trans HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 448 of 1395

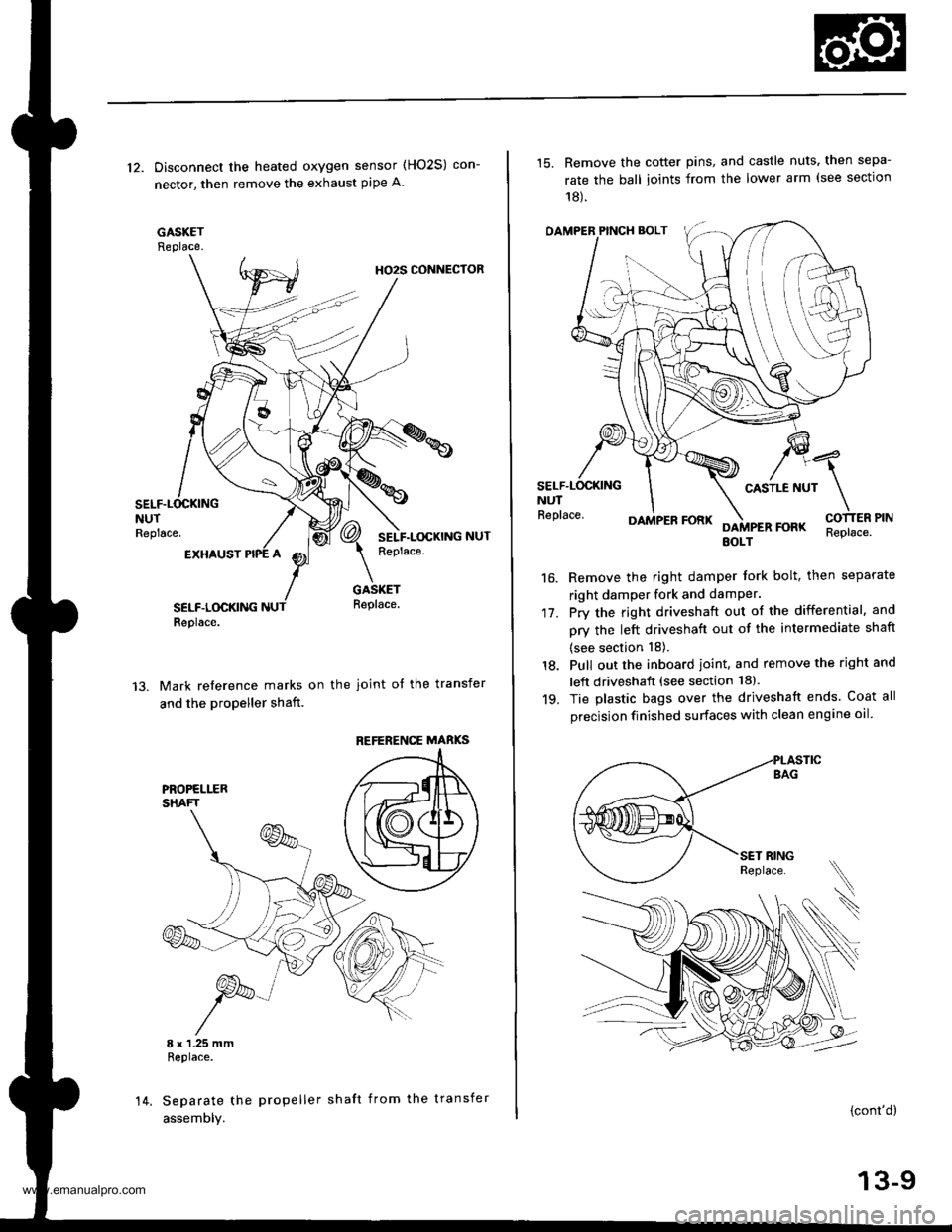

12. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove the exhaust pipe A.

GASKETReplace.

HO2S CONNECTOR

NUTReplace.

EXHAUST

SELF.LOCKINGReplace.

GASKETReplace.

Mark reference marks on the joint of the transfer

and the propeller shaft.

8 x 1.25 mmReplace.

Separate the propeller shaft from the transfer

assemDly.

REFERENCE MABKS

14.

15. Remove the cotter pins, and castle nuts. then sepa-

rate the ball ioints from the lower arm (see sectlon

18).

OAMPER PINCH BOLT

CASTLE NUTNUTReplace.

17.

16.

DAMPER FORKFOFKEOLTReplace.

Remove the right damper tork bolt, then separate

right damper fork and damPer.

Pry the right driveshaft out of the differential, and

pry the left driveshaft out of the intermediate shaft

(see section 18).

Pull out the inboard ioint, and remove the right and

left driveshaft (see section 18).

Tie plastic bags over the driveshatt ends. Coat all

precision finished surfaces with clean engine oil

18.

19.

\

{cont'd}

13-9

www.emanualpro.com

Page 449 of 1395

Transmission Assembly

Removal (cont'd)

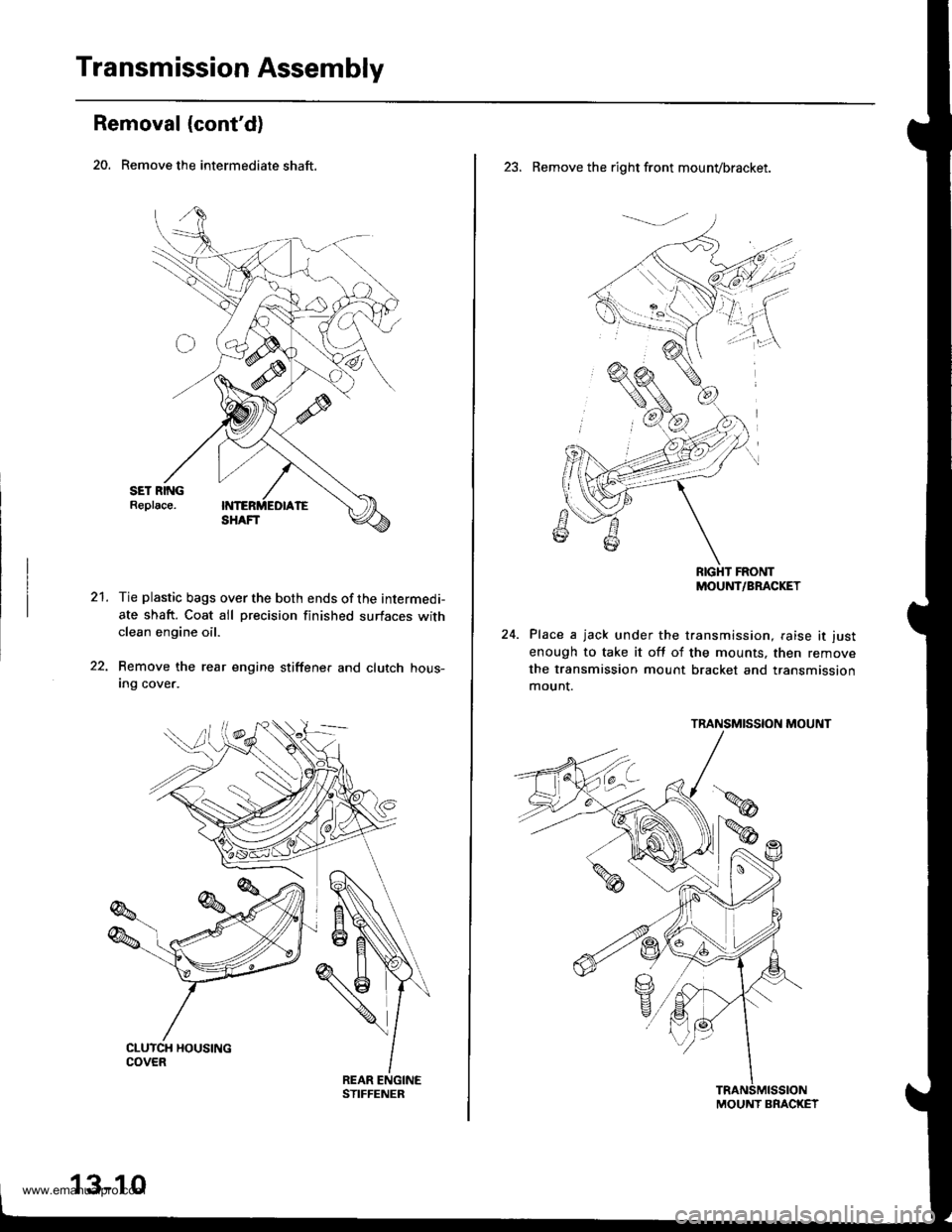

20. Remove the intermediate shaft.

21.Tie plastic bags over the both ends of the intermedi-

ate shaft. Coat all precision finished surfaces withclean engine oil.

Remove the rear engine stiffene. and clutch hous-Ing cover.

13-10

23. Remove the right front mounvbracket.

RIGHT FRONTMOUNT/BRACKET

Place a jack under the transmission, raise it just

enough to take it off of the mounts, then remove

the transmission mount bracket and transmission

mount.

TRANSMISSION MOUNT

MOUNT BRACKET

www.emanualpro.com

Page 450 of 1395

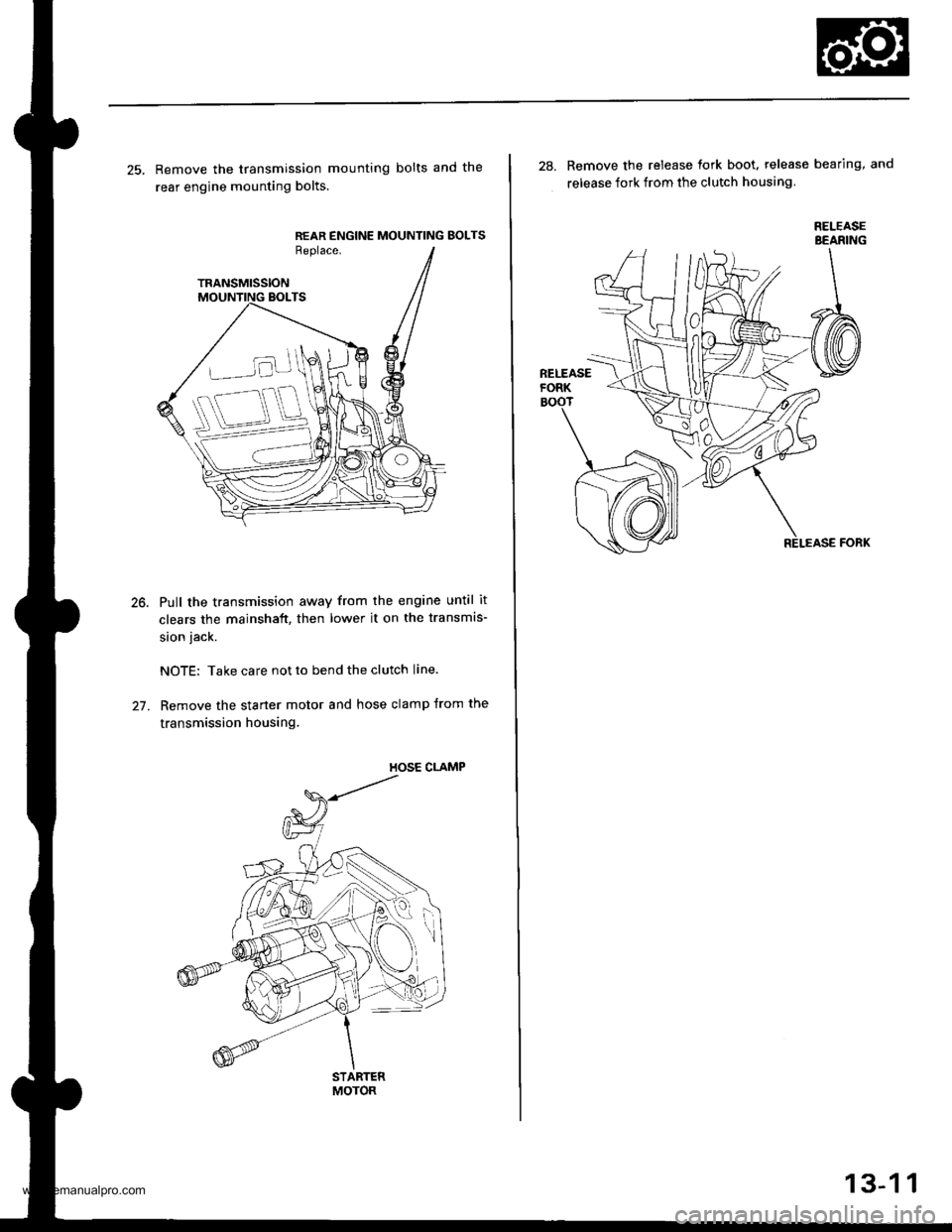

25. Remove the transmission mounting bolts and the

rear engine mounting bolts.

REAR ENGINE MOUNTING BOLTSReplace.

TRANSMISSION

Pull the transmission away from the engine until it

clears the mainshaft, then lower it on the transmis-

sion jack.

NOTE: Take care not to bend the clutch line.

Remove the starter motor and hose clamp from the

transmission housing.

STARTERMOTOR

28. Remove the release tork boot. release bearing, and

release fork from the clutch housing

RELEASEBEANING

13-1 1

www.emanualpro.com

Page 451 of 1395

Transmission Assembly

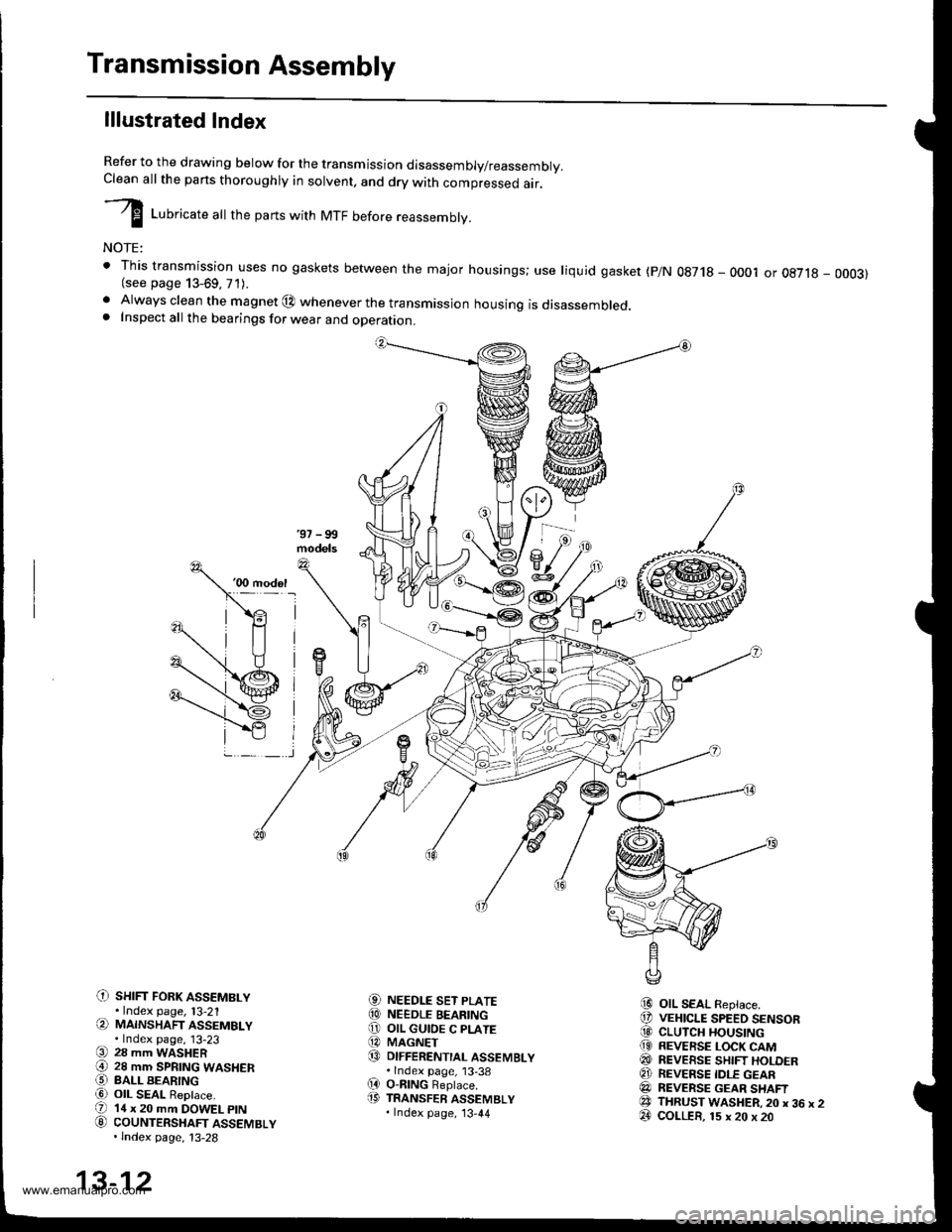

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.Clean all the pans thoroughly in solvent, and drv with comoressed air.

I LuUri""r" utt the parts with MTF before reassembly.

NOTE:

t This transmission uses no gaskets between the major housings; use liquid gasket (p/N 0g718 - 0001 or oE7l8 - 0003)(see page 13-69, 71).. Always clean the magnet @ whenever the transmissjon housing is disassembled.. Inspect all the bearings for wear and operation.

C) sHrFr FoRK ASSEMBLY.Index page, l3-21(a MAINSHAFT ASSEMBLY.Index page, 13-23(9 28 mm WASHER€) 28 mm SPRTNG WASHERO BALL BEARINGa6) OIL SEAL ReDlace.(D 14 x 20 mm DOWEL ptN

G) couNTERSHAFT ASSEMBLY.lndex page, 13-28

NEEDLE SET PLATENEEDLE BEARINGOIL GUIOE C PLATEMAGNETDIFFERENTIAL ASSEMBLY.lndex page, 13-38O-nlNG Beplace.TRANSFER ASSEMBLY.Index page, '13,44

OIL SEAL Replace.VEHICLE SPEED SENSORCLUTCH HOUSINGREVERSE LOCK CAMREVEESE SHIFT HOLDERREVERSE IDLE GEARREVERSE GEAR SHAFTTHRUST WASHER,20 x 36 x 2COLLER, 15 x 20 x 20

aol

@o@@

(D

i9

@@@(9

@@@e3@

13-12

www.emanualpro.com

Page 452 of 1395

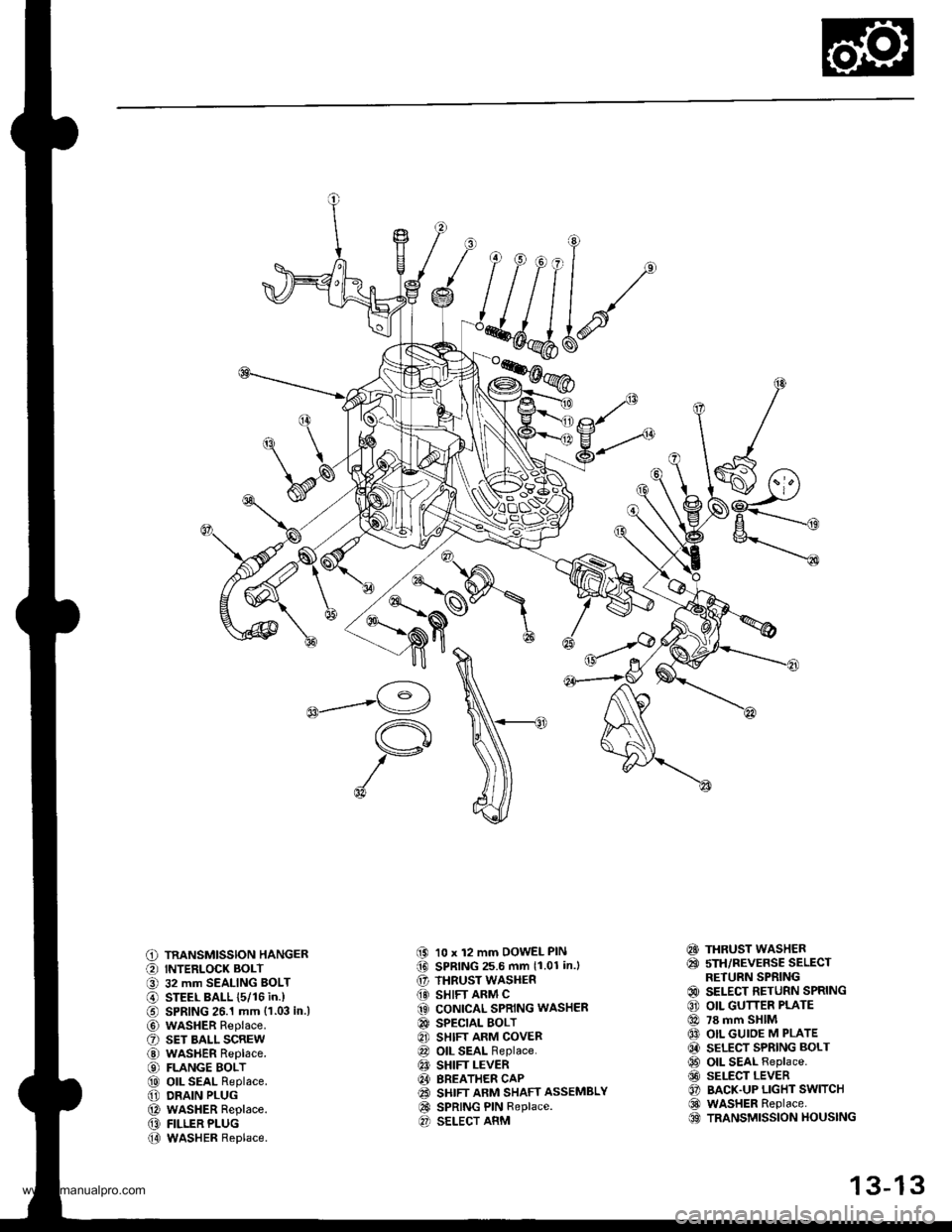

C) TRANSMISSION HANGER

O INTERLOCK BOLT

O 32 mm SEALING BOLT

@ STEEL BALL {5/16 in.)

€) SPRING 26.1 mm {1.03 in.l

@ wasHER Replace.

O sET BALL scREw

@ WASHER Replace.

€) FLANGE BOLT

@ oll SEAL Replace.

@ DRAIN PLUG

@ WASHER Replace.

@ FILLER PLUG

@ WASHER Replace.

(9 10 x 12 mm DOWEL PIN(D SPRING 25.6 mm 11.01 in.l

€' THRUST WASHER

@} SHIFT ARM C(3 CONICAL SPRING WASHER

@ SPECTAL BOLT

8] SHIFT ARM COVER

@ OIL SEAL Replace.

€! SHIFT LEVER

@I BREATHER CAP(2! SHIFT ARM SHAFT ASSEMBLY

@ SPRING PIN Replace.O SELECT ARM

€!} THRUST WASHER

@ sTH/REVERSE SELECTRETURN SPRING

@ SELECT RETURN SPRING

€) OIL GUTTER PLATE

@ 78 mm SHIM

@ OIL GUIOE M PLATE

@ SELECT SPRING BOLT

@ OIL SEAL Replace.

@ SELECT LEVER

O BACK.UP LIGHT SWITCH

@ WASHER Replace.OO TRANSMISSION HOUSING

13-13

www.emanualpro.com

Page 453 of 1395

Transmission Assembly

Disassembly

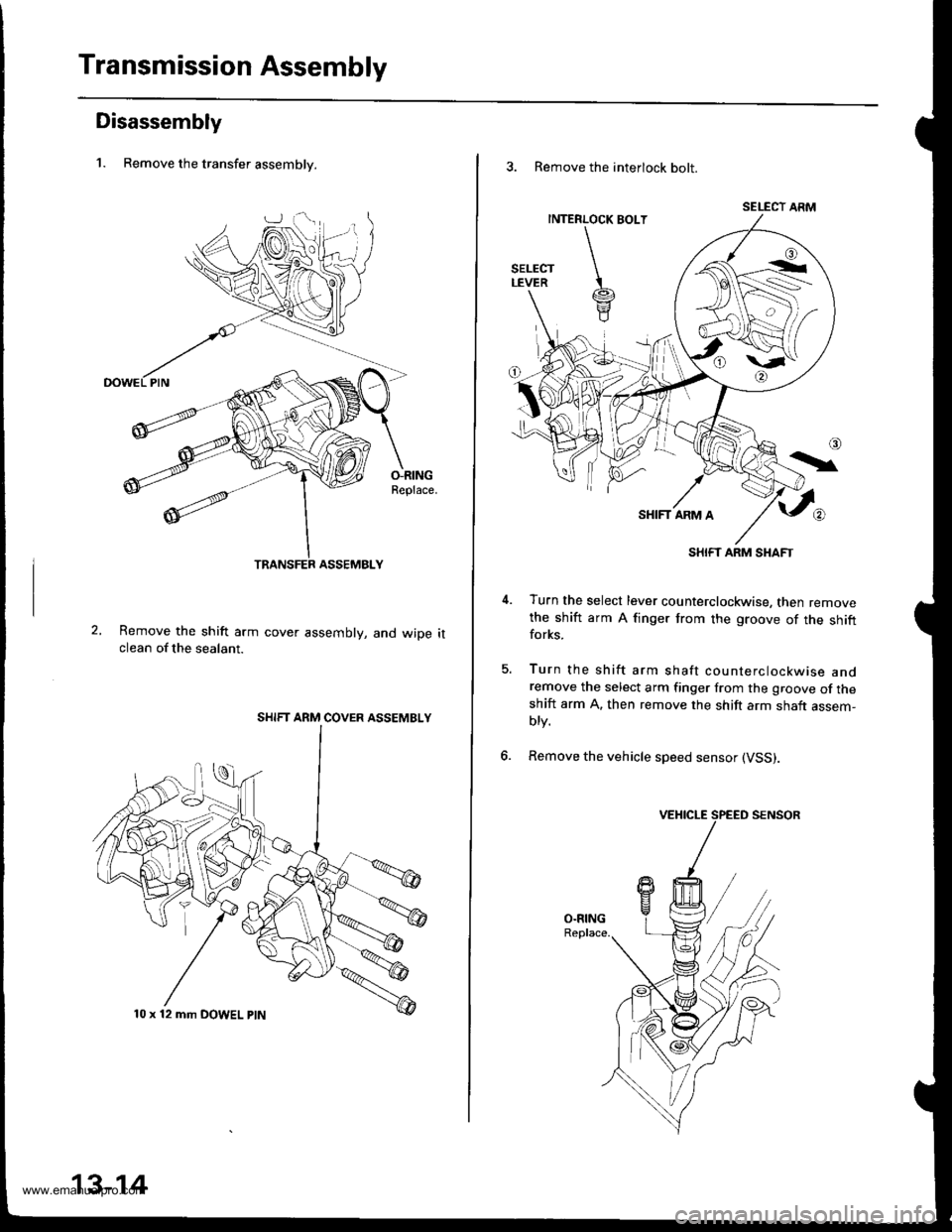

1. Remove the transfer assemblv.

O-RINGReplace.

Remove the shift arm cover assembly, and wiDe itclean of the sealant.

SHIFT ARM COVER ASSEMBLY

10 x 12 mm DOWEL ptN

13-14

3. Remove the interlock bolt.

SELECT ARM

SHIFT ARM SHAFT

Turn the select lever counterclockwise, then removethe shift arm A finger from the groove of the shiftforks.

Turn the shift arm shaft counterclockwise andremove the select arm finger from the groove of theshift arm A. then remove the shift arm shaft assem-blv.

Remove the vehicle speed sensor (VSS).

5.

6.

www.emanualpro.com

Page 454 of 1395

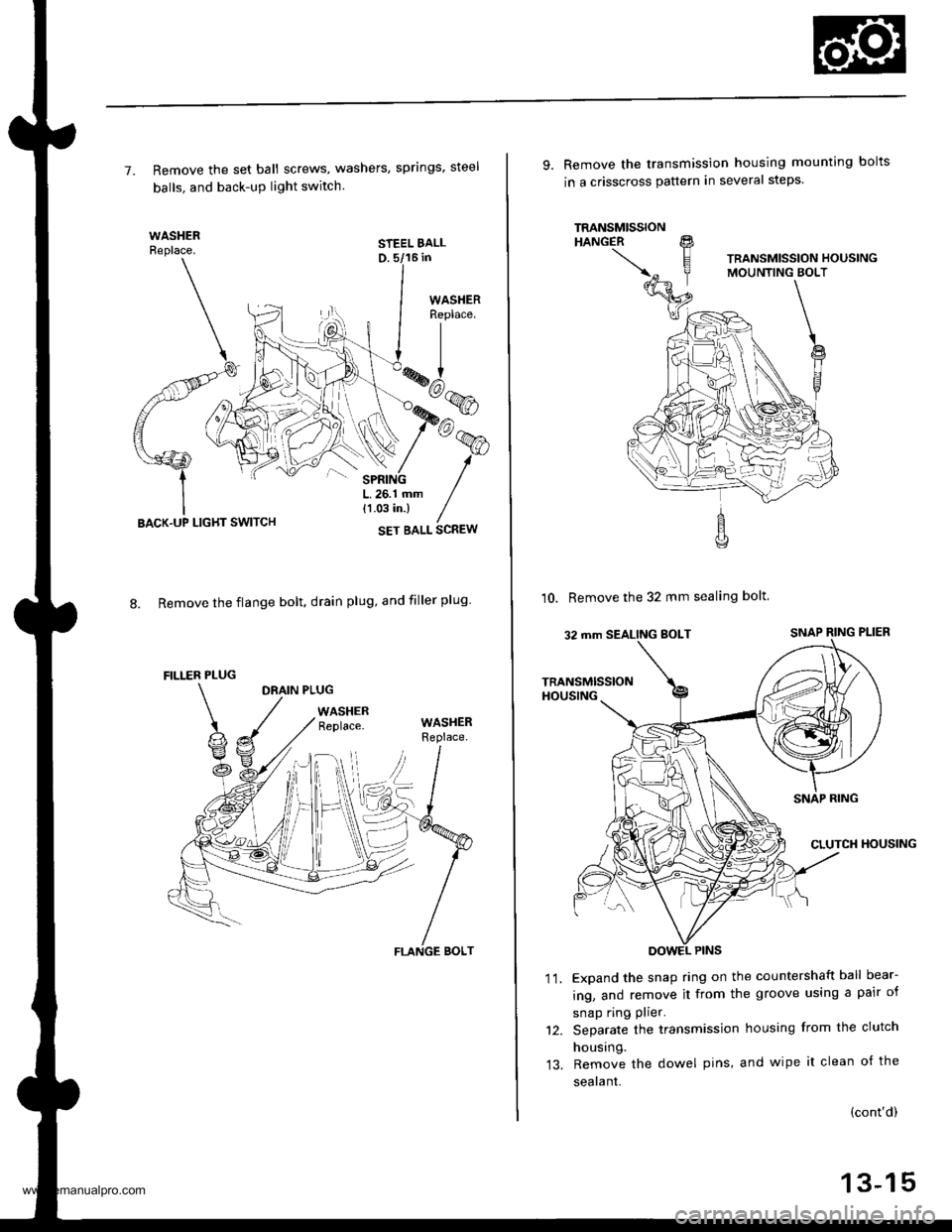

7. Remove the set ball screws, washers, springs, steel

balls. and back-uP light switch.

STEEL BALLD. 5/16 in

8. Remove the flange bolt. drain plug, and filler plug

DRAIN PLUG

WASHERReplace.

LIGHT SWITCH

FILLER PLUG

WASHERReplace.

FLANGE BOLT

9. Remove the transmission housing mounting bolts

in a crisscross pauern in several steps.

10. Remove the 32 mm sealing bolt

Expand the snap ring on the countershaft ball bear-

ing, and remove it from the groove using a pair of

snap ring plier.

Separate the transmission housing from the clutch

housing.

Remove the dowel pins, and wipe it clean of the

sealant.

'I t.

(cont'd)

13-15

www.emanualpro.com

Page 455 of 1395

Transmission Assembly

Disassembly (cont'dl

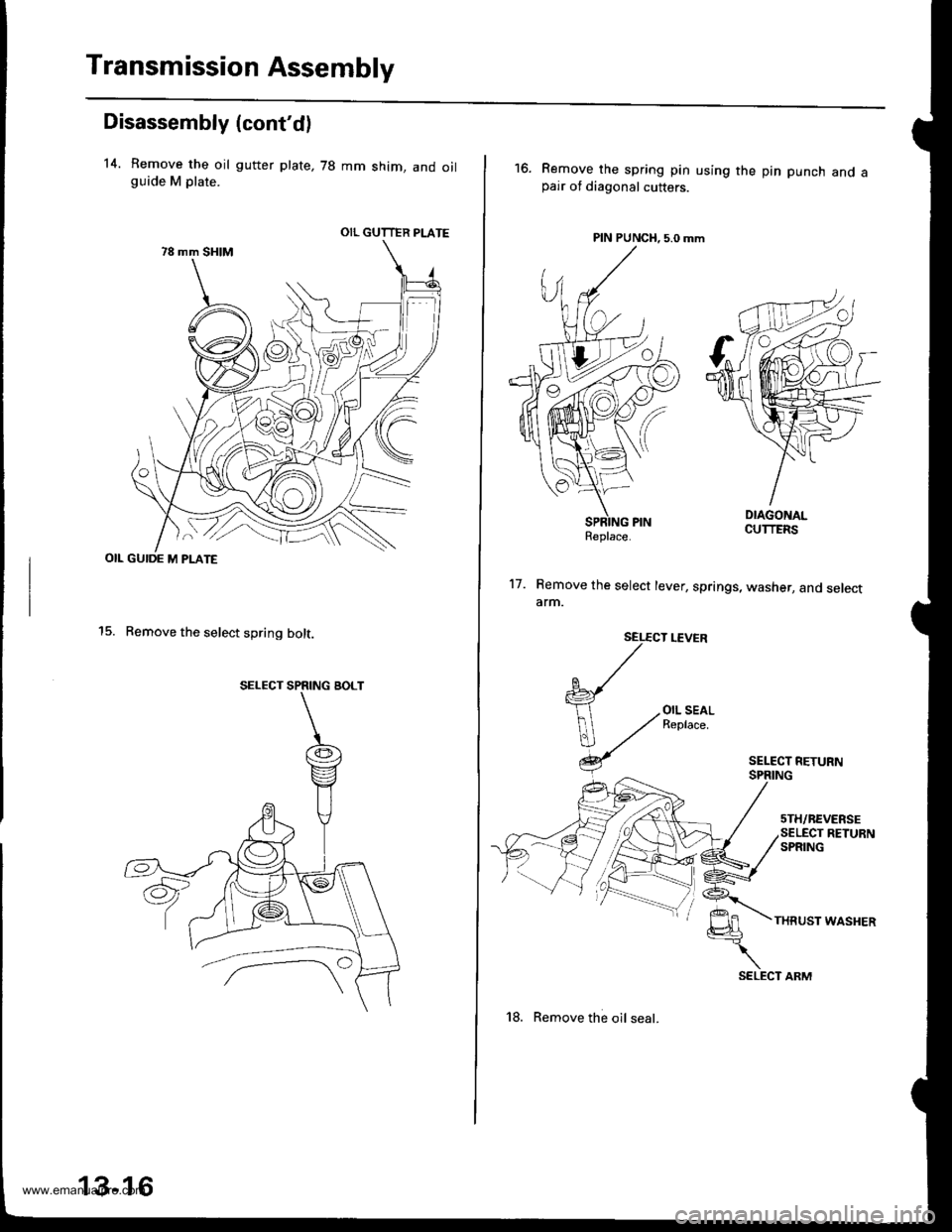

14. Remove the oil gutter plate, 78 mm shim, and oilguide M plate.

OIL GUIDE M PLATE

15. Remove the select spring bolt.

OIL GUTTER PLATE

SELECT SPRING BOLT

13-16

18. Remove the oil seal.

16.Remove the spring pin using the pin punch and apair of diagonal cutters.

PIN PUNCH, 5.0 mm

17. Remove the select lever, springs, washer, and selectarm.

SEL€CT LEVER

{

V

OIL SEALReplace.

THRUST WASHER

Replace.

SELECT ARM

www.emanualpro.com

Page 477 of 1395

Differential

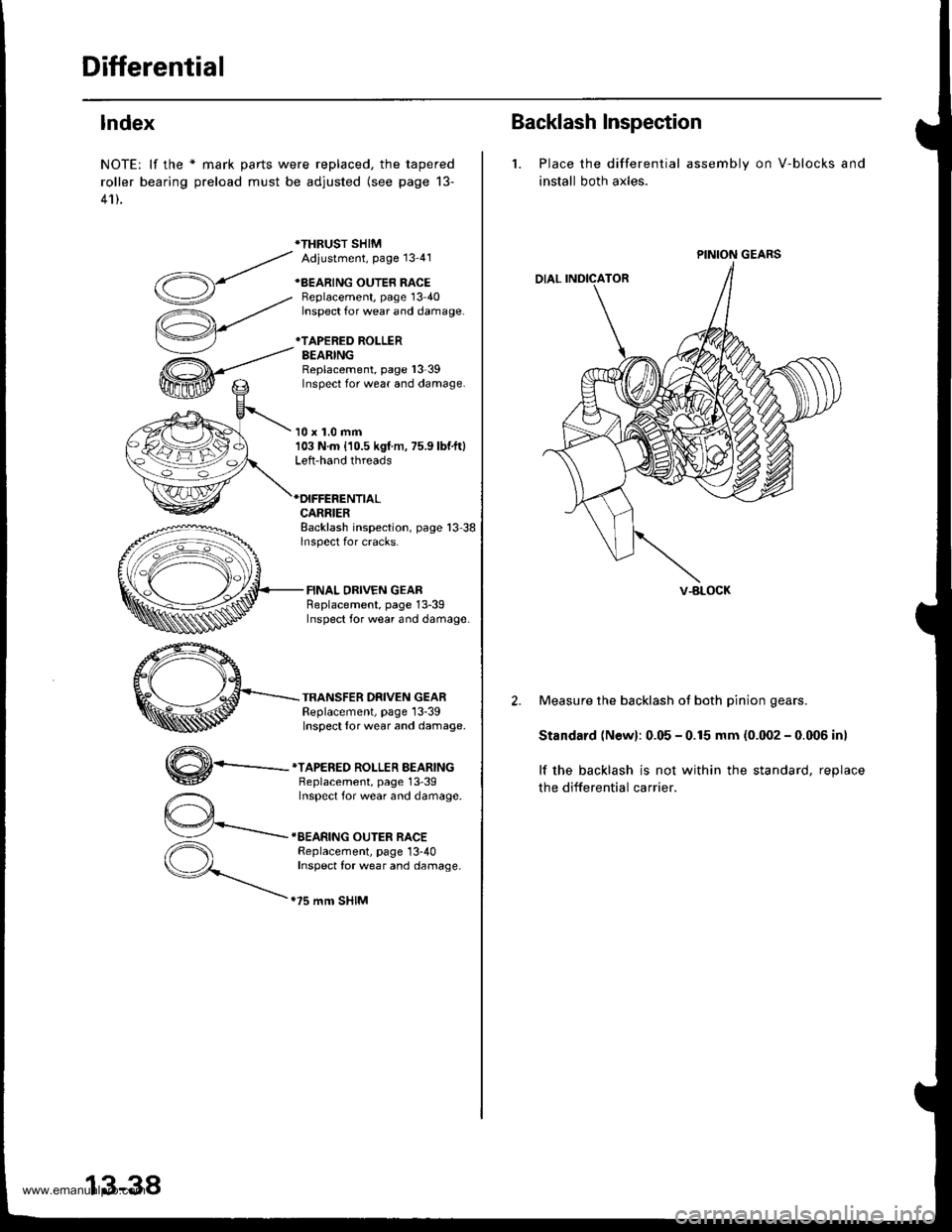

lndex

NOTE: lf the * mark parts were replaced, the tapered

roller bearing preload must be adjusted (see page 13-

41).

*THRUST SHIMAdiustment, Page 13'41

+BEARING OUTER RACEBeplacement, page 13 40Inspect for wear and damage.

*TAPERED ROLLERBEARINGReplacement, page l3-39Inspect for wear and damage.

10 x 1.0 mm103 N.m {10.5 kgf m, 75.9 lbf.ft}Left-hand threads

CARRIERBacklash inspection, page 13 38lnspect for cracks.

FINAL DRIVEN GEARReplacement, page 13-39Inspect for wear and damage

TRANSFER DRIVEN GEARReplacement, page 13-39Inspect {or wear and damage.

,,4\

W-

*TAPERED ROLLER BEARINGBeplacement, page 13'39Inspect for wear and damage.

IEEARING OUTER RACEReplacement, page 13-40Inspect for wear and damage.

.75 mm SHIM

13-38

Backlash Inspection

1. Place the differential

install both axles.

assembly on V-blocks and

PINION GEARS

V-BLOCK

2. Measure the backlash ot both pinion gears.

Standard (Newl: 0.05 - 0.15 mm (0.002 - 0.006 inl

lf the backlash is not within the standard, reolace

the differential carrier.

www.emanualpro.com

Page 478 of 1395

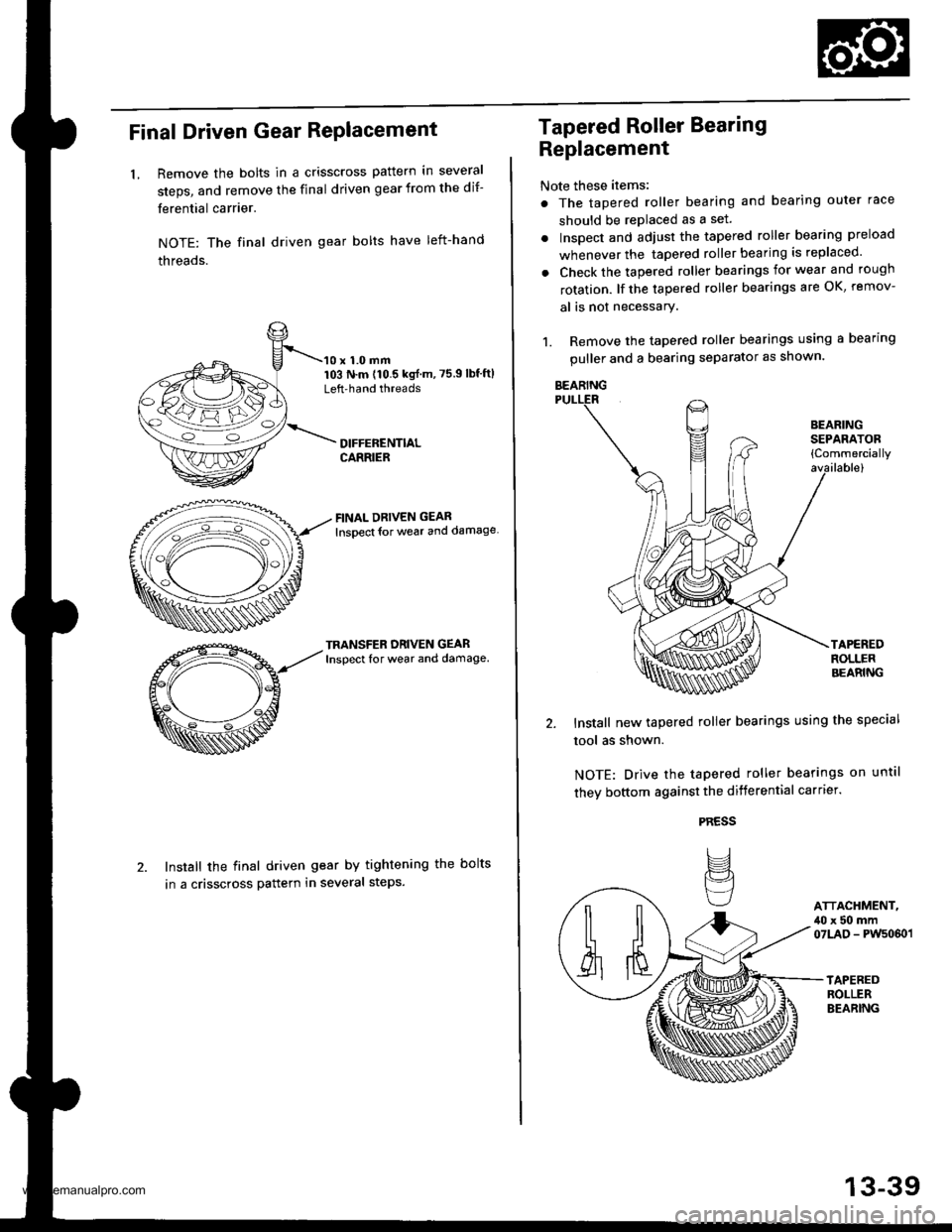

Final Driven Gear RePlacement

LRemove the bolts in a crisscross pattern in several

steps, and remove the final driven gear from the dif-

ferential carrier.

NOTE: The final driven gear bolts have left-hand

threads.

10 x 1.0 mm103 N.m (10.5 kgf m,75.9lbf'ftlLeft'hand threads

FINAL DRIVEN GEAR

lnsoect {or weal and damage

TRANSFER ORIVEN GEARInspect for wear and damage.

Install the final driven gear by tightening the bolts

in a crisscross pattern in several steps.

Tapered Roller Bearing

Replacement

Note these items:

. The tapered roller bearing and bearing outer race

should be replaced as a set.

. Inspect and adiust the tapered roller bearing preload

whenever the tapered roller bearing is replaced'

. Check the tapered roller bearings for wear and rough

rotation. lf the tapered roller bearings are OK, remov-

al is not necessary.

1. Remove the tapered roller bearings using a bearing

puller and a bearing separator as shown.

Install new tapered roller bearings using the special

tool as shown.

NOTE: Drive the tapered roller bearings on until

they bottom against the differential carrter.

PRESS

IJ

BEARINGSEPAFATOB{Commercially

ATTACHMENT,,10 x 50 mm07LAD - PWs060 l

BEARING

13-39

www.emanualpro.com