Minutes HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 242 of 1413

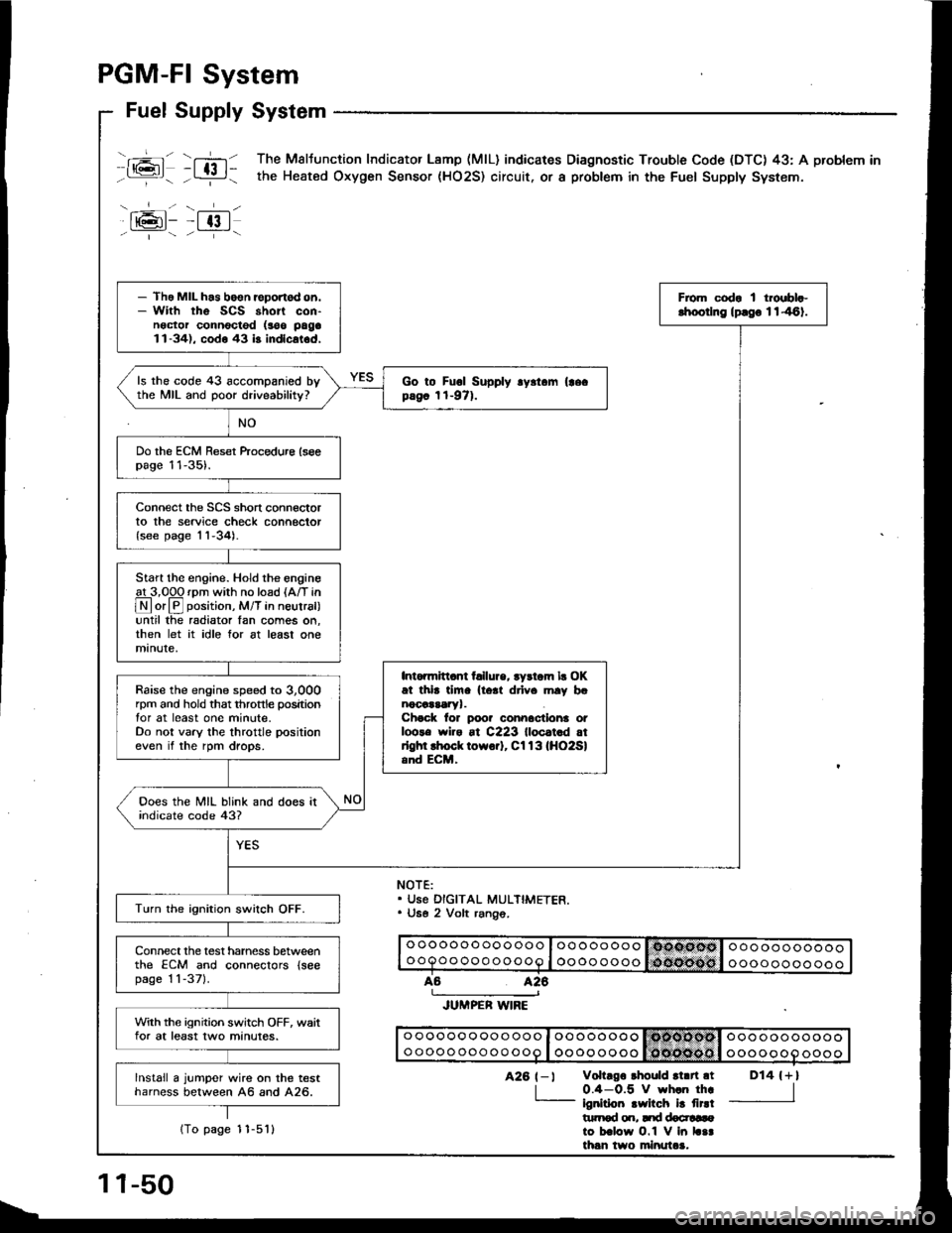

PGM-FI System

rj-t

--t-.

Fuel Supply System

-+-lt@t- -t 13 |- ' "- - --i--

T,-n The Maltunction Indicator Lamp (MlL) indicares Diagnostic Trouble Code (DTC) 43: A problem in

- L:!-i - the Heated Oxygen Sensor (HO2S) circuit. or a probtem in the Fuel Supply System.

NOTE:. Use DIGITAL MULTIMETER.. U6e 2 Volt rang6.

o oooooo oooooo I oo oooooooooooooooooooQoo ooo ooooo I oooo ooooooooooooooo

426

JUMPER WIRE

o ooooo oooo ooo I oo oooooo Isdtcllodsl ooo ooooooooo oooo ooo oo ooo I oooo ooooooooooooooo

D14 {+l

I

426 t-l vohrgo rhould rl.n.t

| 0.4-0.5 V wh.n th..- ignirioo .wilch i! firdt|rtrod o.r, Itd docr!6ato b.low O.1 V in L..th6n two minutaa.

- Tho MIL h.s boen reportod on.- With rhe SCS short con-noctor connocted (soo paga1l-34), codo 43 b indlcat.d,

From codr I troebl.-lhoorlng lprgo 1146).

ls the code 43 accompanied bythe MIL and poor driveability?Go to Fuol Supply .y.t.m (|ecpag6 1t-971.

Do the ECM Reset ftocedure lseepage 11-35).

Connect the SCS short connectorto the service check connector{see page 'l1-34).

Start the engine. Hold the engineat 3,00O rDm with no load {A/T in

@or@ position, M/T in neutral)until the radiator Ian comes on,then let it idle for at least onemanute,

Intonnitl.nt t llure, tydom lr OKat thi. tim. lto.t drlv. mly b.nocaararyr.Chock lor poo? connactlona otloots wiro at C223 lloc.t.d atrlghl lhock towo.]. Cl13lHO2Sland ECM,

Raise the engine speed to 3,000rpm and hold that throttle positiontor at least one minute.Do not vary the throttle positioneven if the rpm drops.

Ooes the MIL blink and does itindicate code 43?

Turn the ignition swilch OFF.

Connect the test harness betweenthe ECM and conneclors {seepage 1 1-371.

With the ignition switch OFF, waitfor at least two minutes.

lnstall a jumper wire on the testharness between A6 and A26.

11-50

1To page 1 1-5'l l

Page 385 of 1413

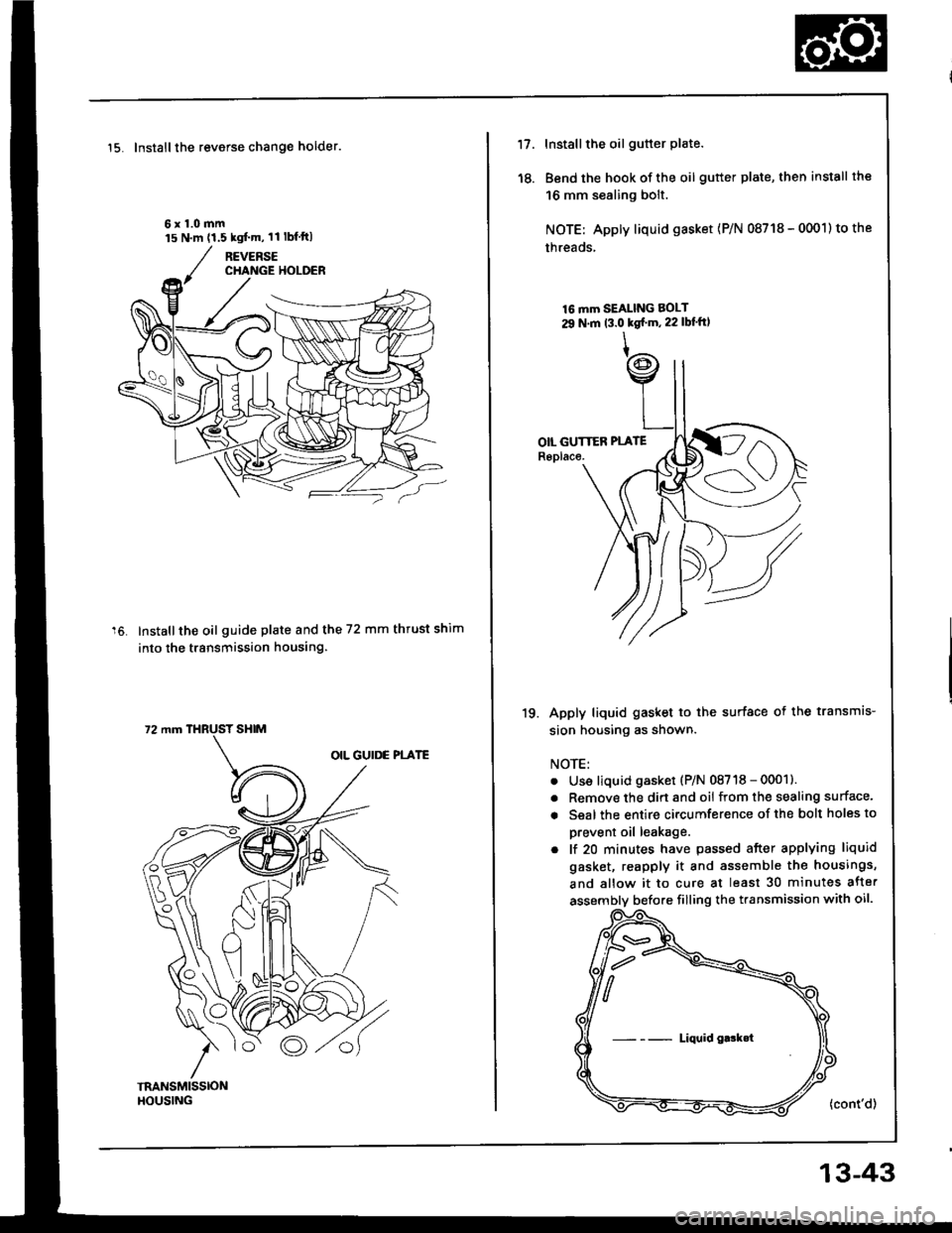

15. Installthe reverse change holder.

6x1.0mm

Installthe oil guide plate and the 72 mm thrust shim

into the transmission housing.

15 N.m (1.5 kgt'm,11 lbfftl

72 mm THRUST SHIM

'18.

Installthe oil gutter plate.

Bend the hook of the oil gutter plate, then install the

16 mm sealing bolt.

NOTE: Apply liquid gasket {P/N 08718 - 0001) to the

threads,

16 mm SEAI-ING BOLT

29 N.m t3.0 kgf m, 22 lbl'ftt

Apply liquid gasket to the surface ot the transmis-

sion housing as shown.

NOTE:

Use liquid gasket (P/N 08718 - 0001)

Remove the dirt and oil from the sealing surface'

Seal the entire circumference of the bolt holes to

prevent oil leakage.

lf 20 minutes have passed after applying liquid

gasket, reapply it and assemble the housings,

and allow it to cure at least 30 minutes after

assembly before filling the transmission with oil.

(cont'd)

19.

a

a

Liquid g.!k.t

13-43

Page 443 of 1413

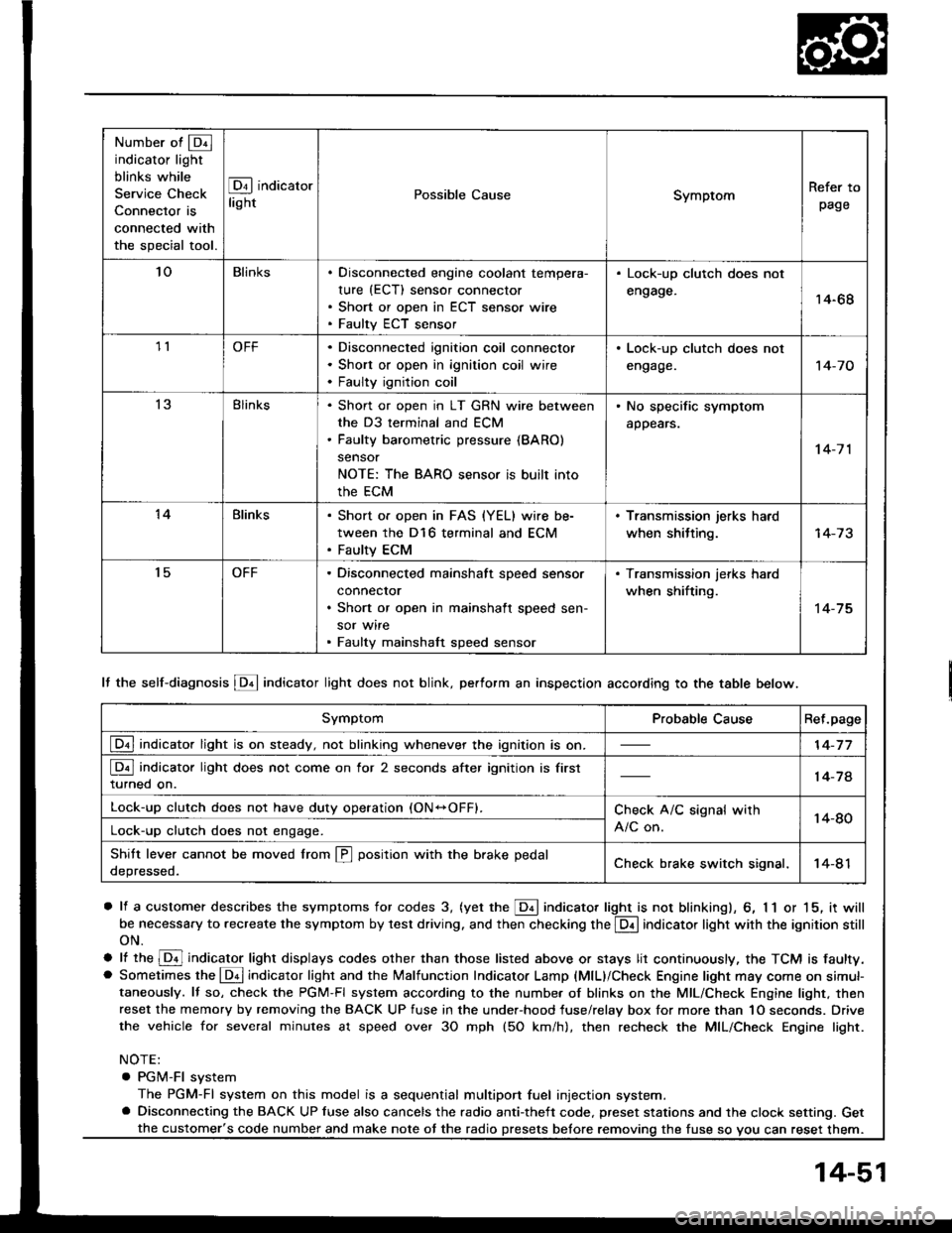

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@ indicator

lightPossible CauseSymptomRefer to

page

'loBlinksDisconnected engine coolant tempera-

rure (ECT) sensor connector

Short or open in ECT sensor wire

Faulty ECT sensor

Lock-up clutch does not

engage.14-68

1lOFFDisconnected ignition coil connector

Short or open in ignition coil wire

Faulty ignition coil

. Lock-up clutch does not

engage.'t 4-7 0

13Blinks. Shon or open in LT GRN wire between

the D3 terminal and ECM. Faulty barometric pressure {BARO)

sensor

NOTE: The BARO sensor is built into

the ECM

. No specific symptom

appears.

14-7 1

14Blinks. Short of open in FAS {YEL} wire be-

tween the D16 terminal and ECM. Faulty ECM

. Transmission jerks hard

when shitting.

't5OFFDisconnected mainshaft speed sensor

connecror

Short or open in mainshaft speed sen-

sor wire

Faulty mainshaft speed sensor

. Transmission jerks hard

when shifting.

14-75

SymptomProbable CauseRet.page

LQ! indicator light is on steady, not blinking whenever the ignition is on.14-77

[Q3] indicator light does not come on for 2 seconds after ignition is first

turned on.14-78

Lock-up clutch does not have duty operation (ON-OFFI.Check A/C signal with

A/C on.14-80Lock-up clutch does not engage.

Shitt leve. cannot be moved lrom @ position with the brake pedal

depressed.Check brake switch signal,14-41

It the self-diagnosis LQ4 indicator light does not blink, perform an inspection according to the table below.

a lf a customer describes the symptoms for codes 3, (yet the LQ! indicator light is not blinkingl, 6, 1 1 or 15, it will

be necessa.y to recreate the symptom by test driving. and then checking the @ indicator light with the ignition still

oN.

e lt ttre @ indicator light displays codes olher than those listed above or stays lit continuously, the TCM is faulty.. Sometimes the Lqd indicator light and the Malfunction Indicator Lamp (MlL)/Check Engine light may come on simul-taneously. lf so, check the PGM-Fl system according to the numbe. of blinks on the MIL/Check Engine light. thenreset the memory by removing the BACK UP fuse in the unde.-hood fuse/relay box for more than 1O seconds. Drive

the vehicle for several minutes at speed over 30 mph (5O km/h), then recheck the MIL/Check Engine light.

NOTE:

. PGM-FI system

The PGM-Fl system on this model is a sequential multiport fuel injection system.a Disconnecting the BACK UP luse also cancels the radio anti-theft code. preset stations and the clock setting. Get

the fuse so vou can reset them.the customer's code number and make note ot the radio

14-51

Page 484 of 1413

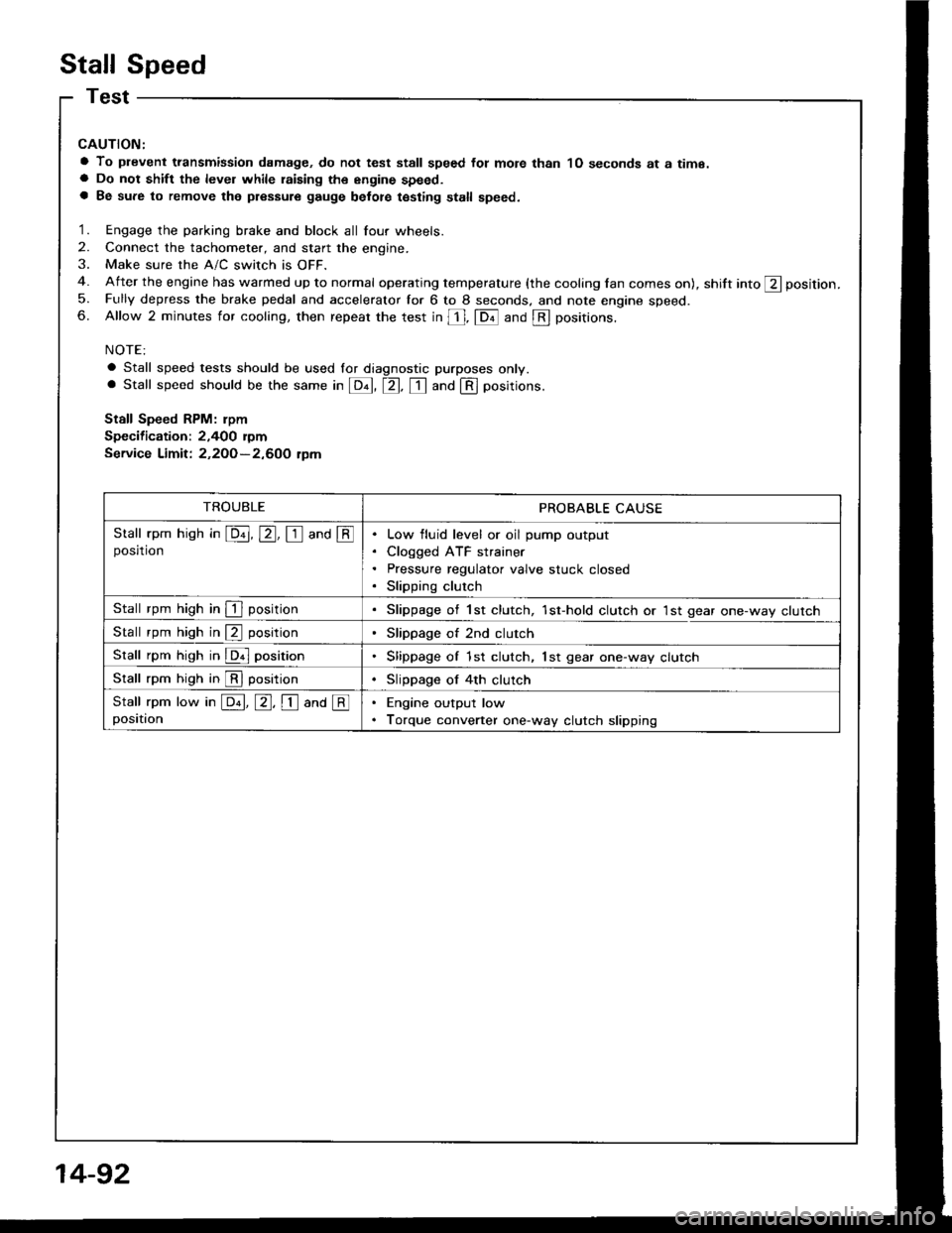

Stall Speed

CAUTION:

a To plevent transmission damage, do not test stall speed fot mote than 1O seconds at a time.a Do not shift the level while raising th€ engine speed.a Be sure to remove the pressure gauge belot€ testing stall speed.

1. Engage the parking brake and block all four wheels.

2. Connect the tachometer, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the cooling lan comes on), shift into ft position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds. and note engine speed.6. Allow 2 minutes for cooling, then repeat the test in [, fDil and @ positions.

NOTE:

a Stall speed tests should be used lor diagnostic purposes only.. Stall speed should be the same in E, tr. tr and @ positions.

Stall Speed RPM: rpm

Specification: 2,400 rymService Limit: 2,2OO-2,600 tpm

TROUBLEPROBABLE CAUSE

Stall rpm hish in E, E, I and @posrtronLow fluid level or oil pump output

Cloqged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in I positionSlippage of 1st clutch, 1st-hold clutch or 1st gear one-way clutch

Stall rpm high in @ positionSlippage of 2nd clutch

Stall rpm high in @ positionSlippage of 1st clutch, lst gear one-way clutch

Stall rpm high in @ positionSlippage of 4th clutch

Stall rpm low in E, E, I ana @positionEngine output low

Torque converter one-way clutch slipping

14-92

Page 508 of 1413

Valve Body

Repair

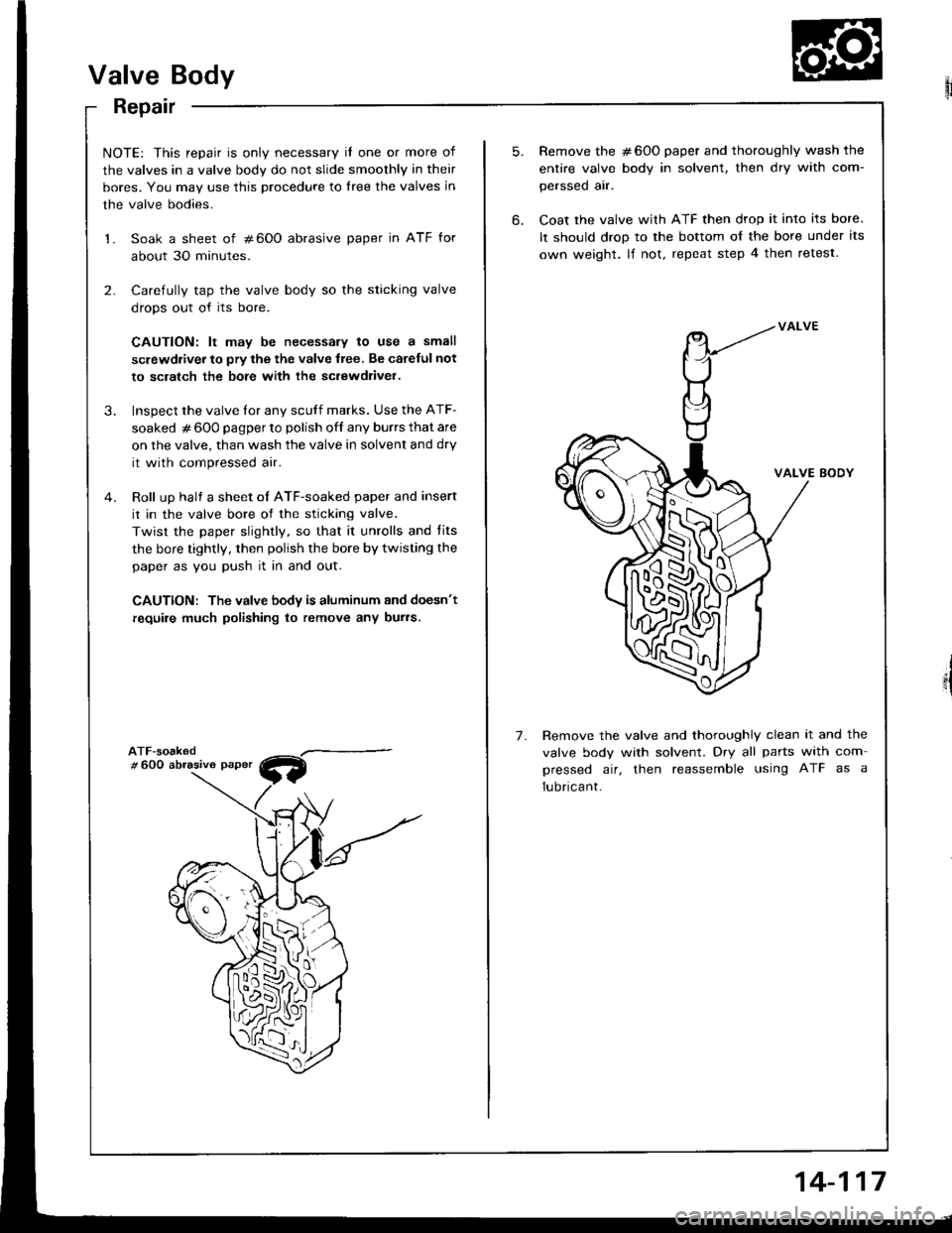

NOTE: This repair is only necessary il one or more of

the valves in a valve body do not slide smoothly in their

bores. You may use this procedure to lree the valves in

the valve bodies.

1. Soak a sheet of #600 abrasive paper in ATF for

about 30 minutes.

2. Carefully tap the valve body so the sticking valve

drops out of its bore.

CAUTION: lt may be necessary to use a small

screwdiiver to pry the the valve lree. Be carelul not

to sclatch the bore with ihe sc.ewdliver.

3. Inspect the valve tor any scuff marks. Use the ATF-

soaked # 600 pagper to polish off any burrs that are

on the valve, than wash the valve in solvent and dry

it with compressed air.

4. Roll up halt a sheet oI ATF-soaked paper and insert

it in the valve bore of the sticking valve.

Twist the paper slightly, so that it unrolls and fits

the bore tightly, then polish the bore by twisting the

paper as you push it in and out.

CAUTION: The valve body is aluminum and doesn't

require much polishing to remove any burs.

W

5.

6.

7.

Remove the #600 paper and thoroughly wash the

entire valve body in solvent, then dry with com-

perssed air.

Coat the valve with ATF then drop it into its bore.

It should drop to the bottom o{ the bore under its

own weight. lf not. repeat step 4 then retest.

VALVE BODY

Remove the valve and thoroughly clean it and the

valve body with solvent. Dry all parts with com

pressed air, then reassemble using ATF as a

lubricant.

14-117

Page 539 of 1413

Clutch

Reassembly (cont'd)

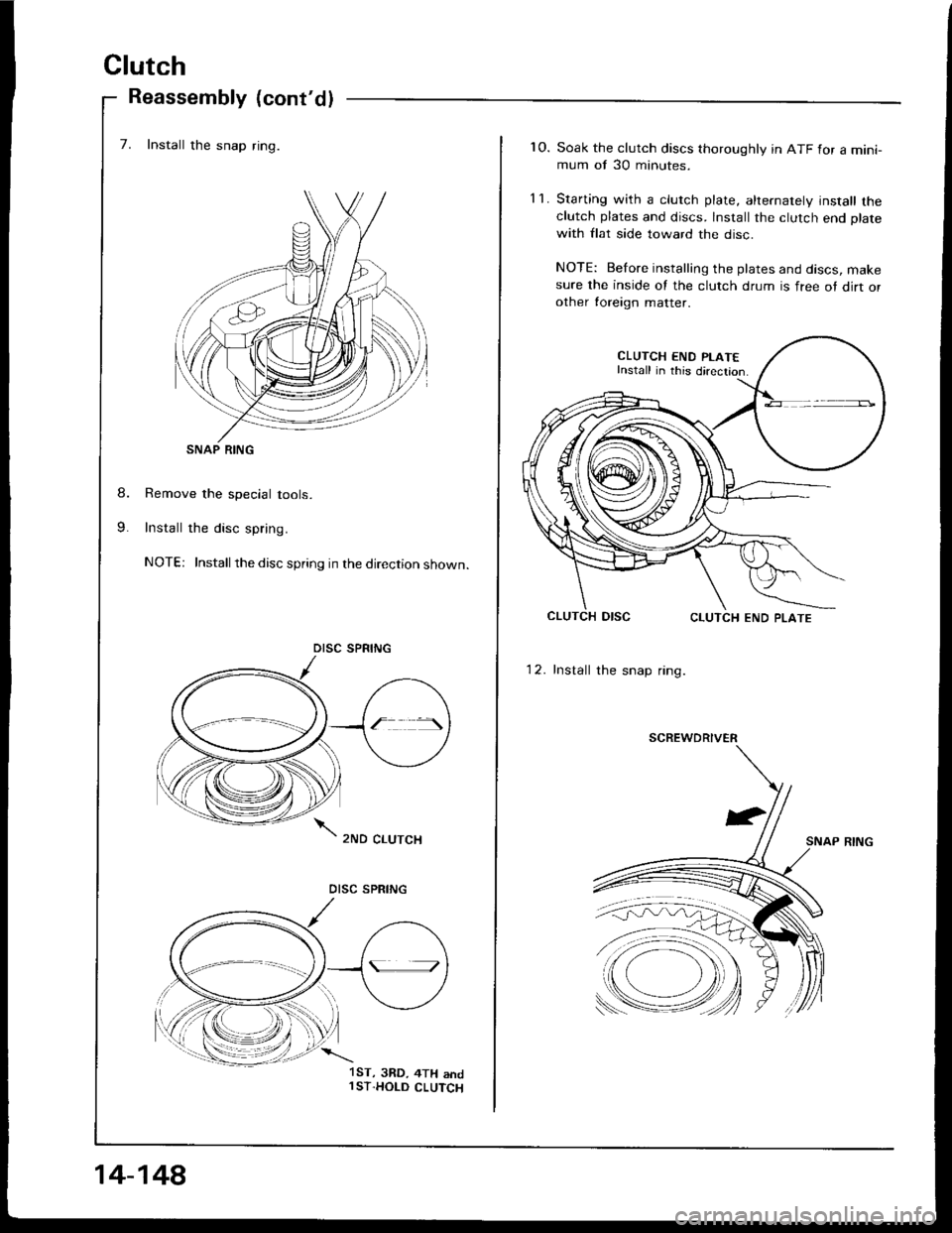

7. Install the snap ring.

Remove the special tools.

Install the disc spring.

NOTE: Installthe disc spring in the direction shown.

SNAP RING

DISC SPRING

.\

):ll

14-148

1ST, 3RD, 4TH andl ST.HOLD CLUTCH

1O. Soak the clutch discs thoroughly in ATF for a mini-mum of 30 minutes.

11. Starting with a clutch plate, alrernately install theclutch plates and discs. Install the clutch end plate

with flat side toward the disc.

NOTE: Before insralling the plates and discs, makesure the inside of the clutch drum is free ot dirt orother toreign matter.

CLUTCH END PLAT€Install in this direction

12. Install the snap ring.

SNAP RING

SCREWDRIVER

Page 558 of 1413

Transmission

Cooler Flushing

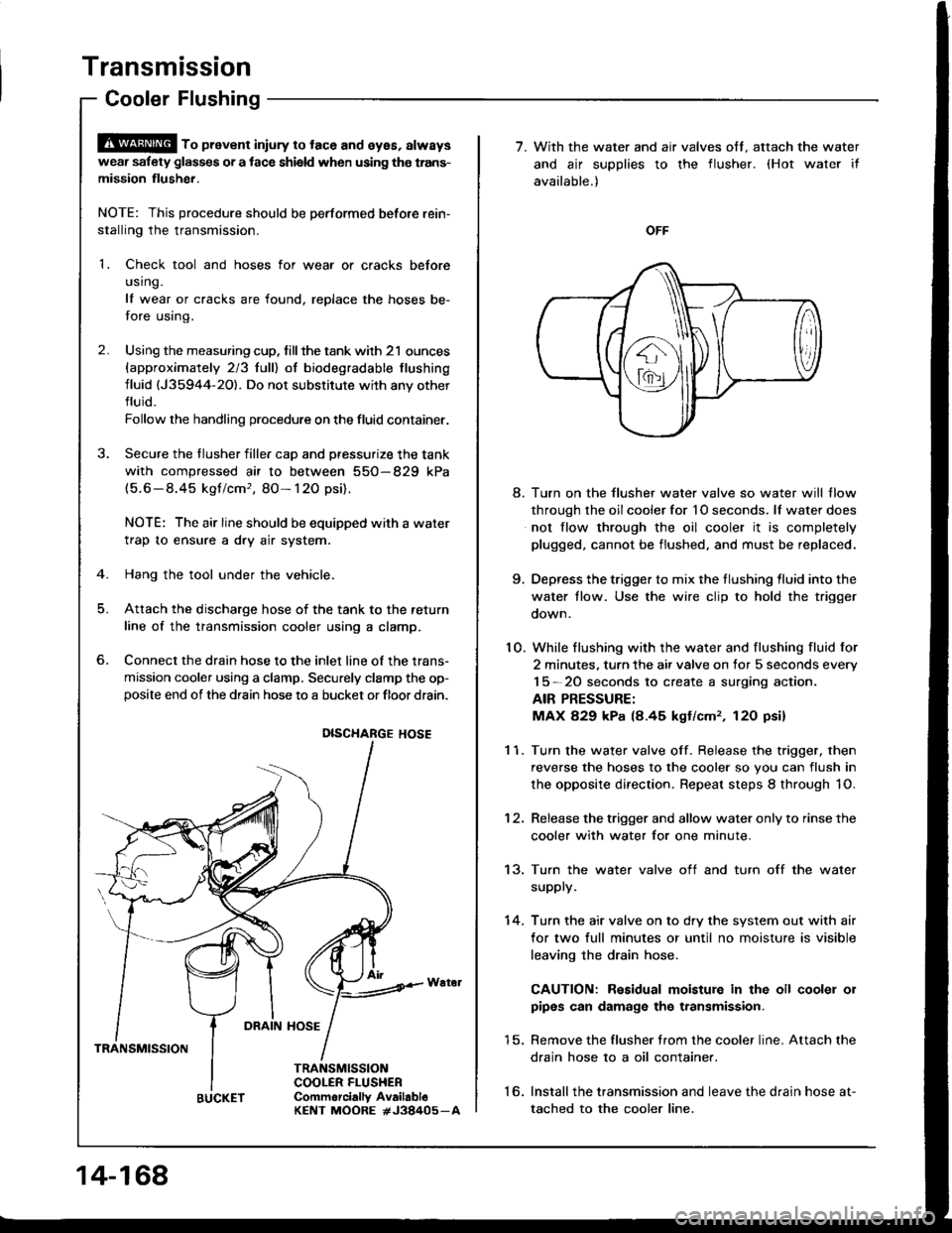

S!@ ro prevent iniury to tace and eyes, always

wear safety glas$es or a tace shield when using the trans-

mission flusher.

NOTE: This procedure should be performed before rein-

stalling the transmission.

1. Check tool and hoses for wear or cracks before

using.

lf wear or cracks are found, replace the hoses be-

fore using.

2. Using the measuring cup, tillthe tank with 21 ounces

{approximately 213 lulll of biodegradable tlushing

fluid (J35944-20). Do not substitute with any other

fluid.

Follow rhe handling procedure on the fluid container.

Secure the tlusher filler cap and pressurize the tank

with compressed air to between 550-829 kPa(5.6-8.45 kgt/cm,, 80- 120 psi),

NOTE: The air line should be equipped with a water

trap to ensure a dry air system.

Hang the tool under the vehicle.

Attach the discharge hose of the tank to the return

line of the transmission cooler using a clamp.

Connect the drain hose to the inlet line of the trans-

mission cooler using a clamp. Securely clamp the op-posite end of the drain hose to a bucket or floor drain.

6.

DRAIN HOSE

TRANSMISSION

TRANSMISSIONCOOLER FLUSHEBCommorcially AvailabloKENT MOORE #J38405_A

DISCHARGE HOSE

14-168

BUCKET

7. With the water and air valves off. attach the water

and air supplies to the flusher. (Hot water it

available.)

OFF

8. Turn on the flusher water valve so water will tlow

through the oil cooler for 1O seconds. lf water does

not flow through the oil cooler it is completely

plugged, cannot be flushed, and must be replaced.

9. Depress the trigger to mix the tlushing lluid into the

water tlow. Use the wire clip to hold the trigger

oown.

10. While flushing with the water and flushing fluid for

2 minutes. turn the air valve on for 5 seconds every

15-20 seconds to create a surging action.

AIR PRESSURE:

MAX 829 kPa (8.45 kgt/cm,, 12O psi)

1 1. Turn the water valve off. Release the trigger, then

reverse the hoses to the cooler so you can flush in

the opposite direction. Repeat steps 8 through 1O.

12. Release the trigger and allow water only to rinse the

cooler with water for one minute.

13. Turn the water valve off and turn off the water

supply.

14. Turn the air valve on to dry the system out with air

for two full minutes or until no moisture is visible

leaving the drain hose.

CAUTION: Residual moisture in the oil cooler 01

pipes can damage the transmission.

15. Remove the flusher trom the cooler line. Attach the

drain hose 10 a oil container.

16. lnstallthe transmission and leave the drain hose at-

tached to the cooler line.

Page 621 of 1413

Troubleshooting

Noise and Vibration

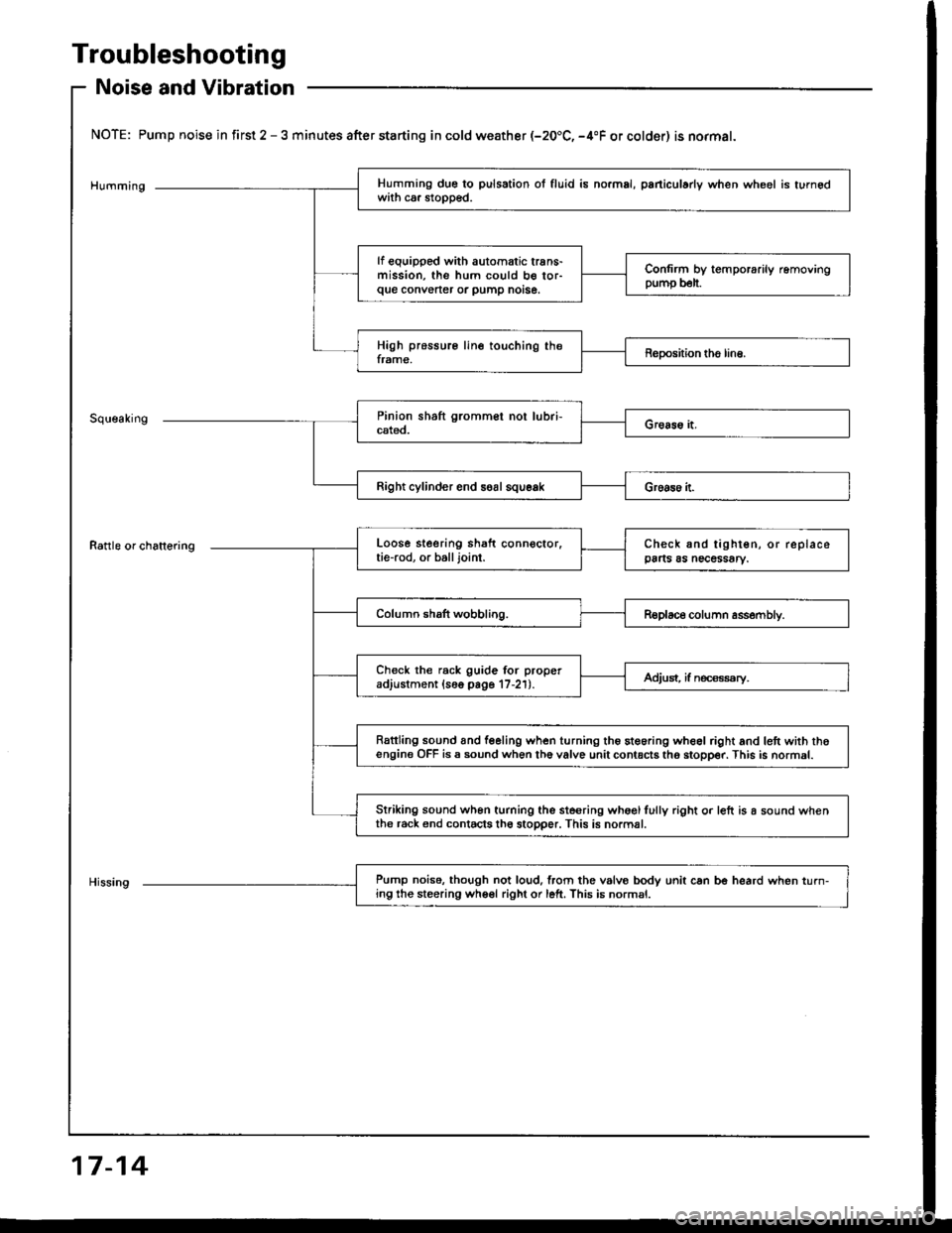

NOTE: Pump noise in first 2 - 3 minutes after starting in cold weather (-20.C, -4"F or colder) is normal.

Humming

Rattle or chattering

Right cylinder end soal squeak

Pump noise. though not loud,lrom the vslvo bodv unit can be heard when turn-ing the steering wheel right or left. This is normsl.

Humming due to pulsation ol fluid is no.mal, paniculady when wheel is turnedwith ca. stopped.

lf equipped with automatic trans-mission, the hum could b€ tor-que convener or pump notse.

Confirm by temporarily removingpump b€lt.

High pressure line touching theframe,Reposhion tho line.

Loose steering shaft connector.tie-rod, or balljoint.Check and tighten, or replacepa s as necessary.

Column shaft wobbling.Replace column assembly.

Check the rack guide for properadjustment (16o page 17-21).Adjust, if n€ca€ssry.

Rattling sound and feeling when turning the steoring wheel right and lett with thoengine OFF is a sound when th6 valve unit contacts tho stopper. This is normal.

Striking sound wh6n turning the ste€ring whoglfully right o. left is a sound whenthe r6ck end contacts th6 stopper. This is normal.

17-14

Page 622 of 1413

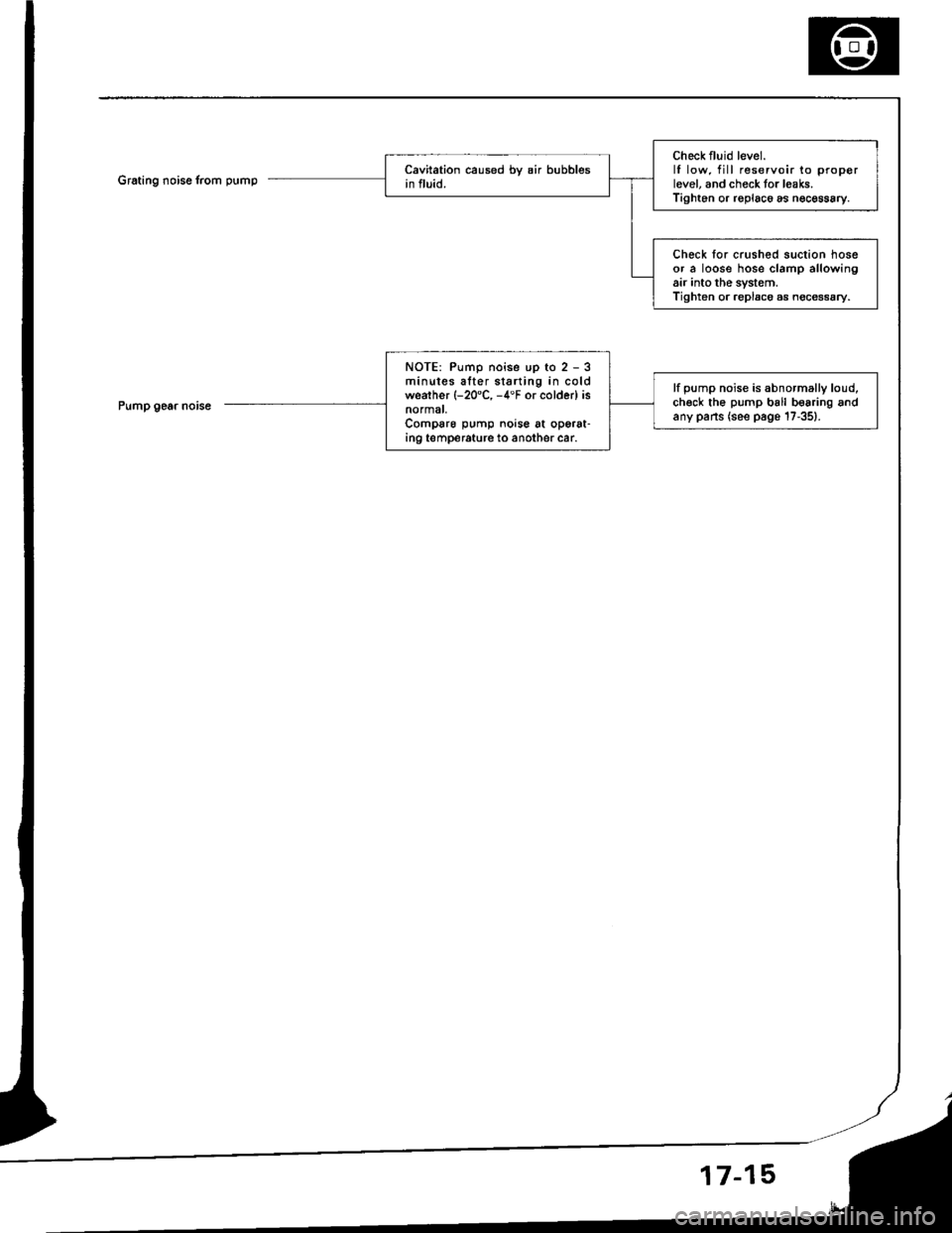

Grating noise from pump

Pump gear noise

Check fluid level.lf low. fill reservoir to properlevel, and check tor l€aks.Tighten or roplac6 as n€cessary.

Check for crushed suction hoseor a loose hose clamp allowingair into the system.Tighten or replace as noce$ary.

NOTE: Pump noise up to 2 - 3minutes alter starting in coldweather (-20'C, -4'F or colder) isnormat,Comparo pump noise at operat-in9 temperature to another car.

lf pump noise is abnormally loud,chgck the pump ball b€aring andany pans (see page 17-351.

17-15

Page 927 of 1413

Windshield

Installation (cont'd)

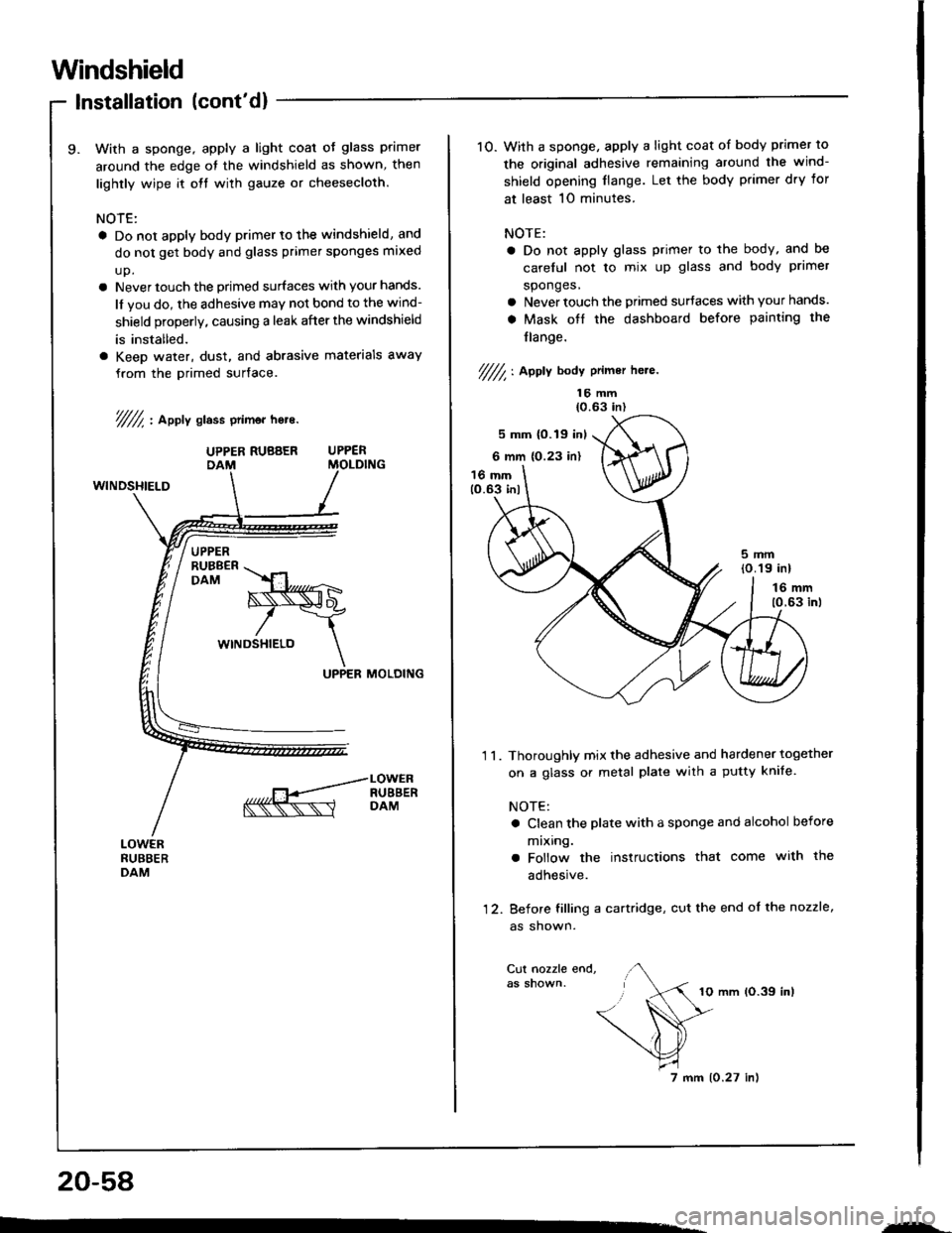

With a sponge. apply a light coal oJ glass primer

around the edge ot the windshield as shown, then

lightly wipe it olt with gauze or cheesecloth.

NOTE:

a Do not apply body primer to the windshield, and

do not get body and glass primer sponges mlxed

up.

a Never touch the primed surfaces with your hands.

ll you do, the adhesive may not bond to the wind-

shield properly, causing a leak afterthe windshield

is installed.

o Keep water, dust, and abrasive materials awaY

from the primed surface.

V//f, : apptv stass ptimer hors.

WINDSHIELD

RUBBER -DAM .YJ * o

>\ast,

/\WINDSHIELD

\UPPER MOLOING

UPPER RUBBER UPPER

10. With a sponge, apply a light coat of body primer to

the original adhesive remaining around the wind-

shield opening flange. Let the bodY primer dry tor

at least 1O minutes.

NOTE:

a Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges,

a Never touch the primed surfaces with your hands.

a Mask otl the dashboard before painting the

flange.

//////, I Aeely bodv Primer h6te.

16 mm{0.63 in)

5 mm {0.19 inl

6 mm (0.23 in)

16 mm1O.63 inl

5mm(O.19 inl

16 mm

10.63 inl

1 1 . Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

a Clean the plate with a sponge and alcohol before

mixlng.

a Follow the instructions that come with the

adhesive.

12. Before filling a cartridge, cut the end ol the nozzle,

as shown.

Cut nozzle end,

10 mm (O.39 inl

20-58

7 mm 10.27 in)

,*-