Oil HONDA CR-V 1998 RD1-RD3 / 1.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 443 of 1395

Transfer Assembly

lnspection

@ Make sure tifts, iacks, and satety stands

are placed properly (see section 1).

L Raise the front of the vehicle, and support it with

safety stands (see section 1).

2. Set the parking brake, and block both rear wheels

securely.

3. Shift to neutral oosition.

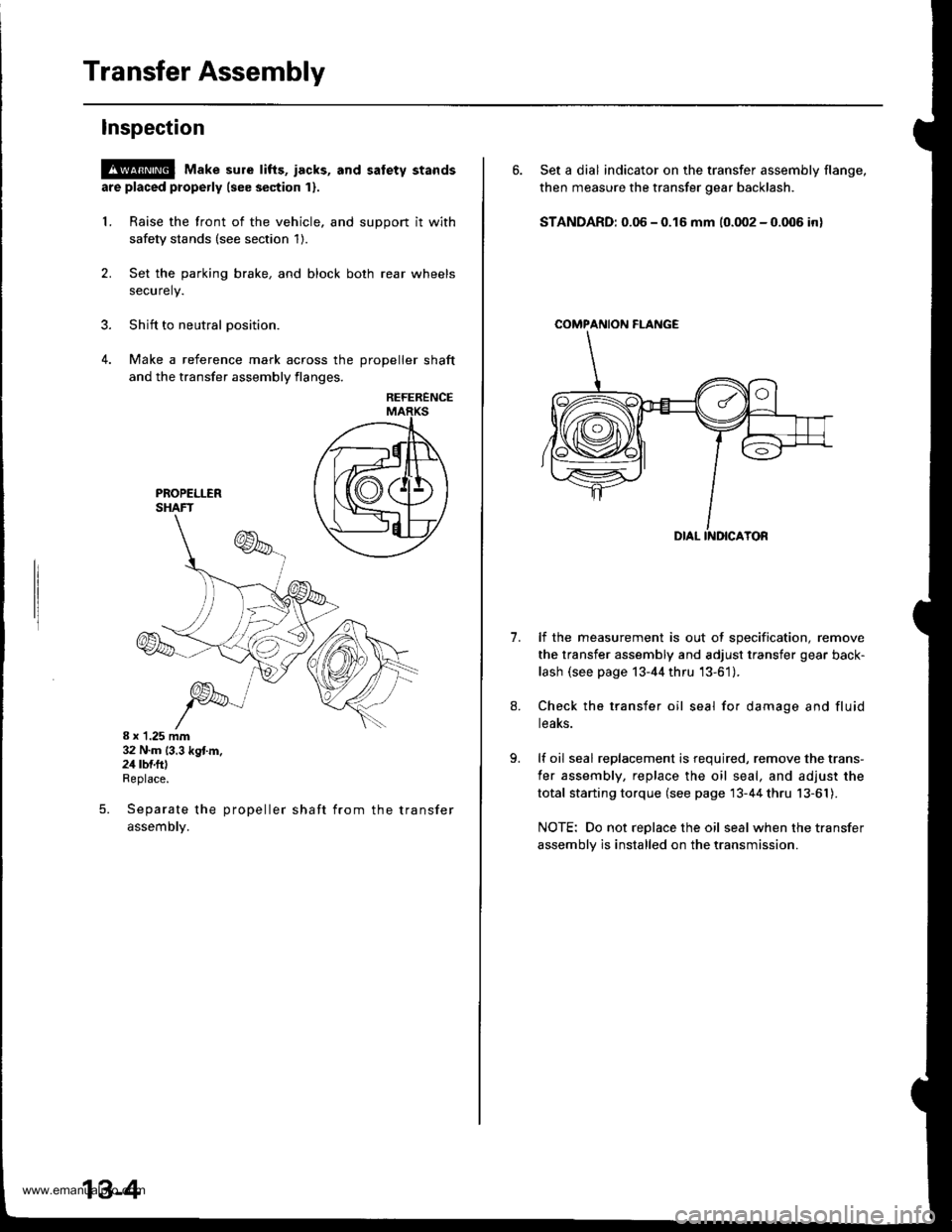

4. Make a reference mark across the DroDeller shaft

and the transfer assembly flanges,

REFERENCE

8 x 1.25 mm32 N.m (3.3 kg{.m.24 rbf.ftlReplace.

Separate the propeller shaft from the transfer

assemDty.

5.

13-4

6. Set a dial indicator on the transfer assembly flange,

then measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm (0.002 - 0.006 in)

COMPAf{ION FI-ANGE

1.lf the measurement is out of specification, remove

the transfer assembly and adjust transfer gear back-

lash (see page 13-44 thru '13-61).

Check the transfer oil seal for damage and fluid

teaKs.

lf oil seal replacement is required, remove the trans-

fer assembly, replace the oil seal, and adjust the

total starting torque (see page 13-44 thru 13-61).

NOTE: Do not replace the oil seal when the transfer

assembly is installed on the transmission.

www.emanualpro.com

Page 448 of 1395

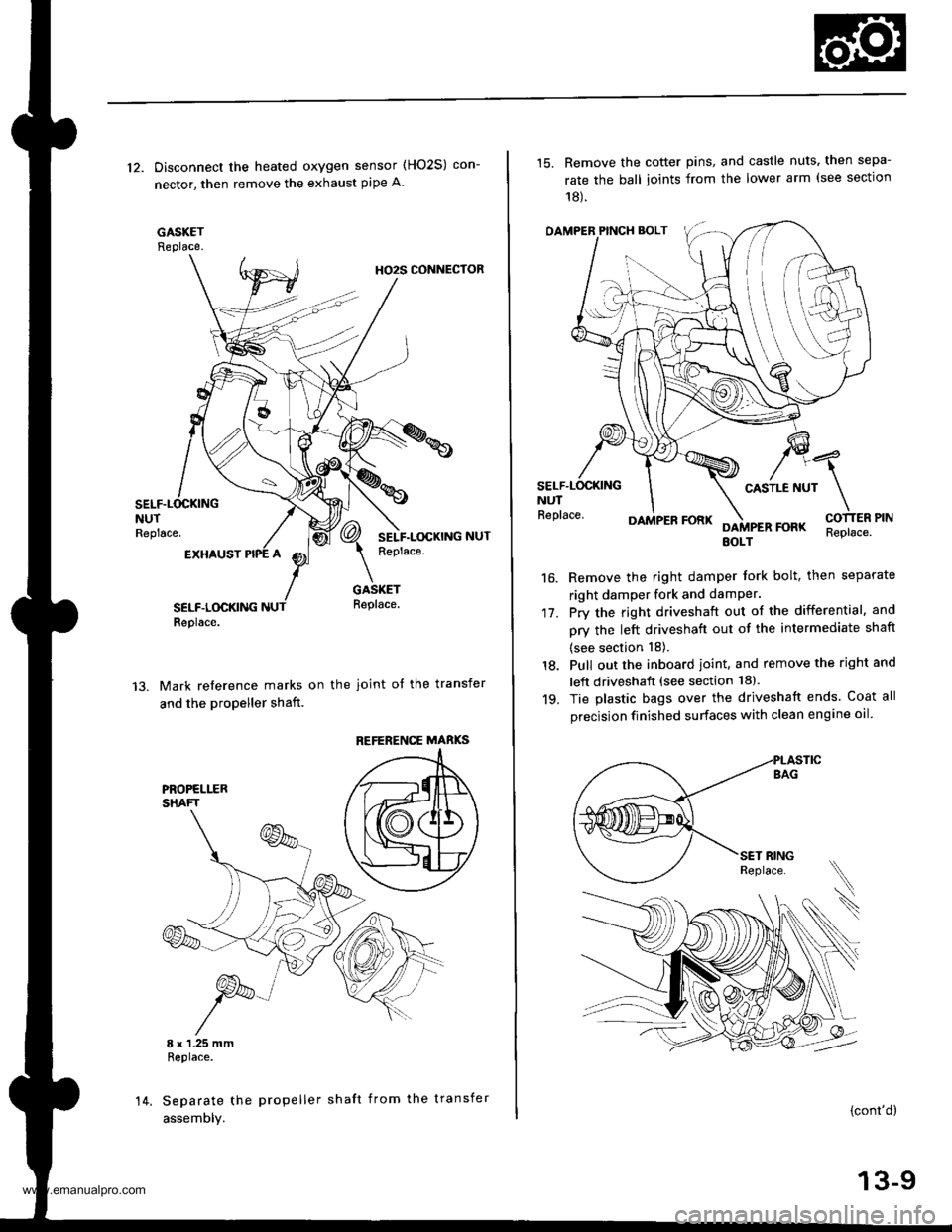

12. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove the exhaust pipe A.

GASKETReplace.

HO2S CONNECTOR

NUTReplace.

EXHAUST

SELF.LOCKINGReplace.

GASKETReplace.

Mark reference marks on the joint of the transfer

and the propeller shaft.

8 x 1.25 mmReplace.

Separate the propeller shaft from the transfer

assemDly.

REFERENCE MABKS

14.

15. Remove the cotter pins, and castle nuts. then sepa-

rate the ball ioints from the lower arm (see sectlon

18).

OAMPER PINCH BOLT

CASTLE NUTNUTReplace.

17.

16.

DAMPER FORKFOFKEOLTReplace.

Remove the right damper tork bolt, then separate

right damper fork and damPer.

Pry the right driveshaft out of the differential, and

pry the left driveshaft out of the intermediate shaft

(see section 18).

Pull out the inboard ioint, and remove the right and

left driveshaft (see section 18).

Tie plastic bags over the driveshatt ends. Coat all

precision finished surfaces with clean engine oil

18.

19.

\

{cont'd}

13-9

www.emanualpro.com

Page 449 of 1395

Transmission Assembly

Removal (cont'd)

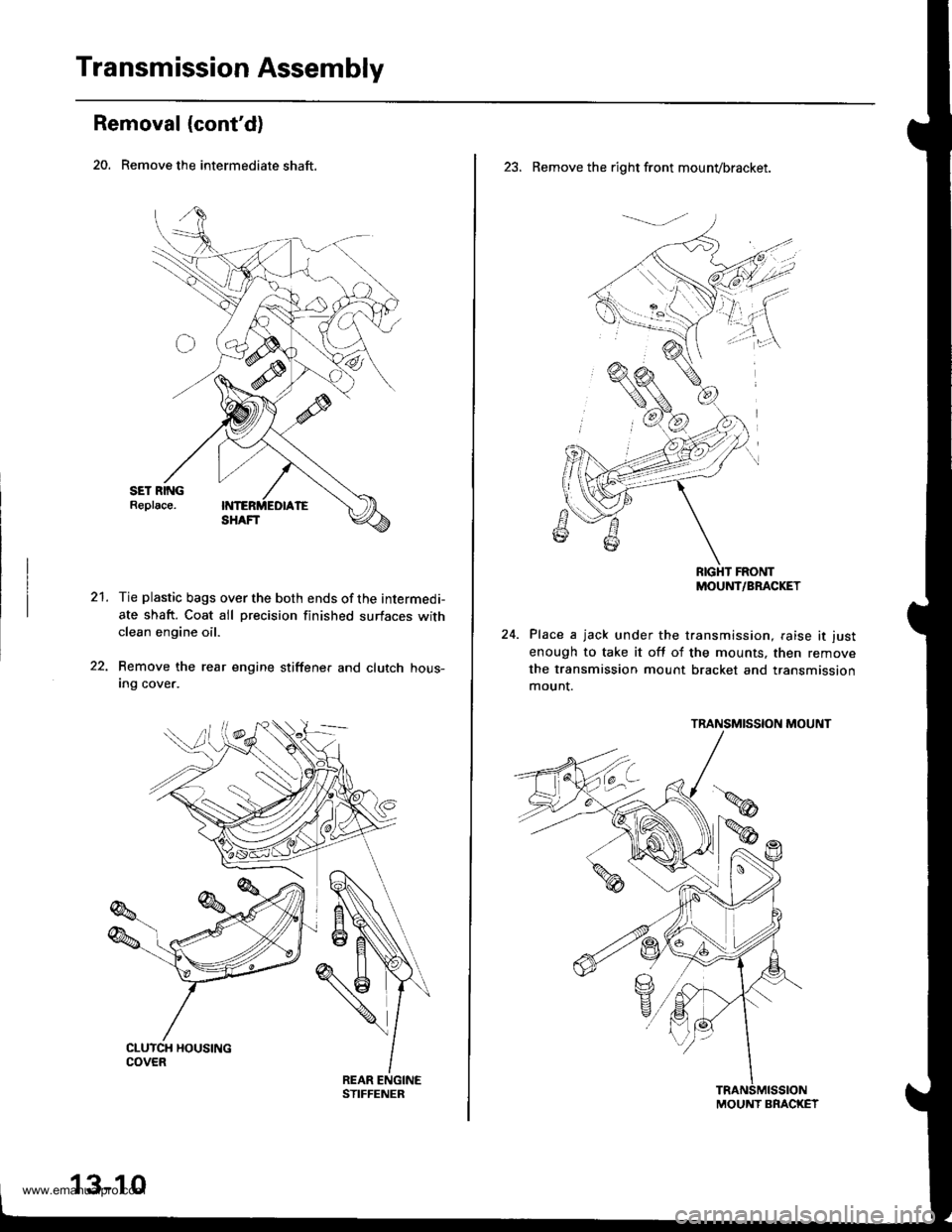

20. Remove the intermediate shaft.

21.Tie plastic bags over the both ends of the intermedi-

ate shaft. Coat all precision finished surfaces withclean engine oil.

Remove the rear engine stiffene. and clutch hous-Ing cover.

13-10

23. Remove the right front mounvbracket.

RIGHT FRONTMOUNT/BRACKET

Place a jack under the transmission, raise it just

enough to take it off of the mounts, then remove

the transmission mount bracket and transmission

mount.

TRANSMISSION MOUNT

MOUNT BRACKET

www.emanualpro.com

Page 451 of 1395

Transmission Assembly

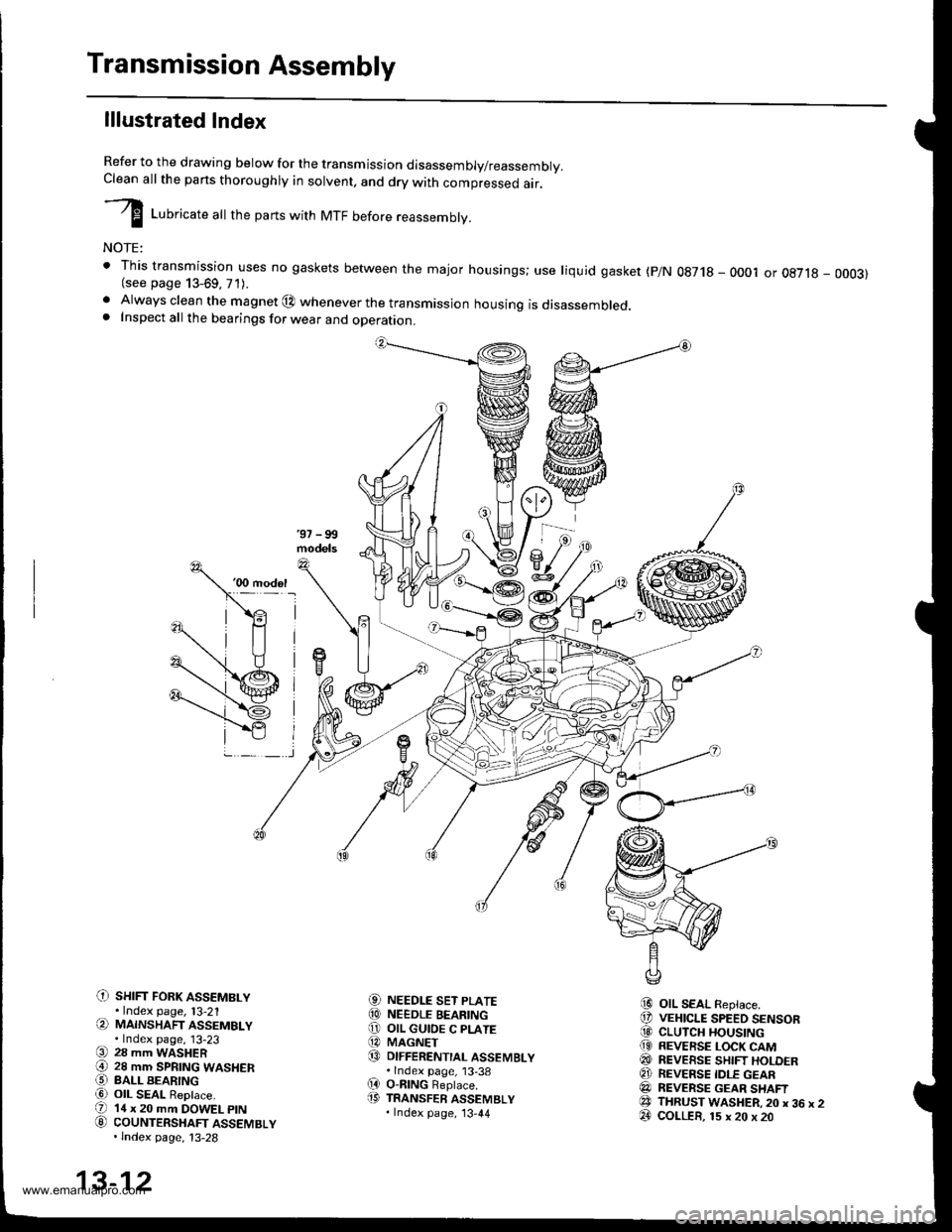

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.Clean all the pans thoroughly in solvent, and drv with comoressed air.

I LuUri""r" utt the parts with MTF before reassembly.

NOTE:

t This transmission uses no gaskets between the major housings; use liquid gasket (p/N 0g718 - 0001 or oE7l8 - 0003)(see page 13-69, 71).. Always clean the magnet @ whenever the transmissjon housing is disassembled.. Inspect all the bearings for wear and operation.

C) sHrFr FoRK ASSEMBLY.Index page, l3-21(a MAINSHAFT ASSEMBLY.Index page, 13-23(9 28 mm WASHER€) 28 mm SPRTNG WASHERO BALL BEARINGa6) OIL SEAL ReDlace.(D 14 x 20 mm DOWEL ptN

G) couNTERSHAFT ASSEMBLY.lndex page, 13-28

NEEDLE SET PLATENEEDLE BEARINGOIL GUIOE C PLATEMAGNETDIFFERENTIAL ASSEMBLY.lndex page, 13-38O-nlNG Beplace.TRANSFER ASSEMBLY.Index page, '13,44

OIL SEAL Replace.VEHICLE SPEED SENSORCLUTCH HOUSINGREVERSE LOCK CAMREVEESE SHIFT HOLDERREVERSE IDLE GEARREVERSE GEAR SHAFTTHRUST WASHER,20 x 36 x 2COLLER, 15 x 20 x 20

aol

@o@@

(D

i9

@@@(9

@@@e3@

13-12

www.emanualpro.com

Page 452 of 1395

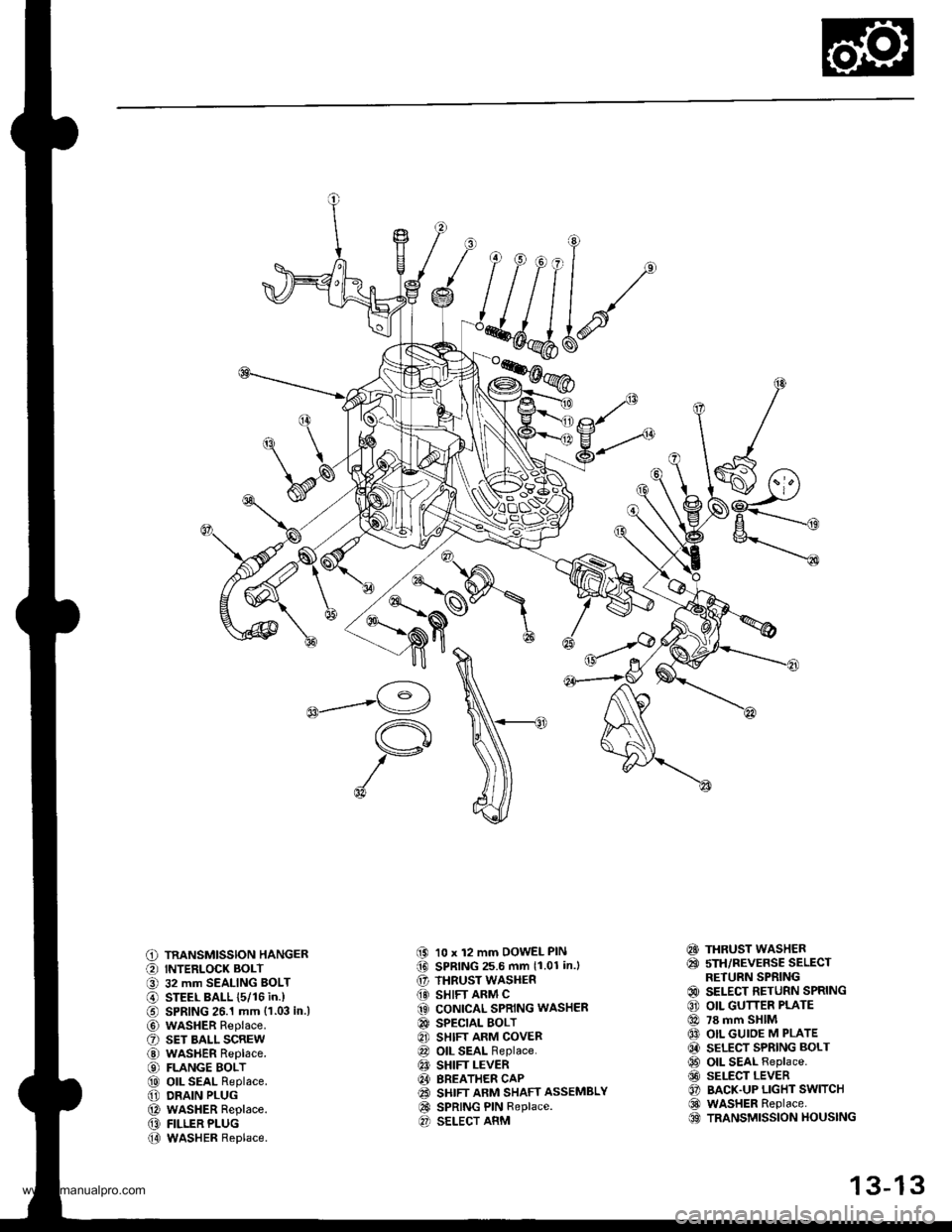

C) TRANSMISSION HANGER

O INTERLOCK BOLT

O 32 mm SEALING BOLT

@ STEEL BALL {5/16 in.)

€) SPRING 26.1 mm {1.03 in.l

@ wasHER Replace.

O sET BALL scREw

@ WASHER Replace.

€) FLANGE BOLT

@ oll SEAL Replace.

@ DRAIN PLUG

@ WASHER Replace.

@ FILLER PLUG

@ WASHER Replace.

(9 10 x 12 mm DOWEL PIN(D SPRING 25.6 mm 11.01 in.l

€' THRUST WASHER

@} SHIFT ARM C(3 CONICAL SPRING WASHER

@ SPECTAL BOLT

8] SHIFT ARM COVER

@ OIL SEAL Replace.

€! SHIFT LEVER

@I BREATHER CAP(2! SHIFT ARM SHAFT ASSEMBLY

@ SPRING PIN Replace.O SELECT ARM

€!} THRUST WASHER

@ sTH/REVERSE SELECTRETURN SPRING

@ SELECT RETURN SPRING

€) OIL GUTTER PLATE

@ 78 mm SHIM

@ OIL GUIOE M PLATE

@ SELECT SPRING BOLT

@ OIL SEAL Replace.

@ SELECT LEVER

O BACK.UP LIGHT SWITCH

@ WASHER Replace.OO TRANSMISSION HOUSING

13-13

www.emanualpro.com

Page 455 of 1395

Transmission Assembly

Disassembly (cont'dl

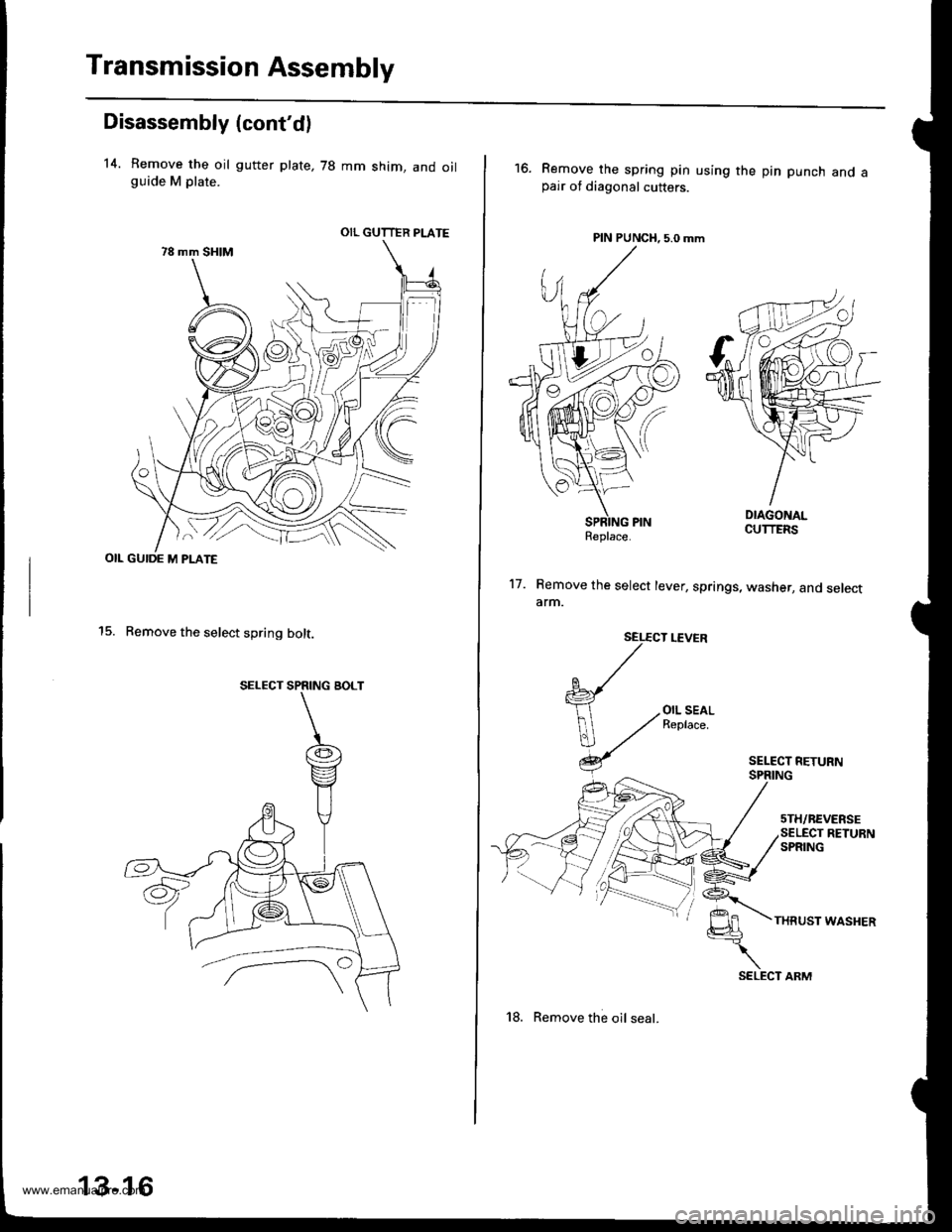

14. Remove the oil gutter plate, 78 mm shim, and oilguide M plate.

OIL GUIDE M PLATE

15. Remove the select spring bolt.

OIL GUTTER PLATE

SELECT SPRING BOLT

13-16

18. Remove the oil seal.

16.Remove the spring pin using the pin punch and apair of diagonal cutters.

PIN PUNCH, 5.0 mm

17. Remove the select lever, springs, washer, and selectarm.

SEL€CT LEVER

{

V

OIL SEALReplace.

THRUST WASHER

Replace.

SELECT ARM

www.emanualpro.com

Page 457 of 1395

Shift Arm Cover/Shift Arm Shaft Assembly

Disassembly/Reassembly

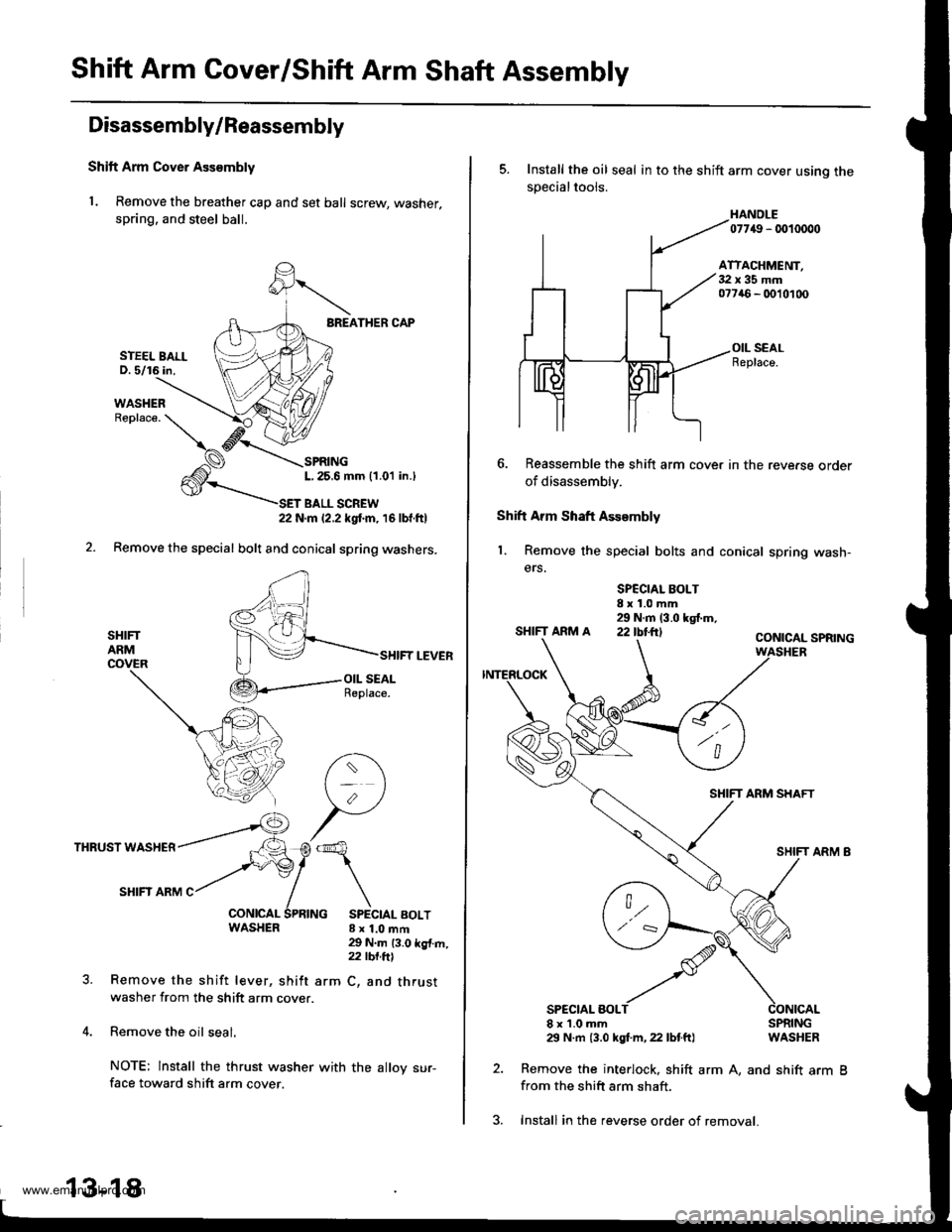

Shift Arm Cover Ass€mbly

1. Remove the breather cap and set ball screw, washer,

spring. and steel ball.

BREATHER CAP

SPRINGL,25.6 mm (1.01 in.l

T BALL SCREW22 N.m 12.2 kgtm, 16lbf.ftl

Remove the special bolt and conical spring washers.

SHIFTARMCOVER

THRUST WASHER

SHIFI ARM C

WASHER 8x1.0mft

SHIFT LEVER

29 N.m 13.0 kg{.m,z2 tbt.ftl

arm C, and thrustRemove the shift lever, shift

washer from the shift arm cover.

Remove the oil seal.

NOTE: lnstall the thrust washer

face toward shift arm cover.

STEEL BALLD. 5/16 in,

13-18

with the alloy sur-

3. Install in the reverse order of removal.

5. Install the oil seal in to the shift arm cover usino thesDecialtools.

HANOLE07749 - 0010000

ATTACHMENT,32x35mm077a6 - 0010100

OIL SEALReplace.

6. Reassemble the shift arm cover in the reve.se order

of disassembly.

Shift Arm Shaft Assembly

1. Remove the special bolts and conical spring wash-

ers.

SPCCIAL BOLT8x1.0mm29 N.m (3.0 kgf.m,SHIFTARMA 22IbI.ftICONICAL SPRING

SHIFT ARM SHAFT

SPECIAL BOLT8x1.0mm29 N.m {3.0 kgf.m, 22 lbtft}

2. Remove the interlock, shift

from the shift arm shaft.

SPRINGWASHER

arm A, and shift arm B

www.emanualpro.com

Page 465 of 1395

Mainshaft Assembly

Inspection

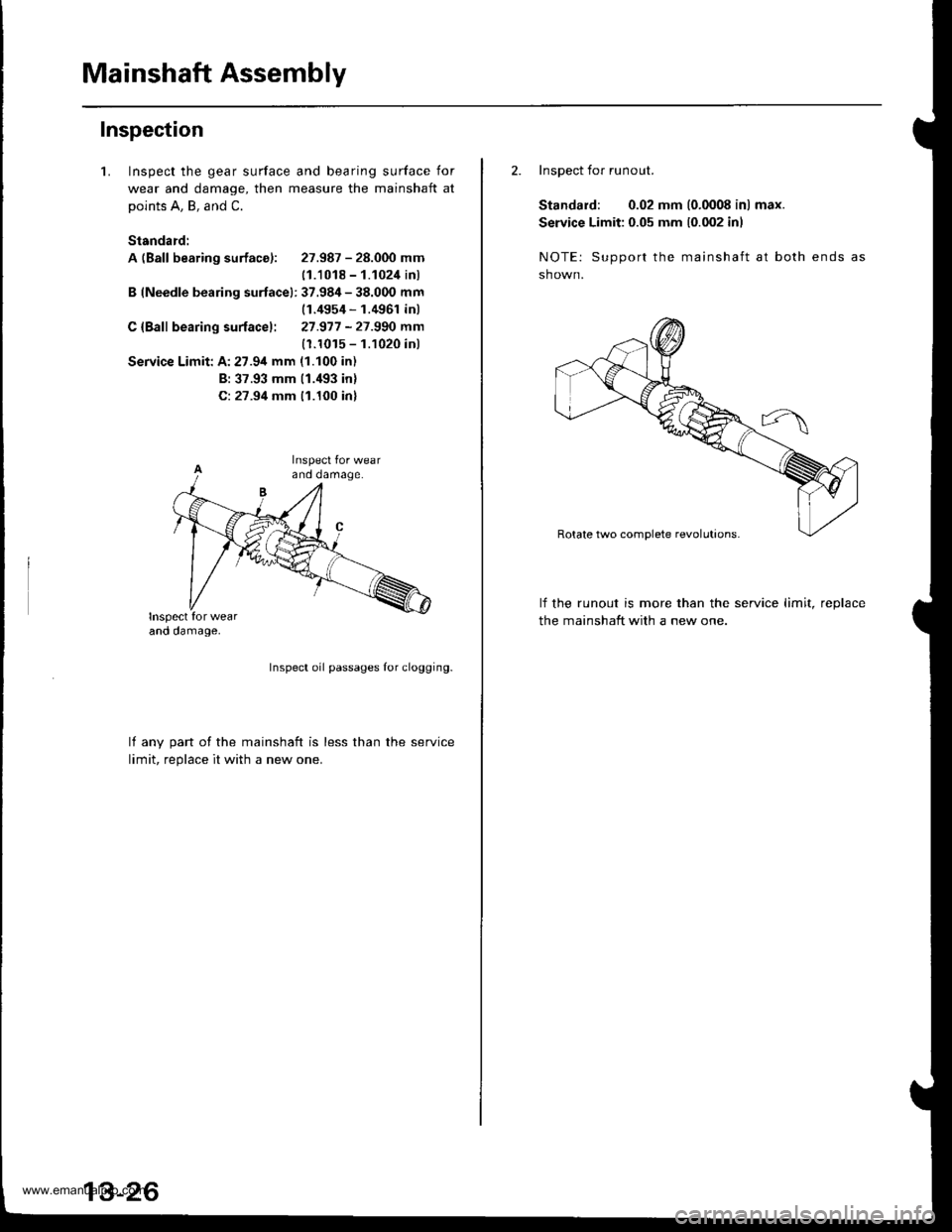

1.Inspect the gear surface and bearing surface for

wear and damage, then measure the mainshaft at

points A, B, and C.

Standard:

A (Ball bearing surface): 27.987 - 28.000 mm

11.1018 - 1.1024 inl

B (Needle bearing surfacel: 37.984 - 38.000 mm(1.4954 - 1.4961 inl

C {Bafl bearing surfacel: 27.977 -27.990 mm

(1.1015 - 1.1020 inl

Service Limit: A:27.94 mm (1.100 in)

B: 37.93 mm (1.'193 inl

C: 27.94 mm 11.100 inl

Inspect oil passages Ior clogging.

lf anv oart of the mainshaft is less than the service

limit. reolace it with a new one.

2. Inspect for runout.

Standard: 0.02 mm (0.0008 in) max.

Service Limit: 0.05 mm 10.002 inl

NOTE: Support the mainshaft at both ends

sh own.

lf the runout is more than the service limit, reDlace

the mainshaft with a new one.

www.emanualpro.com

Page 476 of 1395

Synchro Ring, Gear

Inspection

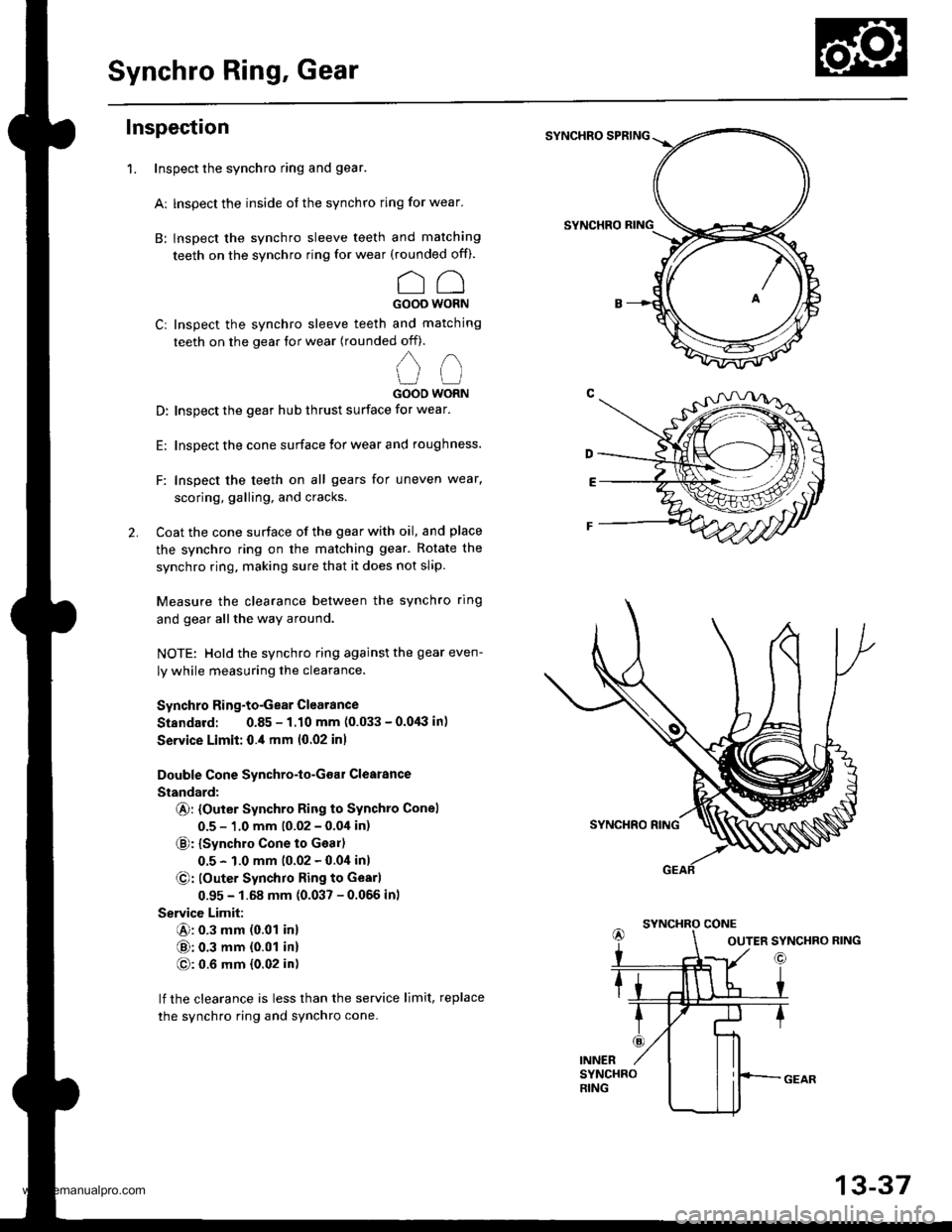

Inspect the synchro ring and gear.

Ar lnspect the inside of the synchro ring for wear.

B: lnspect the synchro sleeve teeth and matching

teeth on the synchro ring for wear (rounded of0.

CCGOOO WORN

Cr Inspect the synchro sleeve teeth and matching

teeth on the gear tor wear (rounded off).

,,

u (-l

GOOO WORN

D: Inspect the gear hub thrust surface for wear.

E: Inspect the cone surface lor wear and roughness.

F: Inspect the teeth on all gears for uneven wear,

scoring, galling, and cracks.

2. Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear. Rotate the

synchro ring, making sure that it does not slip.

Measure the clearance between the synchro ring

and gear allthe way around.

NOTE: Hold the synchro ring against the gear even-

ly while measuring the clearance.

Synchro Ring-to-Gear Clearance

Standard: 0.85 - 1.10 mm (0.033 - 0.0,lil in)

Service Limit: 0.,1 mm 10.02 inl

Double Cone Synchro-lo-Goar Clearance

Standard:

@: {Outer Synchro Ring to Synchto Conel

0.5 - 1.0 mm (0.02 - 0.04 in)

€): {synchro cone to Geal)

0.5 - 1.0 mm (0.02 - 0.0i1inl

@: louter Synchro Ring to Gearl

0.95 - 1.68 mm (0.037 - 0.056 inl

Service Limit:

@: 0.3 mm (0.01 inl

@: 0.3 mm {0.01 in}

@: 0.6 mm {0.02 in)

lf the clearance is less than the service limit, replace

the synchro ring and synchro cone.

SYNCHRO SPRING

SYNCHRO

1.

OUTER SYNCHRO RING

13-37

www.emanualpro.com

Page 479 of 1395

Differential

Bearing Outer Race Replacement

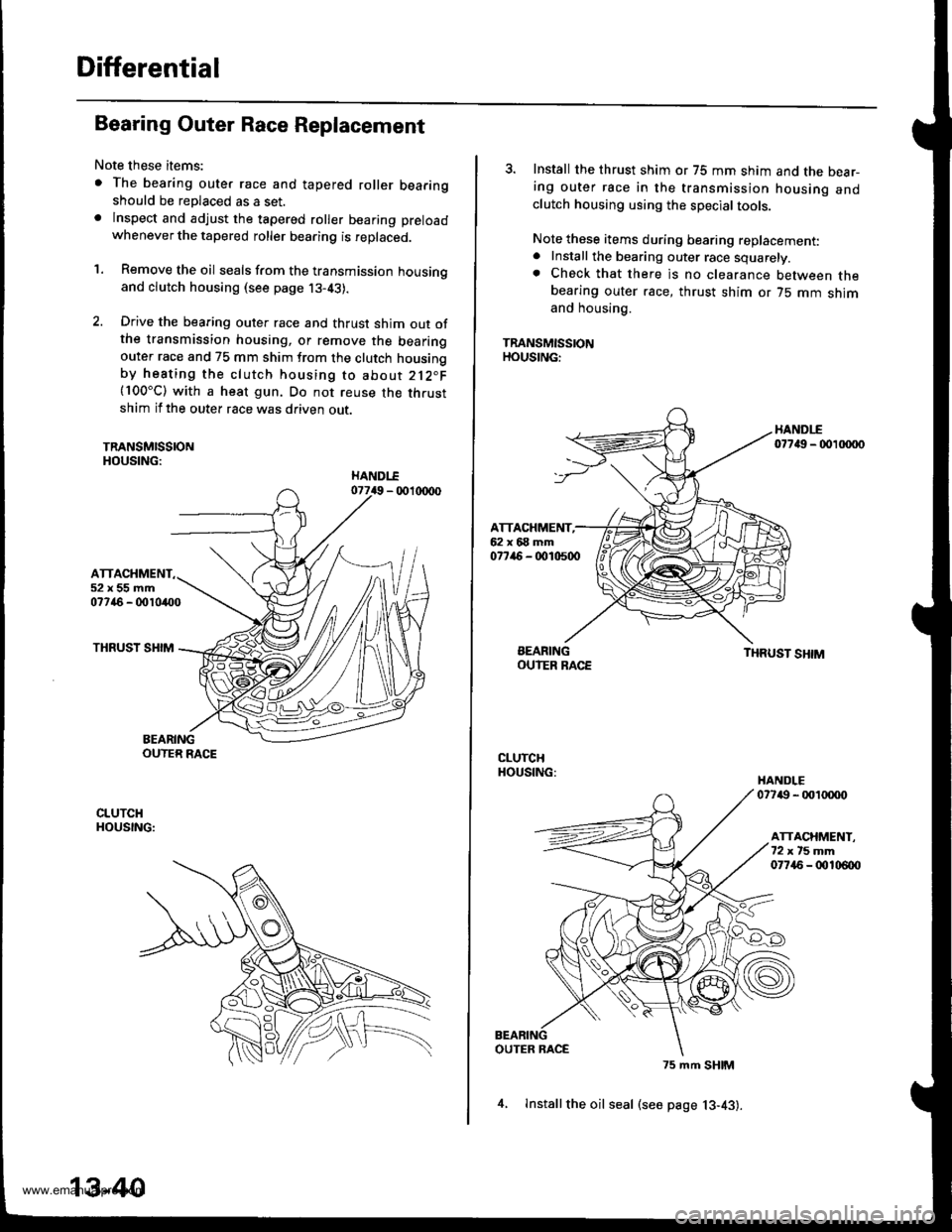

Note these items:

. The bearing outer race and tapered roller bearingshould be replaced as a set.. lnspect and adjust the tapered roller bearing preload

whenever the tapered roller bearing is replaced.

'1. Remove the oil seals from the transmission housingand clutch housing (see page j3-43).

2. Drive the bearing outer race and thrust shim out ofthe transmission housing, or remove the bearingouter race and 75 mm shim from the clutch housingby heating the clutch housing to about 212"F(100"C) with a heat gun. Do not reuse the thrustshim if the outer race was driven out.

TRANSMISSIONHOUSING:

ATTACHMENT52x55mm07746 - 0010400

THRUST SHIM

BEARINGOUTER RACE

CLUTCHHOUSING:

13-40

4, lnstallthe oil seal (see page 13-43).

3. Install the thrust shim or 75 mm shim and the bear-ing outer race in the transmission housing andclutch housing using the special tools.

Note these items during bearing replacement:. Install the bearing outer race squarely.. Check that there is no clearance between thebearing outer race, thrust shim or 75 mm shimand housing.

TRANSMISSIONHOUSING:

HANDI-E07749 - 00 xxto

ATTACHMENT,62x68mm077ir6 - 0010500

BEARINGOUIER RACETHRUST SHIM

CLUTCHHOUSING:HANDLE07749 - 001tXX)o

ATTACHMENT.72xt5mm07745 - 00106{x)

OUTER RACE

75 mm SHIM

www.emanualpro.com