HONDA ELEMENT 2009 1.G Owners Manual

Manufacturer: HONDA, Model Year: 2009, Model line: ELEMENT, Model: HONDA ELEMENT 2009 1.GPages: 345, PDF Size: 18.9 MB

Page 261 of 345

5. If the level is below the lowermark, add fluid into the dipstick

hole to bring it to the level

between the upper and lower

marks.

Pour the fluid slowly and carefully

so you do not spill any. Clean up

any spill immediately; it could

damage components in the engine

compartment.

Always use Honda Genuine

ATF-Z1 (automatic transmission

fluid).

Use only Honda Genuine ATF-Z1

(Automatic Transmission Fluid). Do not

mix with other transmission fluids.

Using transmission fluid other than

Honda Genuine ATF-Z1 may cause

deterioration in transmission operation

and durability, and could result in

damage to the transmission.

Damage resulting from the use of

transmission fluid other than Honda

Genuine ATF-Z1 is not covered by the

Honda new vehicle warranty.

6. Insert the dipstick all the way backinto the transmission securely as

shown in the illustration.

The transmission should be drained

and refilled with new fluid according

to the maintenance minder (see page

243).

If you are not sure how to add fluid,

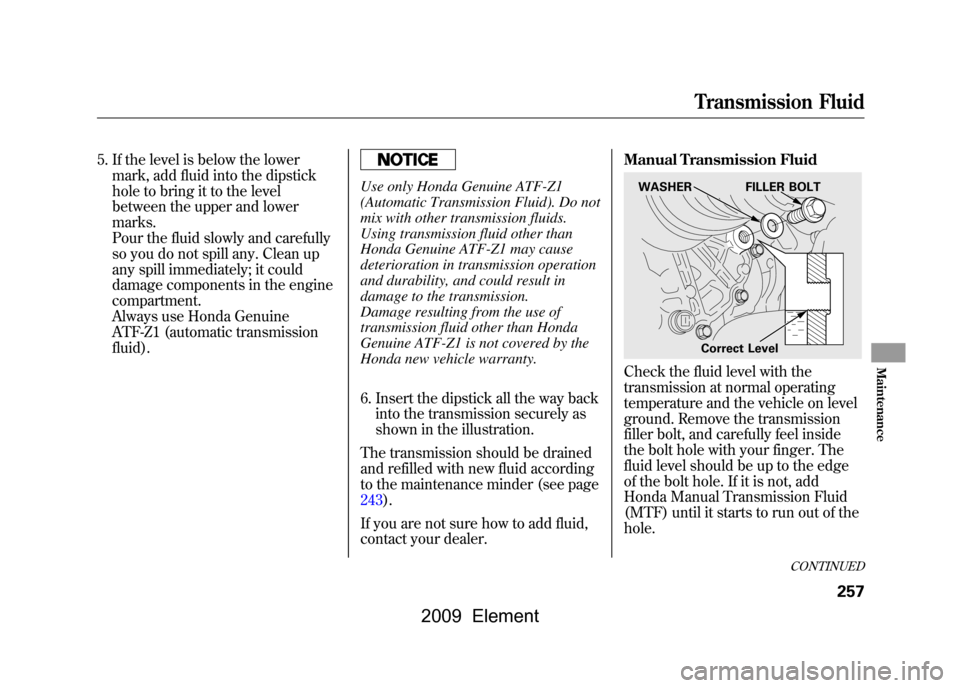

contact your dealer. Manual Transmission Fluid

Check the fluid level with the

transmission at normal operating

temperature and the vehicle on level

ground. Remove the transmission

filler bolt, and carefully feel inside

the bolt hole with your finger. The

fluid level should be up to the edge

of the bolt hole. If it is not, add

Honda Manual Transmission Fluid

(MTF) until it starts to run out of the

hole.WASHER FILLER BOLT

Correct Level

CONTINUED

Transmission Fluid

257

Maintenance

2009 Element

Page 262 of 345

Put a new washer on the filler bolt,

then reinstall the filler bolt and

tighten it securely.

If Honda MTF is not available, you

may use an SAE 10W-30 or 10W-40

viscosity motor oil with the API

Certification seal that says‘‘FOR

GASOLINE ENGINES ’’as a

temporary replacement. However,

motor oil does not contain the proper

additives, and continued use can

cause stiffer shifting. Replace as soon

as it is convenient.

The transmission should be drained

and refilled with new fluid according

to the maintenance minder (see page

243).

If you are not sure how to check and

add fluid, contact your dealer. Rear Differential Fluid

4WD models onlyThe rear differential should be

drained and refilled with new fluid

according to the time and distance

recommendations shown on the

maintenance minder display. Have

your dealer replace the rear

differential fluid.

Use Honda Dual Pump Fluid II only.

Do not use automatic transmission

fluid (ATF).

Brake and Clutch Fluid

Check the fluid level in the

reservoirs monthly.

There are up to two reservoirs,

depending on the model. They are:

●Brake fluid reservoir (all models)●Clutch fluid reservoir (manual

transmission only)

Replace the brake fluid according to

the time recommendation in the

maintenance minder schedule.

Always use Honda Heavy Duty

Brake Fluid DOT 3. If it is not

available, you should use only DOT 3

or DOT 4 fluid, from a sealed

container, as a temporary

replacement.

Transmission Fluid, Rear Differential Fluid, Brake and Clutch Fluid258

2009 Element

Page 263 of 345

Using any non-Honda brake fluid can

cause corrosion and decrease the life

of the system. Have the brake

system flushed and refilled with

Honda Heavy Duty Brake Fluid DOT

3 as soon as possible.

Brake fluid marked DOT 5 is not

compatible with your vehicle's

braking system and can cause

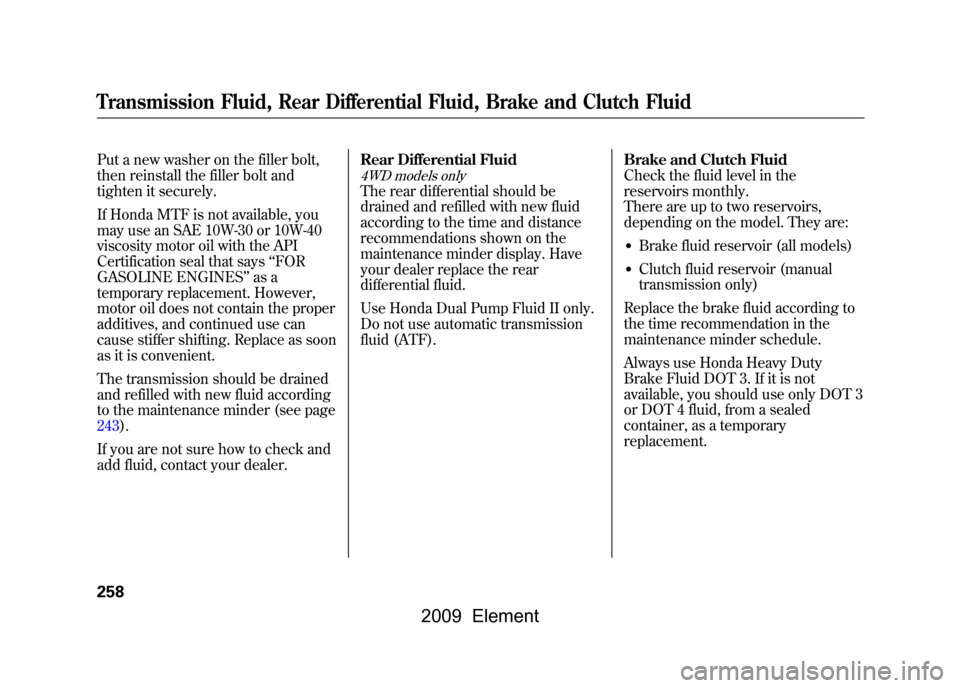

extensive damage.Brake Fluid

The fluid level should be between

the MIN and MAX marks on the side

of the reservoir. If the level is at or

below the MIN mark, your brake

system needs attention. Have the

brake system inspected for leaks or

worn brake pads.Clutch Fluid

On vehicles with manual transmissionThe fluid level should be between

the MIN and MAX marks on the side

of the reservoir. If it is not, add brake

fluid to bring it up to that level. Use

the same fluid specified for the brake

system.

A low fluid level can indicate a leak in

the clutch system. Have this system

inspected as soon as possible.

MAX

MIN

MAX

MIN

Brake and Clutch Fluid

259

Maintenance

2009 Element

Page 264 of 345

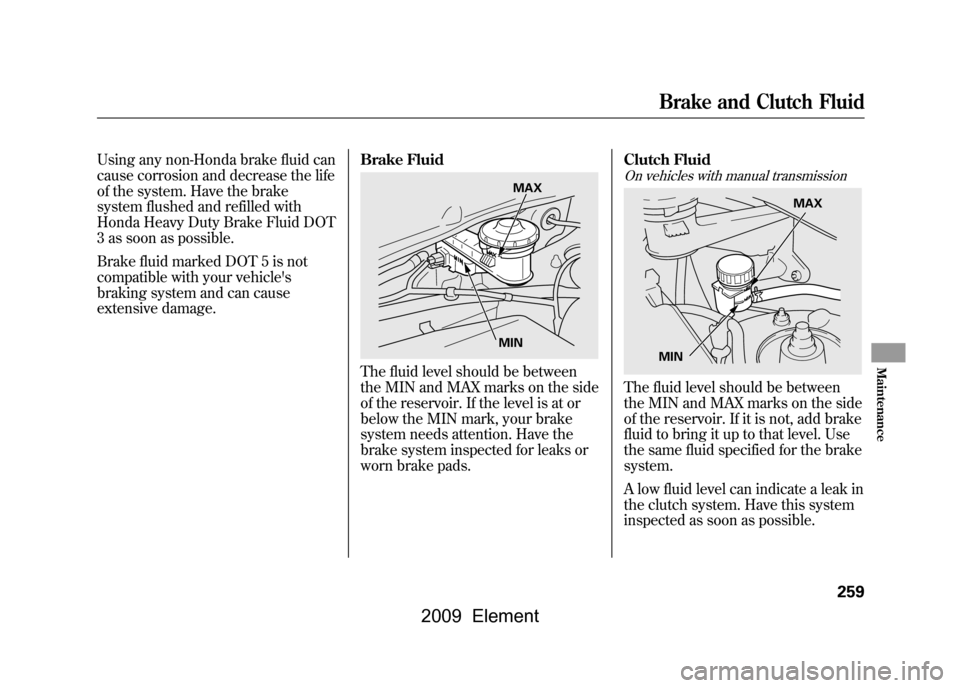

Power Steering FluidCheck the level on the side of the

reservoir when the engine is cold.

The fluid should be between the

UPPER LEVEL and LOWER LEVEL.

If not, add power steering fluid to the

UPPER LEVEL.

Pour the fluid slowly and carefully so

you do not spill any. Clean up any

spills immediately; it could damage

components in the engine

compartment.Always use Honda Power Steering

Fluid. You may use another power

steering fluid as an emergency

replacement, but have the power

steering system flushed and refilled

with Honda PSF as soon as possible.

A low power steering fluid level can

indicate a leak in the system. Check

the fluid level frequently, and have

the system inspected as soon as

possible.

If you are not sure how to add fluid,

contact your dealer.

Turning the steering wheel to full left or

right lock and holding it there can

damage the power steering pump.

Cleaning the Body Panels

If equipped with body panelsTo clean the gray composite body

panels, wash them with soap and

water only. Do not apply wax to the

panels; it will cause discoloration.

UPPER LEVEL

LOWER LEVEL

Power Steering Fluid, Cleaning the Body Panels260

2009 Element

Page 265 of 345

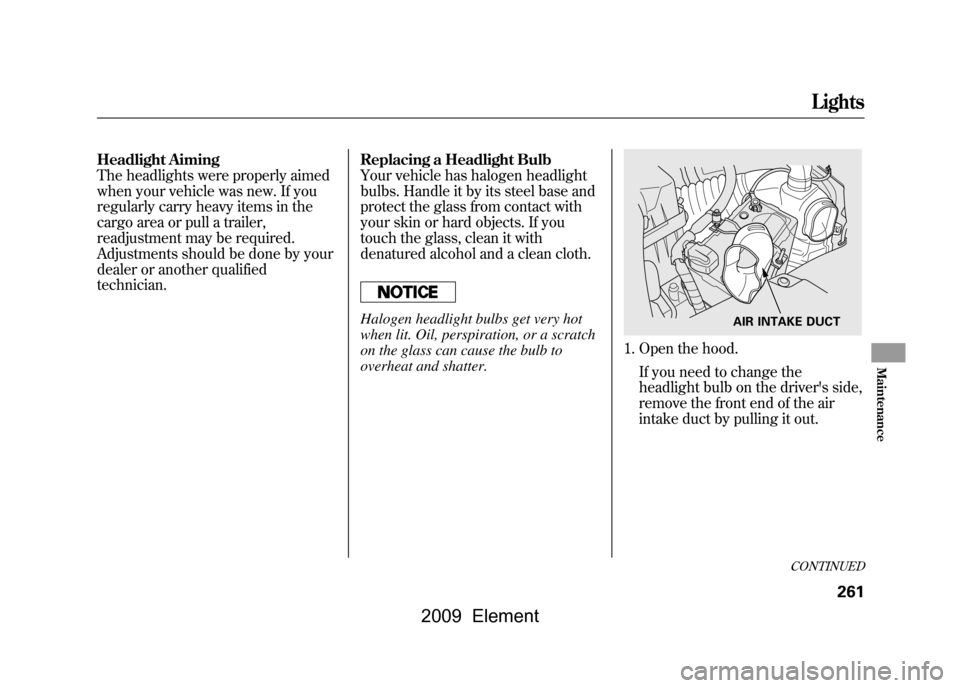

Headlight Aiming

The headlights were properly aimed

when your vehicle was new. If you

regularly carry heavy items in the

cargo area or pull a trailer,

readjustment may be required.

Adjustments should be done by your

dealer or another qualified

technician.Replacing a Headlight Bulb

Your vehicle has halogen headlight

bulbs. Handle it by its steel base and

protect the glass from contact with

your skin or hard objects. If you

touch the glass, clean it with

denatured alcohol and a clean cloth.

Halogen headlight bulbs get very hot

when lit. Oil, perspiration, or a scratch

on the glass can cause the bulb to

overheat and shatter.

1. Open the hood.

If you need to change the

headlight bulb on the driver's side,

remove the front end of the air

intake duct by pulling it out.

AIR INTAKE DUCT

CONTINUED

Lights

261

Maintenance

2009 Element

Page 266 of 345

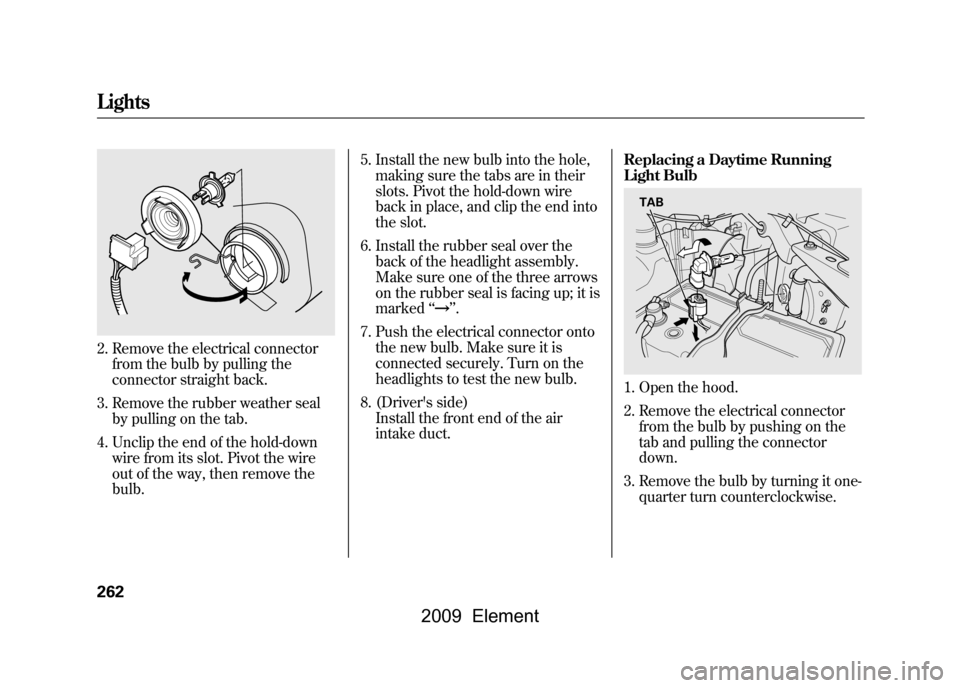

2. Remove the electrical connectorfrom the bulb by pulling the

connector straight back.

3. Remove the rubber weather seal by pulling on the tab.

4. Unclip the end of the hold-down wire from its slot. Pivot the wire

out of the way, then remove the

bulb. 5. Install the new bulb into the hole,

making sure the tabs are in their

slots. Pivot the hold-down wire

back in place, and clip the end into

the slot.

6. Install the rubber seal over the back of the headlight assembly.

Make sure one of the three arrows

on the rubber seal is facing up; it is

marked ‘‘

’’.

7. Push the electrical connector onto the new bulb. Make sure it is

connected securely. Turn on the

headlights to test the new bulb.

8. (Driver's side) Install the front end of the air

intake duct. Replacing a Daytime Running

Light Bulb

1. Open the hood.

2. Remove the electrical connector

from the bulb by pushing on the

tab and pulling the connector

down.

3. Remove the bulb by turning it one- quarter turn counterclockwise.

TAB

Lights262

2009 Element

Page 267 of 345

4. Insert the new bulb into the hole,and turn it one-quarter turn

clockwise to lock it in place.

5. Push the electrical connector back onto the bulb. Make sure it is on

all the way.

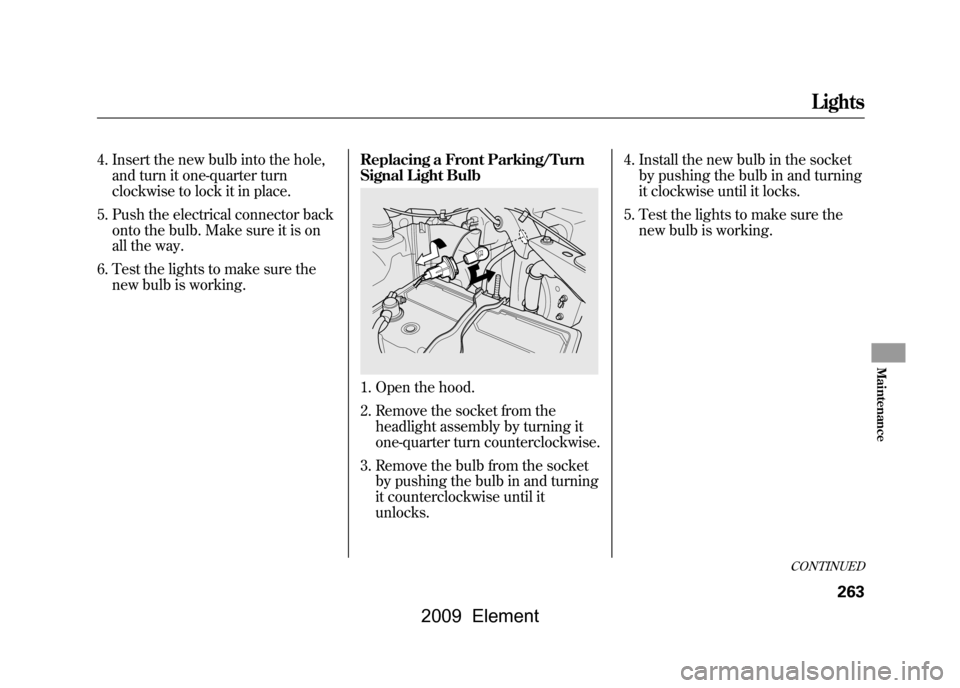

6. Test the lights to make sure the new bulb is working. Replacing a Front Parking/Turn

Signal Light Bulb

1. Open the hood.

2. Remove the socket from the

headlight assembly by turning it

one-quarter turn counterclockwise.

3. Remove the bulb from the socket by pushing the bulb in and turning

it counterclockwise until it

unlocks. 4. Install the new bulb in the socket

by pushing the bulb in and turning

it clockwise until it locks.

5. Test the lights to make sure the new bulb is working.

CONTINUED

Lights

263

Maintenance

2009 Element

Page 268 of 345

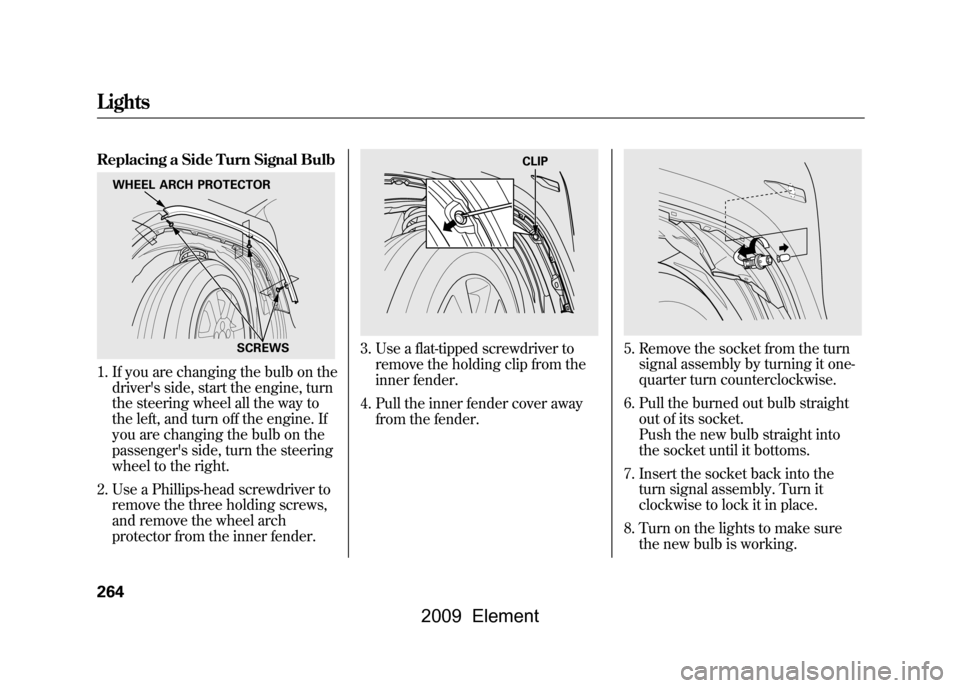

Replacing a Side Turn Signal Bulb1. If you are changing the bulb on thedriver's side, start the engine, turn

the steering wheel all the way to

the left, and turn off the engine. If

you are changing the bulb on the

passenger's side, turn the steering

wheel to the right.

2. Use a Phillips-head screwdriver to remove the three holding screws,

and remove the wheel arch

protector from the inner fender.

3. Use a flat-tipped screwdriver to

remove the holding clip from the

inner fender.

4. Pull the inner fender cover away from the fender.

5. Remove the socket from the turnsignal assembly by turning it one-

quarter turn counterclockwise.

6. Pull the burned out bulb straight out of its socket.

Push the new bulb straight into

the socket until it bottoms.

7. Insert the socket back into the turn signal assembly. Turn it

clockwise to lock it in place.

8. Turn on the lights to make sure the new bulb is working.

WHEEL ARCH PROTECTOR

SCREWS

CLIP

Lights264

2009 Element

Page 269 of 345

9. Put the inner fender cover in place.Install the holding clip.

Lock the clip in place by pushing

on the center.

Install the wheel arch protector

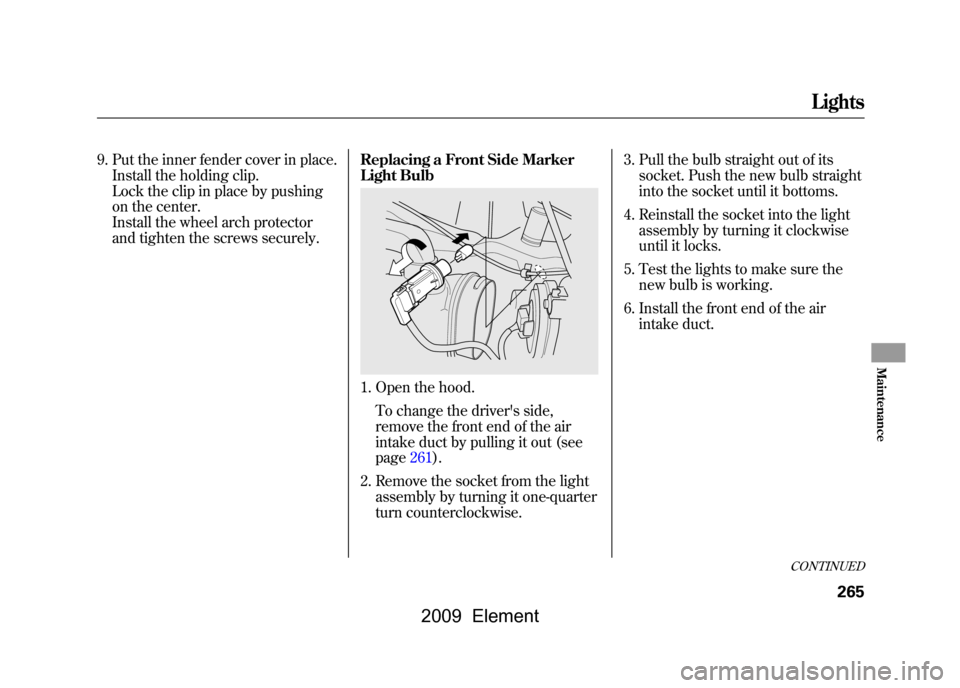

and tighten the screws securely. Replacing a Front Side Marker

Light Bulb

1. Open the hood.

To change the driver's side,

remove the front end of the air

intake duct by pulling it out (see

page261).

2. Remove the socket from the light assembly by turning it one-quarter

turn counterclockwise. 3. Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

4. Reinstall the socket into the light assembly by turning it clockwise

until it locks.

5. Test the lights to make sure the new bulb is working.

6. Install the front end of the air intake duct.

CONTINUED

Lights

265

Maintenance

2009 Element

Page 270 of 345

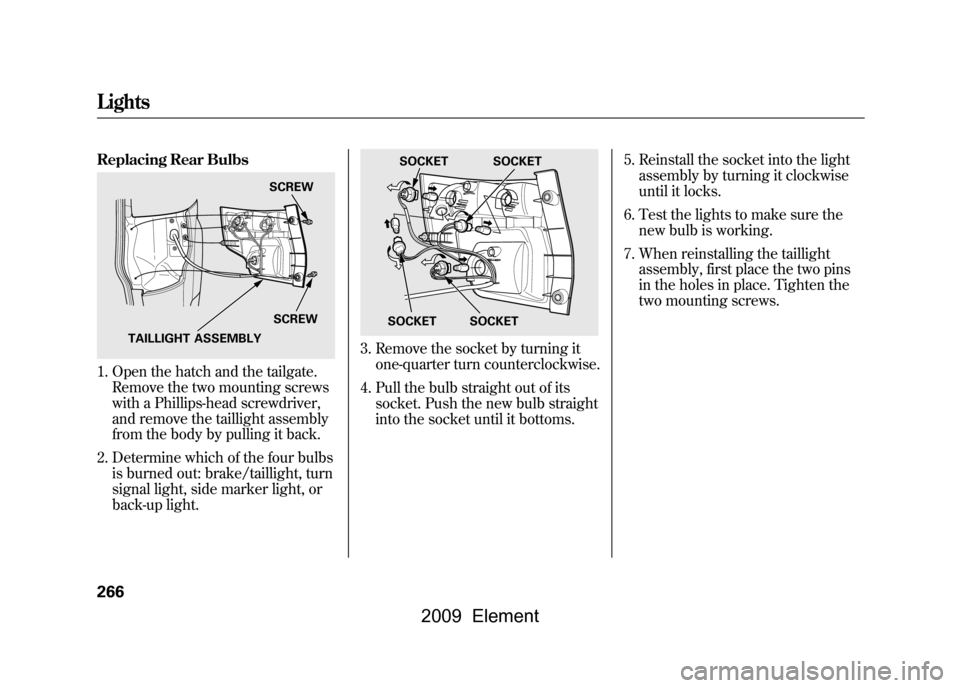

Replacing Rear Bulbs1. Open the hatch and the tailgate.Remove the two mounting screws

with a Phillips-head screwdriver,

and remove the taillight assembly

from the body by pulling it back.

2. Determine which of the four bulbs is burned out: brake/taillight, turn

signal light, side marker light, or

back-up light.

3. Remove the socket by turning it

one-quarter turn counterclockwise.

4. Pull the bulb straight out of its socket. Push the new bulb straight

into the socket until it bottoms. 5. Reinstall the socket into the light

assembly by turning it clockwise

until it locks.

6. Test the lights to make sure the new bulb is working.

7. When reinstalling the taillight assembly, first place the two pins

in the holes in place. Tighten the

two mounting screws.

SCREW

SCREW

TAILLIGHT ASSEMBLY

SOCKET SOCKET

SOCKET

SOCKET

Lights266

2009 Element