Electrical HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1195 of 1413

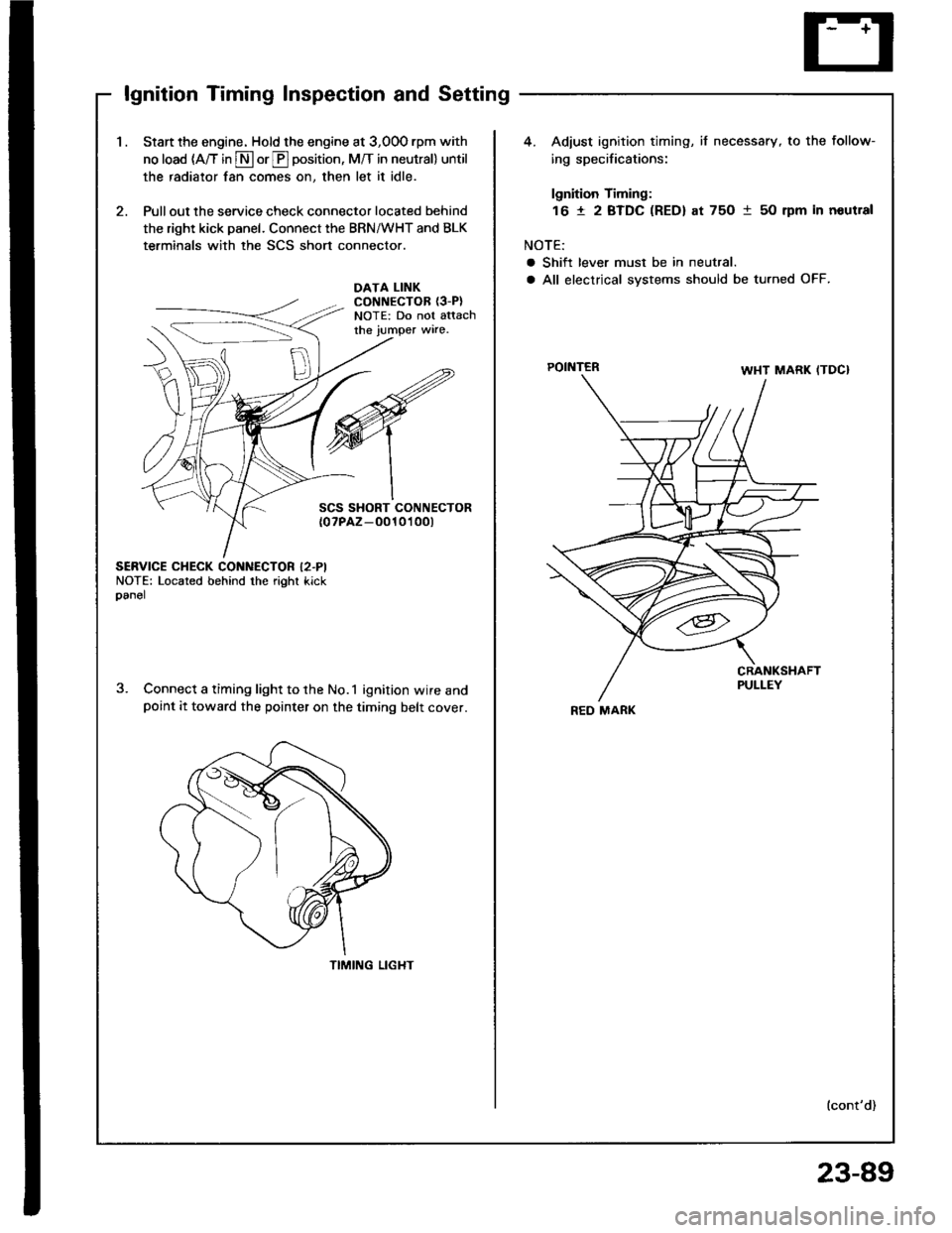

lgnition Timing Inspection and Setting

1.Start the engine. Hold the engine at 3,00O rpm with

no load (A/T in S or E position, M/T in neutral) until

the radiator fan comes on, then let it idle.

Pull out the service check connector located behind

the right kick panel. Connect the BRN/WHT and BLK

terminals with the SCS short connector.

4. Adiust ignition timing, if necessary, to the follow-

ing specifications:

lgnition Timing:

16 t 2 BTDC (RED) at 75O 1 50 rpm in noutral

NOTE:

a Shift lever must be in neutral.

a All electrical systems should be turned OFF.DATA LINKCONNECTOR {3-P}NOTE: Do not attachthe jumper wire.

POINTER

SCS SHORT CONNECTOR{0?PAZ-O010't 00t

SERVICE CHECK CONNECTOR I2.PINOTE: Located behind the right kickoanel

Connect a timing light to the No.1 ignition wire andpoint it toward the pointer on the timing belt cover.

TIMING LIGHT

lcont'd)

REO MARK

23-89

Page 1196 of 1413

lgnition System

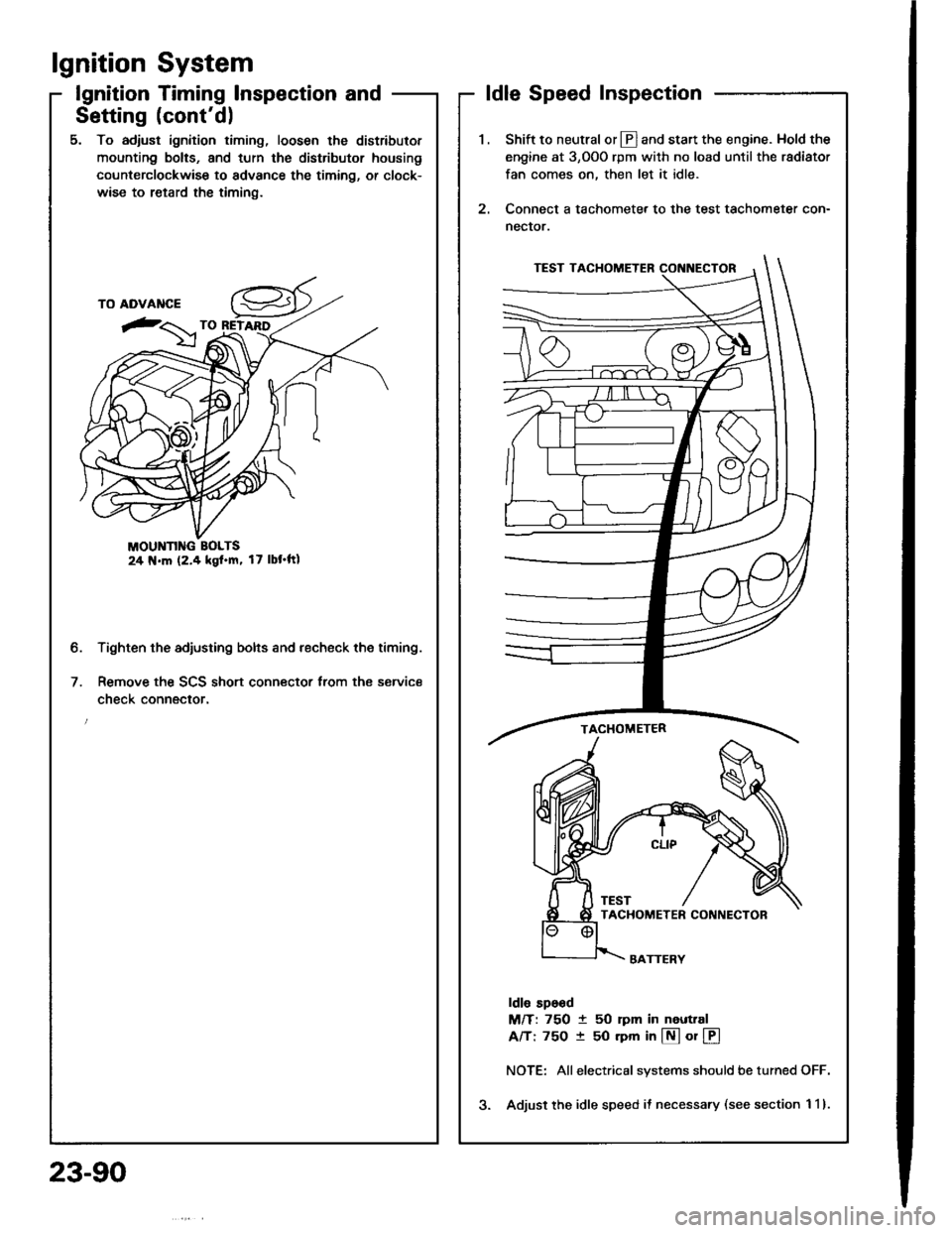

lgnition Timing lnspection and

Setting (cont'd)

5. To adjust ignition timing, loosen the distributor

mounting bolts, and turn the distributor housing

counterclockwise to advance the timing, or clock-

wise to retard the timing.

MOUNN G BOLTS24 N.m (2.4 kgl.m, 17 lbt'ftl

Tighten the adjusting bolts and recheck the timing.

Remove the SCS short connector trom the service

check connector.

2.

ldle Speed Inspection

Shift to neutral or Ll] and start the engine. Hold the

engine at 3,OOO rpm with no load until the radiator

fan comes on, then let it idle.

Connect a tachometer to the test tachometer con-

nector.

ldle sp6od

M/T: 750 t 50 rpm in neuttal

A/T: 75O t 50 rpm in @ or @

NOTE: Allelectrical systems should be turned OFF.

Adjust the idle speed il necessary (see section 1 1).

b.

23-90

Page 1204 of 1413

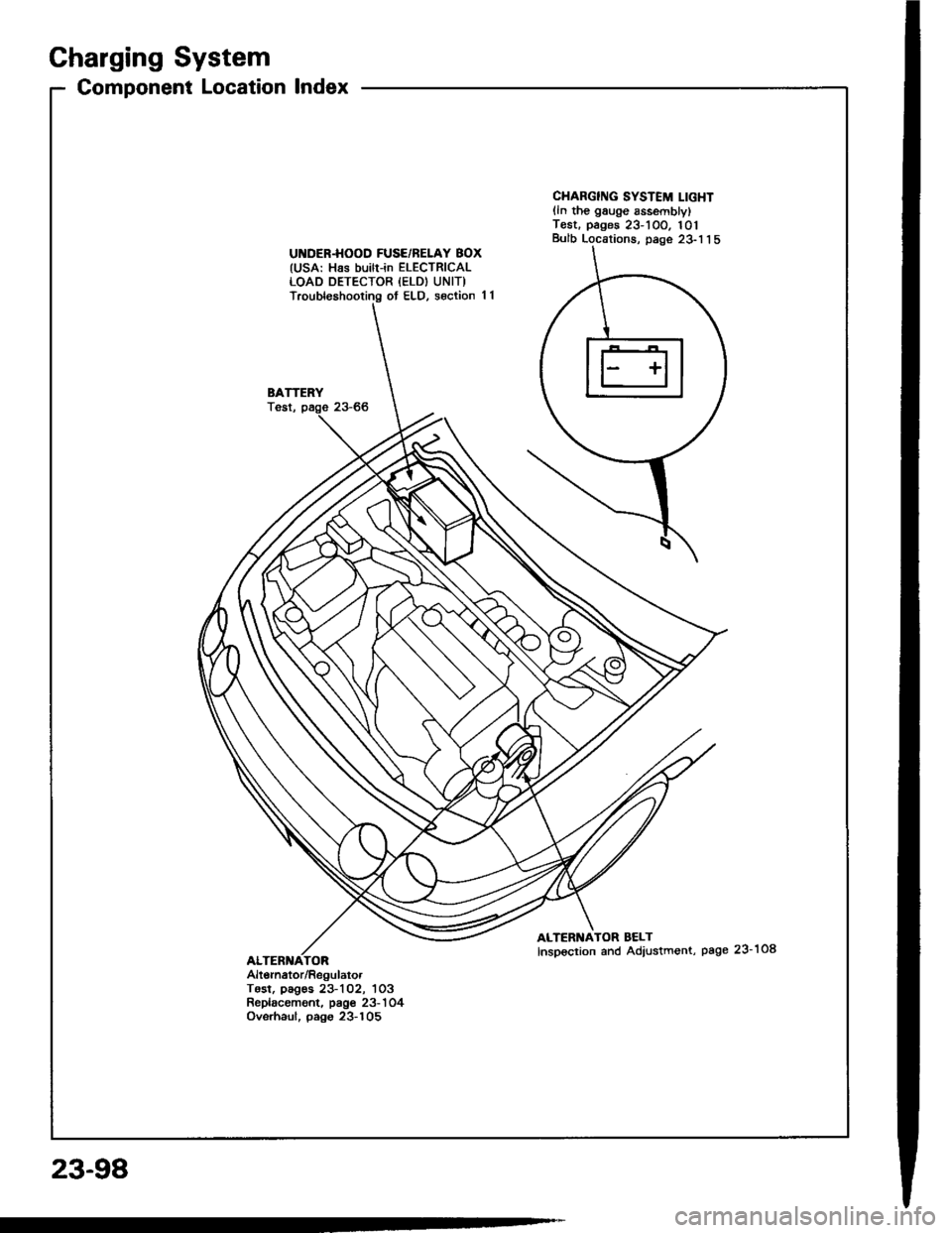

Charging System

Component Location lndex

UI{DER.HOOD FUSE/BELAY BOX(USA: Has builr-in ELECTRICALLOAD DETECTOR {ELD) UNIT)Troubleshooting ot ELD, s€ction 11

BATTERYTost,

CHARGING SYSTEM LIGHTlln the gauge sssemblylT€st. pages 23-1OO. 101Bulb Locations, page 23-1 1 5

ALTERNATOR BELTInspoction and Adiustment, page 23-108

Alt6rnator/RegulatorTosl, pag€s 23-102, 1O3Replacament. page 23-'l 04Ovsrhaul, pago 23-105

23-98

Page 1208 of 1413

Charging System

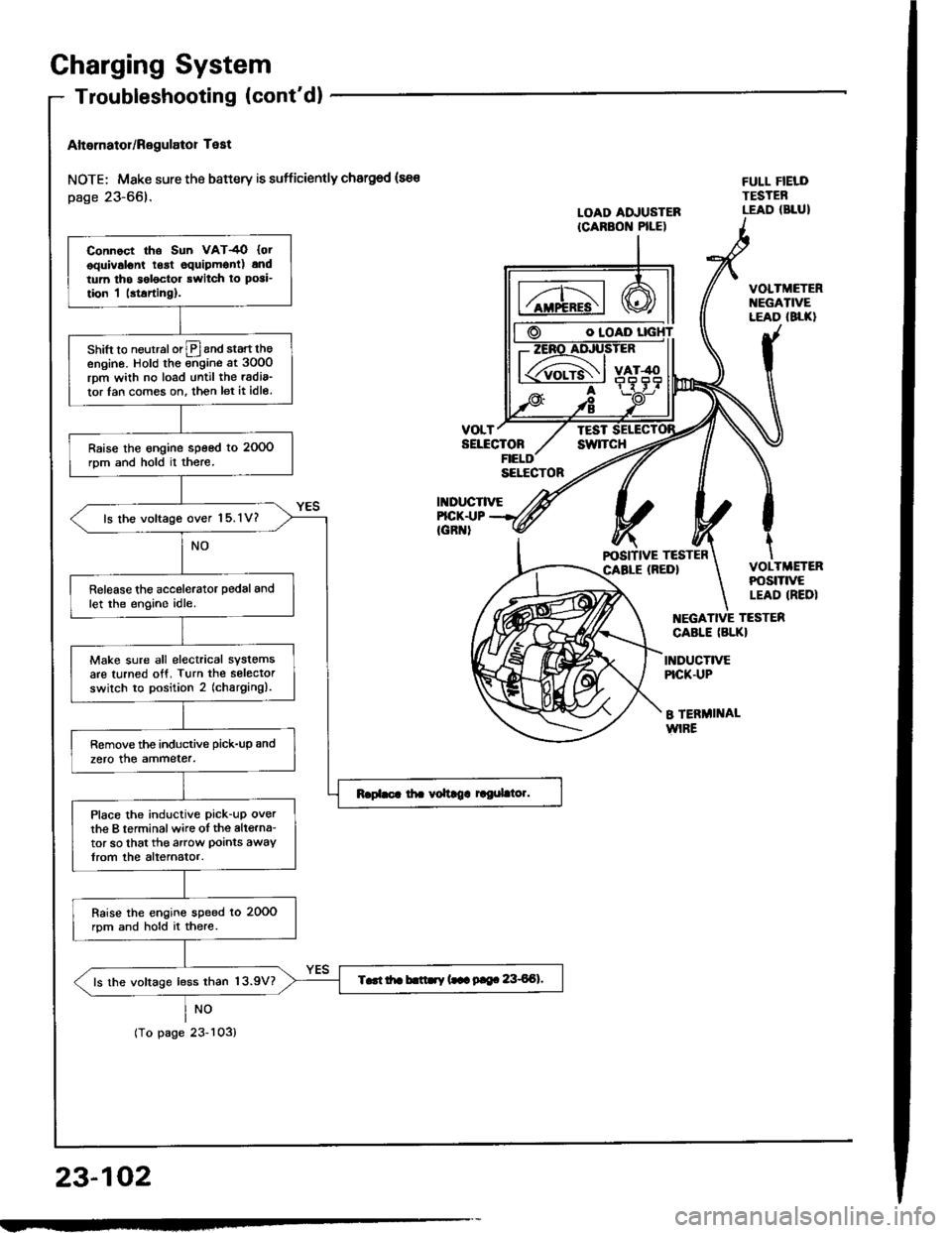

Altornator/Regulator Test

NOTE; Mske sure the battery is sufficiently chargod (sa€

page 23-66).

NO

tropagezJ-ruJ,

O IOAD

VOLTTESTSELECTONswlTcH

II{DUCTIVE

FULL FIELDTESTEBLEAD (BLUILOAD ADJUSTERICARBON PILE)

FICK.I.|PIGR '

VOLTMETERt{EGATIVELEAD (8LK}

VOLTMETERPOStTtVELEAD IREDI

EGATIVE TESTER

CABLE (BLKI

INDUCTIVEPICK.UP

B TERMI]TALWIRE

23-102

Connoct tho Sun VAT4O {otooulvslont lgrt equipmonl) andtum tho s6l6ctor rwitch ro posi_

tion I |rtarting).

shift to neurralorlPland start theengino. Hold the ;;gine at 3oO0rpm wiih no load until the radia_

tor lan com€s on. then let it idle.

Raise the engine speed to 2OOOrom and hold il there.

ls lhe voltage over 15.1V?

Release the accelerator pedal andlet the engino idle.

Make sure all electrical systemsare turned otf. Turn the selectorswilch to position 2 (charging).

Remove the inductive pick-up and

zero the ammeter.

Place the inductive pick-uP overthe B terminalwire oI the altgrna-tor so that the arow Doints awaytrom the alternator.

Raise the engins speed lo 20OOrpm and hold it there.

T..t itr b.ttry (.- 9|e. 8€Al.ls the voltage less than 13.9V?

Page 1219 of 1413

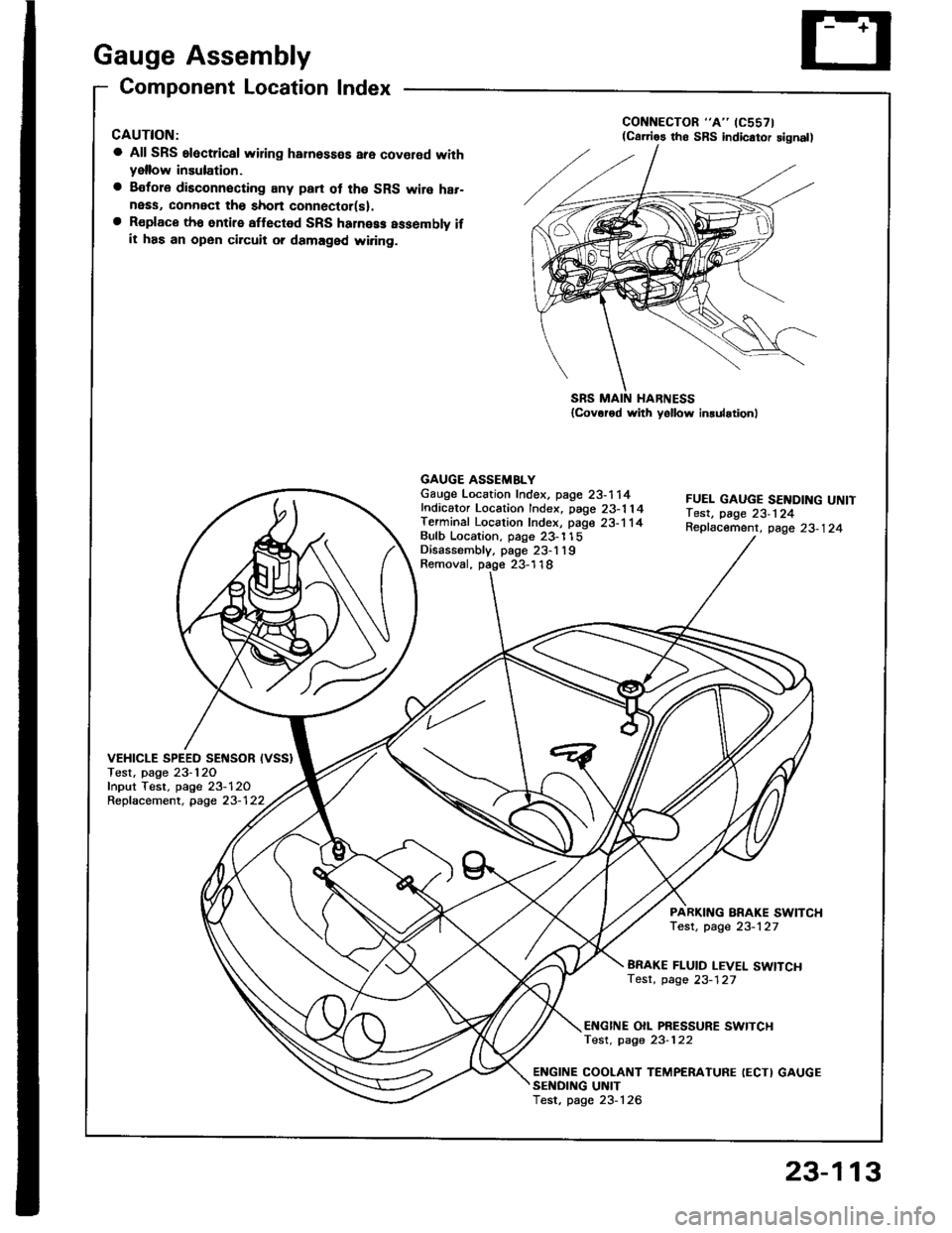

Gauge Assembly

Component Location Index

CAUTION:

a All SRS electrical wiring harnosses are cov€rod withyellow insulation.

a Bofore disconnecting any prn ot th€ SRS wire har-ness, connect tho short connector(sl.a R€place th6 entirs affGcted SRS halne$ assembly ifit has an open circuit o? damaged wiring.

SRS MAIN HARNESS{Cov.r6d with yollow inrularionl

GAUGE ASSEMBLYGauge Location Index, page 23-114Indicator Location Index, page 23-1 14Terminal Location Index, page 23-114Bulb Location. page 23-'l 15Disassembly. page 23-1 19Removal, page 23-118

FUEL GAUGE SENDING UNtTTest, page 23'124Repfacemenr, page 23-124

VEHICLE SPEEO SENSOB IVSS}Test, page 23-120fnput Test. page 23-120Repfacement, page 23-122

PARKITTG BRAKE SWITCHTest, page 23-127

BRAKE FLUID LEVEL SWITCHTesr, page 23-127

EI{GINE OIL PBESSURE SWITCHTest, page 23-122

ENGINE COOLANT TEMPERATURE IECTI GAUGESENOING UNITTest, page 23-126

(C61'ios tho SBS indicator signal)

23-113

Page 1224 of 1413

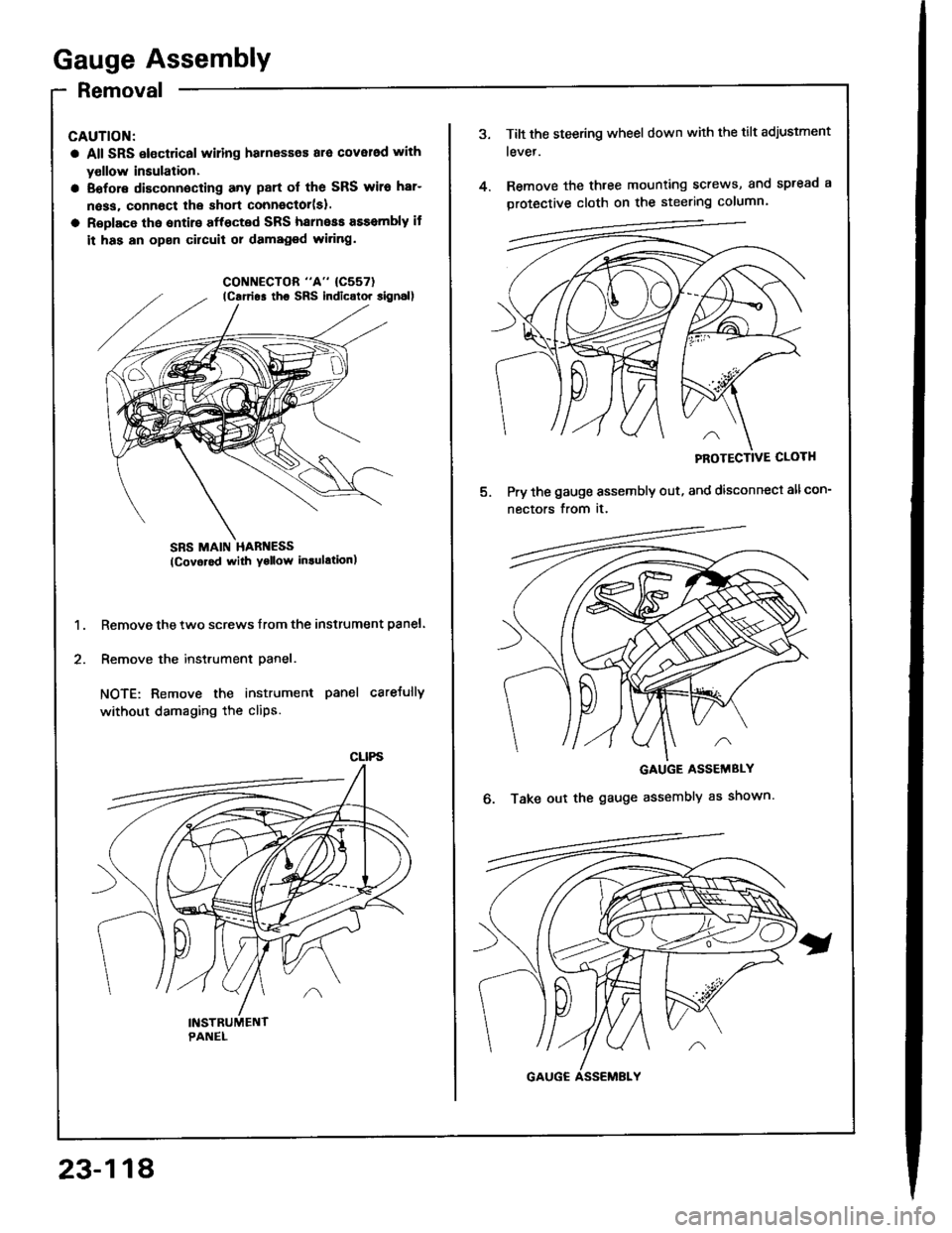

Gauge Assembly

Removal

CAUTION:

a All SRS electrical wiling harnesses ara cover6d with

yollow insulation.

a Eofore disconnecting any part ol the SRS wiro har-

n6ss, connoct lhe short connector(sl.

a Roplace tho entirs affocted SRS harneas assembly if

it has an open circuit 01 damaged wi.ing.

SBS MAIN HARI{ESS(Covor6d with Yollow in.ulationl

Remove the two screws lrom the instrument panel.

Remove the instrument panel.

NOTE: Remove the instrument panel careJully

without damaging the cliPs.

1.

2.

lcarrio. tho SRs indicolor 8ignal)

CLIPS

23-118

Tilt the steering wheel down with the tilt adjustment

tevet.

Remove the three mounting screws, and spread a

protective cloth on the steering column.

PROTECTIVE CLOTH

Pry the gauge assembly out, and disconnect allcon-

nectors from it.

GAUGE ASSEMBLY

Take out the gauge assembly as shown.o.

Page 1240 of 1413

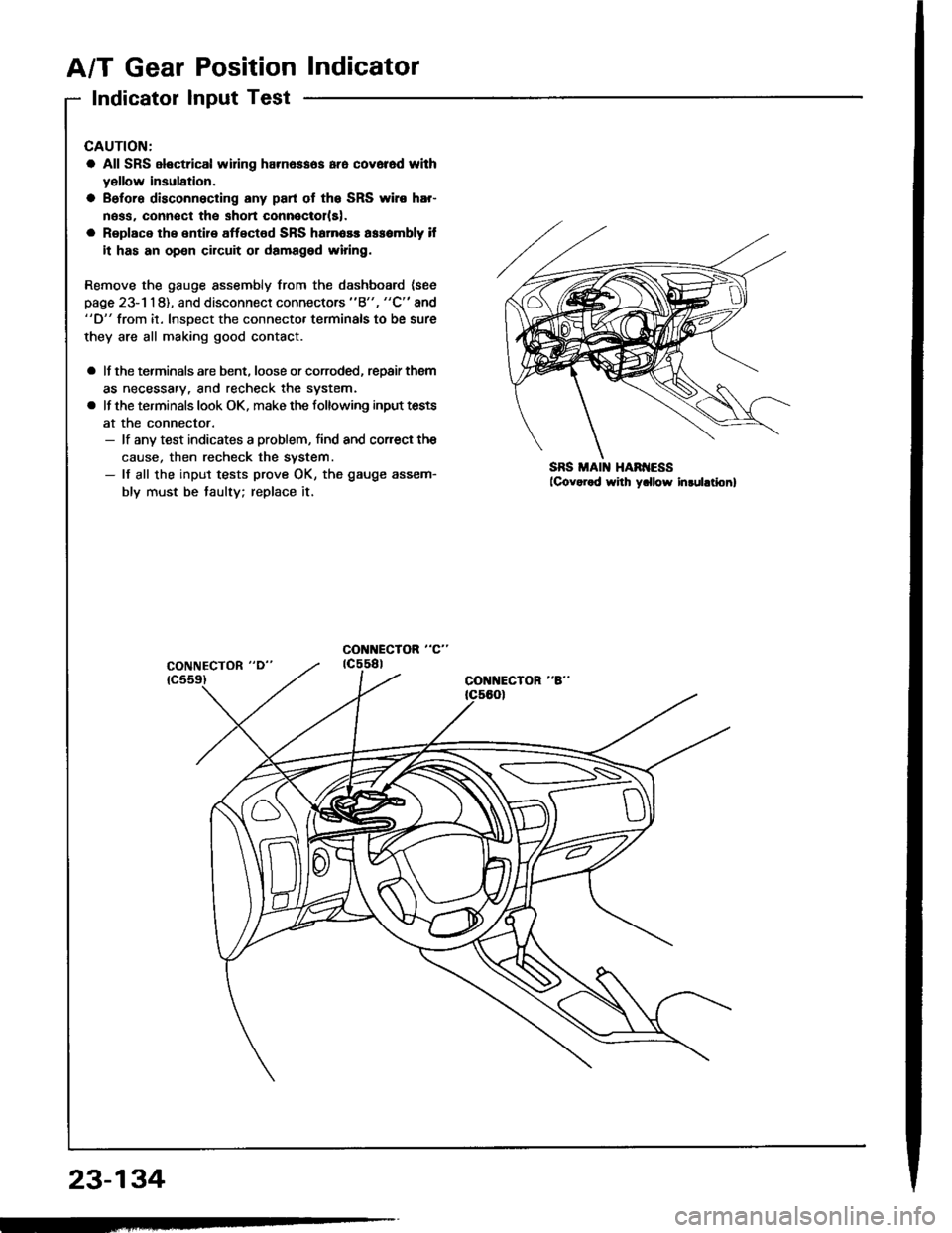

A/T Gear Position Indicator

Indicator Input Test

CAUTION:

a All SRS electrical widng harn6ssos ara cov6r6d whh

yellow insulation.

a Before disconnecting any part ot the SRS wiro hEr-

ness. connect the shon connoctolls).

a Replace the entire affectod SRS harnosr assombly il

it has an op€n circuit or damaged wiring.

Remove the gauge assembly from the dashboard (see

page 23- l 1 8), and disconnect connectors "8", "C" and"D" from it. lnsoect the connecto. terminals to be sure

they are all making good contact.

a lf the terminals are bent. loose or corroded, repair them

as necessary, and recheck the system.

a lf the terminals look OK, make the following input tests

at the connector.- lf any test indicates a problem, find and corect the

cause, then recheck the system.- lf all the input tests prove OK, the gauge assem-

bly must be taulty; replace it.

CONI{ECTOR "8"

SS

23-134

Page 1244 of 1413

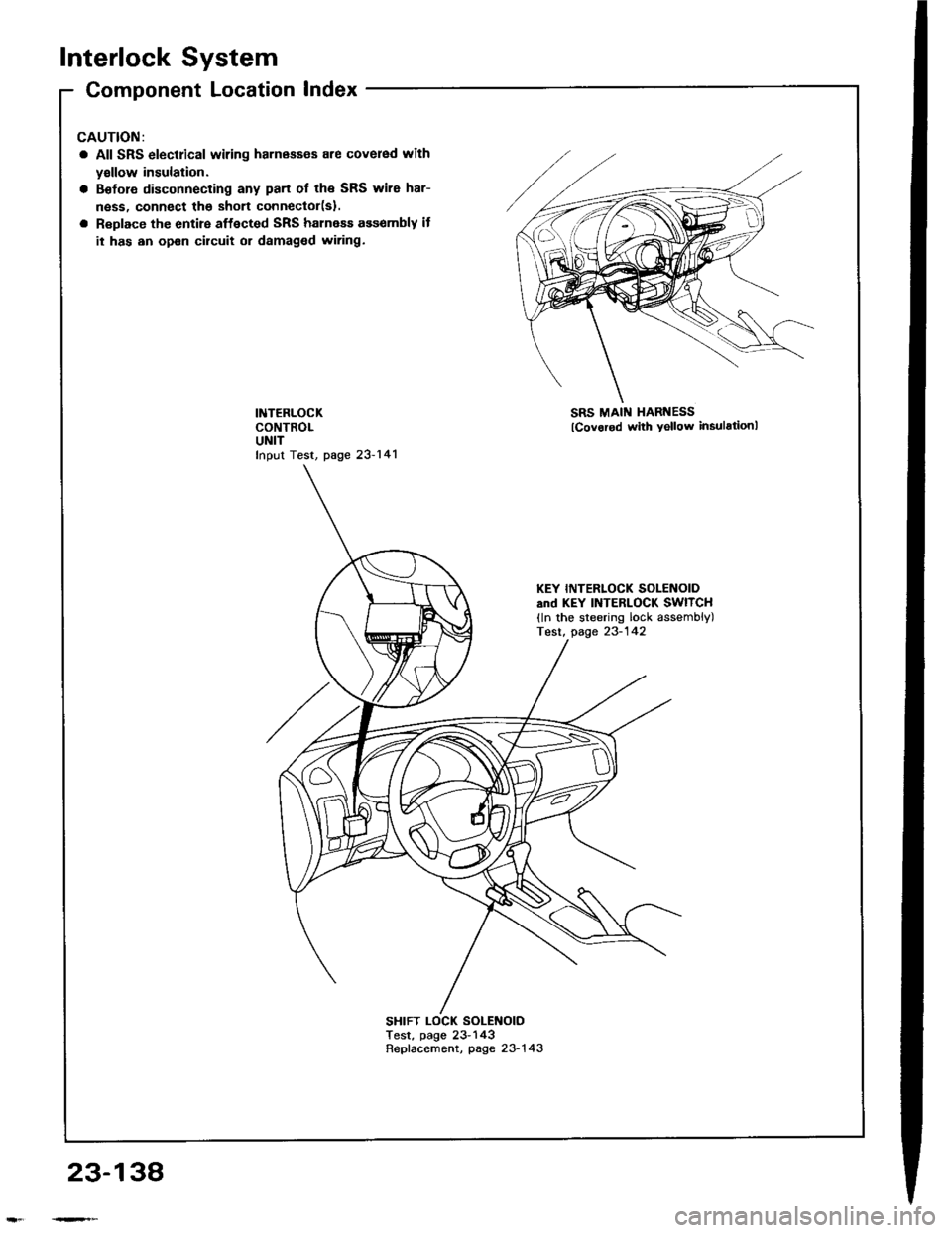

Interlock System

Component Location Index

All SRS electrical wiring harnass€s are covered with

yallow insulation.

Before disconnecting any part of the SRS wire har-

ness, connect the shon connector(sl.

Replace the entire affected SRS halness ass€mbly it

it has an open circuit or damaged wiring.

INTERLOCKCONTROLUNITfnput Test, page 23-141

SRS MAI[{ HARNESS

lcovorod with yellow insulstionl

SHIFT LOCK SOLENOIOTest, page 23- 143Repfacement, page 23-1 43

KEY INTERLOCK SOLENOIDsnd KEY INTERLOCK SWITCH(ln the steering lock assembly)Test, page 23-142

23-138

Page 1248 of 1413

Interlock System

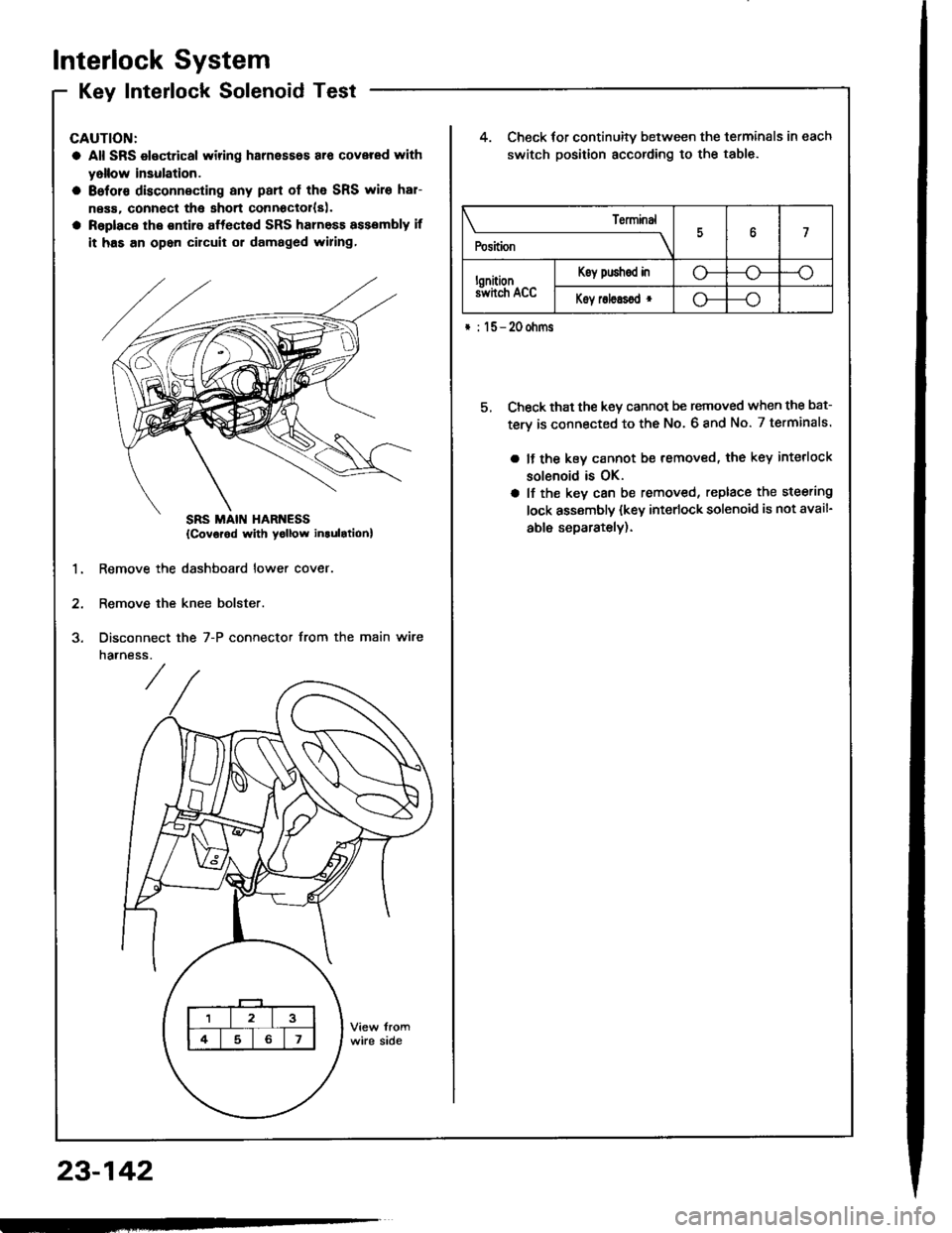

Kev Interlock SolenoidTestKey IntenocK Dorenoro I esr -

CAUTION:

a All SRS electrical wiring harnesses ar€ covered rYith

yollow insulation.

a 8eforc disconnecting any pan of the SRS wire har-

ness. connecl tha short connoclol{s|.

a Raplace the ontire affected SRS harness assembly if

it has an opon circuit or damaged wiring,

4. Check for continuitv between the terminals in each

switch position according to the table.

5, Check that the key cannot be removed when the bat-

tery is connected to the No. 6 8nd No. 7 terminals.

a It the kev cannot be removed, the key interlock

solenoid is OK.

a lf the key can be removed, replace the steering

lock assembly (key interlock solenoid is not avail-

able separately).

1.Remove the dashboard lower cover

Remove the knee bolster.

Disconnect

narness.

the 7-P connector from the main wire

\______________rry

Position7

lonitionS hch Acc

Koy push€d ino---o

Koy roleEsod r--o

* : l5-20ohms

{Covorod with yollow inlulrtionl

23-142

Page 1290 of 1413

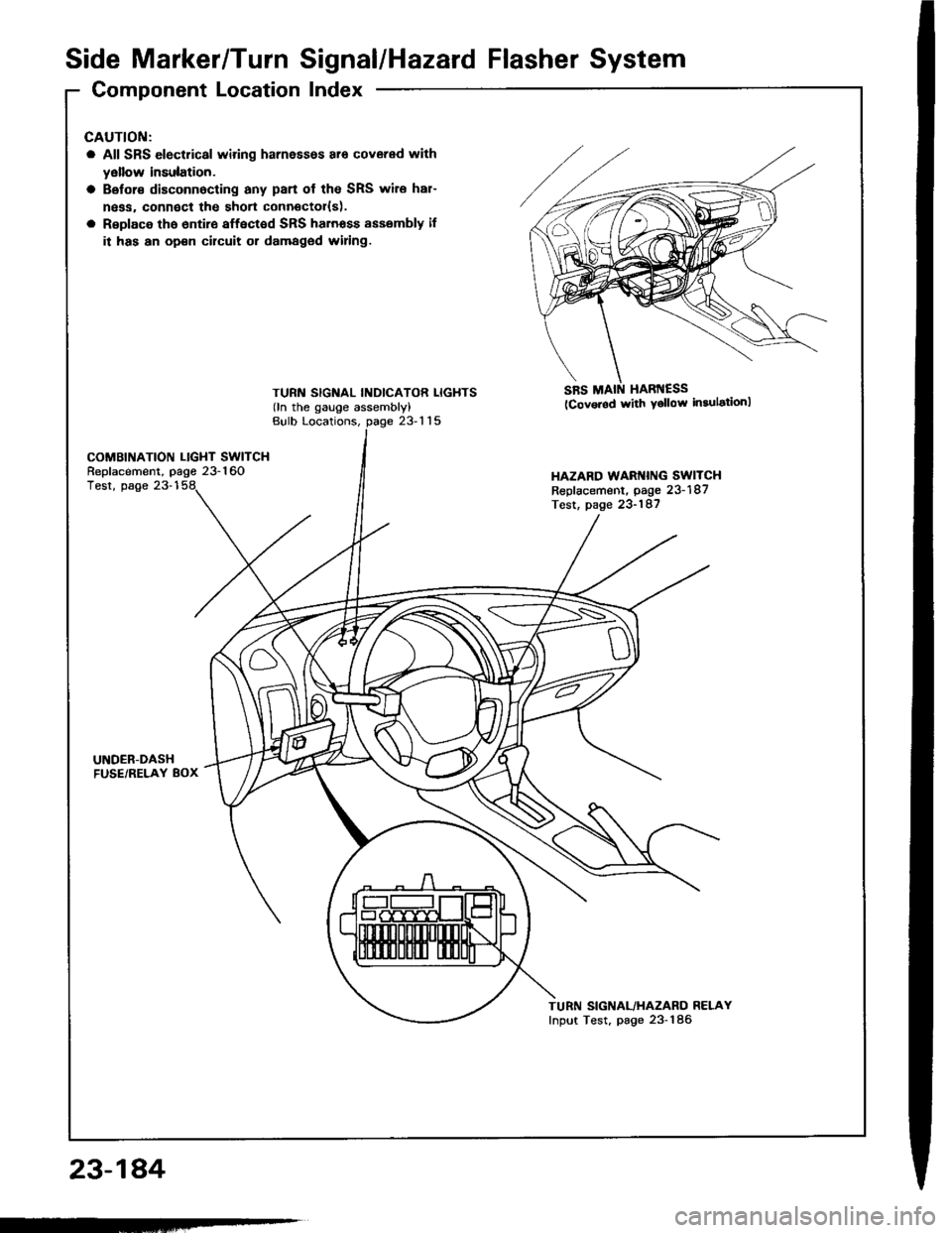

Side Marker/TurnSignal/Hazard Flasher System

Component LocationIndex

23-184

GAUTION:

a All SRS electrical wiring harnessos ar6 covered with

yellow insulation.

a Belor€ disconnocting any pan of the SRS wire har-

ngss, connoct the short connector{s).

a Rsplace tho 6ntir€ affect€d SRS harnoss sssembly il

it has an op€n cilcuit or damaged widng.

TURN SIGNAL INDICATOR LIGHTS(ln the gauge assembly)

SRS MAIN HARI{ESS(Cov.rod with Ysllow in3ulationl

Bulb Locations,23-115

COMBINATION LIGHT SWITCHReplacement, page 23-160HAZARD WARI{ING SWITCHReplacement, page 23-187Test, page 23-187

Test, page 23-1

UNDER-DASHFUSE/RELAY 8OX

TURN SIGNAL/HAZARO RELAYInput Test, page 23-186

-