Troubleshooting HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 51 of 1395

Engine Electrical

Speciaf Tools ............. 4-2

Starting System

Component Location Index ............ 4-3

Circuit Diagram ................................ 4-4

Starter Test ........... 4-5

Starter Solenoid Test ...................... 4'5

Starter Replacement ....................... 4-7

Field Winding Test ........................... 4-7

Starter Overhaul ............................,. 4-8

Brush Inspection ...........................,., 4-9

Overrunning Glutch Inspection ...... 4-9

Armature lnspection and Test ........4-10

Brush Holder Test ............................ 4-12

Starter Reassemb|y ......................... 4-1 2

Perf ormance Test ............................. 4- 1 3

lgnition System

Component Location Index ............ 4-14

Circuit Diagram ................................ 4-15

lgnition Timing Inspection and

Setting .......................................... 4-16

Distributor Replacement ........,........ 4-17

Distributor Overhaul .............,,......... 4-18

lgnition Control Module (lCM) Input

Test ..............................,................ 4-19

fgnition Coil Test .............................. 4-2O

lgnition Wire Inspection and

Test ............................................... 4-20

Spark Plug Inspection ..................... 4-21

-+

ENGINE

Charging System

Component Location Index ............ 4-22

Circuit Diagram ....................,........... 4-23

Troubleshooting .............................. 4-24

Alternator Replacement ..........,....... 4-30

Alternator Overhaul .......,,................ 4-31

Rectifier Test .........4-32

Alternator Brush Inspection ........... 4-32

Rotor Slip Ring Test ........................ 4-33

Stator Test ............. 4-33

Alternator Belt Inspection and

Adiustment ........4-34

Gruise Control

Component Location Index .,,,........ 4-36

Circuit Diagram ................................ 4-37

Control Unit Input Test ................... 4-38

Main Switch Test/Replacement ..... 4-40

Set/Resume Switch Test/

Replacement .......................,........ 4'40

Actuator Test ....,,., 4-41

Actuator Replacement ...............,.... 4-42

Actuator Cable Adiustment ............ 4-43

Clutch Switch Test .......................... 4-43

Brake Switch Test .................. .......... 4-44

Actuator Solenoid Test .............. ...,. 4-44

Actuator Disassembly ..................... 4-45

www.emanualpro.com

Page 72 of 1395

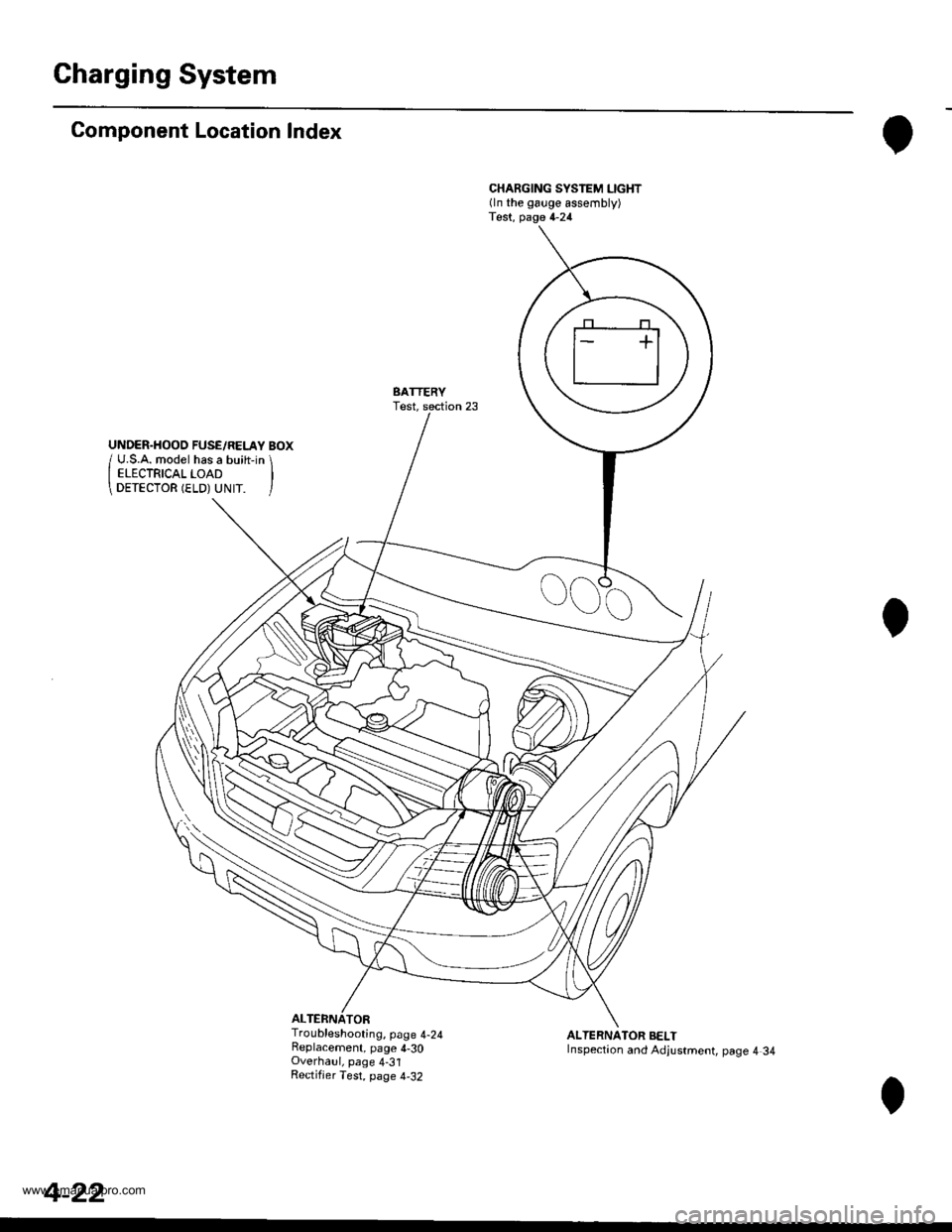

Charging System

Component Location Index

ALTERNATOR

CHARGING SYSTEM LIGHT(ln the gauge assembly)Test, page 4-24

BATTERYTest,

Troubleshooting, page 4-24Replacement, page 4-30Overhaul, page 4-31Rectifjer Test, page 4,32

ALTERNATOR BELTInspection and Adjustment, page 4 34

4-22

www.emanualpro.com

Page 74 of 1395

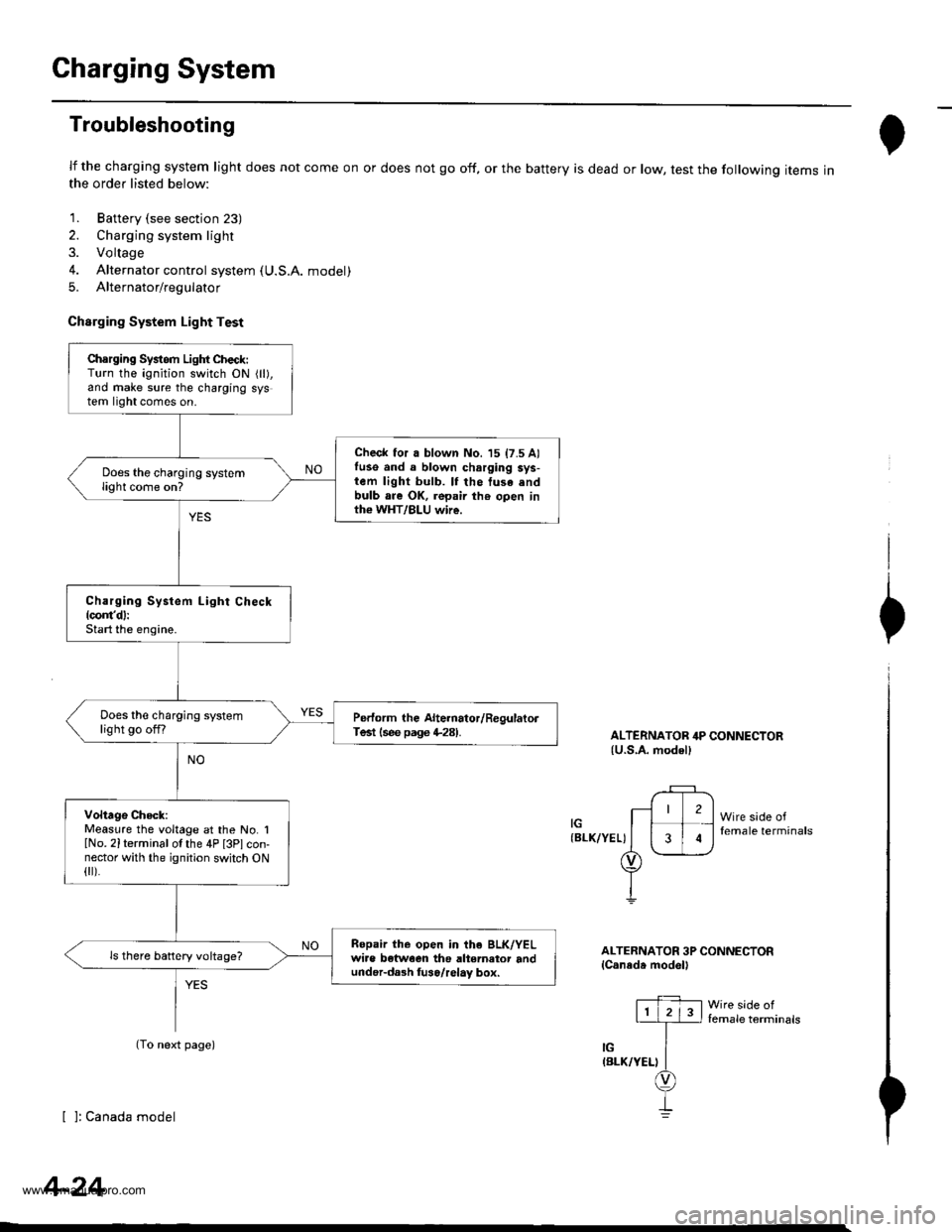

Gharging System

Troubleshooting

lf the charging system light does not come on or does not go off, or the battery is dead or low, test the following items inthe order listed below:

1. Battery (see section 23)

2. Charging system light

3. Voltage

4. Alternator control system (U.S.A. model)

5. Alternator/regulator

Charging System Light Test

ALTERNATOR 4P CONNECTOR{U.S,A. modell

(BLK/YEL)

2

3

Wire sade offemale terminals

I

I

I

ALTERNATOR 3P CONNECTORlCaneda model'

Iemale terminals

[ ]: Canada model

Chsrging Systom Light Check:Turn the ignition switch ON {ll),and make sure the charging system light comes on.

Check for a blown No. 15 17.5 Alfuse and a blown charging sys-tem light bulb. lf the tusa .ndbulb are OK, repair th€ open inth€ WHT/BLU wire.

Does the charging systemlight come on?

Charging System Light Check{com'd}:Start the engine.

Does the charging systemlight go offfPerform the Alte.nator/RegulatorTest lsee page +281.

Voltage Check:Measure the voltage at the No. IlNo. 2iterminal of the 4P [3Plcon-nector with the ignition switch ON{ ).

Ropair the open in the BLK/YELwiae betwoen the altemator andunder-da3h luso/relay box.

ls there battery voltage?

(To next page)

4-24

www.emanualpro.com

Page 76 of 1395

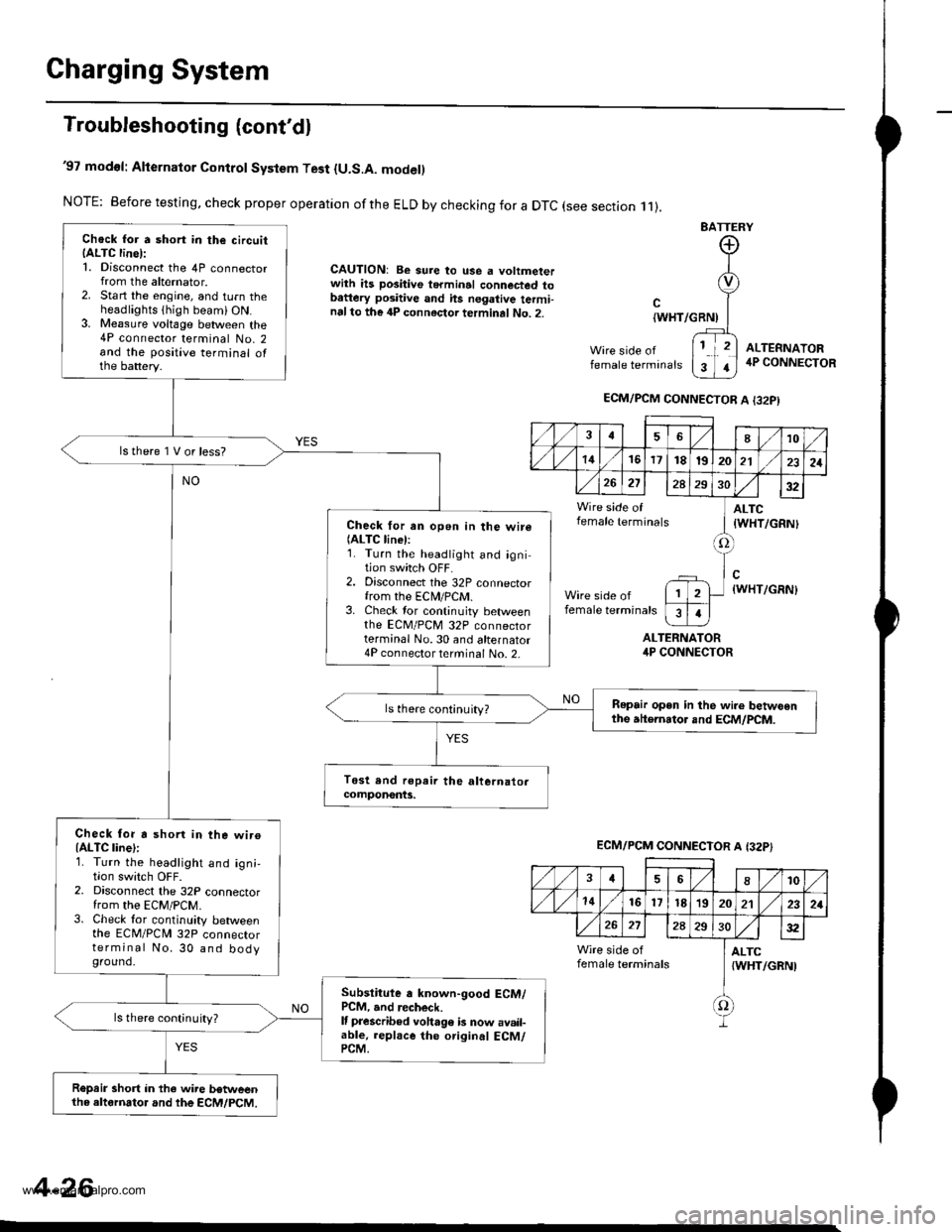

Charging System

Troubleshooting (cont'dl

'97 modol: Alternator Control System Test {U.S.A. model)

NOTE: Before testing, check proper operation ofthe ELD by checking for a DTC (see section .11).

CAUTION: Be sure to use a voltmeterwith ils positive terminal connected tobattery positive and hs negative termi-nalto the 4P connector terminal No. 2.

BATTERY

Wire side offemale terminals

{WHT/GRNI

ALTERNATORirP CONNECTOR

ALTEFNATOR4P CONNECTOR

Chock for a short in the circuitIALTC line):1. Disconnect the 4P connectorfrom the alternator.2. Start the engine, and turn theheadlights thigh beami ON.3. Me8sure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

lstherelVorless?

Check for an open in the wire(ALTC linel:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectorfrom the ECN4/PCM.3. Check tor continuity betweenthe EcM/PcM 32P connectorterminal No.30 and alternator4P connector terminal No. 2-

Repair open in the wi.e betwoenthe atternator and ECM/PCM.ls there continuity?

Check for a shorl in the wiroIALTC line):1. Turn the headlight and ign;,I|on swrtcn UFF2. Disconnect the 32P connectorfrom the EcM/PcM.3. Check tor continuity betweenthe ECM/PCN4 32P connectorterminal No. 30 and bodyground.

Subslitute a known-good ECM/PCM, and recheck.It prescribed voha96 b now avail-able, replace the original ECM/PCM.

ls there continuity?

R€prir short in the wire betweenthe altornator and the ECM/PCM.

ECM/PCM CONNECTOR A I32PI

,/1./1810

./ l./t4161718t9202121

26272A293032

Wire side of ] ALTCfemale terminals I tWHT/cRNl

tlWHT/GRN)

female terminals

I

1

ECM/PCM CONNECTOR A {32P}

,/ ,/46810

,/1,/1416l7t8'1920212321

272A2S30:t2

Wire side of I ALTCfemale terminals {WHT/GRNI

f)

4-26

www.emanualpro.com

Page 78 of 1395

Gharging System

Troubleshooting (cont'd)

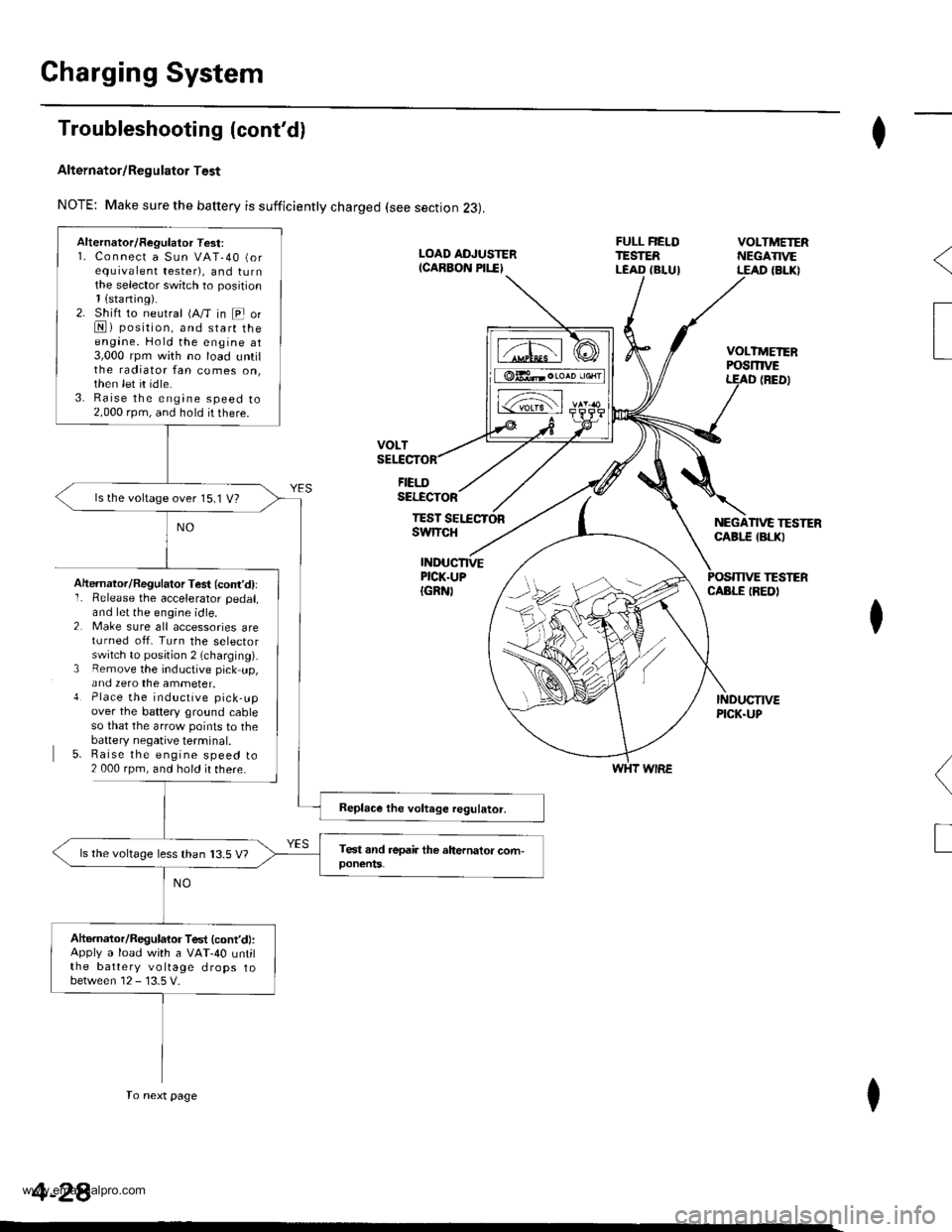

Alternator/Regulator Test

NOTE: Make sure the battery is sufficiently charged (see section 23).

FIELDSELECTOR

TESTswtTcH

I

VOLTMEIERPOSmVEt

NEGATIVE TESTERCABI.E {BLKI

(BED)

TESTERINDUCTIVEPICK.UP{GRN)CABLE IREDIAhernator/Regulator Test (cont'd)lI� Release the accelerator pedal,and let the engine idle.2 Make sure all accessories areturned off. Turn the selectorswitch to posjtion 2 (charging).3 Remove the inductive pick up,and zero the ammeter.{ Place the inductive pick-upover the battery ground cableso that the arrow points to thebaftery negative terminal.5. Raise the engine speed to2 000 rpm, and hold ir there.

I

(

T

I

WHT WIRE

Alternator/Regulator Test:1. Connect a Sun VAT-40 (orequrvalent tester), and turnthe selector switch to position1{sraning).2. Shift to neutral (A/T in E orN) position, and start theengane. Hold the engine at3,000 rpm with no load untilthe radiator fan comes on,then let it idle.3. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

ls the voltage less than 13.5 V?

Altarnator/Regulator Test (cont'd:Apply a load with a VAT-40 untilthe battery voltage drops tobetween 12 - 13.5 V.

To next page

4-28

www.emanualpro.com

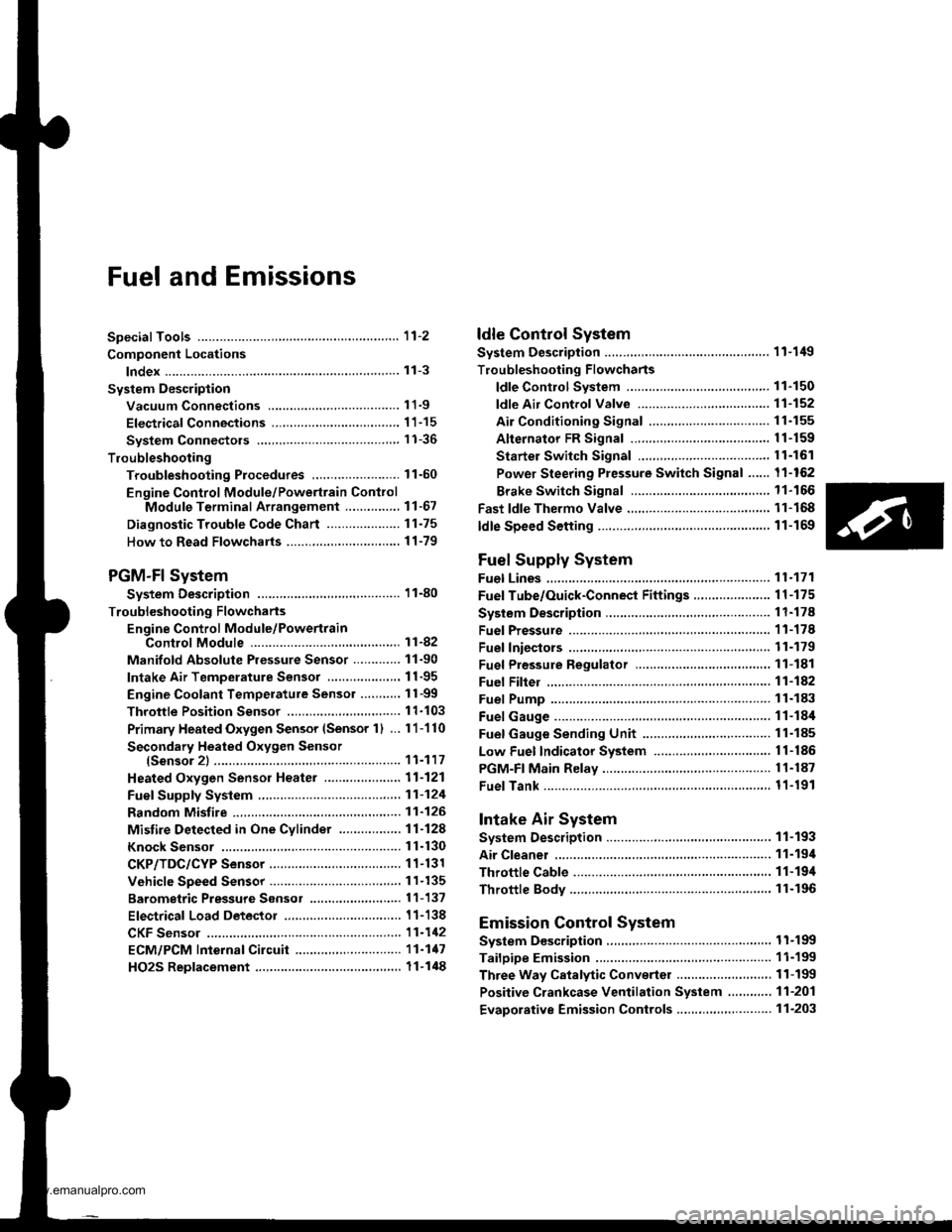

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 206 of 1395

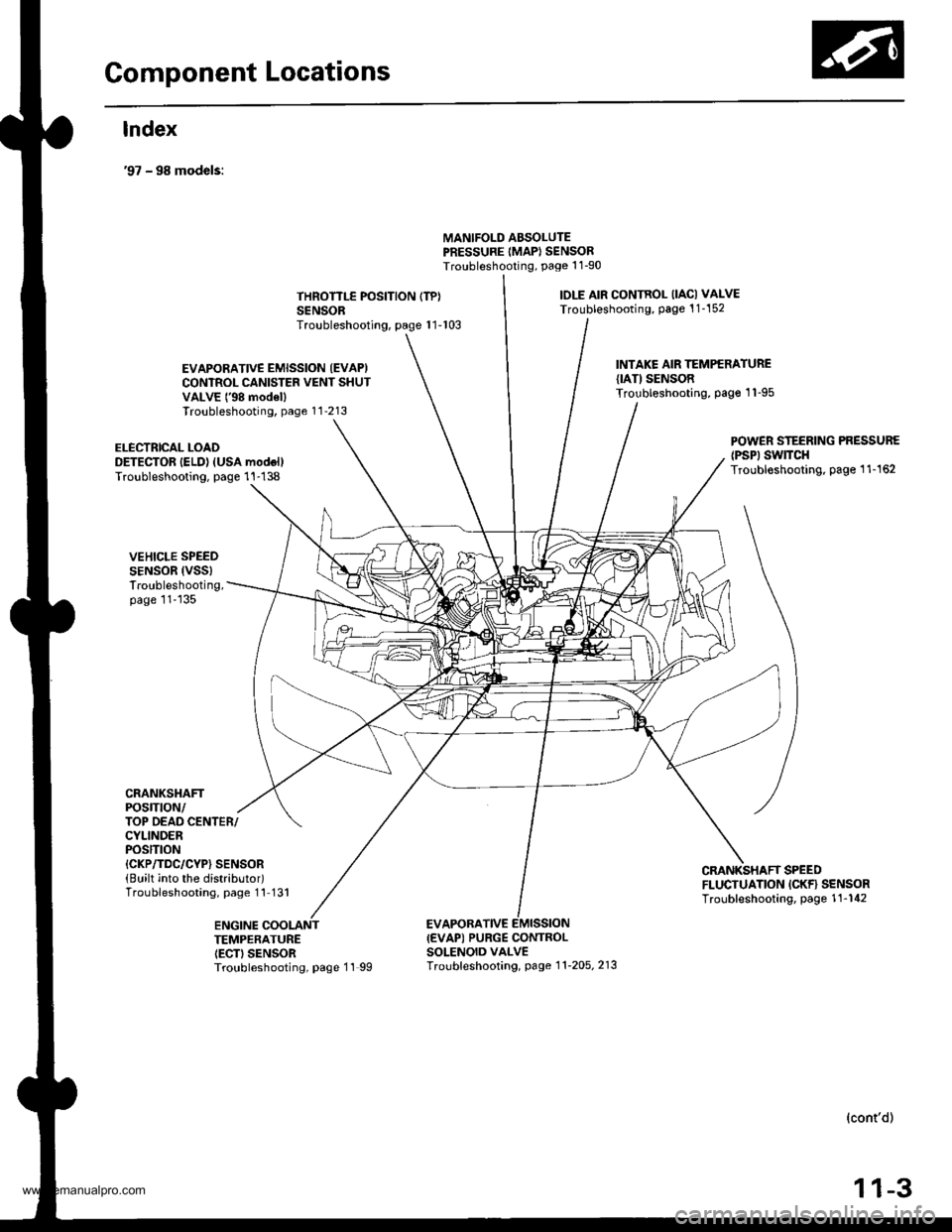

Component Locations

lndex

'97 - 98 models:

MANIFOLD ABSOLUTEPRESSURE IMAP} SENSORTroubleshooting, Page 1 1-90

THROTTLE POSITION (TP}

SENSORTroubleshooting, page 1 1-103

toLE AtR CONTROL llAcl VAI-VE

Troubleshooting, page 1 1-152

EVAPORATIVE EMISSION (EVAP)

CONTROL CANISTER VENT SHUTVALVE t'98 mod€llTroubleshooting, page 11'213

INTAKE AIR TEMPERATUREIIATI SENSORTroubleshooting. page 1 'l -95

ELECTRICAL LOADDETECTOR IELD) (USA modol)Troubleshooting, page 1 1-138

VEHICLE SPEEDSENSOR (VSS)

Troubleshooting,page 11'135

CRANKSHAFTPOSTTtON/

POWER STEERING PRESSURElPsPl swtrcHTroubloshooting, page 1 1-162

TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP} SENSOR(Built into the distributor)Troubleshooting, page 1 l-131

CMNKSHAFT SPEEDFLUCTUATION ICKF} SENSORTroubleshooting. page 1'!-142

ENGINE COOLANTTEMPERATUREIECTI SENSORTroubleshooting, page 11 99

EVAPORATIVEI€VAP) PURGE CONTROLSOLENOID VALVETroubf eshooting, page 1 1'2o5, 213

(cont'd)

11-3

www.emanualpro.com

Page 207 of 1395

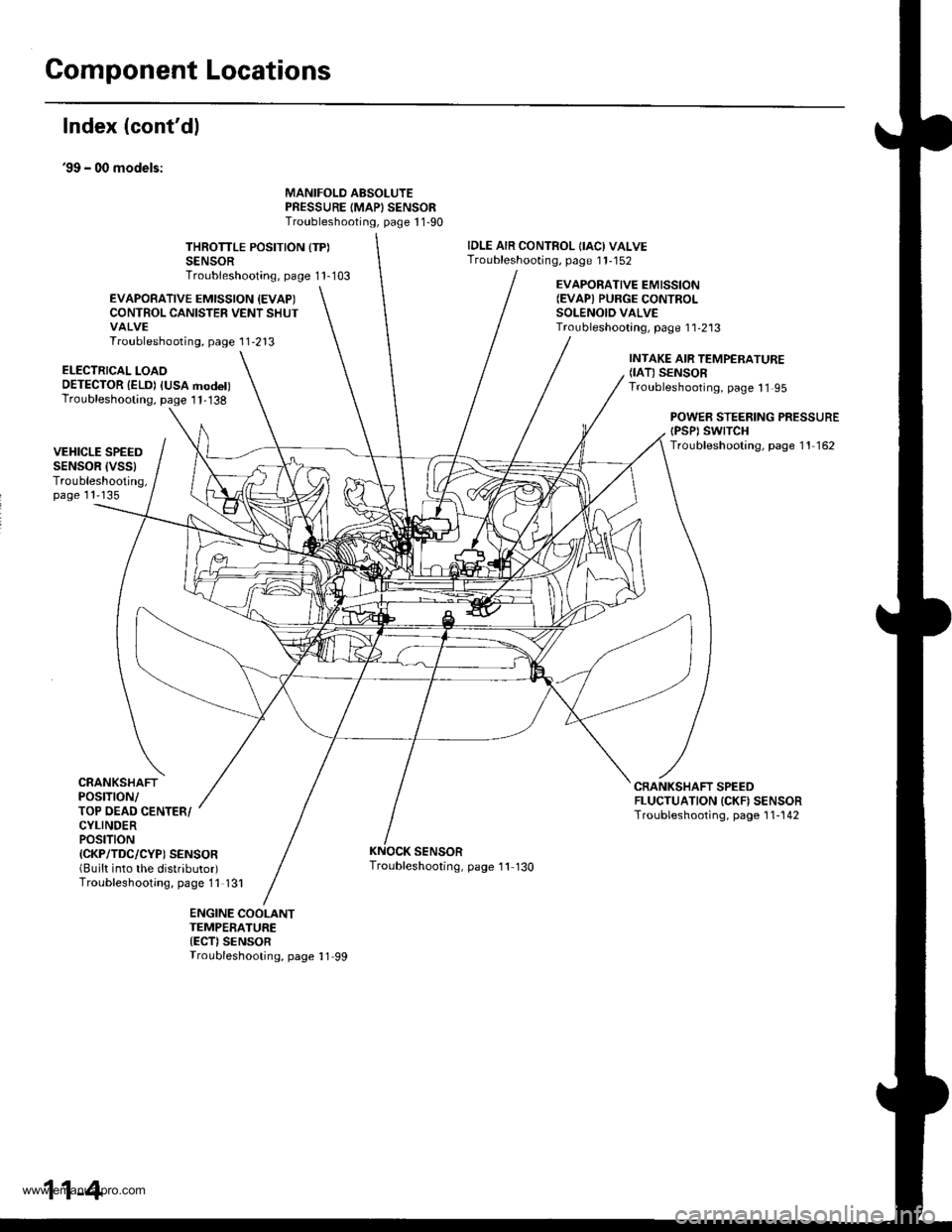

Component Locations

Index (cont'dl

39 - 00 models:

MANIFOLD ABSOLUTEPRESSURE IMAPISENSORTroubleshooting, page 1 1-90

THROTTLE POSITION {TP)SENSORTroubleshooting, page 1 1-103

IDLE AIR CONTROL OACI VALVETroubleshooting, page 1 1-152

EVAPOBATIVE EMISSION {EVAPICONTROL CANISTER VENT SHUTVALVETroubleshooting, page 1 1-213

EVAPORATIVE EMISSION(EVAPI PURGE CONTROI-SOLENOID VALVETroubleshootang, page 1 1-2'13

ELECTRICAL LOAOOETECTOR {ELD) IUSA modet)Troubleshooting, page I 1-138

INTAKE AIR TEMPERATURE(IAT) SENSORTroubleshooting, page 11 95

POWEB STEERING PRESSUREtPsPt swtTcHTroubleshooting, page 11 162VEHICLE SPEEDSENSOR IVSSITroubleshooting,page 11'135

CRANKSHAFTPOSTTTON/TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP) SENSOR(Built into the distributor)Troubleshooting, page 11 131

CRANKSHAFT SPEEDFLUCTUATION ICKN SENSORTroubleshooting, page 1 1-142

SENSORTroubleshooting, page '11 130

ENGINE COOLANTTEMPERATURE{ECT)SENSORTroubleshooting, page 11 99

11-4

www.emanualpro.com

Page 208 of 1395

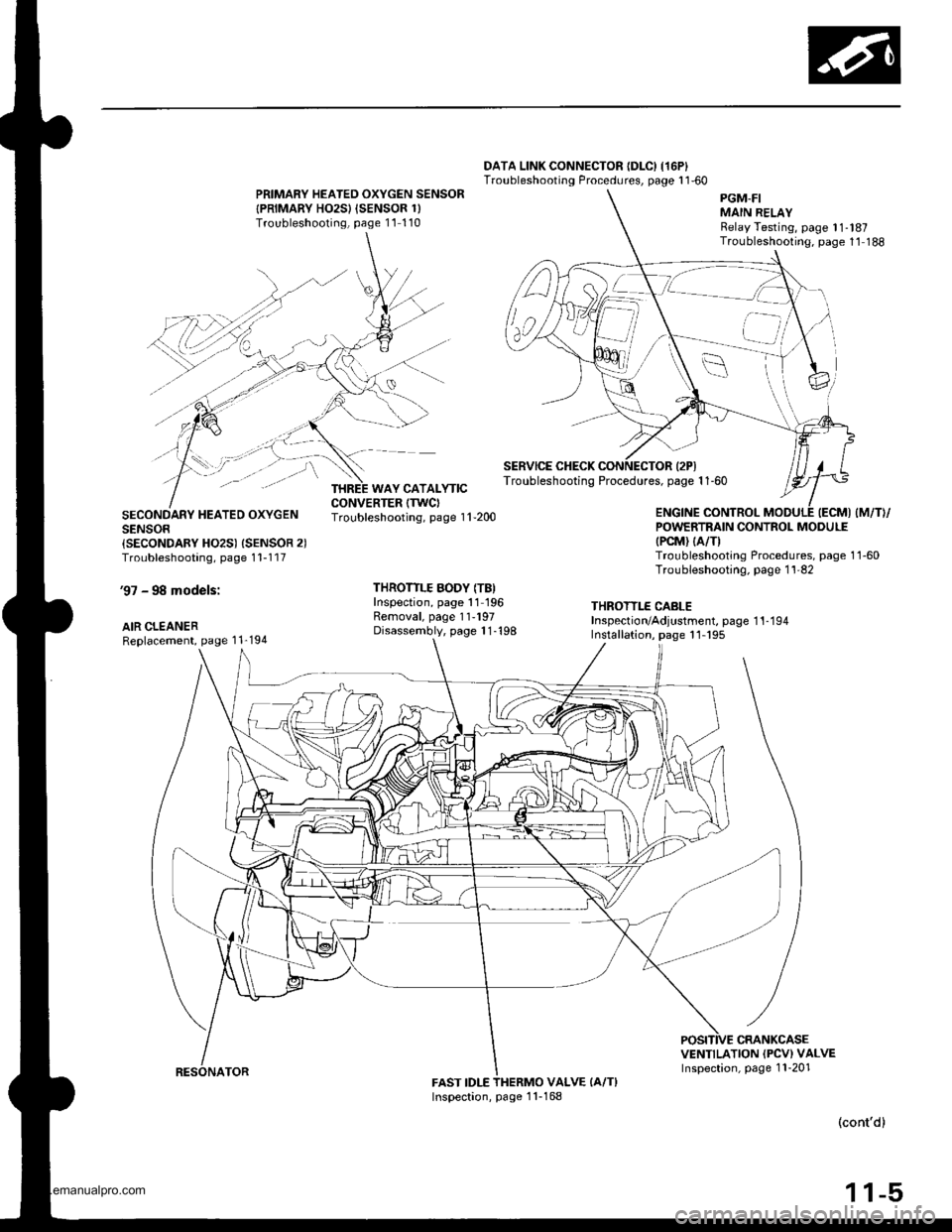

DATA LINK CONNECTOR {DLC) I16P}Troubleshooting Procedures, page 1 1'60PRIMARY HEATED OXYGEN SENSOR

{PRIMARY HO2SI {SENSOR 1)Troubleshooling, page 11 110

SECONDARY HEATED OXYGENSENSOR{SECONDARY HO2S) {SENSOR 2)Troubleshooting, page 1 1-1 17

'97 - 98 models:

AIR CLEANERReplacement, page 1 1'194

Troubleshooting, page 1 'l -200

THROTTLE BODY (TB)Inspection, page 11 196Removal, page 11-197Disassembly, page 1 1-'198

POWERTRAIN CONTROL MODULE(PCM) (A/TI

Troubleshooting Procedures, page 1 1-60Troubleshooting. page 1 1'82

THROTTLE CABLEInspection/Adjustment, page 1 1-1 94Installation, page 11- 195

VENTILATION (PCV) VALVEInspection, page 1 1-201FAST IDLEVALVE (A/T}

(cont'd)

1 1-5

PGM-FIMAIN RELAYRelay Testing, page 11-l87Troubleshooting. page 1'1 188

SERVICE CHECK CONNECTOR {2PITroubleshooting Procedures, page 1 1-60

,a'=_-_

WAY CATALYTIC

Inspection, page 1 1-168

www.emanualpro.com

Page 210 of 1395

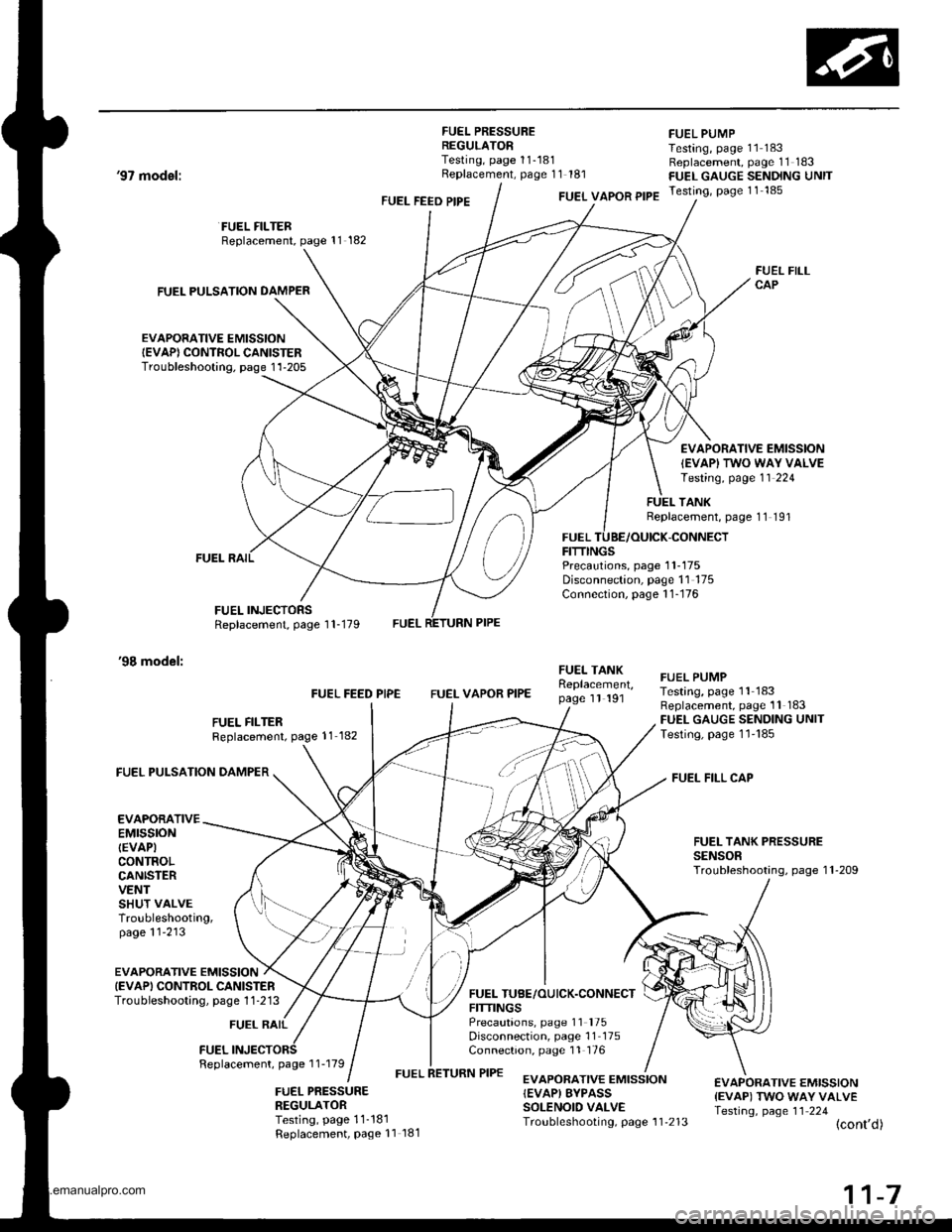

FUEL PRESSUREREGULATORTesting, page 11-181Replacement, page 11 181

FUEL PUMPTesting, page 11 183Replacement, page 11 183FUEL GAUGE SENDING UNITTesting, page 11 185

'97 model:

'98 model:

FUEL PULSATION DAMPER

EVAPORATIVE EMISSIONIEVAP) CONTROL CANISTERTroubleshooting. page 1'l-205

FUEL FILTERReplacement, page 11 182

FUEL INJECTORSReplacement, page 1 1-179

FUEL FEED PIPEFUEL VAPOR PIPE

FUELFITTINGS

FUEL FILLCAP

EVAPORATIVE EMISSION

IEVAPI TWO WAY VALVETesting, page 11 224

TANKReplacement, page 11 191

-CONNECT

Precautions, page 1 1-175Disconnection, page 11 175Connection, page 1 1-176

FUEL FILTERReplacement, page 11 182

FUEL FEED PIPEFUEL VAPOR PIPE

FUEI- TANKReplacement,page 1l 191

FUEL TUBE/OUICK.CONNECTFITTINGSPrecautions, page 11 '175

Disconnection, page 11 175Connection, page 11 176

FUEL PUMPTesting, page 11 183Replacement, page 11 183FUEL GAUGE SENDING UNITTesting, page 1l'185

FUEL FILL CAP

FUEL TANK PRESSURESENSORTroubleshooting, page 1 l-209

FUEL PULSATION DAMPER

EVAPORATIVEEMTSSTONIEVAPICONTROLCANISTERVENTSHUT VALVETroubleshooting,page 11'213

EVAPORATIVE EMISSIONIEVAPI CONTROL CANISTERTroubieshooting, page 1 1 -213

FUEL RAIL

FUELFeplacement, page 1 1-179

FUEL PRESSURENEGULATORTesting, page 11-181Replacement, Page 11 181

EVAPORATIVE EMISSION{EVAP) EYPASSSOLENOID VALVETroubleshooting, page 1 1'213

€VAPORATIVE EMISSION{EVAP) TWO WAY VALVETesting, page 11 224(cont'd)

www.emanualpro.com