Electrical HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 208 of 1413

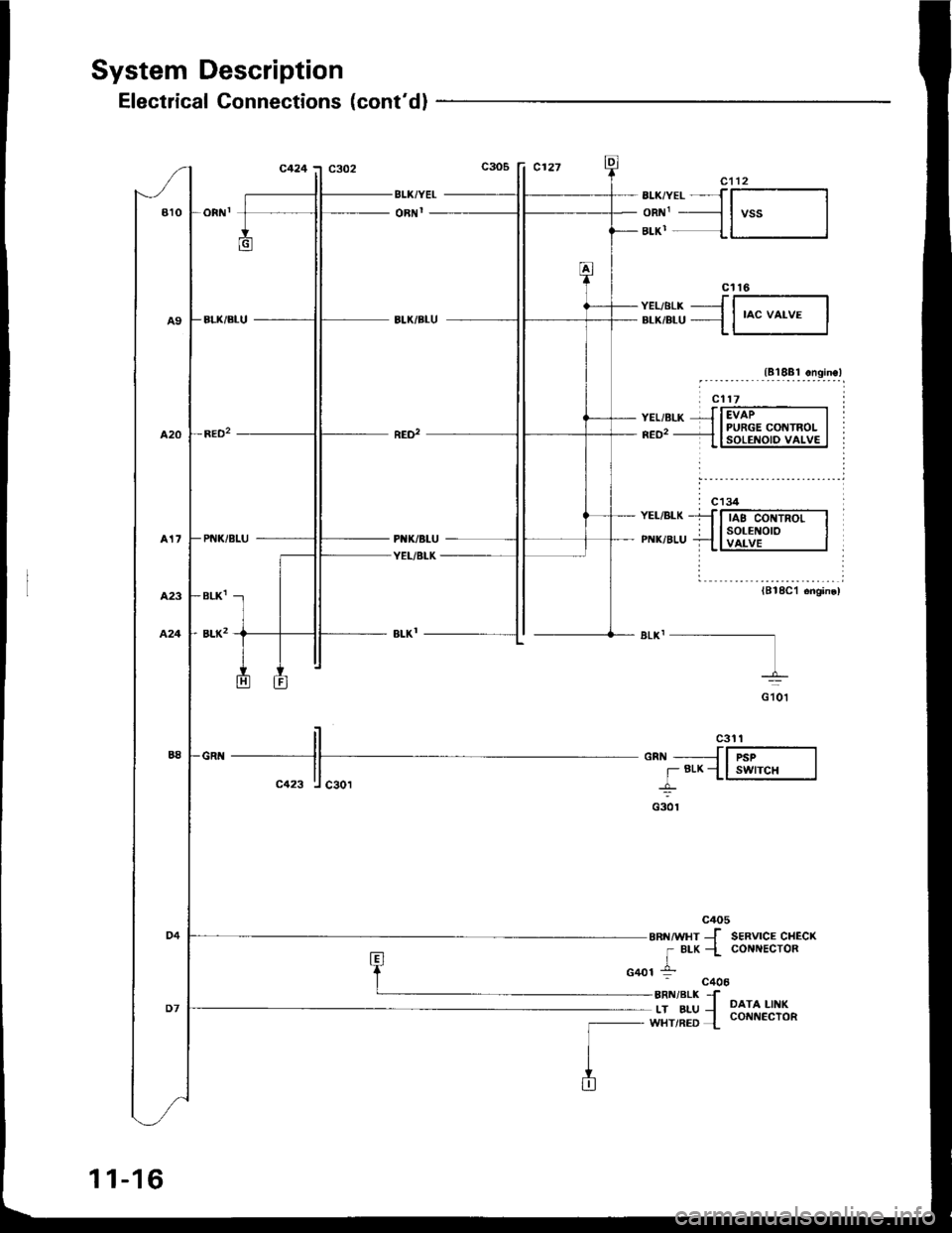

System Description

Electrical Connections (cont'dl

BLI(/YEL

oRI{r

il ".t ttlenn __JlF-----l

ll r Brx_Ll swrcH Ic423 ! caor -L

e s-ot

c405

eaurvxr Jr BLK -l

1-G401 :-

SERVICE CHECKCOIIIIECTOR

DATA LINKcorrttIEcToR

- c40aBRN/BLK fLT BLU IWHT/RED {

BTKiYEL-JT---l

oR 1 ----l I vss IBLK' {l I

c't 16

v:r-,sr-* -J l-----]".*,".u {l

'o" uo.u. I

lA18a1 ongine,

lB18C1 6ngin€)

11-16

Page 210 of 1413

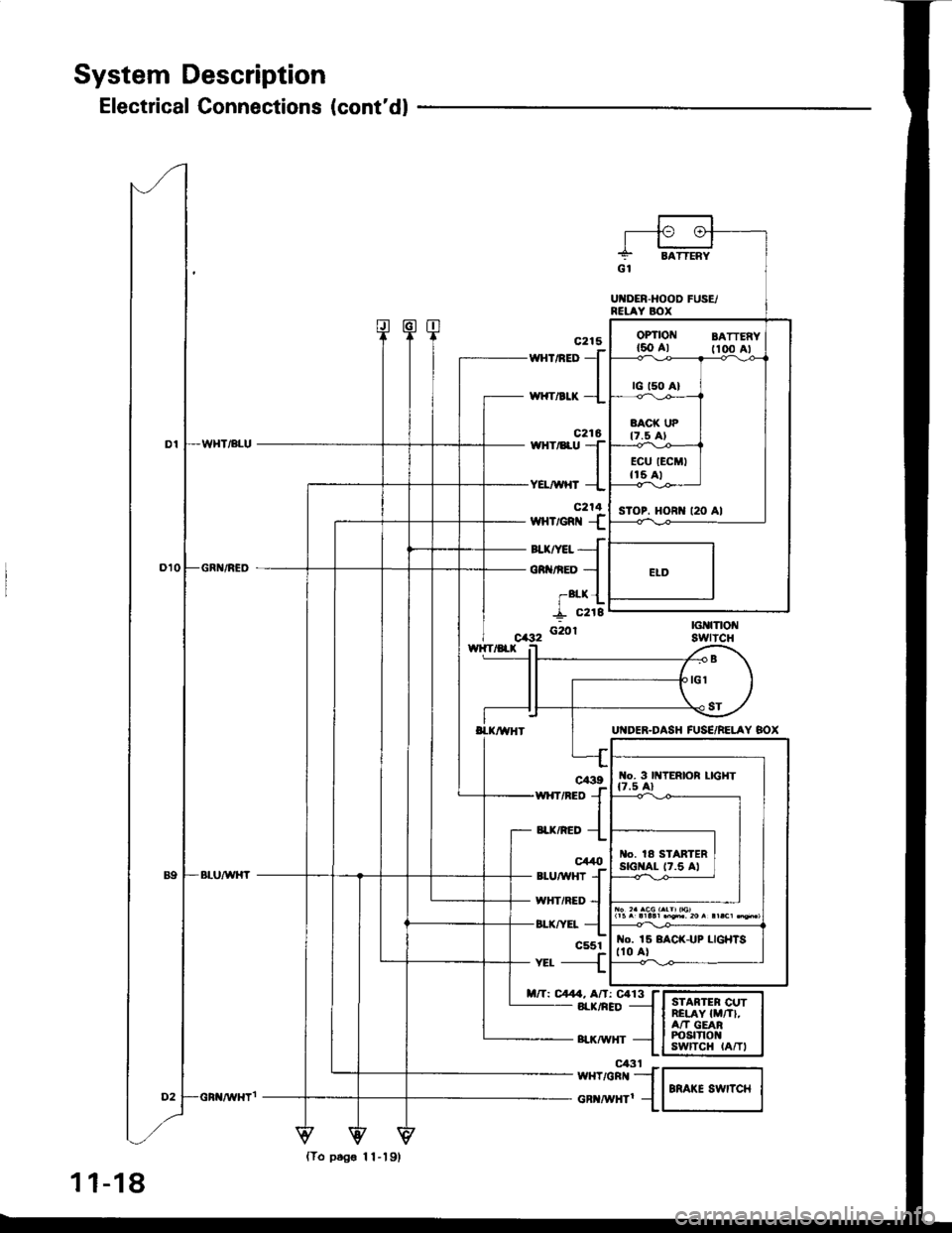

System Description

Electrical Connections (cont'dl

160 Al fioo Al

sToP. HORI{ t20 Al

wnrneo

J

,*rr"a* -l

c216wHr/8ru TIYEL/WHT --L

c214wHvem {

auryet{

oR nED -l

-alx {

I "rti'f_ c218

G20r

wxrneo {

"a*,"ao {

c44t)*utwxr

{wHriRED --l

or-rrv:r- {c551-{

nft C4. Af,: Ca13 f- 8rr(/nED -l

- surwxr -{

I{o. 3 lttTERlOR LIGHT

l|5^.llll.n'i'20r!|.c1q*,

o. la STARTERstGI{At- t7.5 Al

No. 15 8ACK-UP LIGHISt10 al

{To ptg€ 11-19,

1 1-18

el3t Fw{T/GRr{ _-]

cR ^i|Hrl 1

Page 225 of 1413

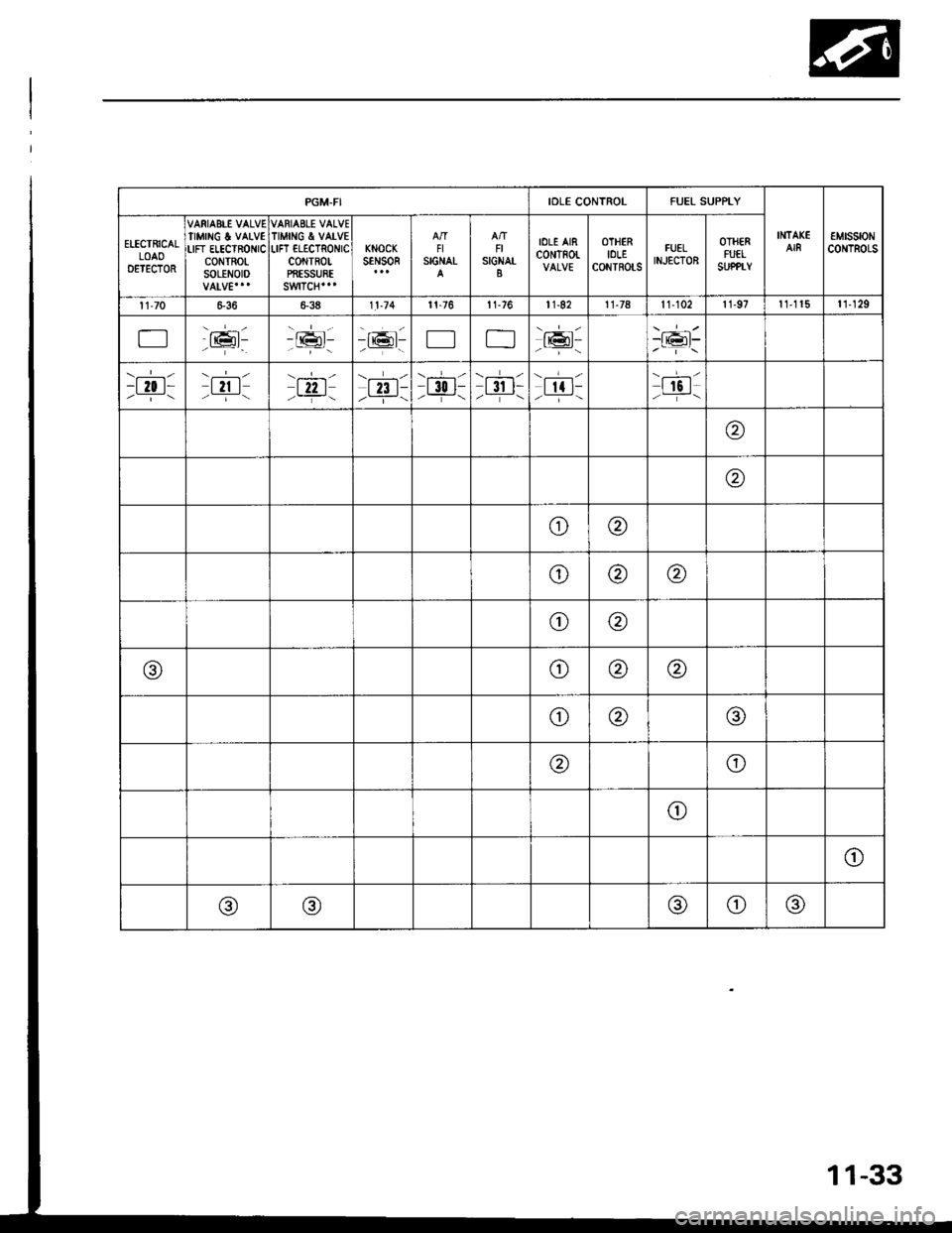

PGM-FIIOLE CONTROLFUEL SUPPLY

INTAKEAIR€MtsstoNCONTROLSELECTRICALLOAODETECTOR

VARIAEIE VALVETIMINC & VALVELIFT ELECTRONICcoNTRO|-SOLENOID

VARIABLE VALVETIMING & VATVEI-IFT ILECTRONICcottTR0tPffESSURE

KNOCKstNsoRFISIGNALFISIGNAT

IOLE AIRc0NTR0r-OTHERIOLECONTROLS

FUELINJECTOR

OTHERFUELSUPPTY

| 1"70s3811.74r 1-76t 1-7611-8211-78| 1-102r 1-97t 1-1 15ll129

Er6t-- -------16l-/-----..Efl-o_,.''\

\.-r-l-t l0 t----i-\t2t I/ --i-\

\-!-/

l22 l/-- j--\t23 l-/--.i-\-t 30 l-,--T-\

\.--r-z

t3r t-/-.--\

\.---l

[|-/----\I 16 t-/ _-i- \

@

@

o@

o@@

oQ)

@a,@@

o@@

@o

o

(JJ

@@@o@

11-3

Page 228 of 1413

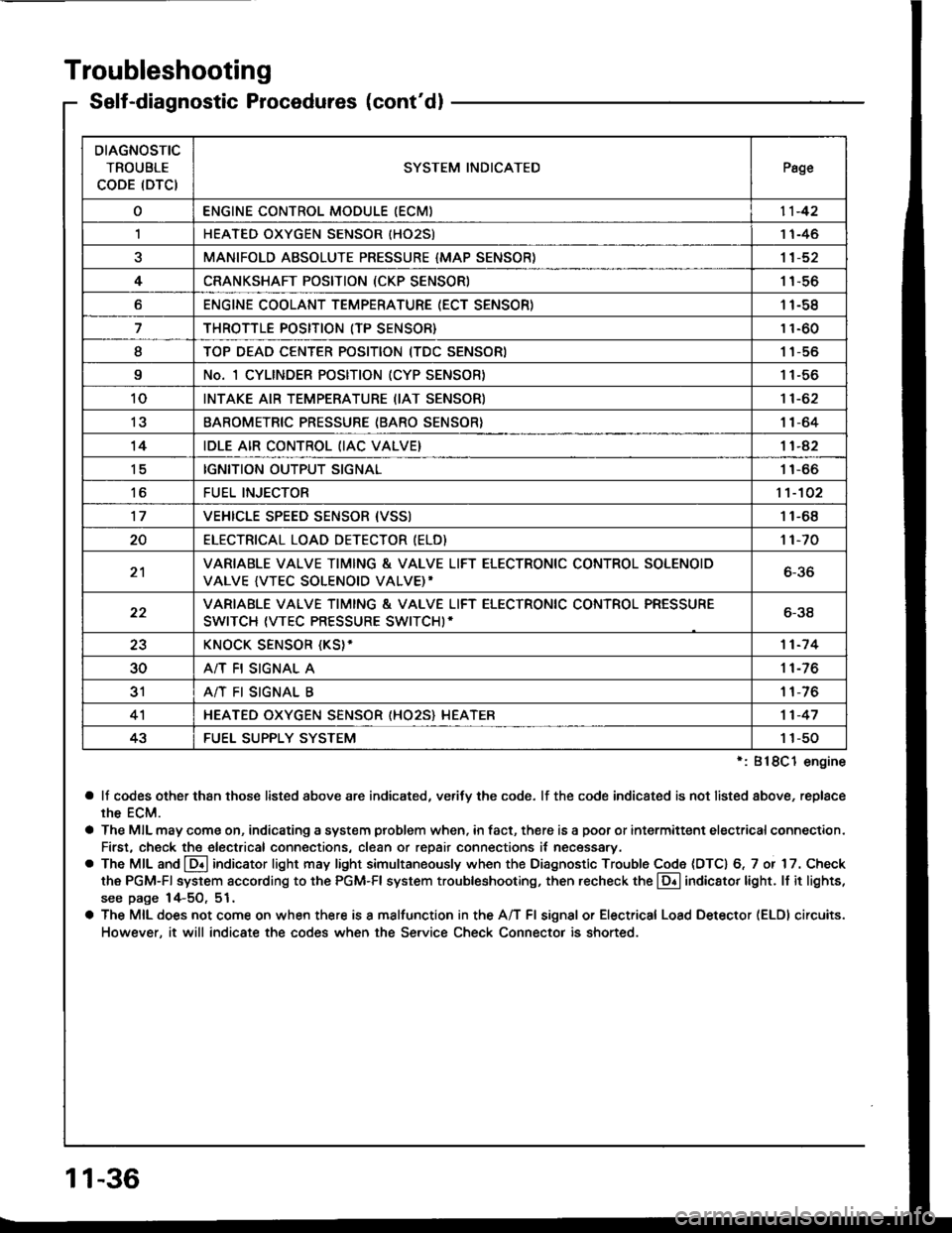

Troubleshooting

Self-diagnostic Procedures (cont'dl

':818C1 engine

a lf codes other than those listed above are indicated, verifv the code. lf the code indicated is not listed above, replace

rhe ECM.

a The MIL may come on, indicating a system problem when, in fact, there is a poor or intermittent electricalconnection.

First, check the electrical connections, clean or repair connections it necessary.

o The MIL and @ indicator light may light simultaneously when the Diagnostic Trouble Code (DTC) 6, 7 or 17. Check

the PGM-Fl system according to the PGM-Fl system troubleshooting, then recheck the l!! indicator light. ll it lights,

see page 14-5O, 51.

a The MIL does not come on when there is a malfunction in the A/T Fl signal or Electrical Load Detector (ELDI circuits.

However, it will indicate the codes when the Service Check Connector is shorted.

DIAGNOSTIC

TROUBLE

CODE (DTCISYSTEM INDICATEDPsge

oENGINE CONTROL MODULE IECM)11-42

,lHEATED OXYGEN SENSOR IHO25)1 1-46

aMANIFOLD ABSOLUTE PRESSURE {MAP SENSOR)11-52

4CRANKSHAFT POSITION (CKP SENSOR)1 1-56

oENGINE COOLANT TEMPERATURE (ECT SENSOR)11-58

THROTTLE POSITION (TP SENSOR}11-60

ITOP DEAD CENTER POSITION (TDC SENSORI1 1-56

9No. 1 CYLINDER POSITION (CYP SENSOR)1 1-56

10INTAKE AIR TEMPERATURE (IAT SENSOR)11-62

13BAROMETRIC PRESSURE (BARO SENSOR}1|-64

14IDLE AIR CONTROL (IAC VALVE}11-42

tcIGNITION OUTPUT SIGNAL11-66

toFUEL INJECTOR1't-102

17VEHICLE SPEED SENSOR {VSSI11-68

20ELECTRICAT LOAD DETECTOR (ELD)'t 1-70

21VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL SOLENOID

VALVE {VTEC SOLENOID VALVE)'6-36

22VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL PRESSURE

SWITCH (VTEC PRESSURE SWITCHI-6-38

23KNOCK SENSOR {KS}-11-7 4

30A/T FI SIGNAL A11-76

3'rA/T FI SIGNAL B1 1-76

4'lHEATED OXYGEN SENSOR (HO25} HEATER11-47

43FUEL SUPPLY SYSTEM1 1-50

11-36

Page 231 of 1413

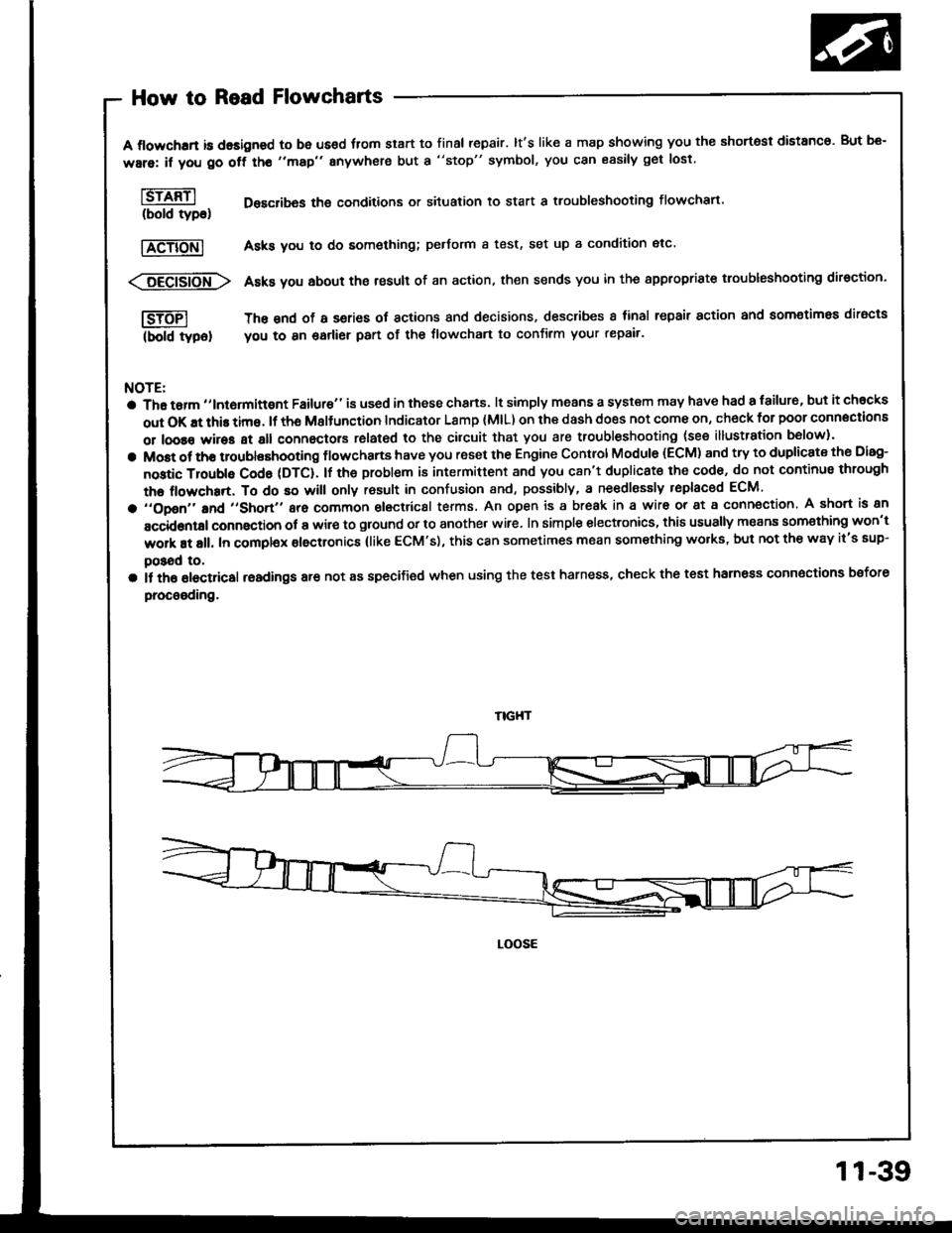

How to Read Flowcharts

A flowchrrt is dasigned to be us€d fiom start to final repair. lt's like a map showing you the shortest distanco. But be-

ware: if you go off tho "map" anywhere but a "stop" symbol, you can easily get lost

l6rffil Desclibas the conditions or situation to start a troubleshooting flowchart.(bold tyDo)

|TeTiONl Asks you to do something; pedorm a test, set up a condition etc'

<:6Eei6io-fr\> Asks you about the result of an action, then sends you in the appropriste troubleshooting direction.

I-SJTFI The snd of a series ot actions and decisions, describes I tinal repair action and aomotimea diracts

(bold typel you to 8n garlier part of the tlowchart to confirm your repair'

NOTE:

a Tha tarm ,,lntormittgnt Failure" is used in these chans. lt simply means a system may have had a failur6, but it chocks

out OK !t this time. lf th6 Msltunction Indicator Lamp (MlL) on ihe dash does not come on, check for poor connections

or loose wires at all connectors rolated to the cilcuit that you are troubleshooting (see illustration b6low).

a Most ot tho troublashooting flowchans have you reset the Engine Control Module (ECM) and try to duplicate the Disg-

nostic Troubls Cod6 (DTC). lf the problem is intermittent and you c8n't duplicat€ the cod6, do not continus through

the flowchart, To do so will only rosult in confusion and, possibly, a ne€dlessly replaced ECM

a ,,opon,'and ,,short,, are common electrical terms. An open is a break in a wir6 or at a conn€ction. A short is an

accidontal connaction ot a wir€ to ground or to another wire. In simple electronics, this usually means som€thing won't

work at all. In complex electronics (like ECM's), this can sometimes mean something wolks, but not the way it's sup-

poSad to,

a il th6 olectricsl readings are not as specified when using the test harness, check the test harness connoctions bsfore

procooding.

LOOSE

11-39

Page 244 of 1413

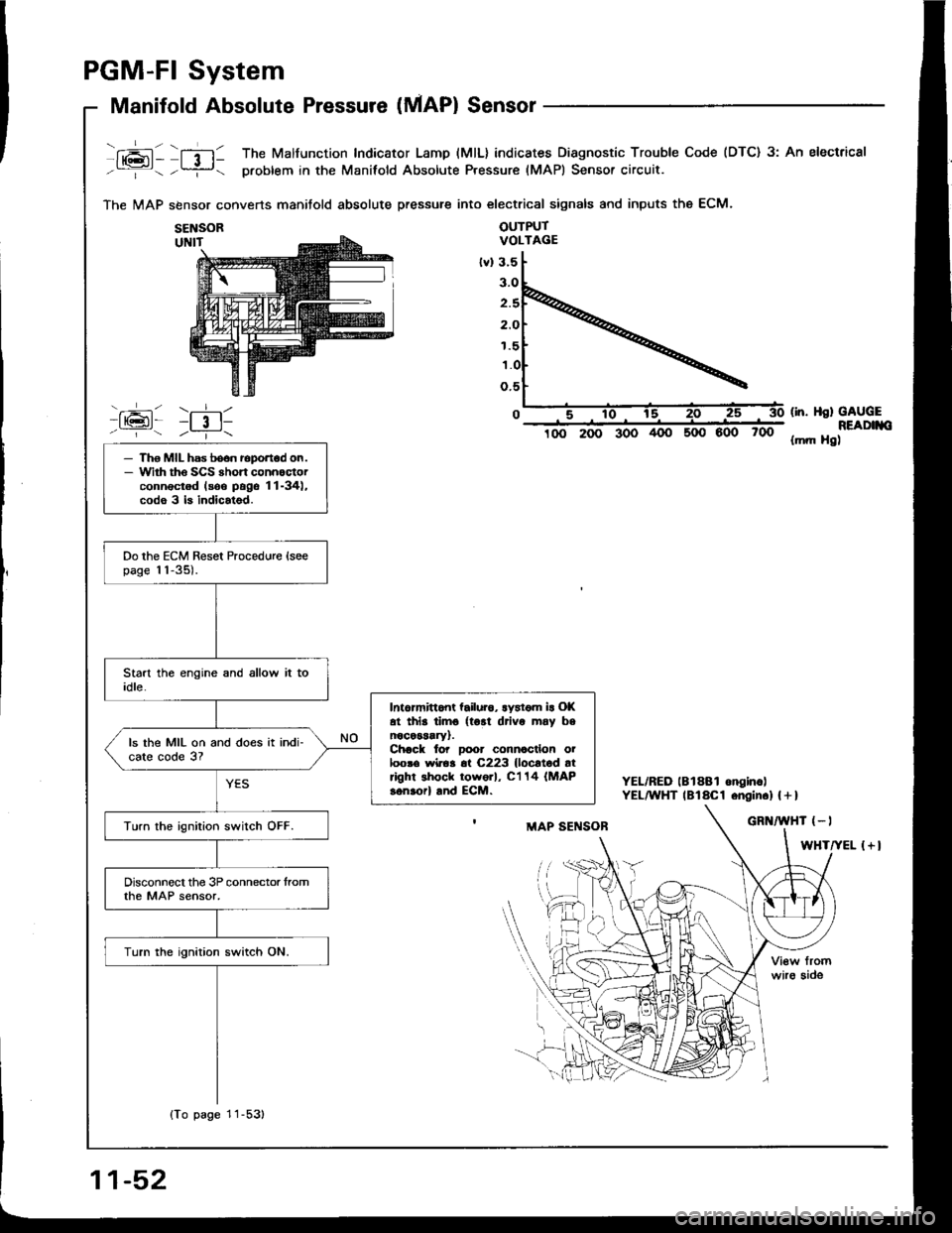

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor

fxai - lfil1 The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 3: An electrical

-:- -?- problem in the Manifold Absolute Pressure (MAPI Sensor circuit.

The MAP sbnsor converts manitold absolute pressure into electrical signals and inputs the ECM.

OUTPUTVOLTAGE

600 700

(in. Hsl GAUGEREADIIIO{mft Hg)

YEL/RED lBlSBl onginc)YEL^YHT lBlaCl .ngin.l | + I

{+l

SENSOR

1.5

- Tho MIL has boon roportod on.- Wirh tho SCS rhort connoctorconnectod lsoo pags 11-34),codo 3 b indicatsd.

Do the ECM Reset Procedure {soepage 11-35).

Intormittont tailuro, lystom ir Ol(at thls timo {tort drivo may bsnocessary).Chack to? Door connocllon oiloosa wiroa 6t C223 {locltod atright shock tow6rl, C'l 14 (MAP

sonaorl and ECM.

ls the MIL on and does it indi-cate code 3?

Turn the ignition switch OFF.

Disconnect the 3P connector tromthe MAP sensor,

Turn the ignition switch ON.

{To page 11-53)

11-52

Page 260 of 1413

![HONDA INTEGRA 1994 4.G User Guide PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With HONDA INTEGRA 1994 4.G User Guide PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With](/img/13/6067/w960_6067-259.png)

PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With lho SCS lhon connectolconnoctod {ree pago 11-34}, cod.20 is indicatod.

Do the ECM B6set Procedurs {seepage 1 'l-35).

Start engine and keep engin€speed at idle.Turn on headlights.

lntennlna tlllure, lyrtom lt Ol(!t irl. dm. (lgtt driv. mly [email protected] for Door connactlona oaloota wiro. rt C218 IELD, lndEctrt.

Ooes the MIL indicato code 20?

Romove the undgr-hood fusg/relay box and remove the tus6/relav box lowet cover.

Turn lhe ignition switch ON.

Measure voltage betw€on BLK/YEL (+l terminal and BLK (-)terminal.

Msasuro voltag€ b€tweon BLK/Y€L {+) terminal snd bodvground.ls there bartory voltagel

Rcpir oo.n in BLK wir.batwaan lha 3P connrc-tor lnd G2Ol {loc.t.dtroit ot angh|. comprn-m.r dghl .ld.l,

B.p.lr op.n in BLKrYEL wlrr b.-tw..n o.24ACG (ALn flcl115A: Bl88l .ngln!, 20 A:818C1cnginol fu!. In thr und.r{..htu.o/r.lly bor lnd tho 3P con-rcclo?.

View tromwire side

BLK (-)

(To page 11-7'l)

GRn/iED I - |

BLK/YEL I + I

11-70

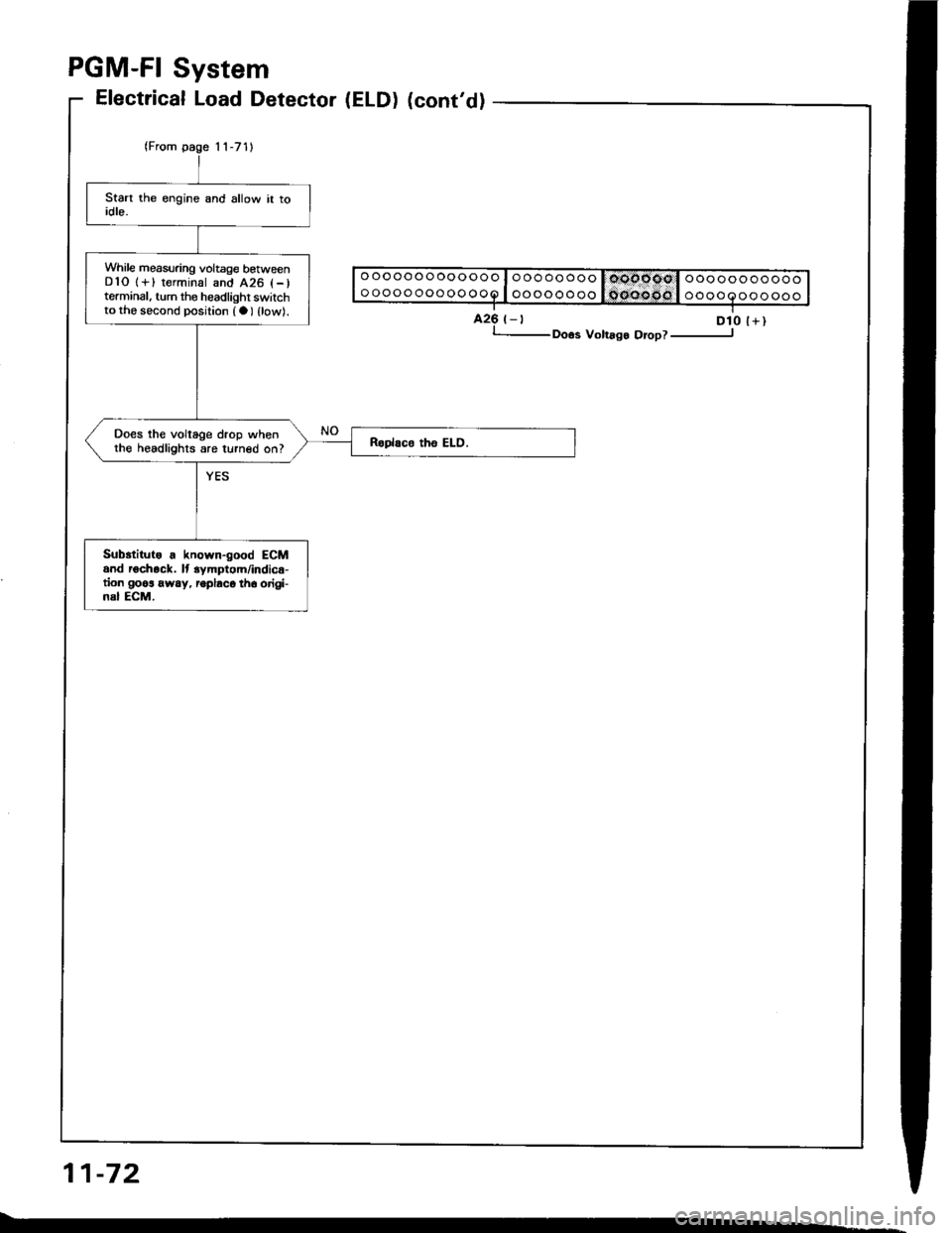

Page 262 of 1413

PGM-FI System

11-72

While measuring voltage betweenDlO 1+) terminal and 426 l-)terminal, turn the headlighr switchto the second position (a) {low).

Does the voltage drop whenthe headlights are turned on?

Subrtitute . known-good ECMand rochock. lt 3ymptom/indic€-tion goos away, ioplaco th6 origi-nal ECM.

Electrical Load Detector (ELD) (cont'd)

425 t-t D10 l+), Doos Volrago Orop? ----------------J

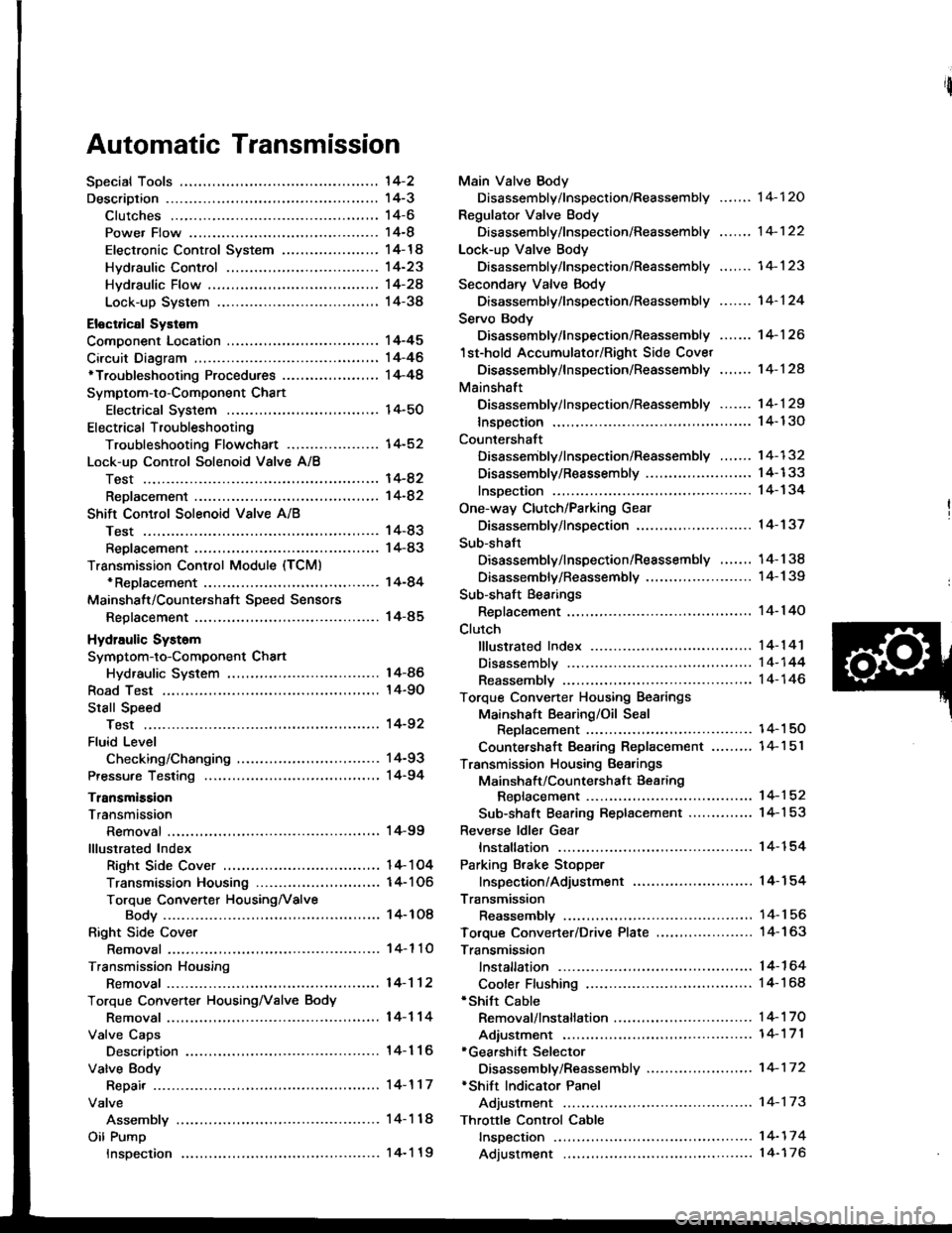

Page 393 of 1413

Automatic Transmission

'l4-2

14-3't 4-6

14-8

14-14

14-23

Hvdraulic Flow ...--...... 14-24

Lock-up System ........ 14-38

Eloctrical Systom

Component Location ............,...,................ I 4-45

Circuit Diagram ............. 14-46'Troubleshooting Procedures ........,..........., l4-48

Symptom-to-Component Chart

Electrical System ...... 14-50

Electrical Troubleshooting

Troubleshooting Flowchart .................... 14-52

Lock-uo Control Solenoid Valve A/8

Test .................. --.... \4-82

ReDlacement ,...,...,..,. 14-82

Shift Control Solenoid Vslve A/B

Test .................. ...... 14-83

Reolacement .............. 14-83

Transmission Control Module (TCM)*ReDlacement ........... 14-84

Mainshalt/CountershaJt SDeed Sensors

Reolacement ............. 14-85

Hydraulic Systom

Symptom-to-Component Chart

Hydraulic System

Road Test

Slall Speed

Test ..................

Fluid Level

Checking/Changing

Pressu.e Testing

Transmission

Transmission

Removal ............. ...... 14-99

lllustrated Index

Right Side Cover .................................. 1 4- 1 04

Transmission Housin9 ..................,,....... I 4-1 06

Torque Converter HousingNalve

Body .................. ... 14- 1O8

Right Side Cover

Removal ............. ...... 14-110

Transmission Housing

Removal ............. .-..-. 14-112

Torque Convener HousingNalve Body

Removal ............. ...... 14-114

Valve Caps

Description ................ 14-116

Valve Body

Repair ................ ...-.. 14-117

Valve

Assembly ...........

Oil Pump

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly .......

Secondary Valve Body

Disassembly/lnspection/Reassembly .......

Servo Body

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Covet

Oisassembly/lnspection/Reassembly .,..,..

Mainshaft

Disassembly/lnspection/Reassembly -.. -... 1 4- 1 29

lnsDection ................. 14- 130

Countershaft

Disassembly/lnspection/Reassembly ....... 14-132

Disassembly/Reassembly ....................... 1 4-1 33

lnsDection ................. 14-134

One-way Clutch/Parking Gear

Disassembly/lnspection .................... -.. -. 1 4-137

Sub-shaft

Disassembly/lnspection/Reassembly ....... 14-138

Disassemblv/Reassemblv ....................... 1 4-1 39

Sub-shaft Bearings

Replacement ............. l4-140

Clutch

fllustrated lndex ................. -..-...-.......... 14-1 41

Disassembly ,,,.,,........ 14-144

Reassembly .............. 14-146

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Reolacement ......... 14-1 50

Countershaft Bearing Replacement .......,, 14-1 5l

Transmission Housing Bearings

Mainshsft/Countershaft Bearing

Repfacement ...-..-..14-152

Sub-shaft Bearing Replacement .............. 1 4-1 53

Reve.se ldler Gear

lnstallation ................ 14-154

Parking Brake Stopper

lnspection/Adjustment ..........................'14-'154

Transmission

Reassemblv .............,. .14_156

Toroue Converter/Drive Plate ..,..,............... 1 4- 1 63

Transmission

14-120

14-122

14-123

14-124

14-126

14-124

14-86

14-90

't4-92

14-93

14-94

lnstallation

Cooler Flushing'Shitt Cable

Removal/lnstallation ..............................

Adiustment ...-..-......-. 14-'171*Gearshift Selector

Disassembly/Reassembly .....................,. 1 4-17 2*Shift Indicator Panel

Adjustment -..........-...14-173

Throttle Control Cable

fnspection .......,..,...... 14-17 4

Adjustment .............. 14-176

14-164

14-168

14-'t 7 0

Inspection

Page 442 of 1413

![HONDA INTEGRA 1994 4.G User Guide Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

Bl HONDA INTEGRA 1994 4.G User Guide Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

Bl](/img/13/6067/w960_6067-441.png)

Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

BlinksDisconnected lock-up control solenoidvalve A connector

Short or open in lock-up control sole-noid valve A wire

Faulty lock-up control solenoid valve A

Lock-up clutch does not

engage.

Lock-up clutch does not

disengage.

Unstable idle speed.

14-52

BlinksDisconnected lock-up control solenoidvalve B connector

Short or open in lock-up control sole-noid valve B wire

Faulty lock-up cont.ol solenoid valve B

. Lock-up clutch does not

enga9e.

14-54

Blinks or

OFF

Disconnected throttle position (Tp)

sensor connector

Short or open in TP sensor wireFaully TP sensor

. Lock-up clutch does not

engage.14-56

4BlinksDisconnected vehicle speed sensor(VSS) connector

Short or open in VSS wire

Faulty VSS

. Lock-up clutch does not

engage.'t 4-57

Blinks. Short in A/T gear position switch wire. Faulty A/T gear position switch

. Fails to shift other than

2nde4th gears.. Lock-up clutch does not

engage.

14-58

OFFDisconnected A/T gear position switch

connector

Open in A/T gear position switch wireFaulty A/T gear position switch

Fails to shift other than

2nd-4th gears.

Lock-up clutch does not

en98ge.

Lock-up clutch engages

and disengages alter-

nately.

14-60

7BlinksDisconnected shift control solenoidvalve A connector

Short or open in shitt control solenoidvalve A wire

Faulty shift control solenoid valve A

. Fails to shift (between

1st-4th, 2nd-4th or

2nd-3rd gears only).. Fails to shift (stuck in

4th gear).

14-62

8BlinksDisconnected shitt control solenoid

valve B connector

Shon or open in shift control solenoidvalve B wi.e

Faulty shift control solenoid valve B

. Fails to shiJt (stuck in

lst or 4th gears).'t 4-64

aBlinksDisconnected countershatt speed sen-sor connector

Short or open in the countershaft

speed sensor wire

Faulty countershaft speed sensor

. Lock-up clutch does not

engage_

14-50