Wheel HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 52 of 1413

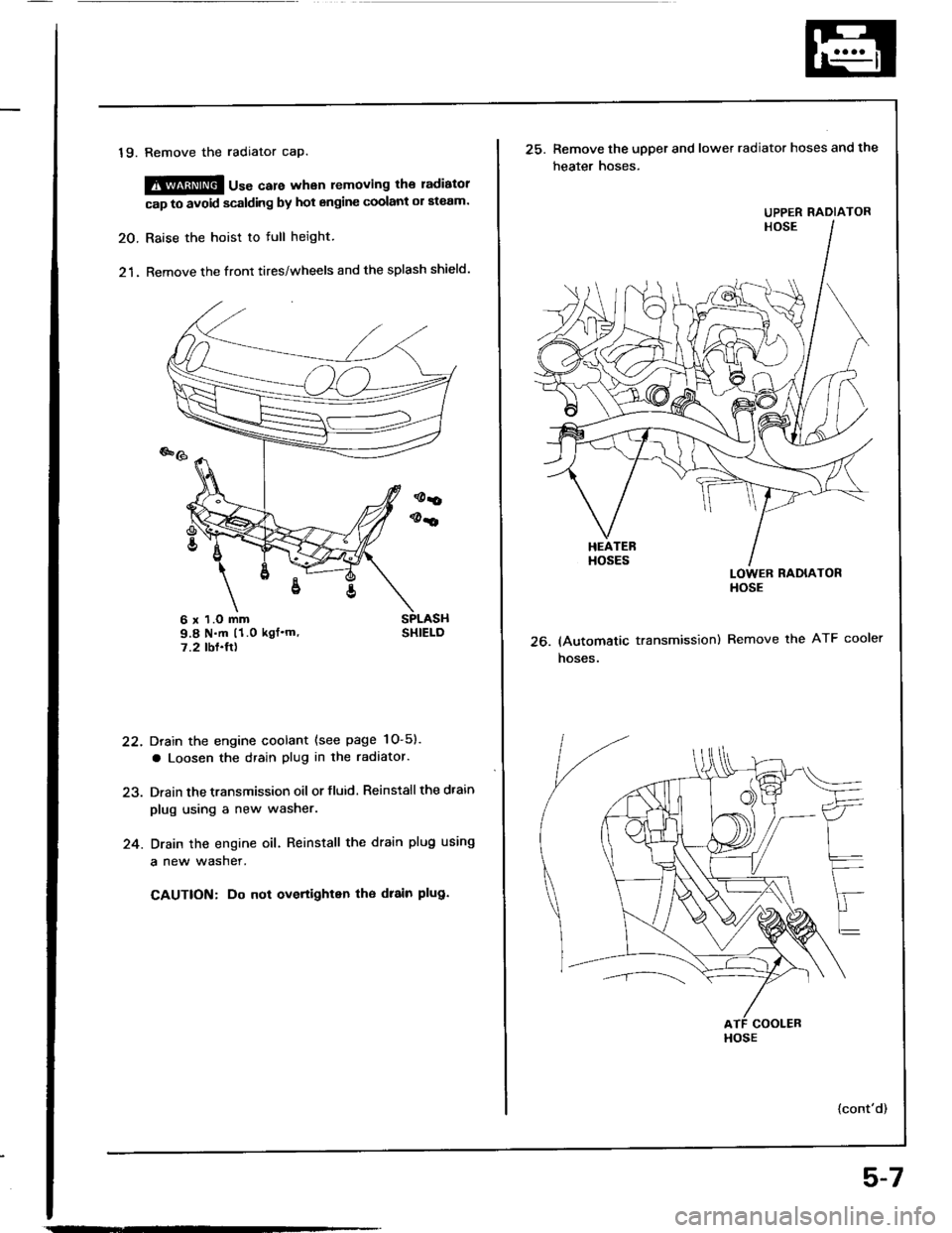

19. Remove the radiator cap.

@@ u"" care whan removing the ladiatol

cap to avoid scalding by hot engine coolant ol ateam.

20. Raise the hoist to full height.

21. Remove the front tires/wheels and the splash shield.

Drain the engine coolant (see page 1O-5).

a Loosen the drain plug in the radaator.

Drain the transmission oil or fluid. Reinstall the dtain

plug using a new washer.

Drain the engine oil. Reinstall the drain plug using

a new wasner.

CAUTION: Do not overtighten tho drain plug.

22.

24.

6 x 1.O mm9.8 N.m (1.0 kgf'm'7.2 tbf.ft)26.

25. Remove the upper and lower radiator hoses and the

heater hoses.

LOWER RADIATORHOSE

(Automatic transmission) Remove the ATF cooler

hoses.

{cont'd)

UPPER RADIATOR

HOSE

5-7

Page 110 of 1413

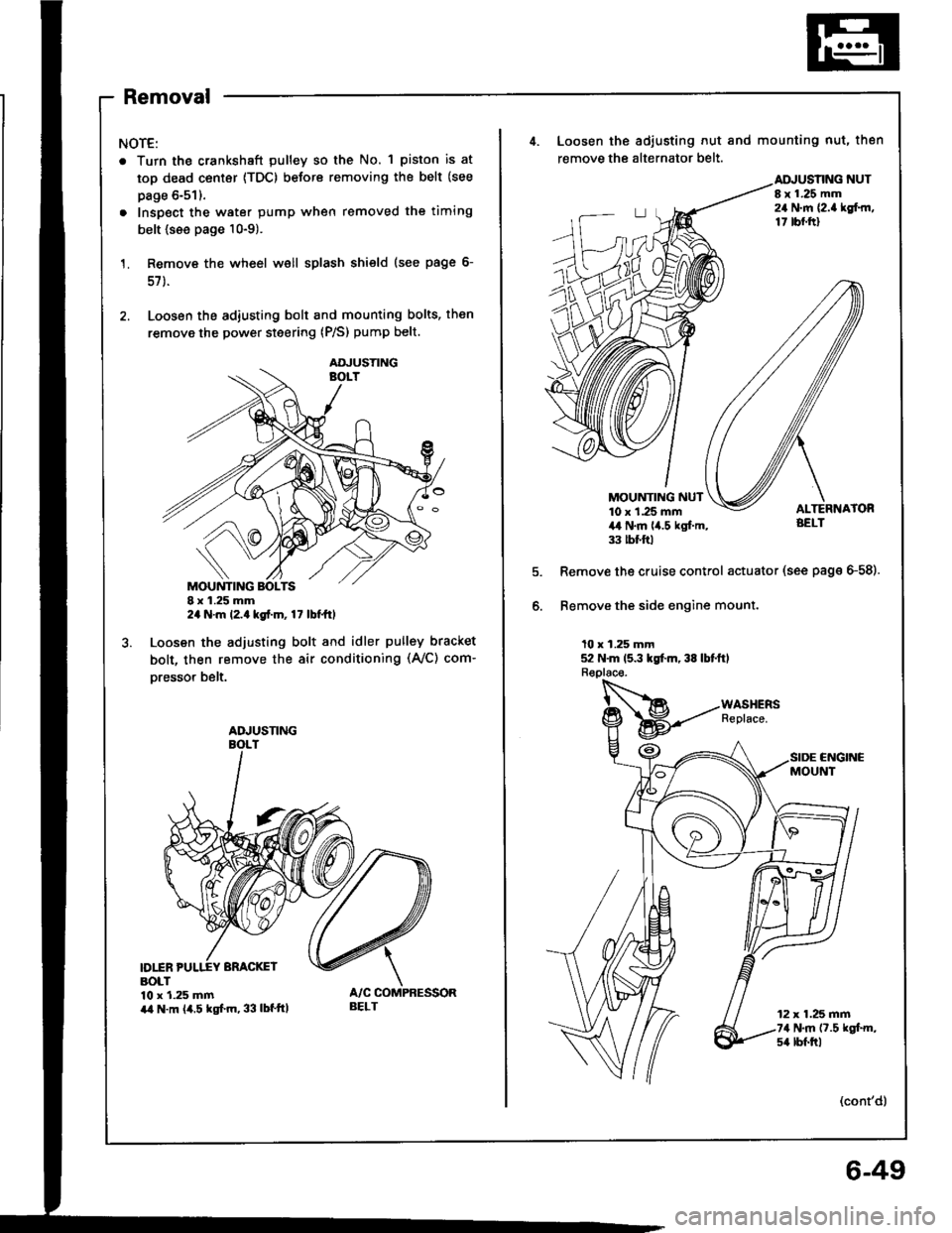

Removal

NOTE:

. Turn the crankshaft pulley so the No. 1 piston is at

top dead center {TDC) before removing the belt (see

page 6-51).

. Inspect the water pump when removed the timing

belt {see page 10-9).

Remove the wheel well splash shield (see page 6-

57 ).

Loosen the adiusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt.

I x 1.25 mm2a N.m l2.a kgt.m, 17 lbt ttl

Loosen the adjusting bolt and idler pulley bracket

bolt, then remove the air conditioning (Ay'C) com-

oresso. belt.

D1INBOLT10 x 1.25 mmira N.m (4.5 kgf.m, 33 lbf'ttl

AOJUSTING

ADJUSNNG

BELT

4. Loosen the adiusting nut and mounting nut, then

remove the alternator belt.

NUTI x 1.25 mm24 N.m {2.a lgf.rn,17 tbf.ftl

MOUNTING NUT10 x 1.25 mm4,t N.m lia.5 kgl.m,33 tbt ftl

Remove the cruise control actuator (see page G58).

Bemove the side engine mount.

10 x 1.25 mm52 N.m 15.3 kgt m, 38 lbtftl

CNGINCMOUNT

12 x 1.25 mm74 N.m (7.5 kgt m,s4 lbf.trl

(cont'd)

6-49

Page 141 of 1413

Engine Block

Speciaf Tools .............7'2

lllustrated Index ................................... 7-3

Flywheel and Drive Plate

Repfacement .........7-7

Main Bearings

Clearance ,.............. 7-8

Selection ................ 7-8

Connecting Rod Bearings

Clearance ............... 7-9

Selection ................ 7-9

Crankshaft

Removal .................7-10

End Play .................7-12

lnspection ........,,,.,,7-12

fnstallation .............7'22

Cylinder Block

Inspeetion ..............7-13

Bore Honing .....,.,,.7'14

Pistons

Inspaction ..............7-15

Installation .............7-16

Piston Rings

Replacement .........7-16

End Gap .................7-17

Ring-To-Groove C|earance,,,,.,,,...... 7 -17

Alignment ..............7-18

Piston Pins

Removal ........,........7-18

Installation (818B1 engine) ............. 7-19

fnstaffation (818C1 enginel ............. 7-20

fnspection ..............7-2O

Connecting Rods

End Play .................7-21

Sefeetion ..........,,,,,,7-22

Oil Seal

fnstaffation .............7-25

Installation

(engine removal not requiredl.. .......7-26

Page 143 of 1413

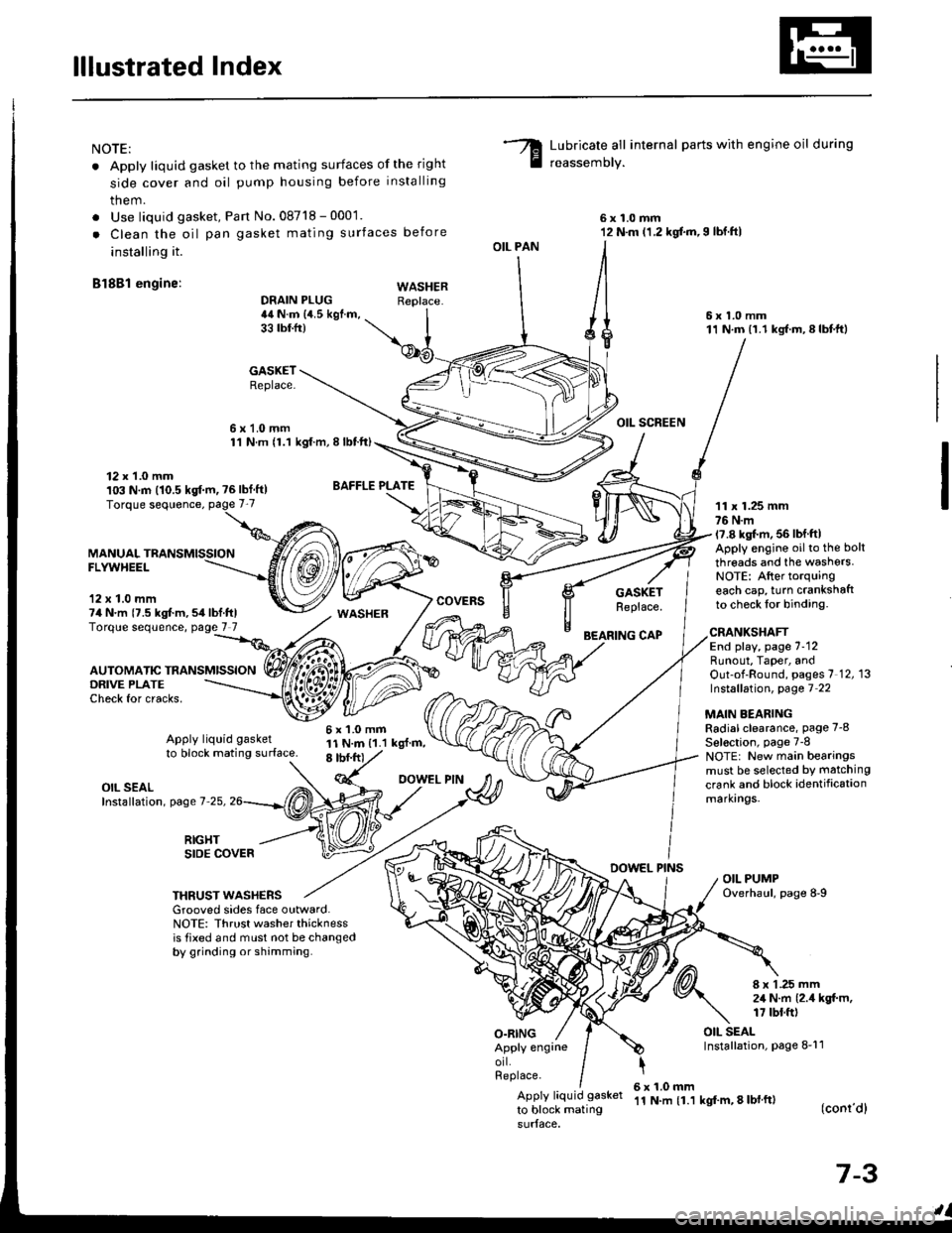

lllustrated Index

NOTE:

. Apply liquid gasket to the mating surfaces of the right

side cover and oil pump housing before installing

them.

. Use liquid gasket, Pan No.08718 - 0001.

. Clean the oil pan gasket mating surfaces before

installing it.

Bl8Bl engine: wAsHEF

Lubricate all internal parts with engine oil during

reassemory.

6x1.0mm12 N.m (1.2 kgf.m,I lbf.ftl

6x1.0mm11 N.m (1.1 kgf.m,8lbtft)

OIL SCREEN

11 x 1.25 mm76 N.m17.8 kgl.m, 56 lbf ftlApply engine oilto the bolt

threads and the washers.NOTE: After torquingeach cap, turn crankshaftto check lor binding.

DRAIN PLUG44 N.m {4.5 kgf.m,33 tbtfr)

GASKETReplace.

6x1.0mm1'l N.m {1.1 kgt.m, I lbtft)

OIL PAN

O.RING

GASKETReplace.

BEARING CAP

12 x 1.0 mm103 N.m (10.5 kgf.m, ?6lbf ft)

MANUALFLYWHEEL

'12 x 1.0 mm74 N.m {7.5 kgt m,54lbf.ftlTorque sequence, page 7 7

DRIVE PLATECheck for cracks,

AUTOMATIC TRANSMISSION

WASHER

6x1.0mm11 N.m {1.1 kgl.m,8 tbf.frt

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7 12, 13Instsllation, page 7 22

MAIN BEARINGRadial clearance, page 7-8

Sel€ction, page 7-8NOTE: New main bearingsmust be selected by matching

crank and block identificationmarkrngs.

Apply liquid gasket

to block mating surface.

OIL SEALInstallation, page 7-25,

RIGHTSIDE COVERDOWEL PINSOIL PUMPOverhaul, page 8-9THRUST WASHERSGrooved sides face outward.NOTE: Thrust washer thicknessis tixed and must not be changedby grinding or shamming.

8 x 1 .25 mm2,1 N.m {2.4 kgt m,17 tbt.ft)

OIL SEALInstallation, page 8-11Apply engrneorl.Replace.

Apply liquid gasket

to block mating

6x1.0mm'11 N.m {1.1 kgf'm, 8 lbl ft)(conr'dl

7-3

Page 147 of 1413

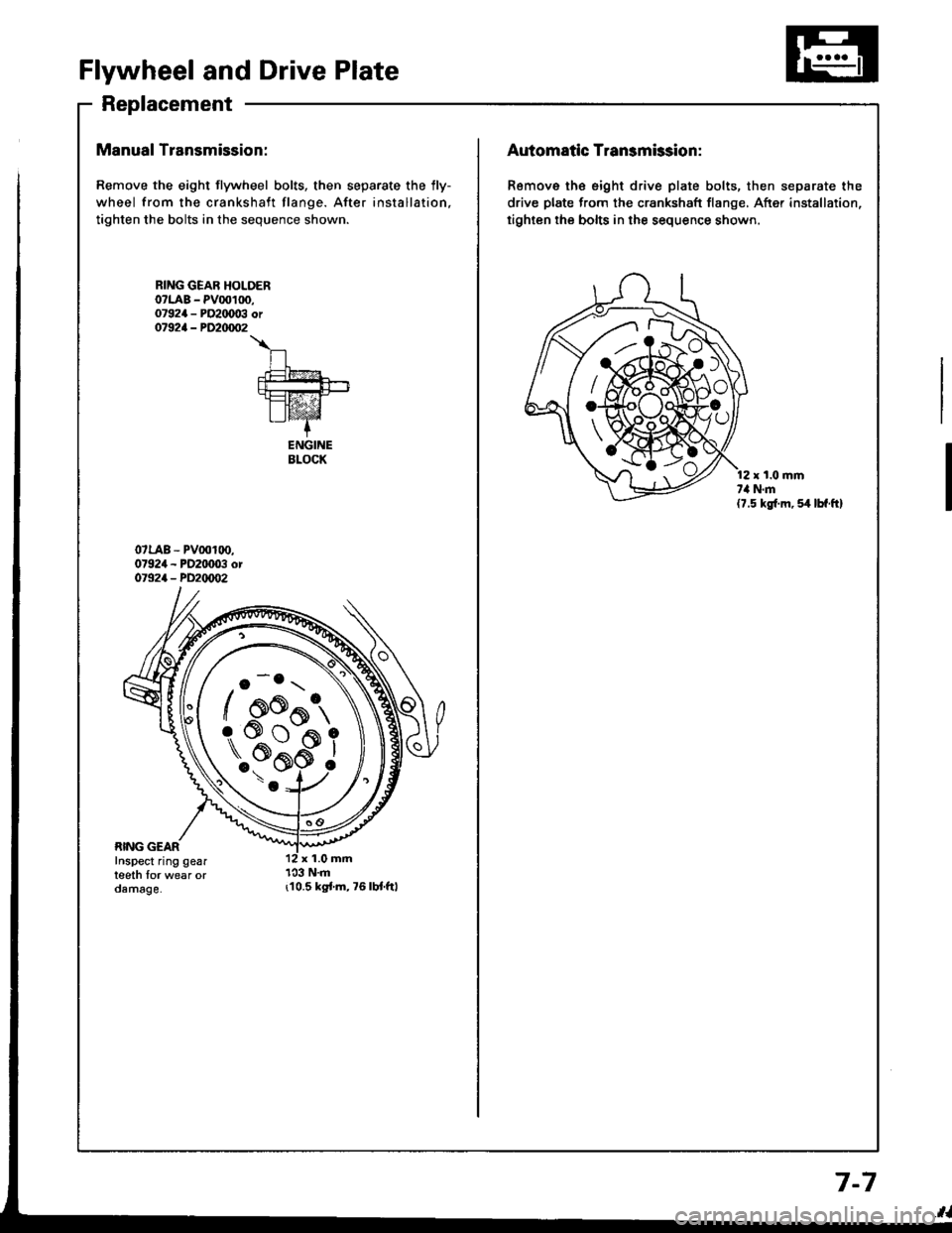

Flywheel and Drive Plate

Replacement

Manual Transmission:

Remove the eight flywheel bolts, then separate the lly-

wheel from the crankshaft flange. After installation,

tighten the bolts in the sequence shown.

r10.5 kgi.m,76lbt.ftl

RING GEAR HOLOERo?LAB - PV00100,07924 - PO2IX)03 or07924 - PD20/m�2

\

n.t=?4

fut!!-+-rt=tz-21I lvaz'Z-+

ENGINEBLOCK

o -o.r \

/ oo^t,

\..?bi

/ AK{:{AAo

rs#*ffi_9

Automatic Transmission:

Remove th€ eight drive plate bolts, then separate the

drive plate from the crankshaft flange, After installation,

tighten the bolts in the sequence shown.

r t.0 mmt,l N.m(7.5 kg{.m, 54 lbf.ft}

7-7

Page 148 of 1413

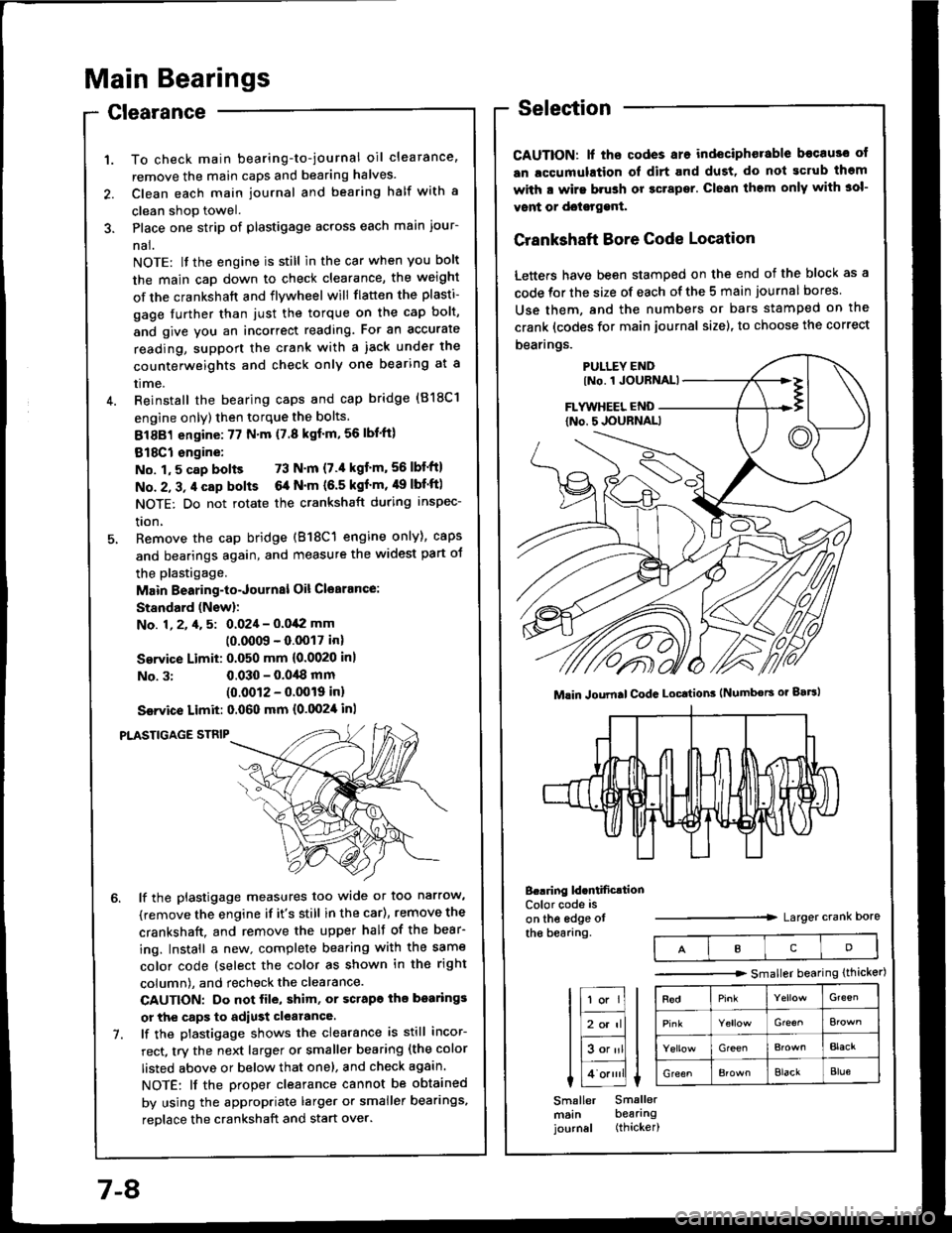

Main Bearings

Clearance

To check main bearing-to-journal oil clearance,

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

Place one strip of plastigage across each main iour-

nal.

NOTE: lf the engine is still in the car when you bolt

the main caD down to check clearance, the weight

of the crankshaft and flywheel will flatten the plasti-

gage further than just the torque on the cap bolt,

and give you an incorrect reading. Fot an accurate

reading, support the crank with a iack under the

counterweights and check only one bearing at a

trme.

Reinstall the bearing caps and cap bridge (818C1

engine only) then torque the bolts.

81881 engine:77 N'm (7.8 kgf'm,56lbl'ft)

818C1 engine:

No. 1,5 cap bolts 73 N'm (7.'l kgt'm,56lbf'ftl

No. 2, 3, 4 cap bolts 6a N'm (6.5 kgf'm, 49 lbf'ftl

NOTE: Do not rotate the crankshaft during inspec-

tron,

Remove the cap bridge (818C1 engine only), caps

and bearings again, and measure the widest part oJ

the plastigage.

Main Bearing-to-Journal Oil Cl€arance:

Standard (Newl:

No. 1, 2, 4, 5: 0.024 - 0.042 mm

10.0009 - 0.0017 inl

Service Limit: 0.050 mm {0.0020 inl

No. 3:0.030 - 0.0,18 mm(0.0012 - 0.0019 inl

Ssrvice Limit: 0.060 mm {0.0024 inl

PLASTIGAGE STNIP

lf the plastigage measures too wide or too narrow,

(remove the engine if it's still in the car), remove the

crankshaft. and remove the upper half of the bear-

ing. Install a new. complete bearing with the same

color code (select the color as shown in the right

column), and recheck the clearance.

CAUTION: Do not file, shim, or scrapo ihe bo.rings

or the caps to adiust clearance.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again.

NOTE: lf the Droper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

reolace the crankshaft and start over.

Selection

CAUTION: lf ths codes are indeciphorable becau3o ot

an lccumulation ol dirt and dust, do not gcrub thgm

with a wirs brush or gcrapsr. Clean them only with 3ol-

vont or doisrggnt.

Crankshaft Bore Code Location

Letters have been stamped on the end of the block as a

code for the size of each of the 5 main journal bores

Use them, and the numbers or bars stamped on the

crank (codes for main journal size), to choose the correct

bearings.

B..ring ld.ntificrtionColor code is

on the edge otthe bearang.Larger crank Dore

Mlin Joumal CodG Locttion3 (Numbors or gaBl

IcD

tr;;lIl

Itr-tl

lE;tl I tlHlt

I Lo.""li L

Smaller Smallermsin bearingjournal (thicker)

-------.r> smaller bearing (thicker)

G'een

Gre€^

GreenBlacr

GreenElackBlue

7-8

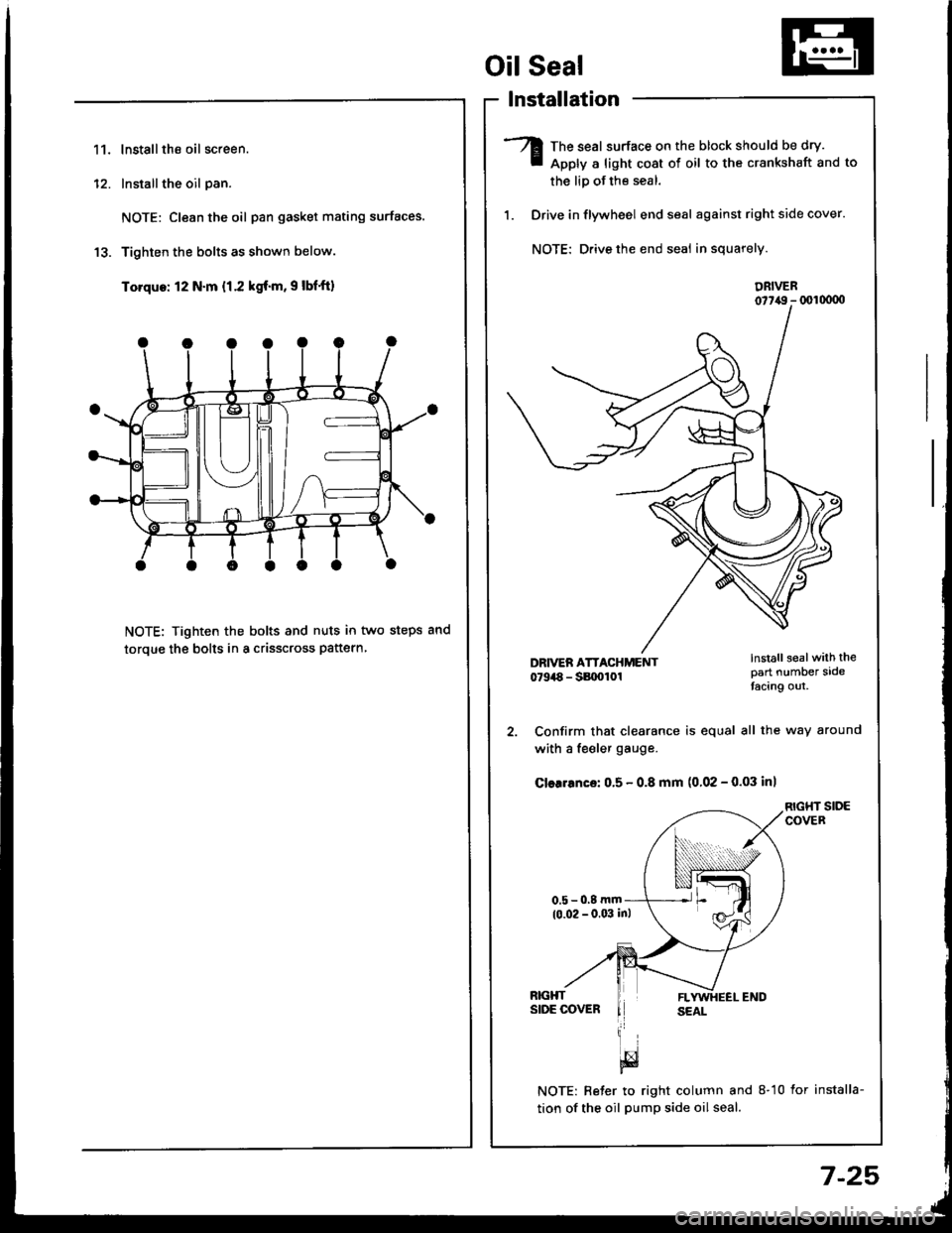

Page 165 of 1413

11.lnstallthe oil screen.

Installthe oil pan.

NOTE: Clean the oil pan gasket mating surfaces.

Tighten the bolts as shown below.

Torque: 12 N.m {1.2 kgf.m, 9 lbf'ft)

NOTE: Tighten the bolts and nuts in two steps and

toroue the bolts in a crisscross pattern

1'�I

Oil Seal

lnstallation

The seal surface on the block should be dry.

Apply a light cost of oil to the crankshaft and to

the liD of the seal.

Drive in flywheel end seal against right side cover.

NOTE: Drive the end seal in squarely.

DRIVER07t,49 - (xll(xtoo

2. Confirm that clearance is equal all the way around

with a fe€ler gauge.

Cler.6nce: 0.5 - 0.8 mm (0.02 - 0.03 inl

RIGHT SIDECOVER

NOTE: Reter to right column and 8-10 lor installa-

tion of the oil pump side oil seal.

lnstall sealwith thepart number sidetacing out.

7-25

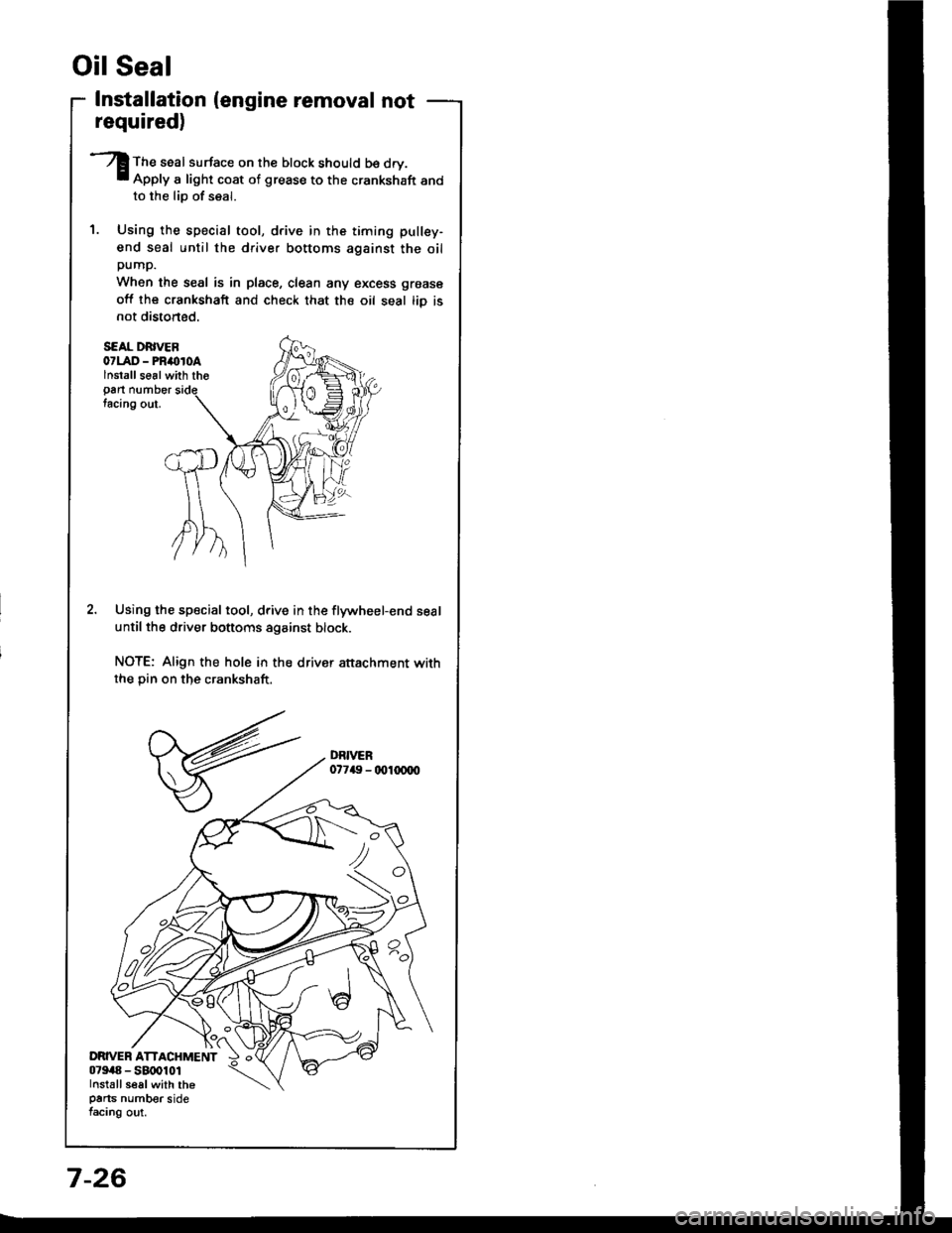

Page 166 of 1413

Installation (engine removal not

S€AL DRIVEB07LAD - PRimroAlnstallse6lwith tho

Pan numbertacing out.

Using the special tool, drive in the flywheel-end seal

until the driver bottoms against block.

NOTE: Align the hole in the drivsr attachment withthe Din on the crankshaft.

Oil Seal

required)

The seal surface on the block should b€ dry.Apply a light coat of grease to the crankshaft andto the lio of seal.

Using the special tool, drive in the timing pullsy-

end seal until the driver bottoms against the oilpump.

When the seal is in place, clean any excess grease

off lhe crankshaft and check that the oil seal tiD isnot distoned.

7-26

Page 258 of 1413

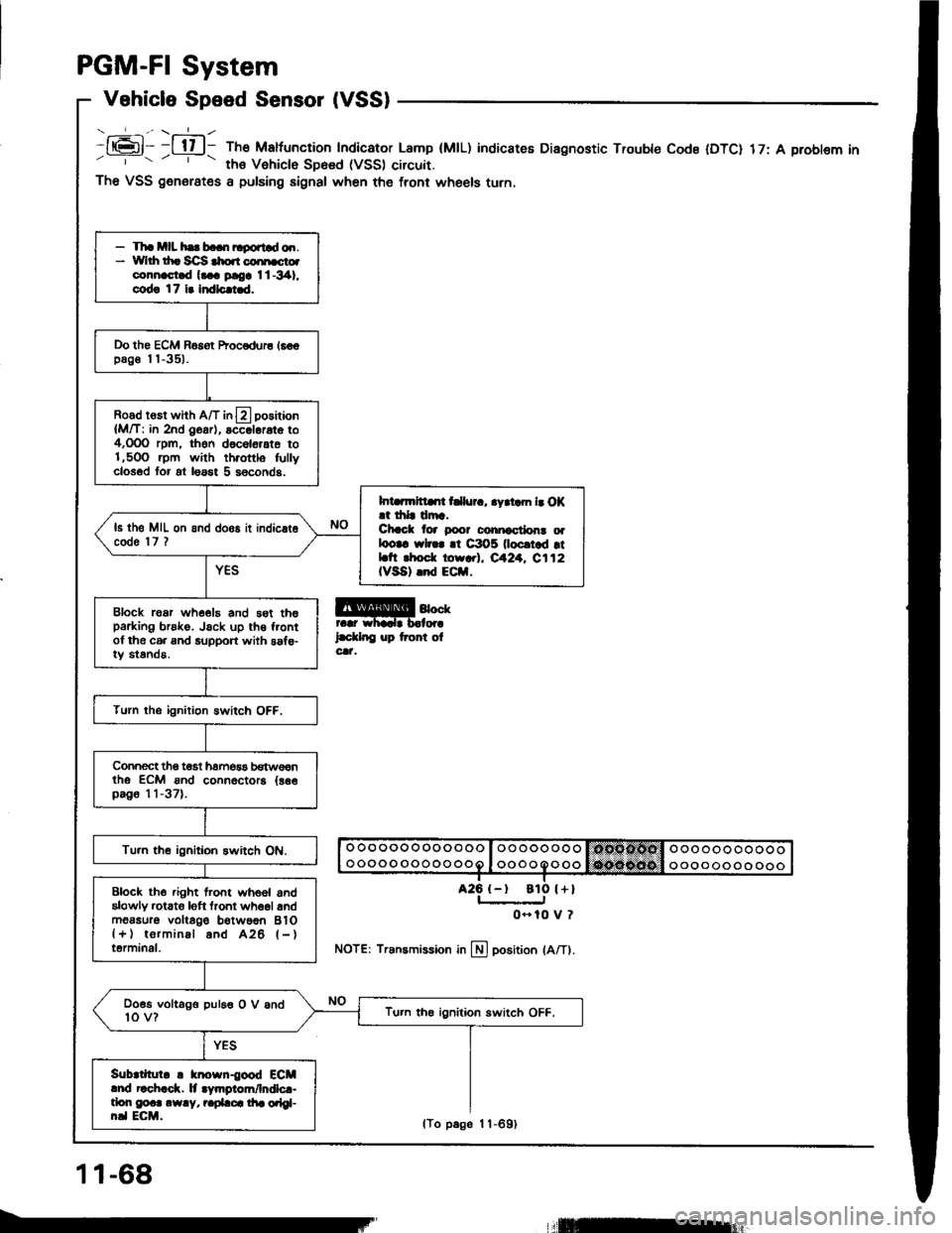

PGM-FI System

Vehicle Speed Sensor (VSS)

- _-_f_-., \-=1_ -

It6l- -l tl l- The Maltuncrion Indicator Lamp (MtL)' ths Vehiclo SD6sd (VSS) circuit.

indicateE Diagnostic Trouble Code IDTC) 17: A problem in

a25 {-t

The VSS generates a pulsing signal when the front wheels turn.

@4""rr.r whadr b.lor.

l.d.lnC up tront olcat,

NOTE: Transmission in llj position lA/Tl.

- Tha mll hs b..n ltgortld o.r.* Yvlrh th. Sc]S $o.r coi[cto.connast.d l... ploa I l -341,

cod! 17 i. Indlc.i.d.

Do the ECM Basot Procodur6 16€€pag€ I I -351.

Road rosr whh A/T in13 positaon

{M/T: in 2nd O6ar), accol6rat6 to4,OOO rpm, thon d6c6l6,ate to1,5OO .pm with th.ottlo fullyclosod tor at loast 5 s6conds.

Int rmltllrt t llur., .yrtam b O|(.t drlr drr.Chcct lor poor conicctlon! oalootc wl... !t C3O5 0ocrtad rtLtt rhod. torr.l, eA24. C112IVSA) .nd ECil.

ls th6 MIL on and doos it indic.t6code 'l7 ?

Block roar whe€19 and 5st th6parking brsko. Jsck up th€ f.ontof the c6. and support with saf€-iy standa.

Turn the ignition Bwitch OFF.

Connect tho t€st hamos3 b€tw€€ntho ECM ond connoctora {as€pag6 11-37).

Tu.n th€ ignitioh switch ON.

Block the .ight lront whoel andalowly rctato loft tront wh6ol andm6asur6 voltago b€twoon BlO{+) torminal and A26 l-}terminal.

Doss voltago puleo O V and10 v?Tu.n th€ ignition switch OFF.

Sub|tllul. ! knosn{ood ECMlnd r!ch.ck. lt .Vmgiom/lndlc.-tlon g@.. .w.y, r.pLca di. orlgl-n.l ECM.

ato l+l

0- 10 V ?

11-68

lTo p6ge 1 1-691

llEur

Page 259 of 1413

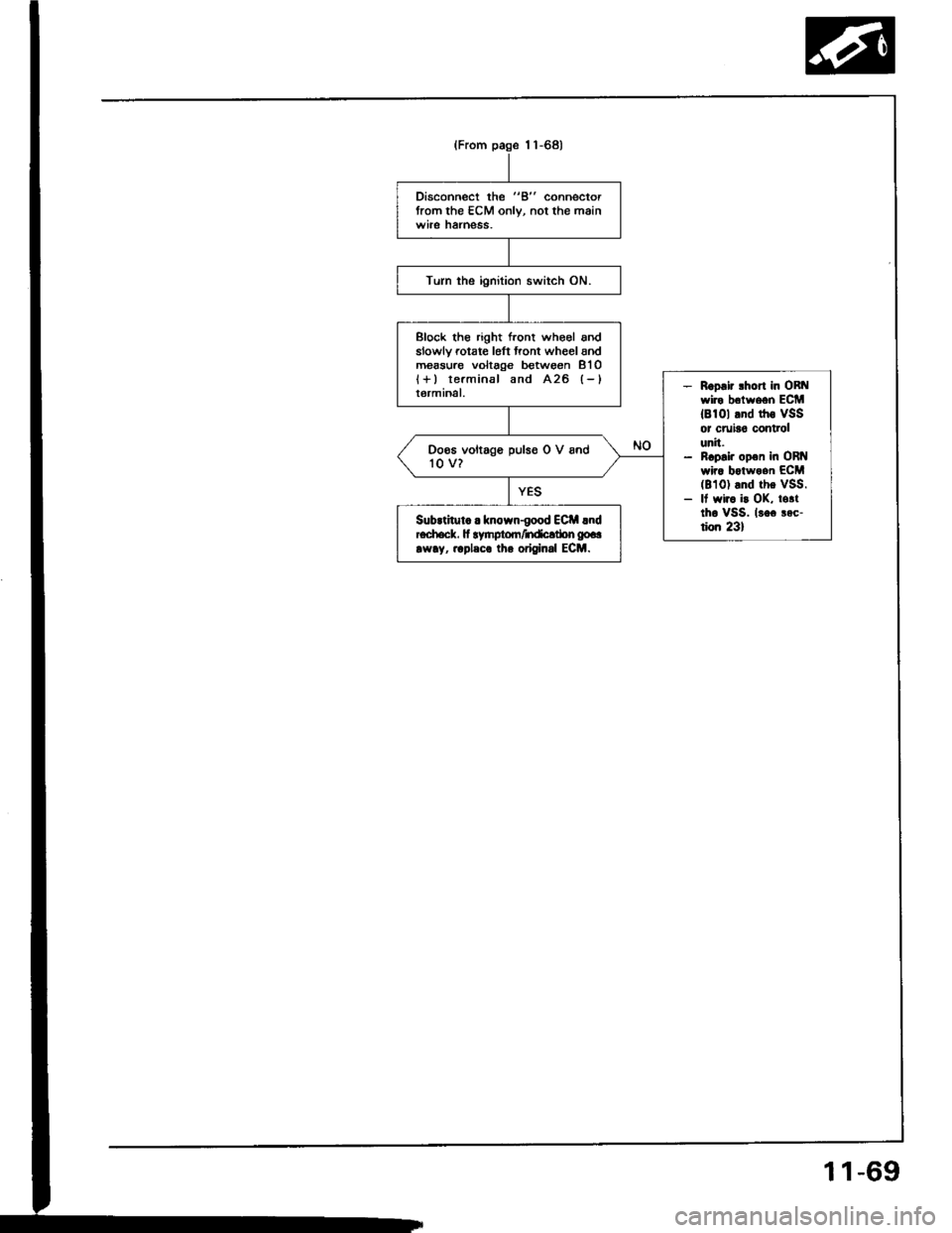

Disconnect the "B" connectorfrom the ECM only, not the mainwile hatness.

Turn the ignition switch ON.

Block tho right front who€l andslowlv rotate l6ft front wheel andm€asure voltage between 8'l Ol+) terminal and A26 (-)

terminal.- Roo.ir lhort in ORt{wire belween ECM18101 tnd rhs VSSor cruia6 controlunit.- ncp.i. op€n in ORI{wira botwoan ECM(8101 and the vSS.- It wir. i! OK, totttho vSS. lsoc aec-tion 231

Doos voltage pulso O V and'to v?

SubrtituL . known-good ECil lndEch.ck. fi lynptom/ndcltbn gp..

rw!y, .rpleco lh. original ECM.

(From page 1 1-68)

1 1-69