srs HONDA CR-V 2000 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1209 of 1395

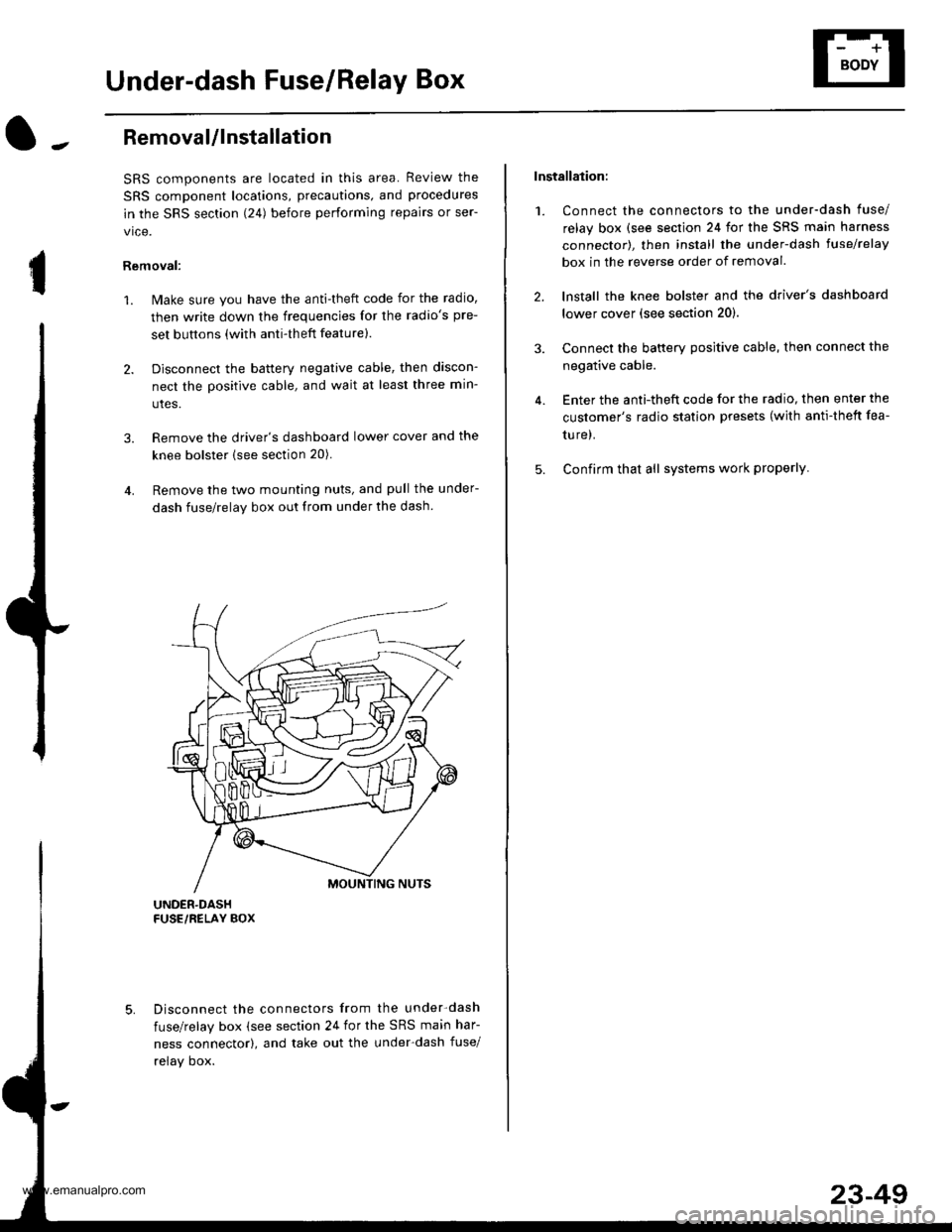

Under-dash Fuse/Relay Box

I

Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (241 before performing repairs or ser-

vice.

Removal:

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio's pre-

set buttons (with anti-theft feature).

2. Disconnect the battery negative cable, then discon-

nect the positive cable, and wait at least three min-

utes.

3. Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

4. Remove the two mounting nuts, and pull the under-

dash fuse/relay box out from under the dash

Disconnect the connectors from the under-dash

fuse/relay box (see section 24 for the SRS main har-

ness connector), and take out the under-dash fuse/

relay oox.

Installation:

1. Connect the connectors to the under-dash fuse/

relay box (see section 24 for the SRS main harness

connector), then install the under-dash lusehelay

box in the reverse order of removal.

2. lnstall the knee bolster and the driver's dashboard

lower cover (see section 20).

3. Connect the battery positive cable, then connect the

negative cable.

4. Enter the anti-theft code for the radio, then enter the

customer's radio station presets (with anti-thett fea-

ture).

5. Confirm that all systems work properly

23-49

www.emanualpro.com

Page 1214 of 1395

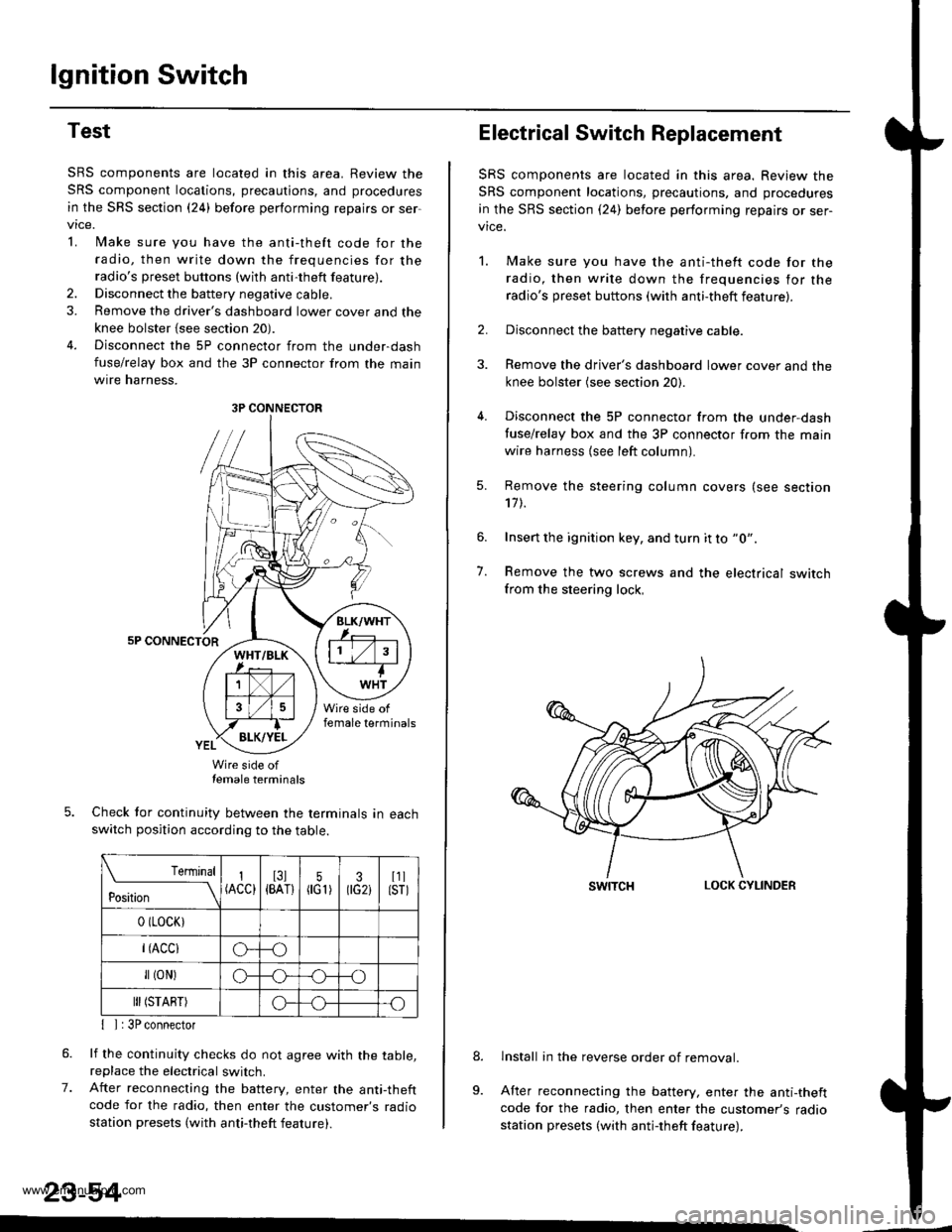

lgnition Switch

Test

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24} before performing repairs or ser

vtce.

L lMake sure you have the anti-theft code for the

radio, then write down the frequencies for theradio's preset buttons (wilh anti-theft feature).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and the

knee bolster {see section 20).

4. Disconnect the 5P connector from the under-dash

fuse/relay box and the 3P connector from the main

wtre narness,

5P CONNECTOR

Wire side oftemale terminals

Check tor continuity between the terminals in eachswitch position according to the table.

rernrnal

ros[ron \

I(ACC)I3l{BAT}5flG1)30G2iI1llsrl

0 (LocK)

r(Acclo--o

fl (oN)G_o

III (START)o--.o

7.

{ I | 3P connector

lf the continuity checks do not agree with the table,replace the electrical switch.

After reconnecting the battery, enter the anti-theftcode for the radio, then enter the customer's radio

station presets (with anti-theft feature).

23-54

3P CONNECTOR

Electrical Switch Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24) before performing repairs or ser-vice.

1. Make sure you have the anti-thett code for the

radio, then write down the frequencies for the

radio's preset buttons (with anti-theft feature).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

4. Disconnect the 5P connector from the under,dash

tuse/relay box and the 3P connector f.om the main

wire harness {see left column).

7.

Remove the steering column covers (see section'17 t.

Insert the ignition key, and turn it to "0".

Remove the two screws and the electrical switchfrom the steering lock,

swrTcHLOCK CYLINDER

lnstall in the reverse order of removal.

After reconnecting the battery, enter the anti-theftcode for the radio, then enter the customer's radiostation presets (with antj-theft feature).

9.

www.emanualpro.com

Page 1215 of 1395

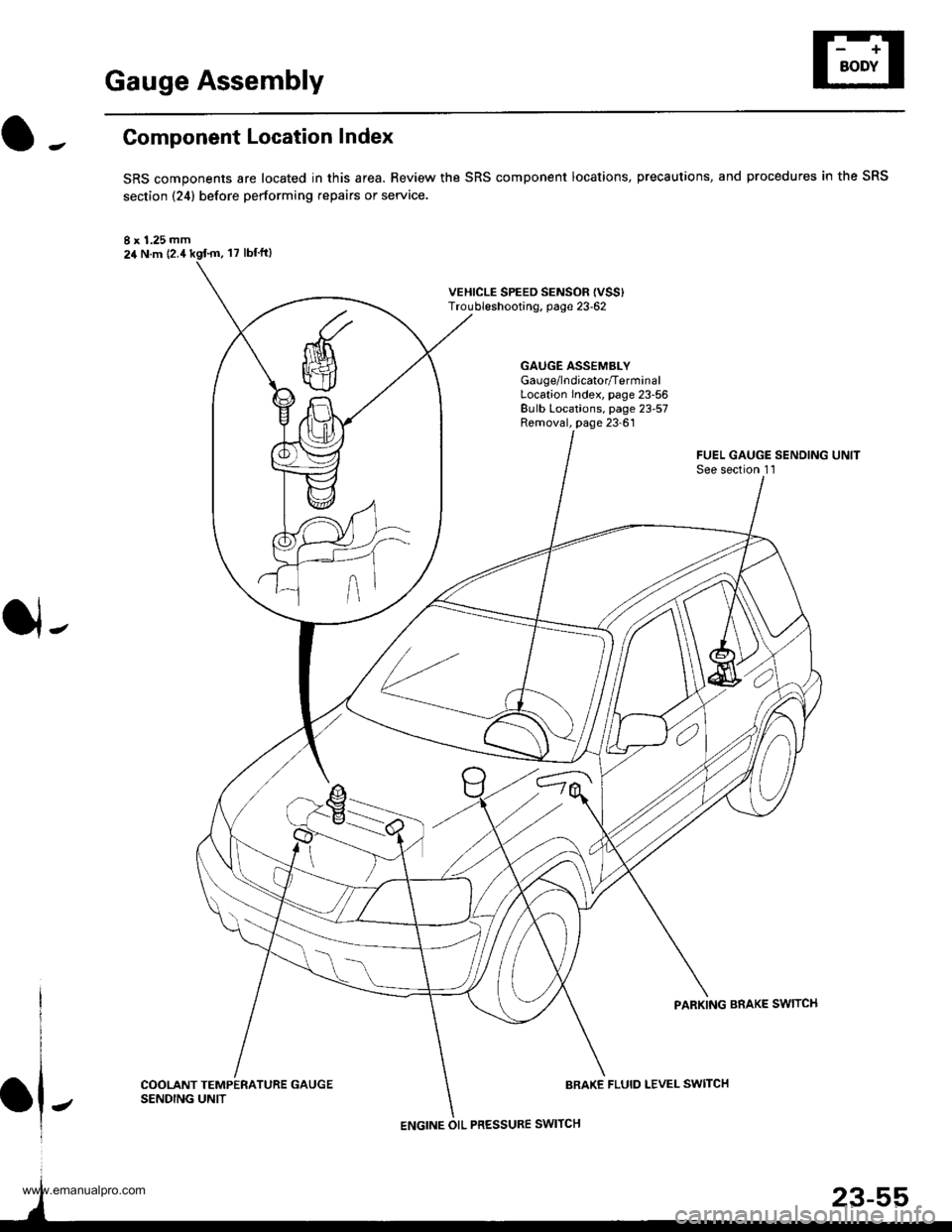

Gauge Assembly

Component Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24} before performing repairs or service.

I x 1.25 mm24 N.m {2.4

VEHICLE SPEED SENSOF {VSS'Troubleshooting, page 23-62

GAUGE ASSEMBLYGau ge/lndicator/TerminalLocation Index, page 23-56Bulb Locations, page 23-57Removal, page 23-61

J-

FUEL GAUGE SENDING UNITSee section 1 l

PARKING BRAKE SWITCH

COOLANT TEMPERATURE GAUGESENDING UNITBRAKE FLUID LEVEL SWITCH

ENGINE OIL PRESSURE SWITCH

www.emanualpro.com

Page 1216 of 1395

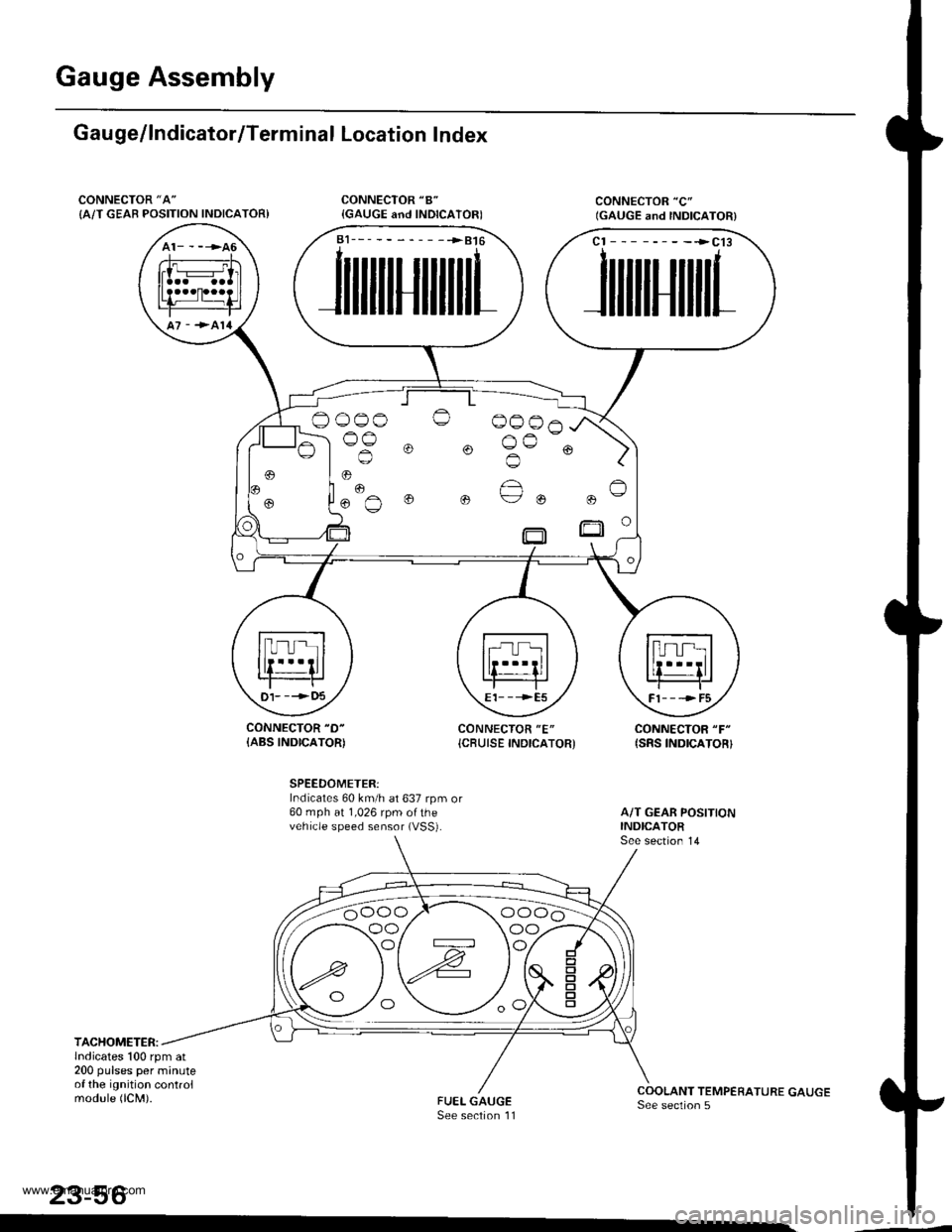

Gauge Assembly

Gau ge/lndicator/Terminal Location Index

CONNECTOR "A"

{A/T GEAB POSITION INDICATOR)

CONNECTOR "D-

{ABS INDICATOR)CONNECTOR "E"

{CBUISE INDICATOR'CONNECTOR "F"

{SRS INDICATOR}

SPEEDOMETER:Indicates 60 km/h at 637 rpm or60 mph at 1,026 rpm ofthevehicle speed sensor (VSS).

TACHOMETER:lndicates 100 rpm at200 pulses per minuteof the ignition controlmodule (lCM).

23-56

a1___-__-____>816

JilililIJililil1

cl --------->cl3

JililtHililL

,

.. "€""^

o o ue ou

t)1- --->t)5E1- - -->E5Fl---->F5

oo/ \oo

www.emanualpro.com

Page 1217 of 1395

l-

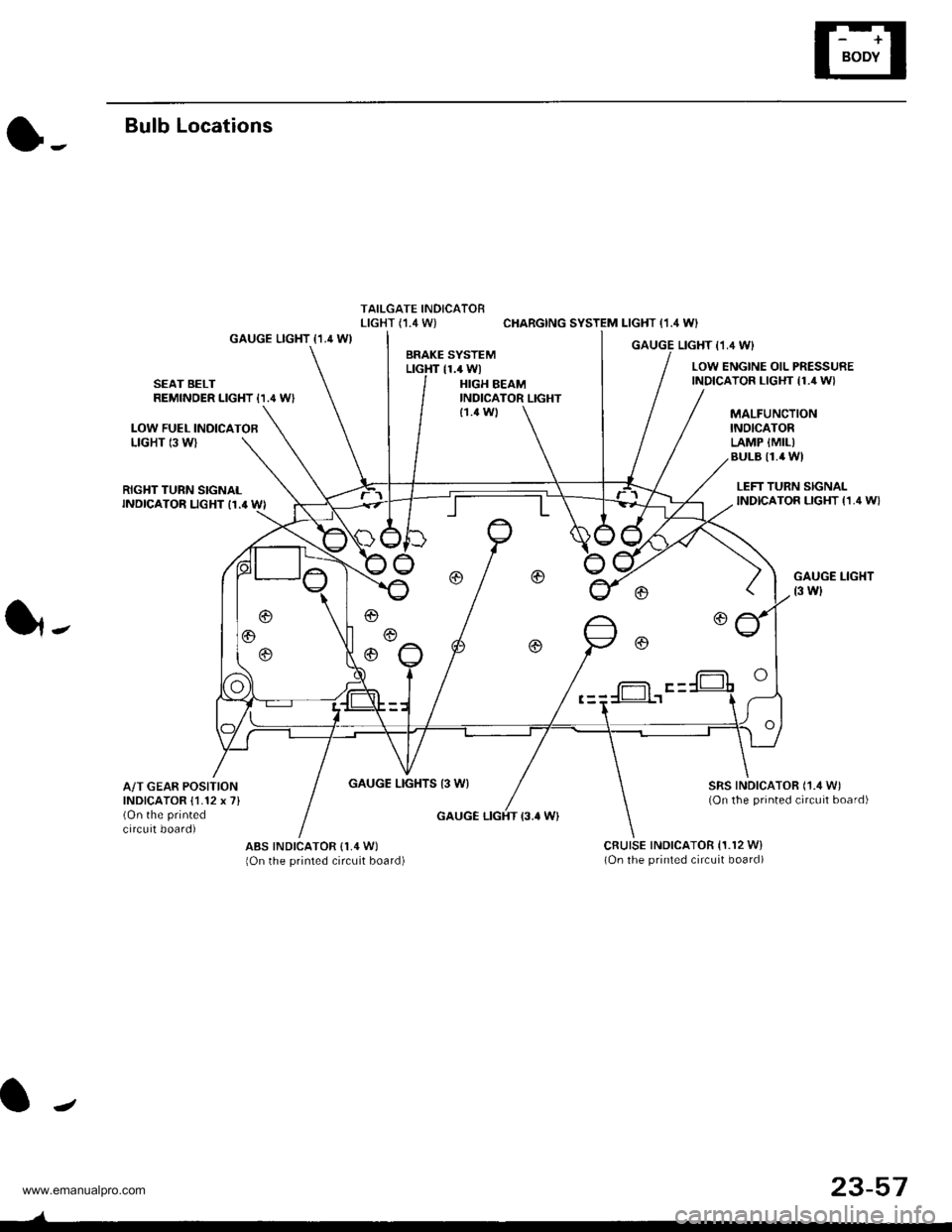

Bulb Locations

TAILGATE INDICATORLIGHT (,I.4 W) CHARGING SYSTEM LIGHT (1.4 WI

GAUGE LIGHT {1.4 WIGAUGE LIGHT I1,4 WIBRAKE SYSTEMLTGHT 11.4 WlLOW ENGINE OIL PRESSUREINDICATOR LIGHT {1./r W}SEAT BELTREMINDER LIGHT {1.' W'HIGH BEAMINDICATOR LIGHT

LOW FUEL INOICATOBLIGHT 13 WI

MALFUNCTIONINOICATORLAMP {MIL)BULB I1.4 WI

{1.4 Wl

RIGHT TURN SIGNALINDICATOR LIGHT I1.' WI

GAUGE LIGHTS 13 WI

LEFT TURN SIGNALINDICATOR LIGHT {1,4 W}

GAUGE LIGHT

t3 wl

SRS INDICATOR ('1./t W)(On the printed circuit board)

1,.

A/T GEAR POSITIONINDICATOR {1.12 x 7}(On the printed

circuit board)GAUGE LIGHT {3.' W}

ABS INDICATOR (1,4 W)

lOn the printed circuit board)cRutsE tNDtcAToR 11.r2 w)(On the printed circuit board)

f-= F -

J

23-57

www.emanualpro.com

Page 1218 of 1395

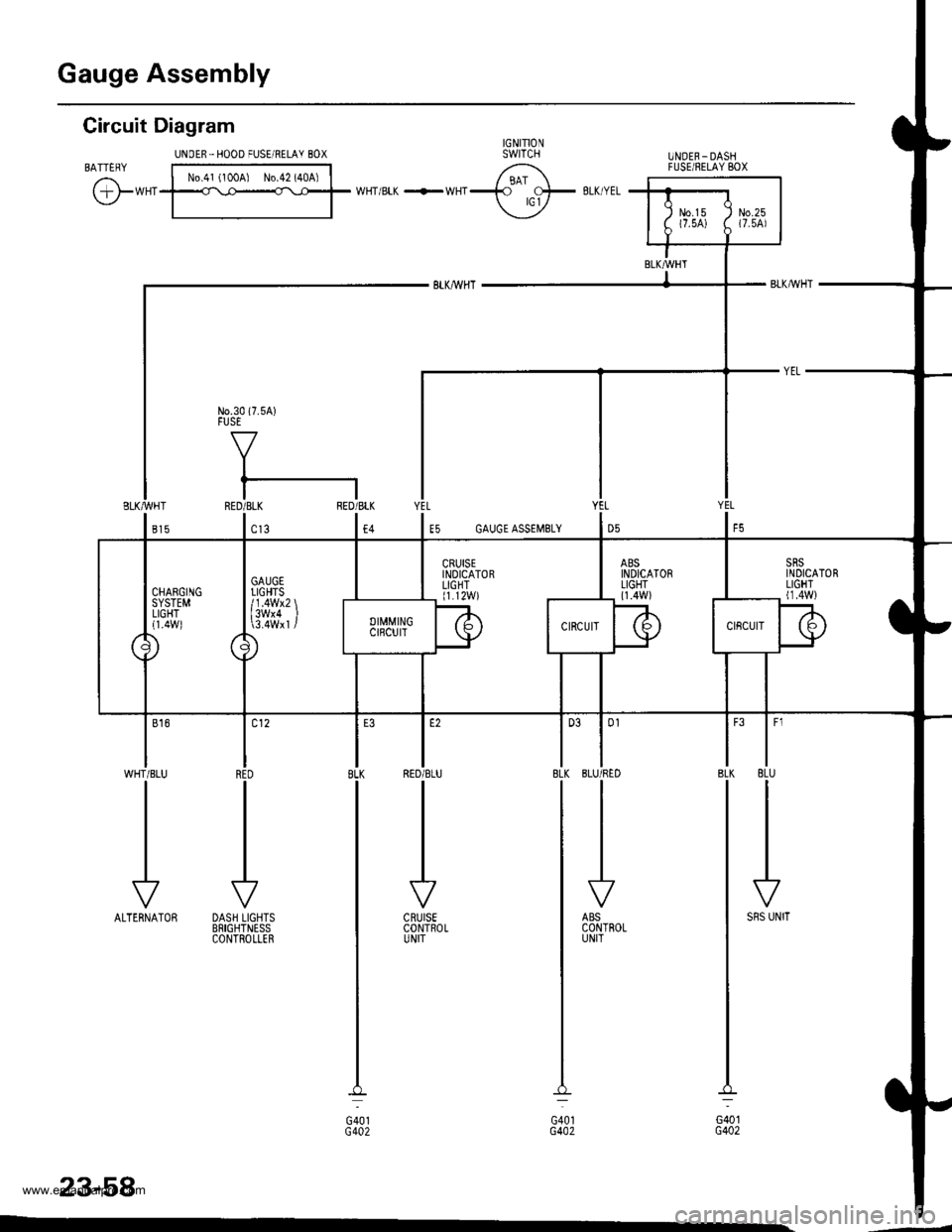

Gauge Assembly

Circuit Diagram

BATTERY

@*"

UNOER.IIOOD FUSE/RELAY 8OX

No.41 (100A) No.42 (40A)

UNOER_DASHFUSEiNELAY BOX

|

'''

IRED

-I

DASH LIGHTSBRIGHTNESSCONTROLLER

l-8LK

G401G4A2

CRUISECONTROLUNIT

23-58

JALTERNATOR

| 0l

IBLU/RED

-I

ABSCONTROLUNIT

JSRS UNIT

YEL

E5 GAUGE ASSEMSLY

www.emanualpro.com

Page 1228 of 1395

Integrated Gontrol Unit

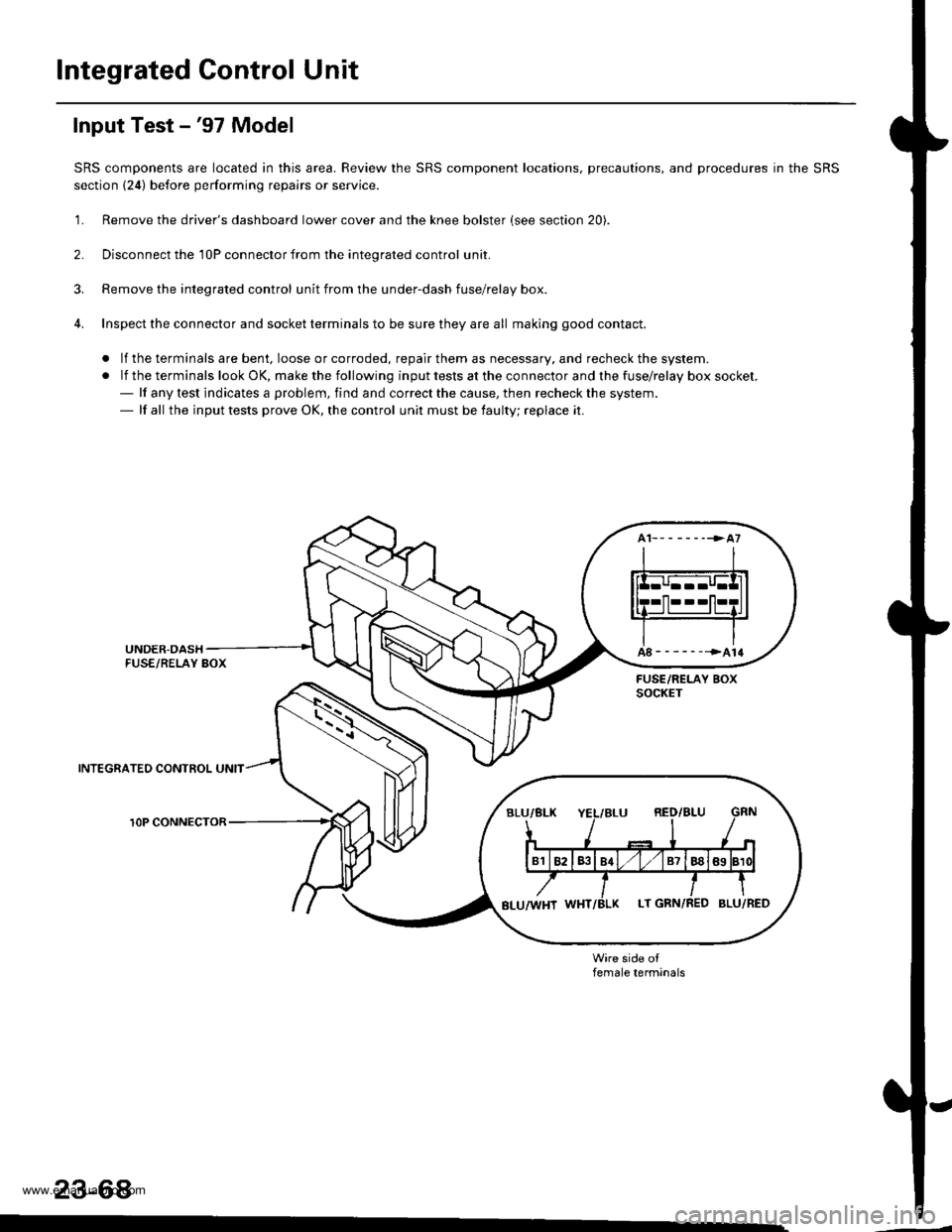

Input Test -'97 Model

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24) before performing repairs or service.

'1. Remove the driver's dashboard lower cover and the knee bolster (see section 20).

2. Disconnect the 'l0P connector from the inteorated control unit.

3. Remove the integrated control unit from the under-dash fuse/relay box.

4. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded, repair them as necessary, and recheck the system.

.lftheterminalslookOK,makethefollowinginputtestsattheconnectorandthefuse\

/relayboxsocket.- lf any test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the control unit must be faulty; replace it.

INTEGRATEO CONTROL UNIT

rOP CONNECTOR

female terminals

23-68

www.emanualpro.com

Page 1231 of 1395

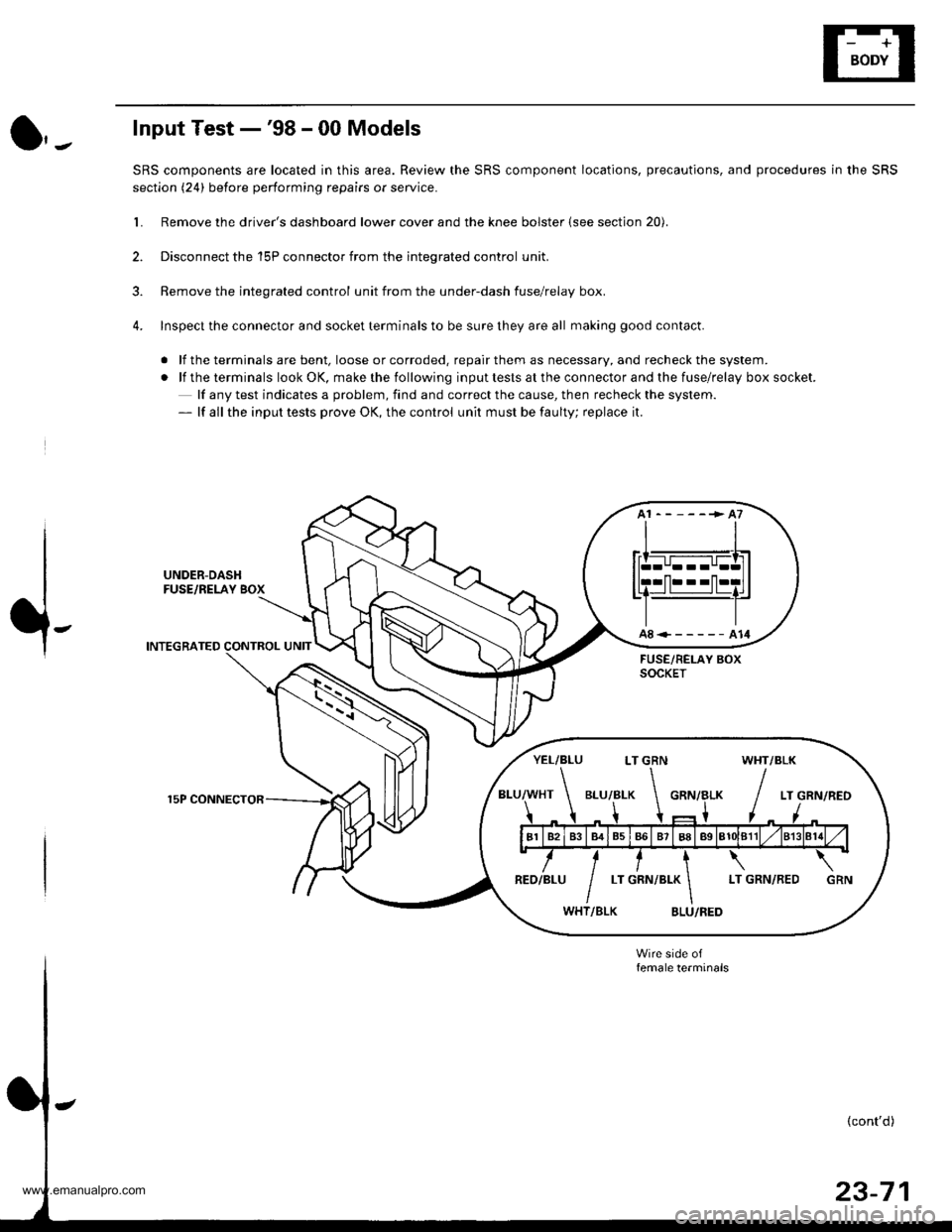

Input Test -'98 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

L Remove the driver's dashboard lower cover and the knee bolster (see section 20).

2. Disconnect the 'l5P connector from the inteqrated control unit.

3. Remove the integrated control unit from the under-dash fuse/relay box.

4. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded. repair them as necessary, and recheck the system.

.lftheterminalslookOK,makethefollowinginputtestsattheconnectorandthefuse\

/relayboxsocket.

lf any test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the control unit must be faulty; replace it.

UNDER-DASHFUSE/RELAY BOX

INTEGRATED CONTROL UNIT

15P CONNECTOR

A8<------A14

YEL/BLU LT GRN WHT/BLK

www.emanualpro.com

Page 1239 of 1395

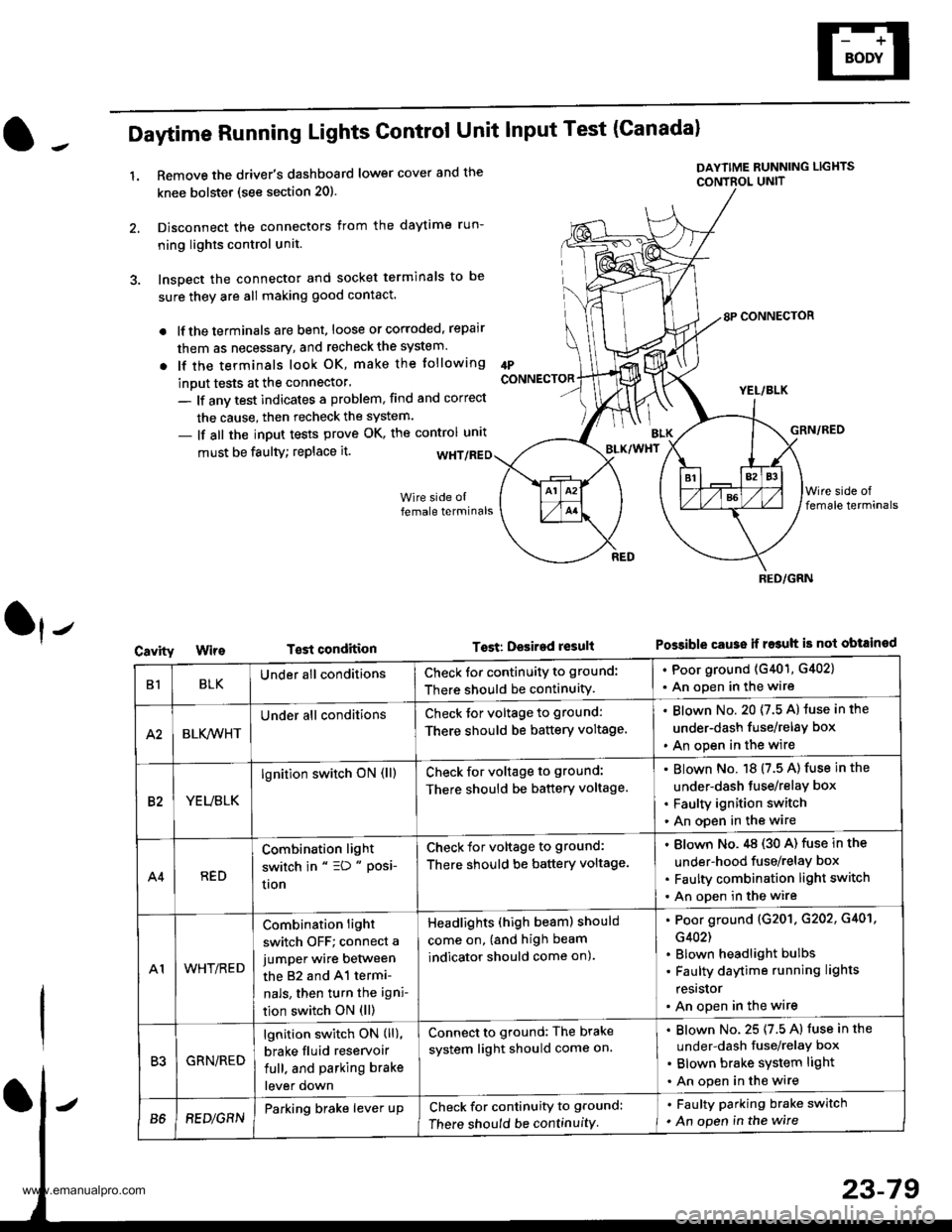

Daytime Running Lights Control Unit Input Test (Canadal

1.Remove the driver's dashboard lower cover and the

knee bolstet (see section 20).

Disconnect the connectors from the daytime run-

ning lights control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

lf the terminals are bent, loose or corroded, repair

them as necessary, and recheck the system.

lf the terminals look OK, make the tollowing

inout tests at the connector'

- lf anv test indicates a problem, find and correct

the cause, then recheck the system.

- lf all the input tests prove OK, the control unrt

IPCONNECTOR

must be faulty; replace it.

T€st condition

DAYTIME RUNNING LIGHTS

CONTBOL UNIT

Tost: Desired result

8P CONNECTOR

YEL/BLK

GRN/RED

Possible cause ii r$uh is not obtained

BLK/WHT

Cavity

RED/GRN

B1BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402)

. An open in the wire

A2BLK,4iVHT

Under all conditionsCheck tor voltage to ground:

There should be battery voltage.

Blown No. 20 (7.5 A) luse in the

under-dash fuse/relay box

An open in the wire

82YEUBLK

lgnition switch oN (ll)Check for voltage to ground:

There should be battery voltage.

Blown No. 18 (7.5 A) fuse in the

under-dash tuse/relay box

Faulty ignition switch

An open in the wire

A4RED

Combination light

switch in " =D " Posi-

uon

Check for voltage to ground:

There should be battery voltage.

Blown No.,tg (30 A) fuse in the

under-hood fuse/relay box

Faulty combination light switch

An open in the wire

A1WHT/RED

Combination light

switch OFF; connect a

jumper wire between

the 82 and 41 termi-

nals, then turn the igni-

tion switch ON (ll)

Headlights (high beam) should

come on, (and high beam

indicator should come on).

Poor ground (G201. G202, G401,

G402)

Blown headlight bulbs

Faulty daytime running lights

resrslor

An open in the wire

R'IGRN/RED

lgnition switch ON (ll),

brake fluid reservoir

full. and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relaY box

Blown brake system light

An open in the wire

B68EDlGRNParking brake lever upCheck for continuity to ground:

There should be continuity

. Faulty parking brake switch

. An open in the wire

www.emanualpro.com

Page 1246 of 1395

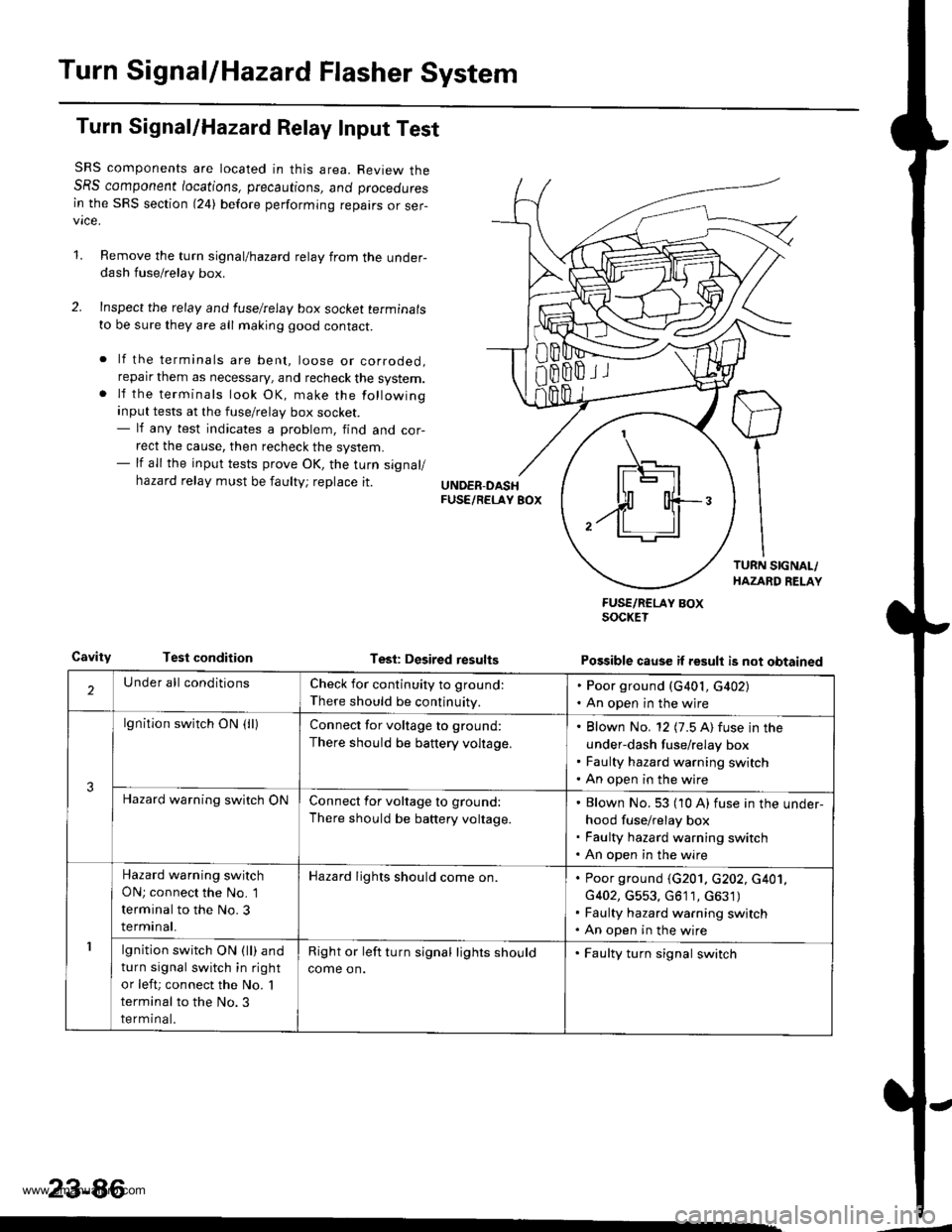

Turn SignallHazard Flasher System

Turn Signal/Hazard Relay Input Test

SRS components are located in this area. Review theSRS component /ocations, precautions, ano proceoures

in the SRS section (24) before performing repairs or ser-vice.

1.Remove the turn signal/hazard relay from the under-dash fuse/relay box.

Inspect the relay and luselrelay box socket terminals

to be sure they are all making good contact.

lf the terminals are bent, loose or corroded,reparr them as necessary, and recheck the system.lf the terminals look OK, make the following

input tests at the fuse/relay box socket.- lf any test indicates a problem, find and cor-

rect the cause, then recheck the system.- lf all the input tests prove OK, the turn signal/

hazard relay must be faulty; replace it.

CavityTest conditionTesl: Desired results

FUSE/RCLAY BOXSOCKET

Possible cause if result is not obtained

'1

IF\_-'l -]l

$ o{+-/ll ll

2Under all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402). An open in the wjre

3

lgnition switch ON (lllConnect for voltage to ground:

There should be battery voltage.

Blown No. 12 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty hazard warning switch

An open in the wire

Hazard warning switch ONConnect for voltage to ground:

There should be battery voltage.

Blown No. 53 (10 A) fuse in the under-

hood fuse/relay box

Faulty hazard warning switch

An open in the wire

1

Hazard warning switch

ON; connect the No. 1

terminal to the No. 3

terminal.

Hazard lights should come on.Poor ground (G201. c202, c401,

G402, G553, G611, c631)

Faulty hazard warning switch

An open in the wire

lgnition switch ON (ll) and

turn signal switch in right

or left; connect the No. 'l

terminal to the No.3

terminal.

Right or left turn signal lights should

come on.

. Faulty turn signal switch

23-86

www.emanualpro.com