Pin HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 445 of 1395

Transfer Assembly

lnstallation

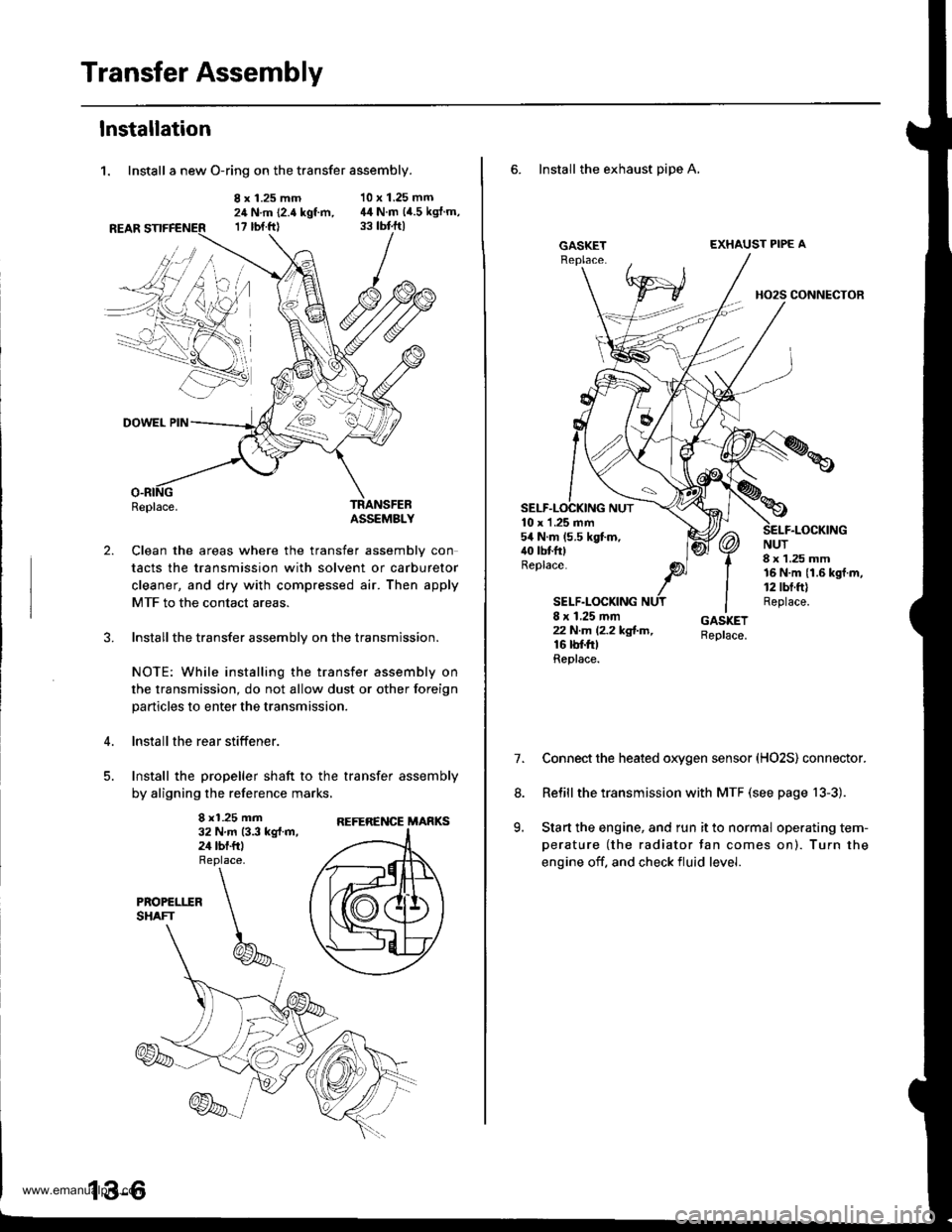

1. Install a new O-ring on the transfer assembly.

8 x 1.25 mm24 N.m (2.4 kgt m,17 rbt.ftl

10 x 1.25 mm44 N.m (4.5 kgJ.m,

2.

DOWEL PIN

Replace.TRANSFEBASSEMBLY

Clean the areas where the transfer assembly con

tacts the transmission with solvent or carburetor

cleaner, and dry with compressed air. Then apply

MTF to the contact areas.

Installthe transfer assembly on the transmission.

NOTE: While installing the transfer assembly on

the transmission, do not allow dust or other foreign

particles to enter the transmission.

lnstall the rear stiffener.

Install the propeller shaft to the transfer assembly

by aligning the reference marks,

8 x1.25 mm32 N.m 13.3 kg{.m,24 tbf.ftl

REFERENCE MARKS

6. Install the exhaust pipe A,

GASKETEXHAUST PIPE A

HO2S CONNECTOR

10 x 1 .25 mm54 N.m (5.5 kgt m,40 tbtfttReplace.

SELF.LOCKING

NUT8 x 1.25 mm16 N.m {1.6 kgf.m,12 tbt.ft)Replace.8 x 1.25 mmzzN.m l2.2kg!-m,16 rbf.trtReplace.

7.Connect the heated oxygen sensor (HO2S) connector.

Relill the transmission with MTF (see page 13-3).

Start the engine, and run it to normal operating tem-

perature (the radiator tan comes on). Turn the

engine off. and check fluid level.

8.

9.

www.emanualpro.com

Page 447 of 1395

Transmission Assembly

Removal (cont'dl

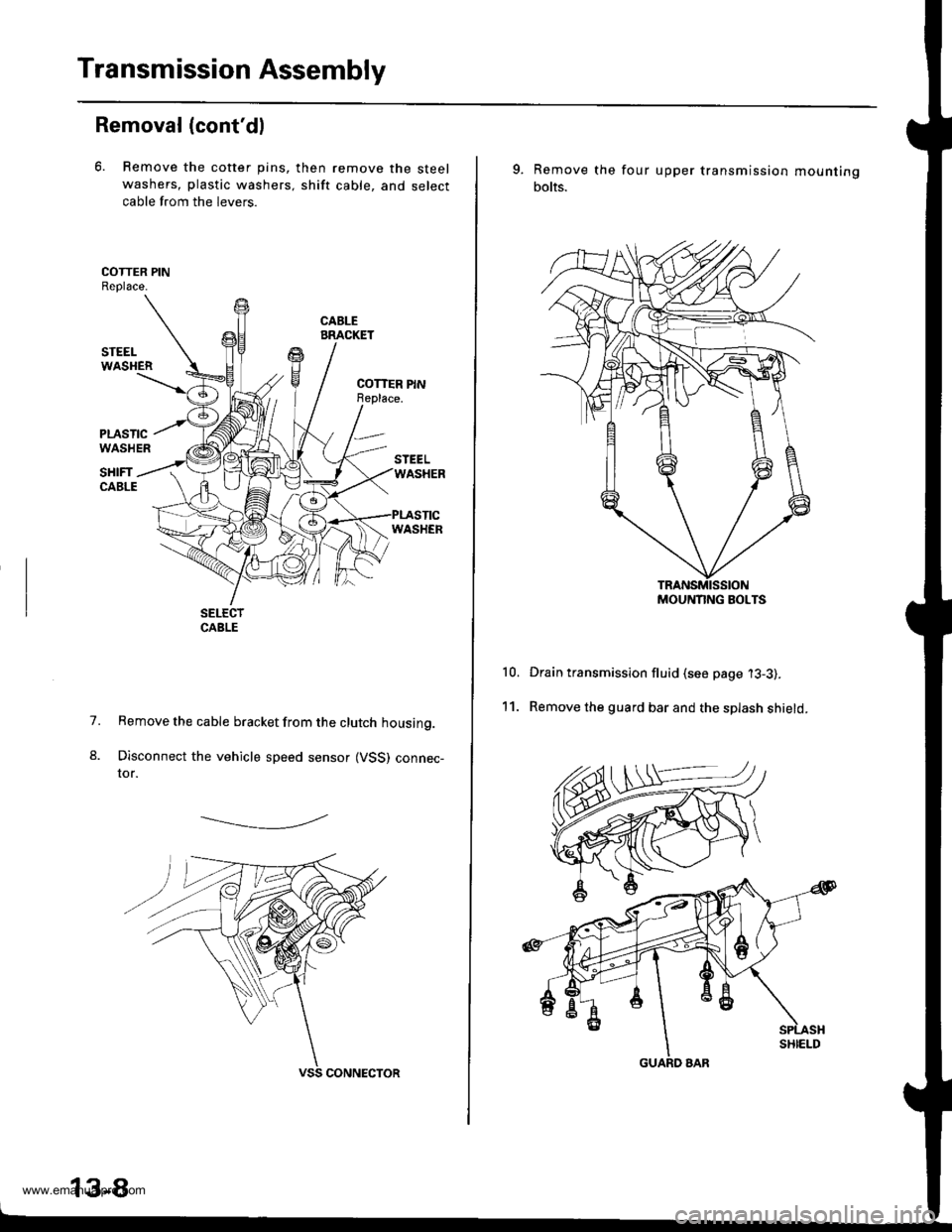

6. Remove the cotter pins,

washers, plastic washers.

cable from the levers.

then remove the steel

shift cable, and select

1.

8.

Remove the cable bracket from the clutch housing.

Disconnect the vehicle speed sensor (VSS) connec-tor.

-------------.2

13-8

9. Remove the

bolts.

four upper transmission mou nting

10.

11.

Drain transmission fluid (see page '13-3).

Remove the guard bar and the splash shield.

MOUNNNG BOLTS

www.emanualpro.com

Page 448 of 1395

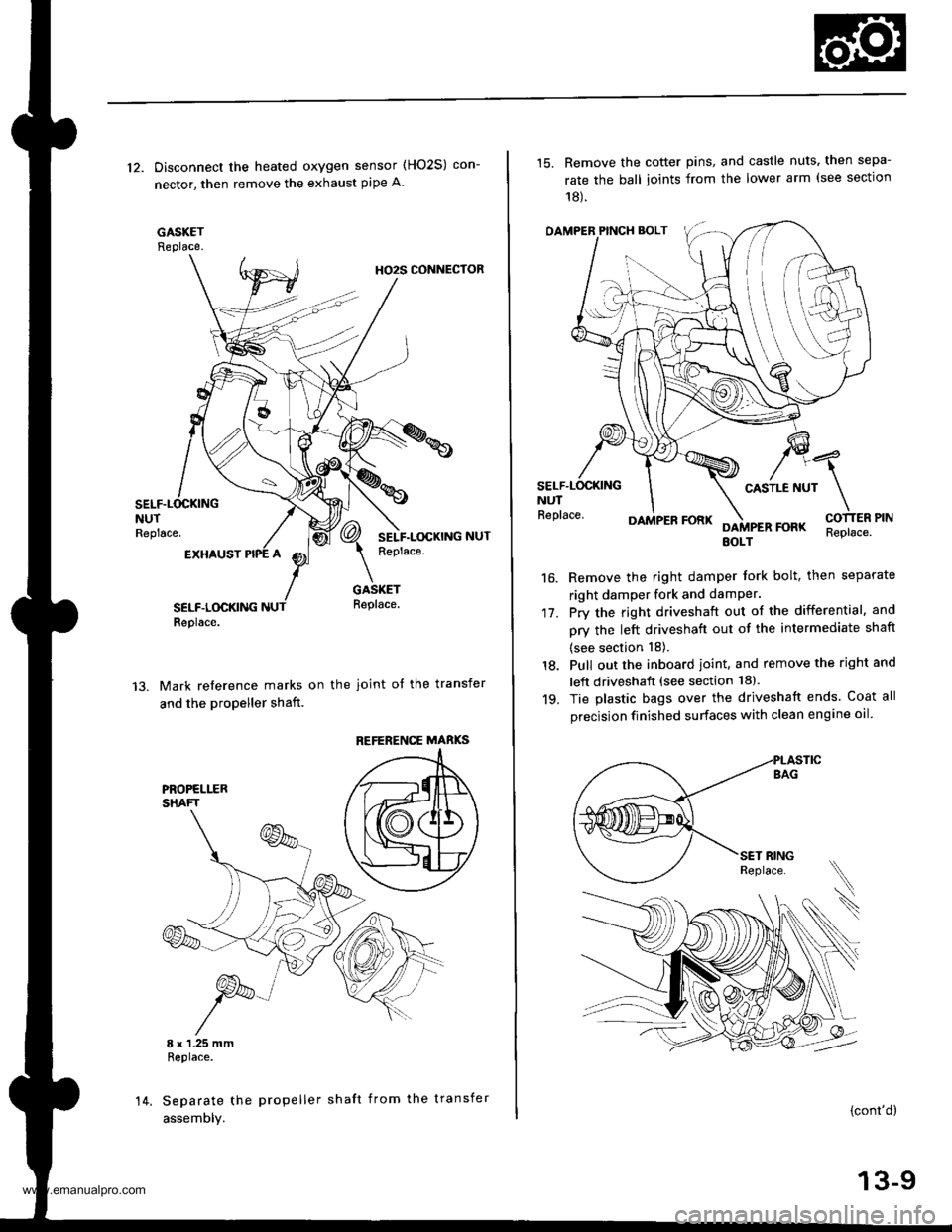

12. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove the exhaust pipe A.

GASKETReplace.

HO2S CONNECTOR

NUTReplace.

EXHAUST

SELF.LOCKINGReplace.

GASKETReplace.

Mark reference marks on the joint of the transfer

and the propeller shaft.

8 x 1.25 mmReplace.

Separate the propeller shaft from the transfer

assemDly.

REFERENCE MABKS

14.

15. Remove the cotter pins, and castle nuts. then sepa-

rate the ball ioints from the lower arm (see sectlon

18).

OAMPER PINCH BOLT

CASTLE NUTNUTReplace.

17.

16.

DAMPER FORKFOFKEOLTReplace.

Remove the right damper tork bolt, then separate

right damper fork and damPer.

Pry the right driveshaft out of the differential, and

pry the left driveshaft out of the intermediate shaft

(see section 18).

Pull out the inboard ioint, and remove the right and

left driveshaft (see section 18).

Tie plastic bags over the driveshatt ends. Coat all

precision finished surfaces with clean engine oil

18.

19.

\

{cont'd}

13-9

www.emanualpro.com

Page 452 of 1395

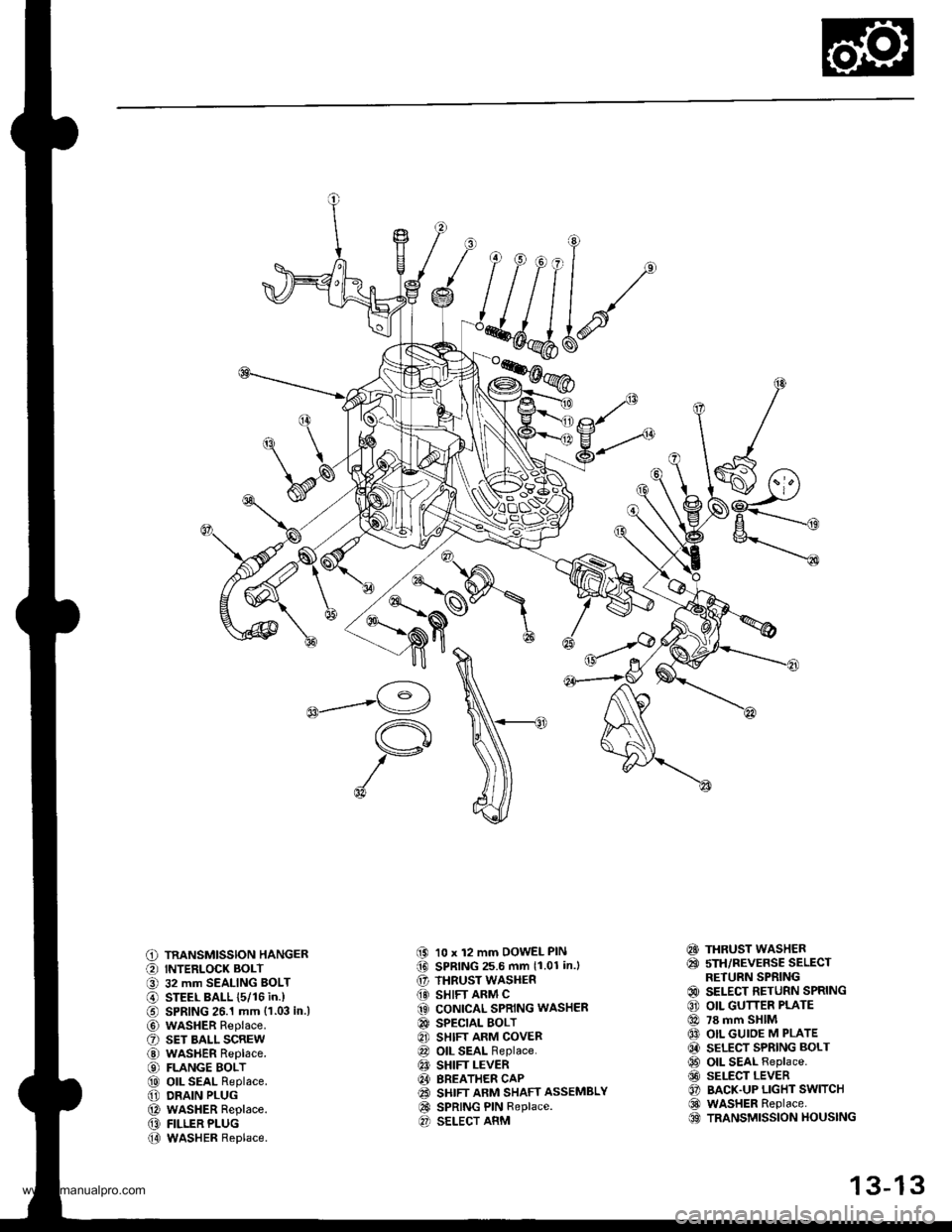

C) TRANSMISSION HANGER

O INTERLOCK BOLT

O 32 mm SEALING BOLT

@ STEEL BALL {5/16 in.)

€) SPRING 26.1 mm {1.03 in.l

@ wasHER Replace.

O sET BALL scREw

@ WASHER Replace.

€) FLANGE BOLT

@ oll SEAL Replace.

@ DRAIN PLUG

@ WASHER Replace.

@ FILLER PLUG

@ WASHER Replace.

(9 10 x 12 mm DOWEL PIN(D SPRING 25.6 mm 11.01 in.l

€' THRUST WASHER

@} SHIFT ARM C(3 CONICAL SPRING WASHER

@ SPECTAL BOLT

8] SHIFT ARM COVER

@ OIL SEAL Replace.

€! SHIFT LEVER

@I BREATHER CAP(2! SHIFT ARM SHAFT ASSEMBLY

@ SPRING PIN Replace.O SELECT ARM

€!} THRUST WASHER

@ sTH/REVERSE SELECTRETURN SPRING

@ SELECT RETURN SPRING

€) OIL GUTTER PLATE

@ 78 mm SHIM

@ OIL GUIOE M PLATE

@ SELECT SPRING BOLT

@ OIL SEAL Replace.

@ SELECT LEVER

O BACK.UP LIGHT SWITCH

@ WASHER Replace.OO TRANSMISSION HOUSING

13-13

www.emanualpro.com

Page 454 of 1395

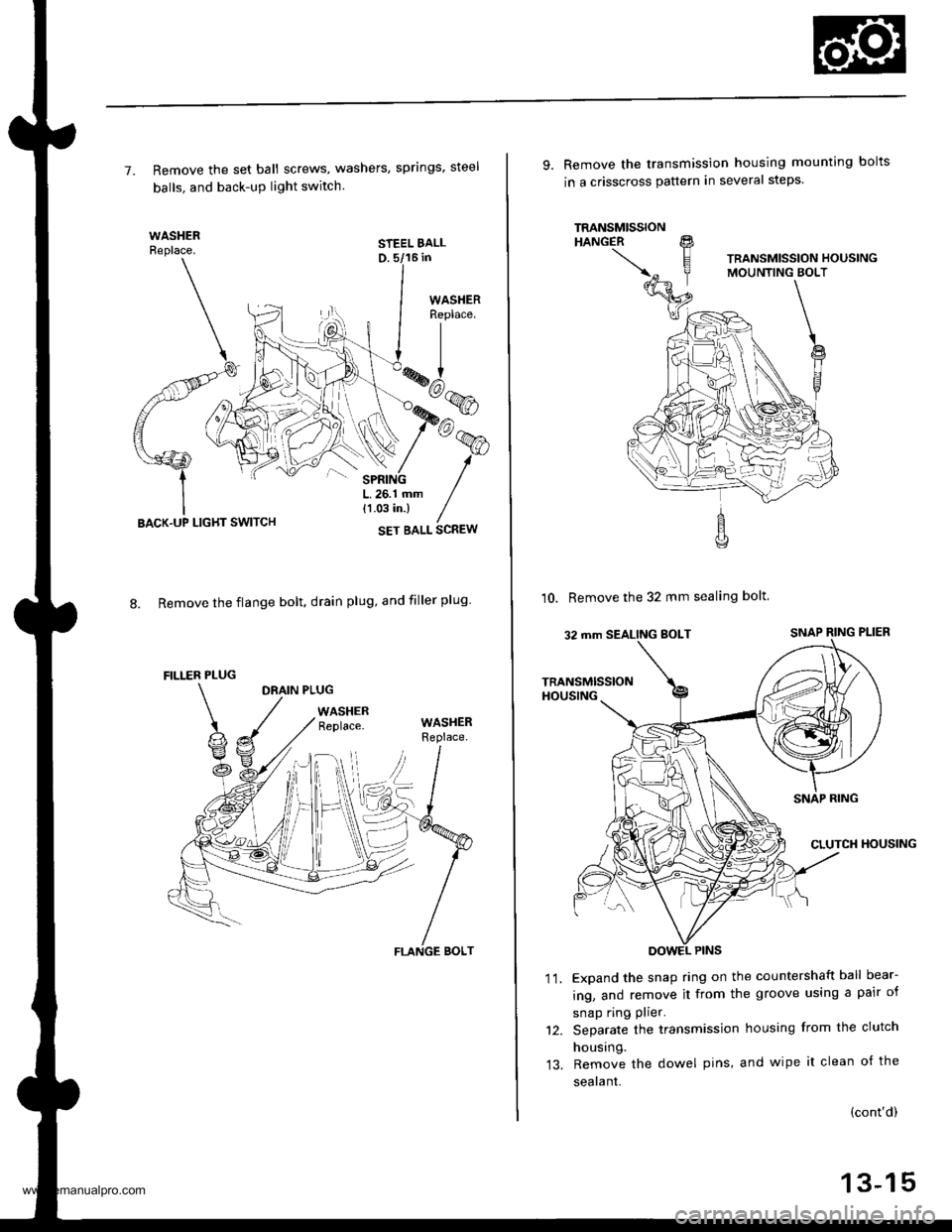

7. Remove the set ball screws, washers, springs, steel

balls. and back-uP light switch.

STEEL BALLD. 5/16 in

8. Remove the flange bolt. drain plug, and filler plug

DRAIN PLUG

WASHERReplace.

LIGHT SWITCH

FILLER PLUG

WASHERReplace.

FLANGE BOLT

9. Remove the transmission housing mounting bolts

in a crisscross pauern in several steps.

10. Remove the 32 mm sealing bolt

Expand the snap ring on the countershaft ball bear-

ing, and remove it from the groove using a pair of

snap ring plier.

Separate the transmission housing from the clutch

housing.

Remove the dowel pins, and wipe it clean of the

sealant.

'I t.

(cont'd)

13-15

www.emanualpro.com

Page 455 of 1395

Transmission Assembly

Disassembly (cont'dl

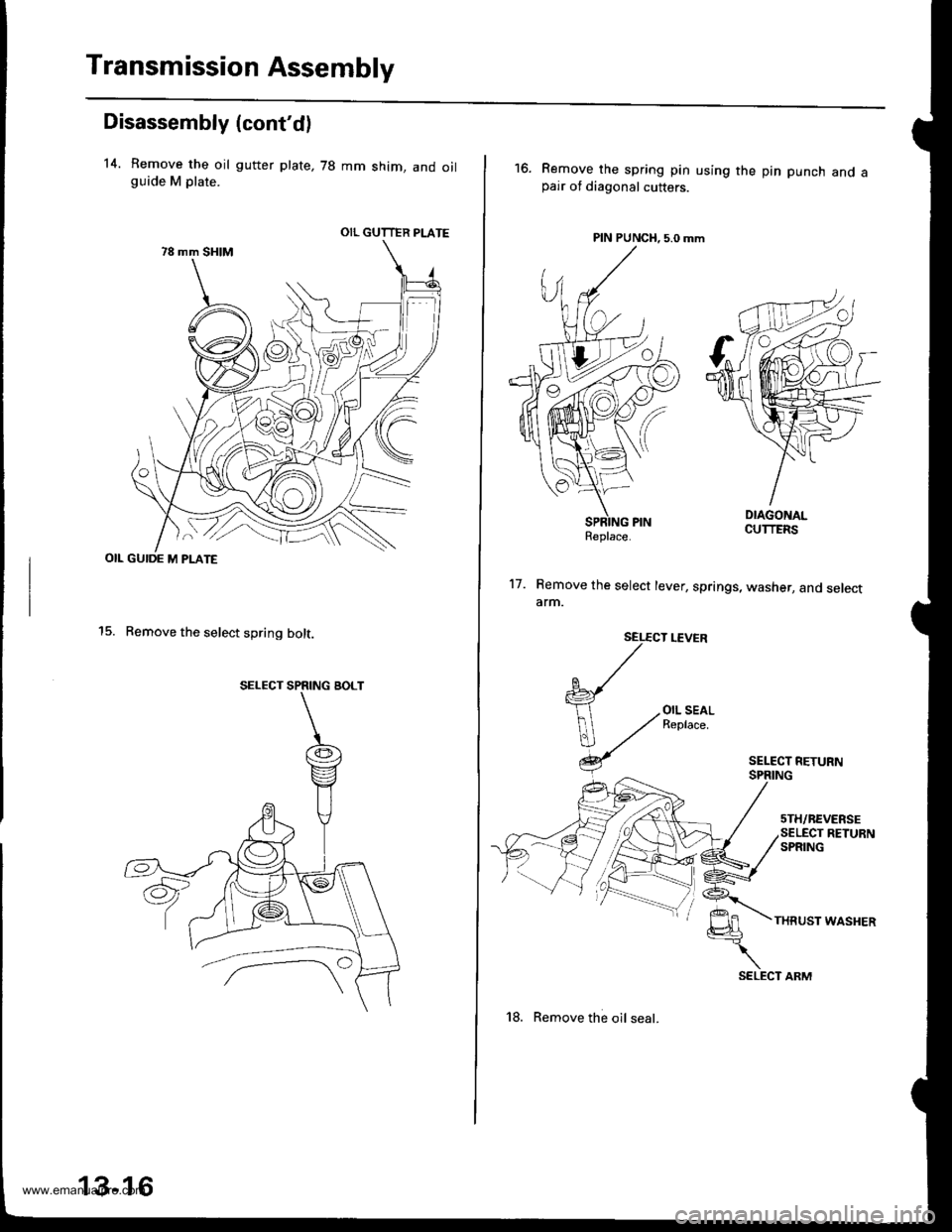

14. Remove the oil gutter plate, 78 mm shim, and oilguide M plate.

OIL GUIDE M PLATE

15. Remove the select spring bolt.

OIL GUTTER PLATE

SELECT SPRING BOLT

13-16

18. Remove the oil seal.

16.Remove the spring pin using the pin punch and apair of diagonal cutters.

PIN PUNCH, 5.0 mm

17. Remove the select lever, springs, washer, and selectarm.

SEL€CT LEVER

{

V

OIL SEALReplace.

THRUST WASHER

Replace.

SELECT ARM

www.emanualpro.com

Page 458 of 1395

2.

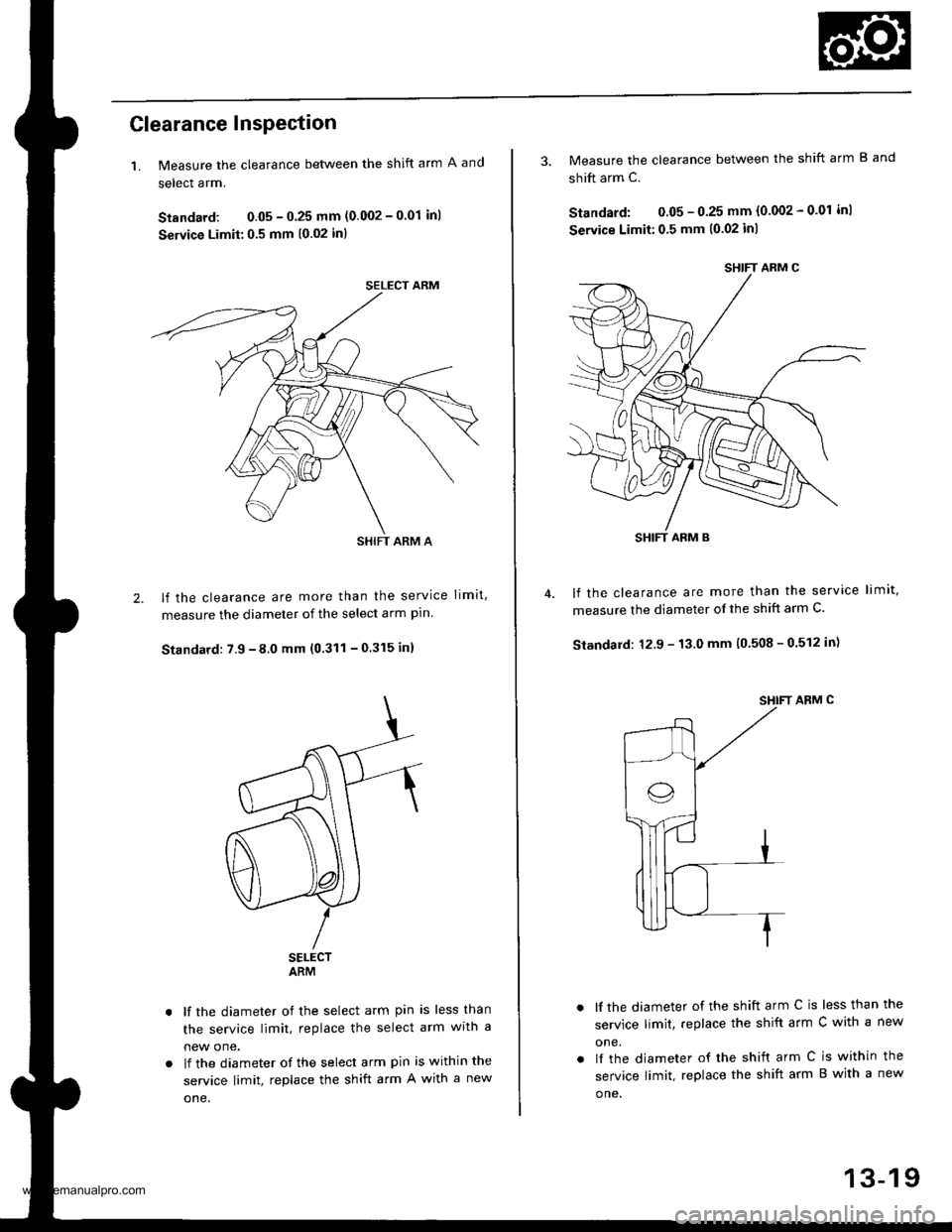

Clearance InsPection

1. Measure the clearance between the shift arm A and

select arm.

Standard: 0.05 - 0 25 mm (0.002 - 0'01 inl

Service Limit:0.5 mm (0.02 in)

lf the clearance are more than the service limit,

measure the diameter of the select arm pln

Standard: 7.9 - 8.0 mm (0.311 - 0.315 in)

SELECTARM

lf the diameter of the select arm pin is less than

the service limit, replace the select arm wrtn a

new one.

lf the diameter of the select arm pin is within the

service limit, replace the shift arm A with a new

one.

SELECT ARM

SHIFT ARM A

SHIFT ARM C

SHIFT ARM B

3. Measure the clearance between the shift arm B and

shift arm c.

Standard: 0.05 - 0.25 mm (0.002 - 0.01 inl

Seryice Limit:0,5 mm (0.02 inl

lf the clearance are more than the service limit,

measure the diameter of the shift arm C.

Standard: 12.9 - 13.0 mm (0 508 - 0.512 in)

SHIFT ARM C

lf the diameter of the shift arm C is less than the

service limit, replace the shift arm C with a new

one.

lf the diameter of rhe shift arm C is within the

service limit, replace the shift arm B with a new

o ne.

13-19

www.emanualpro.com

Page 459 of 1395

Reverse Shift Holder

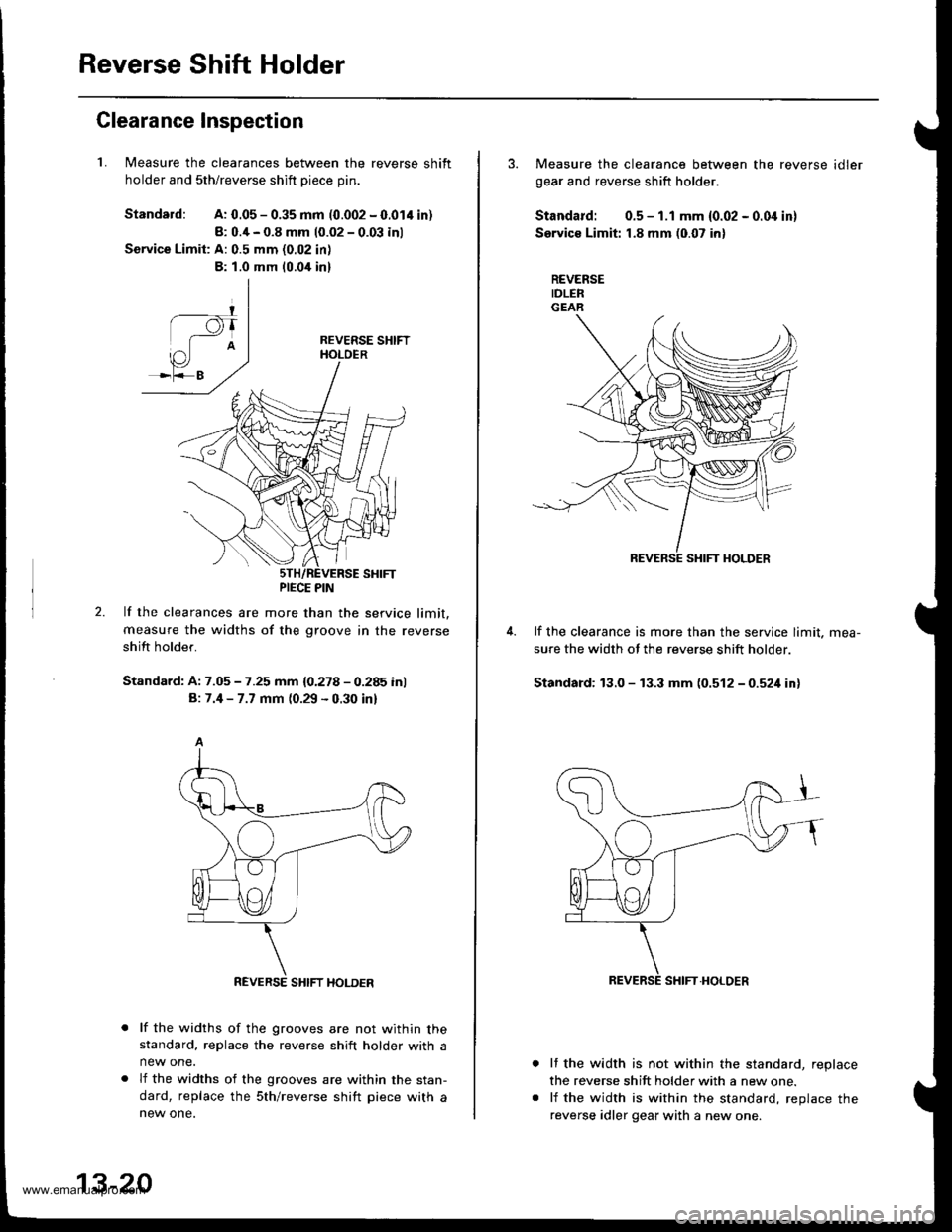

Clearance Inspection

1.Measure the clearances between the reverse shift

holder and sth/reverse shift Diece Din.

Standard:A: 0.05 - 0.35 mm (0.002 - 0.014 in)

8: 0.4 - 0.8 mm 10.02 - 0.03 inl

Service Limit: A: 0.5 mm (0.02 in)

B: 1.0 mm 10.0,[ in]

2.lf the clearances are more than the service limit.

measure the widths of the groove in the reverse

shift holder.

Standard: A: 7.05 - 7.25 mm {0.278 - 0.285 inl

B: 7.4 - 7.7 mm (0.29 - 0.30 inl

lf the widths of the grooves are not within thestandard, replace the reverse shift holder with a

new one.

lf the widths of the grooves are within the stan-

dard, replace the sth/reverse shift piece with anew one.

PIECE PIN

REVERSE SHIFT HOLDER

13-20

3. Measure the clearance between the reverse idler

gear and reverse shift holder.

Standard: 0.5 - 1.1 mm {0.02 - 0.0i1 in}

Service Limit: 1.8 mm (0.07 in)

REVERSEIDLERGEAR

lf the clearance is more than the service limit. mea-

sure the width ot the reverse shift holder.

Standard: 13.0 - 13.3 mm (0.512-0521inl

It the width is not within the standard, replace

the reverse shift holder with a new one.

lf the width is within the standard, reolace the

reverse idler gear with a new one.

www.emanualpro.com

Page 460 of 1395

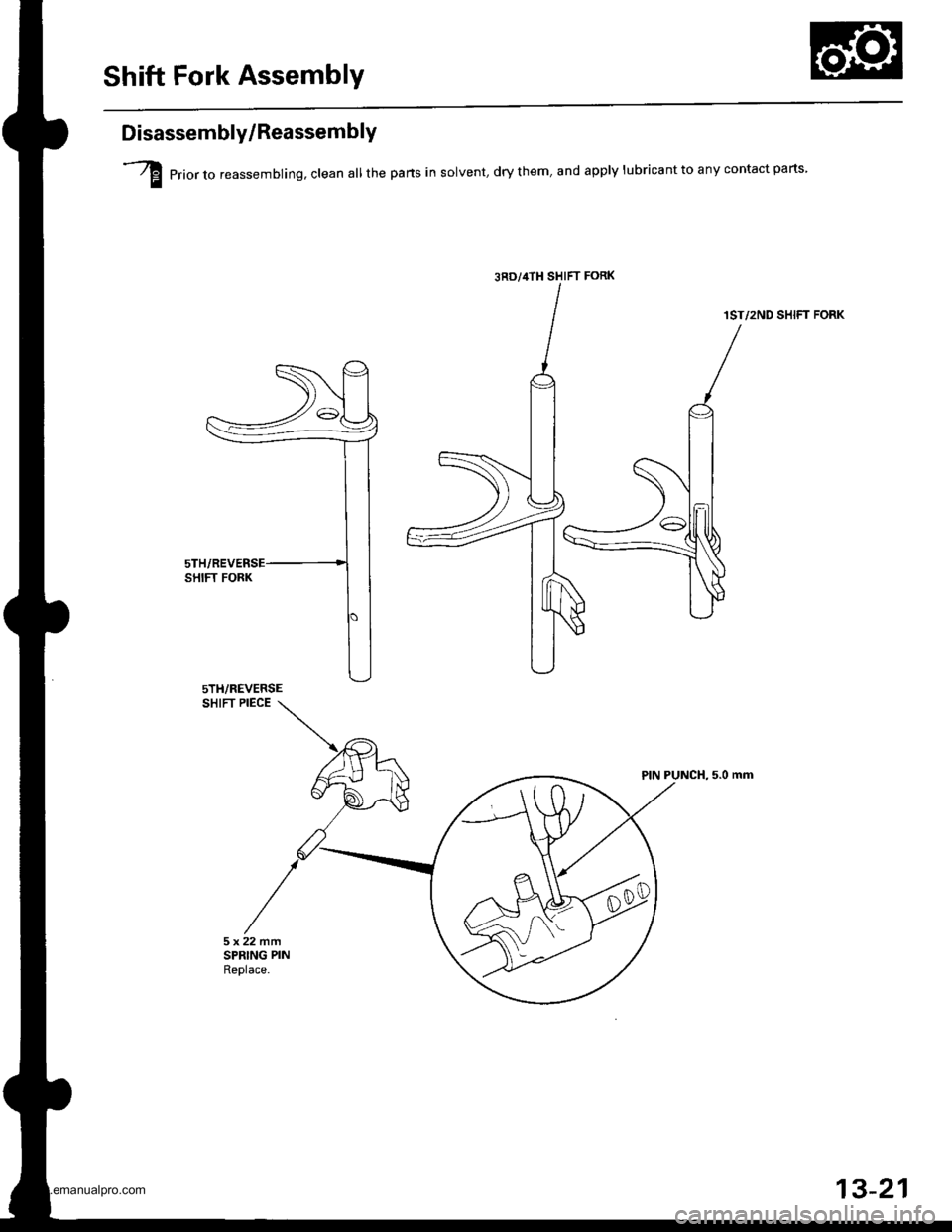

Shift Fork Assembly

Disassembly/ReassemblY

I erior,o reassembling, clean all the pans in solvent, dry them, and apply lubricant to any contact parts

1ST/2ND SHIFT FORK

SHIFT PIECE

PIN PUNCH, 5.0 mm

3RD/,|TH SHIFT FoRK

5TH/REVERSE

13-21

www.emanualpro.com

Page 477 of 1395

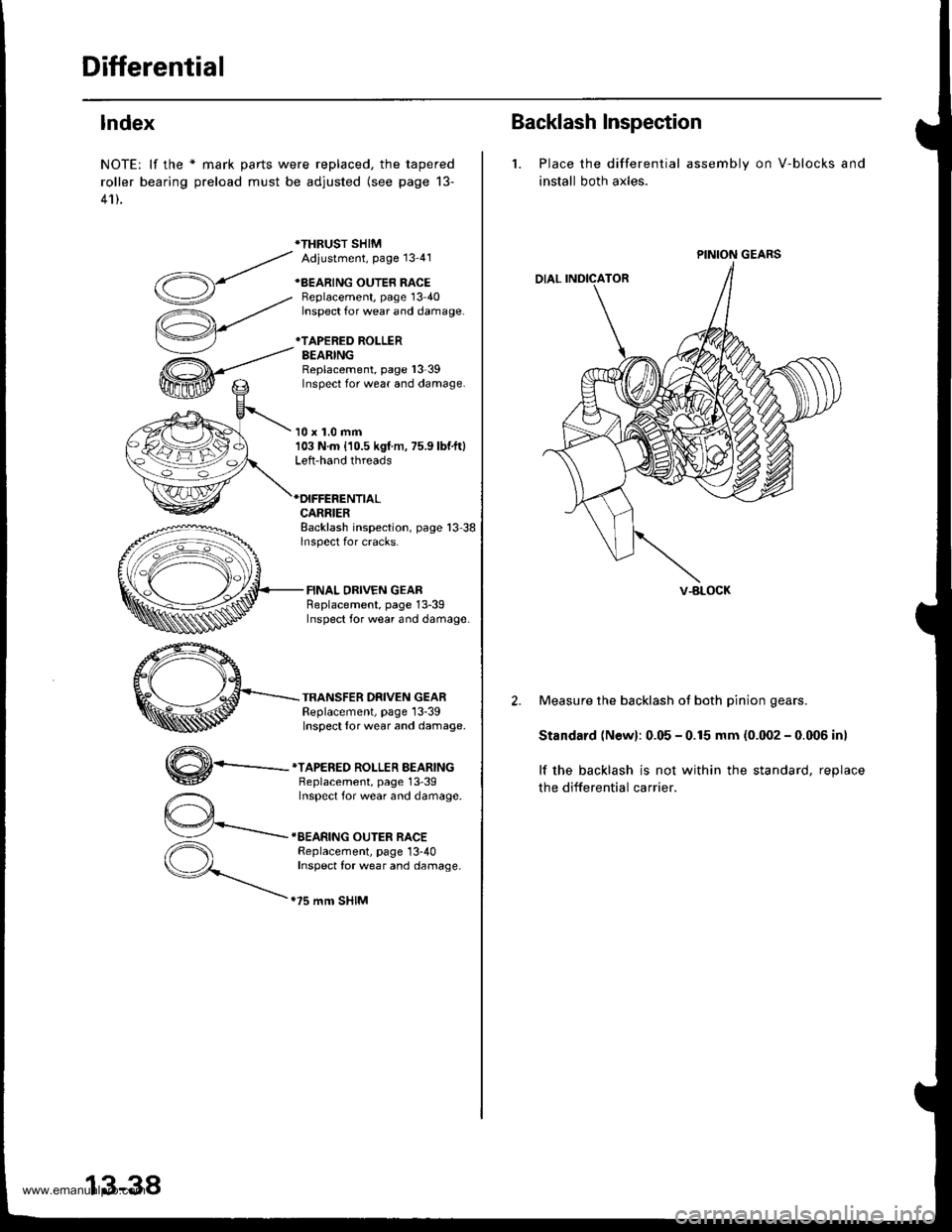

Differential

lndex

NOTE: lf the * mark parts were replaced, the tapered

roller bearing preload must be adjusted (see page 13-

41).

*THRUST SHIMAdiustment, Page 13'41

+BEARING OUTER RACEBeplacement, page 13 40Inspect for wear and damage.

*TAPERED ROLLERBEARINGReplacement, page l3-39Inspect for wear and damage.

10 x 1.0 mm103 N.m {10.5 kgf m, 75.9 lbf.ft}Left-hand threads

CARRIERBacklash inspection, page 13 38lnspect for cracks.

FINAL DRIVEN GEARReplacement, page 13-39Inspect for wear and damage

TRANSFER DRIVEN GEARReplacement, page 13-39Inspect {or wear and damage.

,,4\

W-

*TAPERED ROLLER BEARINGBeplacement, page 13'39Inspect for wear and damage.

IEEARING OUTER RACEReplacement, page 13-40Inspect for wear and damage.

.75 mm SHIM

13-38

Backlash Inspection

1. Place the differential

install both axles.

assembly on V-blocks and

PINION GEARS

V-BLOCK

2. Measure the backlash ot both pinion gears.

Standard (Newl: 0.05 - 0.15 mm (0.002 - 0.006 inl

lf the backlash is not within the standard, reolace

the differential carrier.

www.emanualpro.com