Cylinder HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 665 of 1413

Steering Gearbox

Reassembly lcont'dl

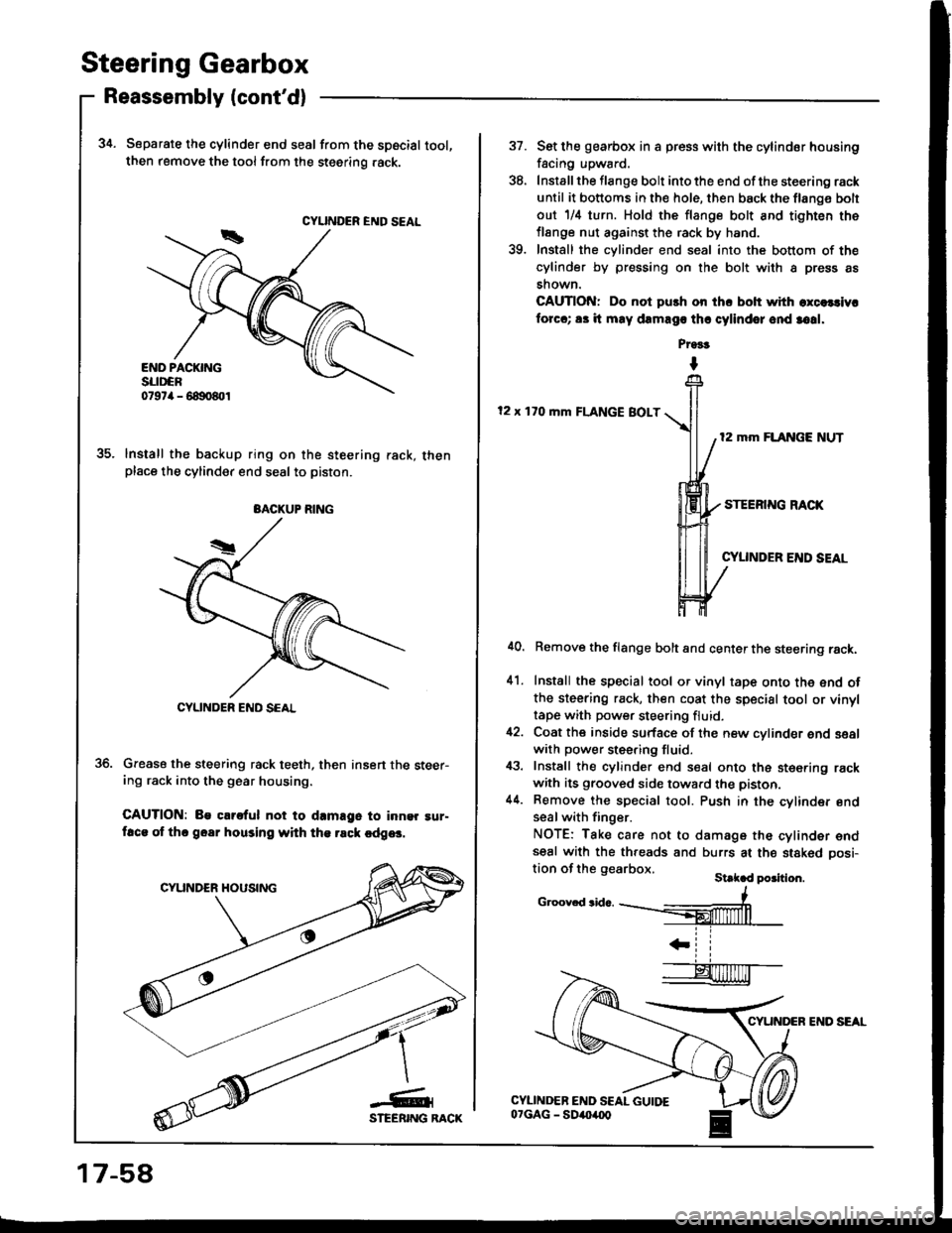

34. Separate the cylinder end seal from the spscial tool,then remove the tool from the steering .ack.

lnstall the backup ring on the steering rack, thenplace the cylinder end seal to piston.

Grease the steering rack teeth, then insert the steer-ing rack into the gear housing.

CAUTION: Be clrs{ul not to d.mage to inn9r !ur-ftca of thc goar housing with th€ rsck cdg6.

CYUNDER END SEAL

BACKUP RING

CYLINDER END SCAL

17-58

CYUNDER END SEAL

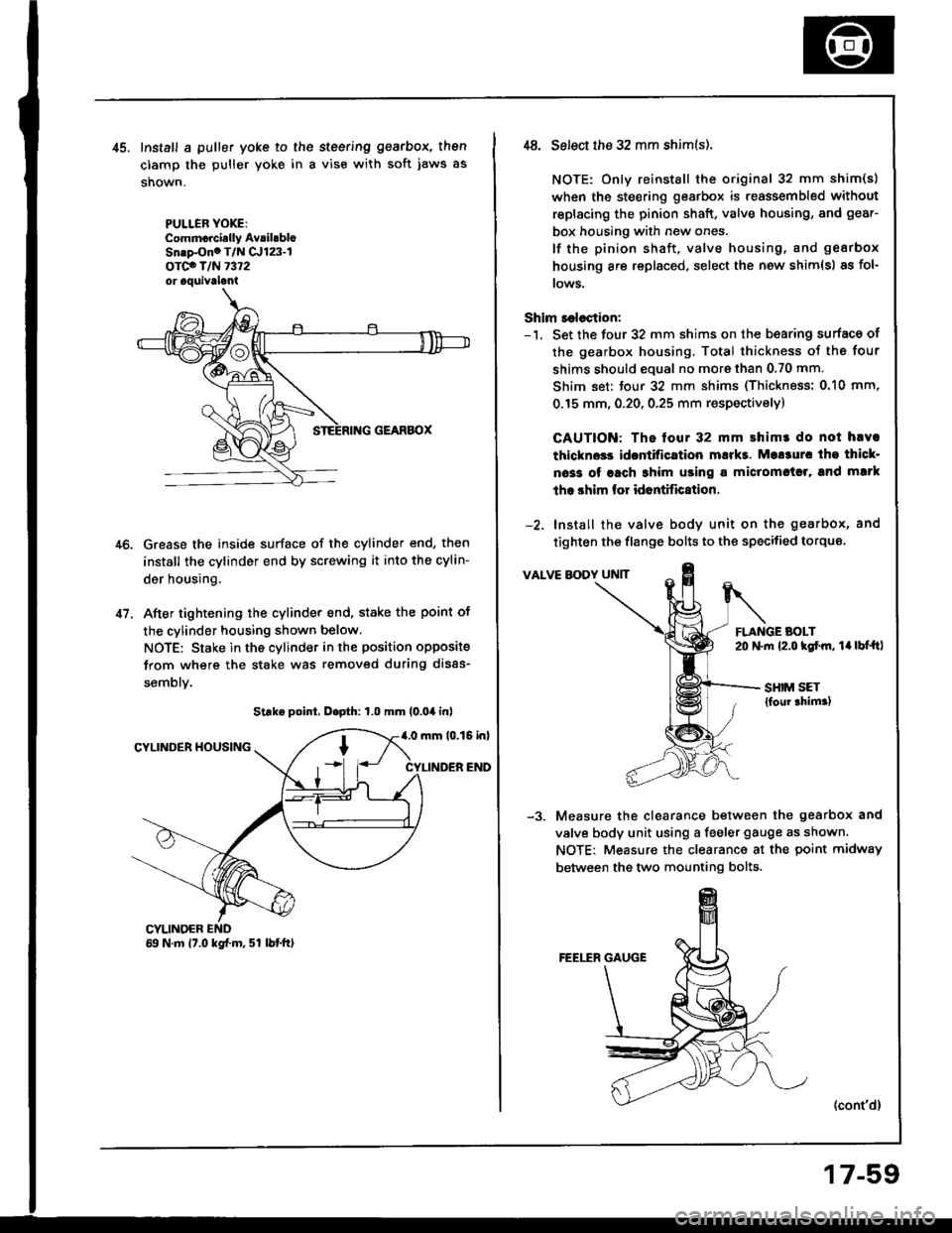

37.

'to

Set lhe gearbox in a press with the cylindor housing

facing upward.

Install the flange bolt into the end of the steering rack

until it bottoms in the hole, then back the flang€ bolt

out 1/il turn. Hold the flange bolt and tighten the

flange nut against the rack by hand.

Install the cylinder end seal into the bottom of the

cylinder by pressing on the bolt with a press as

shown.

CAUTION: Do not push on ihc bolt with excelcivr

forcc; 83 it may dEmago thr cylindor ond 3o!1.

Pr9!t

I

12 x 170 mm FLANGE BOLT

12 mm FLANGE NUT

STEERING RACK

CYUNDER END SEAL

41.

Remove the flange bolt and center the steering rack.

Install the special tool or vinyl tape onto the end ofthe steering rack, then coat the special tool or vinyltape with power steering fluid.

Coat the inside surface of the new cylinder end sealwith power steering fluid.

Install the cylinder end seal onto the ste€ring rackwith its grooved side toward the piston.

Remove the special tool. Push in the cylinder endseal with finger.

NOTE: Take care not to damage the cylinder endseal with the threads and burrs at the stakod oosi-tion of the gearbox.St k d po3ition.

c.oov.d3id...--#

IL ll

Page 666 of 1413

41.

Install a puller yoke to the steering gearbox, then

clamp the puller yoke in a vise with soft jaws as

shown.

PULLER YOXE:Commcrcirlly AvrihbloSn.p-Ono T/N Cr123-lorco T/N 7372or aquivrlani

Grease the inside surface of the cylinder end, then

install the cylinder end by screwing it into the cylin-

der housing.

After tightening the cylinder end, stake the point of

the cylinder housing shown below.

NOTE: Stake in the cylinder in the position opposite

from where the stake was removed during disas-

semblv.

Strke point, D.pth: 1.0 mm (0.04 inl

4.0 mm 10.15 inlCYLINDER HOUSING

CYLINDER END

CYLINOER69 N.m 17.0 kgf.m, 51 lbtft)

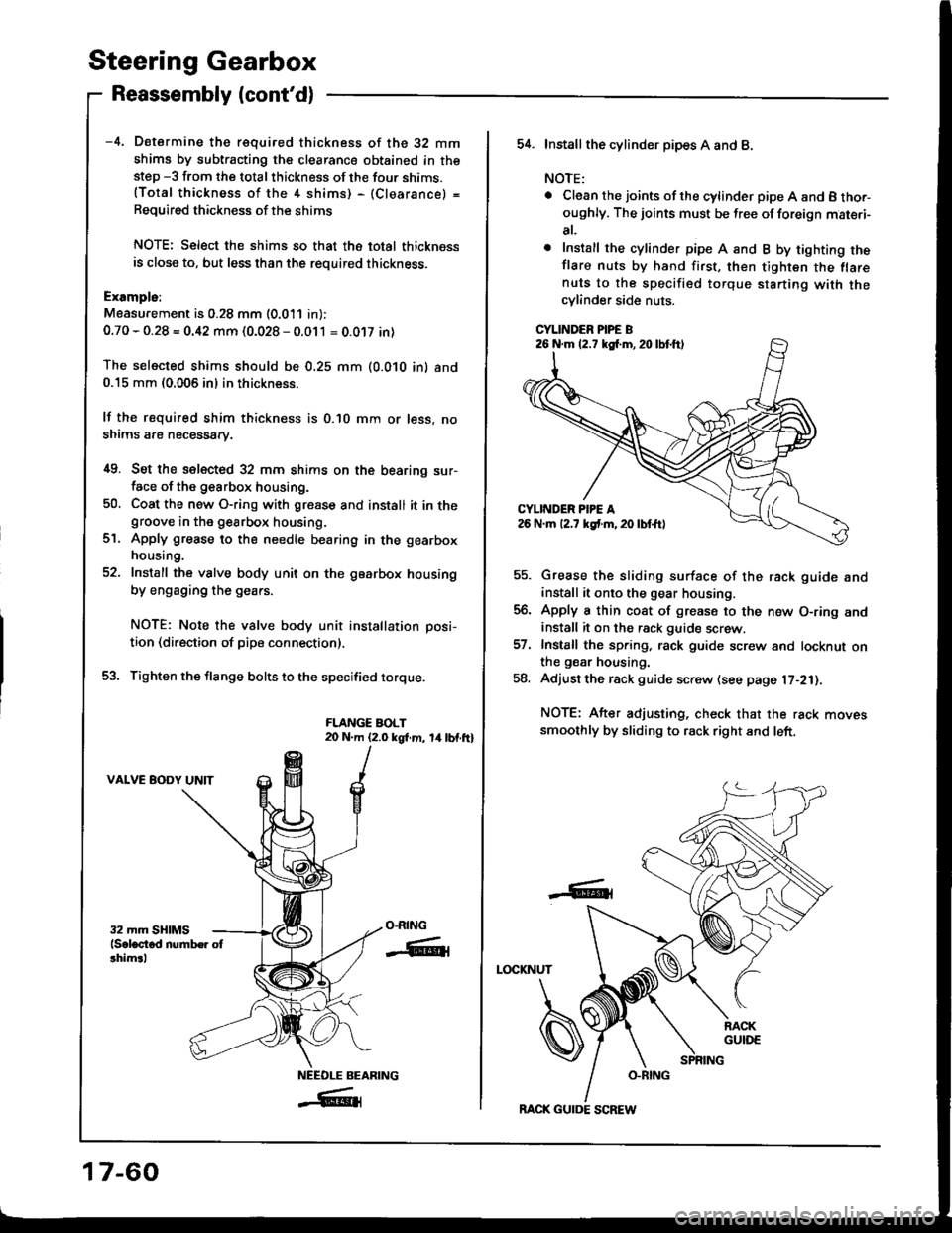

,t8. Select the 32 mm shim(s).

NOTE: Only reinstall the original 32 mm shim(s)

when the steering gearbox is reassembled without

replacing the pinion shaft, valve housing, and gear-

box housing with new ones.

lf the pinion shaft, valve housing, and gearbox

housing are replaced, select the new shim{s) as fol-

rows.

Shim r€lection:-'1. Set the four 32 mm shims on the b€aring surface of

the gearbox housing. Total thickness of the four

shims should eoual no more than 0.70 mm.

Shim set: tour 32 mm shims (Thickness: 0.10 mm,

0.15 mm, 0.20, 0.25 mm respectivelyl

CAUTION: The tour 32 mm shimr do not hlva

thlckn$s idcntitication mukt. Mo!3ur. tho thicl-

oa33 of rach 3him using a miclomctrl, and mlrk

tho shim lor id6ntific8tion.

-2. Install the valve body unit on the gearbox, and

tighten the flange bolts to the specitied torque

VALVE BODY UNIT

FLANGE BOLT20 N.m {2.o kgtm, 14lbt'ftl

SHIM SET{foul thim.)

Measure the clearance between the gearbox and

valve body unit using a feeler gauge as shown.

NOTE: Measure the clearance at the point midway

between the two mounting bolts.

(cont'd)

17-59

Page 667 of 1413

Steering Gearbox

Reassembly lcont'd)

-4. Determine the requifed thickness of the 32 mm

shims by subtracting the clearance obtained in thestep -3 from the total thickness of the four shims.(Total thickness of the 4 shims) - (Clearance) =

Required thickness of the shims

NOTE: Select the shims so that th6 total thicknessis close to, but less than the required thickness.

Exampls:

Measu.ement is 0.28 mm (0.011 in):

0.70 - 0.28 = 0.42 mm (0.028 - 0.011 = 0.0't7 in)

The selected shims should be 0.25 mm (O.O1O in) and0.15 mm (0.005 in) in thickness.

lf the required shim thickness is 0.lO mm or less, no

shims are necessary.

i[9. Set the selected 32 mm shims on the bearing sur-face of the g€arbox housing.

50, Coat the new O-ring with gresse and install it in thegroove in the gearbox housing.

Apply grease to the needle bearing in the gearbox

housing.

Install the valve body unit on the gearbox housing

by engaging the gears.

NOTE: Note the valve body unit installation posi-

tion (direction of pipe connection).

Tighten the flange bolts to the specified torque.

FLANGE BOLT20 N.m (2.0 kgt m, 14lbf.ft)

VALVE BODY UNIT

ct.

O-RING

-ffiti

NEEOLE BEARING

_#{

17-60

BACK GUIDE SCREW

54. Installthe cylind6r pipes A and B.

NOTE:

. Clean the joints ofthe cylinder pipe A and B tho.-oughly. The joints must be free of foreign mat€.i-

at,

o Install the cylinder pipe A and B by tighting theflare nuts by hand first, then tighten the flarenuts to the specified torque starting with thecylinder side nuts.

CYLINDER PIPE B

Grease the sliding surface of the rack guide andinstall it onto the gear housing.

Apply a thin coat of grease to the n€w O-ring andinstall it on the rack guide screw.

Install the spring, rack guide screw and locknut onthe gear housing.

Adjust the rack guide screw (see page l7-21).

NOTE: After adjusting, check that the rack movessmoothly by sliding to rack right and left.

LOCKNUT

-6t

26 N.m (2.7 kg{.m,20lbtft)

Page 669 of 1413

Steering Gearbox

Reassembly (cont'dl

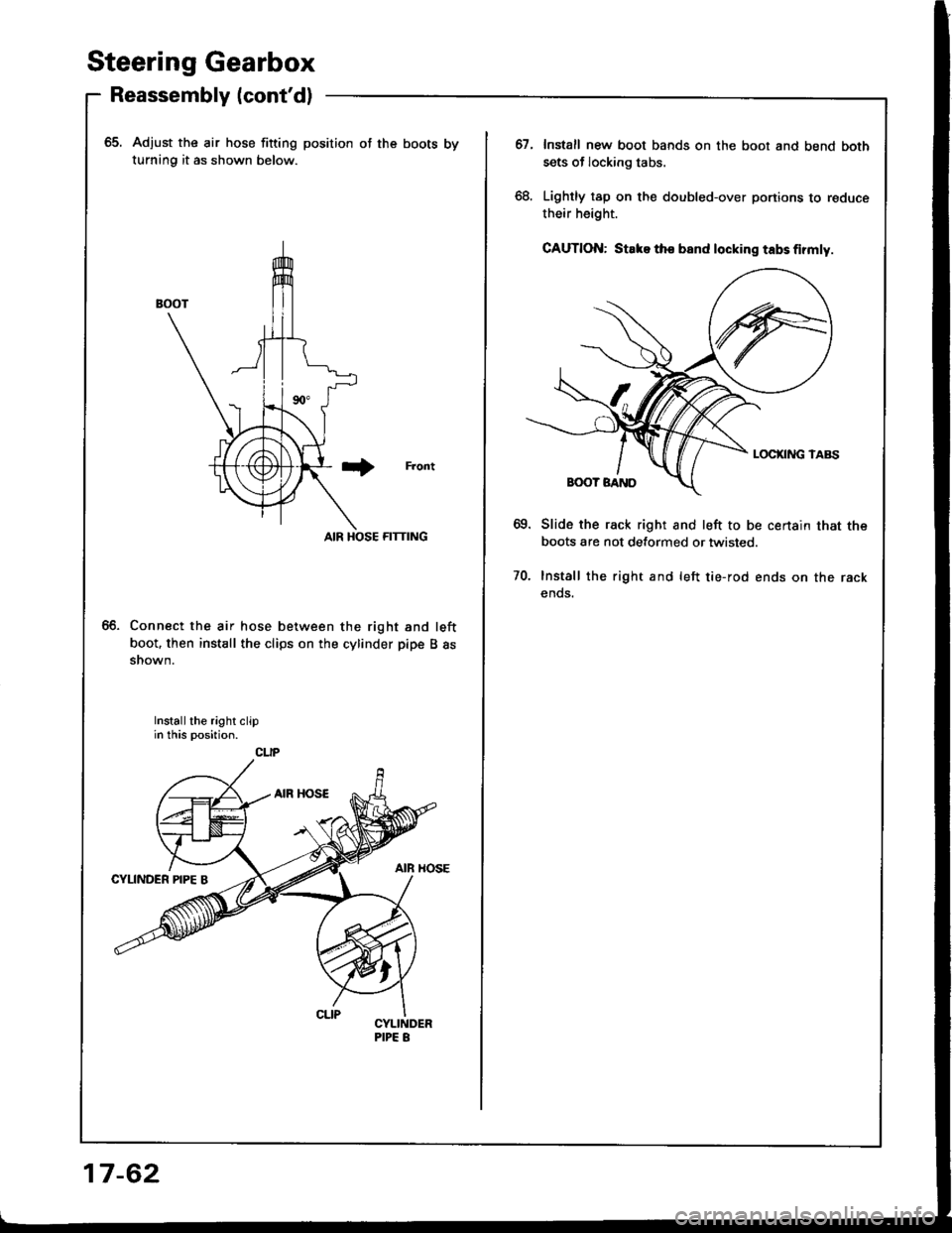

65. Adjust the air hose fitting position of the boots by

turning it as shown below.

Front

AIR HOSE FITTING

Connect the air hose between the right and left

boot. then install the clips on the cylinder pipe B assnown.

Install the right clipin this position.

CLIP

17-62

67.Install new boot bands on the boot and bend both

sets of locking tabs.

Lightly tap on the doubled-over portions to reduce

their height.

GAUTION: Stake tho band locking tabs firmly.

Slide the rack right and left to be certain that the

boots are not detormed or twisted.

Install the right and left tie-rod ends on the rack

ends.

70.

Page 979 of 1413

Seats

Rear Seat Replacement (cont'd)

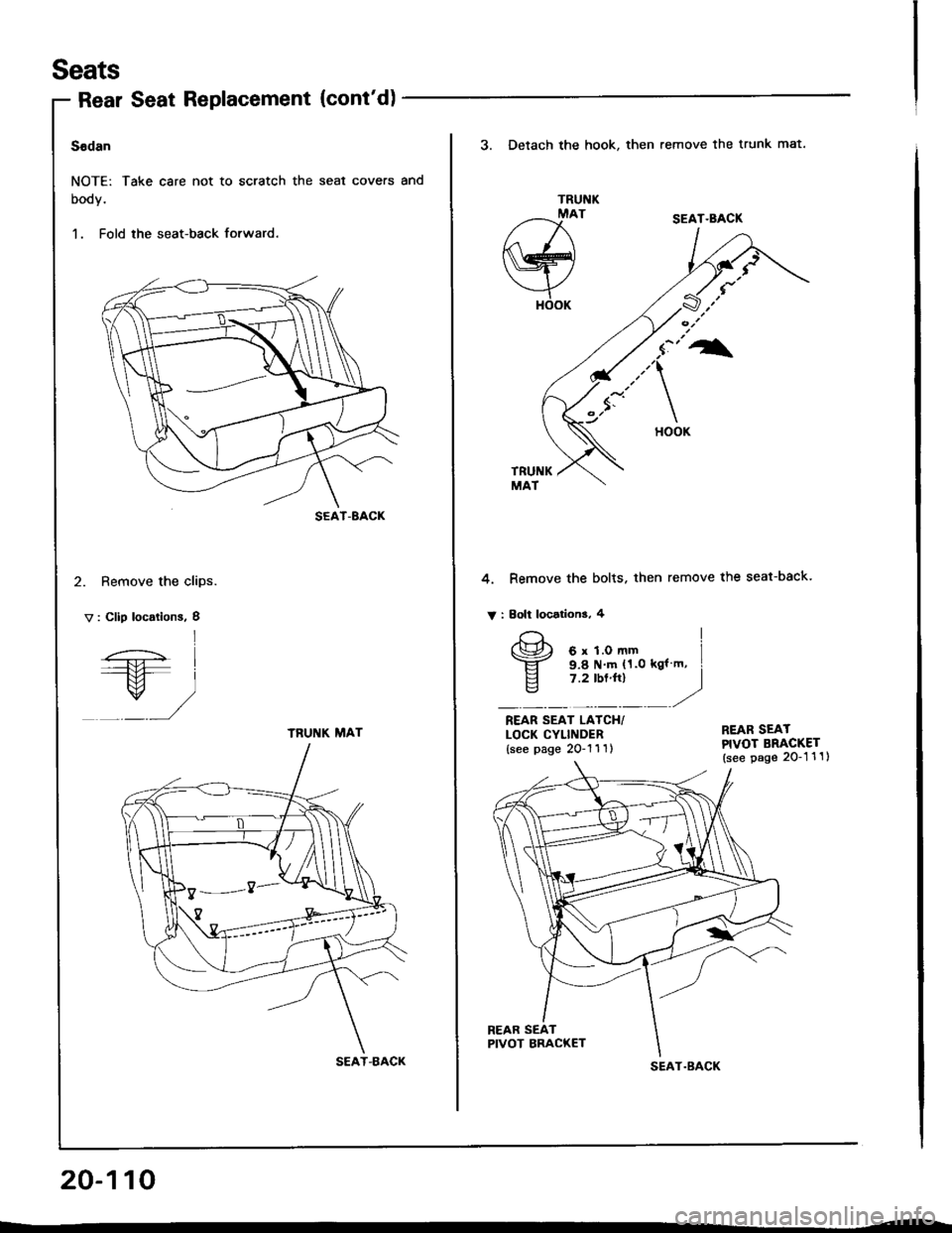

Sedan

NOTE: Take care not to scratch the seal covers and

booy.

1. Fold the seat-back forward.

2. Remove the clips.

V : Clip locations, I

SEAT-8ACK

l

/-.;- I----+tl l---M- I

/ /,/

TRUNK MAT

SEAT-BACK

20-110

3. Detach the hook, then remove the trunk mat.

TRUNKMAT

a-^I{ \

Nry

YHOOK

SEAT.BACK

TRUNKMAT

4. Remove the bolts. then remove the seat-back.

V : Eolt locations, 4

REAR SEAT LAICH/LOCK CYLINDER{see page 2O-'l 1 1l

REAR SEATPIVOT BRACKET(see page 2O-1 1 1)

REAR SEATPIVOT BRACKET

I

I gel?"Til.*,,", i

E 7.2 tbt'trl I" -----r"

SEAT.BACK

Page 980 of 1413

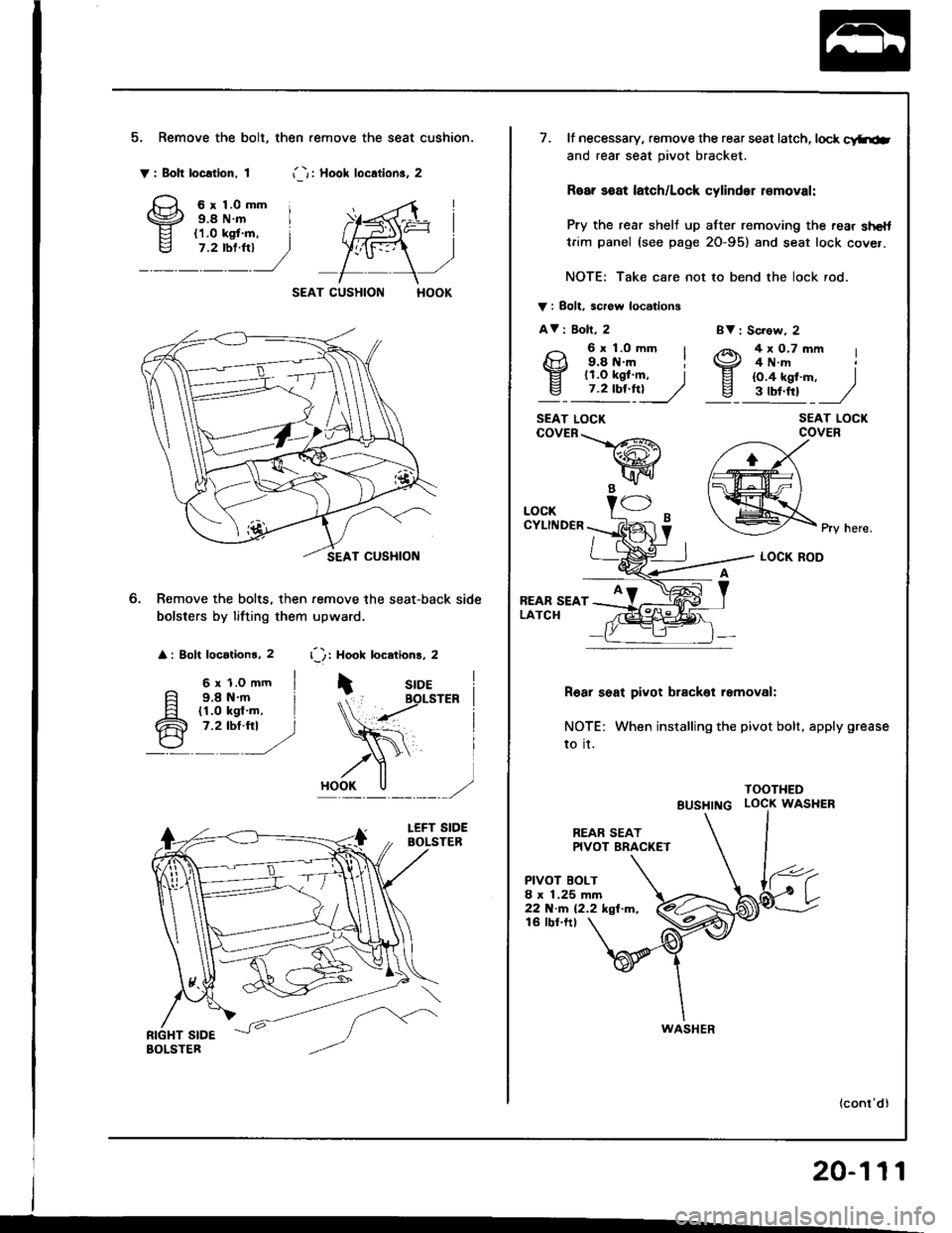

5. Remove the bolt, then .emove the seat cushion.

Y: Bolt location. 1i -r i Hool loc.lion3. 2

6r1.0mm i9.8 N.m I

SEAT CUSHION

Remove the bolts, then remove the seat-back side

bolsters by lifting them upward.

: Bolt locationr, 2 r'): Hook locetions, 2

6 r 1.o mm I9.8 N.m i(1.0 kgl'm, I7.2 tbt.fti )

BV : Sc?ow, 2

SEAT LOCKCOVER

Pry here.

LOCK ROD

R6ar seat pivot brackol removal:

NOTE: When installing the pivot bolt, apply grease

to it.

TOOTHED

BUSHTNG LOCK WASHER

REAR SEATPIVOT BRAC(ET

PIVOT BOLT8 x 1.25 mm22 N.m (2.2 kgf m,16 tbf.ftt

20-111

7. lf necessary, remove the rear seat latch, lock c!ftiab

and rear seat pivot bracket.

Roar soat latch/Lock cylinder r€moval:

Pry the rear shelj up after removing the rear shelttrim panel (see page 2O-95) and seat lock cover.

NOTE: Take care not to bend the lock rod.

V i Bolt. scrow locations

AV i Boll, 2

9: l;o--' I4x0.7mm I4 N.rrt

EI lr.o tgf .m, Iv_ 7.2 tbf.ft!____//

9.8 tt.m il1.O kgf.m, I{O.4 kgf'm, )3tbt.ttt J

SEAT LOCKcovER\-_L/-R\

wB -"1/ -

LOCKCYLINDER

REAR SEATLATCH

WASHER

Page 1024 of 1413

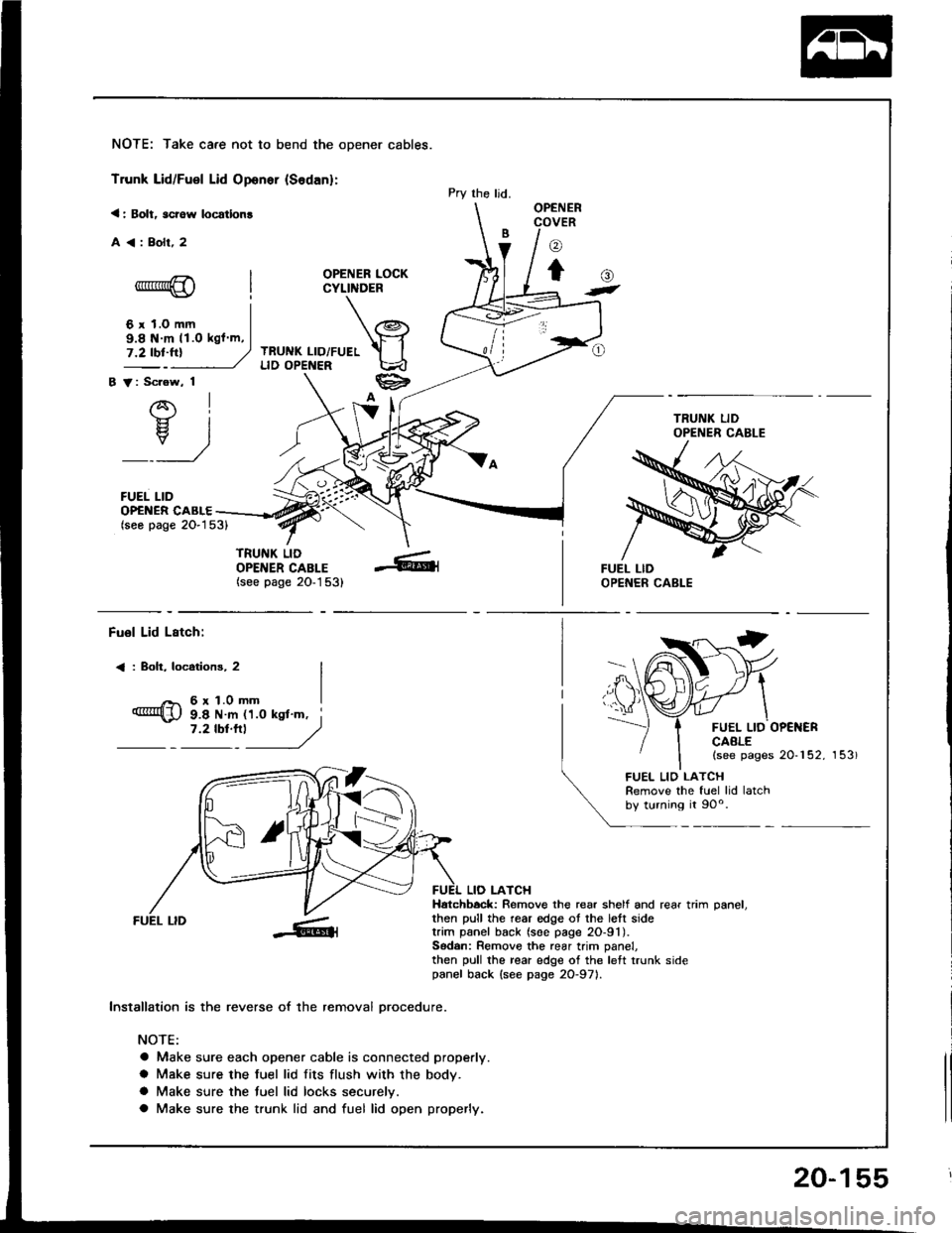

NOTE: Take care not to bend the opener cables.

Trunk Lid/Fuel Lid Oponer {Sodan}:

< : Bolt, scrow locatlon!

A<:Bolr,2

OPENER LOCKCYLINDER

TRUNK LID/FUELLID OPENER

B V: Scrow, 1

AI-}{- IH. I

_:_)

FUEL LID

Pry the ljd.OPENERCOVER

o

to-*rr*@

6 r 1.0 mm

()t

OP€NER CABLE(seo page 2O-153)

TRUNK LIDOPENER CABLE(see page 20-1 53)

9.8 N m 11.O kgl m,

Fuol Lid Lstch:

< : Boh, locotions, 2

6r1.0mm

FUEL LID OP€NERCAALE(see pages 20-152, 153)

9.8 N m 11.0 ksl'm, i7 '2 tbt'''l

------,//

FUEL LID

lnstallation is the reverse of the removal orocedure.

NOTE:

a Make sure each opener cable is connected properly.

a Make sure the fuel lid fits flush with the body.

a Make sure the tuel lid locks securelv.

a Make sure the trunk lid and fuel lid open properly.

LIO LATCHHatchbock: Remove the rear shelf and rear trim oanel.then pull the rear edge ot the lett sidetrim panel back (soe page 2O-91).Sodan: Remove the rear trim panel,then pull the rear edge of the left trunk sidepanel back {see page 2O-971.

FUEL LIO LATCHRemove the fuel lid latchby turning it 90o.

20-155

Page 1025 of 1413

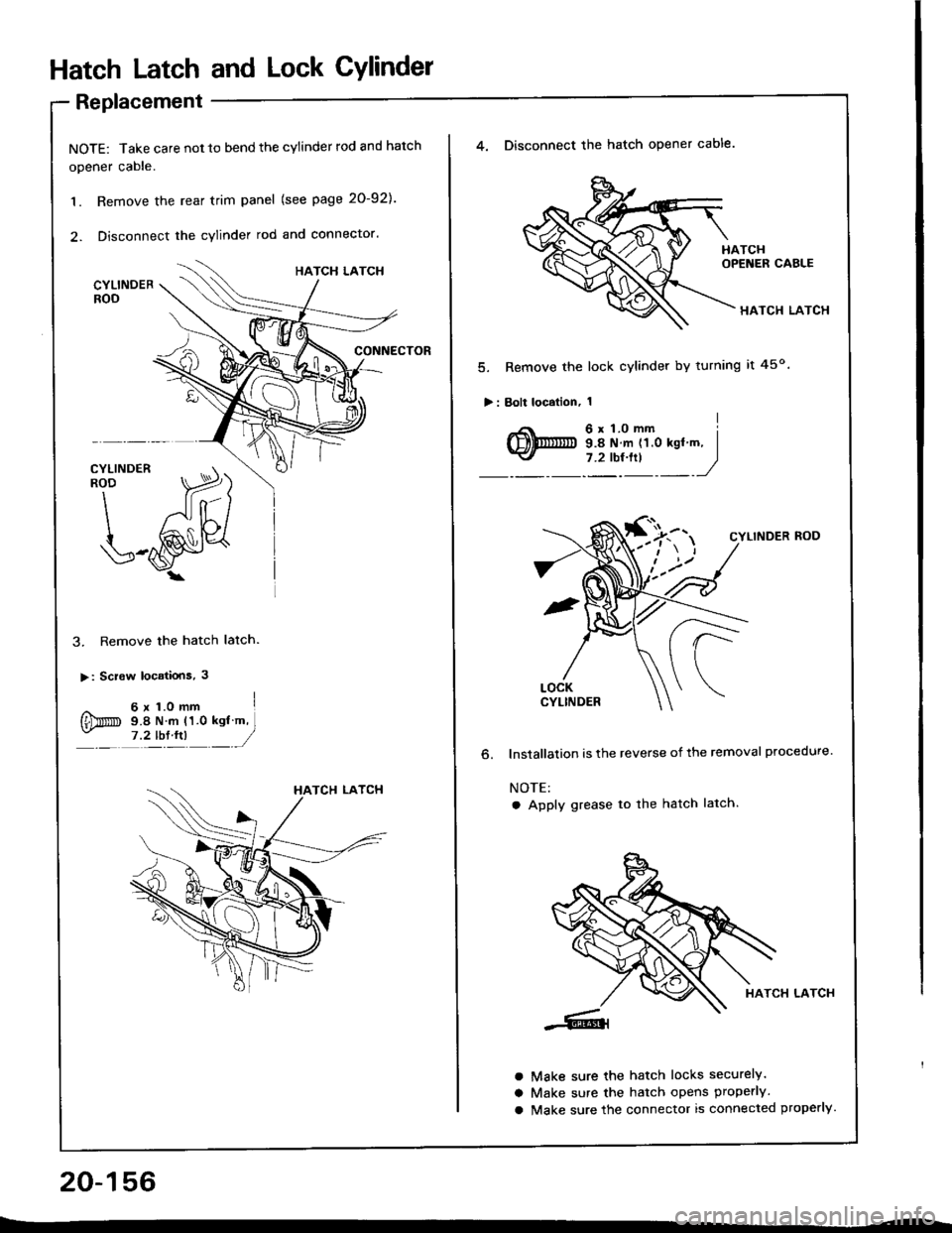

Hatch Latch and Lock CYlindet

Replacement

NOTE: Take care not 10 bend the cylinder rod and hatch

opener cable.

1. Remove the rear trim panel (see page 20-921.

2. Disconnect the cylinder rod and connector.

3. Remove the hatch latch.

>: Screw locatiois, 3

^ 6x1.omm I

{Dm s.e N m (1.0 ksl m,- ,?tb:tn __/

20-156

4. Disconnect the hatch opener cable.

HATCH LATCH

5. Remove the lock cylinder by turning it 45o

>: Bolt localion, 1

o.

CYLINDER ROD

lnstallalion is the reverse of the removal procedure.

NOTE:

a Apply grease to the hatch latch.

HATCH LATCH

Make sure the hatch locks securely.

Make sure the hatch opens properly.

Make sure the connector is connected properly.

a

a

a

Page 1026 of 1413

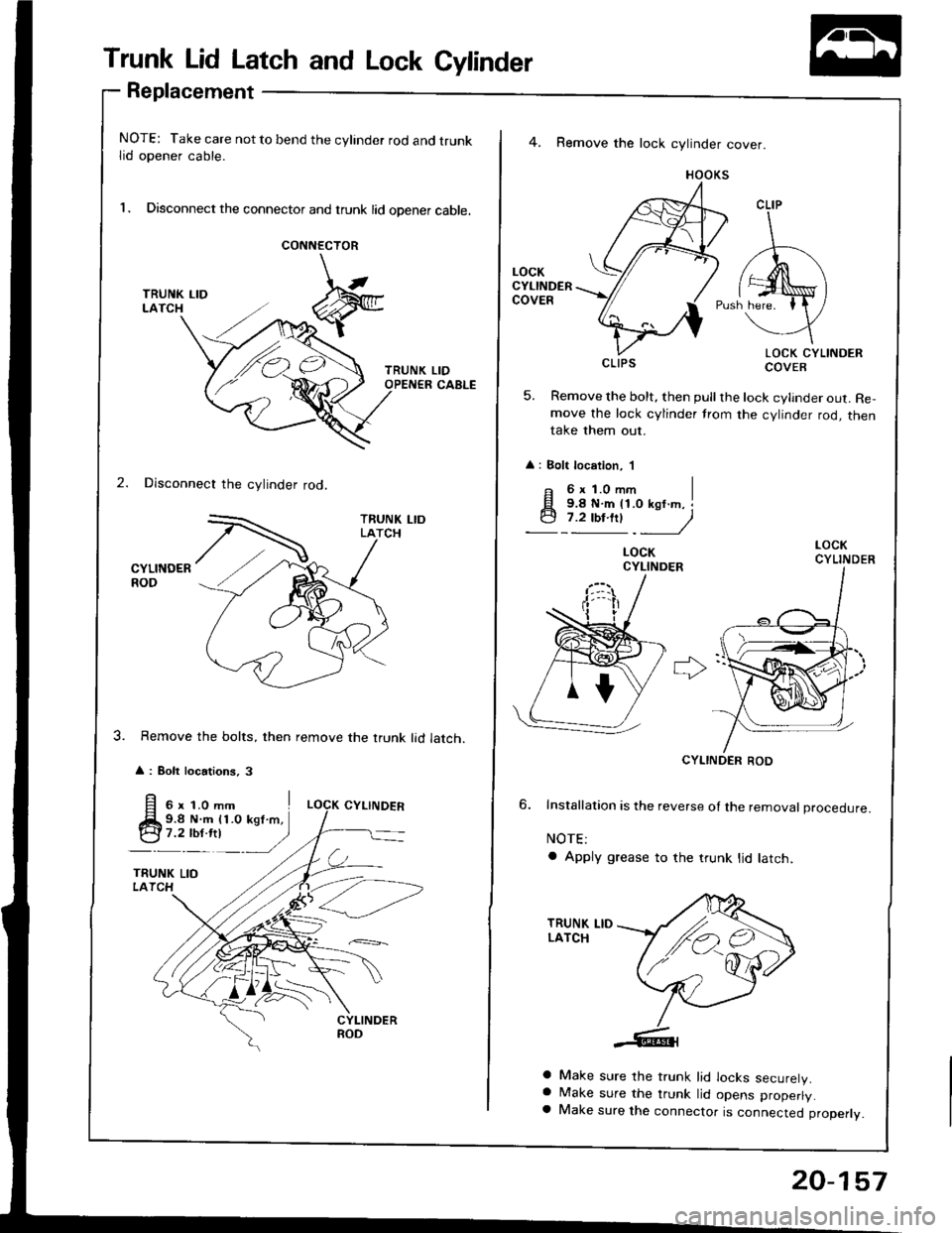

Trunk Lid Latch and Lock Cylinder

Replacement

NOTE: Take care not to bend the cylinder rod and trunklid opener cable.

l. Disconnect the connector and trunk lid opener cable.

CONNECTOR

2. Disconnect the cylinder rod.

CYLINDERROD

Remove the bolts, then remove the trunk lid latch.

A : Bolt locations, 3

LIDCABLE

4. Remove the lock cylinder cover.

HOOKS

LOCK CYLINDERCOVER

5. Remove the bolt, then pull the lock cylinder out. Re,move the lock cylinder trom the cylinder rod, thentake them out.

: Bolt location, 'l

CLIP

CLIPS

F 6xl.Omm I

q;i!!"jy

LOCKCYLINDER

CYLINDER ROD

6. Installation is the reverse ol the removat proceoure.

NOTE:

a Apply grease to the trunk lid latch,

a Make sure the trunk lid locks securelV.a Make sure the trunk lid opens properly.a Make sure the connector is connected properly.

/ ./,.,

,/'e4

20-157

Page 1122 of 1413

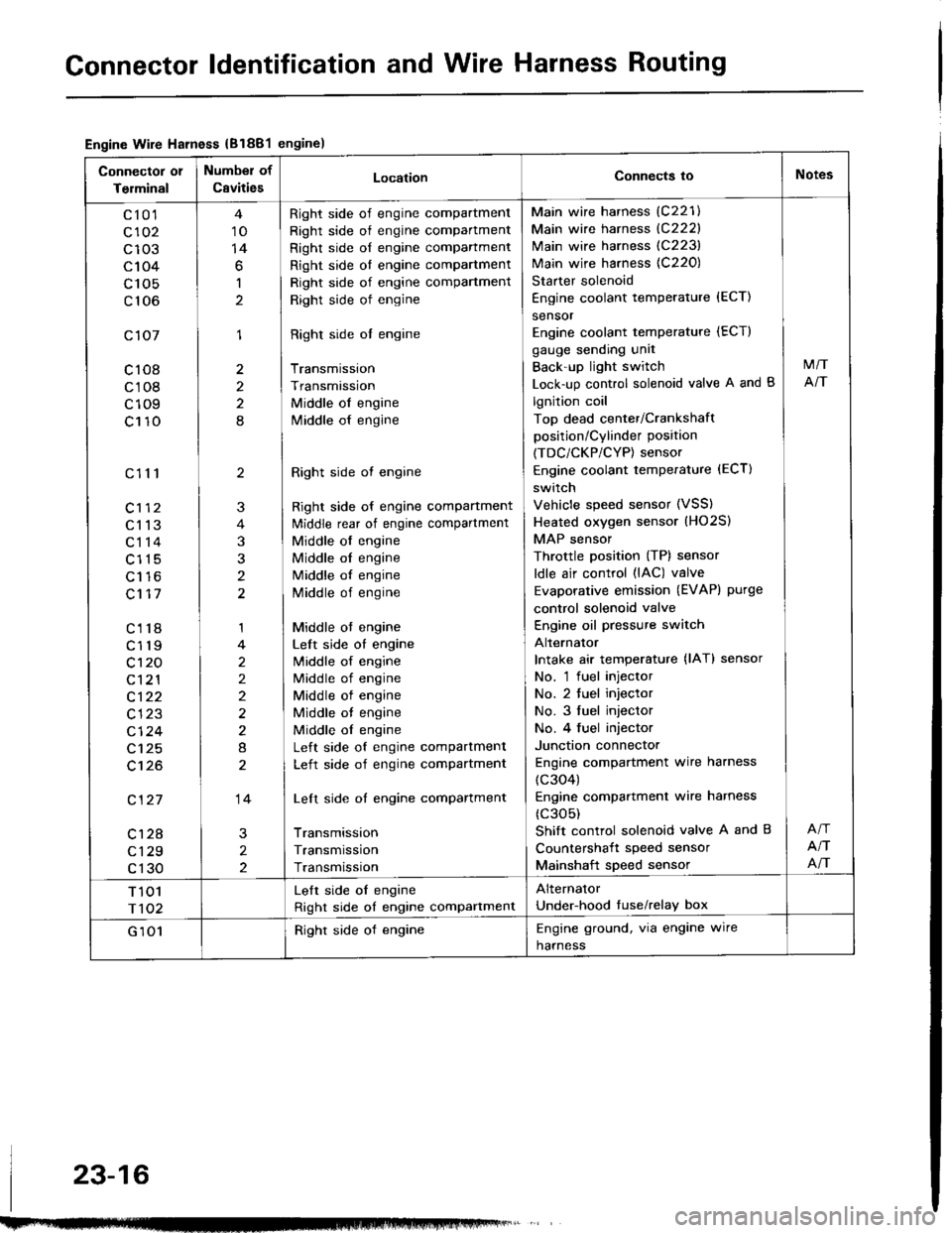

Gonnector ldentification and Wire Harness Routing

Engine Wire Harness {B1881engine)

Connector 01

Terminal

Number of

CavitiesLocationConnects ioNotes

c10'l

c102

c103

c104

c 105

c106

c107

c108

c108

c109

c110

c111

c113

c114

c115

Lt to

c117

c118

c119

c't 20

c121

c122

c123

cl24

c125

c't26

c127

c128

c129

c130

10

14

6

1

1

2

2

8

2

3

t

1

2

2)

2

8

14

2

2

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side ol engine compartment

Right side of engine compartment

Right side of engine

Right side ol engine

Transmission

Transmission

Middle of engine

lvliddle of engine

Right side ot engine

Right side of engine compartment

ldiddle rear of engine compartment

Middle of engine

Middle ol engine

Middle of engine

Middle of engine

Middle ot engine

Left side of engine

lvliddle of engine

Middle of engine

Middle of engine

Middle ot engine

Middle ol engine

Left side of engine compartment

Left side of engine compartment

Left side of engine compartment

Transmission

Transmission

Transmission

Main wire harness (C221)

Main wire harness {C222}

Main wire harness (C223)

Main wire harness {C220)

Starter solenoid

Engine coolant temperature {ECT)

sensor

Engine coolant temperature (ECT)

gauge sending unit

Back'up light switch

Lock-up control solenoid valve A and B

lgnition coil

Top dead center/Crankshaft

position/Cylinder position

(TDC/CKP/CYP) sensor

Engine coolant temperature (ECT)

switch

Vehicle speed sensor (VSS)

Heated oxygen sensor (HO2S)

MAP sensor

Throttle position (TP) sensor

ldle air control (lAC) valve

Evaporative emission (EVAPI purge

control solenoid valve

Engine oil pressure switch

Alternator

Intake air temperature {lAT} sensor

No. 'l fuel injector

No. 2 tuel injector

No. 3 fuel injector

No. 4 fuel injector

Junction connector

Engine compartment wire harness

(c304)

Engine compartmenl wire harness

(c305)

Shift control solenoid valve A and B

Countershait speed sensor

Mainshaft speed sensor

M/T

NT

NT

NT

T 101

r102

Lelt side oI engine

Right side of engine compartment

Alternator

Under-hood tuse/relay box

G 101Right side of engineEngine ground, via engine wire

harness

23-16