Connectors HONDA CR-V 2000 RD1-RD3 / 1.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 631 of 1395

A {32P}

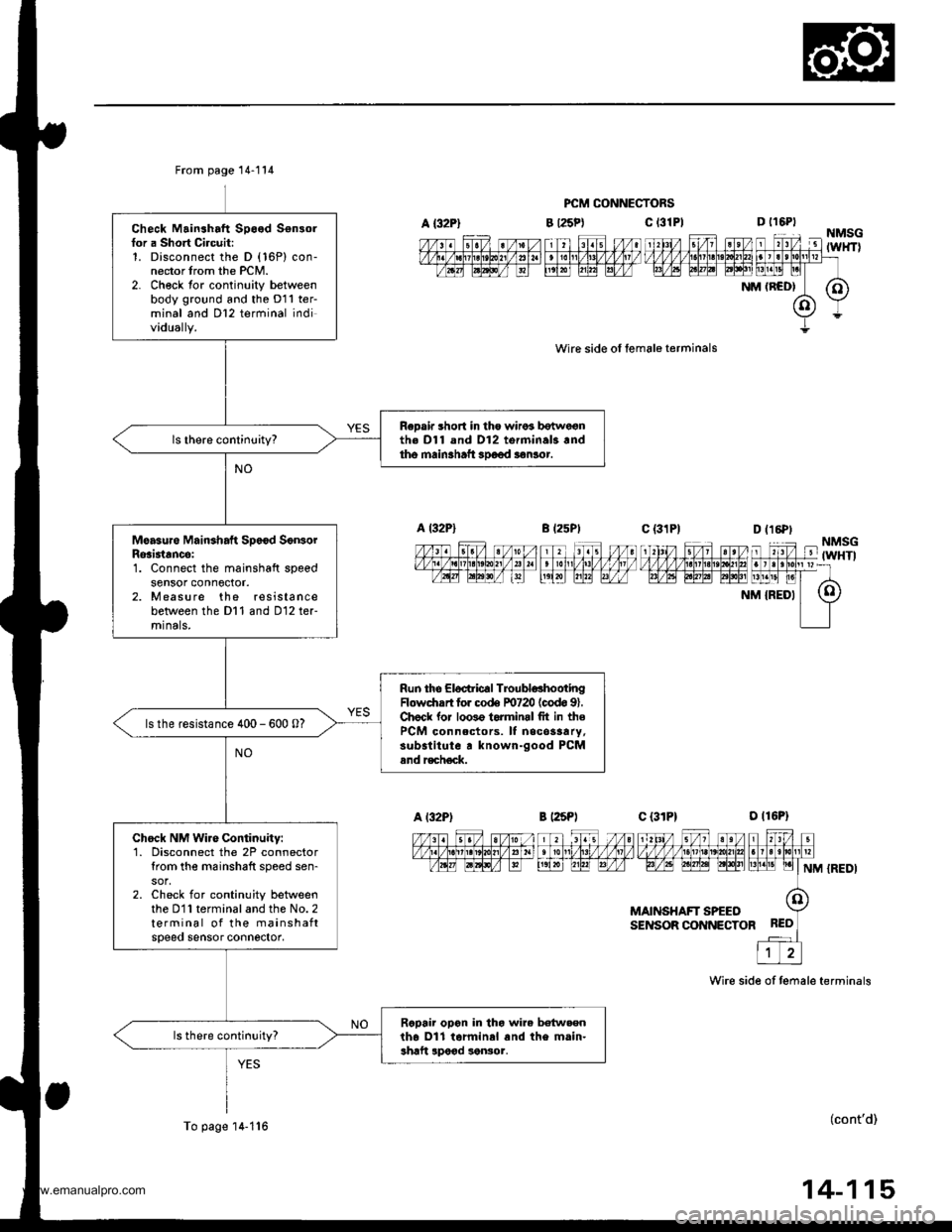

From page 14-114

Check Mainshaft Speed Sensorfor a Short Circuit:1. Disconnect the D (16P) con-nector trom the PCM.2- Ch€ck tor continuity betweenbody ground and the D11 ter-minal and Dl2 terminal individually.

ReDair short in tho wiros botwe€nth€ Dl1 and D12 torminal3.ndtho main3haft 3Doed aonlor.

Moasure Mainshaft Sp6€d SonsorRosi3tancei1. Connect the mainshaft speedsensor conn6ctor.2. Measure the resistancebetween the Dl1 and D12 ter-mrnals,

Run the Eloctric€l TroubldhootingFlowdrrrt for co& F0720 (codo 91.Chock lor loo3o torminrl fit in thePCM connectors. It necos3ary,substitute r known-good PCMand r€ch€ck.

ls the resistance 400 - 600 0?

Chock NM Wire Continuity:1. Disconnect the 2P connectortrom the m6inshaft speed sen-

2. Check for continuity betweenthe D11 terminal and the No. 2terminal of the mainshaftspeeo sensor connector,

Rcpair opon in tho wire betw.enth6 Dll tarminal and the main-shaft lpood sonsor.

To page'14-1'16

PCM CONNECTORS

c t3lPl

wire side ol female terminals

B l25Pt

D t16PtNMSG-'lTZ lit4'l Fl l'1til FTil ,'l unrv v v v v l.t1lLtLt?!/]|,1tut larrlrllllpr=rtavtq tptntat EElt [1!]t! pl

NM (RCD| (O)

(o)Y

Y=

c {31P1--_|--1\‰1,/ s/1 st/v,1zzfififinffiiFrF/l,6t FFF| LrLrEllNM {REDI

MAINSHAFT SPEEOSENSOR CONNECTOR

Wire side of temale terminals

(cont'd)

14-115

www.emanualpro.com

Page 632 of 1395

Electrical Troubleshooting ('98 - 00 Models)

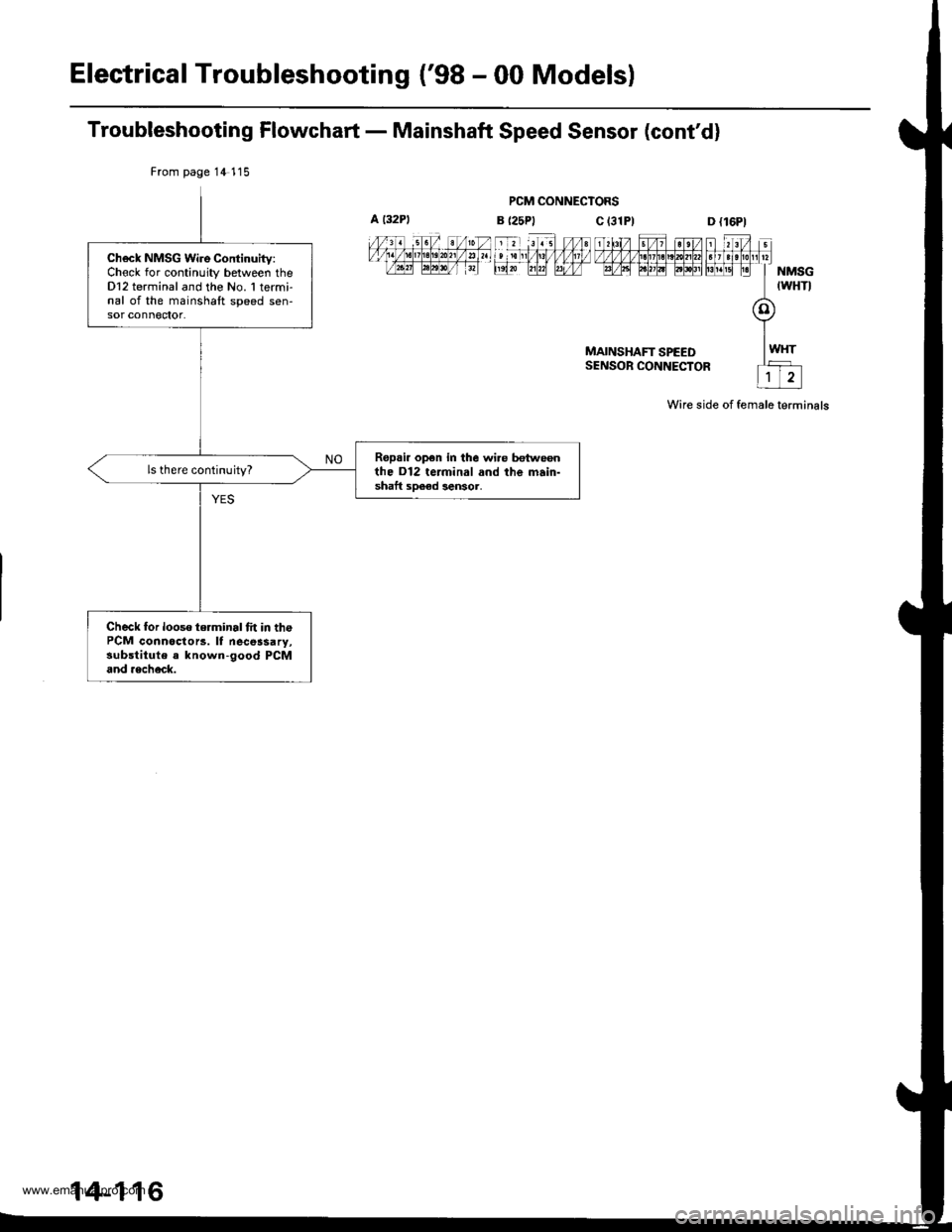

Troubleshooting Flowchart - Mainshaft Speed Sensor (cont'd)

PCM CONNECTORS

MAINSHAFT SPEEDSENSOR CONNECTOR

Wire side of female terminals

From page 14 115

Ch6ck NMSG Wire Continuitv:Chock for continuity between theDl2 terminal and the No. 1 termi-nal of the mainshaft speed sen-sor conn€ctot.

Ropai. op€n in the wi.e hn eonthe D12 terminal and the main-shaft sDeed lensor,

ls there continuity?

Check for looso terminal fit in thePCM connoctorc. lf necessary,substitute a known-good PCMand aech6ck.

14-116

www.emanualpro.com

Page 635 of 1395

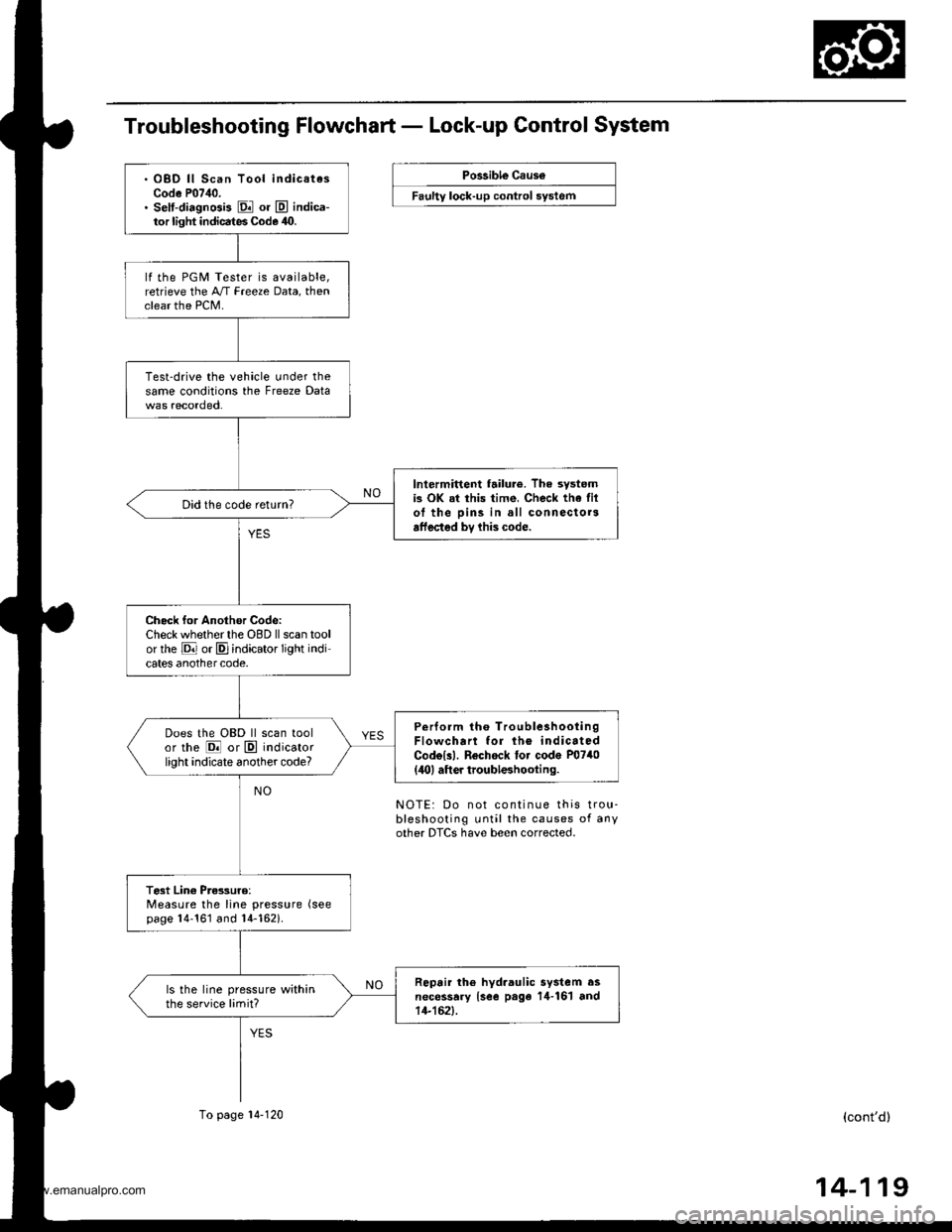

Troubleshooting Flowchart - Lock-up Control System

Possible Caus6

Faulty lock-up control system

. OBD ll Scan Tool indicatesCode P07,10.. selt-diagnGis El or E indica-tor light indicates Code 40.

lf the PGM Tester is available,retrieve the A/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

lntermittent failur6. The systemis OK at this time, Check the filol the pins in all connectorsaffected bv lhis code.

Did the code return?

Check for Another Codc:Check whether the OBD ll scan toolor rhe E or E]indicator light indicates anothercode,

Perform tho TroubleshootingFlowchart for lh6 indicatedCodolll. Rechock tor code P0740(,lO) aft er troubleshooting.

Does the OBD ll scan toolor the @ or E indicatorlight indicate another code?

Test Lin€ Pres3uro:Measure the line pressure (see

page 14'161 and 14-162i.

Repair th6 hyd.aulic system asnecessary {see page 14-161 and14-152).

ls the line pressure withinthe service limit?

To page 14-120

NOTE: Do not continue this trou-bleshooting until the causes of anyother DTCS have been corrected.

(cont'd)

14-119

www.emanualpro.com

Page 637 of 1395

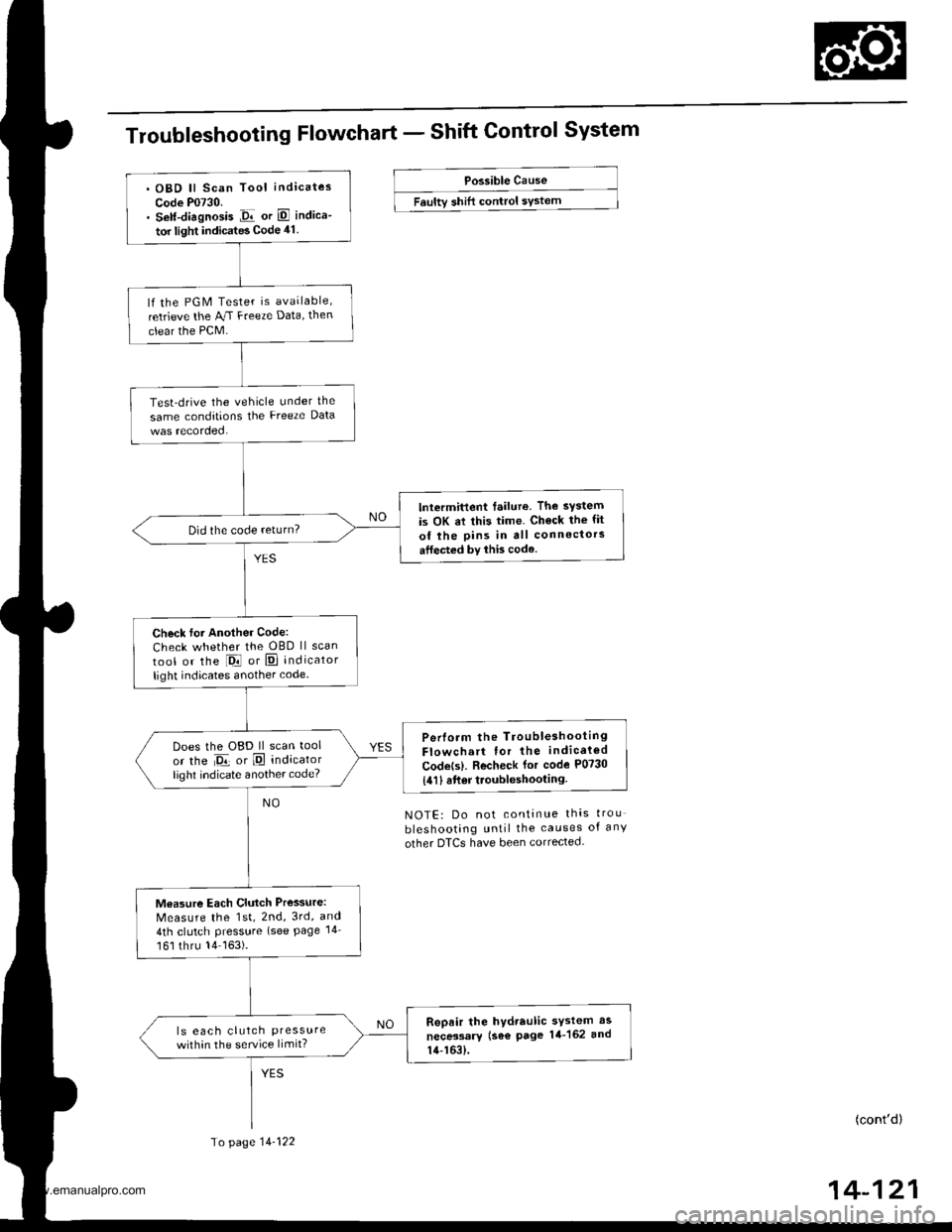

Troubleshooting Flowchart - Shift Control System

Possible Cause

Faultv shift control sYstem

NOTE: Do not continue thas trou

bleshooting until the causes of any

other DTCS have been corrected.

(cont'd)

14-121

. OBD ll Scan Tool indicates

Code P0730.. Self-diagnosis Jir or E indica-

tor light indicates Code 41.

lf the PGM Tester is available,

retrieve the AJ.I Freeze Data, then

clear the PCM.

Test-drive the vehicle under the

same conditions the Freeze Data

lntermittent failure. The system

is OK at this time. Ch€ck the fit

of the pins in all connectors

atfected by this code.

Did the code return?

Check for Another Code:

Check whether the OBD ll scan

tool or the l-Drl or E] indicator

light indicates another code.

Perlorm the TroubleshootingFlowchart for the indicaled

Codets). Recheck for code P0730

{411 6ft6r troubleshooting.

Does the OBD ll scan tool

or the Da or E indicatorlighl indicate another code?

Measure Each Clutch Pressure:

Measure the 1st, 2nd, 3rd, and

4th clutch Pressure (see Page 14

161 thru 14163).

Repair the hydraulic sYstem as

necessary (se€ page 14-162 and

14-163).

ls eac h clutch Pressurewithin the service limit?

To page 14-122

www.emanualpro.com

Page 639 of 1395

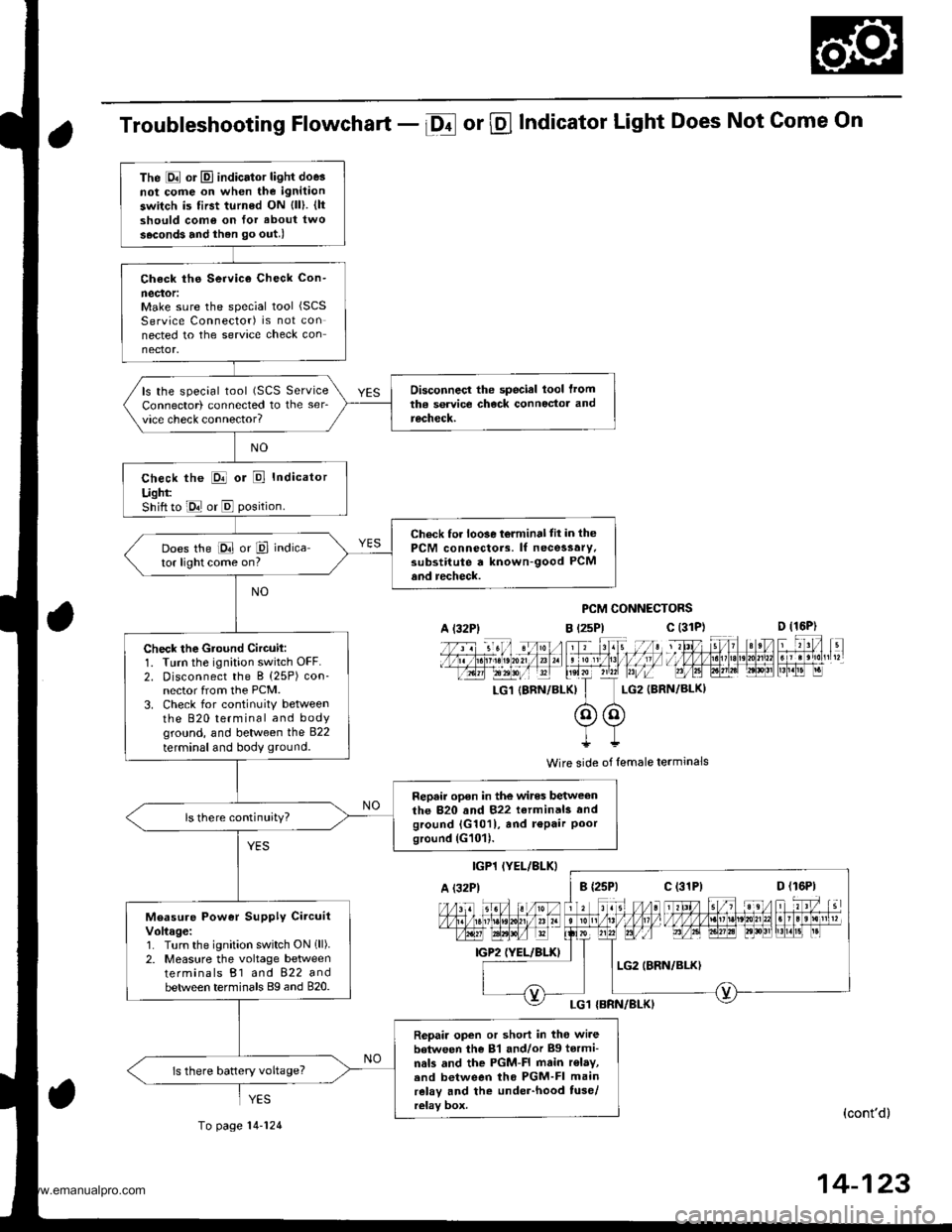

Troubleshooting Flowchart - Df or @ Indicator Light Does Not Come On

PCM CONNECTORS

B t2sPl c (31D (16P)

l*f4tr 8-

f - -- -6 3 rol ,: irr t lrpri$fe?0?r/a)1 e 'oI 13 11/ / l//|rrr I , ltelx ?r2? r,/i-T_LG1 {8RN/BI-KI I LG2 (BRN/BL()I

@@I++

Wire side of lemale terminals

(cont'd)

14-123

The E or El indicator light doe3not cofie on when the ignitaon

switch is first turned ON {ll). {ltshould como on for about two

s.cond3 and ihen go out.l

Check ths Service Check Con-

neclor:Make sure the special tool (SCS

Service Connector) is not connected to the service check connector.

Disconnecl the special lool lromtha service check connoctor andrecheck.

ls the special tool (SCS ServiceConnector) connected to the ser_vice check connector?

check the E or E Indicator

Ught:Shift to E or E position.

Check for loo3e t6lminal tit in thePCM connectors. lf necessary.substitute a known-good PCMand recheck.

Does the E or P indica-tor light come on?

Check the Gtound Circuil:1. Turn the ignition switch OFF.2. Disconnect the B (25P) con-nector from the PCM.3. Check for continuitY betweenthe 820 terminal and bodyground, and between the 822

terminal and body ground.

Repair open in the wires betweenthe 820 and 822 terminals andground {G1011, and r€Pair Poorground (G101).

ls there continuity?

Measure Power Supply CircuitVoltage:1. Turn the ignition switch ON 1ll).2. Measure the voltage betweenterminals B1 and 822 andbetween terminals Bg and 820.

Repair open or short in tho wi.ebetween the 81 and/or Bg tormi-nals and the PGM-FI main r€lay,.nd between tho PGM-FI mainrelay and the under-hood tuse/relay box.

ls there battery voltage?

A l32Plc (31P)

c (31P)

YES

To page 14-124

www.emanualpro.com

Page 640 of 1395

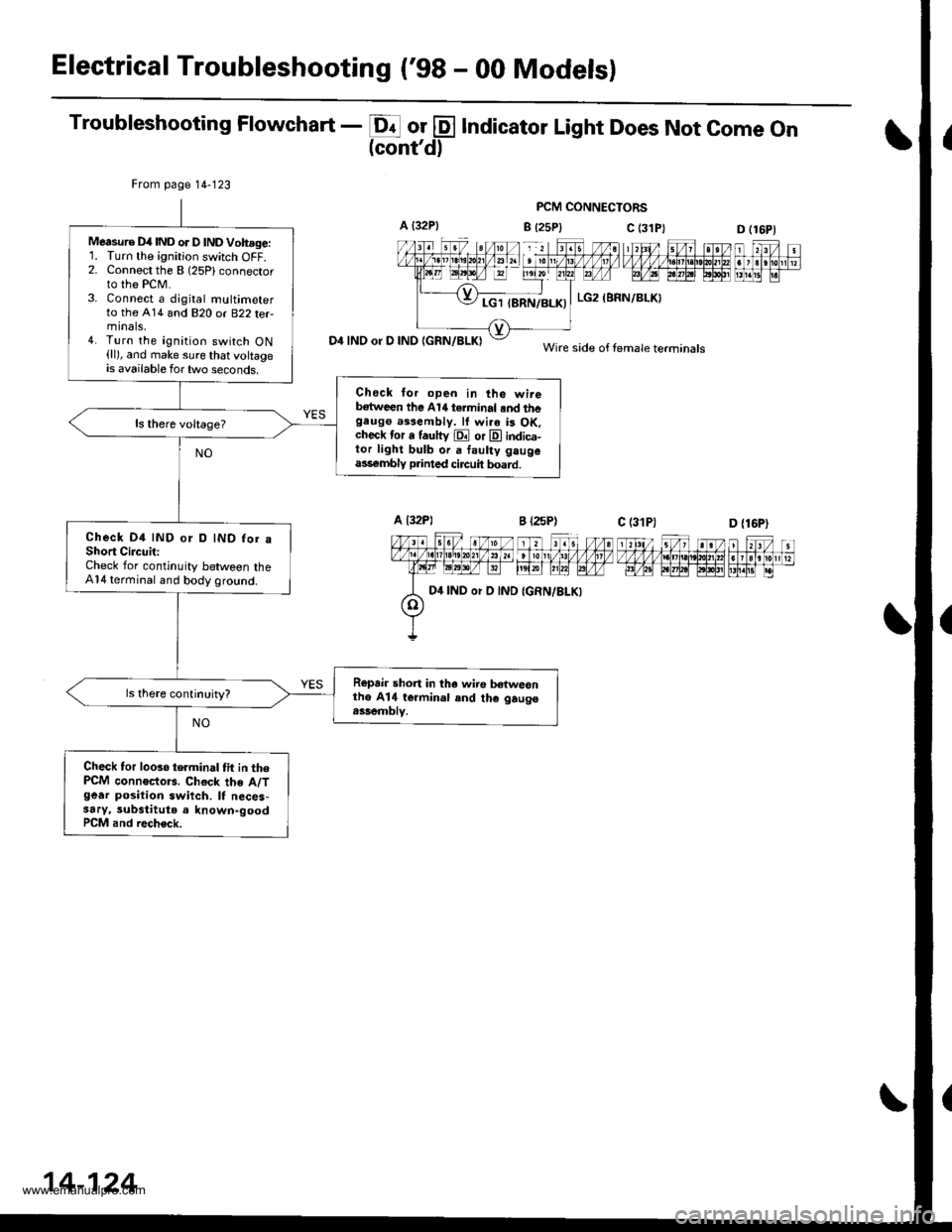

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - E or @ Indicator Light Does Not come on(cont'd)

PCM CONNECTORS

B {25P} C (3D (16P1

n f,-ff nt f,Fjrti.trnnmflnr

D4 INO or D IND IGRN/BLKI

From page 14-123

Measure D4IND or D lNDVoh.ge:'L Turn the ignition switch OFF.2. Connect the B (25Plconnector

to the PCM.3. Connect a djgital multimeterto the A14 and 820 or B22 terminals,4. Turn the ignition switch ON(ll), and make sure that voltageis available for two seconds.

Check lor open in the wireb€tween the Al/t terminal .nd thegeugo a$eftbly. lf wi.a is OK.check tor a fautty E or E indica-tor light bulb or a faulty gaugeass€mbly p.inted circuit board.

Check D4 IND or D IND for aShort CircuitiCheck for continuity between theA14 terminal and body ground.

Ropair short in tha wiro b€twesnthe A14 termin.l and th€ gaugo.ssemblv.

Check tor looso telminal tit in thePCM connoctors. Chock the A/Tgear position swiich. It neces-3ary, substitute a known-goodPCM and rech€ck.

c (31P)

LG2 (BRN/BLKI

Wire side of female terminals

D {16P)

D4 IND or D IND

14-124

www.emanualpro.com

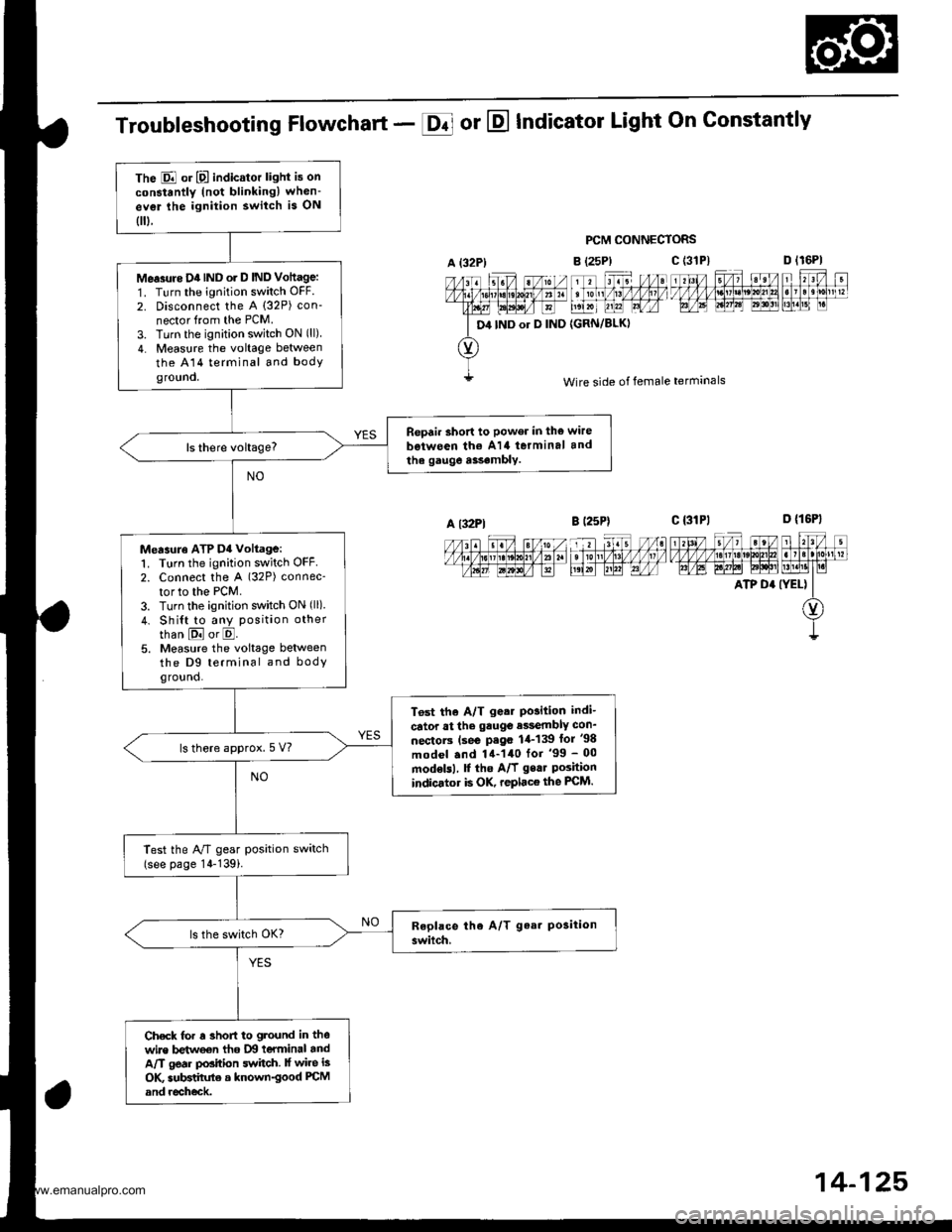

Page 641 of 1395

The E or E indicator light is on

constantly (not blinkingl when-

ev€r lhe ignition switch is ON

0.

Me.3rtre D4IND o. D IND Vottage:

1. Turn the ignition switch OFF.

2. Disconnect the A (32P) con-

nector from the PCM.

3. Turn the ignition switch ON (ll)

4. Measure the voltage between

the A14 terminal and bodyground.

Repair short to power in the wire

b€iween th€ A14 terminal and

the gauge a$.mbly.

Measuro ATP D4 voltage:1. Turn the ignition switch OFF2. Connect the A (32P) connec-

tor to the PCM.

3. Turn the ignition switch ON (ll)

4. Shi{t to any position other

than E or E.5. Measure the voltage betweenthe D9 terminal and bodyground.

T6st the A/T g.ar Po3ition indi-

cator at the gauge e$embly con_

nectorc (se€ P.go 1,1-139 lor '98

model .nd 14-140 for '99 - 00

modelsl, f the A/f gear Poshionindicator is OK, replace the FCM.

ls there approx.5 V?

Test the A/T gear position switch(see page 14-139i.

Check for r 3hofi to ground in thewire betweon tho IXI teYminal andA/T gear position switch. lf wire is

OK subBtihrte a known-good PCM

and recheck.

Troubleshooting Flowchart - E or E Indicator Light On Gonstantly

PCM CONNECTORS

B (25P)

11 tr. //at tonl /1! /1/ /llt /

t',lxr uu?l Lrfr4

{GRN/BLKI

D lr6Pl

F't!4[r

Wire side of female terminals

c t3lPl_=---r-:=-t rl3l/ 5/, ?eV t r?V t

t/l,4lzulErt!t!!j!t!u3t ll]]lll1lglt]|b AE A.W6l ld$!'lLM.l1t I r.i

ATP D' (YEL) II

O)

I

A {32P)

D4 IND or D IND

c (3'tP)

A l32Pl

14-125,

www.emanualpro.com

Page 642 of 1395

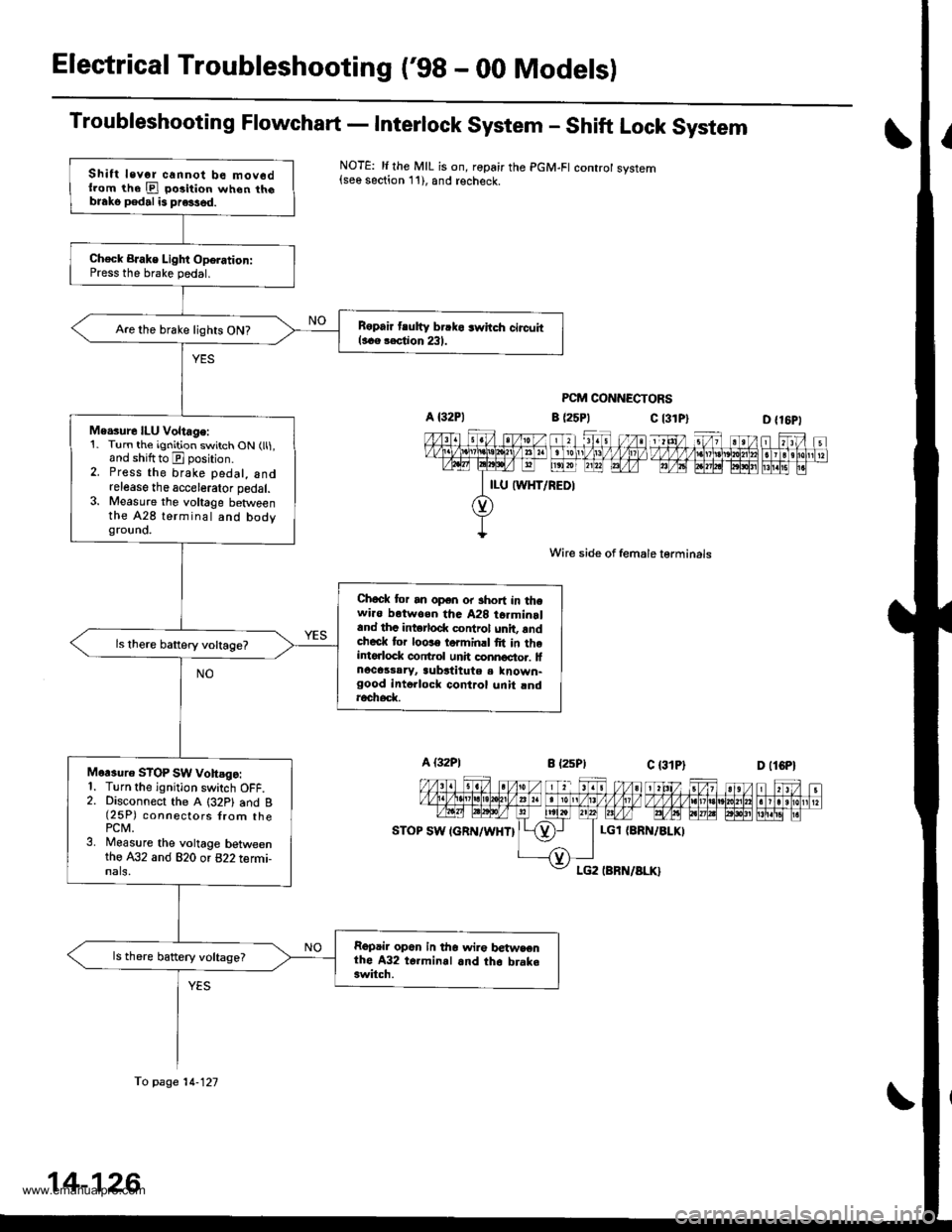

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Interlock System - Shift Lock System

NOTE: li the MIL is on, ropair the PGM-FI controt system{see section 11), and recheck.

PCM CONNECTORS

c l3lPl

Wire side of female lerminals

c t3lPt

D {16P1

1 tttt/ 5t/ 1 a t /tlt 1 t\/t ,/ VVV tl t ttj,r\1e\10l211n . I 3 rholr1 t?m@-@Effilil"

D (lCPl

| 2ttt/ ;t /n) ).tt)/ 1 21:/ tvvvvv nnvl.lnl2

I r r ero

12wE gp]P] polr EI!l!!i r.

a (25P1

LGl {8RN/ALKI

Shift levor cannot be mov6dllom the E po3ition when th6blako pedal is pre3sed.

Ch€ck BJake Light Oporation:Press the brake pedal.

B6pair tlutty brrko 3whch circuitl..e rection 231.Are the brake lights ON?

Me.sure ILU Voltage:1. Turn the ignition switch ON (ll1,and shiftto E position.2. Press the brake pedal, andrelease the accelerator pedal.3. Measure the voltage betweenthe A28 terminal and bodygrouno.

Chock tor an open or short in thewi.o botwoen tha A28 t6rminrland thc intorlod( control unit, rndcheck tor loose torminrl fit in theintorlock conftol unh connoctor. lfnocassaryr aubstitute a known-good intollock control unit rndroch6d(

Mor3uro STOP SW vohsgo:1. Turn the ignition switch OFF.2. Disconnect the A (32P1 and B(25P) connectors {rom thePCM.3. Measure the voltage betweenthe A32 and 820 or 822 termi-nals,

Repair op6n in tho wir€ betwsenthe A32 t6.minal and th6 brake3witch.

ls there battery voltage?

fo page 14-121

14-126

www.emanualpro.com

Page 643 of 1395

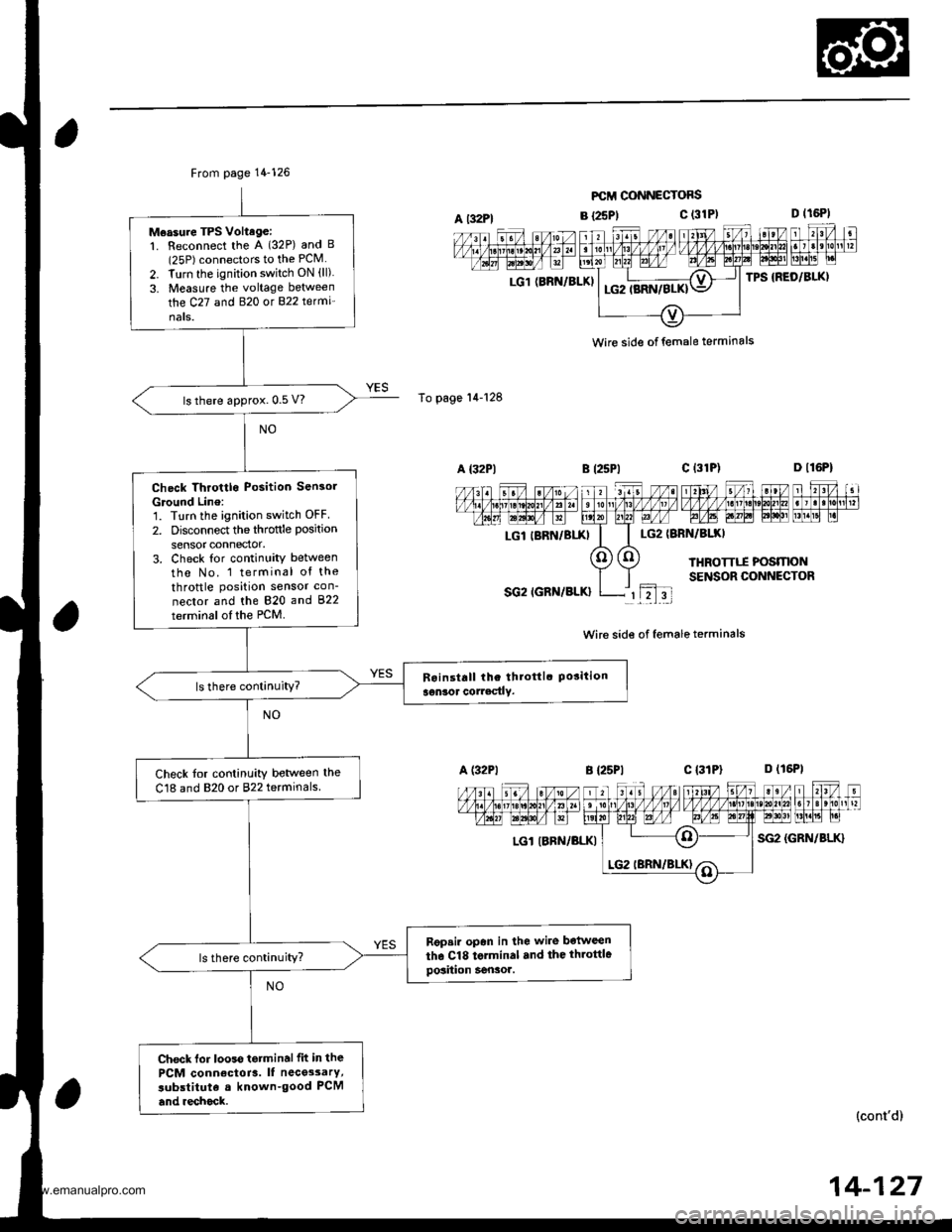

From page 14-126

Measure TPS Voltage:1. Reconnect the A (32P) and B(25P) connectors to the PCM

2. Turn the ignition switch ON (ll)

3. Measure the voltage between

the C27 and B�20 ot 822 te(mi'

nats.

ls there approx. 0.5 V?

Check Throttlo Position Sensol

Ground Line:'1. Turn the ignition switch OFF

2. Disconnect the throftle position

sensor connector.3. Check tor continuity between

tho No. 1 terminal of the

throttle position sensor con-

nector and the 820 and 822

terminsl of the PCM.

ls there continuity?

Check tor continuity betlveen the

C18 and 820 or 822 terminals

Rgpsir opan in lhe wire botween

the Cl8 torminal .nd the throttlegosiiion Sensor.ls there continuity?

Check lor looss tetminalfit in the

PCM conn€ctoia. It nece3sarY,

subslituta a known-good PCM

and .echock.

A t32Pl

To page'14-128

LG1 (BRN/BLKI

FCII CONNECTOFS

B {25P1c (31P)

LG2IBRN/BIXI

THROTTTI POSMONSENSOR CONNECTOR

SG2 IGRN/BLK}rL2l3t

Wire side of female terminals

B {25P1c l3lPl D (16P1

LGl IBRN/BLKISG2 {GRN/BLK}

n l,I-il nFFFTI,T';T;IEFML"| -

(cont'd)

wire side of female terminals

LGl IBRN/BIXI

14-127

www.emanualpro.com

Page 647 of 1395

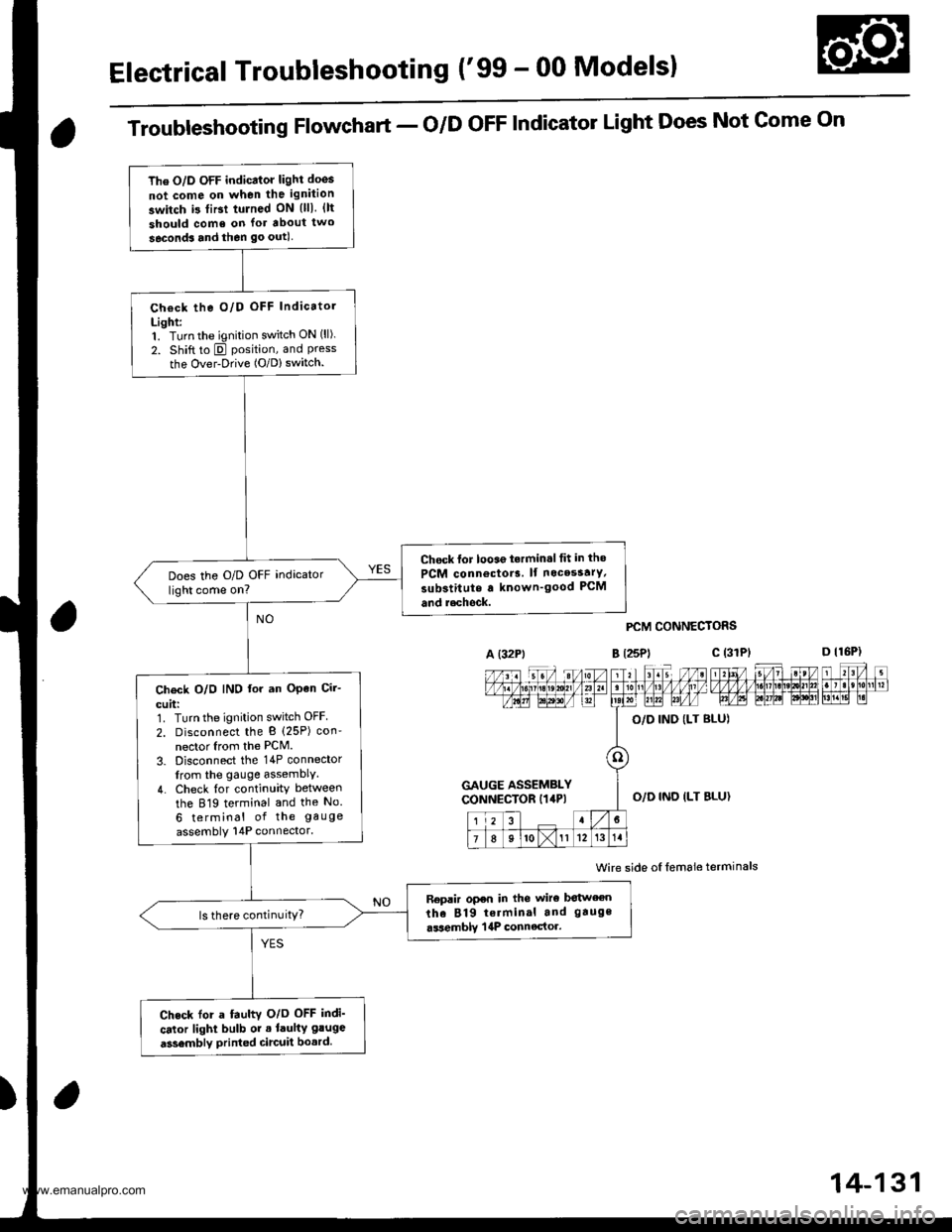

Electrical Troubleshooting ('99 - 00 Modelsl

The O/D OFF indicator light doos

not come on when the ignition

switch i3 tiBt tulned ON {lll. {lt

should come on lor about two

seconds and then go outl

Check the O/D OFF Indicatol

Light:1. Turn the ignition switch ON (ll).

2. Shift to E position, and Pressthe Over-Drive (O/D) switch.

Chock lor looae t.rmin.l tit in tho

PCM connoctor3. lf nocesstrY,

substitute a known'good PCM

and r.chock.

Does the O/D OFF indicator

light come on?

Ch€ck O/O IND lor an OPen Cir-

cuit:1. Turn the ignition switch OFF

2. Disconnect the B (25P) con'

nector Irom the PCM.

3. Disconnect the 14P connector

from the gauge assemblY.

4. Check {or continuity between

the 819 terminal and the No.

6 terminal of the gauge

assembly 14P connector.

Replir open in the wiro botween

the 819 terminal and gauge

.ssemblY | 4P connector.ls there continuitY?

Check for a fauhv O/o OFF indi'

cator light bulb or . laulty gluge

a3sembly printed circuit bo.rd.

Troubleshooting Flowchart - o/D oFF Indicator Light Does Not Gome On

A (32Pt

PCM CONNECTORS

B t25Pl c (31

Wire side oI lemale terminals

a

c (3rPt

GAUGE ASSEMBLYCONNECTOR I14P)O,/D IND ILT BLU}

14-131

www.emanualpro.com