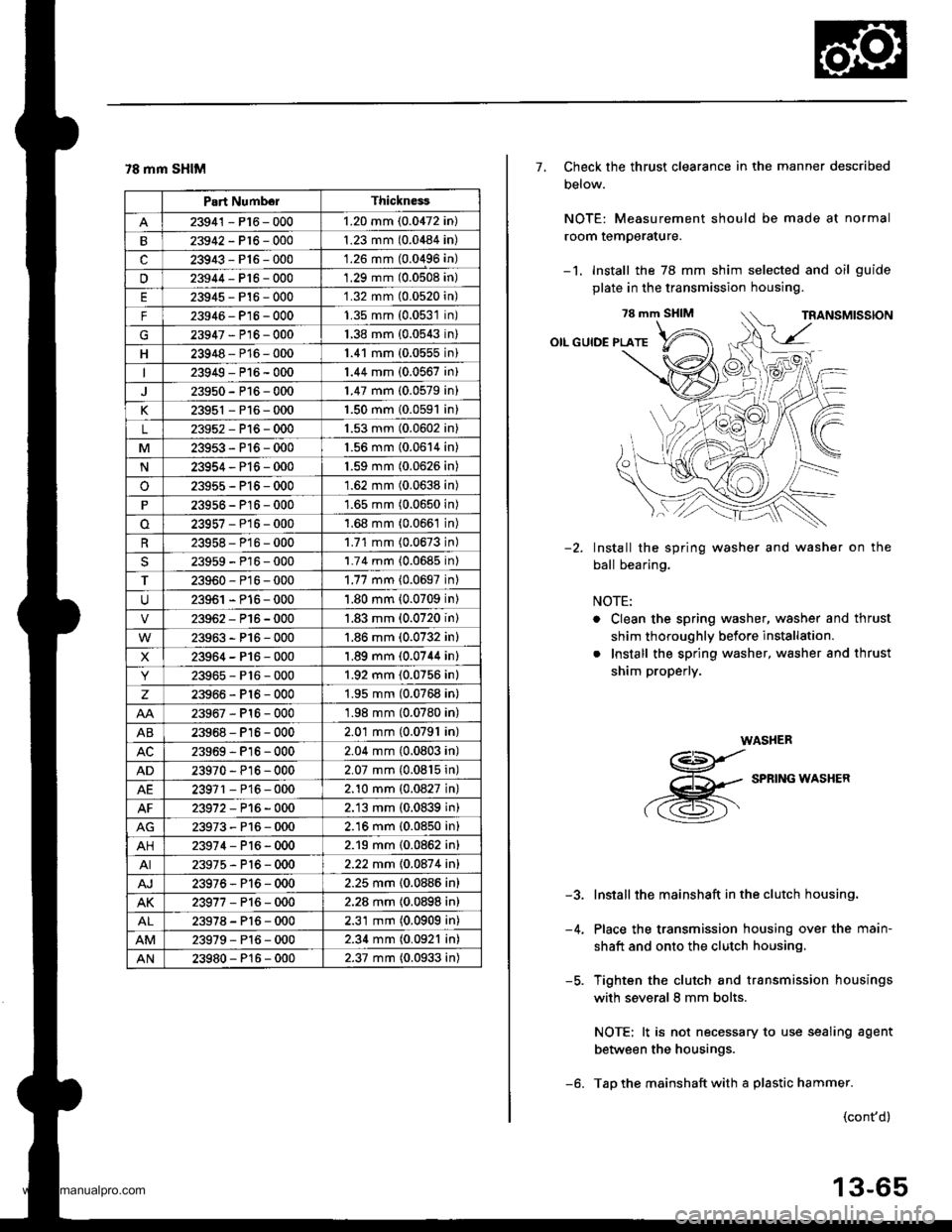

78 mm SHIM

Part NumborThickness

23941 - P16 - 0001.20 mm (0.0472 in)

23942-P16-0001.23 mm (0.0484 in)

c23943-P16-000'1.26 mm (0.0496 in)

u23944-Pt6-0001.29 mm (0.0508 in)

23945-P16-0001.32 mm (0.0520n)

F23946- P16 - 0001.35 mm (0.0531n)

G23947-P16-0001.38 mm {0.0543n)

H23948-P16-0001.41 mm (0.0555n)

23949-P16-0001.44 mm (0.0567 in)

23950-P16-0001.47 mm (0.0579 in)

K23951 - P16 - 0001.50 mm {0.0591 in}

L23952-Pl6-0001.53 mm (0.0602 in)

M23953-P16-0001.56 mm (0.0614 in)

N23954-P16-0001.59 mm (0.0626 in)

o23955-P15-0001.62 mm (0.0638 in)

23956 - P16 - 0001.65 mm (0.0650 in)

23957-P16-0001.68 mm (0.066't in)

23958- P16 - 0001.71 mm (0.0673 in)

23959-P16-0001.74 mm {0.0685 in)

T23960-P16-0001.77 mm {0.0697 inl

23961 - P16 - 0001.80 mm (0.0709 in)

23962-P16-0001.83 mm (0.0720 in)

23963-P16-000'1.86 mm (0.0732 in)

X23964-P16-0001.89 mm (0.0744 in)

23965-P16-0001.92 mm (0.0756 in)

z23966-Pl6-0001.95 mm (0.0768 in)

23967-Pl6-0001.98 mm (0.0780 in)

AB23968-P16-0002.01 mm (0.0791 in)

23969-Pl6-0002.04 mm (0.0803 in)

AD23970 - Pl6-0002.07 mm {0.0815 in)

AE23971 - P16 - 0002.10 mm {0.0827 in}

23972-P16-0002.13 mm (0.0839 in)

23973-P16-0002.16 mm (0.0850 in)

AH23974-P16-0002.19 mm (0.0862 in)

AI23975-P16-0002.22 mm 10.087 4 inl

AJ23976-Pl6-0002.25 mm {0.0886 in}

AK23977-P16-0002.28 mm {0.0898 in)

23978-Pl6-0002.31 mm (0.0909 in)

23979-Pl6-0002.34 mm (0.0921 in)

AN23980-P16-0002.37 mm (0.0933 in)

7, Check the thrust clearance in the manner described

Delow.

NOTE: Measurement should be made at normal

room temperature.

-1. Install the 78 mm shim selected and oil guide

plate in the transmission housing.

78 mm SHIM

OIL GUIDE PLATE

Install the spring washer and washer on the

ball bearing.

NOTE:

. Clean the spring washer, washer and thrust

shim thoroughly before installation.

. Install the spring washer, washer and thrust

shim properly.

WASHER

g

,-g

SPRTNG*ASHER

Install the mainshaft in the clutch housing.

Place the transmission housing over the main-

shaft and onto the clutch housing.

Tighten the clutch and transmission housings

with several 8 mm bolts.

NOTE: lt is not necessary to use sealing agent

between the housings.

Tap the mainshaft with a plastic hammer.

-2.

-5.

(cont'd)

13-65

www.emanualpro.com

Page 506 of 1395

Transmission Assembly

Reassembly

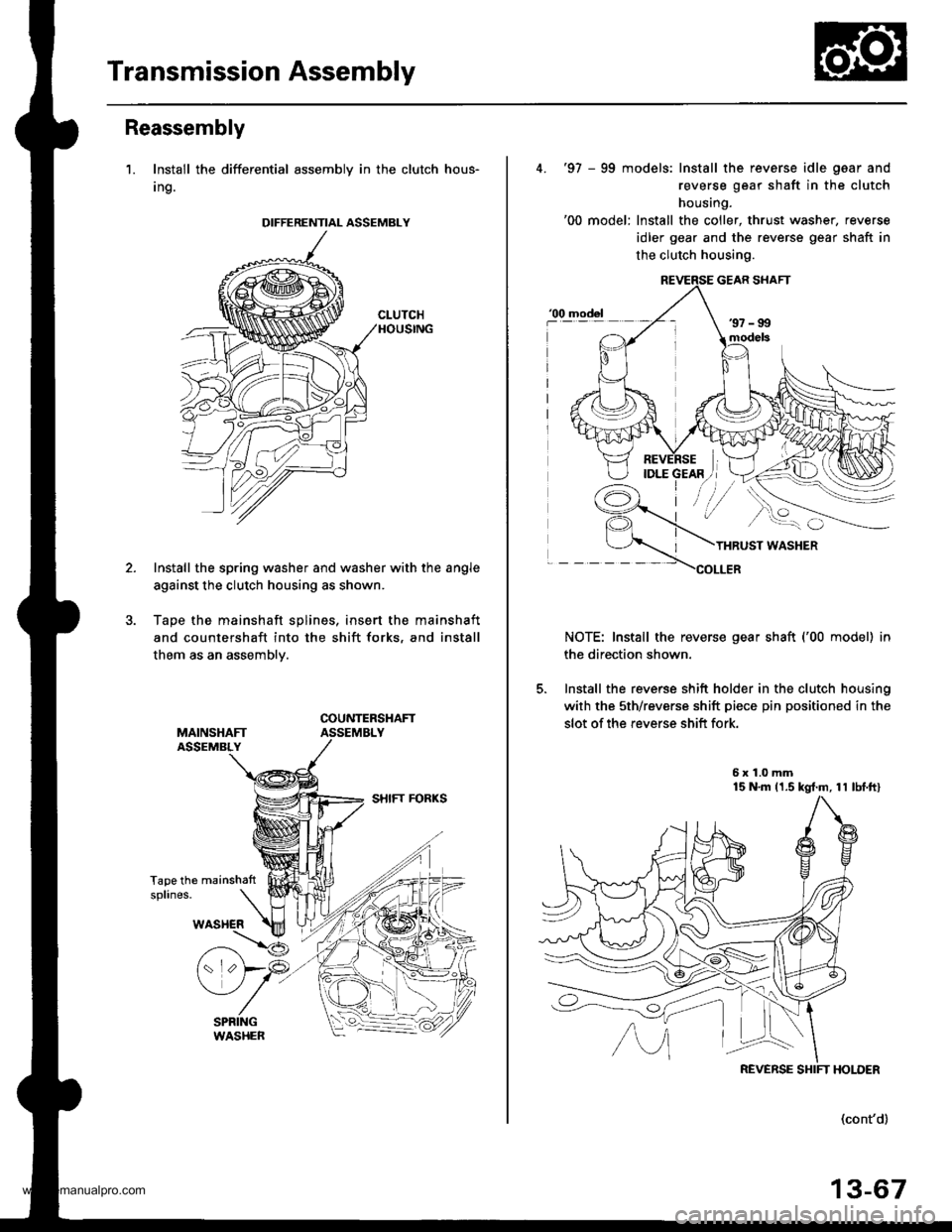

1. Install the differential assembly in the clutch hous-

Ing.

Install the spring washer and washer with the angle

against the clutch housing as shown.

Tape the mainshaft splines. insert the mainshaft

and countershaft into the shift forks, and install

them as an assemblv.

Tape the mainshattsplines.

DIFFERENTIAL ASSEMBLY

4. '97 - 99 models: Install the reverse idle gaar and

reverse gear shaft in the clutch

housing.'00 model: Install the coller, thrust washer, reverse

idler gear and the reverse gear shaft in

the clutch housing.

THRUST WASHER

COLLER

NOTE: Install the reverse gear shaft ('00 model) in

the direction shown.

5. Install the reverse shift holder in the clutch housing

with the sth/reverse shift piece pin positioned in the

slot of the reverse shift fork.

5x1.0mm15 N'm 11.5 kgt.m, 11 lbf.ftl

model

REVERSE SHIFT HOLDER

(cont'd)

13-67

www.emanualpro.com

Page 507 of 1395

Transmission Assembly

Reassembly (cont'dl

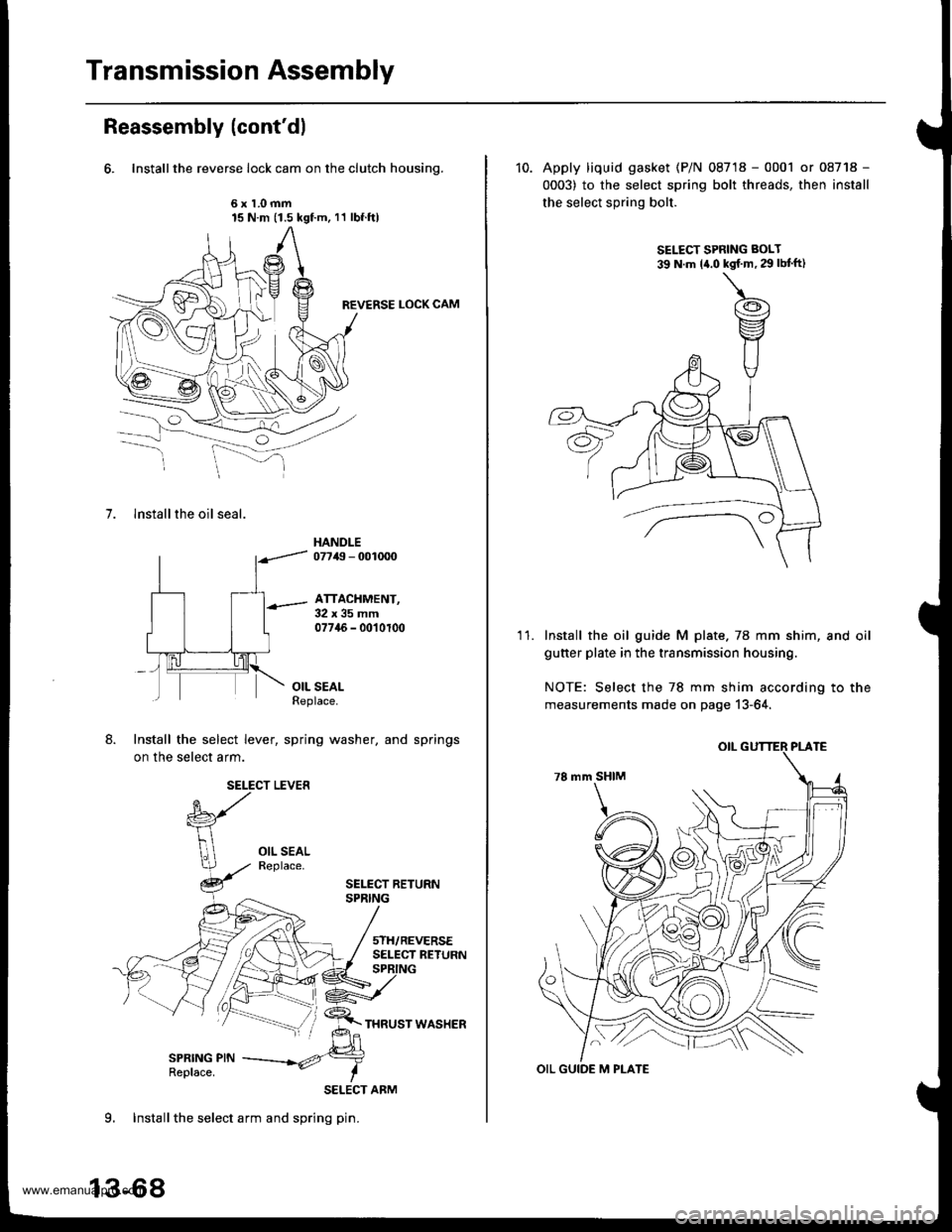

6. Installthe reverse lock cam on the clutch housing.

6x1.0mm15 N.m (1.5 kgf.m, 11 lbf.ftl

REVERSE LOCK CAM

7. lnstall the oil seal.

HANDLE07749 - 001mO

ATTACHMENT,32x35mm07745 - 0010100

OIL SEALReplace.

Install the select lever, spring washer, and springs

on the select arm.

SELECT LEVER

SELECT BETURNSPRING

5TH/REVERSESELECT RETURN

SPRING PINReplace.

SELECT ARM

9. Installthe select arm and spring pin.

13-68

10. Apply liquid gasket (P/N 08718 - 0001 or 08718 -

0003) to the select spring bolt threads, then install

the select spring bolt.

SELECT SPRING BOLT

39 N.m la.o kgf'm,29lbtft)

'I 1.Install the oil guide M plate.78 mm shim, and oil

guner plate in the transmission housing.

NOTE: Select the 78 mm shim according to the

measurements made on page 13-64,

OIL GUIDE M PLATE

www.emanualpro.com

Page 509 of 1395

Transmission Assembly

Reassembly lcont'd)

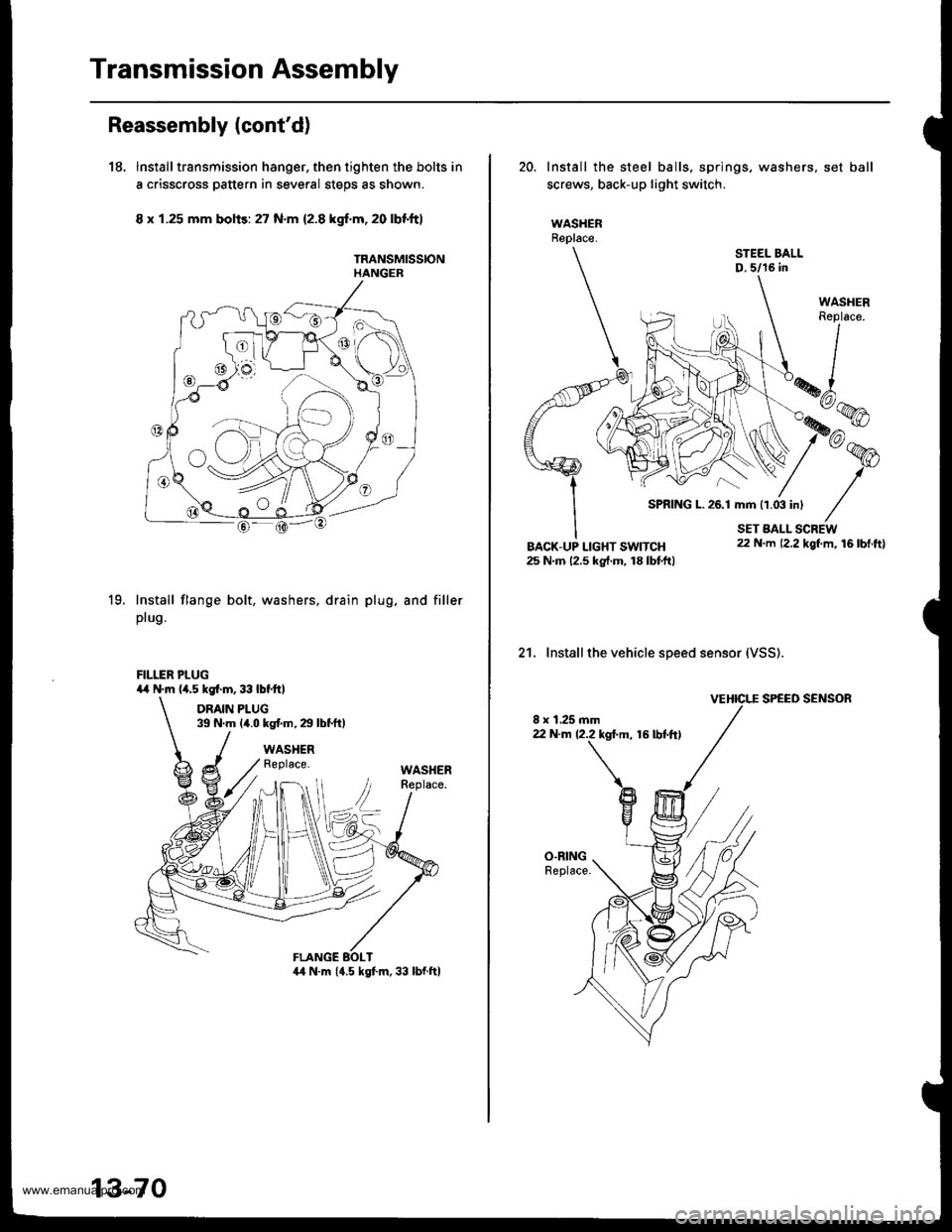

18. Installtransmission hanger, then tighten the bolts in

a crisscross pattern in several steps as shown.

8 x 1.25 mm bolis: 27 N.m 12.8 kgf.m,20 lbf'ft}

TRANSMISSIONHANGER

19.Install flange bolt,

plug.

washers, drain plug. and filler

FILLER PLUG4,r N.m (a.5 kgl.m,33lbtftl

DRAIN PLUG39 N.m {4.0 kg{.m,29lbtftl

WASHERReplace.WASHER

13-70

20. Install the steel balls, springs. washers, set ball

screws, back-up light switch.

WASHERReplace.

STEEL BALLD,5/16 in

21. Installthe vehicle speed sensor (VSS).

VEHICI."E SPEED SENSOR

8 x 1.25 mm22 N.m 12.2 kgl.m, 16 lbt.ftl

SPRING L.26.1 mm 11.03 inl

www.emanualpro.com

Page 517 of 1395

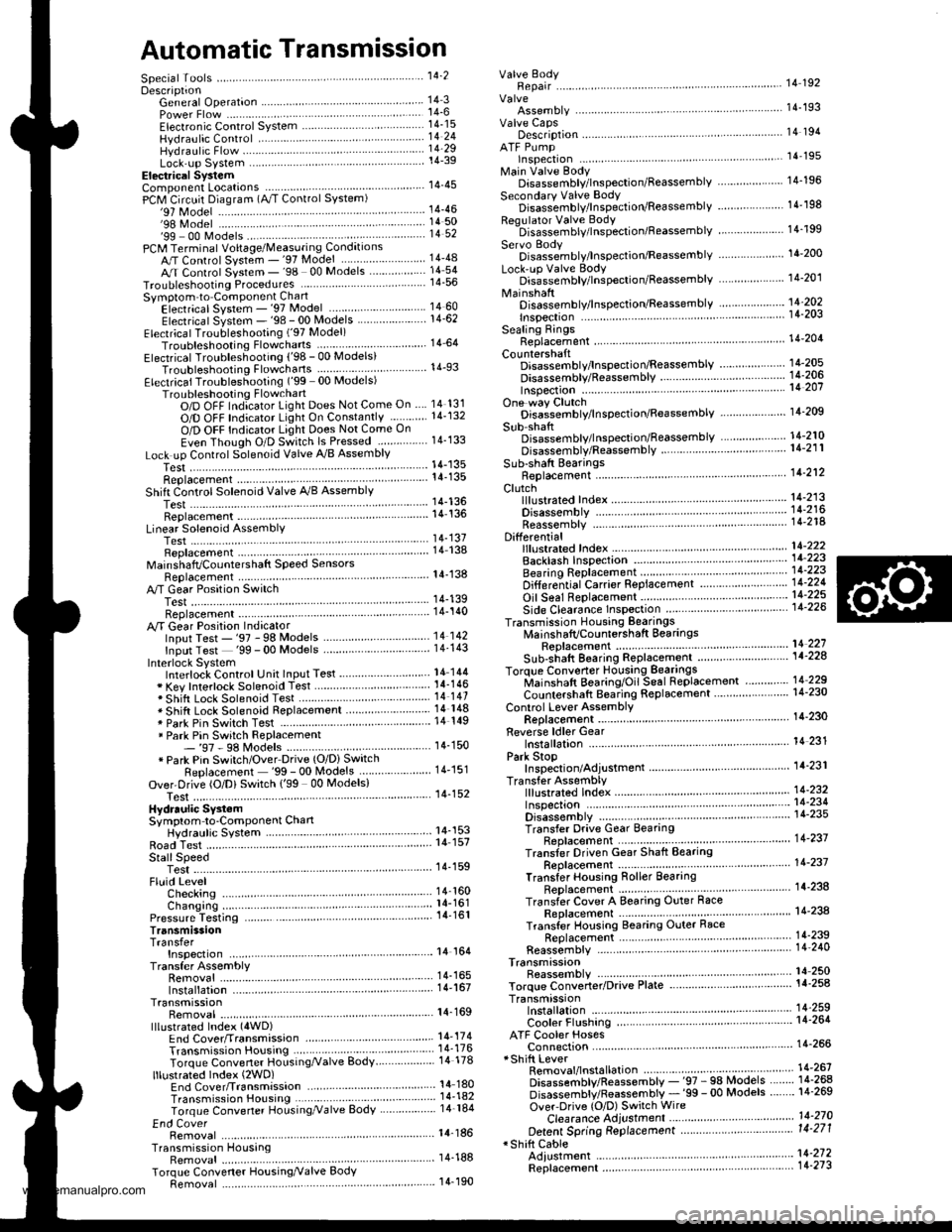

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 518 of 1395

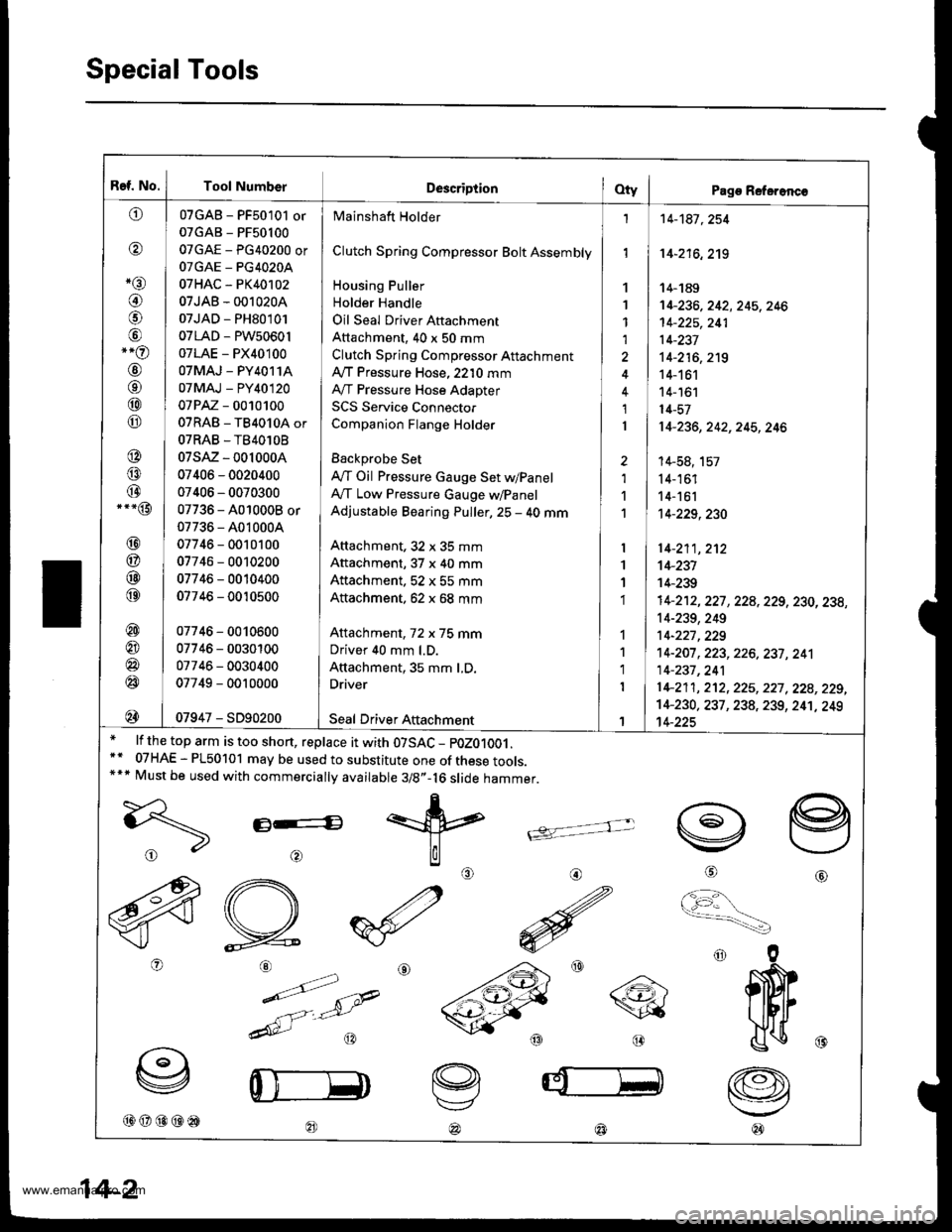

Ref. No.

^tl)

@

*rar

@

@

,-o

@

o

@

@

@

@

@.--@

@

@

@

@

@

@

@

@

@

Tool NumberDescriptionOty I Pago Referonc€

Mainshaft Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Holder Handle

Oil Seal Driver Aftachment

Attachment, 40 x 50 mm

Clutch Spring Compressor Attachment

Ay'T Pressure Hose, 2210 mm

IVT Pressure Hose Adapter

SCS Service Connector

Companion Flange Holder

Backprobe Set

lVT Oil Pressure Gauge Set w/Panel

A,/T Low Pressure Gauge w/Panel

Adjustable Bearing Puller, 25 - 40 mm

Anachment, 32 x 35 mm

Attachment, 37 x 40 mm

Attachment. 52 x 55 mm

Attachment. 62 x 68 mm

Attachment, 72 x 75 mm

Driver 40 mm l.D.

Attachment, 35 mm LD.

Driver

07GAB - PF50101 or

07GAB - PF50100

07GAE - PG40200 or

OTGAE _ PG4O2OA

07HAC - PK40102

07JAB - 001020A

07JAD - PH80101

07LAD - PW50601

07LAE - PX40100

OTMAJ - PY4O114

07MAJ - PY40120

07 PAZ - 0010100

07RAB - TB4010A or

07RAB.TB40lOB

07sAz - 001000A

07406 - 0020400

07406 - 0070300

07736 - 4010008 or

07736 - A010004

07746 - 0010100

07746 - 0010200

07746 - 0010400

07746 - 0010500

07746 - 0010600

07746 - 0030100

07746 - 0030400

07749 - 0010000

07947 - SD90200Seal Driver Aftachment

1

1

1

1,l

1

I

2

1'l

1

I

1

1

1

1

1

1

I

1

14-181 , 254

14-216,219

14-189't4-236,242,245,246

't 4-225, 241

14-237

14-216,2't9

14-161

14- 161

14-57

14-236,242,245,246

14-58, 157

14-161

14-161'14-229,230

14-211, 2't2

14-231

14-239

14-212, 227 , 228,229, 230, 238,

14-239, 249

14-221 ,229't 4-207 , 223,226, 237 , 241

14-237,241

1 +21 1, 2't2, 225, 227, 228, 229,

14-230, 237 , 238, 239, 24't, 249't4-225

lf the top arm is too short, replace it with 07SAC - pOZ01OO1.

07HAE - PL50101 may be used to substitute one of these tools.Must be used with commercially available 3/8"-16 slide hammer.

E----G

@@@@@

@

tvj

'

@@@)

14-2

www.emanualpro.com

Page 543 of 1395

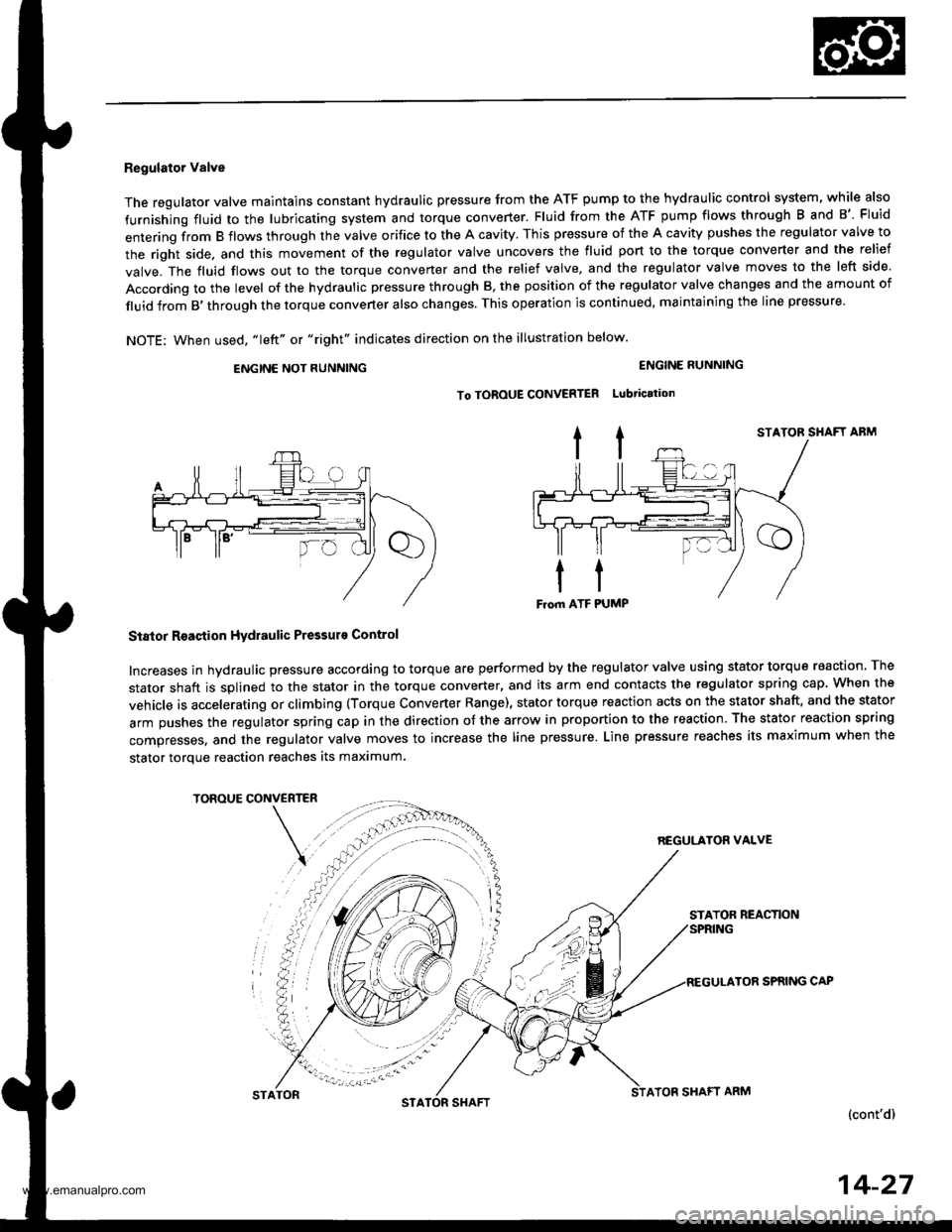

Regulator Valve

The regulator valve maintains constant hydraulic pressure from the ATF pump to the hydraullc control system, while also

furnishing fluid to the lubricating system and torque converter. Fluid from the ATF pump flows through B and B'. Fluid

entering from B flows through the valve orifice to the A cavity. This pressure of the A cavity pushes the regulator valve to

the right side. and this movement of the regulator valve uncovers the fluid port to the torque converter and the relief

valve. The fluid flows out to the torque converter and the relief valve, and the regulator valve moves to the left side.

According to the level of the hydraulic pressure through B, the position of the regulator valve changes and the amount of

fluid from B,through the torque converter also changes. This operation is continued, maintaining the line pressure.

NOTE; When used, "|eft" or "right" indicates direction on the illustration below.

ENGINE NOT RUNNING

STATOR SHAFT ABM

Stator Reaction Hydraulic Pressurs Control

Increases in hydraulic pressure according to torque are performed by the regulator valve using stator torque reaction. The

stator shaft is splined to the stator in the torque converter, and its arm end contacts the regulator spring cap When the

vehicle is accelerating or climbing (Torque Converter Range), stator torque reaction acts on the stator shaft, and the stator

arm pushes the regulator spring cap in the direction of the arrow in proportion to the reaction. The stator reaction spring

compresses, and the regulator valve moves to increase the line pressure. Line pressure reaches its maximum when the

stator torque reaction reaches its maximum.

TOROUE CONVERTER

REGULATON VALVE

STATOR REACTION

TOR SPRING CAP

(cont'd)

ENGINE RUNNING

To TOROUE CONVERTER Lubtication

STATONSTASHAFTATOF SHAFT ARM

14-27

www.emanualpro.com

Page 552 of 1395

Description

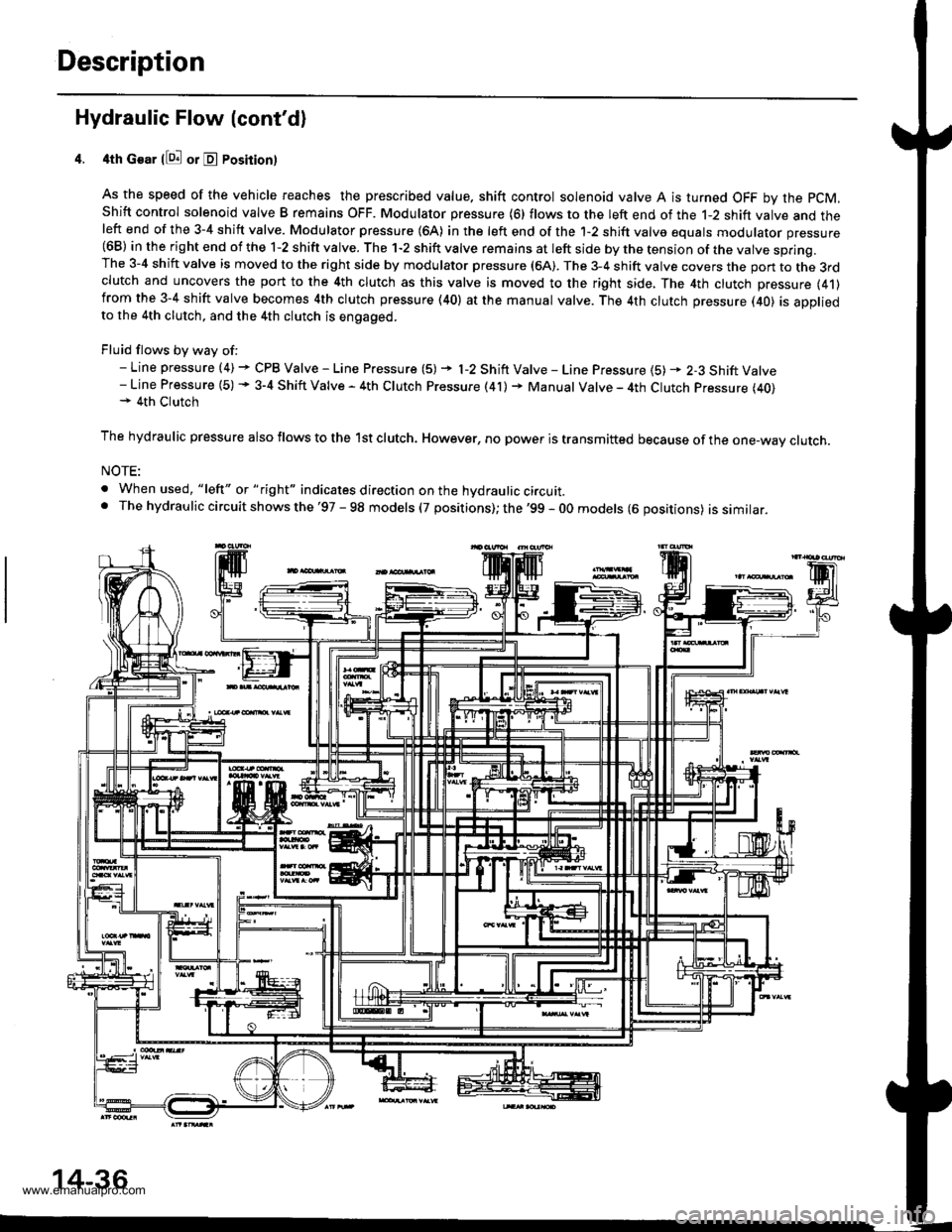

Hydraulic Flow (cont'd)

4th Gear llQ! or E Posirion)

As the speed of the vehicle reaches the prescribed value. shift control solenoid valve A is turned OFF by the pCM,

Shift control solenoid valve B remains OFF. Modulator pressure (6) flows to the left end of the 1-2 shift valve and theleft end of the 3-4 shift valve. Modulator pressure (64) in the left end of the 1-2 shift valve equals modulator pressure(68) in the right end of the 1-2 shift valve. The 1-2 shift valve remains at left side by the tension of the valve spring.The 3-4 shift valve is moved to the right side by modulator pressure (6A). The 3-4 shift valve covers the pon to the 3rdclutch and uncovers the port to the 4th clutch as this valve is moved to the right side, The 4th clutch pressure (41)from the 3-4 shift valve becomes 4th clutch pressure (40) at the manual valve. The 4th clutch pressure (40) is appliedto the 4th clutch, and the 4th clutch is engaged.

Fluid flows by way of:- Line pressure (4) + CPB Valve - Line Pressure (5) + l-2 Shift Valve - Line Pressure {5) * 2-3 Shift Valve- Line Pressure (5) + 3-4 Shift Valve - 4th Clutch Pressure (41) + Manual Valve - 4th Clutch Pressure (40)+ 4th Clutch

The hydraulic pressure also flows to the lst clutch. However, no power is transmitted because of the one-wav clutch.

NOTE:

. When used, "lelt" or " tight" indicates direction on the hydraulic circuit.. The hydrau lic circuit shows the '97 - 98 models (7 positions); the '99 - 0O models (6 oositions) issimilar.

14-36

www.emanualpro.com

Page 556 of 1395

Description

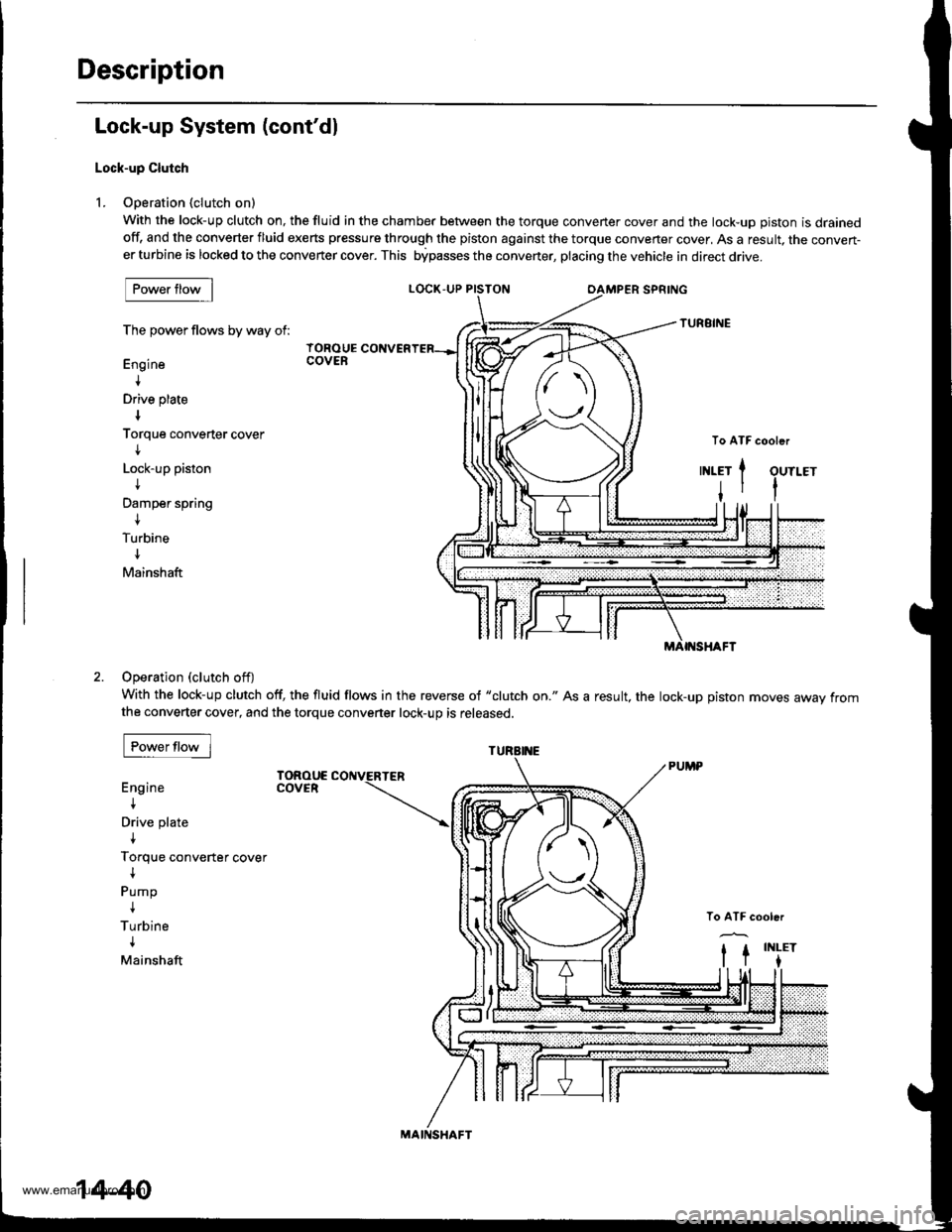

Lock-up System (cont'dl

Lock-up Clutch

L Ooeration (clutch on)

With the lock-up clutch on, the fluid in the chamber between the torque convener cover and the lock-uD oiston is drainedoff, and the converter fluid exerts pressure through the piston against the torque converter cover, As a result, the conven-er turbine is locked to the converter cover. This bipasses the converter, placing the vehicle in direct drive.

LOCK,UP PISTON

The power flows by way of:

Engine

+

Drive plate

Torque converter cover

I

Lock-up piston

t

Damper spring

{

Turbine

Mainshaft

IOROUECOVER

Operation (clutch off)

With the lock-up clutch off, the fluid flows in the reverse of "clutch on." As a result, the lock-up piston moves away fromthe converter cover, and the torque converter lock-up is released.

Engine

I

Drive plate

{

Torque converter cover

{

Pump

I

Turbine

{

Mainshaft

TOROUECOVER

To ATF cooler{(1\\n1INLET

t

Jtl

ort

MAIf{SHAFT

MAII{SHAFT

14-40

www.emanualpro.com