HONDA CR-Z 2013 1.G Owners Manual

Manufacturer: HONDA, Model Year: 2013, Model line: CR-Z, Model: HONDA CR-Z 2013 1.GPages: 325, PDF Size: 11.73 MB

Page 281 of 325

uuIf a Tire Goes FlatuTemporarily Repairing a Flat Tire

280

Handling the Unexpected

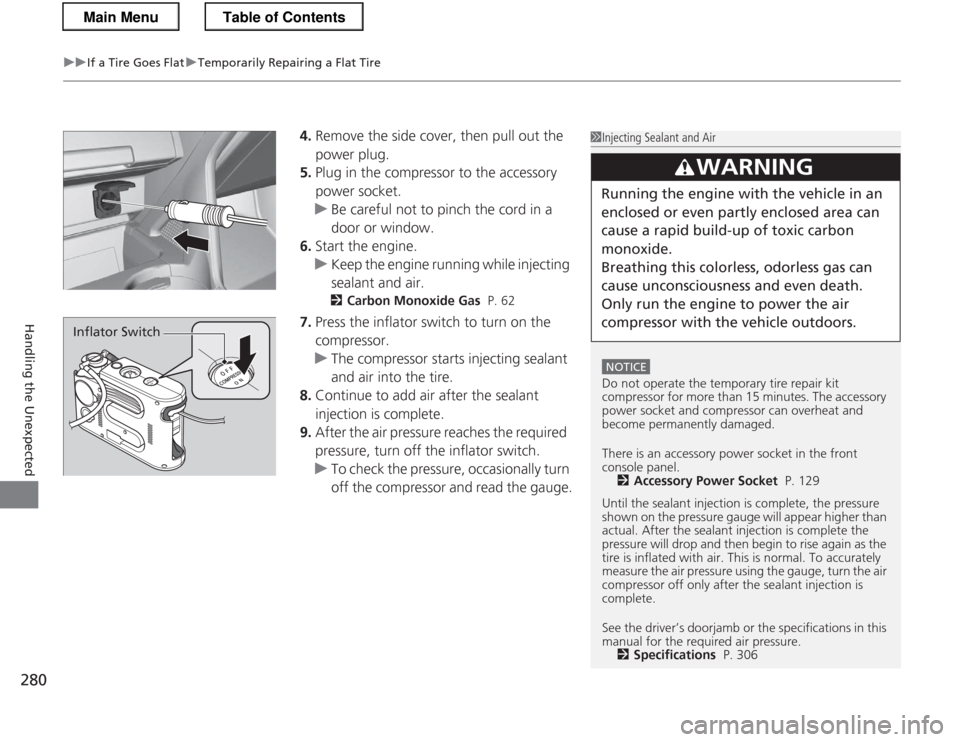

4. Remove the side cover, then pull out the

power plug.

5. Plug in the compressor to the accessory

power socket.

uBe careful not to pinch the cord in a

door or window.

6. Start the engine.

uKeep the engine running while injecting sealant and air.

2 Carbon Monoxide Gas P. 62

7. Press the inflator switch to turn on the compressor.

uThe compressor starts injecting sealant and air into the tire.

8. Continue to add air after the sealant

injection is complete.

9. After the air pressure reaches the required

pressure, turn off the inflator switch.

uTo check the pressure, occasionally turn

off the compressor and read the gauge.

1Injecting Sealant and Air

NOTICE

Do not operate the temporary tire repair kit

compressor for more than 15 minutes. The accessory

power socket and compressor can overheat and become permanently damaged.

There is an accessory power socket in the front

console panel.

2 Accessory Power Socket P. 129

Until the sealant injectio n is complete, the pressure

shown on the pressure gauge will appear higher than

actual. After the sealan t injection is complete the

pressure will drop and then begin to rise again as the

tire is inflated with air. Th is is normal. To accurately

measure the air pressure using the gauge, turn the air

compressor off only after the sealant injection is complete.

See the driver’s doorjamb or the specifications in this

manual for the required air pressure. 2 Specifications P. 306

3WARNING

Running the engine with the vehicle in an

enclosed or even partly enclosed area can

cause a rapid build-up of toxic carbon

monoxide.

Breathing this colorless, odorless gas can

cause unconsciousness and even death. Only run the engi ne to power the air

compressor with the vehicle outdoors.

Inflator Switch

Main MenuTable of Contents

Page 282 of 325

Continued281

uuIf a Tire Goes FlatuTemporarily Repairing a Flat Tire

Handling the Unexpected

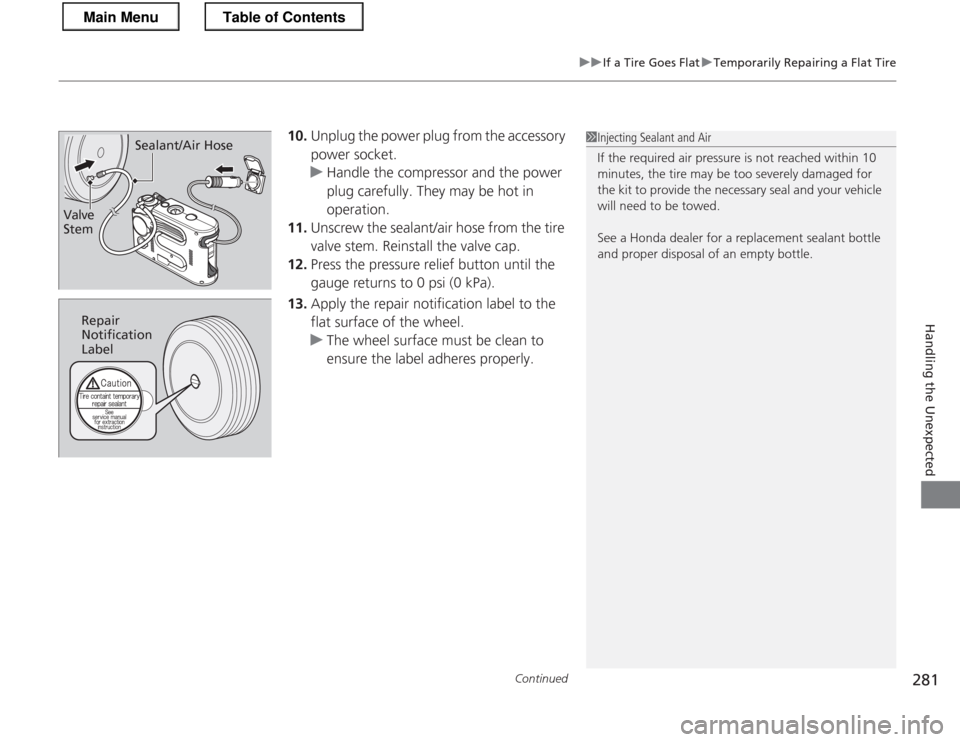

10.Unplug the power plug from the accessory power socket.

uHandle the compressor and the power

plug carefully. They may be hot in operation.

11. Unscrew the sealant/air hose from the tire

valve stem. Reinstall the valve cap.

12. Press the pressure relief button until the

gauge returns to 0 psi (0 kPa).

13. Apply the repair notification label to the

flat surface of the wheel.

uThe wheel surface must be clean to

ensure the label adheres properly.

1Injecting Sealant and Air

If the required air pressure is not reached within 10

minutes, the tire may be too severely damaged for

the kit to provide the necessary seal and your vehicle will need to be towed.

See a Honda dealer for a re placement sealant bottle

and proper disposal of an empty bottle.Sealant/Air Hose

Valve Stem

Repair

Notification Label

Main MenuTable of Contents

Page 283 of 325

uuIf a Tire Goes FlatuTemporarily Repairing a Flat Tire

282

Handling the Unexpected

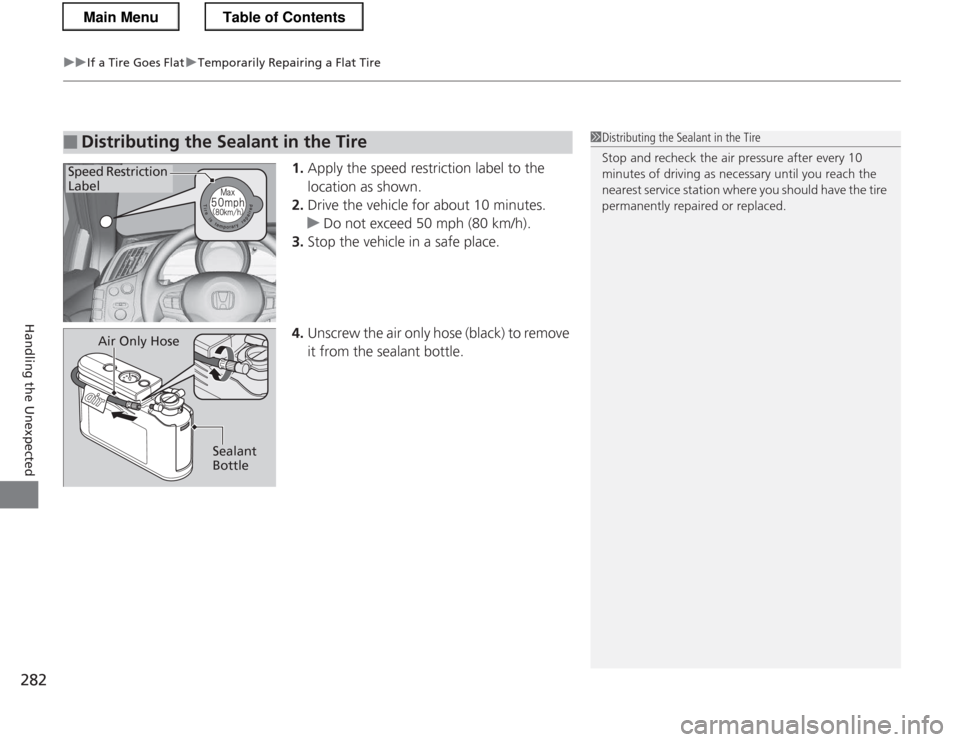

1. Apply the speed restriction label to the

location as shown.

2. Drive the vehicle for about 10 minutes.

uDo not exceed 50 mph (80 km/h).

3. Stop the vehicle in a safe place.

4. Unscrew the air only hose (black) to remove

it from the sealant bottle.

■Distributing the Sealant in the Tire1Distributing the Sealant in the Tire

Stop and recheck the air pressure after every 10

minutes of driving as necessary until you reach the

nearest service station where you should have the tire

permanently repaired or replaced.

Speed Restriction Label

Air Only Hose

Sealant Bottle

Main MenuTable of Contents

Page 284 of 325

Continued283

uuIf a Tire Goes FlatuTemporarily Repairing a Flat Tire

Handling the Unexpected

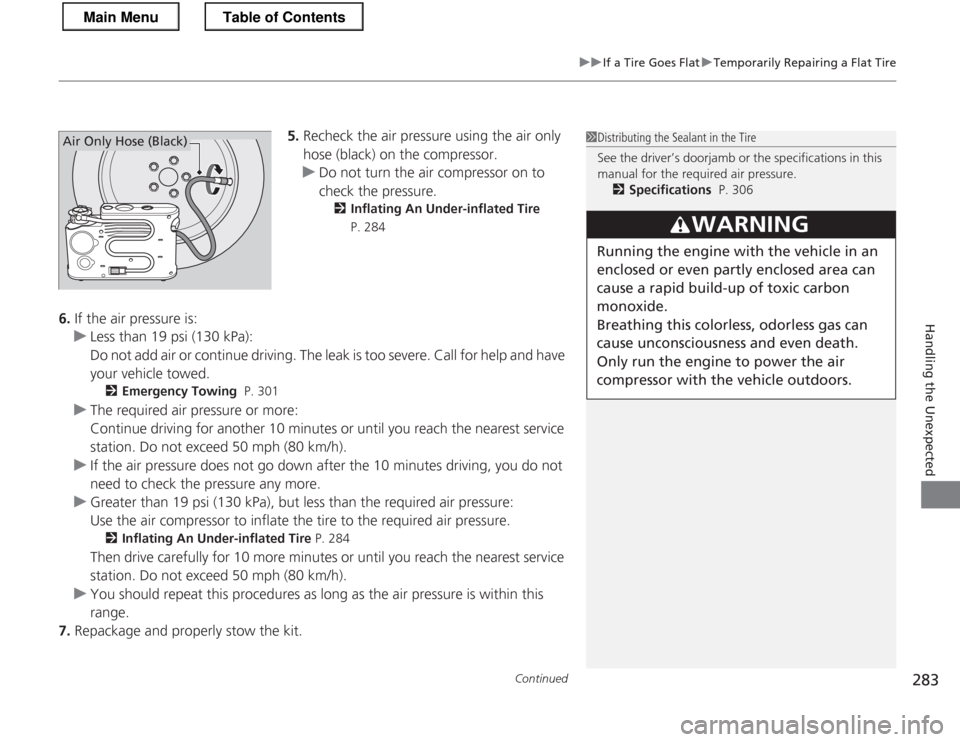

5.Recheck the air pressure using the air only

hose (black) on the compressor.

uDo not turn the air compressor on to

check the pressure.

2 Inflating An Under-inflated Tire

P. 284

6. If the air pressure is:

uLess than 19 psi (130 kPa):

Do not add air or continue driving. The leak is too severe. Call for help and have

your vehicle towed.

2 Emergency Towing P. 301

uThe required air pressure or more:

Continue driving for another 10 minutes or until you reach the nearest service

station. Do not exceed 50 mph (80 km/h).

uIf the air pressure does not go down after the 10 minutes driving, you do not

need to check the pressure any more.

uGreater than 19 psi (130 kPa), but less than the required air pressure:

Use the air compressor to inflate the tire to the required air pressure.

2 Inflating An Under-inflated Tire P. 284

Then drive carefully for 10 more minutes or until you reach the nearest service

station. Do not exceed 50 mph (80 km/h).

uYou should repeat this procedures as long as the air pressure is within this range.

7. Repackage and properly stow the kit.

1Distributing the Sealant in the Tire

See the driver’s doorjamb or the specifications in this

manual for the required air pressure.

2 Specifications P. 306

3WARNING

Running the engine with the vehicle in an

enclosed or even partly enclosed area can

cause a rapid build-up of toxic carbon

monoxide.

Breathing this colorless, odorless gas can

cause unconsciousness and even death. Only run the engi ne to power the air

compressor with the vehicle outdoors.

Air Only Hose (Black)

Main MenuTable of Contents

Page 285 of 325

uuIf a Tire Goes FlatuTemporarily Repairing a Flat Tire

284

Handling the Unexpected

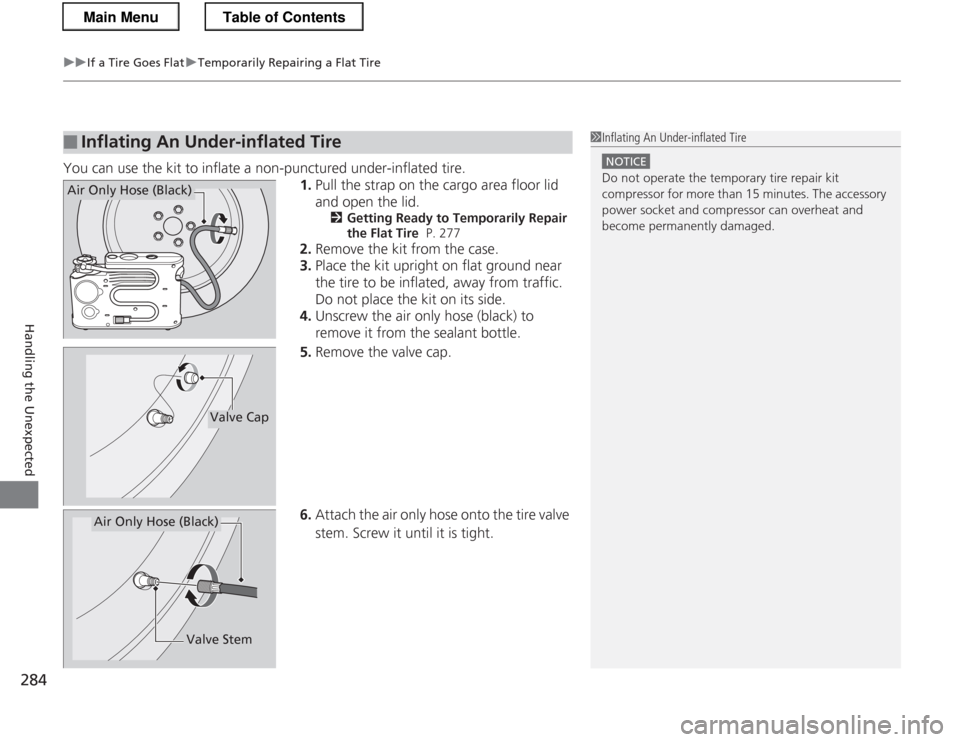

You can use the kit to inflate a non-punctured under-inflated tire. 1.Pull the strap on the cargo area floor lid

and open the lid.

2 Getting Ready to Temporarily Repair

the Flat Tire P. 277

2. Remove the kit from the case.

3. Place the kit upright on flat ground near

the tire to be inflated, away from traffic.

Do not place the kit on its side.

4. Unscrew the air only hose (black) to

remove it from the sealant bottle.

5. Remove the valve cap.

6. Attach the air only hose onto the tire valve

stem. Screw it until it is tight.

■Inflating An Under-inflated Tire1Inflating An Under-inflated Tire

NOTICE

Do not operate the temporary tire repair kit

compressor for more than 15 minutes. The accessory

power socket and compressor can overheat and become permanently damaged.

Air Only Hose (Black)

Valve Cap

Air Only Hose (Black)

Valve Stem

Main MenuTable of Contents

Page 286 of 325

285

uuIf a Tire Goes FlatuTemporarily Repairing a Flat Tire

Handling the Unexpected

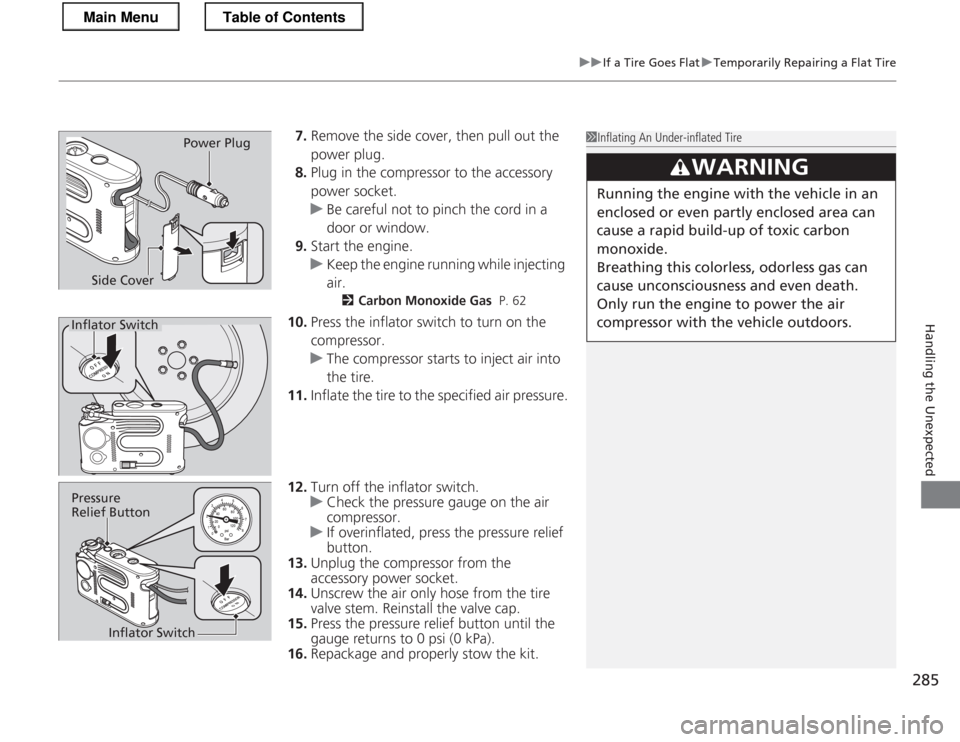

7.Remove the side cover, then pull out the

power plug.

8. Plug in the compressor to the accessory power socket.

uBe careful not to pinch the cord in a

door or window.

9. Start the engine.

uKeep the engine running while injecting air.

2 Carbon Monoxide Gas P. 62

10. Press the inflator switch to turn on the compressor.

uThe compressor starts to inject air into

the tire.

11. Inflate the tire to the specified air pressure.

12. Turn off the inflator switch.

uCheck the pressure gauge on the air

compressor.

uIf overinflated, press the pressure relief button.

13. Unplug the compressor from the

accessory power socket.

14. Unscrew the air only hose from the tire

valve stem. Reinstall the valve cap.

15. Press the pressure relief button until the

gauge returns to 0 psi (0 kPa).

16. Repackage and properly stow the kit.

1Inflating An Under-inflated Tire

3WARNING

Running the engine with the vehicle in an

enclosed or even partly enclosed area can

cause a rapid build-up of toxic carbon

monoxide.

Breathing this colorless, odorless gas can

cause unconsciousness and even death. Only run the engi ne to power the air

compressor with the vehicle outdoors.

Side Cover Power Plug

Inflator Switch

Inflator Switch

Pressure

Relief Button

Main MenuTable of Contents

Page 287 of 325

286

Handling the Unexpected

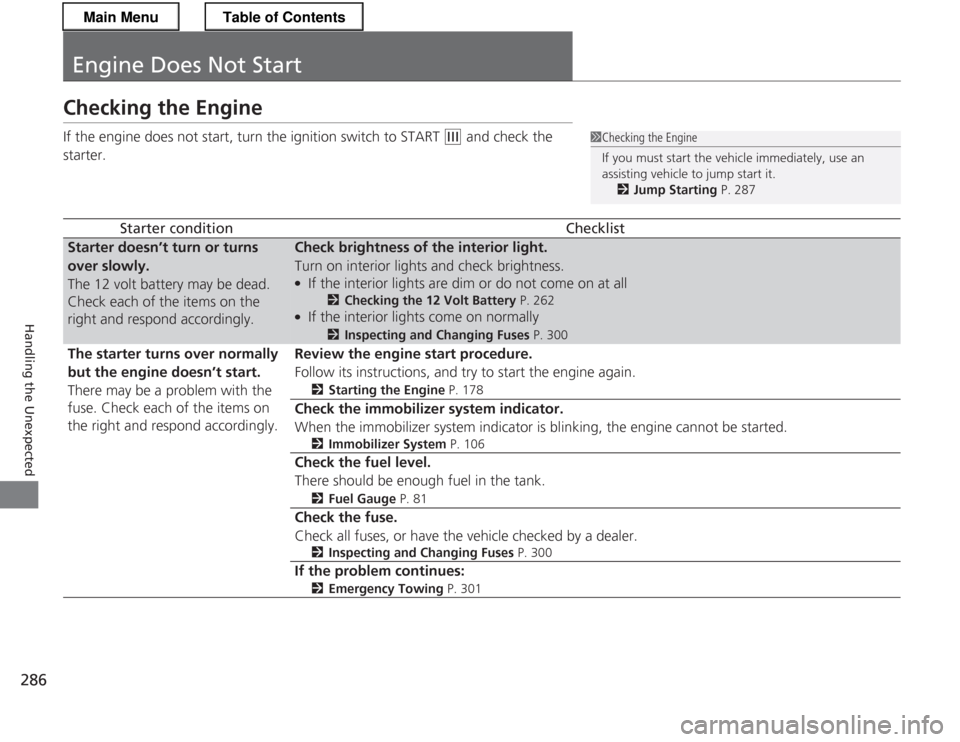

Engine Does Not Start

Checking the Engine

If the engine does not start, turn the ignition switch to START

(e and check the

starter.

Starter conditionChecklist

Starter doesn’t turn or turns over slowly.

The 12 volt battery may be dead.

Check each of the items on the

right and respond accordingly.Check brightness of the interior light.

Turn on interior lights and check brightness. ● If the interior lights are dim or do not come on at all

2Checking the 12 Volt Battery P. 262

● If the interior lights come on normally 2

Inspecting and Changing Fuses P. 300

The starter turns over normally

but the engine doesn’t start.

There may be a problem with the

fuse. Check each of the items on

the right and respond accordingly.Review the engine start procedure.

Follow its instructions, and try to start the engine again. 2Starting the Engine P. 178

Check the immobilizer system indicator.

When the immobilizer system indicator is blinking, the engine cannot be started.

2Immobilizer System P. 106

Check the fuel level. There should be enough fuel in the tank. 2Fuel Gauge P. 81

Check the fuse.

Check all fuses, or have the vehicle checked by a dealer.

2Inspecting and Changing Fuses P. 300

If the problem continues:

2 Emergency Towing P. 301

1Checking the Engine

If you must start the vehicle immediately, use an assisting vehicle to jump start it.

2 Jump Starting P. 287

Main MenuTable of Contents

Page 288 of 325

287

Continued

Handling the Unexpected

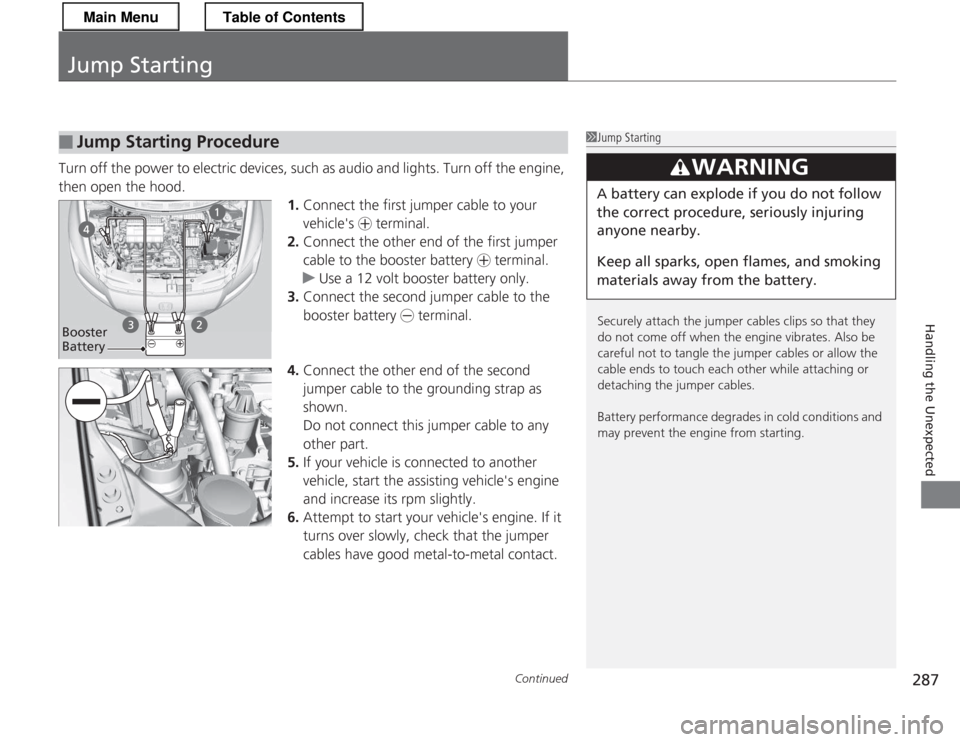

Jump Starting

Turn off the power to electric devices, such as audio and lights. Turn off the engine,

then open the hood.

1.Connect the first jumper cable to your

vehicle's + terminal.

2. Connect the other end of the first jumper

cable to the booster battery + terminal.

uUse a 12 volt booster battery only.

3. Connect the second jumper cable to the booster battery - terminal.

4. Connect the other end of the second

jumper cable to the grounding strap as

shown.

Do not connect this jumper cable to any other part.

5. If your vehicle is co nnected to another

vehicle, start the assisting vehicle's engine

and increase its rpm slightly.

6. Attempt to start your vehicle's engine. If it

turns over slowly, check that the jumper cables have good metal-to-metal contact.

■Jump Starting Procedure1Jump Starting

Securely attach the jumper cables clips so that they

do not come off when the engine vibrates. Also be

careful not to tangle the jumper cables or allow the

cable ends to touch each other while attaching or

detaching the jumper cables.

Battery performance degrades in cold conditions and

may prevent the engine from starting.

3WARNING

A battery can explode if you do not follow the correct procedure, seriously injuring anyone nearby.

Keep all sparks, open flames, and smoking

materials away from the battery.

Booster

Battery

Main MenuTable of Contents

Page 289 of 325

288

uuJump Startingu

Handling the Unexpected

Once your vehicle's engine has started, remove the jumper cables in the following order. 1.Disconnect the jumper cable from your vehicle's ground.

2. Disconnect the other end of the ju mper cable from the booster battery -

terminal.

3. Disconnect the jumper cable from your vehicle's + terminal.

4. Disconnect the other end of the ju mper cable from the booster battery +

terminal.

Have your vehicle inspected by a nearby service station or a dealer.

■What to Do After the Engine Starts

Main MenuTable of Contents

Page 290 of 325

289

Handling the Unexpected

Shift Lever Does Not Move

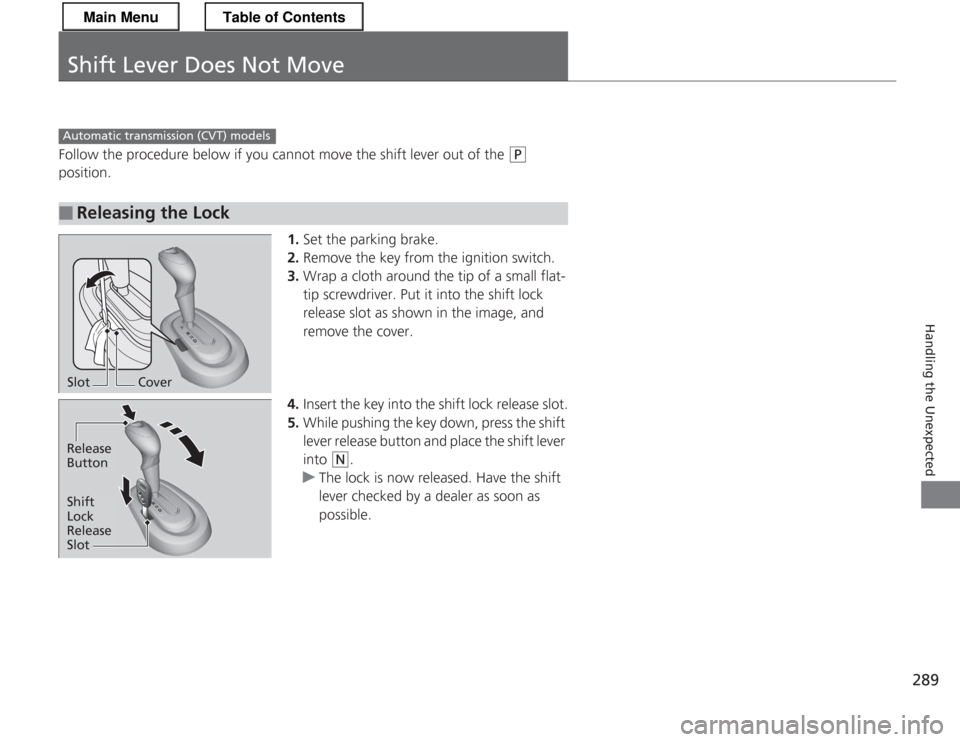

Follow the procedure below if you cannot move the shift lever out of the (P

position.

1.Set the parking brake.

2. Remove the key from the ignition switch.

3. Wrap a cloth around the tip of a small flat-

tip screwdriver. Put it into the shift lock

release slot as shown in the image, and remove the cover.

4. Insert the key into the shift lock release slot.

5. While pushing the key down, press the shift

lever release button and place the shift lever

into

(N .

uThe lock is now released. Have the shift

lever checked by a dealer as soon as

possible.

■Releasing the Lock

Automatic transmiss ion (CVT) models

SlotCover

Release Button

Shift

Lock Release

Slot

Main MenuTable of Contents