Minutes HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 928 of 1413

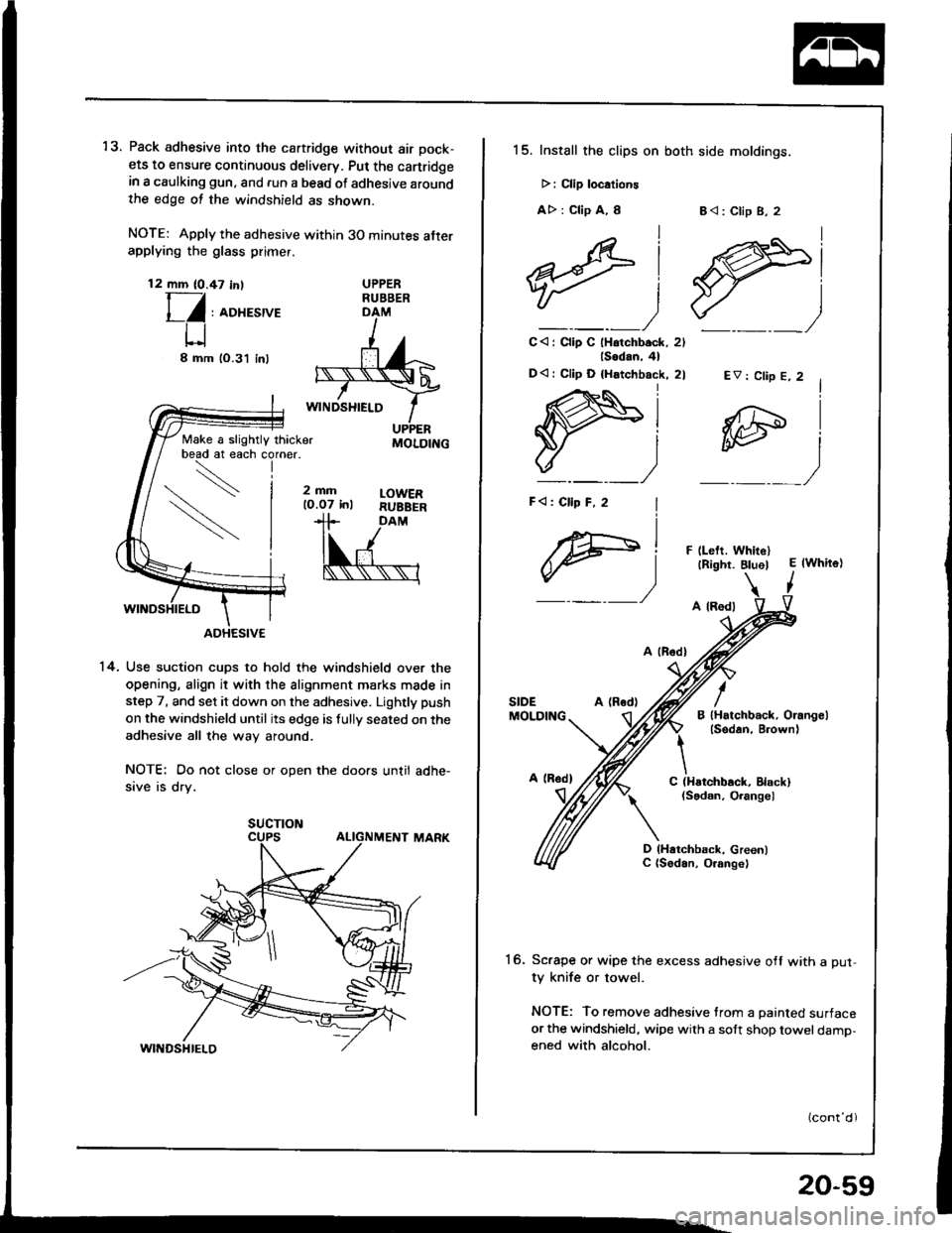

13. Pack adhesive into the cartridge without air pock-

ets to ensure continuous delivery. Put the canridgein a caulking gun, and run a bead ot adhesive aroundthe edge ot the windshield as shown.

NOTE: Apply the adhesive within 30 minutes afterapplying the glass primer.

12 mm (0.47 in,T-/

l_/ : roxesrve

U8mm

Make a slightly thicker

DAM

'14. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly push

on the windshield until its edge is fully seated on the

adhesive all the way around.

NOTE: Do not close or open the doors until adhe-

sive is dry.

UPPERRUBBER

lO.3'l inl

2mfilO.O7 inlLOWERRUBBEB

MOLDING

SUCTION

15. Install the clips on both side moldings.

>: Clip localione

A> : Clip A, I

lsodan,4l

D<: Cllp D {Hatchback, 2l

I

F)

B<: Clip B, 2

lAi

ffil"___)

C<: Clip C lHatchback, 2l_)

EV: Clip E, 2

F llelt. WhitellRight. BluelE lwhite)

I

A (Rod)

A lRodl

B lHatchback, Orangellsedan, B.own)

/SIDEMOLDING

It\C (Hstchback, Elack)(Sodan, Orangel

D lHatchback, Green)C (Sodan, O.ange)

16. Sc.ape or wipe the excess adhesive off with a Dut-ty knife or towel.

NOTE: To remove adhesive trom a painted surface

or the windshield, wipe with a solt shop towel damp-ened with alcohol.

20-59

Page 933 of 1413

Rear Window

Installation (cont'd)

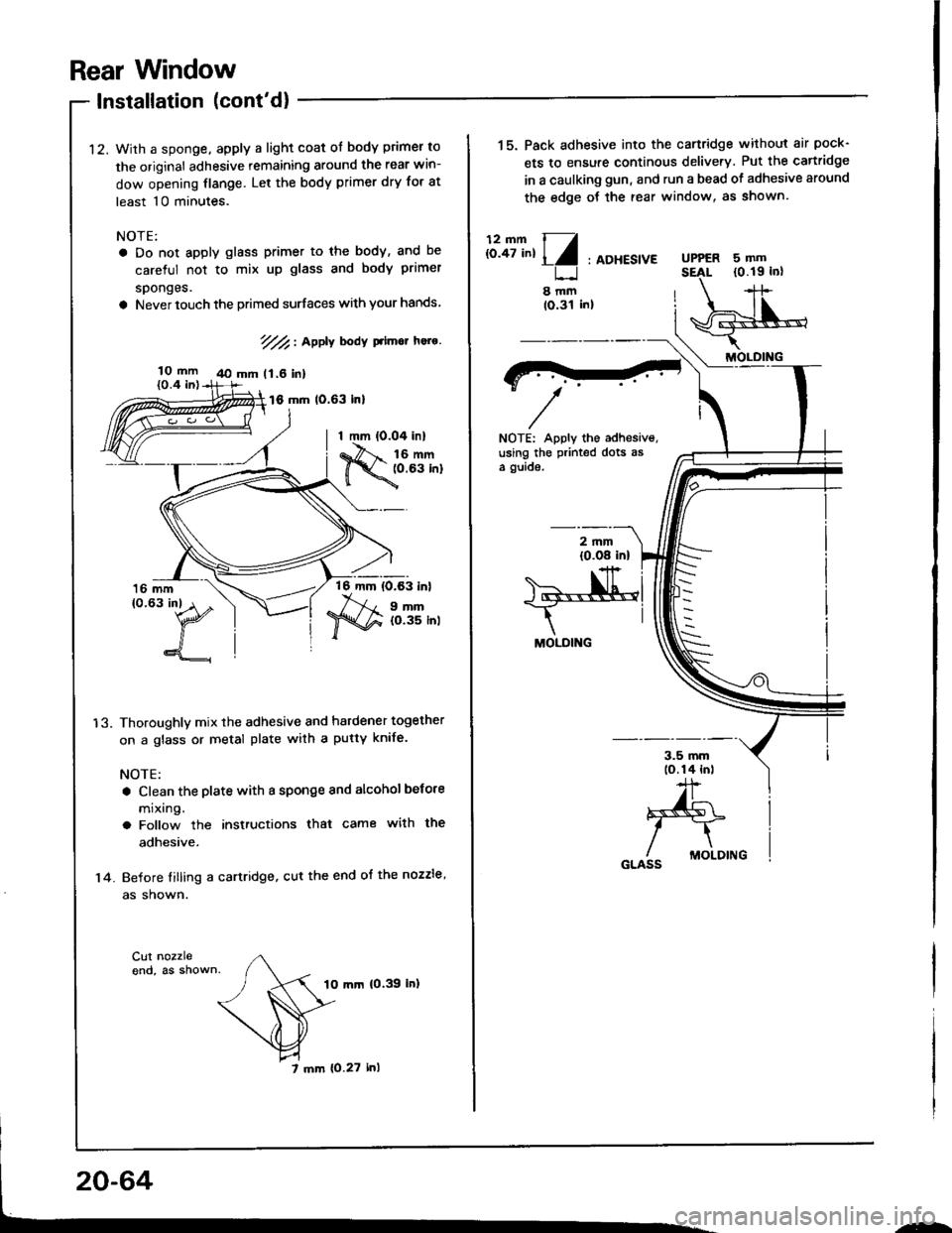

12.

10 mm

{0.4 in)

With a sponge, apply a light coat ol body primer to

the original adhesive remaining around the rear win-

dow opening flange. Let the body primer dry tor at

least 10 minutes.

NOTE:

a Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.

a Never touch the primed surfaces with your hands

16 mm {0.63 inl

t|nm(O.35 Inl

Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife'

NOTE:

a Clean the plate with a sponge and alcohol befole

mixing.

a Follow the instructions that came with the

adhesive.

Before lilling a cartridge, cut the end of the nozzle'

as shown.

1O mm {0.39 inl

7//, I Applv body p.lmor h.]o.

40 mm 11.6 Inl

16 mln 10.63 Inl

1 mm {0.04 inl

fu.:*1",

I J.

14.

7 mm (0.27 inl

.-

it.E\,",1/: ADHESTVE

NOTE: Apply the adhesiv€,using the printed dots aaa guide.

15. Pack adhesive into the cartridge wilhout air pock-

ets to ensure continous delivery. Put the cartridge

in a caulking gun, and run a bead of adhesive around

the edge of ihe rear window, as shown.

UPPERSEAL

-C=

/\/ MOLDINGGLASS

5mm10.19 Inl

8mm10.31 inl

MOLDING

lO.Oa inl

)E--lT-*-\

MOLDING

Page 940 of 1413

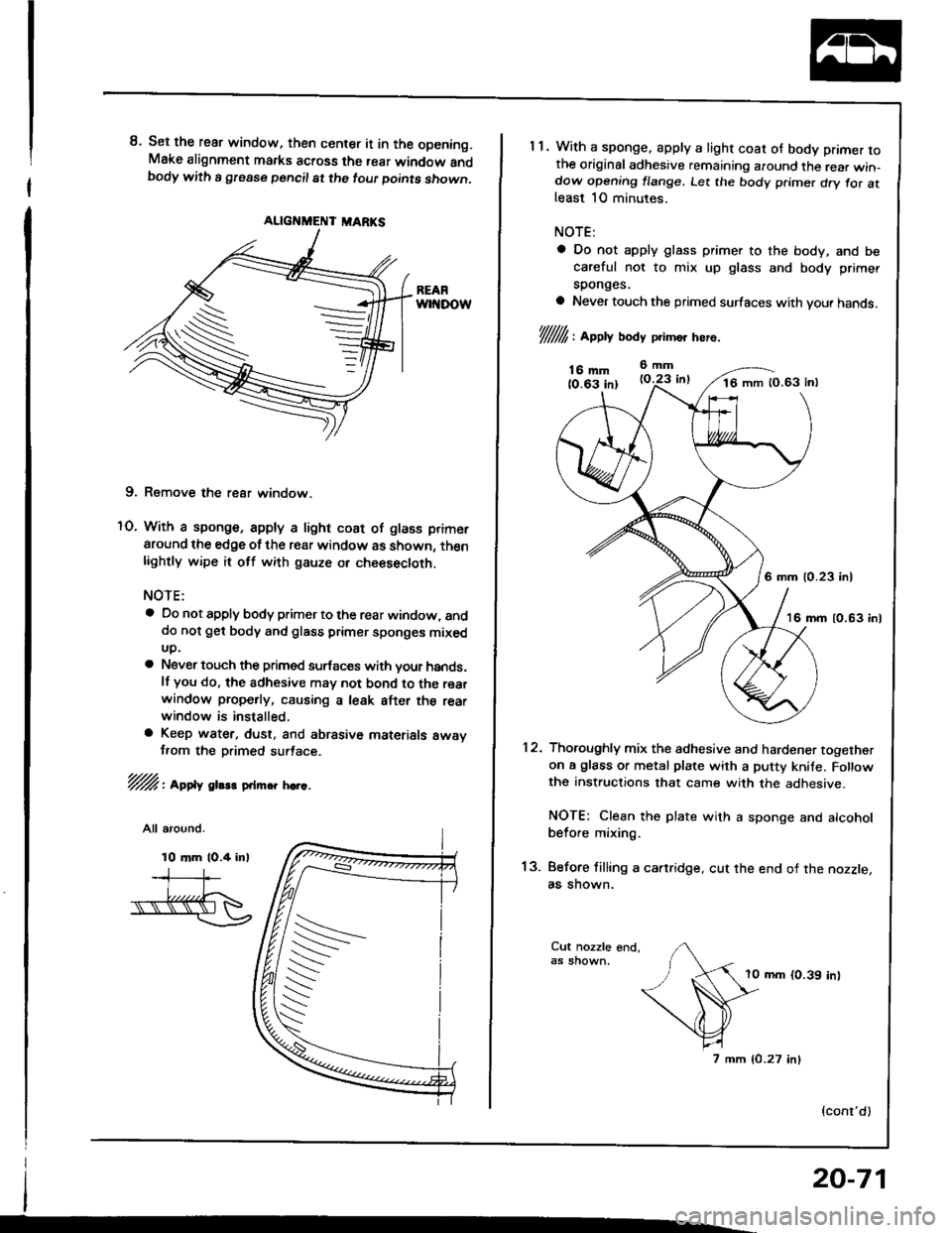

ALIGT{MENT MARKS

S

8. Set the rear window, then center it in the opening.Make alignment marks across the rear window andbody with a gfease pencil at the tout Doints shown.

9. Remove the rear window.

O. With a sponge, apply a light coat of glass primer

around the edge of the rear window as shown, thenlightly wipe it otf with gauze or cheesecloth.

NOTE:

a Do not apply body primer to the rear window, anddo not get body and glass primer sponges mixedup.

a Never touch the primed surfac€s with your hands.lf you do, the adhesive may not bond to the rearwindow prope.ly, causing a leak after the rearwindow is installed.

a Keep water. dust, and abrasive materials awavf,om the D.imed surtace.

72/: Appl,t gltst onmrr sctc.

All around.

10 mm lO.4 inl

/.s

s

20-71

1 1. With a sponge. appty a light coat ot body primer rothe original adhesive remaining around the rear win-dow opening flange. Let the body p.imer d.y tor atleast 10 minutes.

NOTE:

a Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.

a Never touch the primed surfaces with vour hands.

l//////1,: appv body p'imo' hero.

;o:d:';", i"lT16 mm 10.63 inl

6 mm 10.23 inl

16 mm 10.63 inl

12. Thoroughly mix the adhesive and hardener togetheron a glass or metal plate with a putty knife. Fo owthe instructions that came with the adhesive.

NOTE: Clean the plate with a sponge and alcoholbefore mixing.

13. Before filling a cartridge, cut the end of the nozzle,as shown.

10 mm (0.39 in)

7 mm (0.27 inl

{cont'd)

Page 941 of 1413

Rear Wndow

Installation (cont'dl

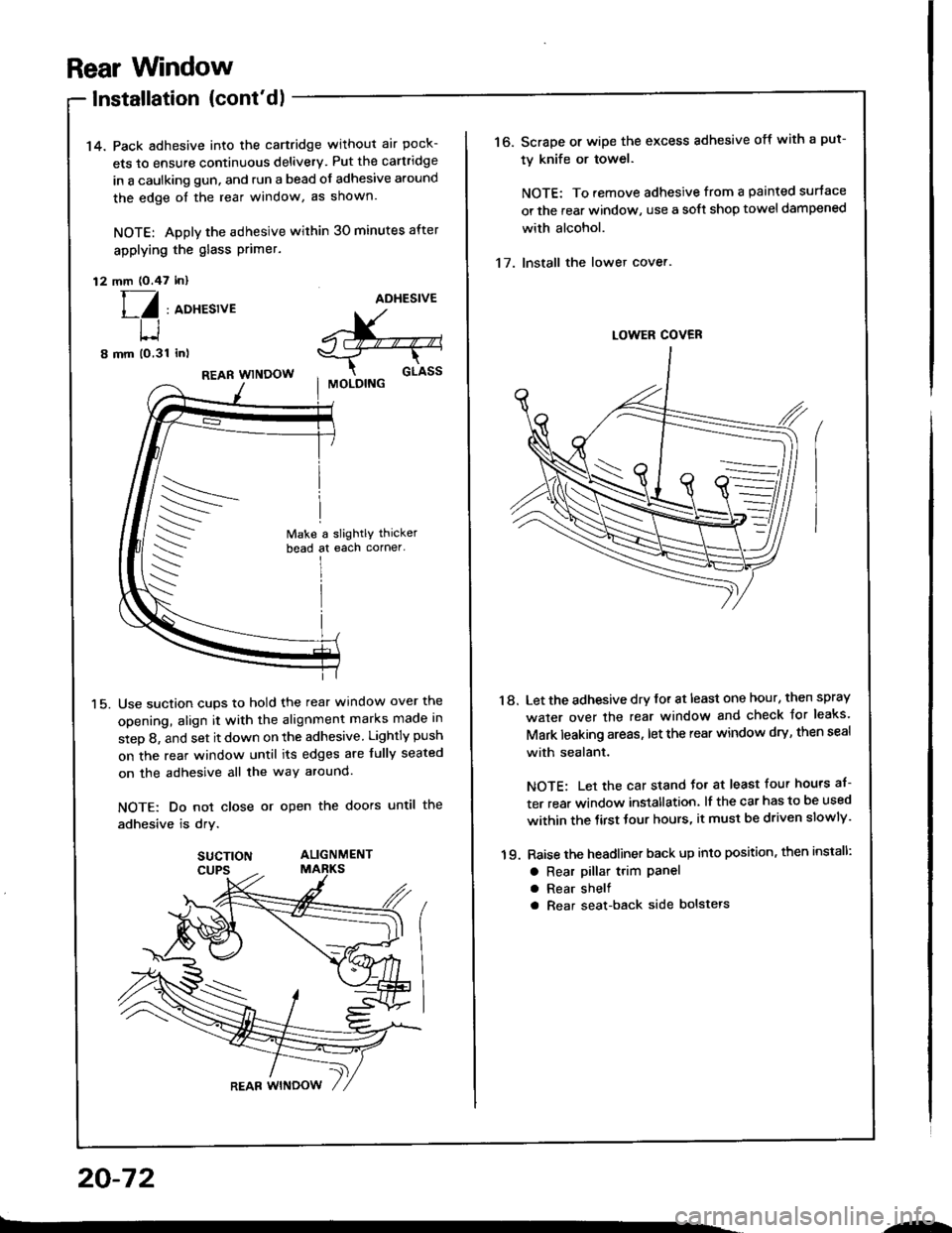

14. Pack adhesive into the cartridge without air pock-

ets to ensure continuous delivery. Put the cartridge

in a caulking gun, and run a bead of adhesive around

the edge oI the rear window, as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass Primer.

12 mm (O.47 inl

[/ , aoxesrveADHESIVE

^X-"--"-,s-_T--r-

cr-rssI MOLOING

t-l

8 mm (o,31 inl

15.

REAR WINDOW

Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 8, and set it down on the adhesive Lightly push

on the rear window until its edges are fully seated

on the adhesive all the way around.

NOTE: Do not close or open the doors until the

adhesive is drv.

SUCTION ALIGNMENT

20-72

.-

16. Scrape or wipe the excess adhesive off with a put-

ty knife or towel.

NOTE: To remove adhesive from a painted surtace

or the rear window, use a soft shop towel dampened

with alcohol.

17. Install the lower cover.

'18. Let the adhesive dry for at least one hour, then spray

water over the rear window and check Jor leaks'

Mark leaking areas, let the rear window dry, then seal

with sealant.

NOTE: Let the car stand Jo. at least four hours af-

ter rear window installation, lf the car has to be used

within the tirst tour hours, it must be driven slowly'

19. Raise the headliner back up into position, then install:

a Rear pillar t.im Panela Rear shelf

a Rear seat-back side bolstels

Page 944 of 1413

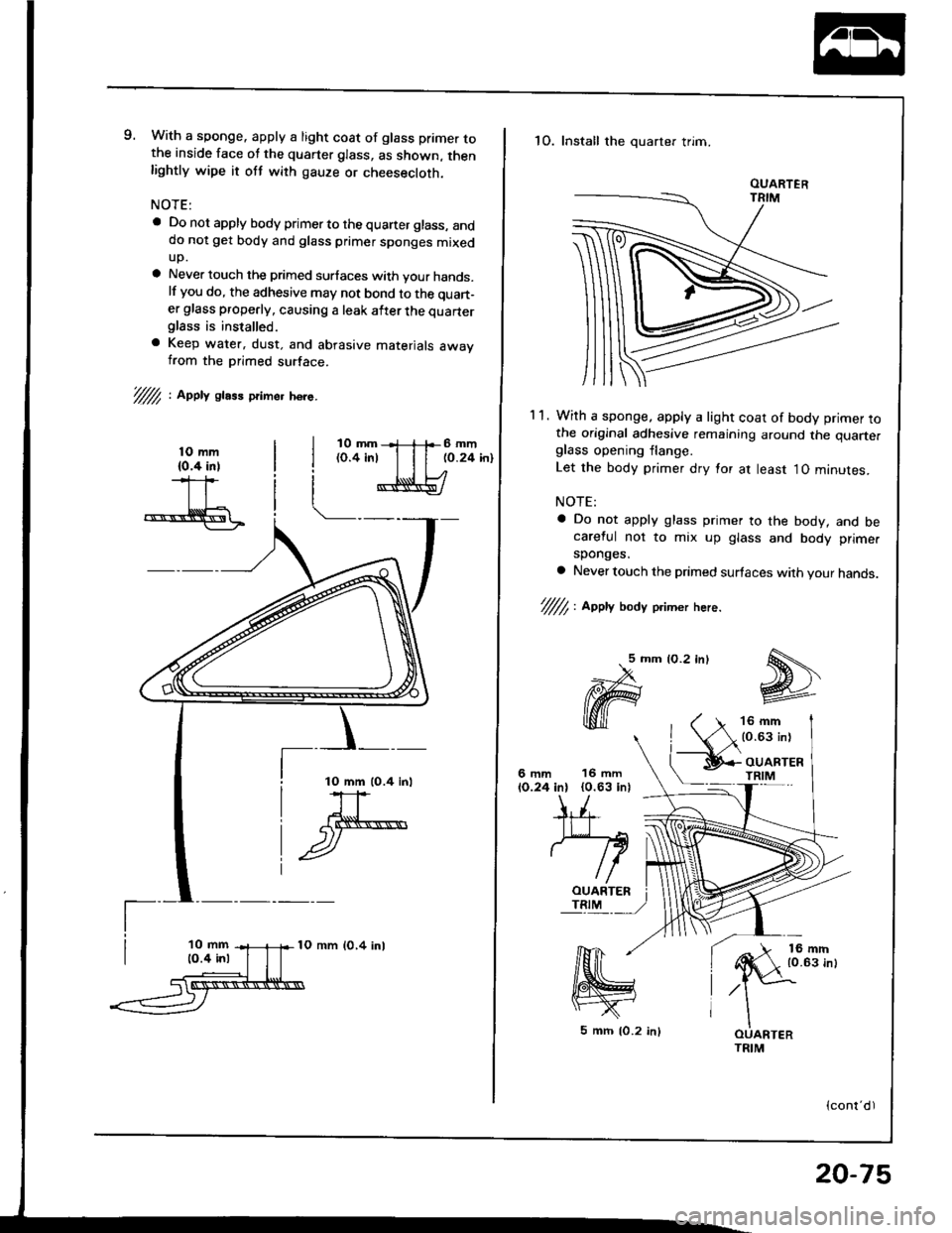

9. With a sponge. apply a light coat of glass primer tothe inside face ot the quarter glass, as shown, thenlightly wipe it ott with gauze or cheesecloth.

NOTE:

a Do not apply body primer to the quaner glass, anddo not get body and glass primer sponges mixedup.

a Never touch the primed surlaces with your hands.lf you do, the adhesive may not bond to the quan-

er glass properly, causing a leak after the quarterglass is installed.

a Keep water, dust. and abrasive materials awavfrom the primed surface.

V/// , AooV glass primer h6re-

10 mm lO.4 inl

10 mm lO,4 inl

1O. Install the quarter trim.

1 1. With a sponge. apply a light coat of body primer tothe original adhesive remaining around the quarte.glass opening flange.

Let the body primer dry lor at least 1O minutes.

NOTE:

a Do not apply glass primer to the body, and becareful no1 to mix up glass and body prime.

sponges.

a Never touch the primed surfaces with your hands.

'////7, , aepty body p.imer here.

lO.2 inl5mm

ffi

16 mm{0.63 in}

'16 mm(0.63 inl

6mm10.24 in)

OUARTERTRIM

(cont'd )

OUARTER

5 mrr| 10.2 inl

20-75

Page 945 of 1413

Ouarter Glass

SIOE SPACER

ADHESIVETAPE A

Replacement (cont'd)

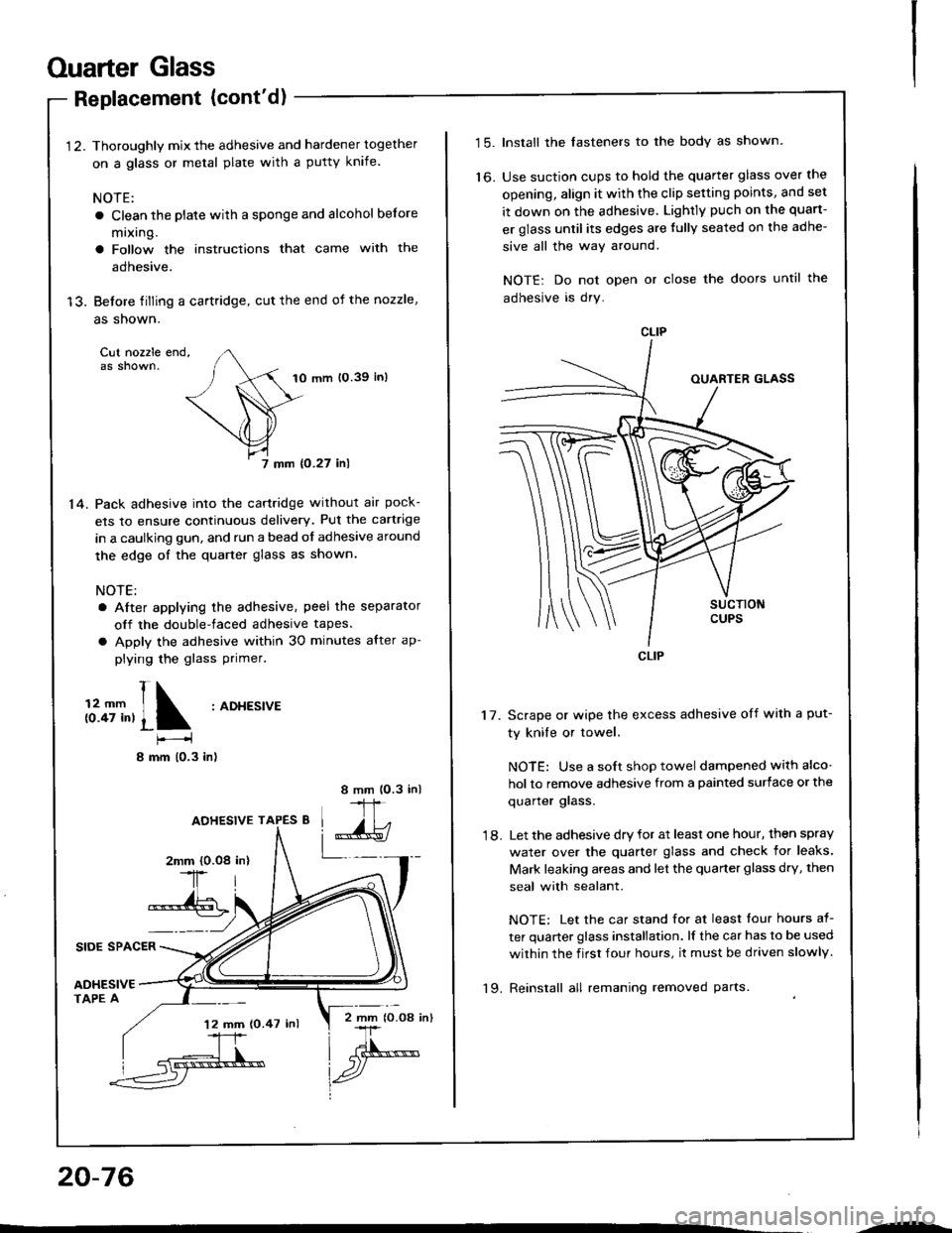

1 2. Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

a Clean the plate with a sponge and alcohol before

mixing.

a Follow the instructions that came with the

adhesive.

13. Before tilling a cartridge, cut the end of the nozzle,

as shown.

Cut nozzle end,as shown.10 mm 10.39 in)

7 mm {0.27 inl

14. Pack adhesive into the cartridge without air pock-

ets to ensure continuous delivery. Put the cartrige

in a caulking gun, and run a bead of adhesive around

the edge of the quarter glass as shown.

NOTE:

a After applying the adhesive, peel the separator

off the double-faced adhesive tapes.

a Apply the adhesive within 30 minutes after ap-

plying the glass Primer.

t1;T,,1 :ADt'�Es'�vE

I mm 10.3 in)

8 mm lO.3 in)

IJ,

L_-_2mm {0.08-1r

*-{6

AOHESIVE TAPES 8

20-76

'12 mm (0.47 inl2 mm lO.O8 in)

--

t5.Install the fasteners to the body as shown.

Use suction cups to hold the quarter glass over the

opening, align it with the clip setting points, and set

it down on the adhesive. Lightly puch on the quart-

er glass until its edges are tully seated on the adhe-

sive all the way around.

NOTE: Do not open or close the doors until the

adhesive is dry.

to.

17. Scrape or wipe the excess adhesive off with a put-

ty knile or towel,

NOTE: Use a soft shop towel dampened with alco-

hol to remove adhesive from a painted surface or the

quarler glass.

18. Let the adhesive dry for at least one hour, then spray

water over the quarter glass and check for leaks'

Mark leaking areas and let the quarter glass dry, then

seal with sealant.

NOTE: Let the car stand for at least tour hours at-

ter quarter glass installation. lf the car has to be used

within the f irst four hours, it must be driven slowly.

'19. Reinstall all remaning removed parts.

Page 1092 of 1413

A/G System Service

Performance Test

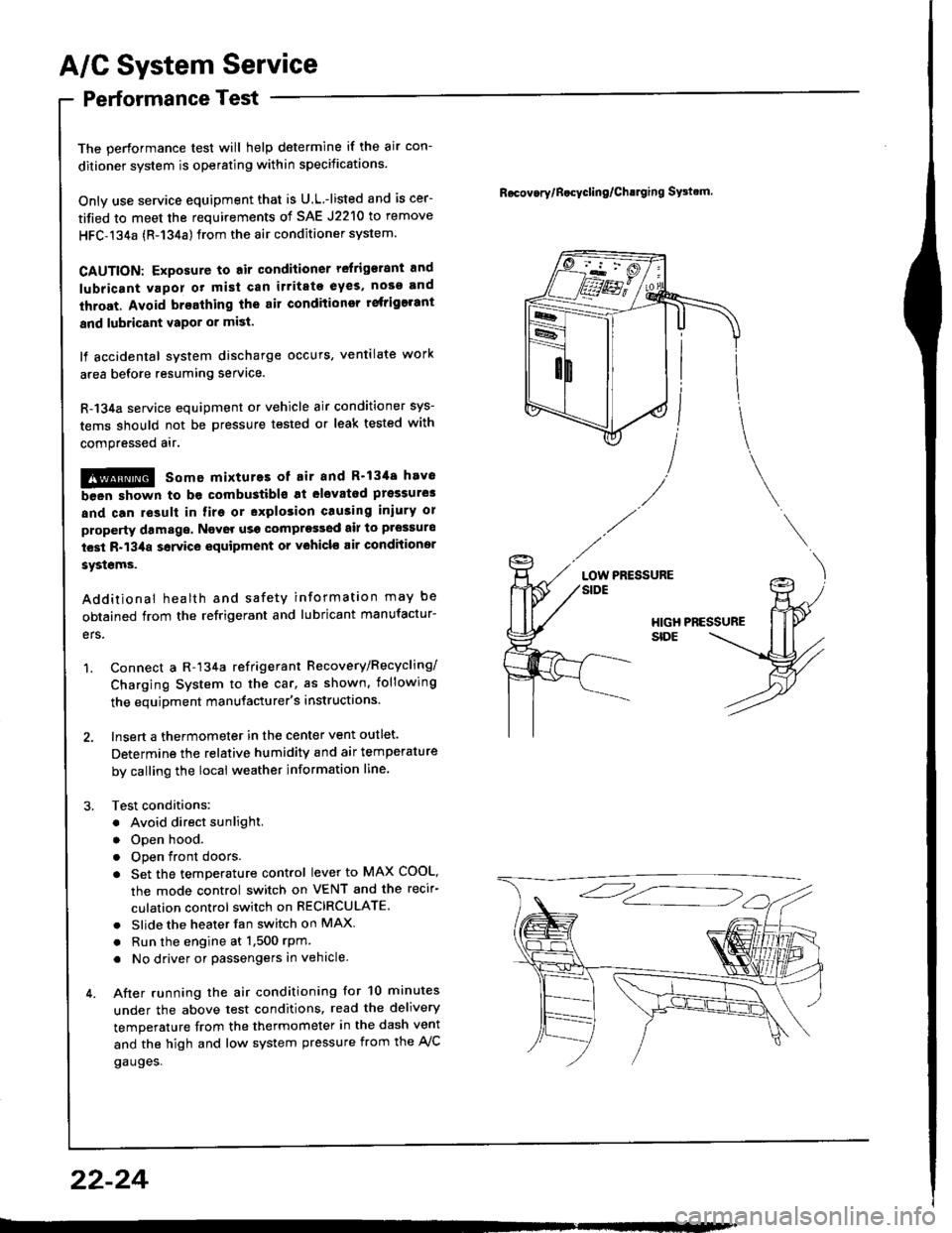

The performance test will help determine if the air con-

ditioner system is operating within specitications.

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a {R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner relrig€rant and

lubricant vapor ot mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner rstrigerant

and lubricant vapor or mi3t.

It accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comPressed atr.

!@ some mixtures ot air and R'1344 hrv6

been shown to be combustibls at elovatod prsssurel

and can result in firg or explosion causing iniury 01

property damage. Ngvor usg compregsed ail to prossuro

t€st R-134a ssrvice equipment or vohicl€ air conditioner

syst€ms.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufactur-

ers.

1. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the car, as shown, iollowing

the equipment manufacturer's instructions.

2. Insert a thermometer in the center vent outlet.

Determine the relative humidity and air temperature

by calling the local weather information line,

3. Test conditions:

. Avoid direct sunlight.

. Open hood.

. Open front doors

. Set the temperature control lever to MAX COOL,

the mode control switch on VENT and the recir-

culation control switch on RECIRCULATE.

. Slide the heater fan switch on MAX

. Run the engine at 1,500 rPm

. No driver or passengers in vehicle.

4. After running the air conditioning for 10 minutes

under the above test conditions. read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A,/C

gauges.

Rocov.rylB.cycling/Ch!lging SFtrm.

PRESSURELOW

22-24

Page 1102 of 1413

A/C Compressor Belt

Adjustment

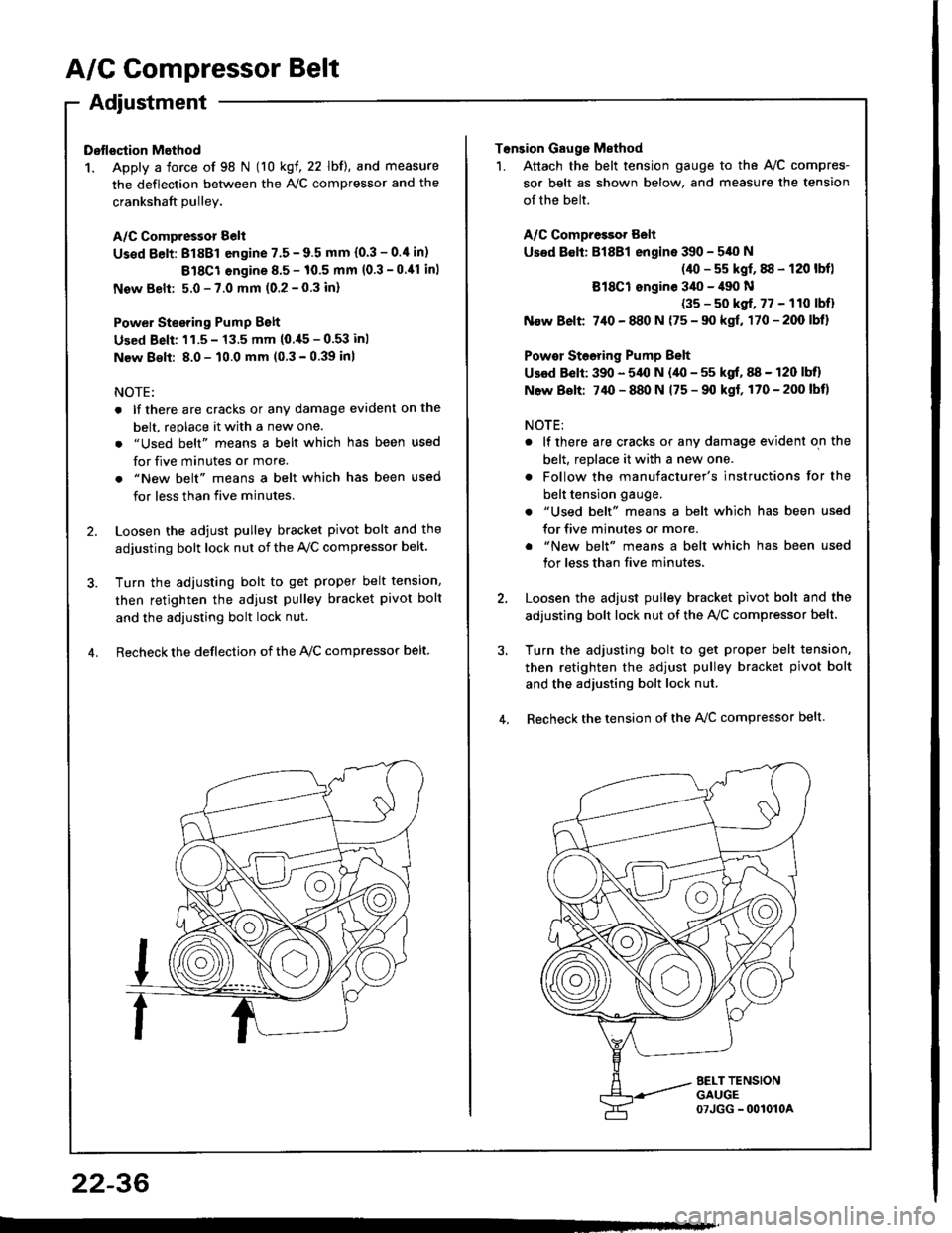

Dstlsqtion Method

1. Apply a force of 98 N (10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft Dullev.

A/C Compressor Belt

Us€d Eelt: 81881 engine 7.5 - 9.5 mm (0.3 - 0.4 in)

Bl8Cl engine 8.5 - 10.5 mm (0.3 -0.11 inl

New Belt: 5.0 - 7.0 mm (0.2 - 0.3 inl

Power Stesring Pump Belt

Used Beli: 'l1.5 - 13.5 mm (0.,[5 - 0.53 inl

New 8€lt: 8.0 - 10.0 mm (0 3 - 0.39 inl

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

2. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the Ay'C compressor belt.

3. Turn the adiusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

4. Recheck the deflection of the lvc compressor belt

22-36

Tonsion Gauge Method

1. Attach the belt tension gauge to the Ay'C compres-

sor belt as shown below, and measure the tension

of the belt.

A/C Compressot Belt

Used 8€lt: Bl8Bl engine 390 - 540 N

(40 - s5 kgf, 88 - 120 lbfl

Bl8Cl ongine 3il0 - il90 N

(35 - s0 kgf, 77 - 110 lbfl

N€w Belt 7,10 - 880 N {75 - 90 kgf, 170-200lbl}

Powor Steoring Pump Belt

Used Belt: 390 - 5,{l N (40 - 55 kgf, 88 - 120 lbll

N6w Bolt: 74O - 880 N 175 - 90 kgf, 170-200lbt)

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. Follow the manufacturer's instructions for the

belt tension gauge.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

tor less than five minutes,

2. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the AVC compressor belt.

3, Turn the adjusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

4. Recheck the tension of the A{/C compressor belt.

Page 1104 of 1413

A/G System Service

Evacuation

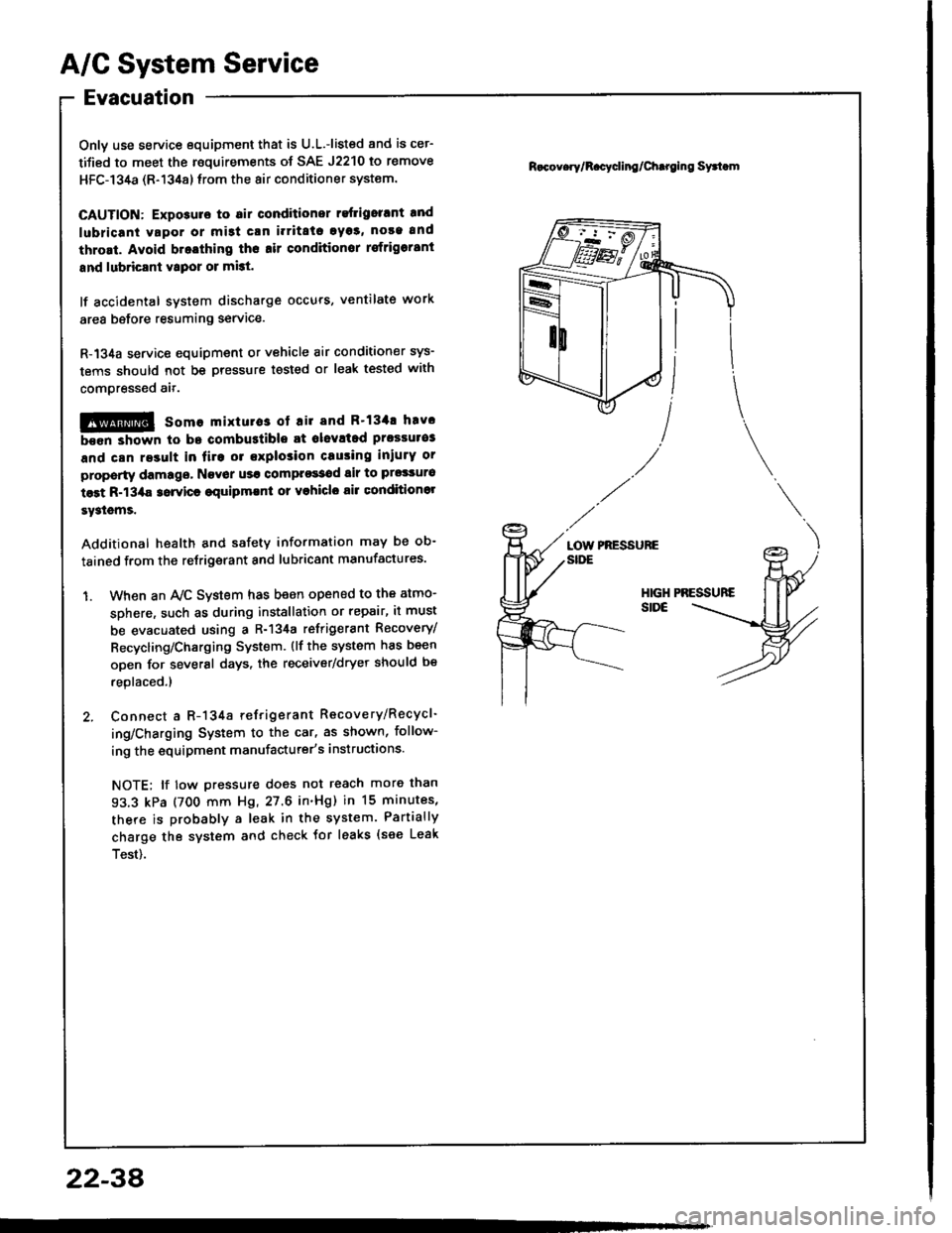

Only use service equipment that is U.L.-listed and is cer-

tified to meet the roquirements of SAE J2210 to remove

HFC-134a (R-134a) lrom the 8ir conditioner system.

CAUTION: Exposulo to 6ir conditioner refligorrnt and

lubricani vapor or mi3t crn i.ritato 9y33, noaa and

thrort. Avoid bratthing ths .ir conditionor rsfrigorrnt

snd lubricsnt vtpor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle 8ir conditioner sys-

tems should not be pressure tested or leak tested with

compressed ait.

!@ somo mixtuto3 ot ril and R'134! hav.

been shown to bo combustible at olevltad prossulo3

and can re3ult in fire or explosion crusing inlurY or

property damago, Navor us! comprossod air to prgsauro

test R-13/aa 3orvicr €quipmlnl or vohiclo air conditionol

sy3lems.

Additional health and safety information may be ob-

tained from the retrigerant and lubricant manufactures.

1. When an Ay'C System has been opened to the atmo-

sDhere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant Recovery/

Recycling/Charging System. {lf the system has been

open for several days, the receiver/dryer should be

replaced.l

2. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the car, as shown, follow-

ing the equipment manufacturer's instructions.

NOTE; lf tow pressure does not reach more than

93.3 kPa (700 mm Hg, 27.6 in'Hg) in 15 minutes,

there is probably a leak in the system. Partially

charge the system and check tor leaks {see Leak

Test).

R.cov.ry/R.cycling/Chtroing Syttom

PRESSUREaotnSIDE

2234

Page 1172 of 1413

Battery

a Battory tluid (6lectrolyt€l contains sulturic acid. lt may cauaa aevere burns iI it gots on your skin or in youl oyos.

Woar protoctivo clothing and I fac€ shield,- ll aloctrolyt6 gots on youl skin or clothos, rimo it off with wator immediately,- lf eloclrolyto g6ts in your oyos, tlush it out by splashing wat6r in youl eyes for at least 15 minutes; call a physiclan

immediately,

a A battery gives off hydrogon gas, lf ignit6d. tha hydrogsn will orploda and could crack tho baflory cas6 and splattor

acid on you. Koep spa*s. flames, and cigarottos away from the baftery.

a Overcharging will raiso ths tempelature ot th€ electrolyte. This may force electrolyte to splay out of the battery venta.

Follow lhe chargor manutacturer's instluctions and chargo tho battory at a prop61 rate.

NOTE: The original radio has a coded theft protection circuit. lt service to the car requires any of the lollowing, be sure

to get the customer's code number before- disconnecting the battery.- removing No. 32 (7.5 Al fuse from the under-hood fuse/relay box- removing the radio,

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed, enter the customer's

s-digir code to restore radio operation,

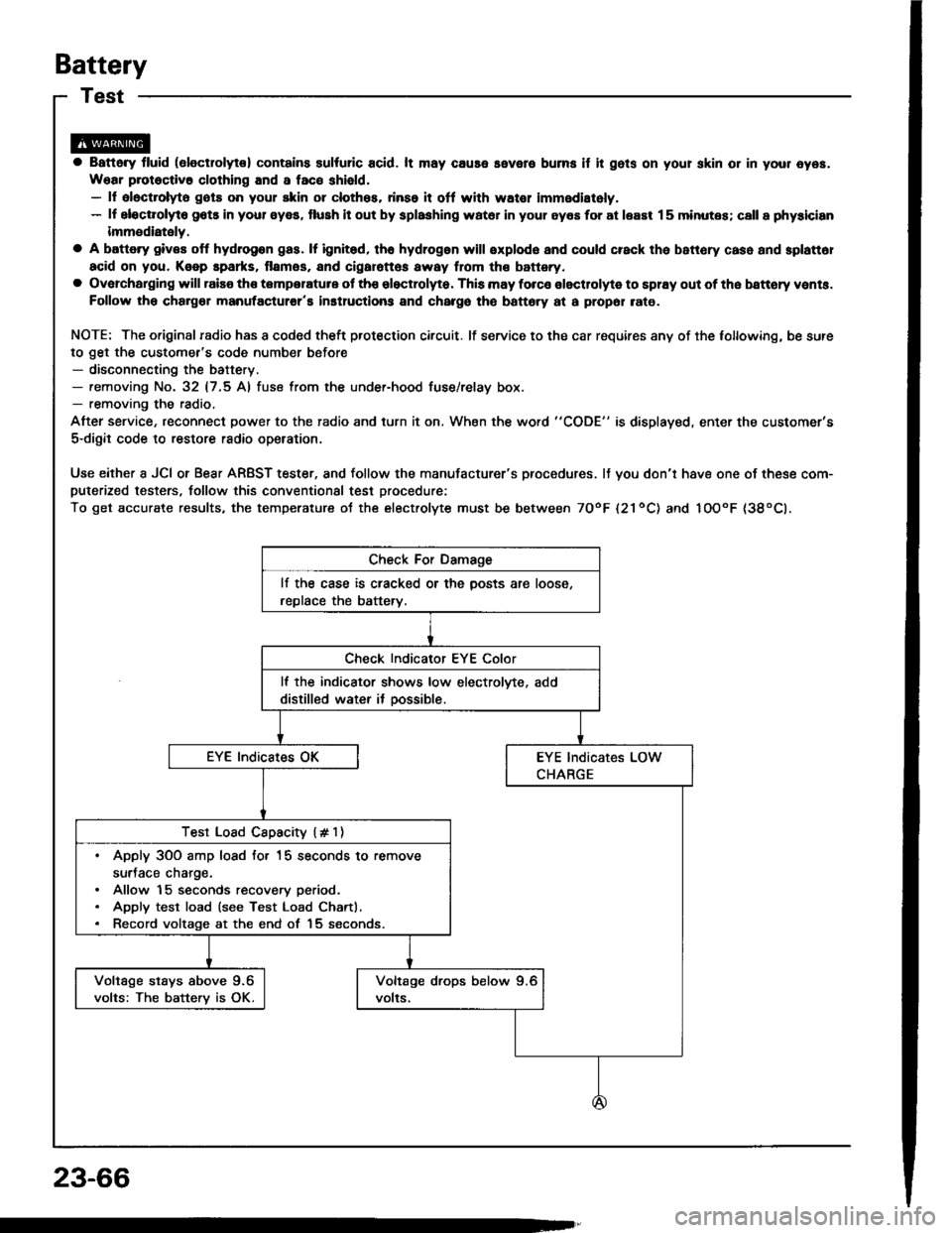

Use either a JCI or Bear ARBST tester, and follow the manufacturer's procedures. It you don'r have one of these com-puterized testers, follow this conventional test procedure:

To get accurate results, the temperature ot the electrolyte must be between TOoF l21ool and IOOoF {38oCl.

lf the case is cracked or the posts are loose,

replace the battery.

lf the indicator shows low electrolvte, add

distilled water it oossible.

Test Load Cspacity (# 1)

. Apply 3OO amp losd fo. 15 seconds to remove

surJace charge.. Allow 15 seconds recovery period.. Apply test load (see Test Load Chartl.. Record voltage at the end of 15 seconds.

Voltage stays above 9.6

volts: The batterv is OK.

23-66