Remove trans HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 352 of 1413

Transmission Housing

Removal

NOTE:

. lf the transmission housing or clutch housing a.ereplaced, the bearing proload must be adjusted(818C1 engine).

. Place the clutch housing on two pieces of wood thickenough to keep the mainshaft from the hitting the

workbench.

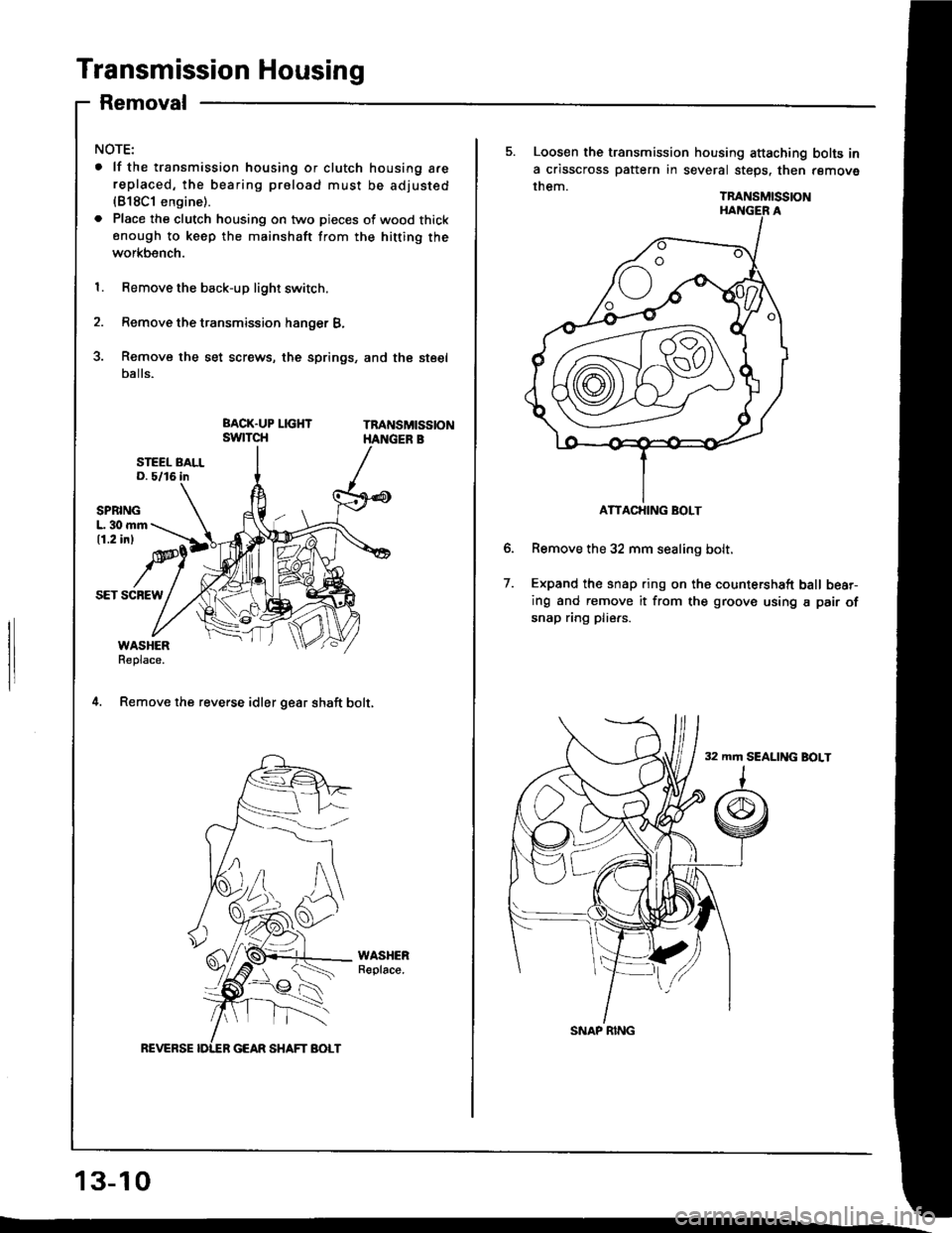

1. Remove the back-up light switch.

2. Remove the transmission hanger B,

3. Remove the set screws, the springs, and the steel

balls.

Tna sMtsstoN

SPBINGL. 30 mm11.2 inl

SET SCBEW

WASHERReplace.

4. Remov€ the reverse idler gear shaft bolt,

WASHERReplace.

REVERSE

L

13-10

ATTACHING BOLT

5. Loosen the transmission housing attaching bolts in

a crisscross pattern in several steps. then remove

them.TRANSMISSION

Remove the 32 mm sealing bolt.

Expand the snap ring on ths countershaft ball bear-

ing and remove it from the groove using a pair of

snap ring pliers.

32 mm SEALING BOLT

7.

SNAP RING

Page 353 of 1413

Reverse Change Holder,

Reverse ldler Gear

Clearance Inspection

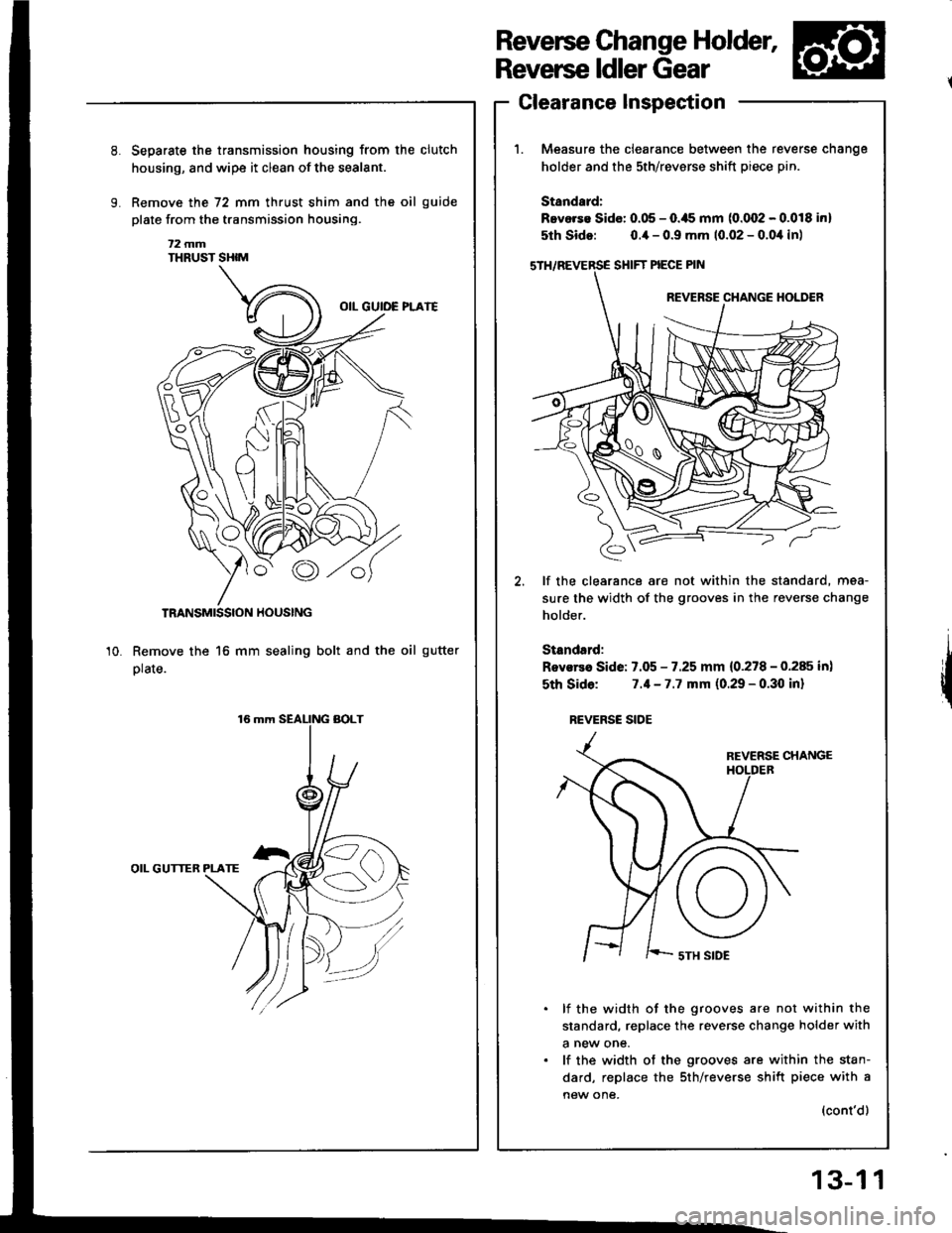

Measure the clearance between the re

holder and the sth/revsrse shift piece p

Standard:

Bevorse Sido: 0.05 - O.ils mm (0.002 - (

5th Sido: o.ia - 0.9 mm 10.02 - 0.0,1

SHIFT PIECE PIN

REVERSE CHANGE

€,

lf the clearance are not within the sti

sure the width of the grooves in the re

holder.

Standsrd:

Rovsrea Side: 7.05 - 7.25 mm {0.278 - (

sth Sido: 7.1-7.7 mm (0.29 - 0.30

REVERSC SIOE

REVERSE

I ' '-- sTH SIDE

lf the width of the grooves are n

standard, replace the reverse chan€

a new one.

lf the width of the grooves are wi

dard, replace the sth/reverse shift

new one,

Separste the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the 72 mm thrust shim and the oil guide

plate from the transmission housing.

t2 mmTHRUST SHIM

TRANSMISSION HOUSING

Remove the 16 mm sealing bolt and the oil gutter

plate.

OIL GUTTER PLATE

10.

reverse cnange

ptn.

.0.018 inl

),1in)

standard, mea-

reverse change

0.285 in)

I inl

not within the

Inge holder with

within the stan-

rift piece with a

(cont'd)

13-1 1

Page 380 of 1413

Mainshaft Thrust Glearance

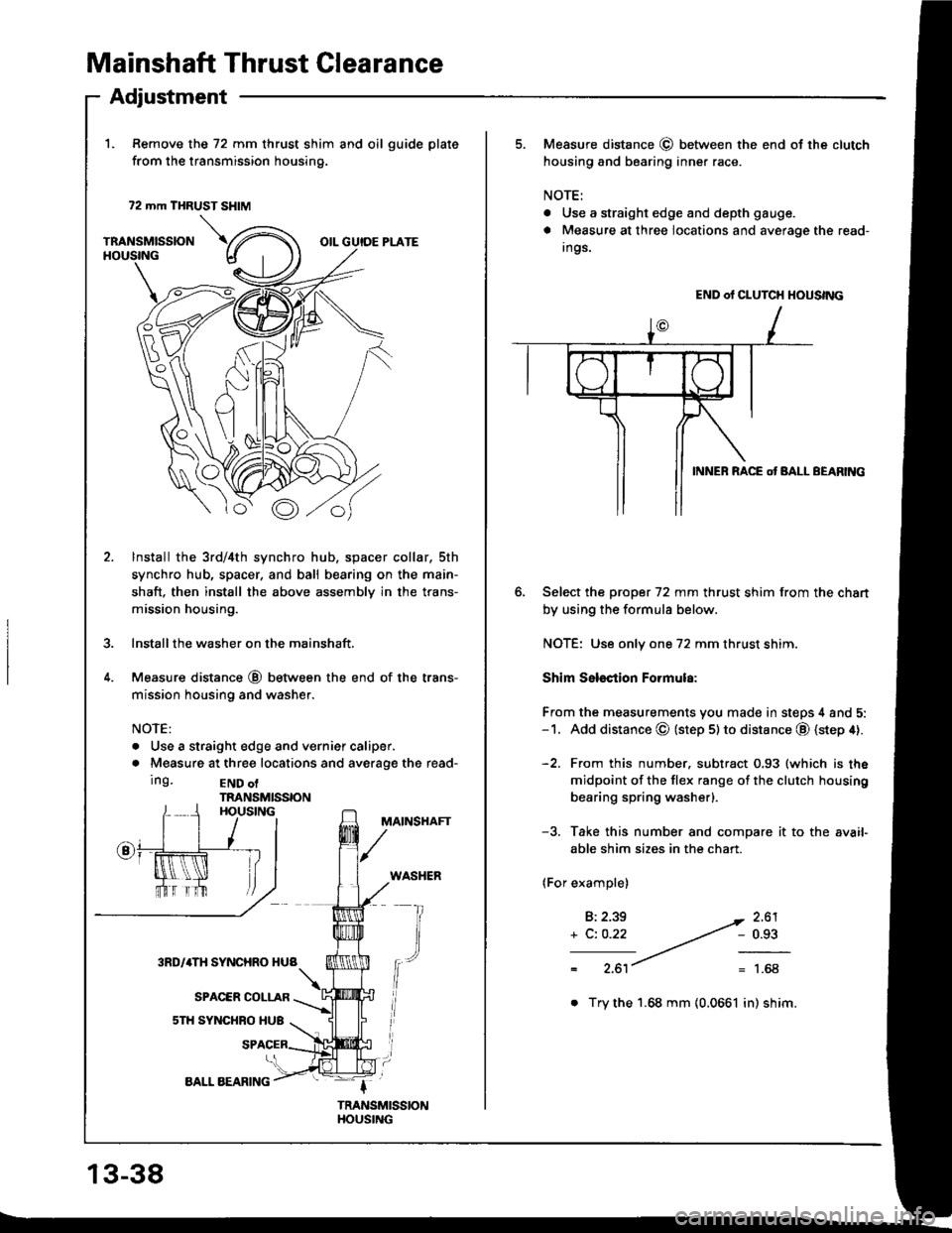

1. Remove the 72 mm thrust shim and oil guide plate

from the transmission housing.

72 mm THRUST SHIM

TRANSMISSIONHOUSINGOIL GUIDE PLATE

Adjustment

\.u

o

Bo

lnstall the 3rd/4th synchro hub, spacer collar, sth

synchro hub, spacer, and ball bearing on the main-

shaft. then install the above assembly in the trans-

mission housing.

Installthe washer on the mainshaft.

Measure distance @ between the end of the trans-

mission housing and washer.

NOTE:

. Use a straight edge and vernief caliper.

. Measure at three locations and averaoe the read-

Ing.END olTRANSMISSIONHOUSINGMAINSHAFT

WASHER

fr

13-38

AALL AEARING

. Try the 1.68 mm (0.0661 in) shim.

5. Measure distance @ betlveen the end of the clutch

housing and bearing inner race.

NOTE:

. Use a straight edge and depth gauge.

a Measure at three locations and average the read-

Ings.

Select the prcpet 72 mm thrust shim from the chart

by using the formula below.

NOTE: Use only one 72 mm thrust shim.

Shim Sslsction Formula:

From the measurements you made in steps 4 and 5:-1. Add distance @ (step 5lto distance @ (step 4).

-2. From this number. subtract 0.93 (which is the

midpoint of the flex range of the clutch housing

bearing spring washerl.

-3. Take this number and compare it to the avaif

able shim sizes in the chart.

(For example)

B:2.39

+ C: O.22

2.61- 0.93

1.68

END of CLUTCH HOUSING

INNEB RACE ot BALL BEARltac

Page 385 of 1413

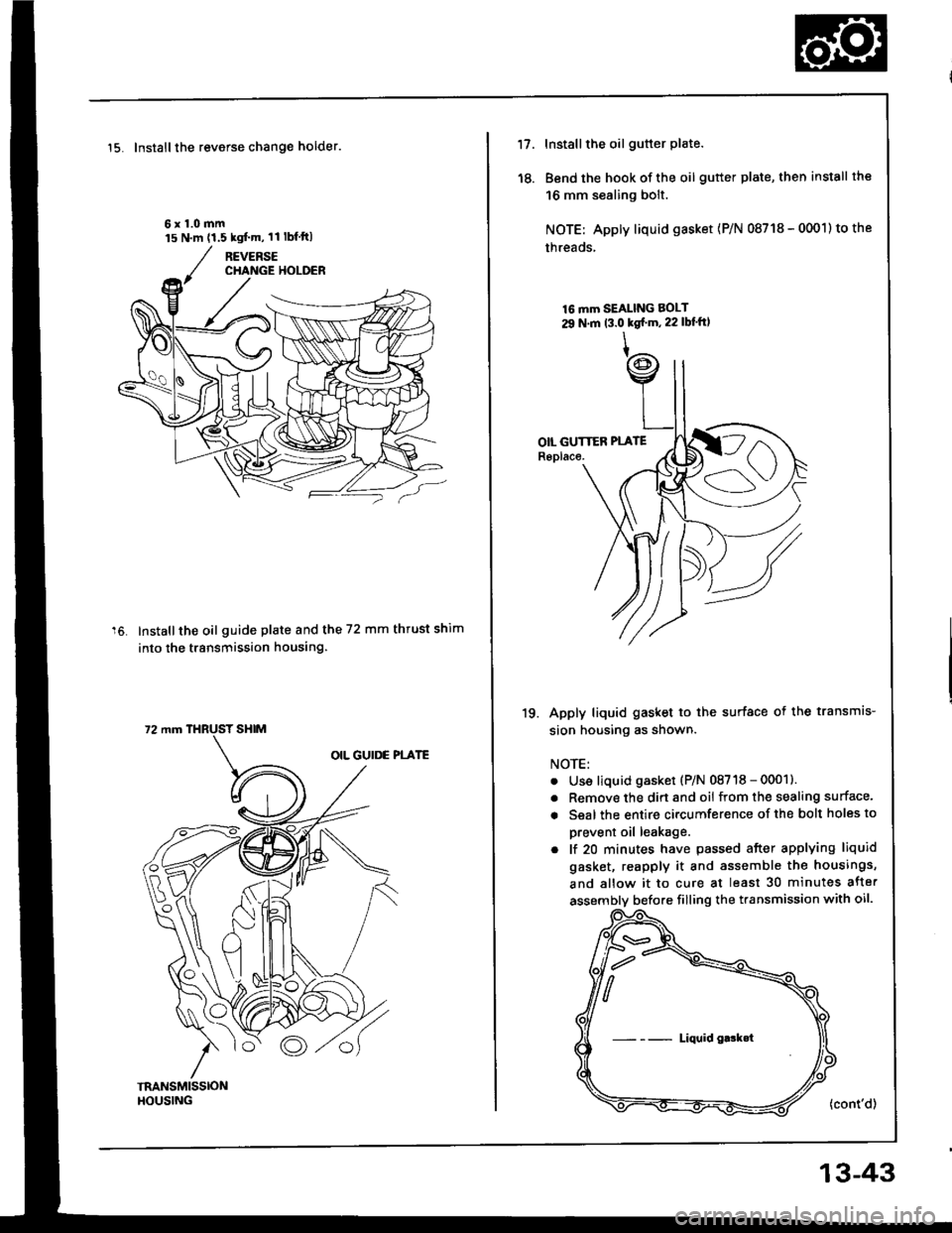

15. Installthe reverse change holder.

6x1.0mm

Installthe oil guide plate and the 72 mm thrust shim

into the transmission housing.

15 N.m (1.5 kgt'm,11 lbfftl

72 mm THRUST SHIM

'18.

Installthe oil gutter plate.

Bend the hook of the oil gutter plate, then install the

16 mm sealing bolt.

NOTE: Apply liquid gasket {P/N 08718 - 0001) to the

threads,

16 mm SEAI-ING BOLT

29 N.m t3.0 kgf m, 22 lbl'ftt

Apply liquid gasket to the surface ot the transmis-

sion housing as shown.

NOTE:

Use liquid gasket (P/N 08718 - 0001)

Remove the dirt and oil from the sealing surface'

Seal the entire circumference of the bolt holes to

prevent oil leakage.

lf 20 minutes have passed after applying liquid

gasket, reapply it and assemble the housings,

and allow it to cure at least 30 minutes after

assembly before filling the transmission with oil.

(cont'd)

19.

a

a

Liquid g.!k.t

13-43

Page 476 of 1413

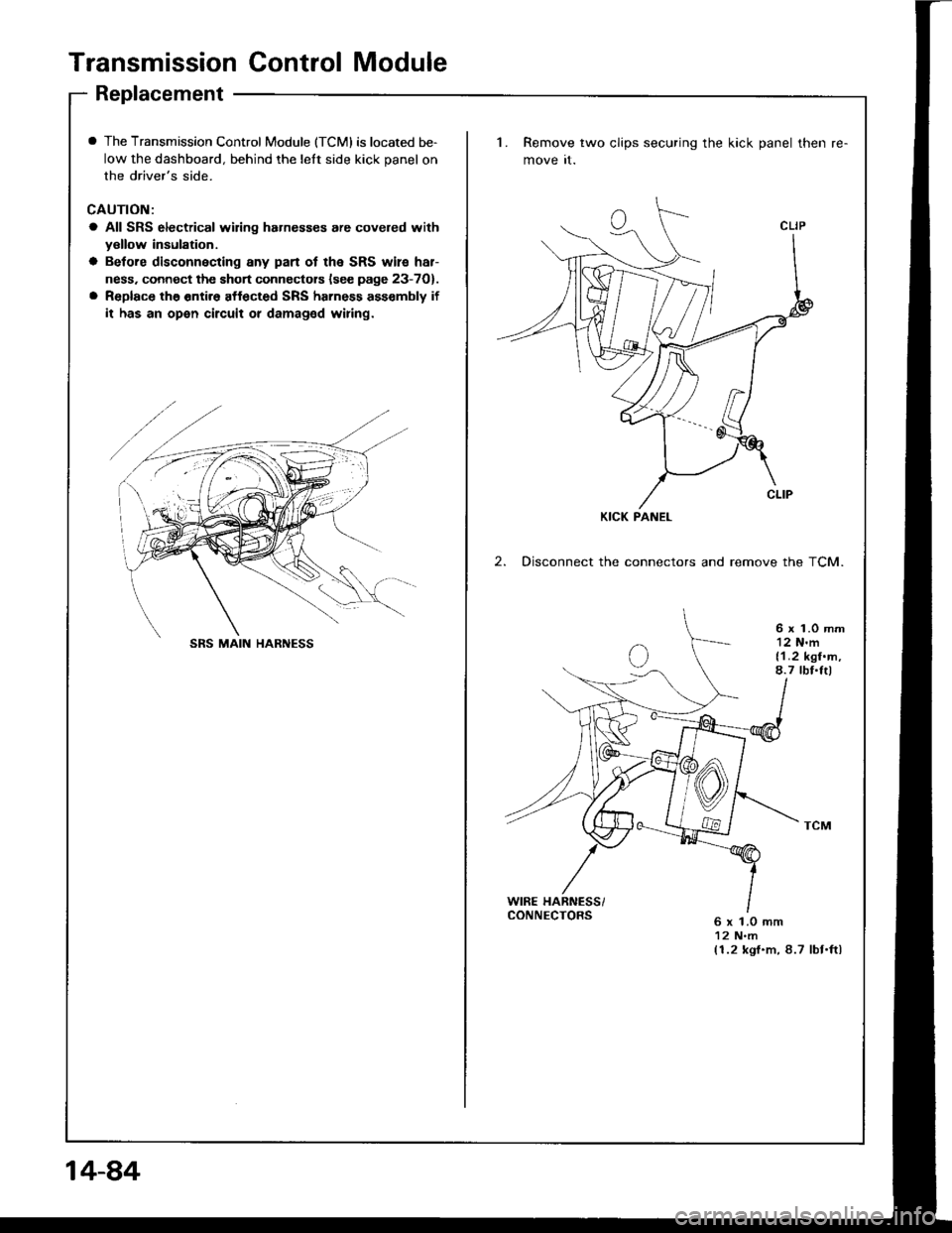

Transmission Control Module

Replacement

I The Transmission Control Module (TCMI is located be-

low the dashboard, behind the lelt side kick panel on

the driver's side.

CAUTION:

a All SRS electrical wiring hahesses are covered withyellow insulation.

a Betore disconnecting any pan ot the SRS wile har-

ness. connect the short connectors lsee page 23-7O).

a Replace the entir6 affected SRS harness ass€mbly if

it has an open circuit or damaged wiring.

1. Remove two clips securing the kick panel then

move it.

2. Disconnect the connectors and remove the TCM.

6 x 1.0 mm12 N'm{1.2 kgf.m,8.7 tbf.Itl

WIRE HARNESS/CONNECTORS6 x 1.0 mm12 N.m(1.2 kgf.m, 8.7 lbt.ftl

KICK PANEL

SRS MAIN HARNESS

14-84

Page 477 of 1413

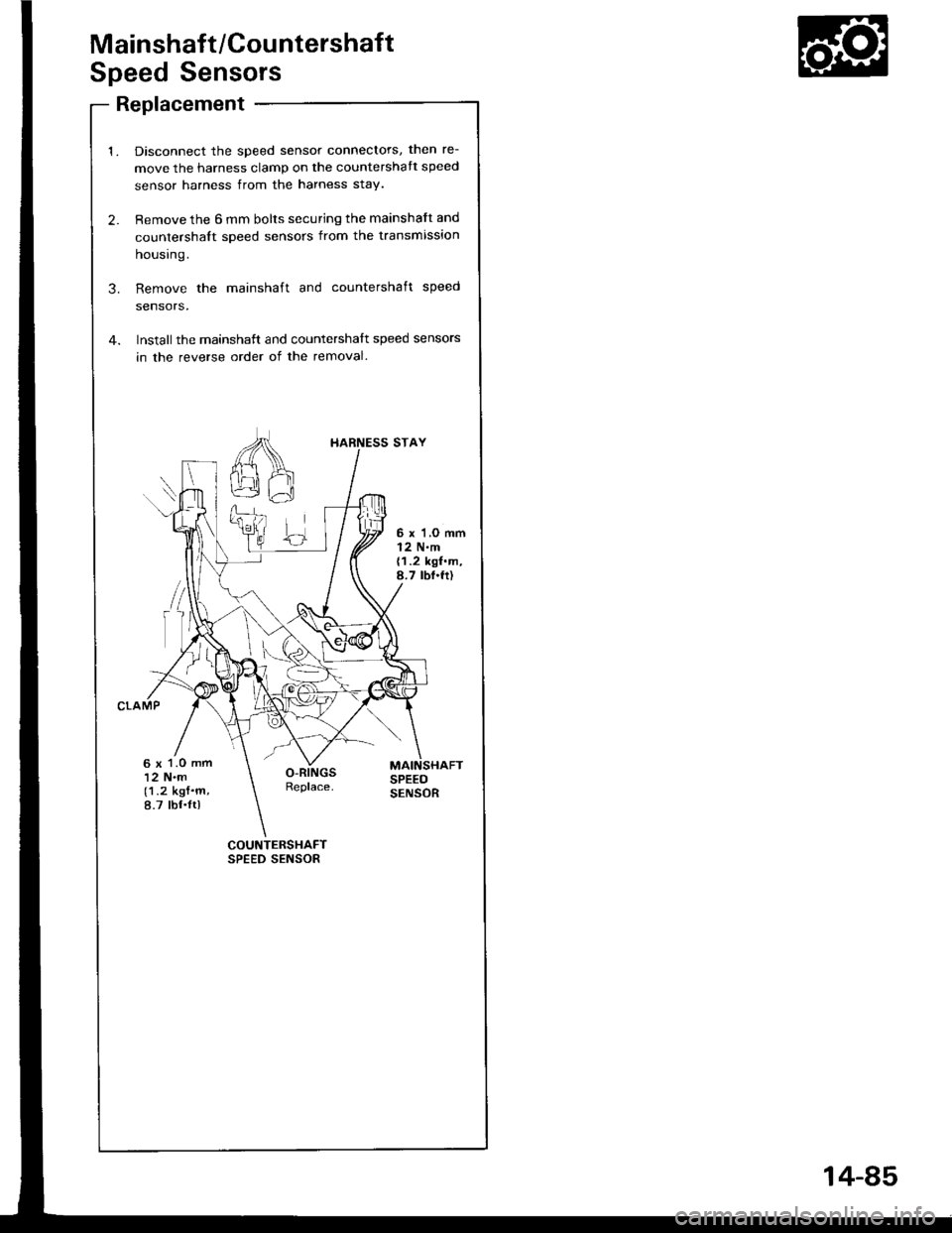

Mainshaft/Countershaft

Speed Sensors

Replacement

Disconnect the speed sensor connectors, then re-

move the harness clamp on the countershatt speed

sensor harness from the harness stay.

Remove the 6 mm bolts securing the mainshaft and

countershalt speed sensors from the transmission

housrng.

Remove the mainshaft and countershaft speed

sensors,

Installthe mainshatt and countershalt speed sensors

in the reverse order of the removal.

COUNTERSHAFTSPEED SENSOR

I{ARNESS STAY

6 x'l,O mml2 N.m{1.2 kgf.m,8.7 tbf.fr)

6 x 1.O mm12 N.m(1.2 kgf.m,8.7 tbf.ltl

14-85

Page 484 of 1413

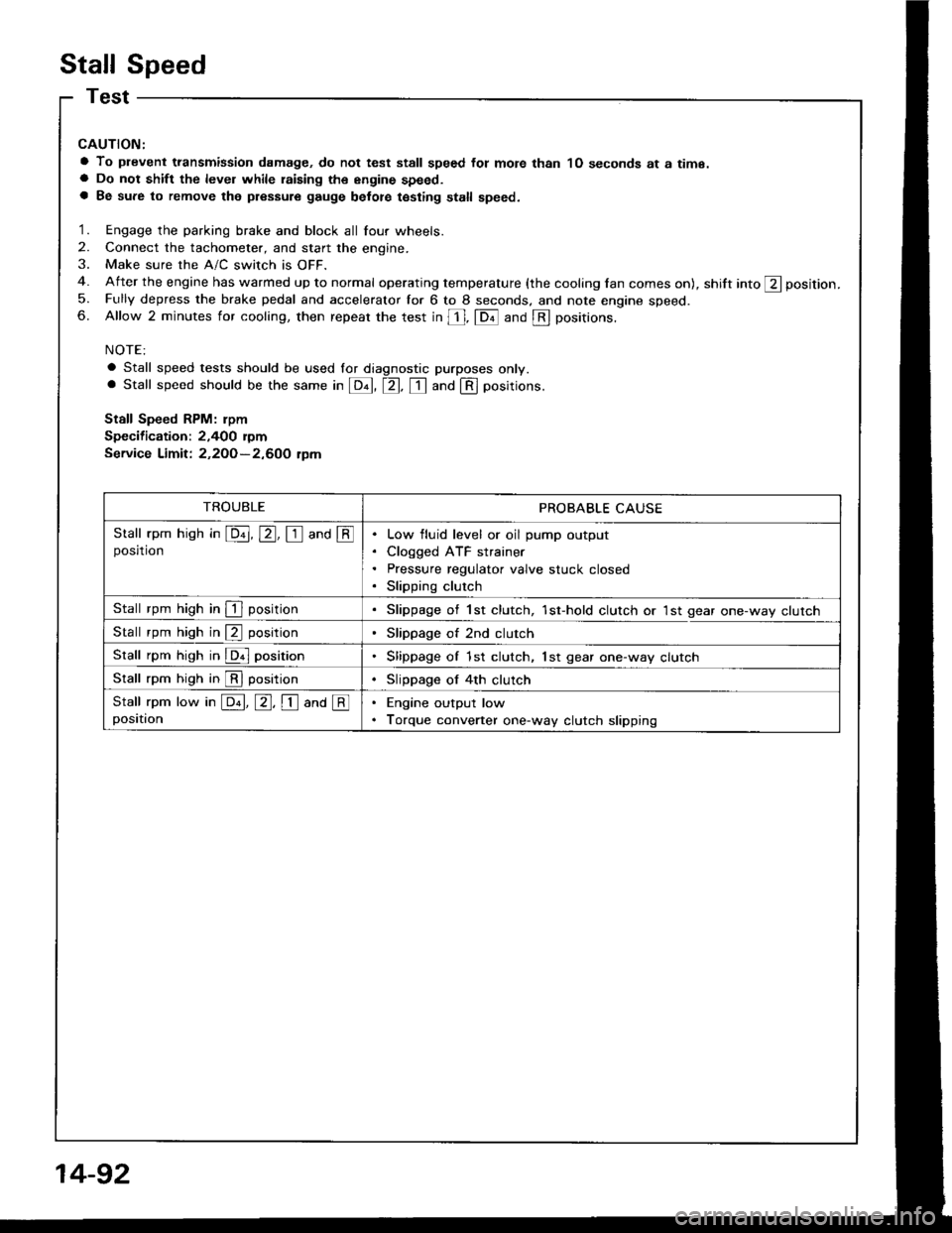

Stall Speed

CAUTION:

a To plevent transmission damage, do not test stall speed fot mote than 1O seconds at a time.a Do not shift the level while raising th€ engine speed.a Be sure to remove the pressure gauge belot€ testing stall speed.

1. Engage the parking brake and block all four wheels.

2. Connect the tachometer, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the cooling lan comes on), shift into ft position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds. and note engine speed.6. Allow 2 minutes for cooling, then repeat the test in [, fDil and @ positions.

NOTE:

a Stall speed tests should be used lor diagnostic purposes only.. Stall speed should be the same in E, tr. tr and @ positions.

Stall Speed RPM: rpm

Specification: 2,400 rymService Limit: 2,2OO-2,600 tpm

TROUBLEPROBABLE CAUSE

Stall rpm hish in E, E, I and @posrtronLow fluid level or oil pump output

Cloqged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in I positionSlippage of 1st clutch, 1st-hold clutch or 1st gear one-way clutch

Stall rpm high in @ positionSlippage of 2nd clutch

Stall rpm high in @ positionSlippage of 1st clutch, lst gear one-way clutch

Stall rpm high in @ positionSlippage of 4th clutch

Stall rpm low in E, E, I ana @positionEngine output low

Torque converter one-way clutch slipping

14-92

Page 485 of 1413

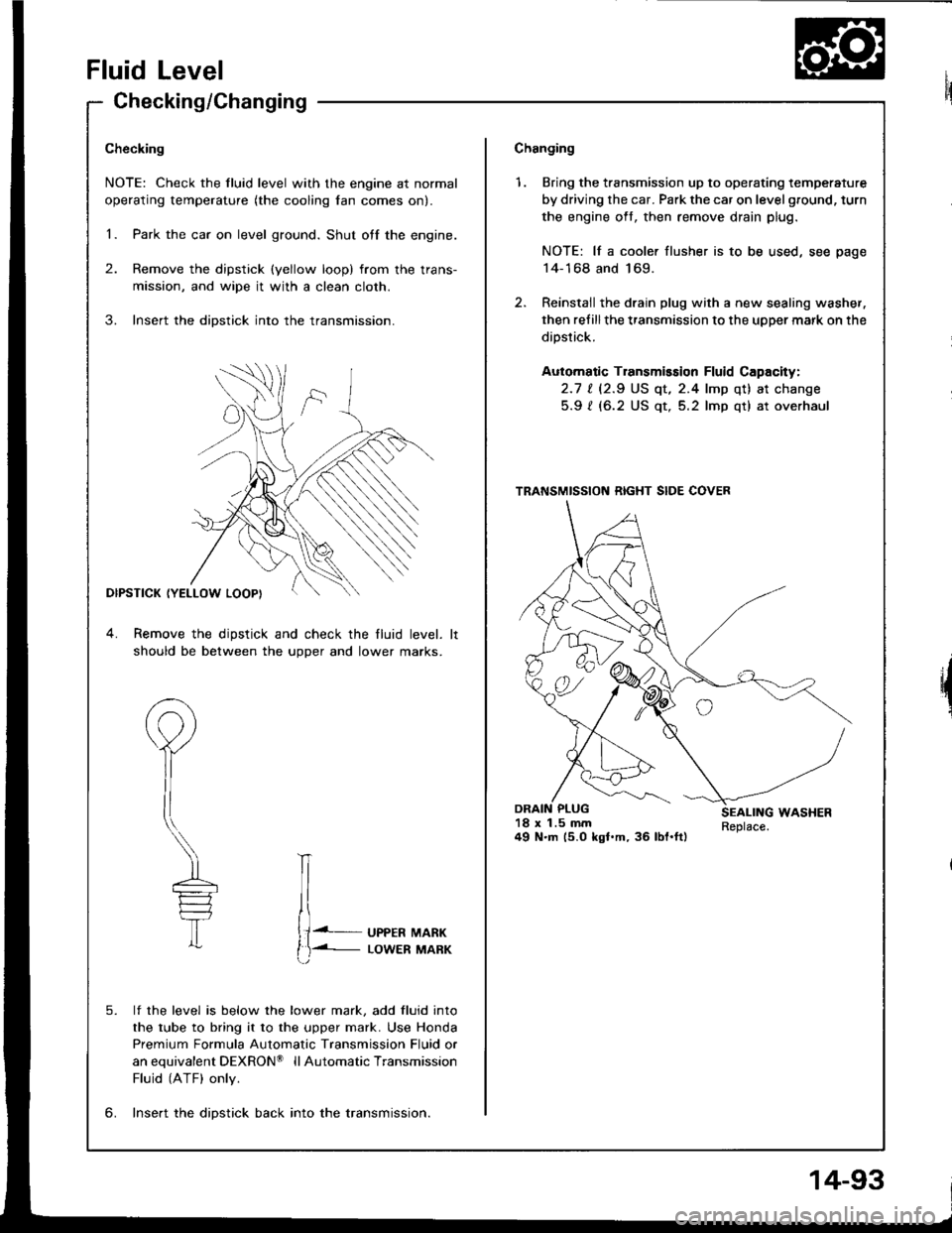

Fluid Level

Checking/Changing

Checking

NOTE: Check the fluid level with the engine at normal

operating temperature (the cooling lan comes on).

1. Park the car on level ground. Shut otf the engine.

2. Remove the dipstick (yellow loop) from the trans-

mission, and wipe it with a clean cloth.

3. Insert the dipstick into the transmission.

DIPSTICK (YELLOW LOOPI

4. Remove the dipstick and check the fluid level.

should be between the uoDer and lower marks.

P

il

\---

T

lf the level is below the lower mark, add fluid into

the tube to bring it to the upper mark. Use Honda

Premium Formula Automatic Transmission Fluid or

anequivalentDEXRON@ llAutomaticTransmission

Fluid (ATF) only.

lnse.t the diDstick back into the transmission.

IT

{J. UPPER MARK

t)-i- LowER MARK

5.

6.

Changing

1. Bring the transmission up to operating temperature

by driving the car. Park the car on level ground, turn

the engine oft, then remove drain plug.

NOTE: lf a cooler flusher is to be used, see page

14-168 and 169.

2. Reinstail the drain plug with a new sealing washer,

then refillthe transmission to the upper mark on the

dipstick.

Automatic Transmission Fluid Capacity:

2.1 | l2.S US qt, 2.4 lmp qt) at change

5.9 ? (6.2 US qt, 5.2 lmp qt) at overhaul

18 x 1.5 mm49 N.m (5.0 kgl.m, 36 lbl.ft)

TRANSMISSION RIGHT SIDE COVER

14-93

Page 491 of 1413

Transmission

Removal

4.Bemove the t.ansmission ground cable from the

transmission hanger.

Disconnect the lock-uD control solenoid valve con-

nector and the shitt control solenoid valve connec-

tor, then remove the harness clamp on the lock-up

control solenoid harness from the harness stav.

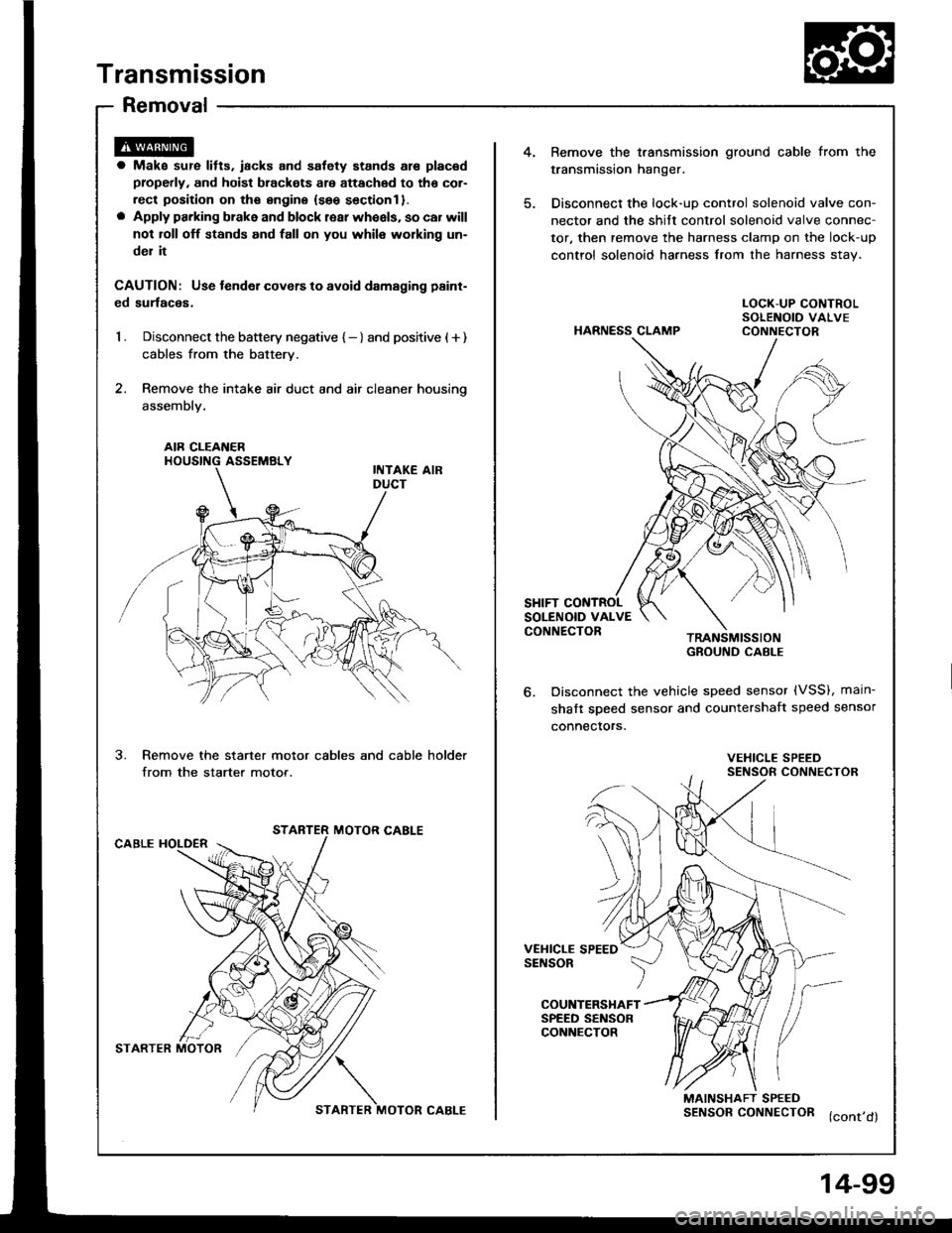

a Make sur€ lifts. iacks and safety stands are placad

properly, and hoist brackots are attachod to tho cor-

rect position on ths sngine {seo sectionl }.o Apply parking brake and block rear wheels, so car will

not roll off stands and fall on you whil6 working un-

del it

CAUTION: Use tender covers to avoid damsging paint-

ed surlaces,

1 . Disconnect the battery negative { - } and positive ( + )

cables from the battery.

2. Remove the intake air duct and air cleaner housino

assembly.

HARNESS CLAMP

LOCK-UP CONTROLSOLENOID VALVECONNECTOR

AIR CLEAI{ERHOUSING ASSEMBLY

SHIFT CONTROLSOLENOID VALVECONNECTORTRANSMISSIONGROUND CABI-E

Disconnect the vehicle speed sensor (VSS), main-

shaft sDeed sensor and countershaft speed sensor

connectors.

3.Remove the starter motor cables and cable holder

from the starter motor.VEHICLE SPEEDSENSOR CONNECTOR

STARTER MOTOR CABLECABLE HOLDER

VEHICLE SPEEDSENSOR

COUNTERSHAFTSPEED SENSORCONNECTOR

MAINSHAFT SPEEDSENSORCONNECTOR (cont,d)

STARTER MOTOR?/\

STARTER MOTOR CABLE

4-99

Page 492 of 1413

Transmission

Removal {cont'd)

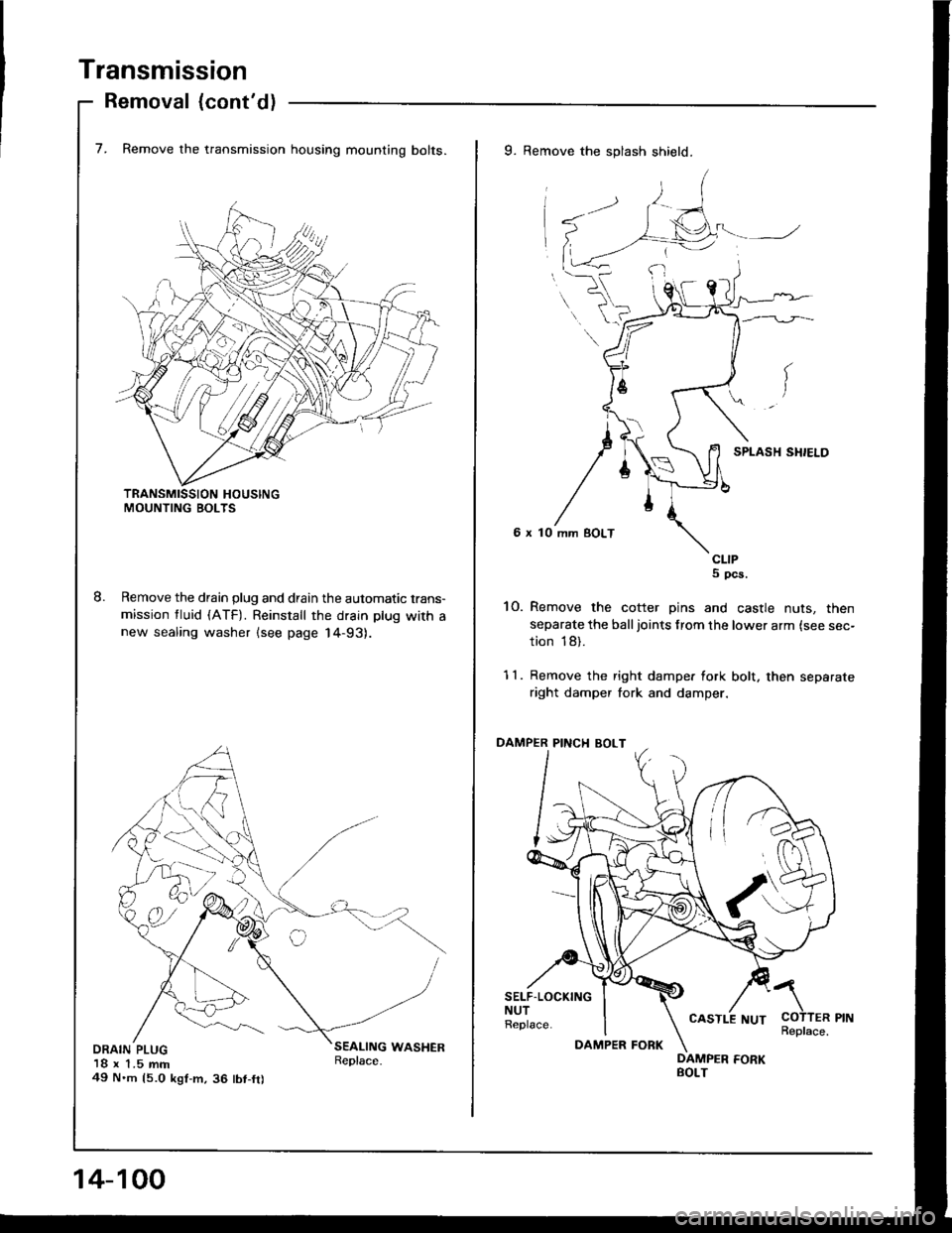

7. Remove the transmission housing mounting bolts.

Remove the drain plug and drain the automatic trans-

mission tluid (ATF). Reinstall the drain plug with anew sealing washer lsee page 14-93).

DRAIN PLUG18 x 1.5 mm49 N'm 15.0 kgt-m,36 tbt-fr)

9. Remove the splash shield.

6 x 10

CLIPS pcs.

10. Remove the cotter pins and castle nuts, then

separate the balljoints from the lower arm {see sec-

tion 18).

11. Remove the right dampe. fork bolt. then separate

right damper fork and damper.

PINCI{ BOLT

SELF.LOCKINGNUTReplace.COTTER PINReplace.

/\

14-100

DAMPER FORK

CASTLE NUT