Switch fan HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 29 of 1395

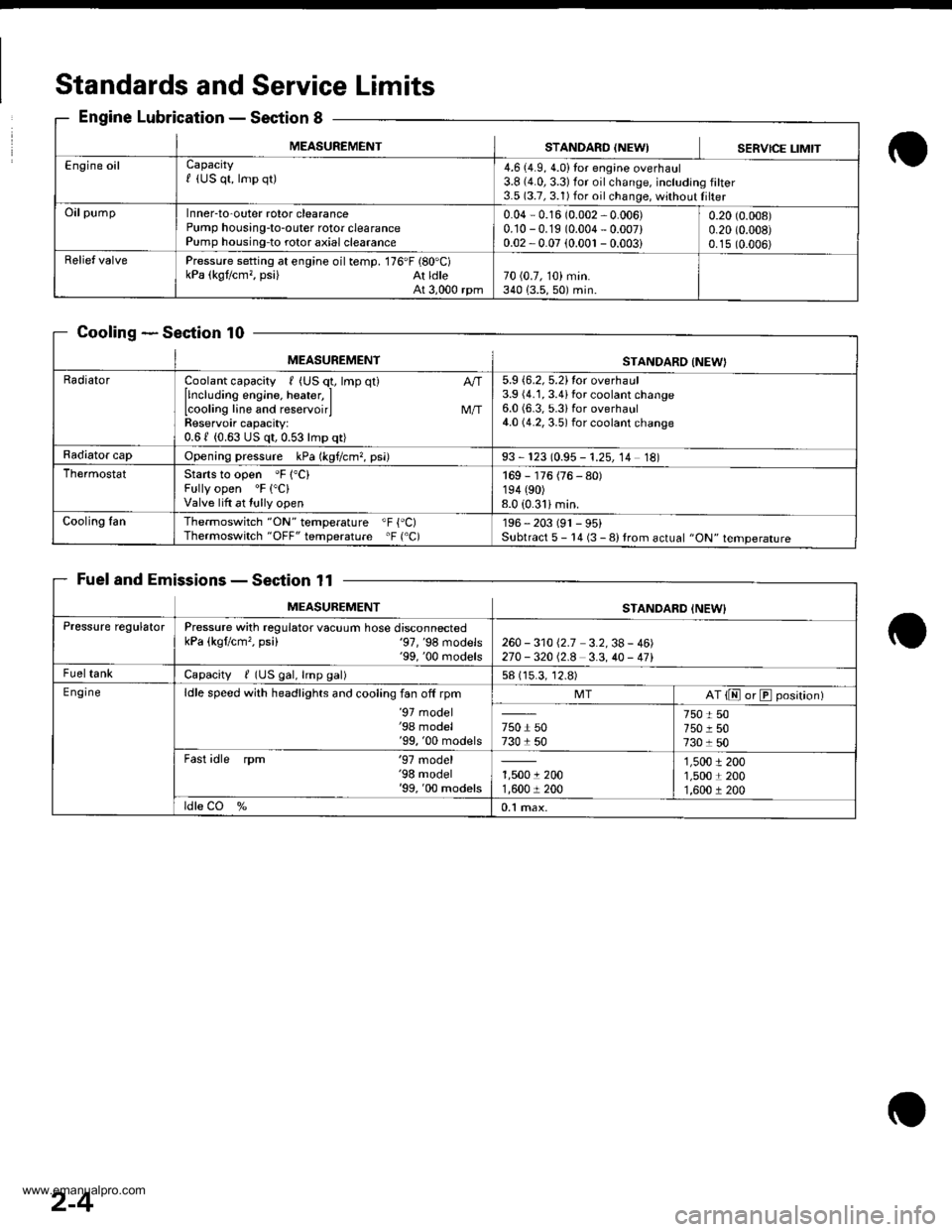

Standards andService Limits

Engine LubricationSection 8

CoolingSection 10

Fuel and EmissionsSection 11

MEASUREMENTSTANDARO {NEWISERVICE LIMIT

Engine oilCapacityf (US qt, lmp qt)4.6 (4.9, 4.0)Ior engine overhaul3.8 {4.0,3.3)for oilchange, including filter3.5 (3.7, 3.1) for oil change, without Iilter

OilpumpInner-to-outer rotor clearancePump housing-to-outer rotor clearancePump housing-to rotor axial clearance

0.04 - 0.16 (0.002 - 0.006)0.10 -0.19 (0.004 - 0.007)0.02 -0.07 (0.001 - 0.003i

0.20 (0.008)

0.20 (0.008)

0.15 (0.006)

Relief valvePressure setting at engine oil temp. 176'F (80'C)kPa (kgt/cm,, psi) At ldleAt 3,000 rpm70 (0.7, 10) min.340 {3.5,50) min.

MEASUREMENTSTANDARO INEW}

RadiatorCoolant capacity , (US q1, lmp qt)

llncluding engine, heater, ILcooling line and reservoirlReservoir capacity:0.61 (0.63 US qt,0.53lmp qt)

M/T

5.9 {6.2, 5.2}tor overhaul3.9 (4.1, 3.4ifor coolant change6.0 (6.3, 5.3ifor overhaul4.0 (4.2, 3.5) for coolant change

Radiator capOpening pressure kPa (kgf/cm?, psi)93 - 123 (0.95 - 1.25, 14 18)

ThermostatStarts to open 'F 1"C)Fully open 'F ("C)

Valve lift at tully open

169 - 176 (76 - 80)194 (90)

8.0 (0.31imin.

Cooling fanThermoswitch "ON" temperature "F {'C)Thermoswitch "OFF" temperature 'F ('C)196 - 203 (91 - 95)Subtract 5 - 14 (3 - 8) trom actual "ON" temperature

MEASUREMENTSTANDARD INEW}

Pressure regulatorPressure with regulator vacuum hose disconnectedkPa (kgflcm'�, psi) '97,'98 models'99, '00 rnodels260 - 31012.7 3.2,38- 46)270 -32012.8 3.3,40 - 471

FueltankCapacity / (US gal, lmp gal)58 (15.3, 12.8)

E ngineldle speed with headlights and cooling fan off rpm'97 model'98 model'99, '00 models

MTAT {E or E position)

750 r 50730 1 50

750 t 50750 r 507301 50

Fast idle rpm '97 model'98 model'99, '00 models1,5001 2001,600 r 200

1,5001 2001,5001 2001,600 r 200

ldle CO %0.1 max.

2-4

www.emanualpro.com

Page 78 of 1395

Gharging System

Troubleshooting (cont'd)

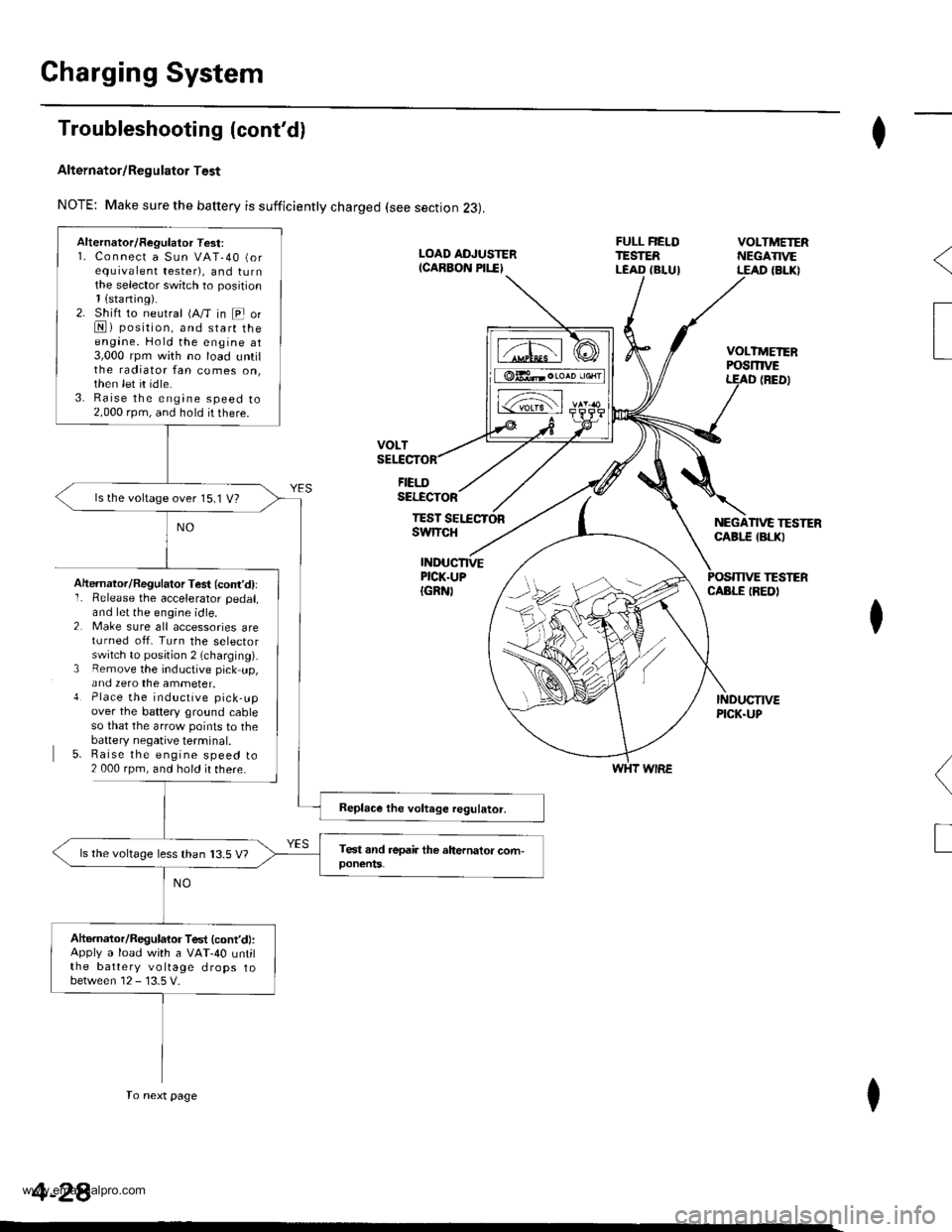

Alternator/Regulator Test

NOTE: Make sure the battery is sufficiently charged (see section 23).

FIELDSELECTOR

TESTswtTcH

I

VOLTMEIERPOSmVEt

NEGATIVE TESTERCABI.E {BLKI

(BED)

TESTERINDUCTIVEPICK.UP{GRN)CABLE IREDIAhernator/Regulator Test (cont'd)lI� Release the accelerator pedal,and let the engine idle.2 Make sure all accessories areturned off. Turn the selectorswitch to posjtion 2 (charging).3 Remove the inductive pick up,and zero the ammeter.{ Place the inductive pick-upover the battery ground cableso that the arrow points to thebaftery negative terminal.5. Raise the engine speed to2 000 rpm, and hold ir there.

I

(

T

I

WHT WIRE

Alternator/Regulator Test:1. Connect a Sun VAT-40 (orequrvalent tester), and turnthe selector switch to position1{sraning).2. Shift to neutral (A/T in E orN) position, and start theengane. Hold the engine at3,000 rpm with no load untilthe radiator fan comes on,then let it idle.3. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

ls the voltage less than 13.5 V?

Altarnator/Regulator Test (cont'd:Apply a load with a VAT-40 untilthe battery voltage drops tobetween 12 - 13.5 V.

To next page

4-28

www.emanualpro.com

Page 93 of 1395

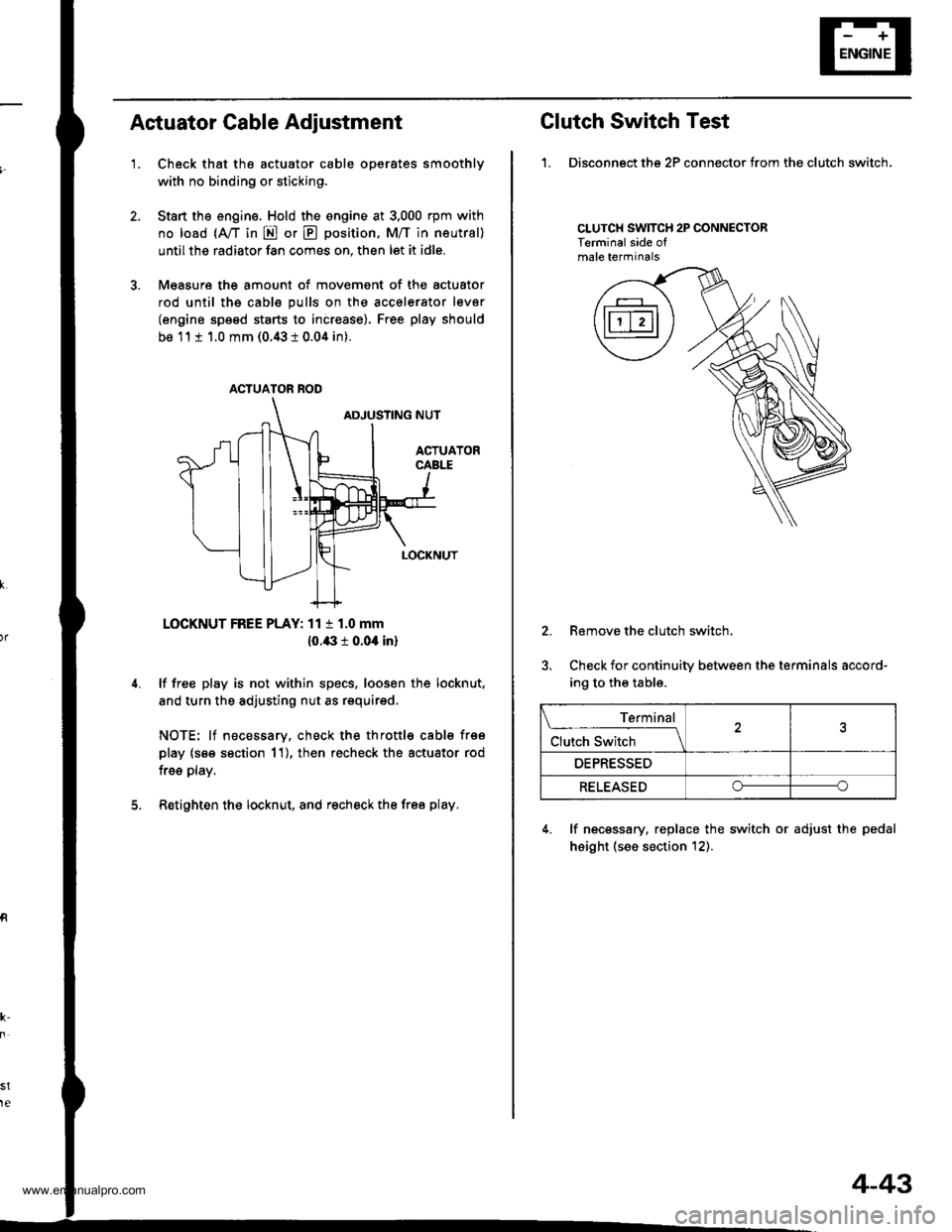

Actuator Cable Adiustment

'1.Check that the actuator cable operates smoothly

with no binding or sticking.

Start the engine. Hold the engine at 3,000 rpm with

no load (A,/T in E or E position, M/T in neutral)

until the radiator fan comes on, then let it idle.

Measure the amount of movement of the actuator

rod until ths cable pulls on the accelerator lever

(engine speed starts to increase). Free play should

be 11 t 1.0 mm (0.43 i 0.04 in).

LOCKNUT FREE PLAY: 11 t 1.0 mm

10.43 r 0.04 in)

lf free play is not within specs, loosen the locknut,

and turn the adjusting nut as requirsd,

NOTE: lf necessary, check the throttl€ cable frso

play (s€e section 11), then recheck the actuator rod

free play.

Retighten the locknut, and recheck the free play.

st

te

ACTUATOR ROD

Clutch Switch Test

1. Disconngct ths 2P connector from the clutch switch.

CLUTCH SWITCH 2P CONNECTORTerminalside ofmale terminals

2.

5.

Remove the clutch switch,

Check for continuity between the terminals accord-

ing to the table.

4. lf necessary, replace the switch or adjust the pedal

height (see section t2).

Terminal

Clutch Switch \

OEPRESSED

RELEASEDoo

4-43

www.emanualpro.com

Page 132 of 1395

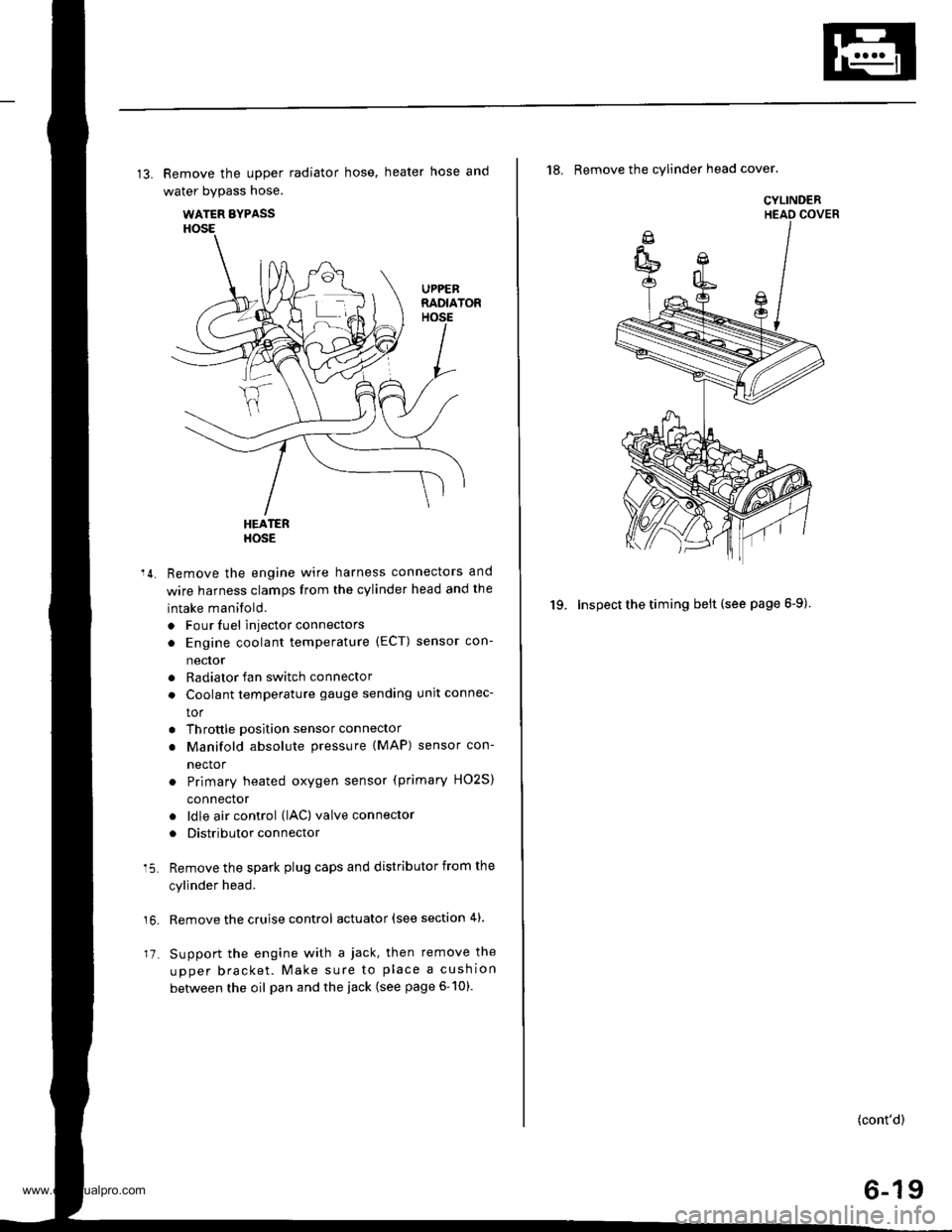

13. Remove the upper radiator hose, heater hose and

water bypass hose.

WATER BYPASS

UPPEBRADIATORHOSE

17

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

neclor

. Radiator fan switch connector

. Coolant temperature gauge sendlng unlt connec-

tor

. Throttle position sensor connector

. Manifold absolute pressure {MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

ldle air control (lAC) valve connector

Distributor connector

Remove the spark plug caps and distributor from the

cylinder head.

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil pan and the iack (see page 6-10).

a

18. Remove the cylinder head cover.

19. Inspect the timing belt (see page 6-9).

CYLINDER

(cont'd)

6-19

www.emanualpro.com

Page 177 of 1395

Oil Pressure SwitchOil Pressure

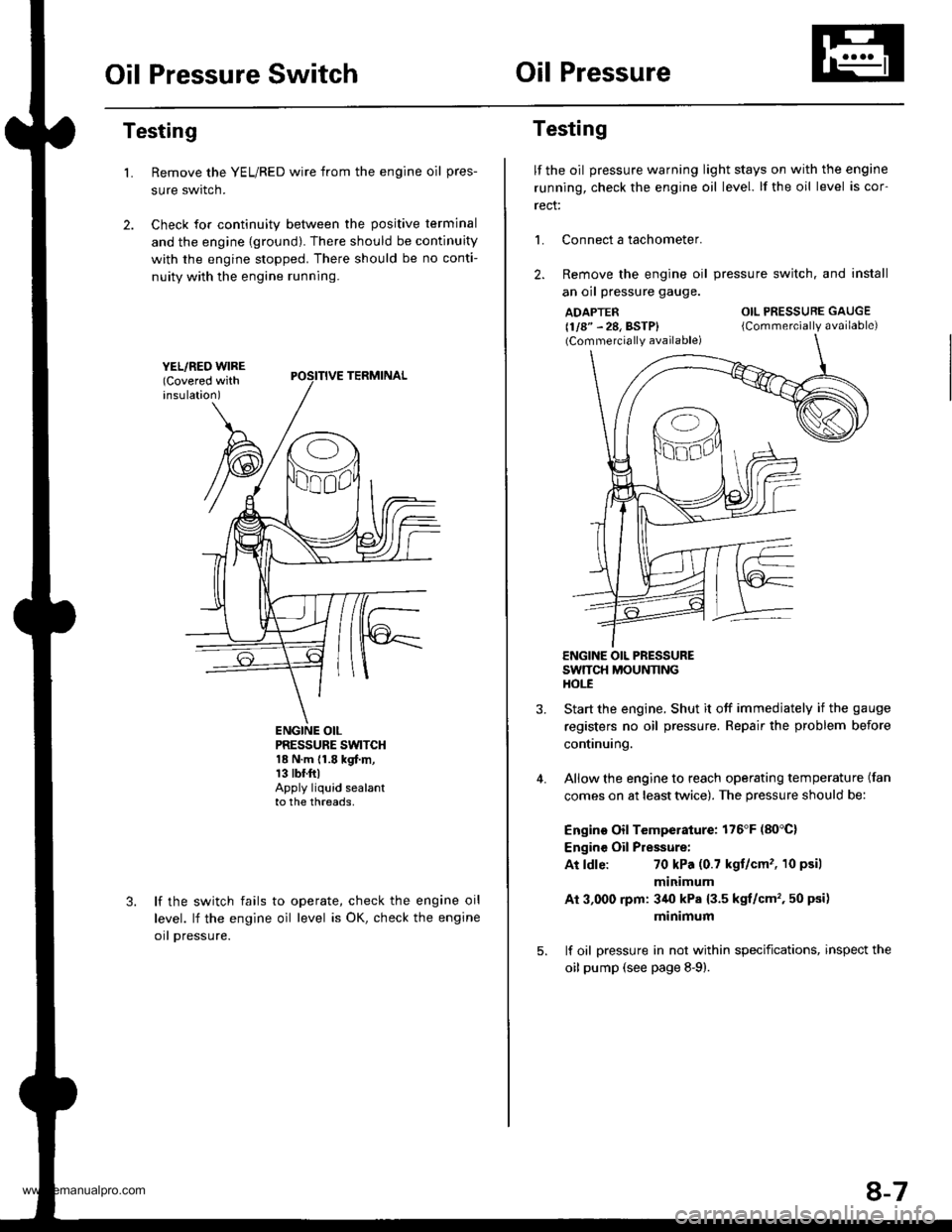

Testing

Remove the YEL/RED wire from the engine oil pres-

sure swrtcn.

Check for continuity between the positive terminal

and the engine {ground). There should be continuity

with the engine stopped. There should be no conti-

nuity with the engine running.

L

PRESSURE SWTCH18 N.m {1.8 kgf.m,13 tbr.ftlApply liquid sealantto the threads,

lf the switch fails

level. lf the engine

orl pressure.

to operate, check the engine oil

oil level is OK, check the engine

Testing

lf the oil pressure warning light stays on with the engine

running, check the engine oil level. lf the oil level is cor-

rect:

L Connect a tachometer.

2. Remove the engine oil

an oil pressure gauge.

ADAPTER(1/8" - 28, BSTP)(Commercially available)

pressure switch. and install

OIL PRESSURE GAUGE

{Commercially available)

4.

ENGINE OIL PRESSURESWTTCH MOUNNNGHOt-E

Start the engine. Shut it off immedjately if the gauge

registers no oil pressure. Repair the problem before

continuing.

Allow the engine to reach operating temperature (fan

comes on at least twice). The pressure should be:

Engino Oil Temperature: 176'F (80'C)

Engine Oil Pressure:

At ldle:70 kPa (0.7 kgt/cm'�, 10 psil

minimum

Ai 3,000 rpm: 3/r0 kPa {3.5 kgt/cm', 50 psi)

minimum

lf oil pressure in not within specifications, inspect the

oil pump (see page 8-9).

8-7

www.emanualpro.com

Page 189 of 1395

Cooling

f ffustrated Index ........... ..... 1O-2

Radiator

Rep|acement ...........,....,...................... 10-4

Engine Coolant Refilling and

Bleeding ..,.,................. 10-5

Cap Testing .................... 10-7

Testing ......10-7

Thermostat

Rep|acement ....................................... 10-8

Testing ...... 10-9

Water Pump

lllustrated lndex ....,..... .. 10-10

Inspection . 10-1 1

Replacement ....................................,.. 10-1 1

Fan Gontrol

Component Location Index ............... 10-12

Circuit Diagram ............. 10-13

Fan Motor Testing ......... 10-14

Radiator Fan Switch Testing ............. 10-14

Coolant Temperature Gauge

Gauge Testing ............... 10-15

Coolant temperature Sending

Unit Testing ........,....... 10-15

www.emanualpro.com

Page 198 of 1395

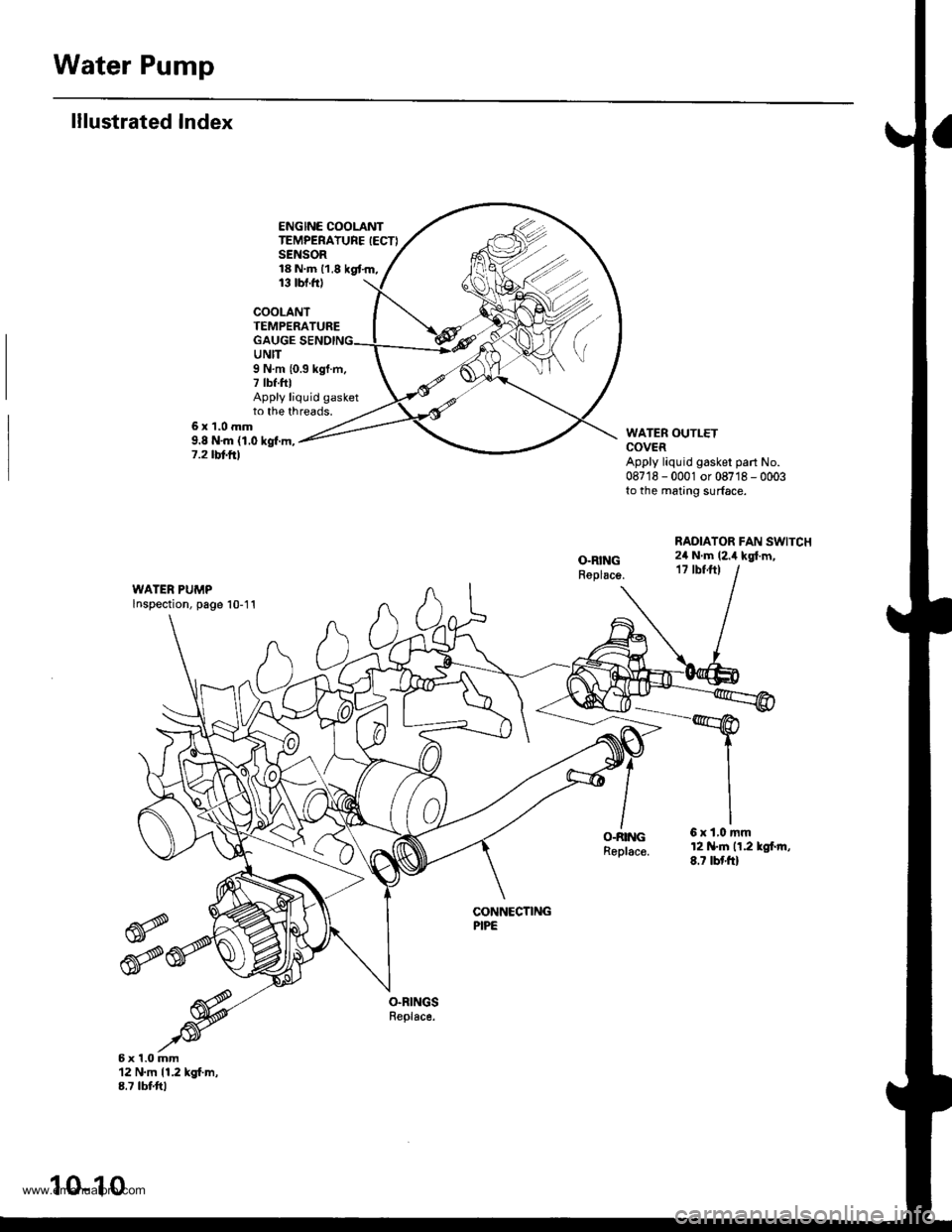

Water Pump

lllustrated Index

ENGINE COOLANTTEMPERATURE IECTISENSOR18 N.m 11,8 kgt.m,13 tbt.ftl

COOLANTTEMPERATUREGAUGEUNIT

6x1.0mm9.8 N'm (1.0 kgf.m,7.2 tbt frl

9 N.m {0.3 kgf.m,7 tbf.fttApply liquid gasketto the threads.

WATER OUTLETCOVERApply liquid gasker part No.087'18 - 0001 or 08718 - 0003to the mating surface.

RADIATOR FAN SWITCH2il N.m (2.i1 kgl.m,17 tbfft)

WATER PUMPlnspection, page 10-11

O-RINGReplac€.

6xl,0mm12 N.tn n.2 lgl.rn,8.7 tbf'ft)

CONNECTINGPIPE

6x1.0mm12 N.m 11.2 kgf.m,8.7 tbtftl

10-10

www.emanualpro.com

Page 201 of 1395

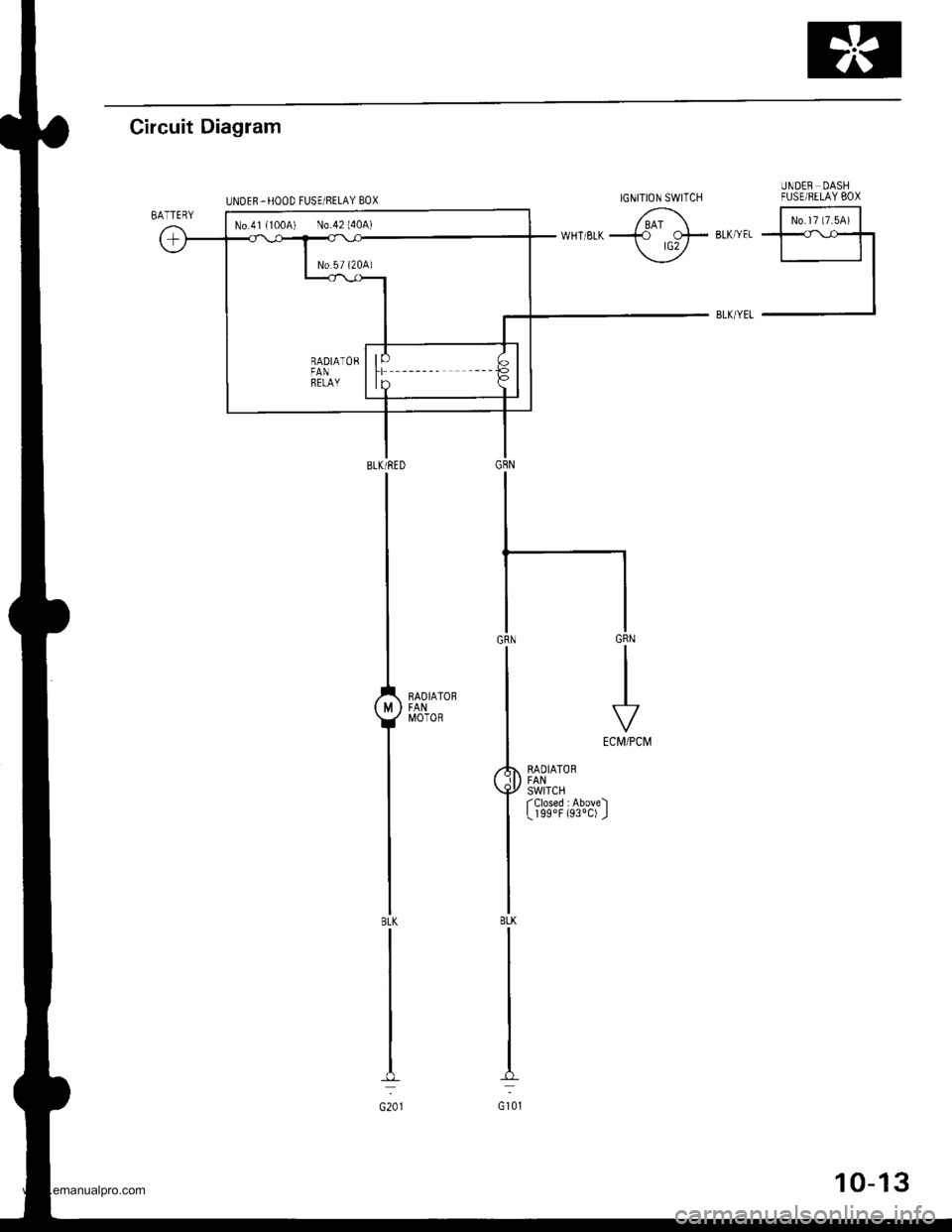

Circuit Diagram

UNDER OASHFUSEiRELAY BOX

6; E;';lwHTsLka rtF',*",El-l

I

RAOIATORFANSWITCHfClosed :Above)L 199oF {930C) J

BLK/RED

I

L^,^,.,

T*'

IBLK

I

I

oro,

IGNITION SWITCH

No.41{100A) N0.42140A)

www.emanualpro.com

Page 202 of 1395

Fan Control

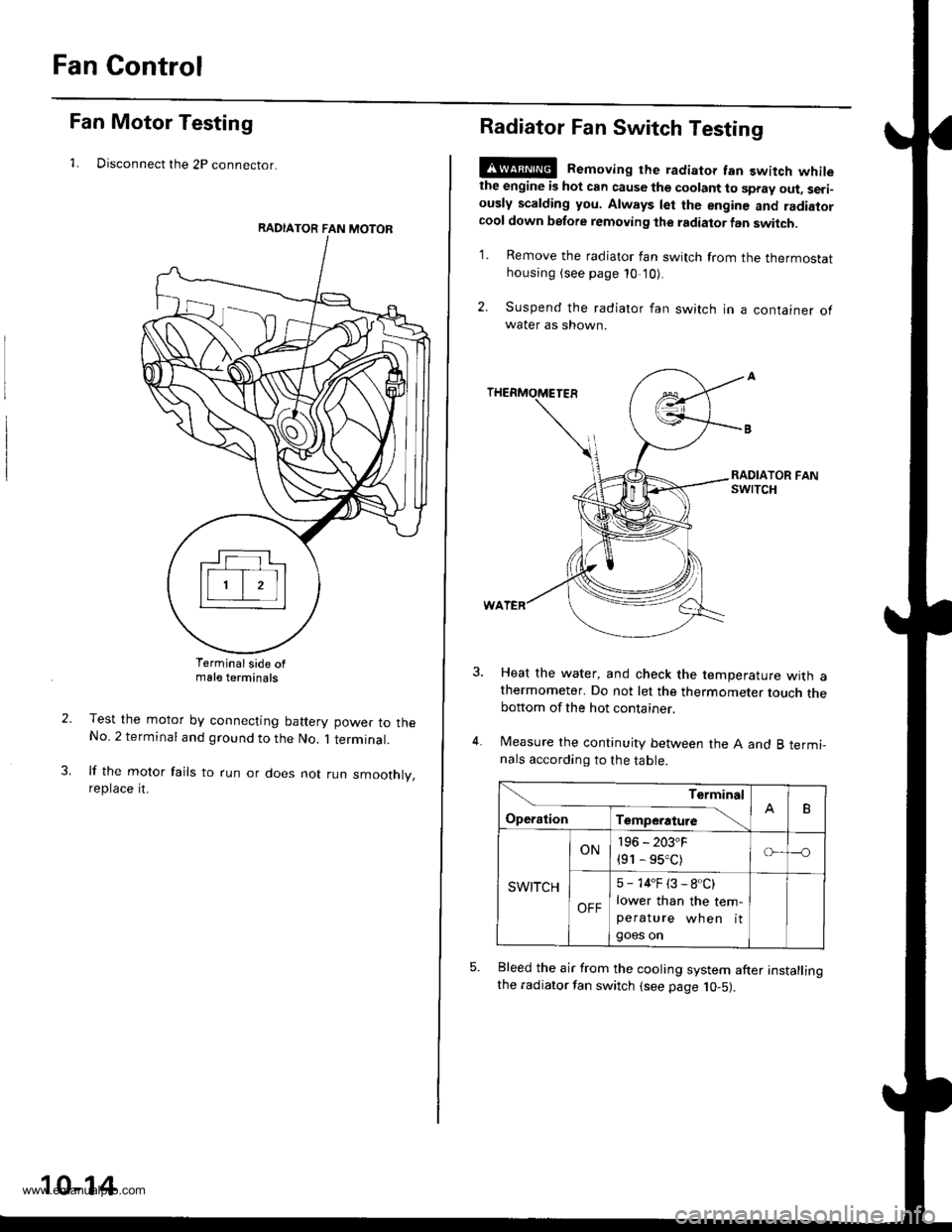

Fan Motor Testing

1. Disconnect the 2P connector.

Terminalside ofmale terminals

Test the motor by connecting battery power to theNo. 2 terminal and ground to the No. 1 terminal.

lf the motor fails to run or does not run smoothly,reptace rt.

RADIATOR FAN MOTOR

10-14

Radiator Fan Switch Testing

E@ Removing the radiator fan switch whilethe engine is hot can cause the coolant to spray out, seri-ously scalding you. Always let the enginc and radiatorcool down before removing the radiator fan switch.

1. Remove the radiator fan switch from the thermostathousing (see page 10 '10).

2. Suspend the radiator fan switch in a container ofwater as shown.

Heat the water, and check the temperature with athermometer. Do not let the thermometer touch thebottom of the hot container.

Measure the continuity between the A and B termi-nals according to the table.

Bleed the air from the cooling system after installingthe radiator fan switch (see page 10-5).

Terminal

op".*i- Tr"ip".a*" \.B

SWITCH

ON196 - 203"F

{91 - 95.C)o---o

OFF

5 - 14"F (3 - 8.C)

lower than the tem-peratu re wh en itgoes on

www.emanualpro.com

Page 269 of 1395

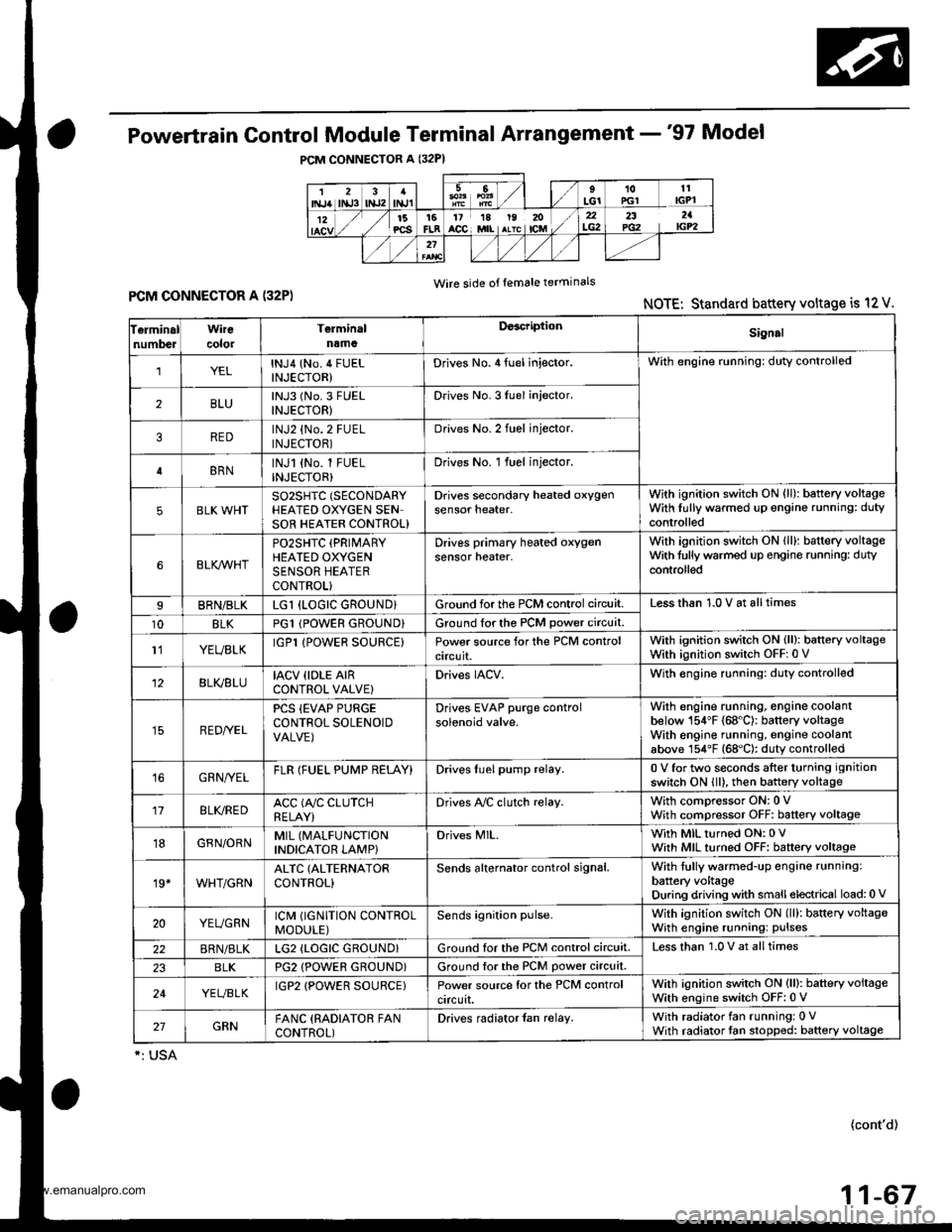

Powertrain Control Module Terminal Arrangement -'97 Model

FCM CONNECTOR A (32P)NOTE: Standard battery voltage is 12 V.

Wire side of lemale terminals

f€rminalnumlreJWirecolor

Telminalnama

DescriptionSignal

YELlNJ4 (No.4 FUELINJECTOR)Drives No. 4 {uel injector.With engine running: duty controlled

2BLUlNJ3 (No.3 FUELINJECTOR)Drives No. 3luel injector.

REDlNJ2 {No.2 FUELINJECTOR)Drives No.2 tuel injector.

BRNlNJl (No. l FUELINJECTOR)Drives No. 1 fuel injector.

5BLK WHTSO2SHIC (SECONDARY

HEATED OXYGEN SENSOR HEATER CONTROL)

D ves secondary heated oxygensensor heater.With ignition switch ON {ll): battery voltageWith fully warmed up engino running: dutycontrolled

6BLKAr'YHT

PO2SHTC (PRIMARY

HEATED OXYGENSENSOR HEATERCONTROL}

Drives primary heated oxygensensor heater,With ignition switch ON lll): battery voltagewith fully warmed up engine running: dutycontroll6d

I8RN/BLKLGl (LOGIC GROUND}Ground forthe PCM control circuit.Less than 1.0 V at all times

10BLKPG1 lPOWER GROUND}Ground for the PCM power circuit.

l1YEUELKIGPl lPOWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltageWith ignition switch OFF: 0 V

12BLI(BLUIACV {IDLE AIRCONTROL VALVE}Drives IACV.With €ngine running: duty controlled

REDryEL

PCS (EVAP PURGECONTFOL SOLENOIDVALVE)

Drives EVAP purge controlsolenoid valve.

With engine running, engine coolantbelow 154'F (68"C): battery voltageWith engine running, engine coolantabove 154"F (68"C): duty controlled

16GRN/VELFLR (FUEL PUMP RELAY)Drives Iuel pump relay.0 V for two seconds after turning ignition

switch ON lll), then battery voltage

118LI(REDACC (A,/C CLUTCHRELAY}Drives Ay'C clutch relay.With comoressor ON: 0 VWith compressor OFF: baftery voltage

18GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP}Drives MlL.With MIL turned ON: 0 VWith MIL turned OFF: baftery voltage

19*WHT/GRNALTC (ALTERNATOR

CONTROL}Sends alternator control signal.With tully warmed-up engine running:

battery voltageDuring driving with smallelectrical load:0 '

20YEUGRNICM (IGNITION CONTROLMODULE)Sends ignition pulse.With ignition switch ON (ll): baftery voltageWith engine running: pulses

22BRN/BLKLG2 (LOGIC GROUND}Ground tor the PCM control circuit.Less than 1.0 V at alltimes

23BLKPG2 {POWER GROUND}Ground lor the PCM power circuit.

24YEUBLKIGP2 {POWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltage

With engine switch OFF: 0 V

27GRNFANC (RADIATOR FANCONTROL)Drives radiator {an relay.With radiator fan running: 0 VWith radiator fan stopped: baftery voltage

*: USA

{cont'd)

11-67

www.emanualpro.com