Minutes HONDA INTEGRA 1994 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1173 of 1413

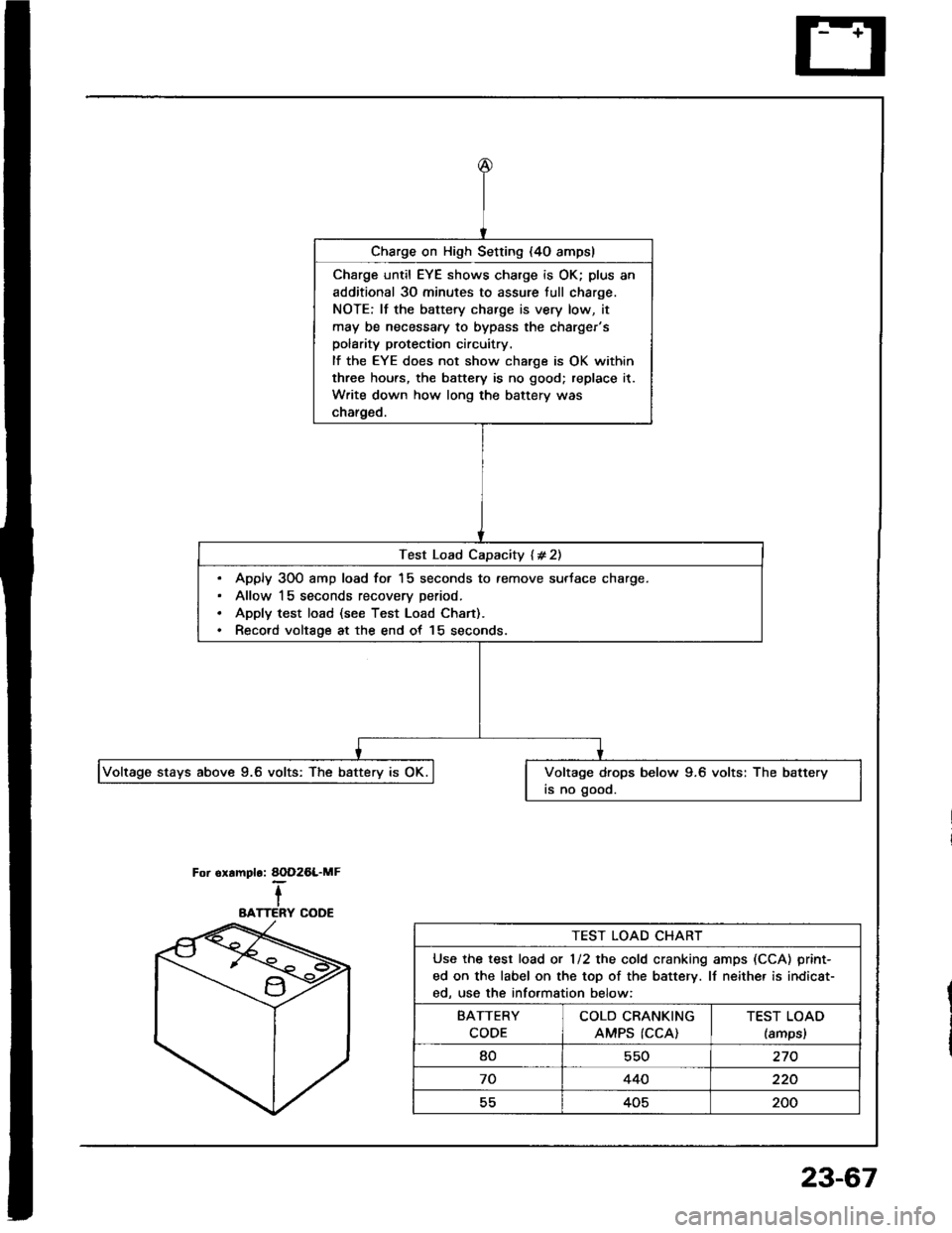

Charge on High Setting {4O ampsl

Charge until EYE shows charge is OK; plus an

additional 30 minutes to assure tull charge.

NOTE: lf the battery charge is very low, it

may be necessary to bypass the charger'spolarity protection circuitry.

lf the EYE does not show charge is OK within

three hours, the battery is no good; replace it.

Write down how long the battery was

charged.

Test Load Capacity l#21

Apply 300 amp load for 15 seconds to remove surface charge.

Allow 15 seconds recoverv Deriod.

Apply test load (see Test Load Chan).

Record voltaoe at the end of 15 seconds.

Voltage stays abov€ 9.6 volts: The Uattery is Of. IVoltage drops below 9.6 volts: The battery

is no good.

AOD26L.MF.-IIERY COOE

For oramplo:

BATTERY COOE

TEST LOAD CHART

Use the test load ot 112 the cold cranking amps (CCA) print-

ed on the label on the top of the battery. lf neithe. is indicat-

ed, us€ the information below:

BATTERY

CODE

COLD CRANKING

AMPS (CCA)TEST LOAD

lamps,

80550270

70440220

55405200

23-67

Page 1214 of 1413

Charging System

Alternator Belt Inspection and Adjustment

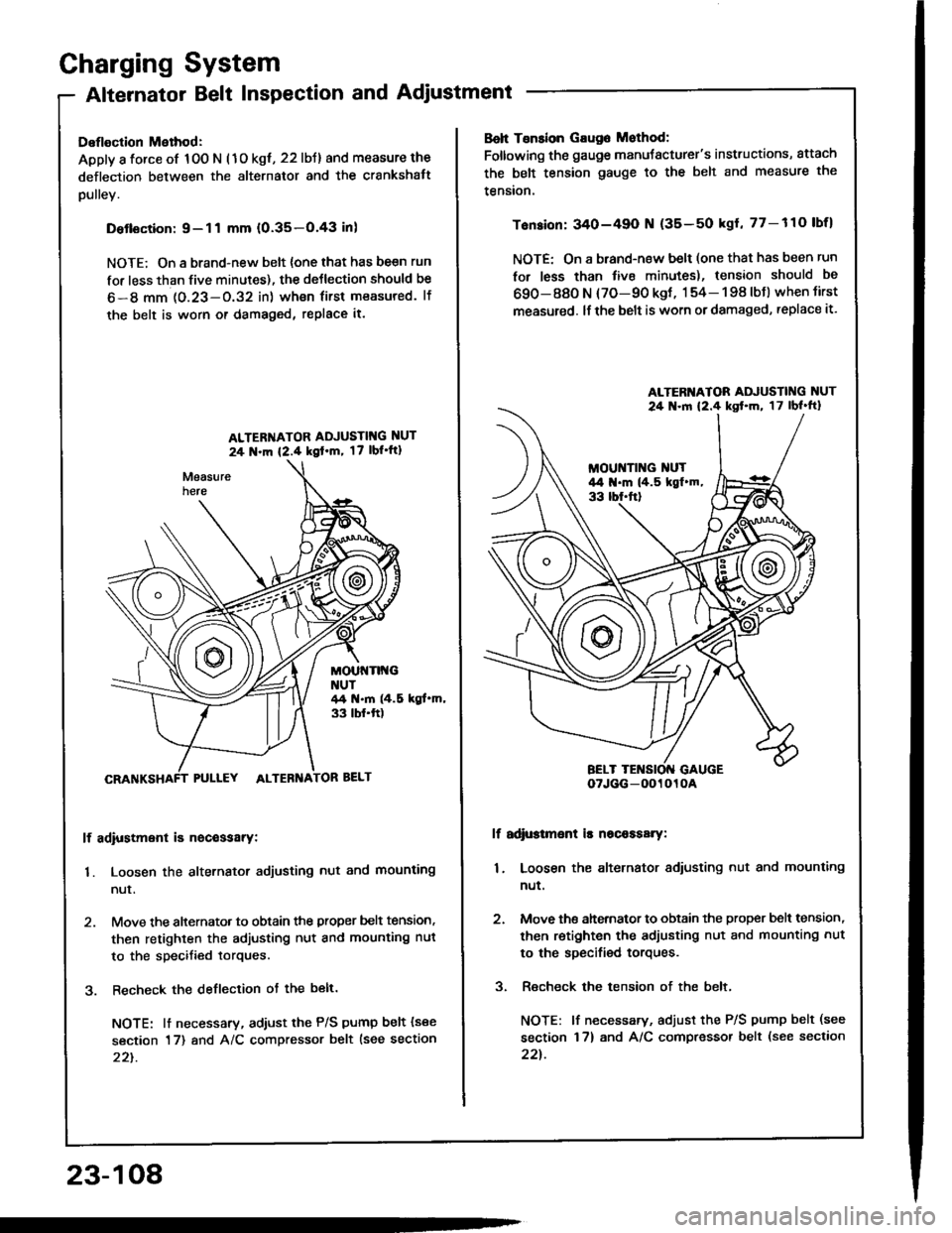

Deflection Method:

Apply a force of 100 N (1o kgt, 22 lbJ) and measure the

deflection between the alternator and the crankshatt

pulley.

Detlsction:9-11 mm (0.35-O.43 inl

NOTE; On a brand-new belt {one that has be€n run

for less than five minutes), the deJlection should be

6-8 mm 1O.23-O.32 in) wh€n first measured. lf

the belt is worn or damaged, replace it.

ALTER'{ATOR ADJUSTIT{G NUT

24 N.m {2.4 kgl'm, 17 lbl'ft1

MOUt{Tlt{GNUT44 t{.m (4.5 kgt.m,33 tbf.ft)

PULLEY ALTEBNA

lf adiustment is nocessarY:

1. Loosen the alternator adjusting nut and mounting

nur.

2. Move the alternator to obtain the proper belt tension,

then retighten the adjusting nut and mounting nut

to the specified torques.

3. Recheck the deflection ot the belt.

NOTE: lt necessary, adiust the P/S pump belt (see

section 17) and A/C compressor belt lsee section

22t.

23-108

Boh Tsnsion Gaug6 Mothod:

Foltowing the gauge manuJacturer's instructions, attach

the belt tension gauge to the belt and measure the

tension.

Tension: 340-49O N (35-50 kgl, 77-110 lbfl

NOTE: On a brand-new belt (one that has been run

for less than tive minutes), tension should be

690-880 N (70-90 kgt, 154- 198 lbJ) when tirst

measured. lf the belt is worn or damaged, replace it.

lf adi$tmsnt is nscaasary:

1. Loosen the alternator adiusting nut and mounting

nut.

2. Move ths ahernator to obtain the proper bslt tension,

then retighten the adjusting nut and mounting nut

to the specified torques.

3. Recheck the tension of the belt,

NOTE: lf necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

22t.

ALTERI{ATOR ADJUSTING NUT

24 .ln 12.4 kst'm, 17lbl'ft}

oTJGG-0O1010A

Page 1231 of 1413

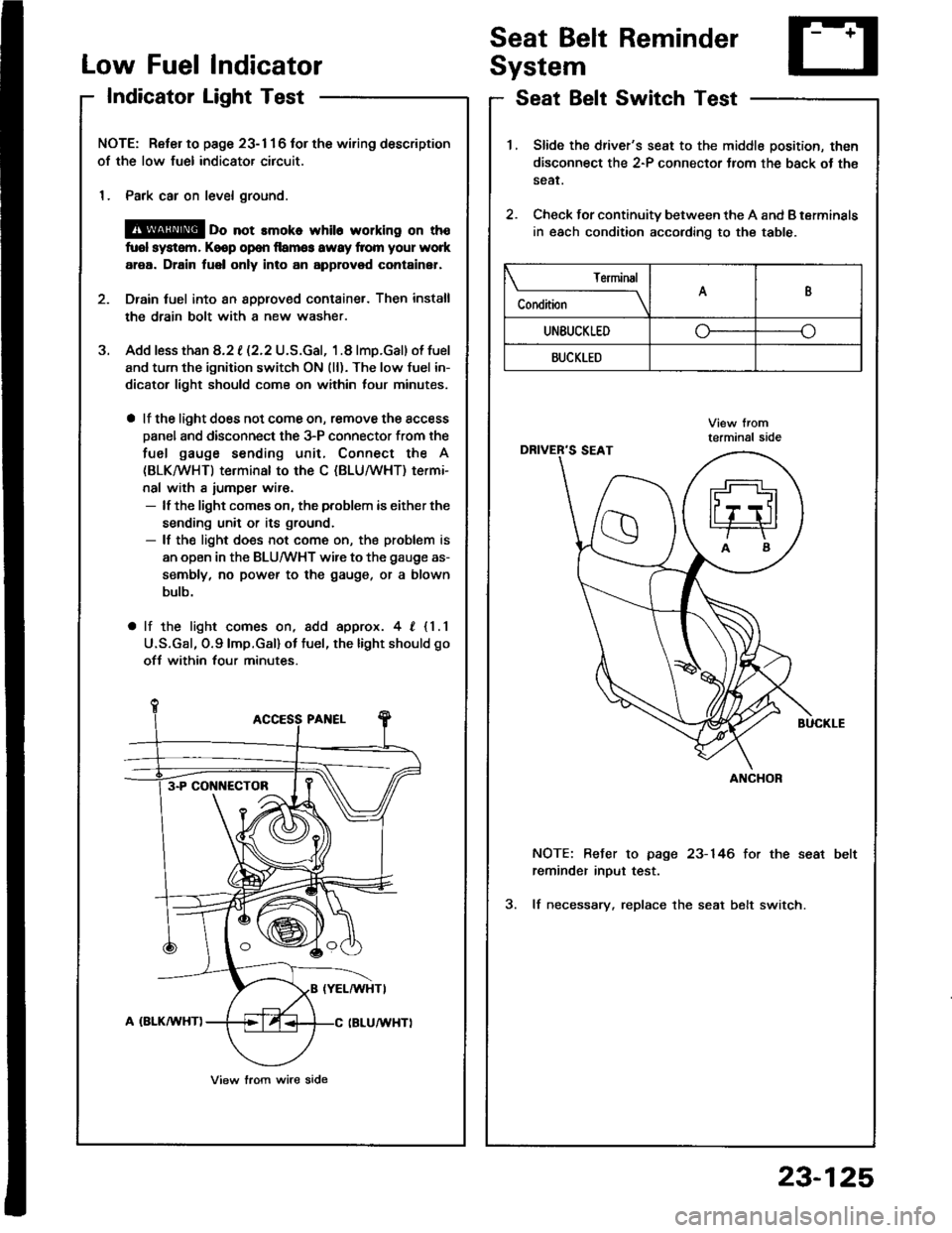

Low FuelIndicator

IndicatorLight Test

Seat Belt Reminder

System

Seat Belt Switch Test

J.

NOTE: Reter to page 23- 1 1 6 tor the wiring description

of the low fuel indicator circuit.

1. Park car on level ground.

@ oo not rmoko whil6 working on th€

fuol system, Keop op€n llamg3 awsy from your work

area. Drain fuel only into an approvod container,

Drain tuel into an 8pplov€d container. Then install

the drain bolt with a new washer.

Add less than 8.2 t (2.2 U.S.Gal, 1.8 lmp.Gal) of fuel

and turn the ignition switch ON (ll). The low fuel in-

dicator light should com€ on within lour minutes,

a lf the light does not come on, remove the access

Danel and disconnect the 3-P connector from the

fuel gauge sending unit, Connect the A

(BLKMHT) terminal to the C (BLU/WHT) termi-

nal with a iumper wir€.- lf the light comes on, the problem is either the

sending unit or its ground.- lf the light does not come on, the problem is

an open in the BLU/WHT wire to the gauge as-

sembly, no power to the gauge, or a blown

bulb.

a lf the light comes on, add approx. 4, {1.1

U.S.Gal, O.9lmp.Gal) ot tuel, the light should go

ofJ within four minutes.

3-P CONI{ECTOB

View lrom wire side

1.Slide the driver's seat to the middle position, then

disconnect the 2-P connector Jrom the back ot th€

sear.

Check for continuity between the A and B terminals

in each condition according to the table.

2.

NOTE: Befer to page 23-146 for the seat

reminder inout test.

3. lf necessary. replace the seat belt switch.

Terminal

C"** \AB

UNEUCKLEDo--o

BUCKLED

ANCHOR

23-125

Page 1312 of 1413

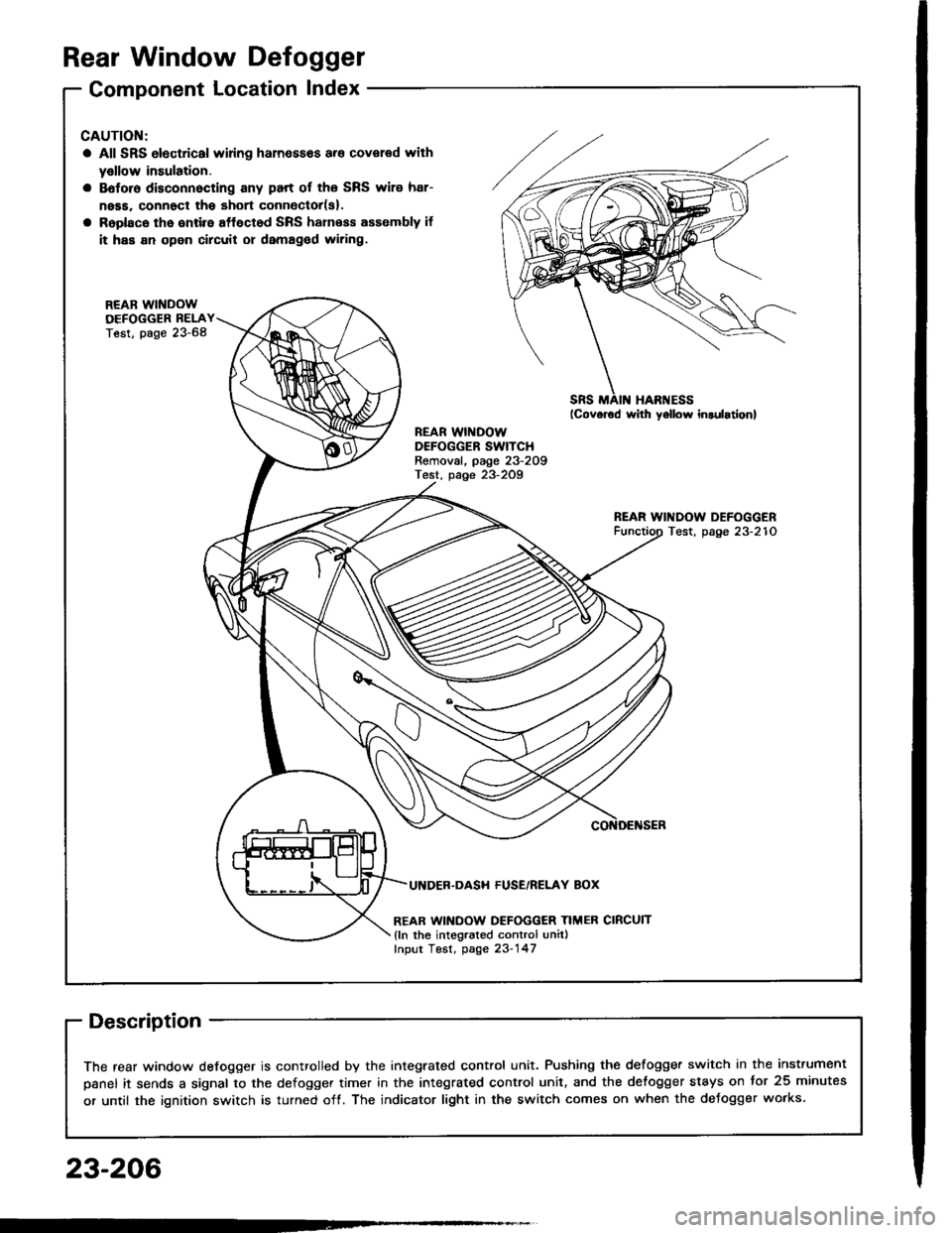

Rear Window Defogger

Component Location Index

CAUTION:

a All SRS olectrical wi ng ham€$6s are covoled with

y€llow insulation.

B6foro disconnocting any part of ths SRS wire har-

ness. connoct tho short connector(s).

Roplacs the ontire affectod SRS harness assombly if

it has an open circuit or damagcd wiring.

REAB WINDOWDEFOGGER RELAYTest, page 23-68

REAR WINDOWDEFOGGER SWITCHRemoval, page 23-209Test, page 23-2Og

REAR WINDOW DEFOGGERTest, page 23-210

UI{DER.DASH FUSE/RELAY BOX

REAR WINDOW DEFOGGER TIMER CIRCUIT

{ln the integrated control unil)fnput Test, page 23-147

SRS MAII{ HAR'{ESS

The rear window defogger is controlled by the integrated control unit, Pushing the defogger switch in the instrument

panel it sends a signal to the defogger time. in the integrated control unit, and the detogger stays on tor 25 minutes

or until the ignition switch is turned off. The indicator light in the switch comes on when the deJogger works.

23-206

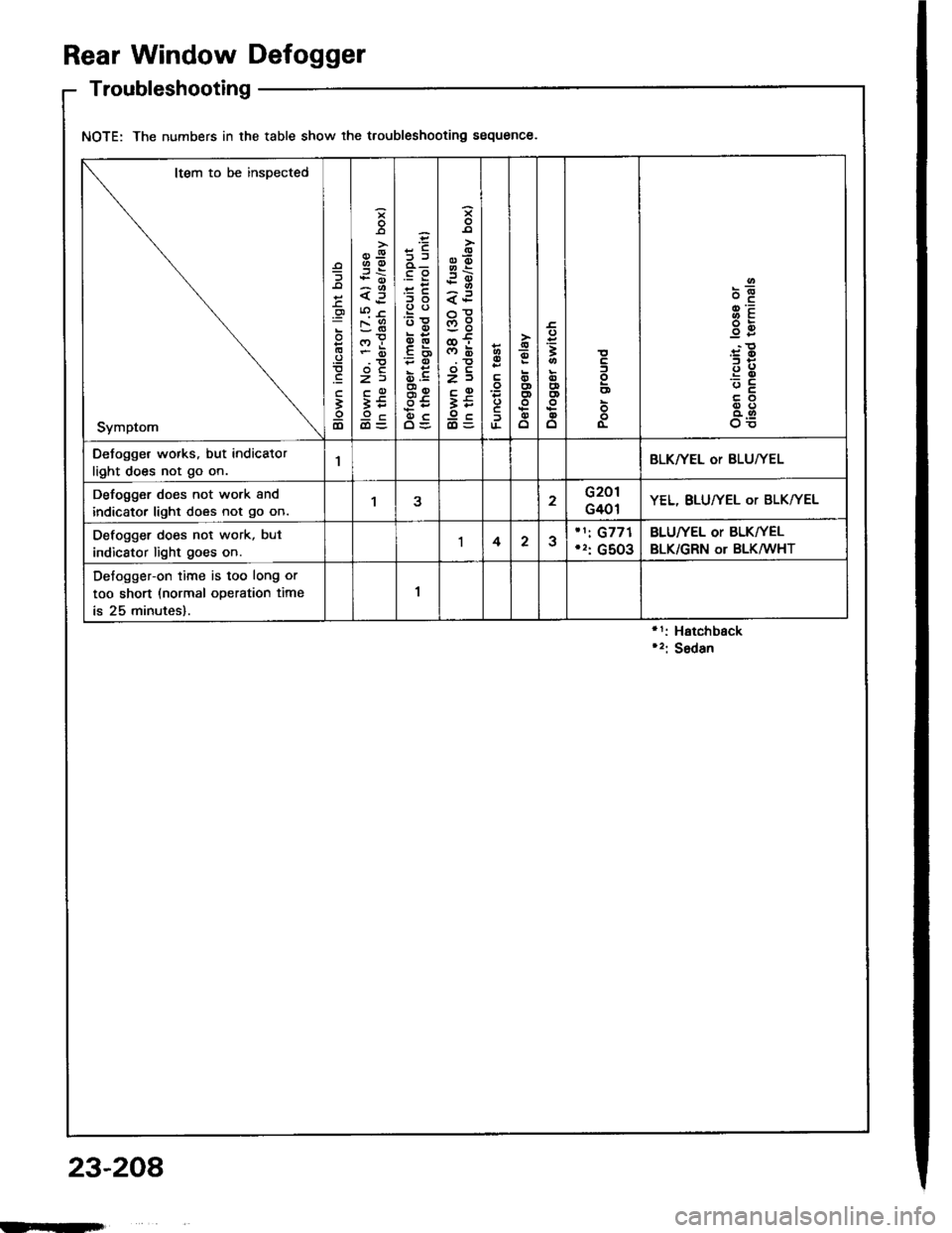

Page 1314 of 1413

Rear Window Defogger

Troubleshooting

NOTE: The numbers in the table show the troubleshooting sequence.

'1: Hatchback'2: Sedan

Item to be inspected

Symptom

o

'

lD

*o--

zi

ii9c

.E

o.-

:E

go

.E6

5.

o0to9\cg

z)

;5

o

!

ooooo

=3

oEDo

o

o

oo-

@=

g8

oo

o5

Defogger works, but indicator

light does not go on.1BLKTYEL oT BLU/YEL

Defogger does not work and

indicator light does not go on.122G201

G401YEL, BLUfYEL or BLK/YEL

Defogger does not work, but

indicstor light goes on.1423'1i G771',: G5O3

BLU|YEL or BLKIYEL

BLK/GRN oT BLKMHT

Defogger-on time is too long or

too short (normal operation time

is 25 minutes).

1

23-208

IINIilfi

Page 1316 of 1413

Rear Window Defogger

Function Test

CAUTION: Be carelul not to scratch 01 damago ths

defogger wires with th€ tsster probe.

1 . Check for voltage between the positive terminal and

body ground with the ignition switch and the delog-

ger switch ON. There should be battery voltage.

a lf there is no voltage, check for

- laulty detogger relay.- faulty defogger switch.- faulty integrated control unit.- an open in the BLK/GRN wire

a lJ there is baftery voltage, go to step 2.

NEGATIVE TERMIiIALPOSITIVE TERMINAL

Turn the rear window detogger switch OFF, Check

for continuity between the negative terminal and

body ground.

a It there is no continuity, check to. an open in the

defogger ground wire.

a ll there is continuity, go to step 3.

Touch the voltmeter positive lead to the halfway

point of each defogger wire, and the negative lead

to the negative terminal.

There should be apptoximately 6 V with the ignition

switch and defogger switch ON.

a lf the voltage is as specified, the defogger wire

is OK.

a lf the voltage is not as specified. repai, the defog-

ger wire:

lf it is more than 6 V, look for the damage on

the negative half on the grid.

- lf it is less than 6 V. iook for the damage on

the positive half of the grid.

Defogger Wires Repair

NOTE: To make an eftective repair. the broken section

must be no longer than one inch.

1 . Lightly rub the area around the break with line steel

wool, then clean it with alcohol.

2. Carefullv mask above and below the broken portion

of the defogger wire with cellophane tape.

Using a small brush, apply a heavy coat of silver con-

ductive paint extending about 3 mm ( 1/8 inl on both

sides of the break. Allow 30 minutes to dry.

NOTE: Thoroughly mix the paint before use.

Check for continuity in the repaired wire.

Apply a second coat of paint in the same way.

it drv three hours betore removing the tape.

4.

OPEN

23-210

tLet

Page 1405 of 1413

Supplemental Restraint System (SRSI

Airbag Assembly Disposal (cont'd)

Connect a l2 volt batterv to the tool:

. lf the green light on the tool comes on, th€

airbag igniter circuit is d€fective and cannot

deploy the airbag. Go to Dsmag€d Airbag

Special Procedure.

. lf the red light on the tool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. Th6 sirbag

should deploy (deployment is both highly audible

and visibls - a loud noise and raDid inflation of the

bag, followed by slow deflationl.

. lf audible/visible deploym€nt happsns and the

green light on the tool comes on, continus with

this Drocedure.

. lf the airbag doesn't deploy, yet the green light

comes ON, its igniter is dofectiv€. Go to

Damaged Airbag Special Procedure.

@ During deploym€nt, the airbsg assom-

bly can become hot enough to burn you. Wait thirty

minutes after deployment beforo touching the

assemblv.

Dispose of the complete airbag sssembly. No pan

of it can be reused. Place it in I sturdy plastic bag

and seal it securelv.

CAUTION:

Woar a taco shiold lnd glov.s whon hlndling !

doploy.d airbag.

Waeh your hands and rin3a tham wall with

wslor aftor handling r deploycd !irb!g.

23-300

Doploying the Airbag: Out-ot{!r.

NOTE: lf an intsct airbag assembly has been removed

from a scrapped car, or has been found dofective or

damagsd during transit, storage or service, it should bs

dsployed as follows:

@ Porition th6 lirbrg rr:.mbly t.ce up, out-

doo6 on flat ground !t lorrt thirty foot from rny ob3t..

clar or pcoplo.

1. Confirm that the special tool is functioning properly

by following the check procedure on this page or on

the tool box label.

2. Remove the short connector from the airbag con-

nector.

3. Folfow steps 5,6,7, and 8 of the in-car deployment

orocequre.

Dlmlged Airbsg Sp.ci8l Procoduro.

E!@ f rn lirbag crnnot be deploy.d, it rhould

not br trcltcd !s normll scrrp; ii 3hould still bc comid-

ercd a potantillly oxplolivr dcvicc thli cln c!u3a 3ari-

ou3 iniury.

1. lf instslled in a car, follow the removal procedure on

page 23-295.

2. In all cases, make sure a short connector is properly

installed on the airbag conn€ctor.

3. Package the airbag in sxacily the same packaging

that the now replacement part cama in.i[. Mark the outside 0f the box "DAMAGED AIRBAG

NOT OEPLOYED" so it does not get confused with

your parts stock.

5. Contact your Acura District Service Manager for

how and where to return it for disoosal.

Dcploymont Tool: Chcck Procedure.

1. Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

2. Push th€ operation switch: green means the tool is

OK; red means the tool is faulty.

3. Disconnect the battery and the yellow clips.