Iac HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 232 of 1413

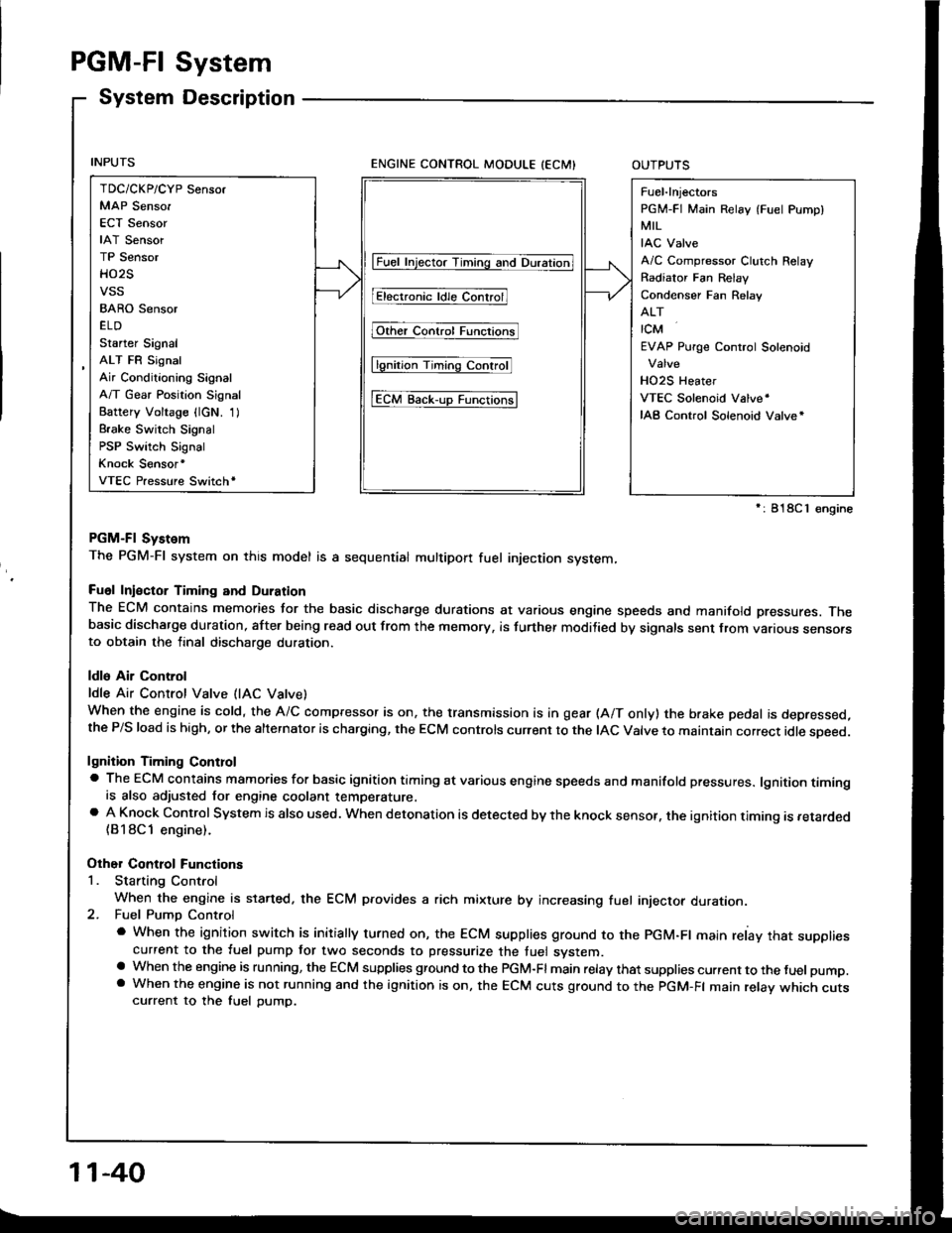

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECMIOUTPUTS

PGM-Fl System

The PGM-Fl system on this model is a sequential multipon fuel injection system,

Fuol Iniector Timing and Duration

The ECM contains memories tor the basic discharge durations at various engine speeds and manifold pressures. Thebasic discharge duration, after being read out from the memory, is turther modilied by signals sent from vanous sensofsto obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Vatve)

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) the brake pedal is depressed,the P/S load is high, or the alternalor is charging, the ECM controls current to the IAC Valve to maintain correct idle soeed.

lgnition Timing Controla The ECM contains mamories for basic ignition timing at various engine speeds and manifold pressures. lgnition timingis also adjusted for engine coolant temperature.a A Knock Control System is also used. when detonation is detected by the knock sensof. the ignition timing is retarded(B18Cl engine).

Other Control Functions

1. Starting Control

When the engine is started. the ECM provides a rich mixture by increasing fuel injector duration.2. Fuel Pump Control

a When the ignition switch is initially turned on, the ECM supplies ground to the PGM-Fl main relay that suppliescurrent to the fuel pump tor two seconds to pressurize the tuel system.a When the engine is running, the ECM supplies gfound to the PGM-Fl main relay that supplies current to the fuel pump.a When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relav which cutscurrent to the fuel pump.

TDC/CKP/CYP Sensor

MAP Senso.

ECT Sensor

IAT Sensor

TP Sensor

HO2S

vss

BARO Sensor

ELD

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Signal

Battery Voltage {lcN. 1)

Brake Switch Signal

PSP Switch Signal

Knock Sensor'

VTEC Pressure Switchr

Fuel-lnjectors

PGM-FI Main Relay (Fuel Pump)

MIL

IAC Valve

A/C Compressor Clutch Relay

Radiator Fan Relav

Condenser Fan Relav

ALT

rcM

EVAP Purge Control Solenoid

HO2S Heater

VTEC Solenoid Valve'

IAB Control Solenoid Valve*

lFuet tnjector Timing and Duration]

I Electr..l"ldle Contr;il

Fit'e' contr; Funcrfit

l6tio; Ttntrlg c..trol

tEcM aack-,rp Functiorlsl

': 818C 1 €ngine

11-40

Page 268 of 1413

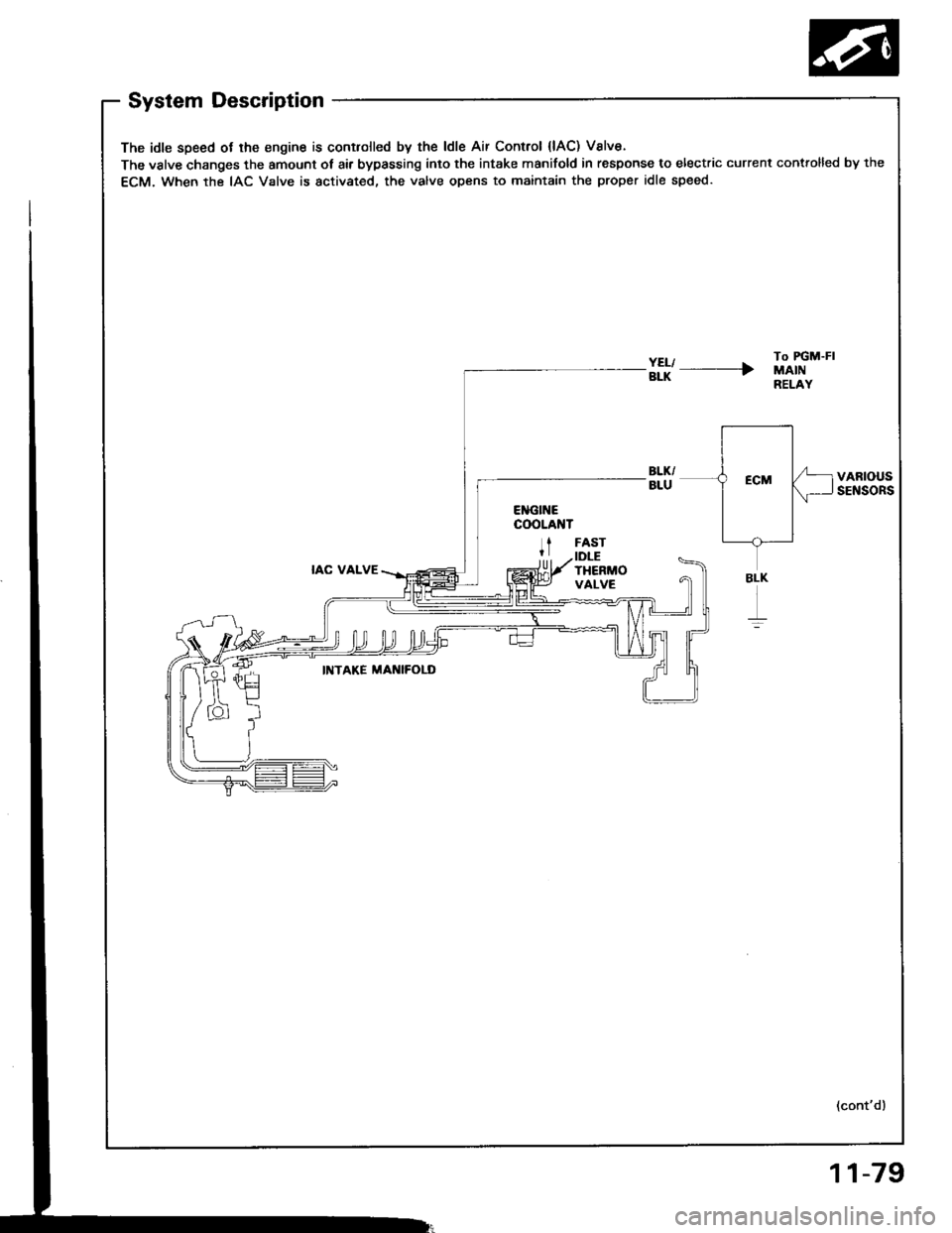

System Description

The idle speed ot lhe engine is controlled by the ldle Air Control {lAC) Valve.

The valve changes the amount ot air bypassing into the intake manifold in response to electric current controlled by the

ECM. When the IAC Valve is activated, the valve opens to maintain the proper idle speed.

#l' ----rTo FGM-FIMAINRELAY

VARIOUSSENSORS

IAC VALVE

FASTIDLETHERMOVALVE

INTAKE MAI{IFOLD

(cont'd)

BLK

r

11-79

Page 269 of 1413

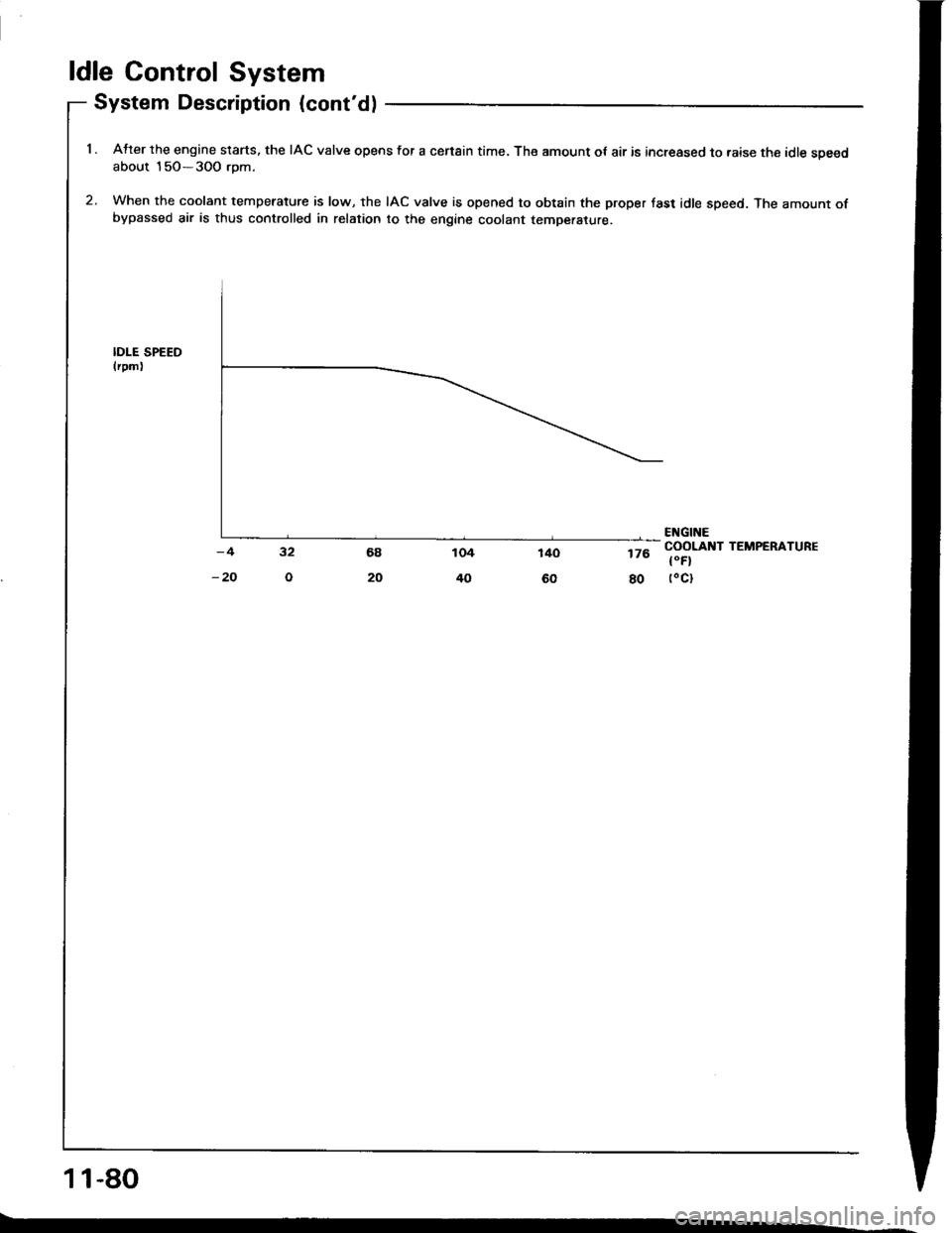

ldle Control System

System Description (cont'd)

1 . Atter the engine slarts. the IAC valve opens for a censin time, The amount ot air is increased to raise the idle soeedabout 15O-3OO rom.

2. When the coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. The amount ofbypassed air is thus controlled in relation to the engine coolant temperature.

IDI-E SPEEDlrpm)

176

80

ENGINECOOLANT TEMPERATURE

t"Fl(oct

11-80

Page 270 of 1413

1. when the idls speed is out of specification and the Malfunction Indicator Lamp (MlLldoes not blink Diagnostic Trou-

ble Code (DTC) 14, check the tollowing items:. Adiust the idle speed {see page I1-95). Air conditioning signal (see page l1-84). ALT FR signal (see page '11-86)

A/T gea, position signal (see page 11-88)

Erake switch signal (see page 1 1-90)

Starter switch signal (see page 1l-921

PSP switch signal (see page 1 1-93)

Fast idl6 thormo valve (see page l1-94)

Hoses and connsctions

IAC valve and its mounting O-rings

2. lf the above items are normal, substitute a known-good IAC vslv€ and readjust the idle speed (see page 11-95)'

. It the idle speed srill cannot be adjusted to speciJication (and the MIL does not blink code 14) after IAC valve

roplacement, substitute a known-good ECM and recheck. It symptom goes away, replsce the original ECM.

1 1-81

Page 271 of 1413

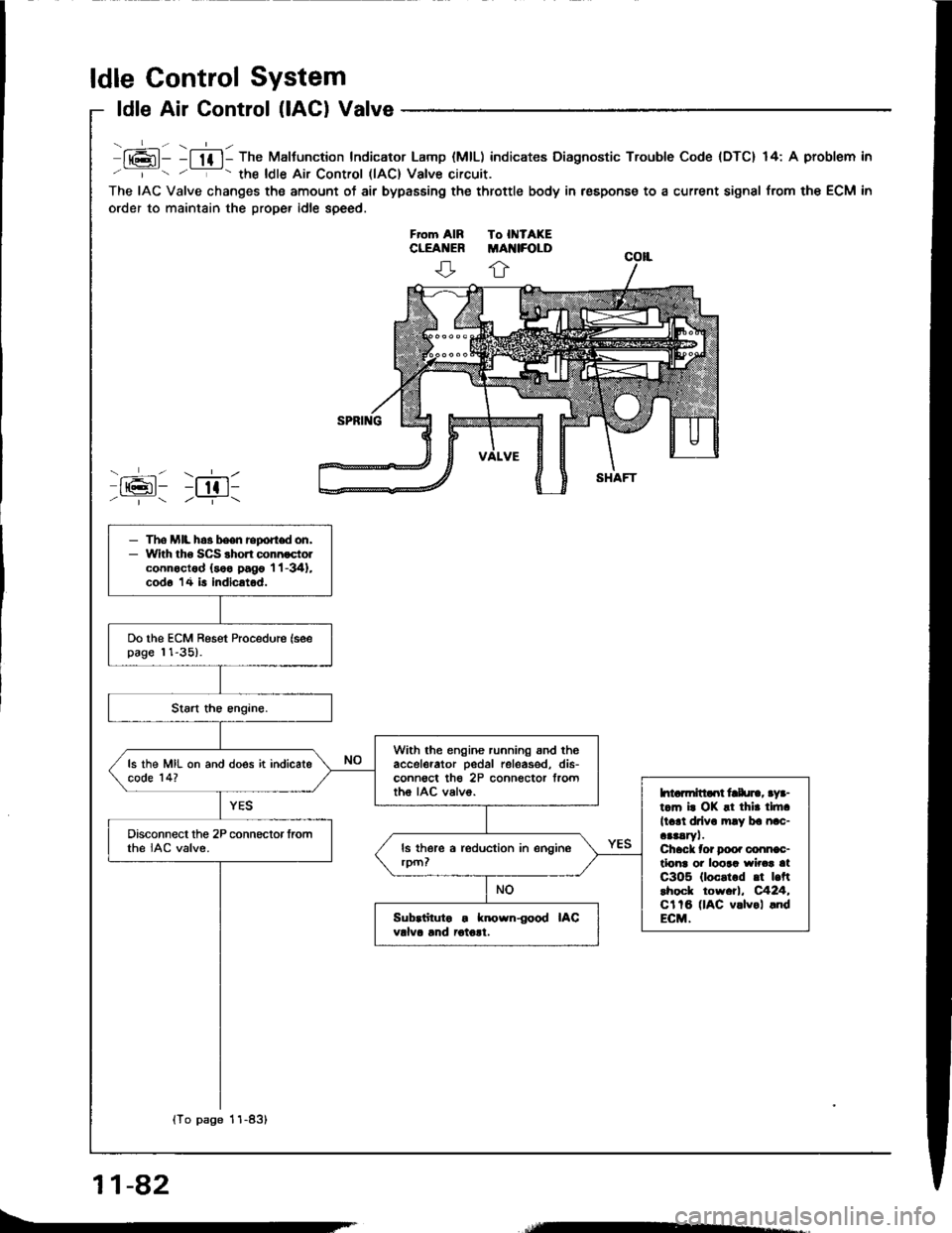

ldle Control System

ldle Air Control (lACl Valve

lt6l- -l lf l- The Maltunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code {DTC} 14: A problem in

' '- the ldle Air Control llAC) Valve circuit.

The IAC Valve changes the amount of air bypasEing the throttle body in respons€ to a current signal from the ECM in

order to maintain the proper idle speed.

ffi: r;611/ | /--T-\

- The MIL h.3 been report don,- With tho SCS shon connoctolconnoctod (soo pago 'l 'l -341,

cod6 14 is indicatod.

Do the ECM Reset Procedure (seepage 11-35).

With the engine running snd theaccelerator pedal releas€d, dis-conn€ct th€ 2P connector frorttho IAC valvo.

ls the MIL on and does it indicatecode 14?

htarmitlaot frlu]., aya-t.m i. OK !t thir tlft.

ll.rl drlv. mly ba nac-aaaaryl.Chack tor Doo. conn€c-tlonr oi loora wirca atC3O5 (loc.t.d .t |.ftlhock tow.tl, C424,Cl tB (lAC v.lvol .ndECM.

Disconnect the 2P connector fromthe IAC valve.

Sub.iituto . known{ood IACvdva lnd iotolt.

{To page 11-83}

11-82

Page 272 of 1413

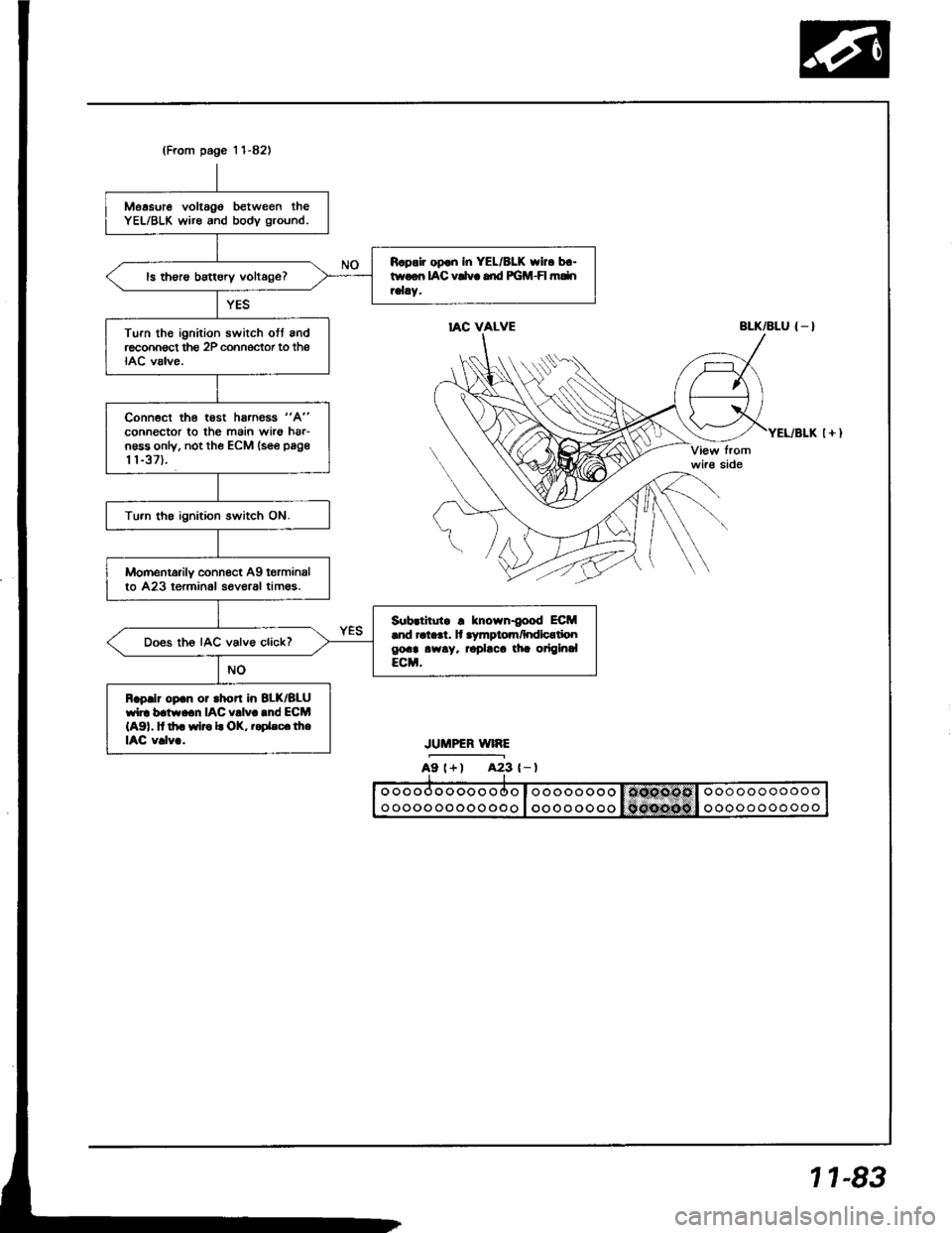

(From page 'l 1-82)

Measure voltago between theYEL/BLK wire and bodv ground.

R.pair op.n In YEL/8LK who b.-twoon IAC vCvc dd PGM-FI mdnrelay.ls th€rs battery voltage?

Turn th€ ignition swirch ott andreconnect thg 2P cohnector to theIAC valve.

Conn€ct the test hs.ness "A"

connector to the main wirs hrr-n6ss only, not the ECM lsee page

t 1-37).

Tu.n tho ignition switch ON.

Momentarily connect Ag torminalto 423 terminol seveaal tim€s.

Sub.titutr ! known{ood ECM.nd ral..t. lt .ymptom/hdlcatioogoa! awsy. rophca tia origlnalECM.

Does th6 IAC valve click?

Raplir op.n or rhort in 8LK/BLUwl]. b.tw.cn IAC v!lv..nd ECM(A91, It th. wlro L OK, r.Dhc.lheIAC v.lv..

IAC VALVEBLK/BLU { _ }

JUMPER WIRE

A9 l+) A23 {-l

1 1-83

Page 284 of 1413

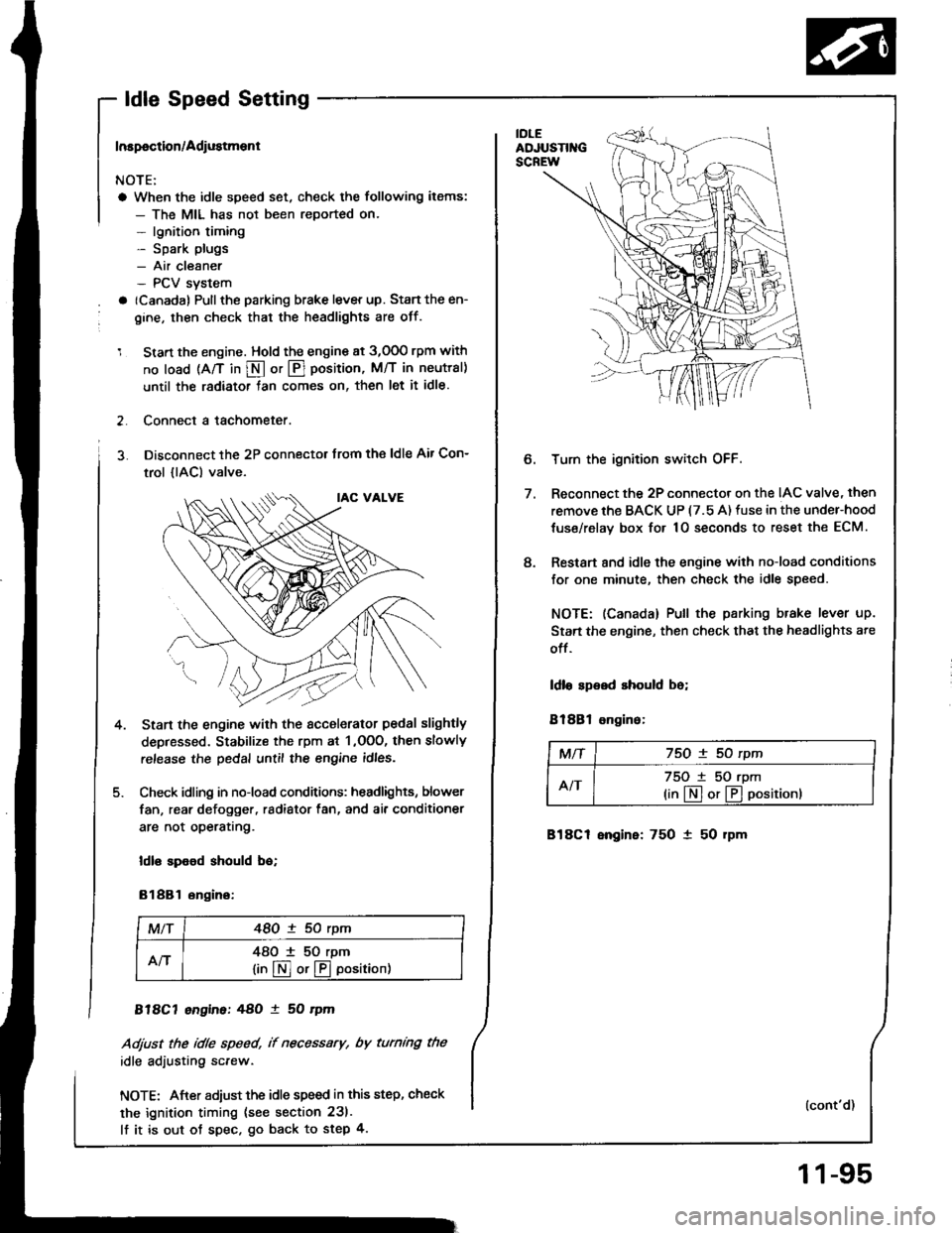

- ldle Speed Setting

Inspoction/Adiustment

NOTE:

a When the idle speed set, check the following items:

- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV svstem

a (Canada) Pullthe parking brake lever up. Stan the en-

gine, then check that the headlights are off.

1 Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in S or @ position, M/T in neutral)

until the radiator tan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the 2P connectot trom the ldle Air Con-

trol {lAC) valve.

Start the engine with the sccelerator pedal slightly

depressed. Stabilize the rpm at 1 ,OOO, then slowly

release the pedal until the engine idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and ai. conditioner

are not operatrng.

ldl€ spood should bo;

81881 ongino:

MlT48O ! 50 rym

An48O I 50 rpm

lin@or@oosition)

818C7 engine:48O ! 50 rym

Adjust the idle speed, if necessary, by turnmg the

idle adiusting screw.

NOTE: After adiust the idle speed in this step, check

the ignition timing (see section 231.

lf it is out ot spec. go back to step 4.

4.

e

Turn the ignition switch OFF.

Reconnect the 2P connector on the IAC valve, then

remove the BACK UP (7.5 A) fuse in the under-hood

tuse/relav box for 1O seconds to reset the ECM.

Restart 8nd idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights ate

off.

ldlo speed should be;

81881 ongino:

MTf75O ! 50 rpm

AIT75O t 50 rpm

(in[]or@positionl

818C1 engine: 750 1 50 rpm

(cont'd)

11-95

Page 306 of 1413

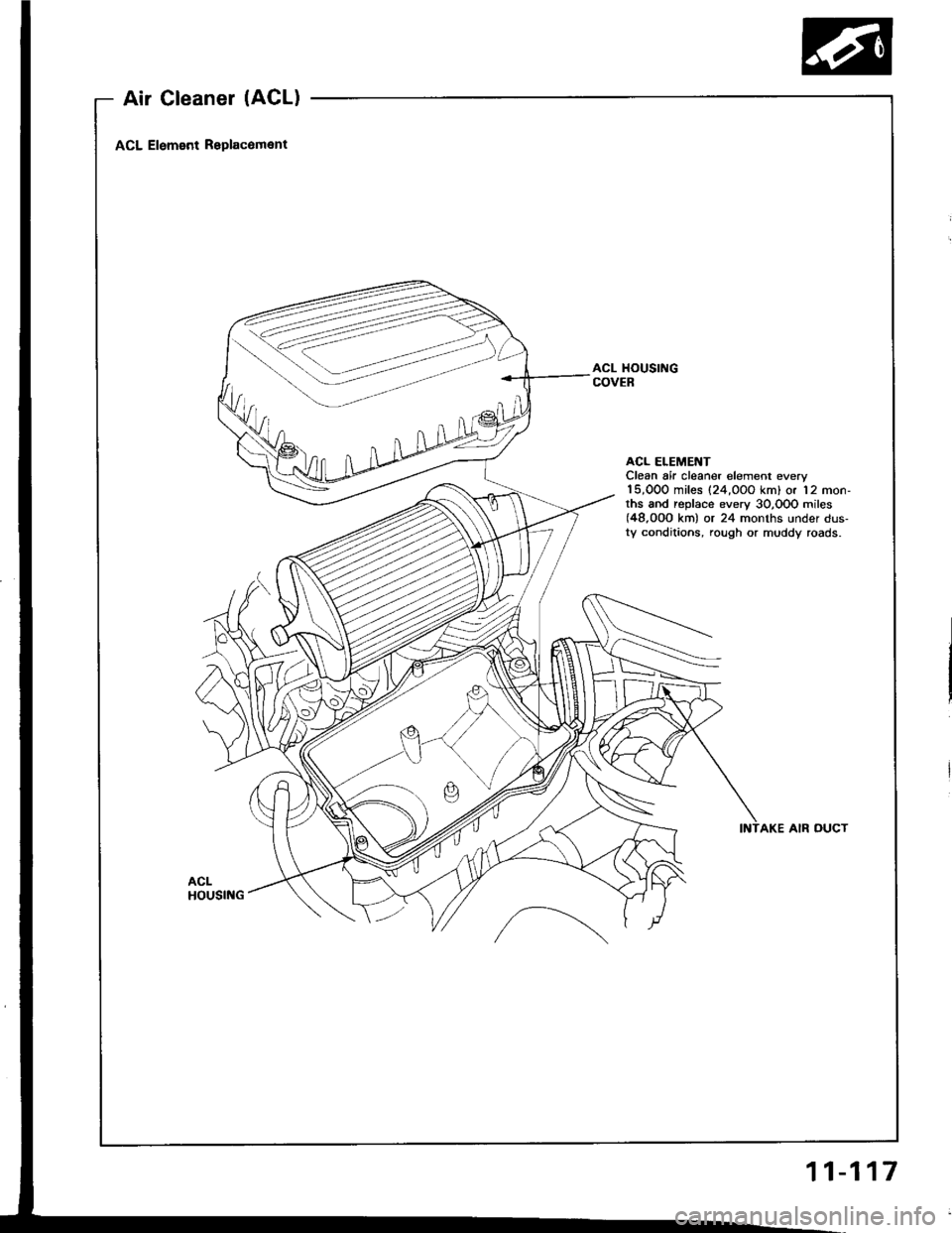

Air Cleaner IACL)

ACL Element Rsplacoment

ACL HOUSINGCOVER

ACL ELEMENTClean air cleaner element everv15,OOO miles (24,OOO km) or 'l2 mon-ths and reDlace everv 3O,OOO miles(48,00O km) or 24 months under dus-ty conditions, rough or muddy roads.

AKE AIR OUCT

11-117

Page 346 of 1413

Transmission Assembly

Removal

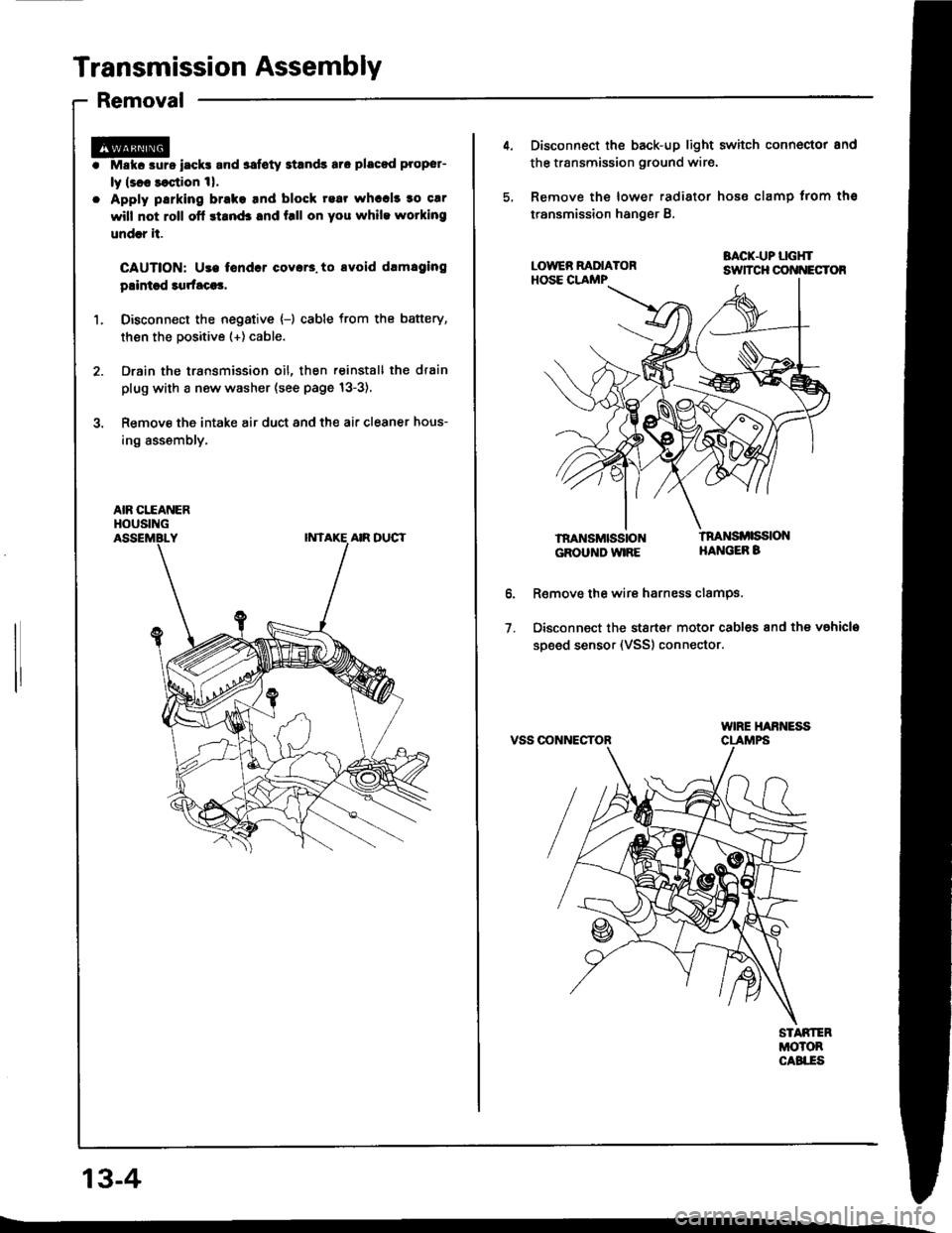

Mskc aurs iack! and safoty Etands aro placod proper-

ly lsl8 saqtion 1|.

Apply parking brake tnd block rear whccl! to car

will not roll ofl stand3 and f.ll on you while wotking

undrr it.

CAUTION: Use tondcr coyar3. to avoid drmlging

plintsd 3qrfaca3,

Disconn€ct the negative {-) cable from the battery,

then the positive (+) cable.

Drain the transmission oil, then reinstall the drain

plug with a new washer (see page 13-3),

Remove the intake air duct and the air cleaner hous-

ing assembly,

AIR CITANERHOUSING

13-4

4. Disconnect the back-up light switch connoctor and

the transmission ground wir€.

5, Remove the lower radiator hose clamp trom ths

transmission hanger B.

BACK.UP LGHTsuTcH cot{t{EcToR

lnaNsMttistoNGROUND WIRE

tnaNsi ssloNHANGEB B

o.

1.

R€move the wire harness clamPs.

Disconnect the stsrt€r motor cables and the vahicla

soeed sensor (VSS) connector.

VSS OONNECTOR

Page 349 of 1413

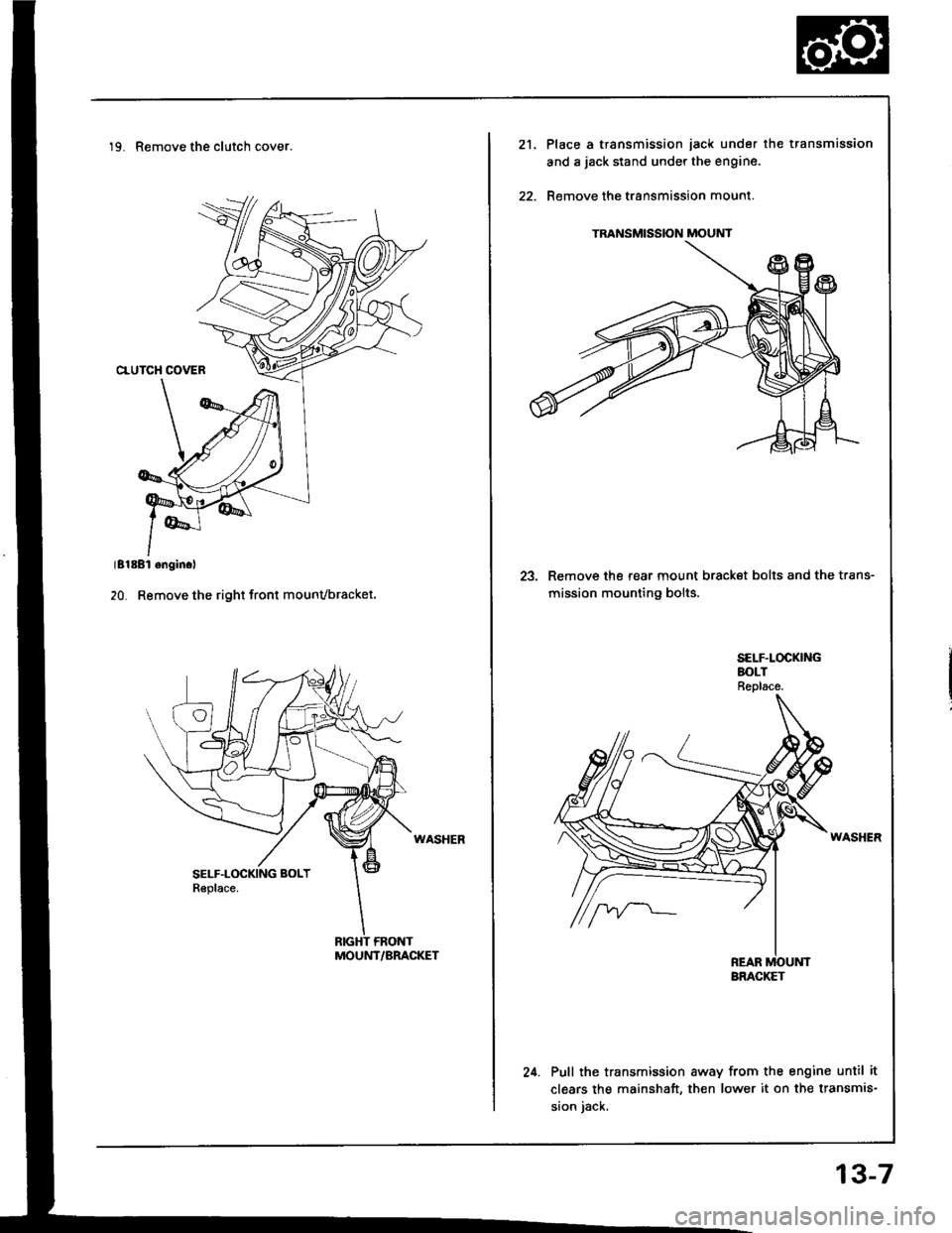

19. Remove the clutch cover.

MOUNT/BRACKET

TRANSMISSION MOUNT

21.Place a transmission iack under the transmission

and a jack stand under the engine.

Remove the transmission mount.

23. Remove the rear mount bracket bolts and the trans-

mission mounting bolts.

24. Pull the transmission away from the engine until it

clears the mainshaft, then lower it on the transmis-

sion iack.

BRACKET

13-7