Bearing HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 757 of 1395

Transfer Gear Bscklash Inspection and Transfer Gear

Tooth Contact Inspection

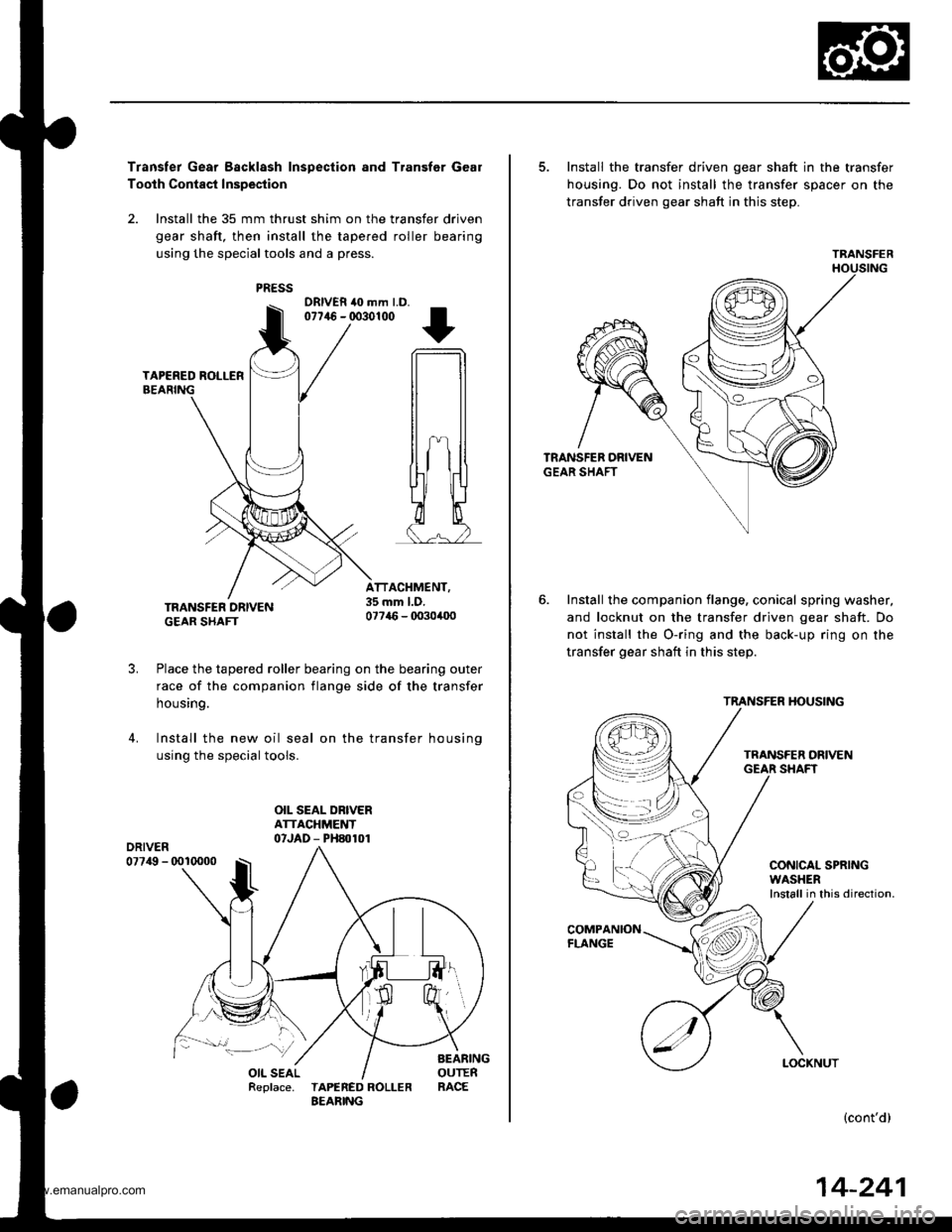

2. Install the 35 mm thrust shim on the transfer driven

gear shaft, then install the tapered roller bearing

using the special tools and a press.

DRIVER {0 mm LD.077146 - 0030100

TRANSFER DRTVEN ;;.GEAR SHAFT u, 745 - 0O304O0

Place the tapered roller bearing on the bearing outer

race of the companion flange side of the transfer

housrng.

Install the new oil seal on the transfer housing

using the special tools.

OIL SEAL DRIVERATTACHMENT07JAD - PH80101

5. Install the transfer driven gear shaft in the transfer

housing. Do not install the transfer spacer on the

transfer driven gear shaft in this step.

Install the companion flange, conical spring washer,

and locknut on the transfer driven gear shaft. Do

not install the O-ring and the back-up ring on the

transfer gear shaft in this step.

6.

COMPANIONFLANGE

{cont'd)

TRANSFER

TRANSFER HOUSING

14-241

www.emanualpro.com

Page 758 of 1395

Transfer Assembly

Reassembly (cont'd)

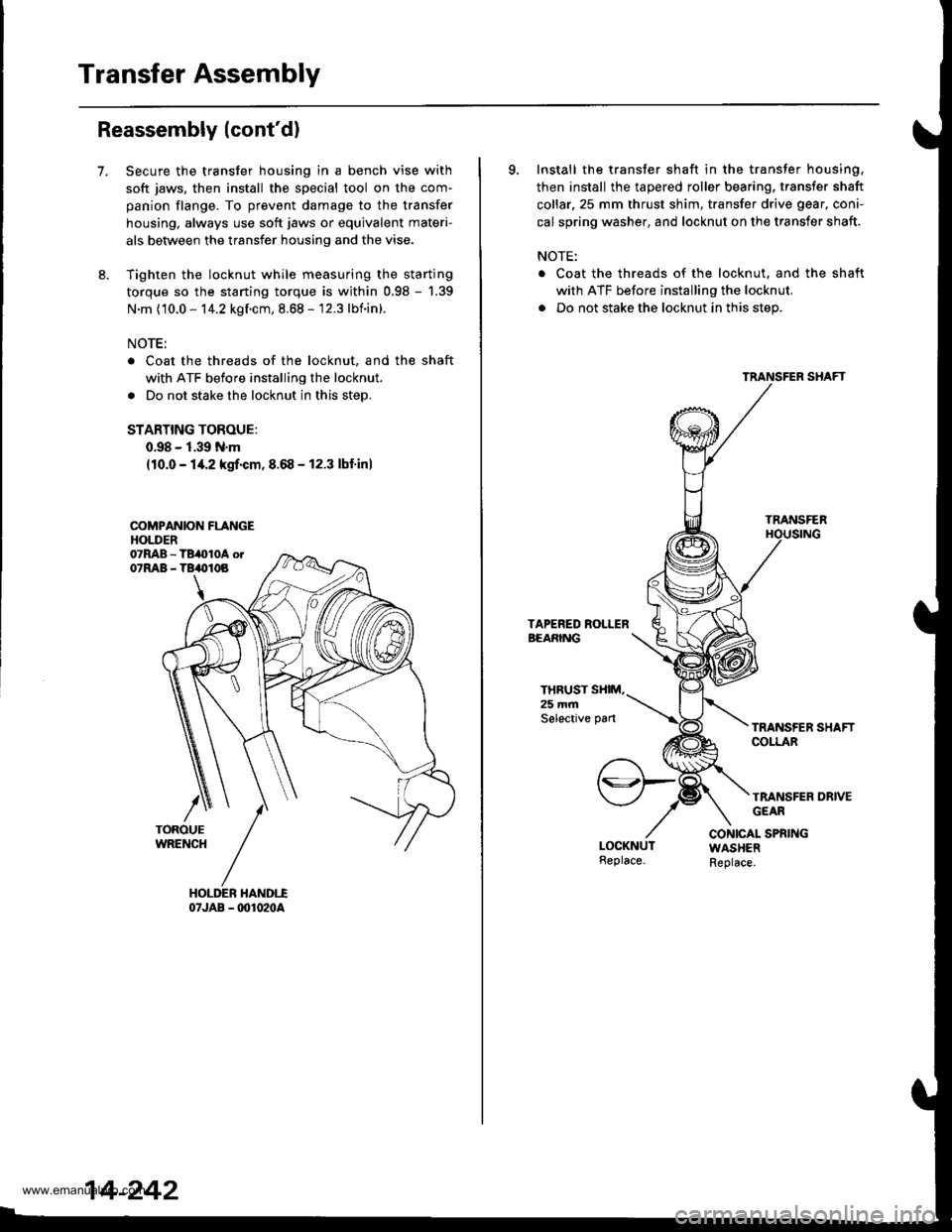

7.Secure the transfer housing in a bench vise with

soft jaws, then install the special tool on the com-

panion flange. To prevent damage to the transfer

housing, always use soft jaws or equivalent materi-

als between the transfer housing and the vise.

Tighten the locknut while measuring the starting

torque so the starting torque is within 0.98 - '1.39

N.m (10.0 - 14.2 kgf.cm, 8.68 - 12.3 lbnin).

NOTE:

Coat the threads of the locknut, and the shaft

with ATF before installing the locknut.

Do not stake the locknut in this step.

STARTING TOROUE:

0.98 - 1.39 N.m

{10.0 - 14.2 kgrf.cm,8.68 - 12.3 lbf'inl

COMPANION FLANGEHOLDER

07JAB - @1020A

14-242

9. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar.25 mm thrust shim, transfer drive gear, coni-

cal spring washer, and locknut on the transfer shaft.

NOTE:

. Coat the threads of the locknut. and the shaft

with ATF before installing the locknut.

. Do not stake the locknut in this step.

TRANSFER

THRUST SXIM,25 mmSelective pan

TRANSFER DRIVEGEAR

CONICAL SPRINGWASHERReplace.

www.emanualpro.com

Page 759 of 1395

10.

11.

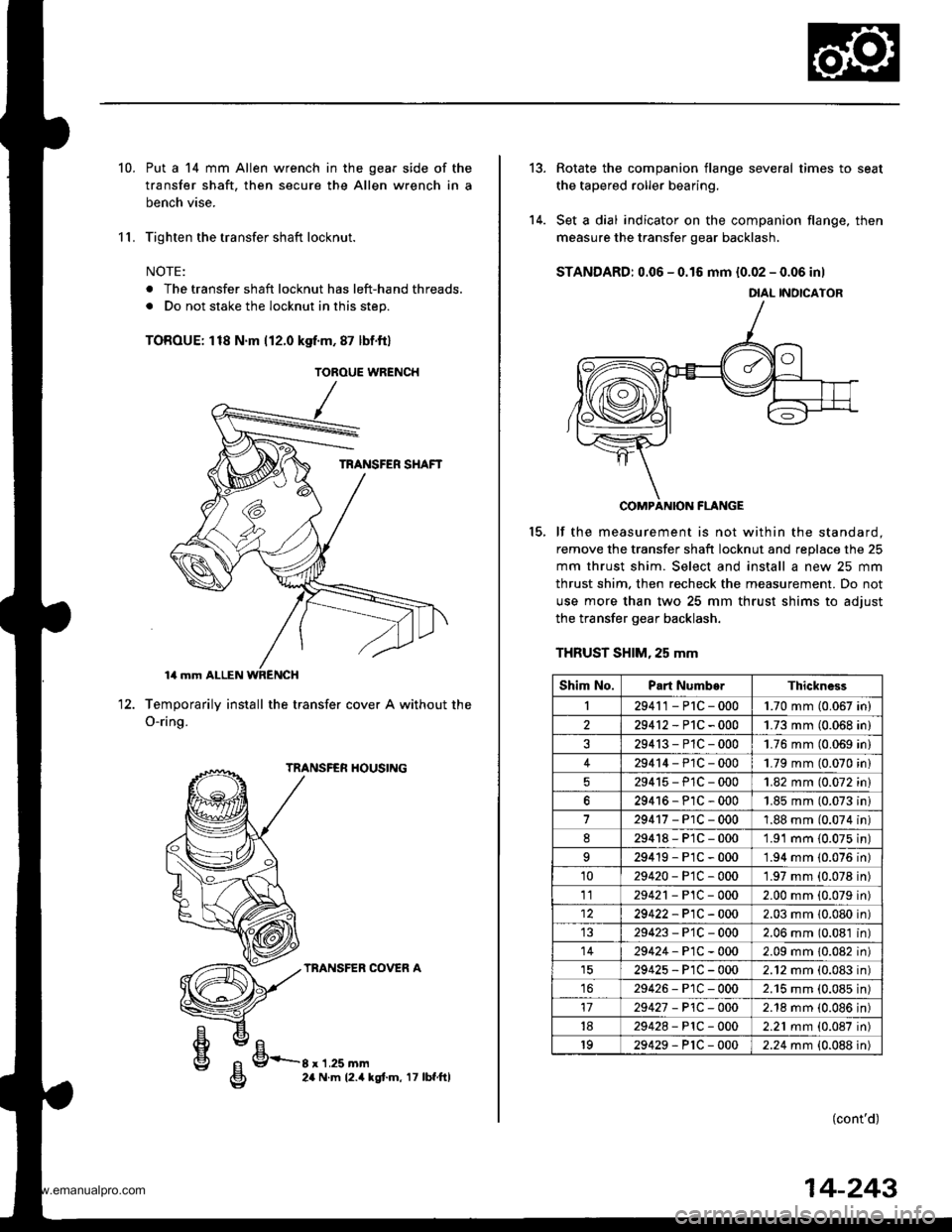

Put a 14 mm Allen wrench in the gear side of the

transfer shaft, then secure the Allen wrench in a

bench vise.

Tighten the transfer shaft locknut.

NOTE:

. The transfer shaft locknut has left-hand threads.

. Do not stake the locknut in this step.

TOROUE: 118 N'm 112.0 kgf.m, 87 lbf.ftl

Temporarily install the transfer cover A without

O-ring.

TRANSFER HOUSING

TRANSFER COVER A

the12.

g/FrE24 N.m 12.4 kgt.m, 17 lbf.ftl

TOROUE WRENCH

tt el

g 9-r'r.ru--g 24 N.m 12.4 |

14-243

13.

14.

Rotate the companion flange several times to seat

the tapered roller bearing.

Set a dial indicator on the companion flange, then

measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm {0.02 - 0.06 inl

COMPANION FLANGE

lf the measurement is not within the standard.

remove the transfer shaft locknut and replace the 25

mm thrust shim. Select and install a new 25 mm

thrust shim. then recheck the measurement. Do not

use more than two 25 mm thrust shims to adiust

the transfer gear backlash.

THRUST SHIM, 25 mm

(cont'd)

15.

DIAL INOICATOR

Shim No.Part NumborThickness

I29411-P1C-0001.70 mm (0.067 in)

229412-P1C-0001.73 mm (0.068 in)

29413-P1C-0001.76 mm (0.069 in)

429414-P1C-0001.79 mm (0.070 in)

29415-PlC-0001.82 mm (0.072 in)

629416-P1C-0001.85 mm (0.073 ini

729417-PlC-0001.88 mm (0.074 in)

d29418-P1C-0001.91 mm {0.075 in)

29419-P1C-0001.94 mm (0.076 in)

1029420-PtC-0001.97 mm (0.078 in)

1129421 - P1C - 0002.00 mm (0.079 in)

29422-P1C-0002.03 mm 10.080 in)

29423-P'1C-0002.06 mm (0.081 in)

1429424-P1C-0002.09 mm 10.082 in)

29425-P1C-0002.12 mm (0.083 in)

1629426-P1C-0002.'15 mm (0.085 in)

1729427 - P1C -O002.18 mm (0.086 in)

1829428-PlC-0002.21 mm (0.087 in)

1929429-P1C-0002.24 mm {0.088 in)

www.emanualpro.com

Page 762 of 1395

Transfer Assembly

Reassembly (cont'd)

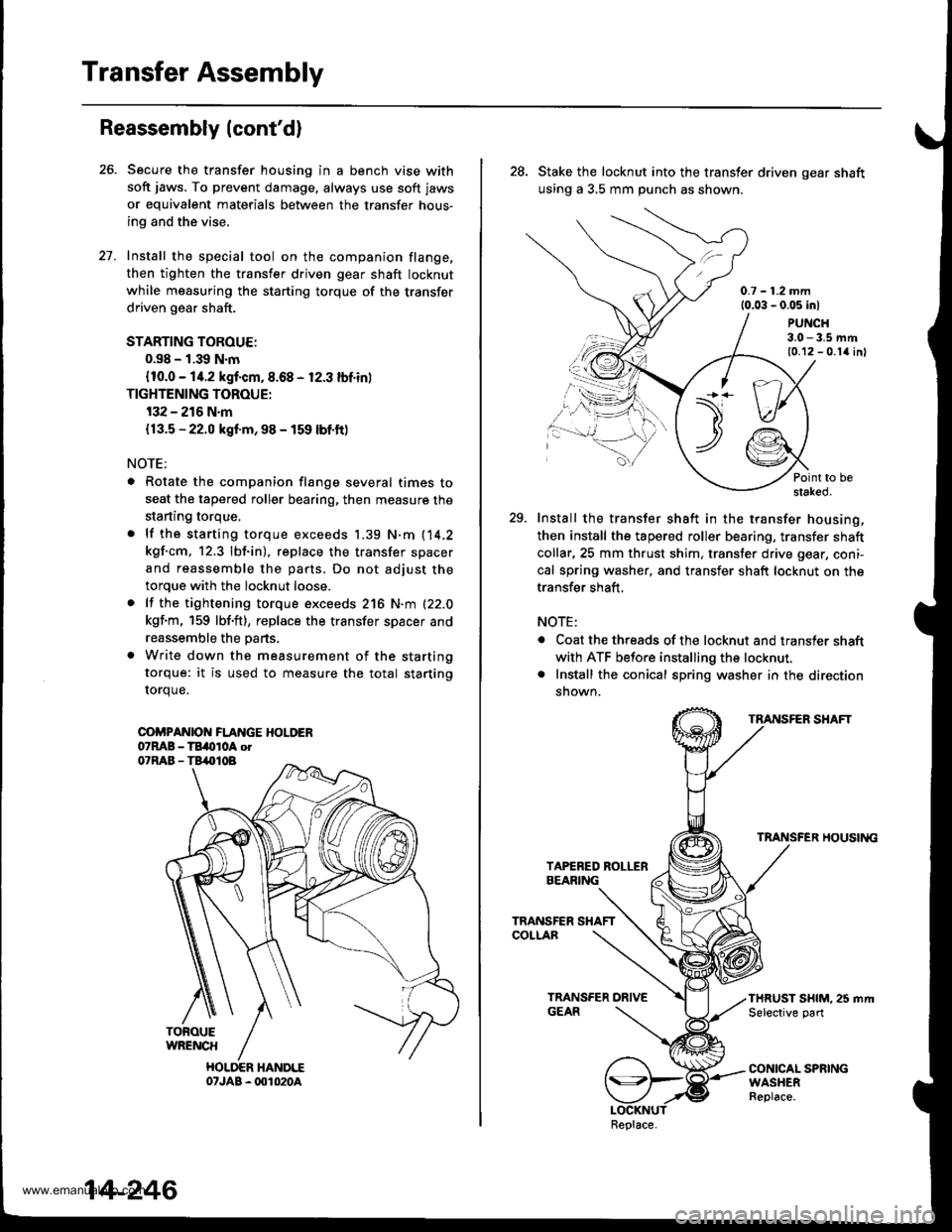

Secure the transfer housing in a bench vise with

soft jaws. To prevent damage, always use soft jaws

or equivalent materials between the transfer hous-

ing and the vise.

Install the special tool on the companion flange,

then tighten the transfer driven gear shaft locknut

while measuring the starting torque of the transfer

driven gear shaft.

STARTING TOROUE:

0.s8 - 1.39 N.m

{10.0 - 14.2 kgf.cm,8.68 - 12.3 lbf.in)

TIGHTENING TOROUE:

132 - 216 N.m

{13.5 - 22.0 kgf.m, 98 - 159 lbf.ft)

NOTE;

. Rotate the companion flange several times to

seat the tapered roller bearing, then measure the

starting torque,

. lf the starting torque exceeds 1.39 N.m (14,2

kgf.cm, 12.3 lbf.in), replace the transfer spacer

and reassemble the parts. Do not adjust the

torque with the locknut loose.

. lf the tightening torque exceeds 216 N.m (22.0

kgf.m, 159 lbf'ft), replace the transfer spacer and

reassemble the parts.

. Write down the measurement of the starting

torque: it is used to measure the total starting

rorque.

COi'PANIOI{ FLANGE HOLDER07MB - TBi(tloA otO'RAB - TB,.|}IOB

TOFOUEWRENCH

HOLDER HANDLE07JAB - 001020A

27.

14-246

28. Stake the locknut into the transfer driven gear shaft

using a 3,5 mm punch as shown.

0.7 - 1.2 mm{0.03 - 0.05 inl

PUNCH3.0 - 3.5 mm10.12 - 0.1{ inl

Point to bestaked.

29. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar,25 mm thrust shim, transter drive gear, coni-

cal spring washer, and transfer shaft locknut on the

transfer shaft,

NOTE:

. Coat the threads of the locknut and transler shaft

with ATF before installing the locknut.. Install the conical spring washer in the direction

snown.

TRANSFER SHAFT

TRANSFER HOUSII{G

THRUST SHIM. 25 mrt|Selective part

CONICAL SPRINGWASHERReplace.

\t)t--/./

.,.-,.,\

Replace.

www.emanualpro.com

Page 763 of 1395

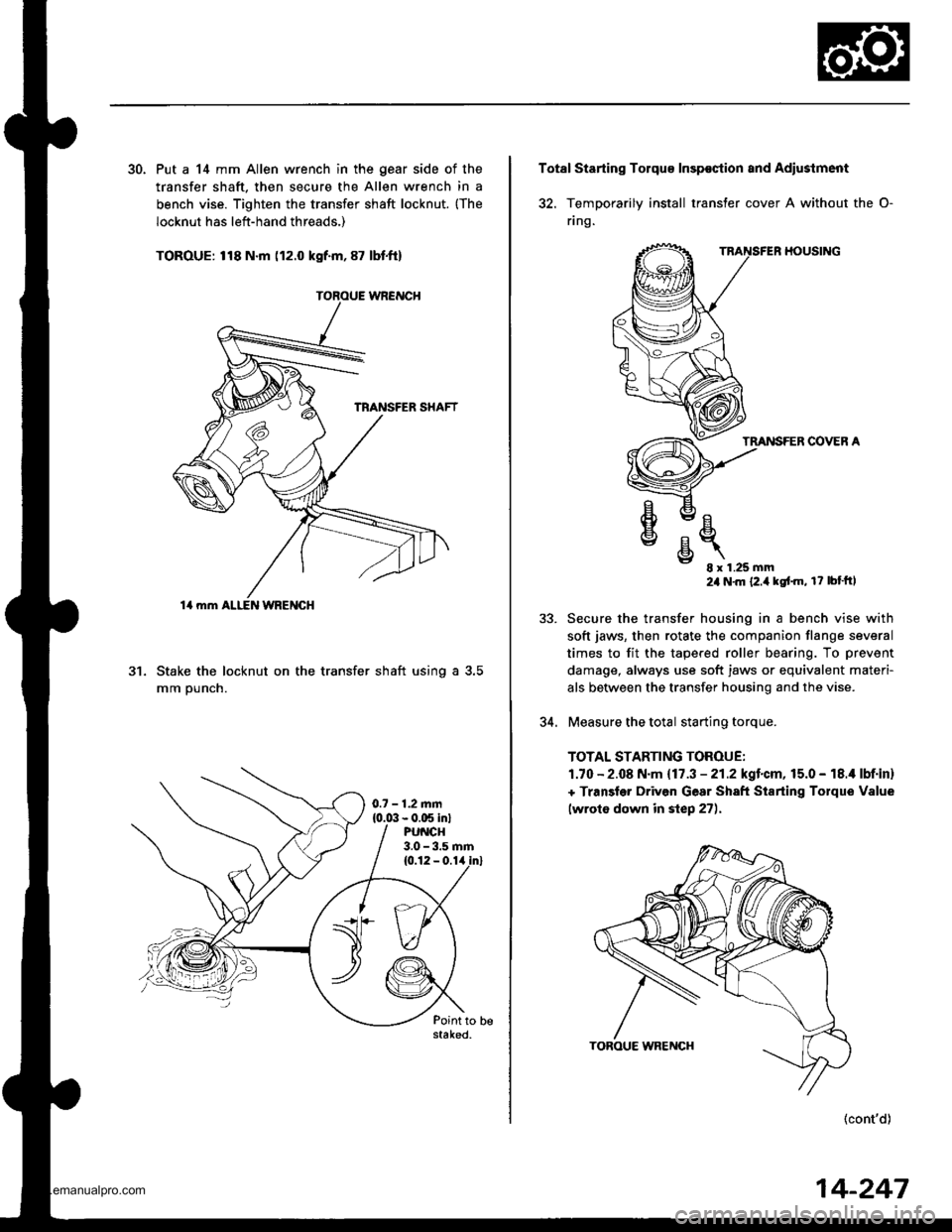

30. Put a 14 mm Allen wrench in the gear side of the

transfer shaft. then secure the Allen wrench in a

bench vise. Tighten the transfer shaft locknut. {The

locknut has left-hand threads,)

TOROUE: 118 N.m (12.0 kgf.m, 87 lbt.ft)

Stake the locknut on the transfer shaft using a 3.5

mm ounch.

al

14 mm ALI-EN WRENGH

0.7 - 1.2.nm{0.0:1- 0.C5 in}PU CH3.0 - 3.5 rnm

Total Starting Tolqu€ Insp€ction and Adiustment

32. TemDorarilv install transter cover A without the O-

flng.

HOUSING

TMNSFER COVER A

e

€

v

E- 8x1.25mm24 N'm {2.i1kgt'm, r? bt'ftl

Secure the transfer housing in a bench vise with

soft jaws, then rotate the companion flange several

times to fit the tapered roller bearing. To prevent

damage, always use soft jaws or equivalent materi-

als betlveen the transfer housing and the vise.

Measure the total starting torque.

TOTAL STARTING TOROUE:

1.70 - 2.08 N.m {17.3 - 21.2kgl.cm,15.0 - 18.i1 lbf.in}

+ Transler Driven Gear Sh8ft Starting Torque Value

lwroto down in step 27).

(cont'd)

5J.

34.

14-247

www.emanualpro.com

Page 768 of 1395

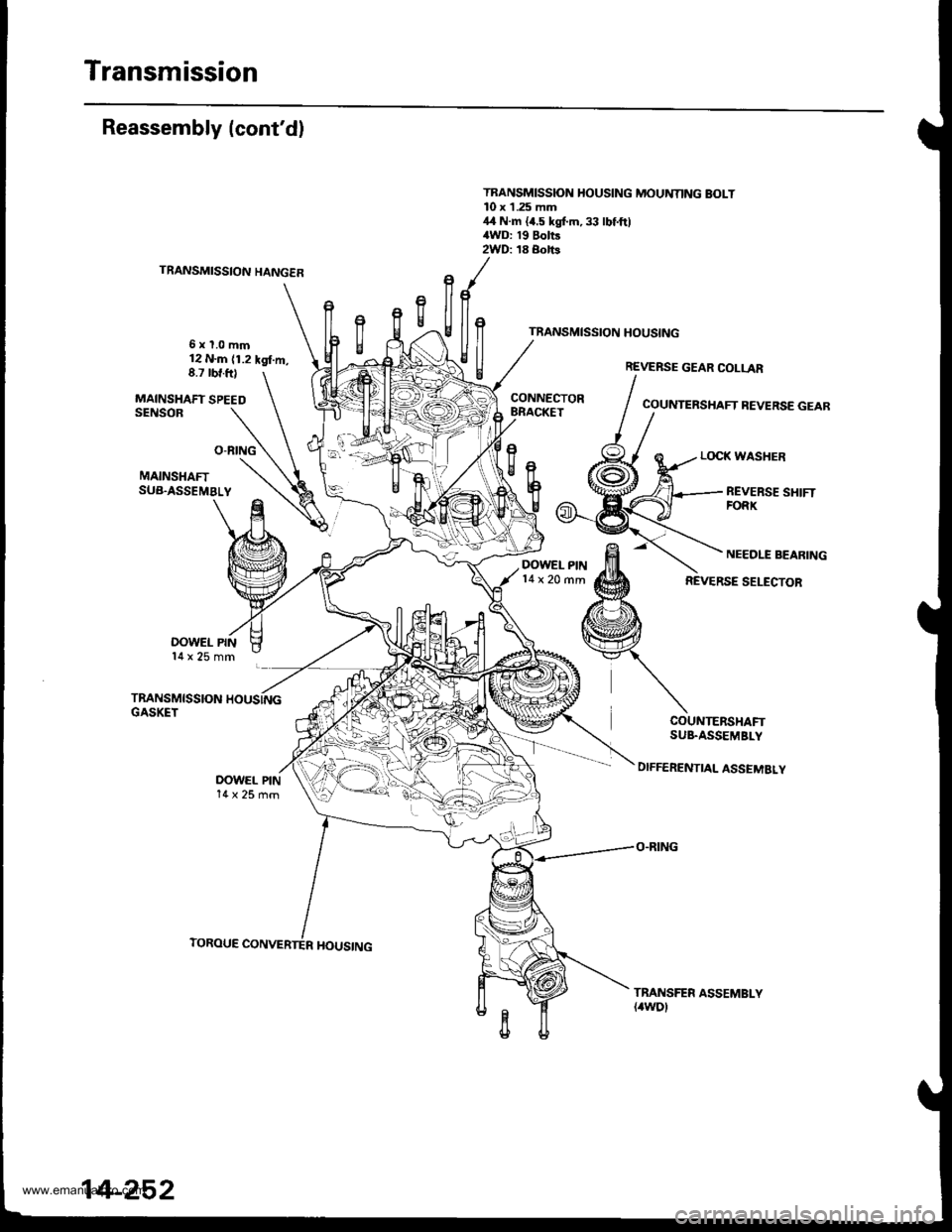

Transmission

Reassembly (cont'd)

TRANSMISSION HANGER

6xl.0mm12 N.m (1.2 kgl.m,8.7 rbt.ft)

MAINSHAFT SPEEDSENSOB

TRANSMISSION HOUSING MOUNNNG BOLT10 x L254,1 N.m {/4WD: 192WD: 18

t

f,

llf, l

gil /

COUNTERSHAFT BEVERSE GEAB

LOCK WASHER

MAINSHAFTSUB.ASSEMBLY

OOWEL PIN14x25mm

TRANSMISSION HOUSINGGASKET

DOWEL PIN14x25mm

REVERSE SHIFTFORK

DOWEL PIN14 x 20 rnm

NEEDLE BEARING

REVERSE SELECTOR

COUNTERSHAFTSUB.ASSEMBLY

DIFFERENTIAL ASSEMBLY

TRANSFES ASSEMBLY(4wDl

14-252

www.emanualpro.com

Page 769 of 1395

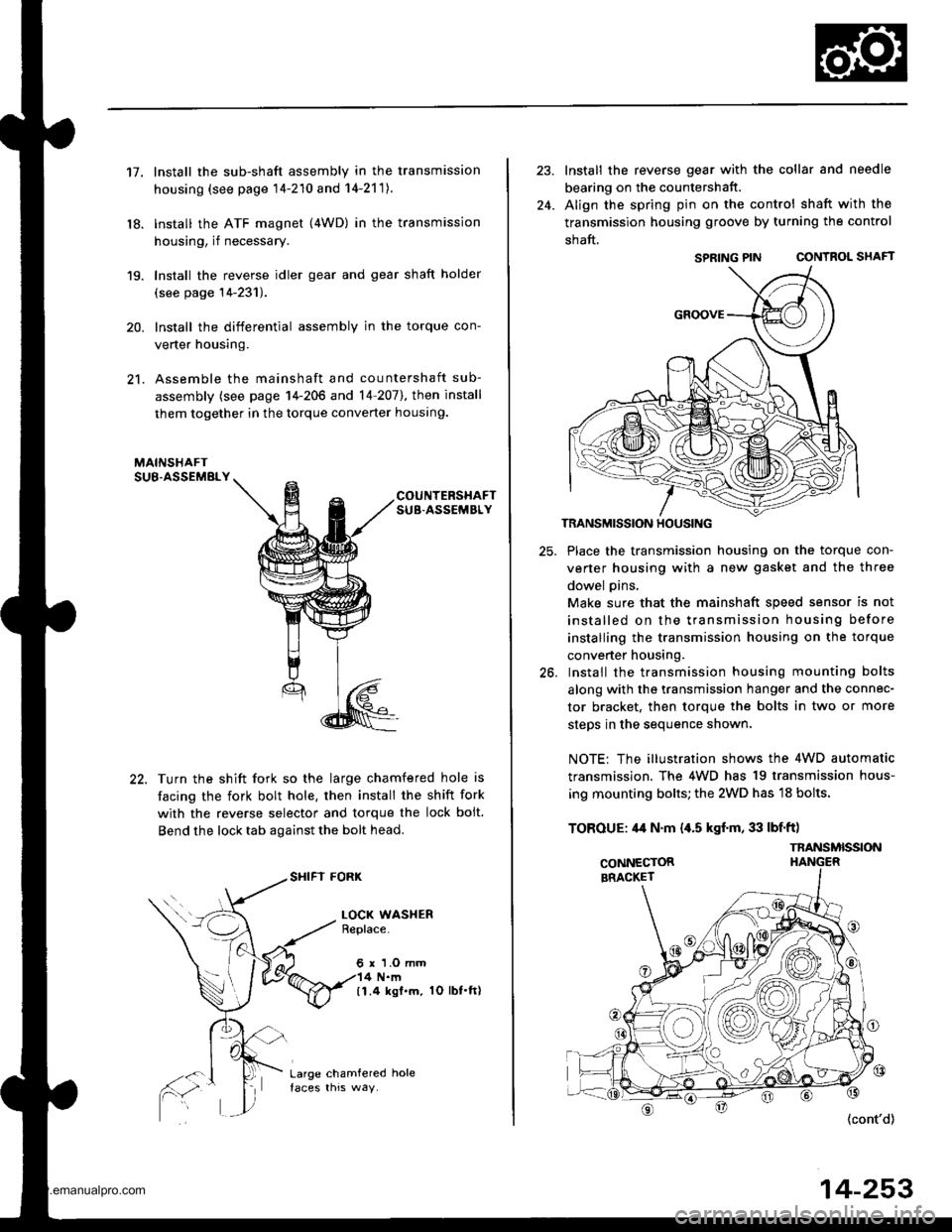

17.

18.

19.

20.

21.

Install the sub-shaft assembly in the transmission

housing (see page 14-210 and 14-2'111.

lnstall the ATF magnet (4WD) in the transmission

housing, if necessary.

Install the reverse idler gear and gear shaft holder

(see page 14-231).

Install the differential assembly in the torque con-

verter housing.

Assemble the mainshaft and countershaft sub-

assembly (see page 14-206 and 14 207],, then install

them together in the torque converter houslng.

COUNTERSHAFTSUB-ASSEMBLY

Turn the shift fork so the large chamfered hole is

facing the fork bolt hole. then install the shift fork

with the reverse selector and torque the lock bolt.

Bend the lock tab against the bolt head.

SHIFI FORK

LOCK WASHERBeplace.

6 r 'l.O mm4 N.m(1.4 ksl.m. 1O lbt.ft)

Large chamfered hole

24.

Install the reverse gear with the collar and needle

bearing on the countershatt.

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

SPRING PIN CONTROL SHAFT

TRANSMISSION HOUSING

25. Place the transmission housing on the torque con-

verter housing with a new gasket and the three

dowel pins,

Make sure that the mainshaft speed sensor is not

installed on the transmission housing before

installing the transmission housing on the torque

converter housing.

26. Install the transmission housing mounting bolts

along with the transmission hanger and the connec-

tor bracket, then torque the bolts in two or more

steos in the seouence shown.

NOTE: The illustration shows the 4WD automatic

transmission. The 4WD has 19 transmission hous-

ing mounting bolts; the 2WD has 18 bolts.

TOROUE: 44 N.m {,[.5 kgf.m, 33 lbf'ft)

{cont'd)

14-253

SPRING PIN

TNANSMISSION

www.emanualpro.com

Page 770 of 1395

Transmission

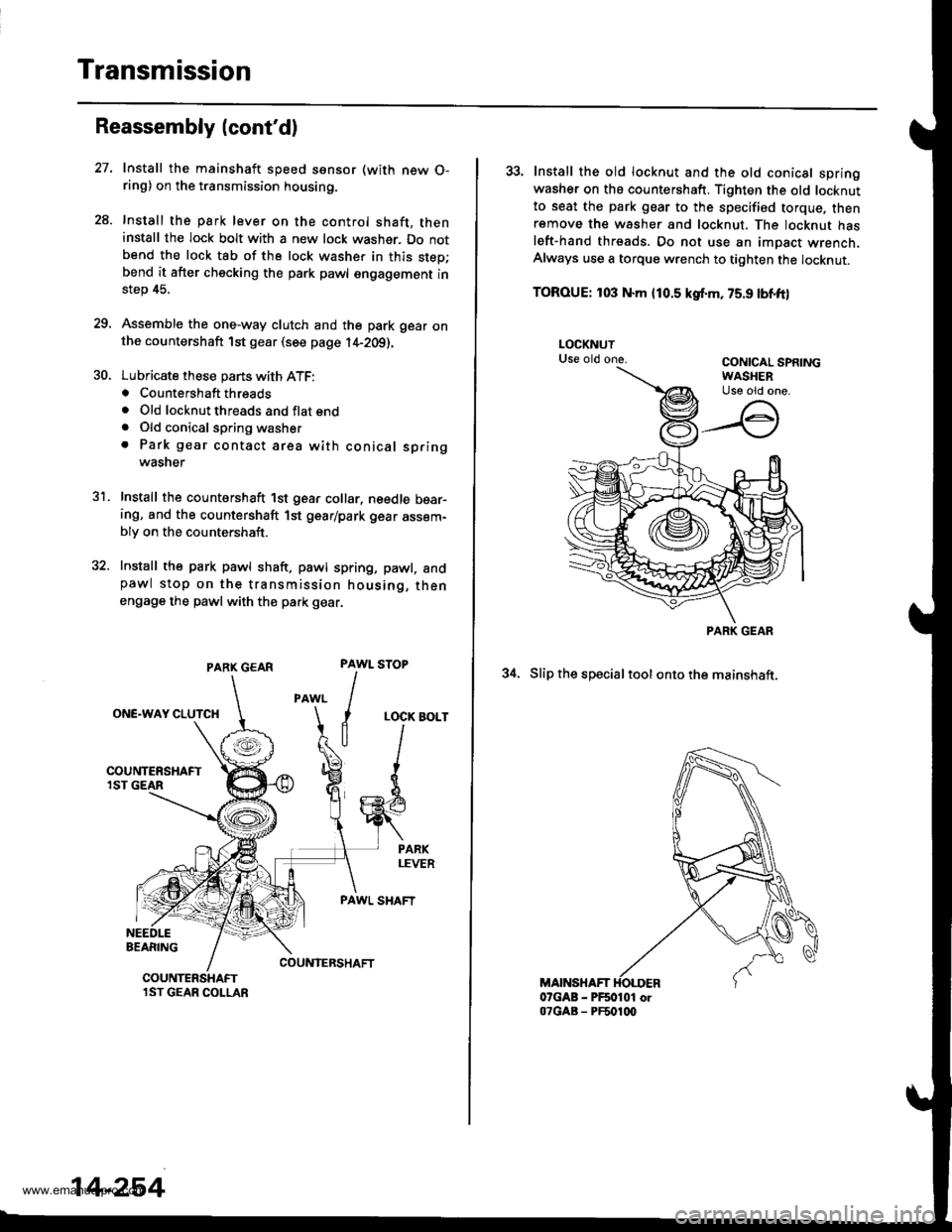

28.

Reassembly (cont'd)

PARX GEAR

ONE.WAY CLUTCH

BEARING

Install the mainshaft speed ssnsor (with new O-ring) on the transmission housing.

Install the park lever on the control shaft, theninstall the lock bolt with a new lock washer. Do notbend the lock tab of the lock washer in this step;bend it after checking the park pawl engagement instep 45.

Assemble the one-way clutch and the park gear onthe countershaft 1st gear (see page l4-2Og).

Lubricate these pans with ATF:. Countershaft threads. Old locknut threads and flat end. Old conical spring washer. Park gear contact area with conical springwasner

Install the countershaft 1st gear collar, needle bear-ing, and the countershaft 1st gear/park gear assem-bly on the countershaft.

Install the park pawl shaft. pawl spring, pawl. andpawl stop on the transmission housing, thenengage the pawl with th€ park gear.

31.

PAWL

I

I

a

STOP

LOCK BOLT

PAWL SHAFT

COUNIERSHAFTCOUNTERSHAFTlST GEAR COLLAR

14-254

33. Install the old locknut and the old conical springwasher on ths countershaft. Tighten the old locknutto seat the park gear to the specified torque, thenremove th€ washer and locknut. The locknut hasleft-hand threads. Do not use an impact wrench.Always use a torque wrench to tighten the locknut.

TOROUE: 103 N.m {10.5 kgf.m, 75.9 lbnft)

34. Slip the specialtool ontothe mainshaft.

MAINSHAFT07GAB - PF50101 or07GAB - PF501q)

PARK GEAR

www.emanualpro.com

Page 771 of 1395

5C.

36.

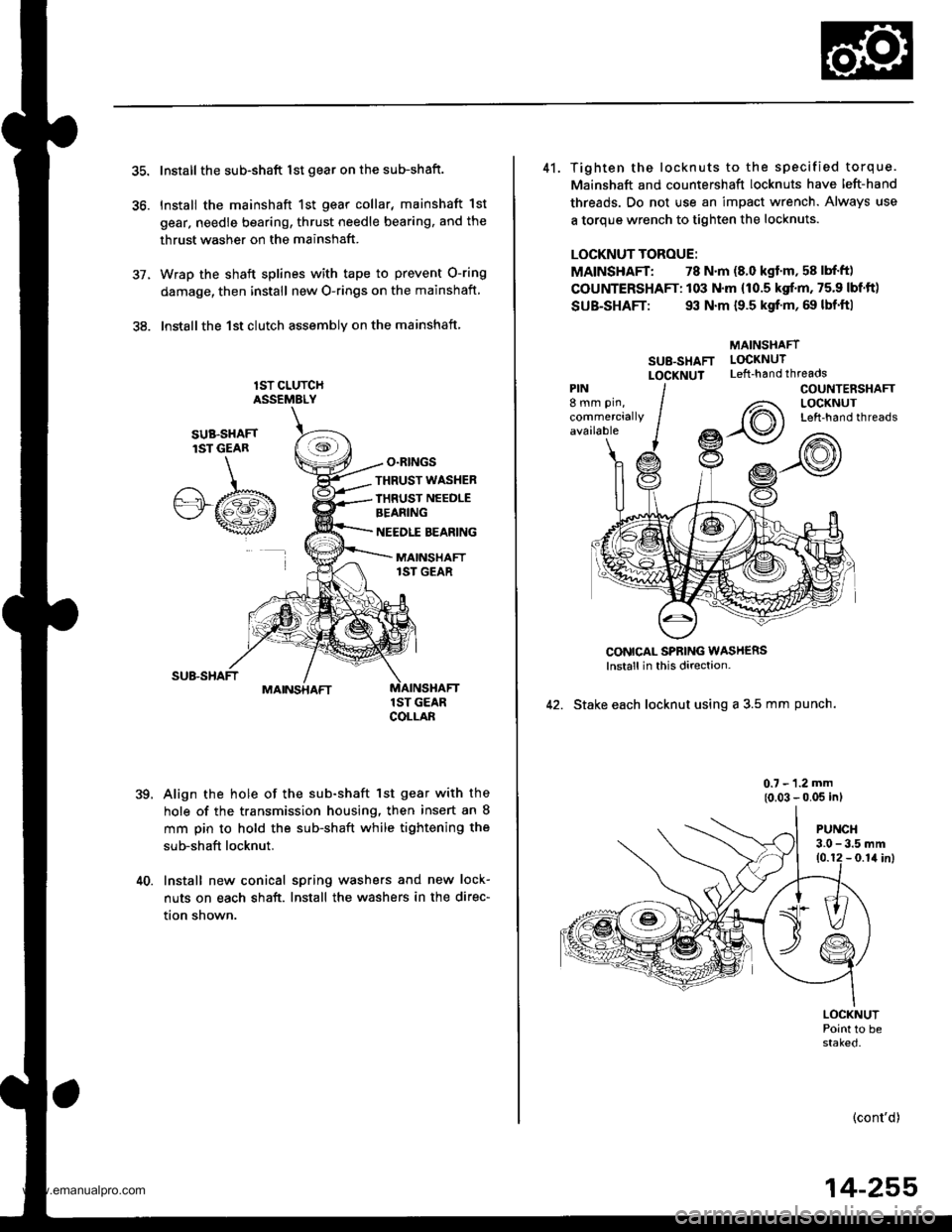

Install the sub-shaft lst gear on the sub-shaft.

Install the mainshaft 1st gear collar, mainshaft 1st

gear, needle bearing, thrust needle bearing, and the

thrust washer on the mainshaft.

Wrap the shaft splines with tape to prevent O-ring

damage, then install new O-rings on the mainshaft

lnstallthe 1st clutch assemblv on the mainshaft

lST CLUTCHASSEMELY

O.RINGS

,te

SUB.SHAFTlST GEAR

.A/.b"'"wt

THRUST WASHER

IHRUST NEEDLEBEANING

NEEDLE BEARING

MAINSHAFT1ST GEAR

MAINSHAFT

39.

1ST GEARCOLLAB

Align the hole of the sub-shaft lst gear with the

hole of the transmission housing, then insert an 8

mm pin to hold the sub-shaft while tightening the

sub-shaft locknut.

40. Install new conical spring washers and new lock-

nuts on each shaft. Install the washers in the direc-

tion shown.

41. Tighten the locknuts to the specified torque.

Mainshaft and countershaft locknuts have left-hand

threads. Do not use an impact wrench. Always use

a torque wrench to tighten the locknuts.

LOCKNUT TOROUE:

MAINSHAFT: 78 N.m (8.0 kgf'm, 58 lbf'ft)

COUNTERSHAFT: 103 N.m (10.5 kgf.m, 75.9 lbf'ft)

SUB-SHAFT: 93 N.m {9.5 kgf'm, 69 lbf'ft|

MAINSHAFT

SU8-SHAFT LOCKNUT

LOCXNUT Left-handthreads

CONICAL SPBING WASH€RSlnstall in this direction-

42. Stake each locknut using a 3.5 mm punch.

0.7 - 1.2 mm

{0.03 - 0.05 inl

PIN8 mm pin,

commerciallyavailable

COUNTENSHAFTLOCKNUTLeft-hand threads

PUNCH3.0 - 3.5 mm10.12 - 0.1il inl

LOCKNUTPoint to bestaked.

(cont'd)

14-255

www.emanualpro.com

Page 798 of 1395

Description

Hydraulic Flow (cont'dl

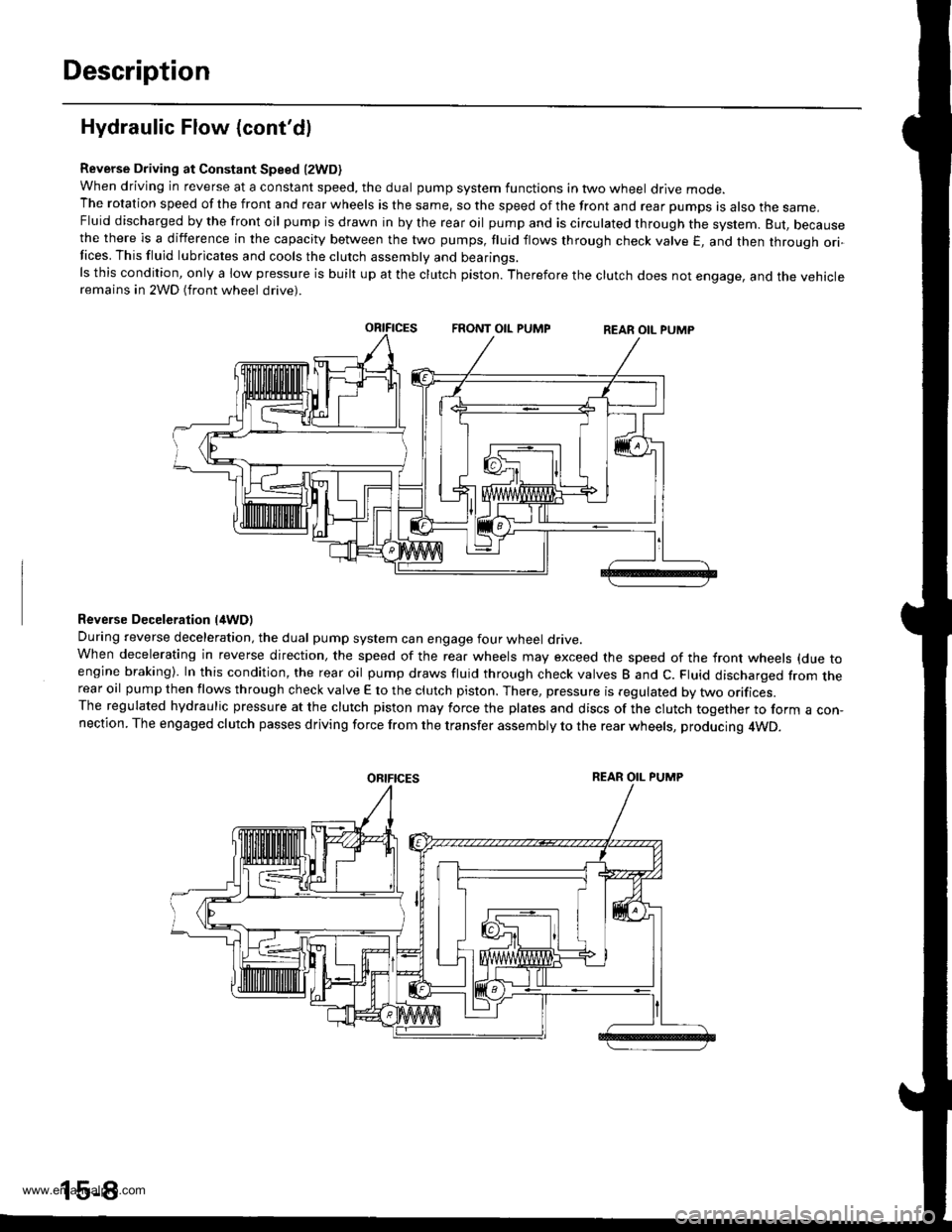

Reverse Driving at Constant Speed l2WD)when driving in reverse at a constant speed, the dual pump system functions in two wheel drive mode.The rotation speed of the front and rear wheels is the same, so the speed of the front and rear pumps is also the same,Fluid discharged by the front oil pump is drawn in by the rear oil pump and is circulated through the system. But, becausethe there is a difference in the capacity between the two pumps, fluid flows through check valve E, and then through ori-Iices. This fluid lubricates and cools the clutch assembly and bearings.ls this condition, only a low pressure is built up at the clutch piston. Therefore the clutch does not engage, and the vehicleremains in 2WD (front wheel drive).

Reverse Deceleration l/tWDl

During reverse deceleration, the dual pump system can engage four wheel drive.When decelerating in reverse direction, the speed of the rear wheels may exceed the speed of the front wheels (due toengine braking). In this condition, the rear oil pump draws fluid through check valves B and C. Fluid discharged from therear oil pump then flows through check valve E to the clutch piston. There, pressure is regulated by two orifices.The regulated hydraulic pressure at the clutch piston may force the plates and discs of the clutch together to form a con,nection. The engaged clutch passes driving force from the transfer assembly to the rear wheels, producing 4WD.

oRtFtcEsREAR OIL PUMP

www.emanualpro.com