Electrical HONDA INTEGRA 1994 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 466 of 1413

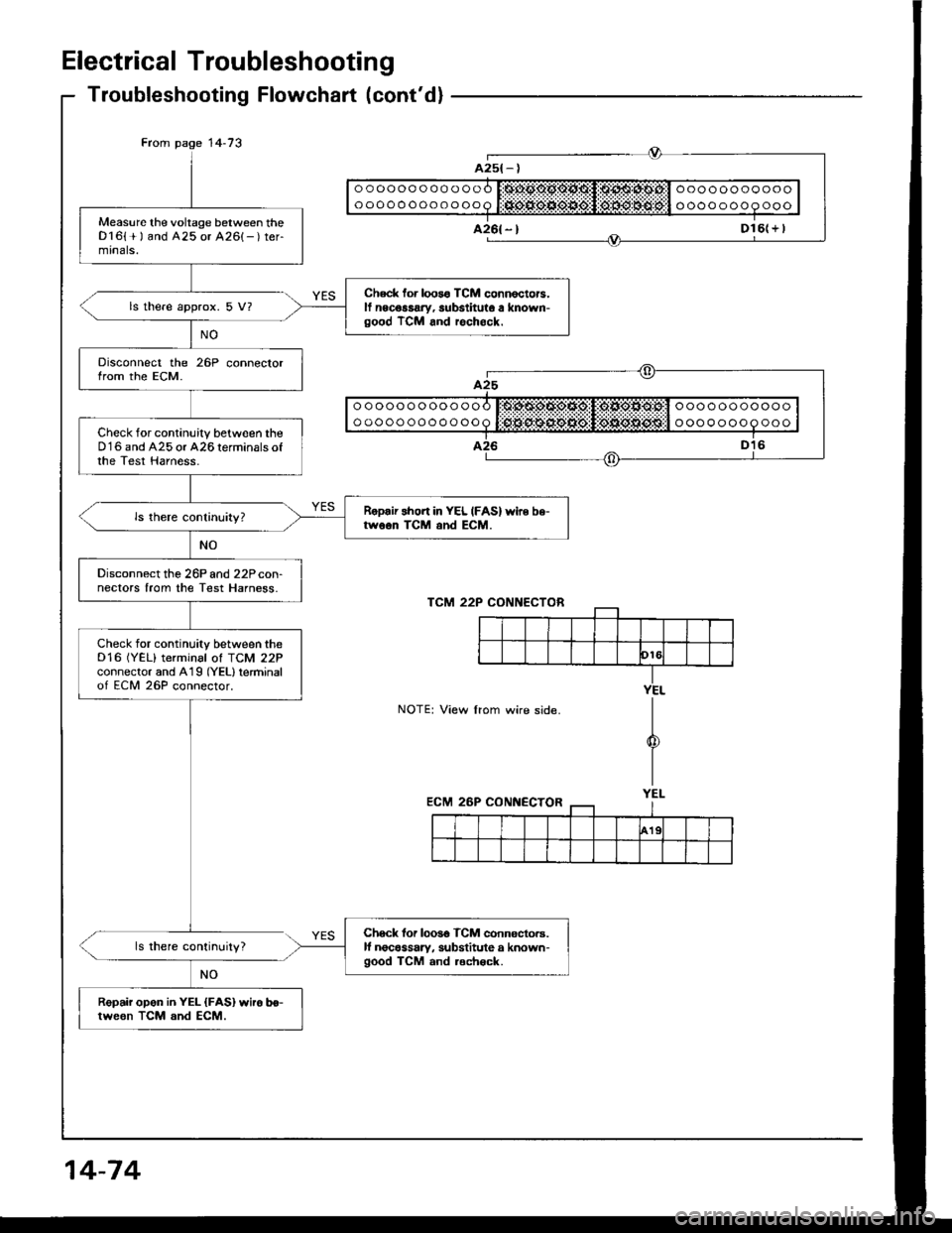

Electrical Troubleshooting

Troubleshooting Flowchart (cont'd)

ls there continuity?

o o o o o o o o O o O o O $:O.COOtt9O$:l:OtO:CtOiOi:l O o O O O O o O o o Oo o o o o o o o o o o o O I:f(O.{iltltO{t{t:I:OFA:F:d:O:l o o o o o o o O o o o

NOTE: View lrom wire side.

NO

From page 14-73

Measure the voltage between theD 16{+ ) and A25 or A26{- ) ter-mtnals.

Check for loos€ TCM connoctors.ll ngcossary, substituto a known-good TCM and rechock.

ls there approx. 5 V?

Disconnect the 26P connectorfrom the ECM.

Check for continuitv between theD16 and A25 or A26 rerminals ofthe Test Harness.

Ropairshort in YEL IFAS) wire be-tw6on TCM and ECM.

Disconnect the 26P and 22P con-nectors from the Test Harness.

Check for continuity between theD16 (YEL) terminal ot fCM 22Pconnector and A19 (YEL) terminalof ECM 26P connector.

Chgck tor loos€ TCM connoctofs.lf nocassary, substitute o known-good TCM and rech6ck.

Ropair opon in YEL {FAS} wiro bo-trve€n TCM and ECM.

oooooooooooo

oooooooooooo

ooooooooooo

ooooooooooo

22P CONNECTOB

Page 467 of 1413

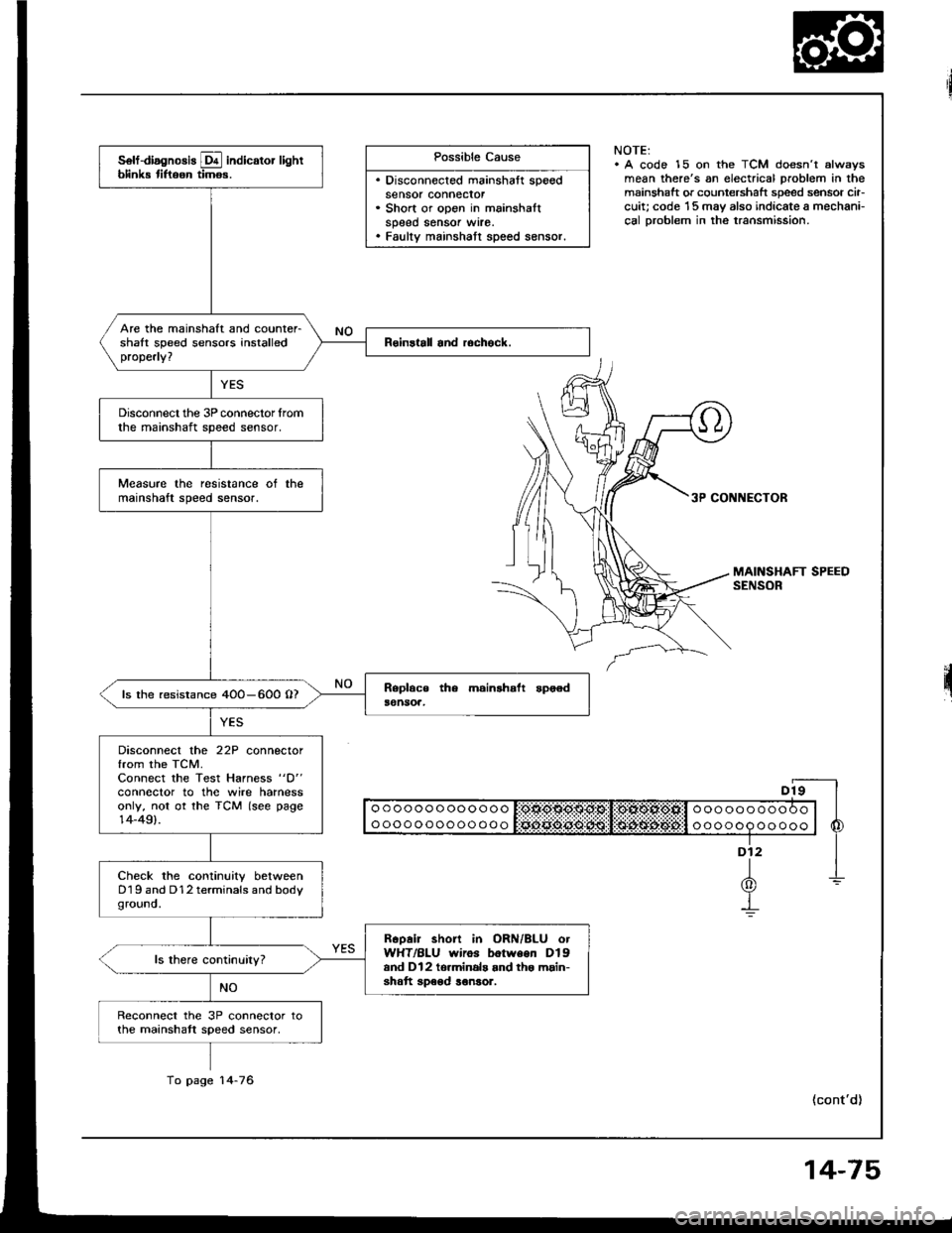

Possible Cause

. Disconnected mainshaft speedsensor connecror. Short or open in mainshaltspeed sensor wrre.. Faulty mainshatt speed sensor.

NOTE:. A code 15 on the TCM doesn't alwsysmean there's an electrical problem in themainshaft or countershaft speed sensor cir-cuit; code '15 may also indicate a mechani-cal Droblem in the transmission.

3P CONNECTOR

II o o o o o o o oo o o o o I:OtlO$O$g:Sl!:OlXOl*Ofill o o o o o o o o o O o | |

I ooooooooooooo l Sciii:ddii:ijii:l:i$idi$;d6#:l o oooop oo ooo | 6

"-f

1-L(0)Y-!

(cont'd)

solf-diagnosis E indicator lightblink tiftoon timos.

Are the mainshaft and counter-shalt speed sensors installedproperly?

Disconnect the 3P connector lromthe mainshaft speed sensor.

Measure the resistance ot themainshaft speed sensor.

ls the resistance 4OO-600 O?

Disconnect the 22P connectorfrom the TCM.Connect the Test Harness "D"

conneclor to the wire harnessonly, not ot the TCM (see page14-49).

Check the continuity betweenD19 and D12 terminals and bodyground.

Rcoair short in ORN/BLU otWHT/BLU wiros botween Dlgand Dl2 to.minals and tho main-shatt speod ronsor.

Reconnect the 3P connector tothe mainshatt speed sensor,

To page 14-76

14-75

Page 468 of 1413

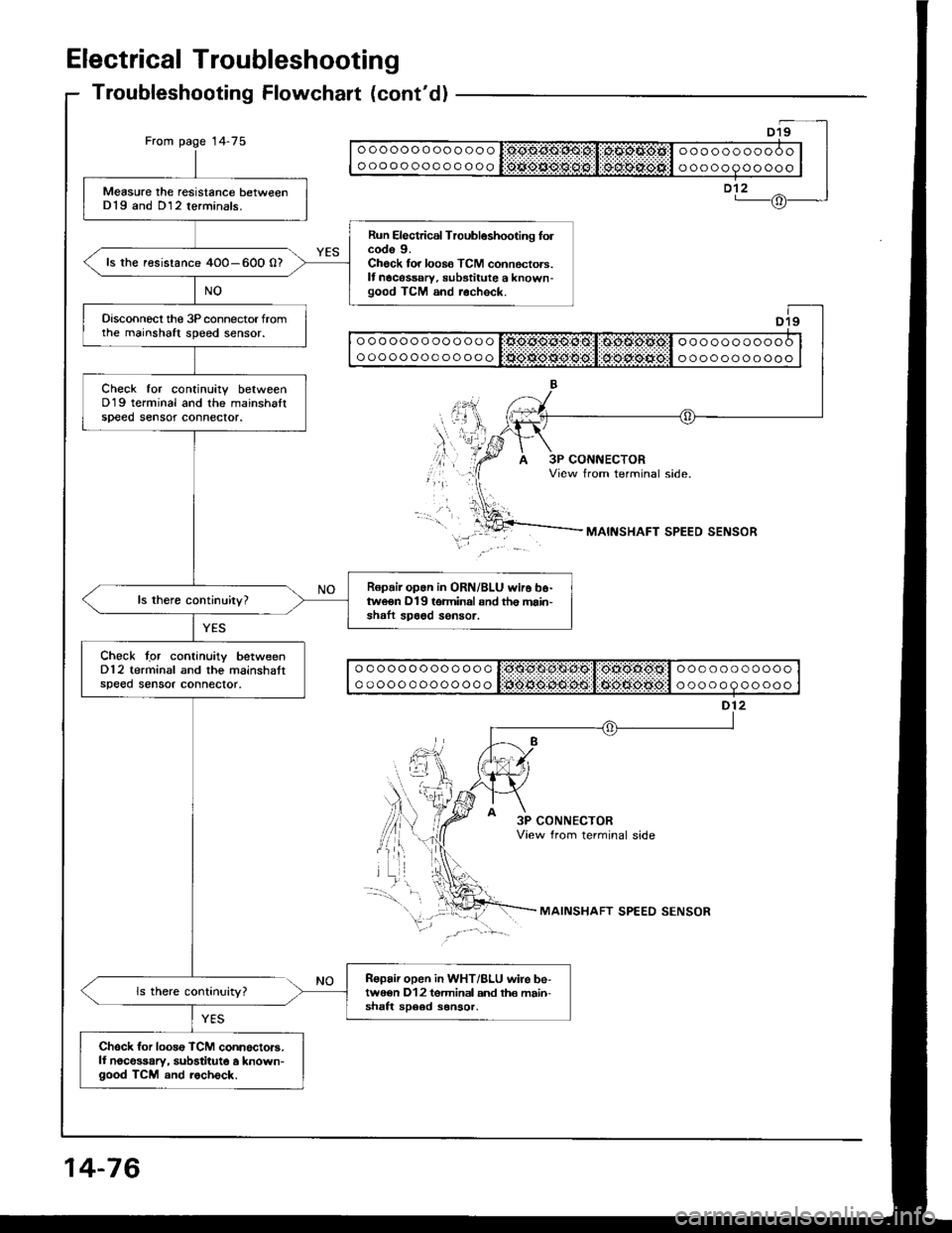

Electrical Troubleshooting

Troubleshooting Flowchalt (cont'd)

From page 14-75ooooooooooooo

oooooooooooooooooooooooo

ooooooooooo

Measure the resistance betweenD19 and D12 terminals.

Run Electrical Troubleshooting folcode 9.Check for loos6 TCM connectors.It nocessary, substitute a known-good TCM and r.check.

ls the resistance 4O0-600 0?

Disconnecl the 3P connector fromthe mainshaft speed sensor.

Check tor continuitv betweenD19 terminal and the mainshaltspeed sensot connector.

Ropair op.n in ORN/BLU wir6 b6-tweon D19 terminal snd th€ main'shaft spa6d sensor.

Chock tgr continuity betweenD12 terminal and the mainshattspeed sensor connector.

Ropair open in WHT/BLU wire be-twe€n D12 tgrminal and th€ main-shaft sD6ed sonsor.

Chsck for loos€ TCM connoctors.ll noco$ary, substitute a known-good TCM and rocheck.

ooooooooooooo

ooooooooooooooooooooooo

ooooooooooo

ooooooooooooo

ooooooooooooo

ooooooooooo

ooooooooooo

MAINSHAFT SPEED SENSOR

3P CONNECTORView from terminal side

MAINSHAFT SPEED SENSOR

14-76

Page 470 of 1413

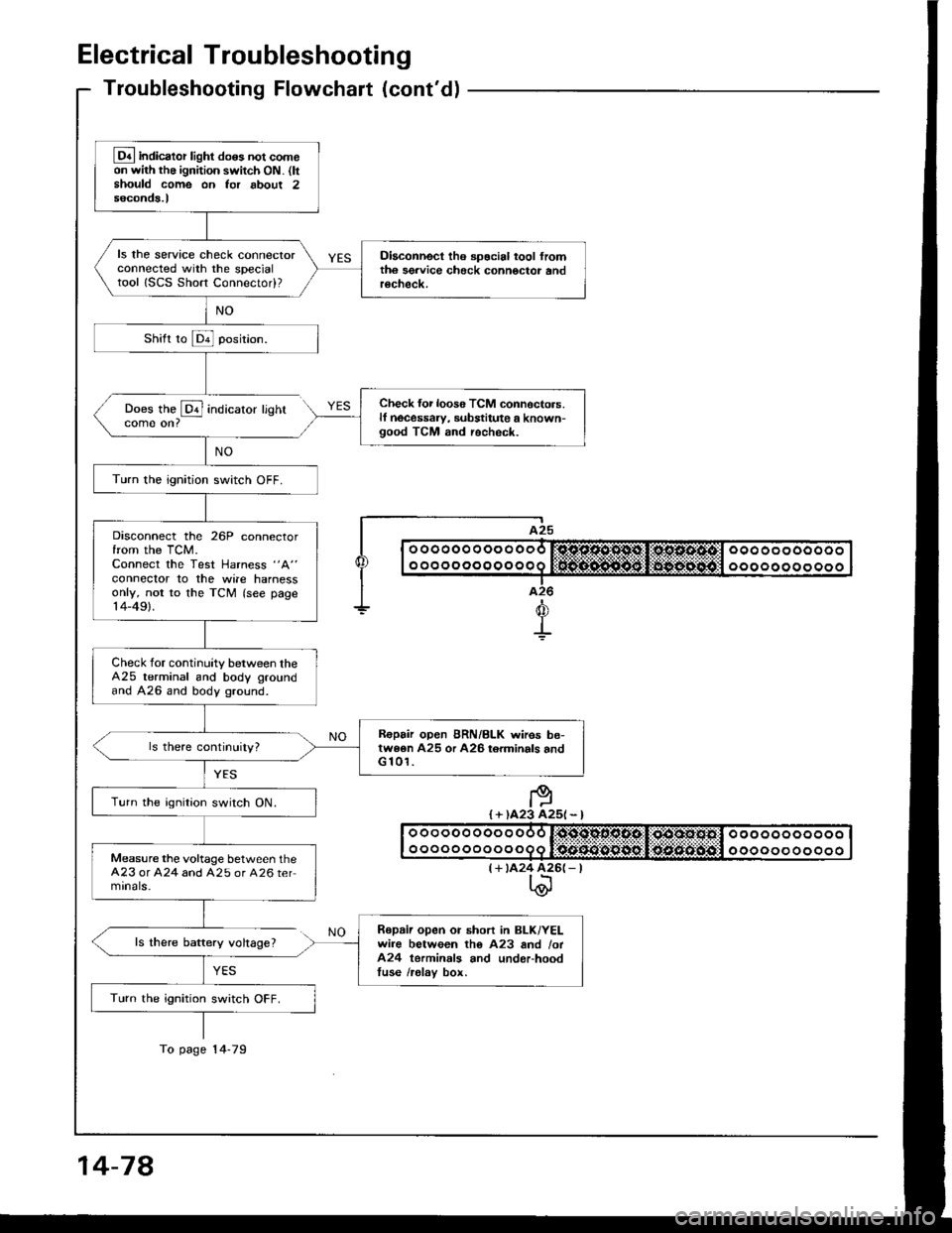

Electrical Troubleshooting

Troubleshooting Flowchaft (cont'dl

Does the @ indicatorcome on?

ls there baftery voltage?

YES

lighr

I A25

| | o ooooo o oo o ooo r:sjc.o.sl'1*st,li*os.s.4tcl ooo oo oooooo I

I I o o o o o o o o o o o o q lifrif.S..n${5git:li$gg-:aiiigitll o o o o o o o o o o o I|--.-T..-I a26

+d

+

I + )A23 A25l - l

(+ tA24 426(- |t\@

Lq4 indicator light do6s not comeon with the ignition switch ON. (ltshould come on Ior about 2seconds.l

ls the service check connectorconnected with the specialtool ISCS Short Connectod?

Diaconnect tho spocial tool fromth6 sgrvice check connoctor andrecheck.

Check {or loos6 TCM connoctors.lf necessaw, substitute a known-good TCM and recheck.

Turn the ignition switch OFF.

Disconnect the 26P connectorfrom the TCM.Connect the Test Harness "A"

conneclor to the wile harnessonly, not to the TCM (see page14-49).

Check for continuity between theA25 terminal and body groundand A26 and body ground.

R€pair open BRN/BLK wires be-twe6n A25 or A26 torminals andG 101.

Turn the ignition switch ON.

Measure the voltage between theA23 or A24 and A25 or A26 termrnals-

Repaii open or short in BLK/YELwire between tho A23 and /ot424 terminals and underhoodtuse /relav box.

Turn the ignition switch OFF.

To page 14-79

14-78

Page 472 of 1413

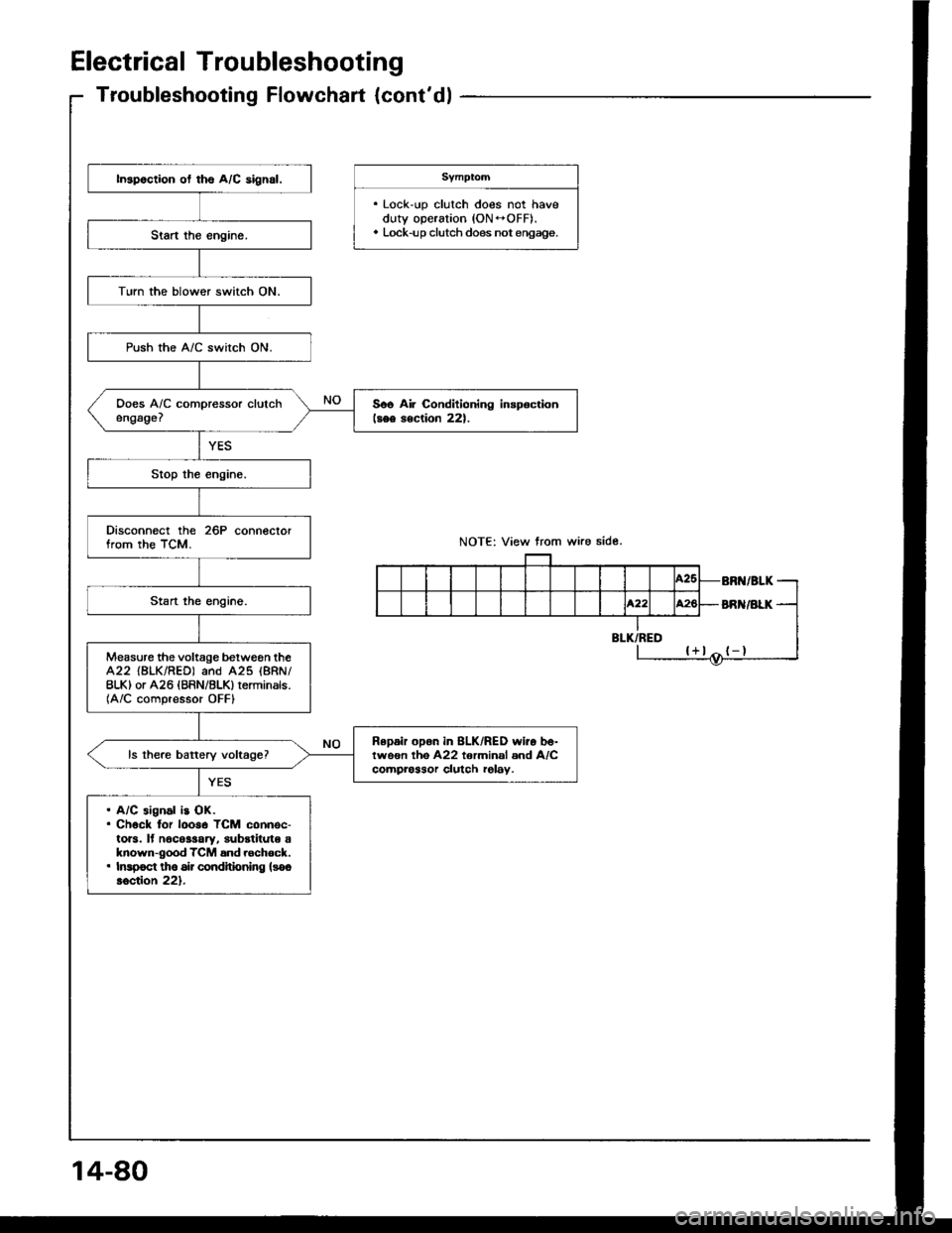

Electrical Troubleshooting

Troubleshooting Flowchart {cont'dl

. Lock-up clutch does not haveduty operation (ON -OFF).. Lock-up clutch does not engage.

In3poction ol ths A/C aign6l.

TLrrn the blower switch ON.

Push the A/C switch ON.

Soe Air Condilioning inspoctionlsee rection 221.

Disconnect the 26P conneclorfrom the TCM.

Measure the voltage between theA22 {BLK/RED) and A25 (8RN/

BLKI or A26 IBRN/BLK) terminals.(A/C compressor OFFI

Repair opon in 8LK/RED wiio b6-twoon lho A22 torminal and A/Ccomprossor clulch rel6y.

. A/C aignal ls OK.. Chock lor looso TCM connec-toB. lf n6co$ary, substitute aknown-good TCM and rschock.. Inrpoct tho 6ir condhioning lsooloction 221.

BR /ALK

Page 476 of 1413

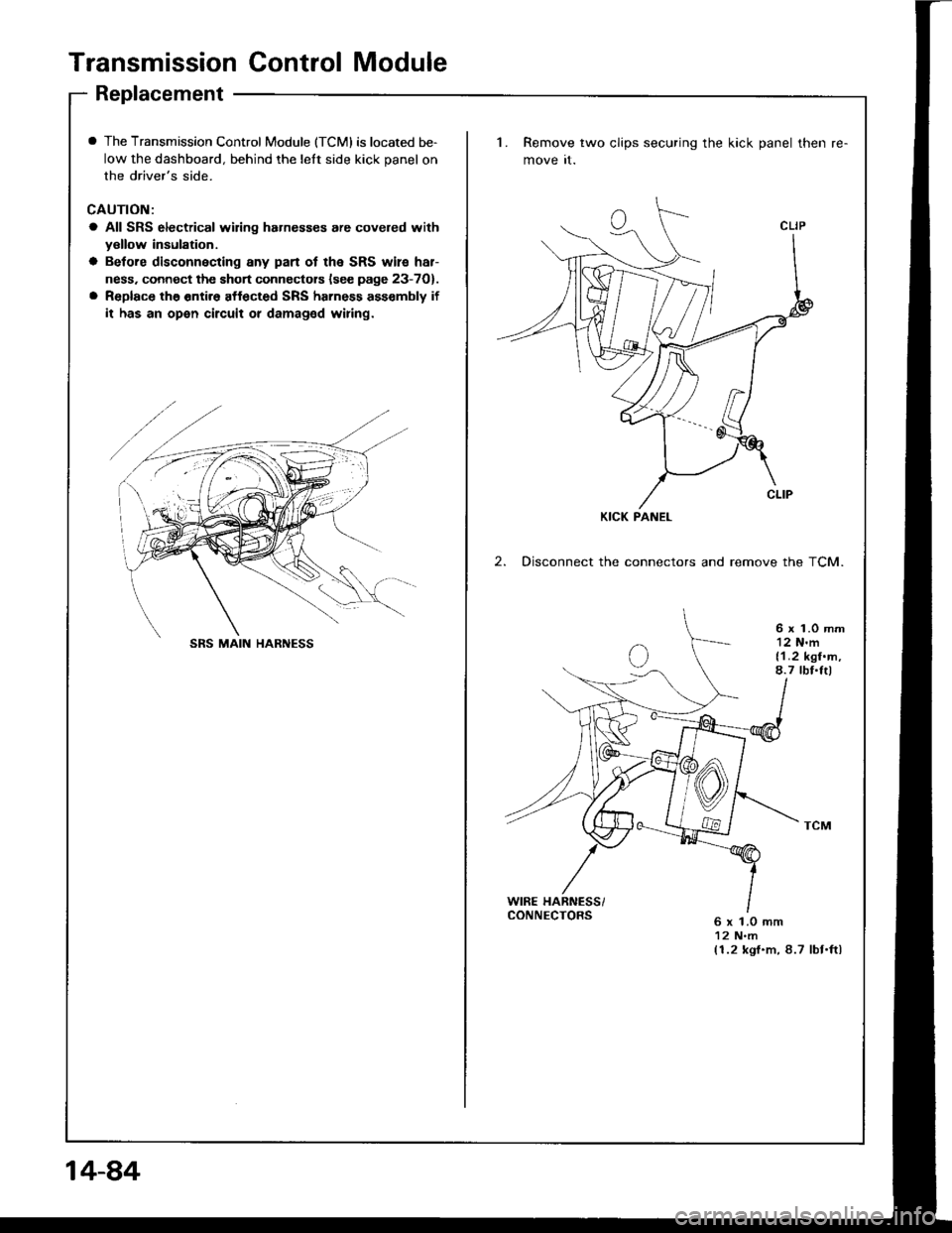

Transmission Control Module

Replacement

I The Transmission Control Module (TCMI is located be-

low the dashboard, behind the lelt side kick panel on

the driver's side.

CAUTION:

a All SRS electrical wiring hahesses are covered withyellow insulation.

a Betore disconnecting any pan ot the SRS wile har-

ness. connect the short connectors lsee page 23-7O).

a Replace the entir6 affected SRS harness ass€mbly if

it has an open circuit or damaged wiring.

1. Remove two clips securing the kick panel then

move it.

2. Disconnect the connectors and remove the TCM.

6 x 1.0 mm12 N'm{1.2 kgf.m,8.7 tbf.Itl

WIRE HARNESS/CONNECTORS6 x 1.0 mm12 N.m(1.2 kgf.m, 8.7 lbt.ftl

KICK PANEL

SRS MAIN HARNESS

14-84

Page 560 of 1413

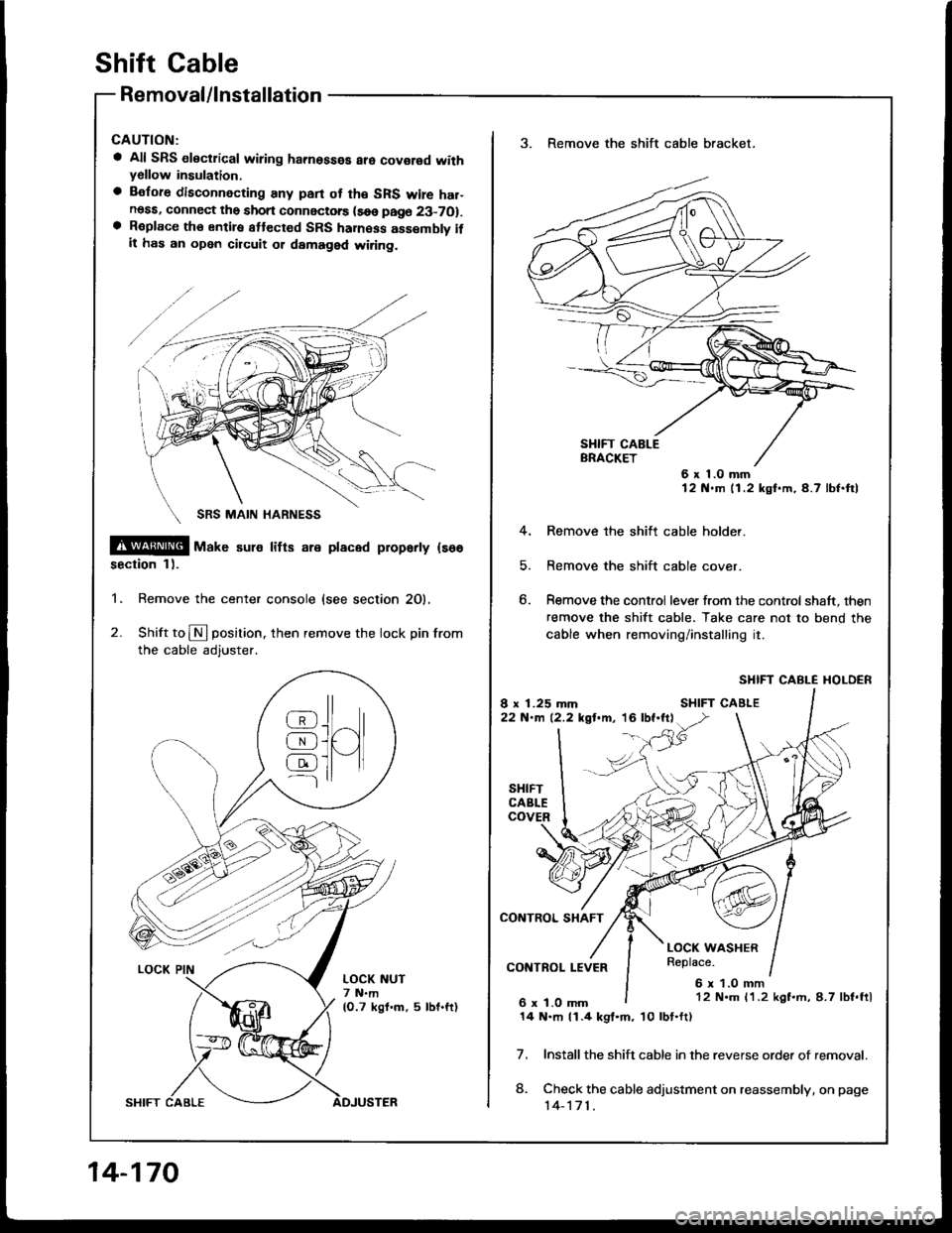

shift cable

Removal/lnstallation

a All SRS electrical wiring hamosses are covor€d withyellow insulation.

a Before disconnecting any pan ot th€ SRS wire har-noss, connect the short connectorc (soe page 23-7O1.a Roplace th€ entiro attect€d SRS haness assembly itit has an open circuit ot damaged wi.ing.

@@[ uar" sul€ litts are placed proparty {so6

section 1).

1. Remove the center console {see section 20).

2. Shift to N position. then remove the lock pin from

the cable adjuster.

@J^ll

AJUI[qJ ]l tl---l

LOCK NUT7 N.m(O.7 kgf.m, 5 lbf.ft)

14-170

3. Remove the shift cable bracket.

6x1.0mm12 N.m 11.2 kgf.m,4.7 lbf.ftl

4. Remove the shitt cable holder.

5. Remove the shift cable cover.

6. Remove the control lever from the control shaft, then

remove the shift cable. Take care not to bend the

cable when removing/installing it.

SHIFT CABLE I{OLDER

Install the shift cable in the reverse orde. of removal.

Check the cable adjustment on reassembly, on page

14-171.

7.

8.

12 N.m 11.2 kgf.rh, 8.7 lbf.ftl

14 N.m 11.4 kgl.m, 10lbt.ft)

Page 561 of 1413

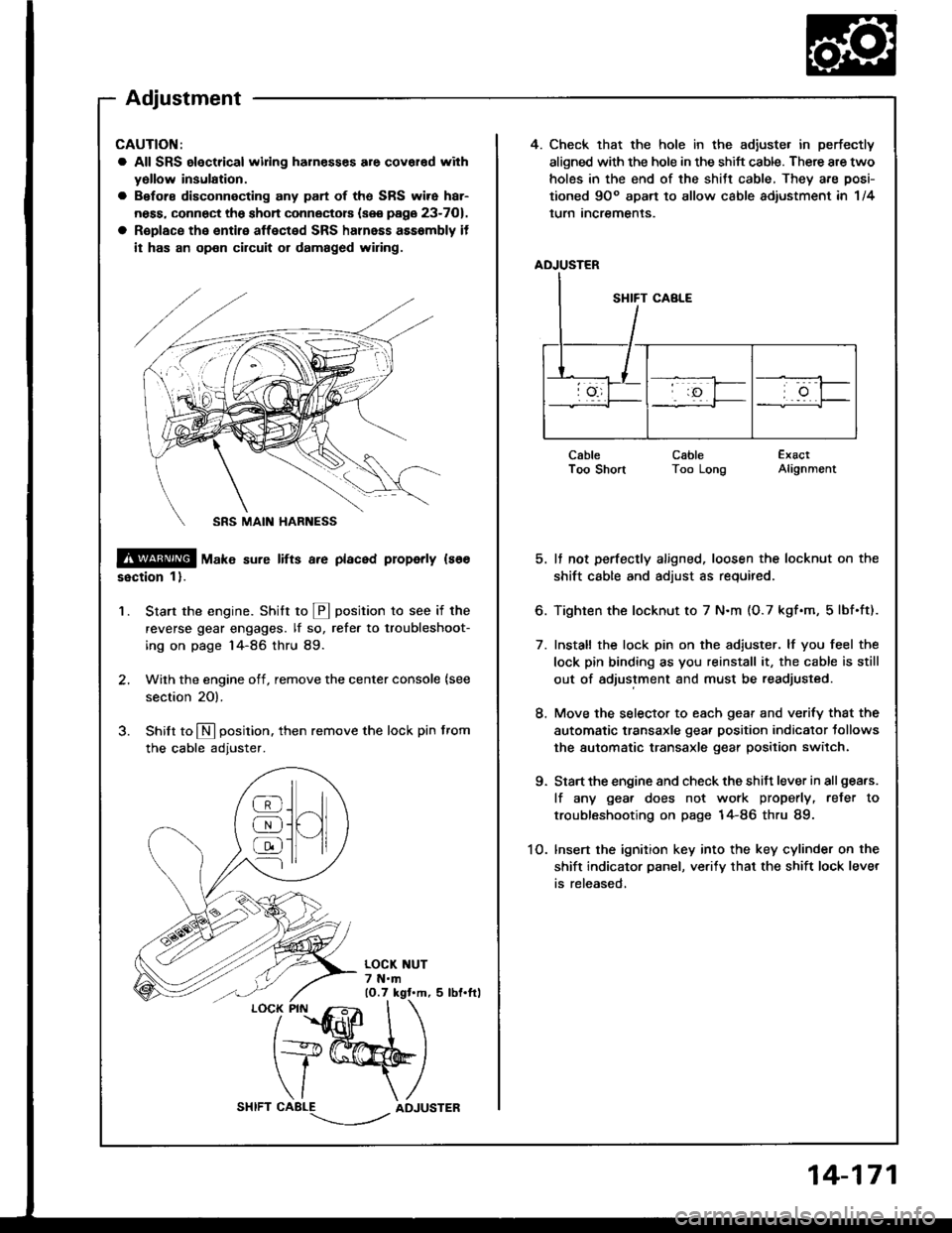

4. Check that the hole in the adiuste. in perfectly

aligned with the hole in the shift cable. There are two

holes in the end of the shitt cable, They are posi-

tioned 9Oo apart to allow cable adiustment in 1/4

lurn Incremenls.

ADJUSTER

CableI oo snonCableToo LongExactAlignment

5. It not perfectly aligned, loosen the locknut on the

shift cable and adjust as required.

6. Tighten the locknut to 7 N.m (O.7 kgf.m, 5lbf.ft).

7. Install the lock pin on the adiuster. lf you feel the

lock pin binding as you reinstall it, the cable is still

out of adjustment and must be readjusted.

8. Move the selector to each gear and verify that the

automatic transaxle gear position indicator tollows

the automatic transaxle gear position switch.

9. Start the engine and check the shift lever in all gea.s.

lf any gea. does not work properly, refer to

troubleshooting on page 14-86 thru 89.

1O. lnsert the ignition key into the key cylinder on the

shift indicator panel, ve.ify that the shift lock lever

is released,

CAUTION:

a All SRS electrical widng harn€sses are covar€d with

yollow insulation.

a Before disconnecting any part of ths SRS wire har-

ness, connect the shon connectors (see page 23-701.

a R€place the entire affected SRS halnass asssmbly it

it has an op€n circuit or damaged wiring.

@ tu"t" sure lifts a.e placed properly ls66

ssction 1).

Start the engine. Stritt to @ position to see if the

reverse gear engages. lf so, refer to troubleshoot-

ing on page 14-86 thru 89.

Wilh the engine off, remove the center console {see

section 20).

Shilt to N position. then remove the lock pin from

the cable adjuster.

'1.

/

''fidlfr

I

t+@

\/ \

CABLE-.'.-_--l../ADJUSTER

]H

@

@

@

Adjustment

14-171

Page 562 of 1413

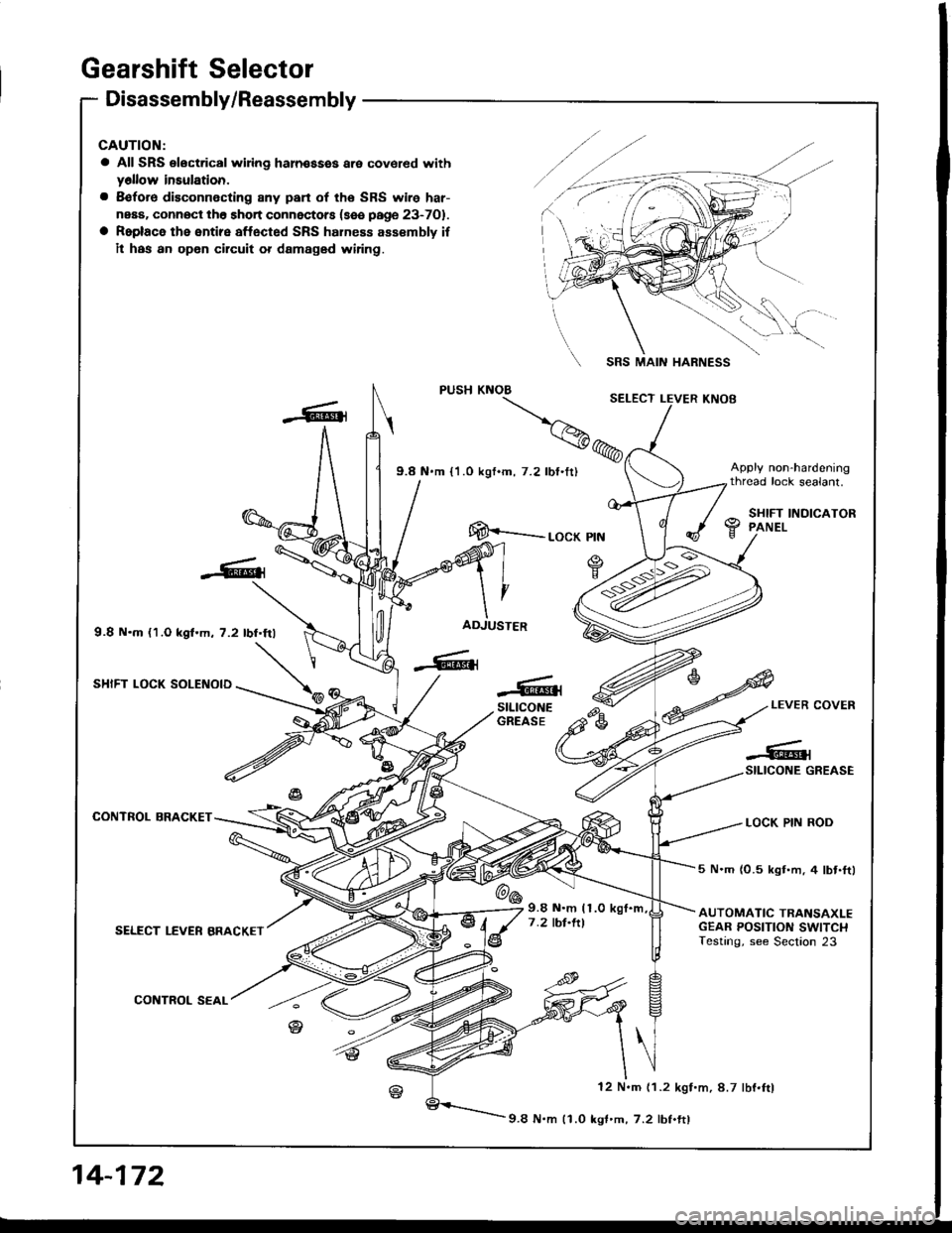

Gearshift Selector

Disassembly/Reassembly

CAUTION:

a All SRS electrical wiing haln€ssss are covered withy6llow insulation.

a 8€fore disconnecting 8ny pan of the SRS wire har-

neaa. connOct th6 short connectors (sse page 23-701.

a Roplace the entire affected SRS hahess assembly if

il has an opon circuit or damaged wiring.

9.8 N.m {1.O kgf.m, 7.2 lbf.frl

SHIFT LOCK SOLENOID

CONTROL BRACKET

SELECT LEVER BRACKET

CONTROL SEAL

SRS MAIN HARNESS

[E--__ rocK ptN

ADJUSTER

-6{stLtcoNEGREASEe-LEVER COVER

LOCK PIN ROD

-#qSILICONE GREASE

@6

5 N.m (0.5 kgt.m, 4 lbt.ftl

AUTOMATIC TRANSAXLEGEAR POSITION SWITCHTesting, see Section 23

9.8 N.m (1.0

7 .2 tbt.ltl

12 N.m (1.2 kgf.m, 8.7 lbf.ftl

9.8 N.m 11.0 kgf'm,7.2 lbf.ftl

14-172

Page 631 of 1413

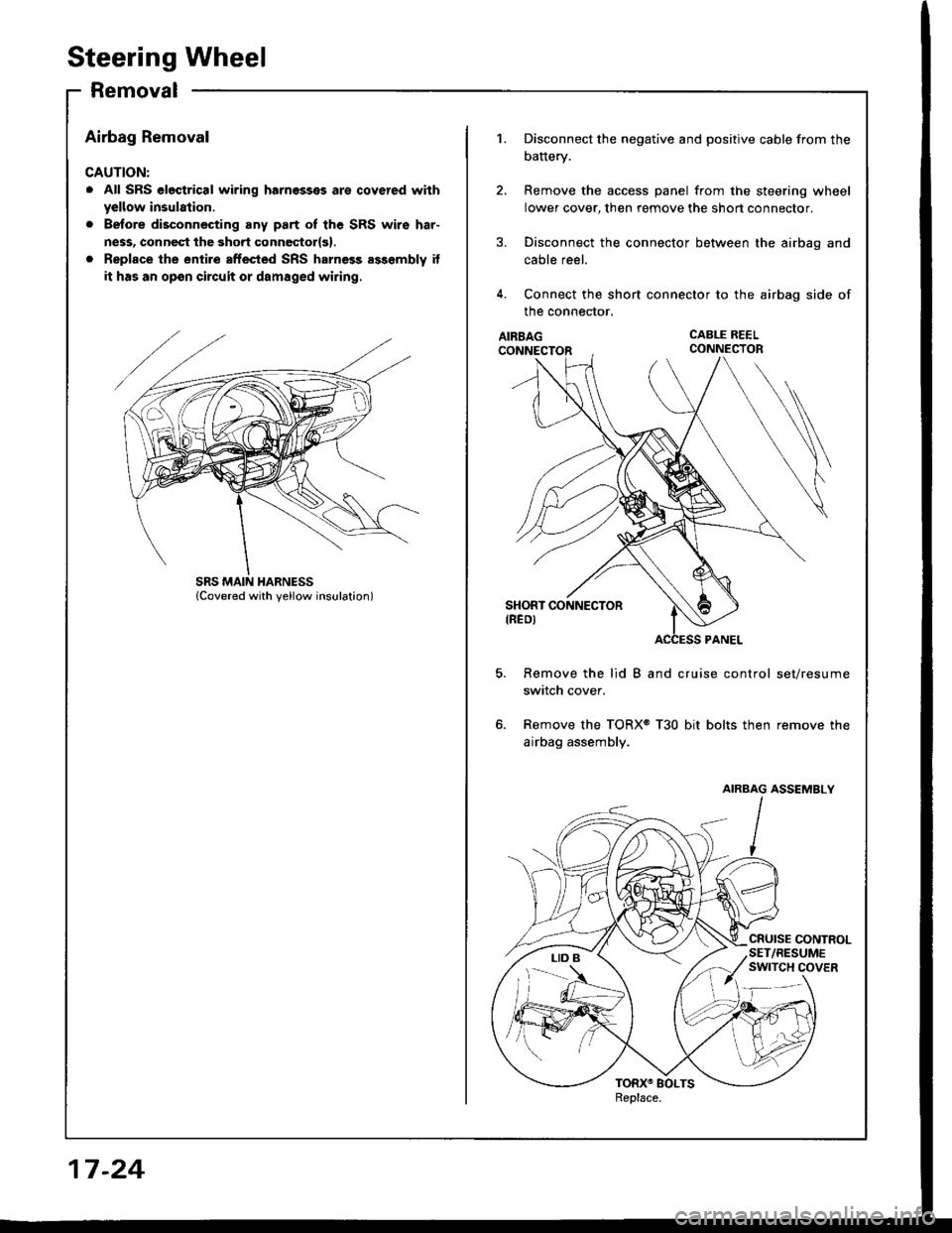

Steering Wheel

Removal

Airbag Removal

CAUTION:

. All SRS electrical wiring harnosses are covered with

yellow insulation.

. Before disconnecting any part oI the SRS wiro har-

ness, connect the 3hort connector{g}.

. Replace the entire sffected SRS harness assembly it

it has an opon circuit or damaged wiring.

17-24

1.

AIRBAGCONNECTOR

CABLE REELCONNECTOR

Disconnect the negative and positive cable from the

battery.

Remove the access panel from the steering wheel

lower cover, then remove the shon connector.

Disconnect the connector between the airbag and

cable reel.

Connect the shon connector to the airbag side of

the connector.

Remove the lid B and cruise control set/resume

switch cover.

Remove the TORX@ T30 bit bolts then remove the

airbag assembly.

AIRBAG ASSEMBLY