hood open HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1039 of 1413

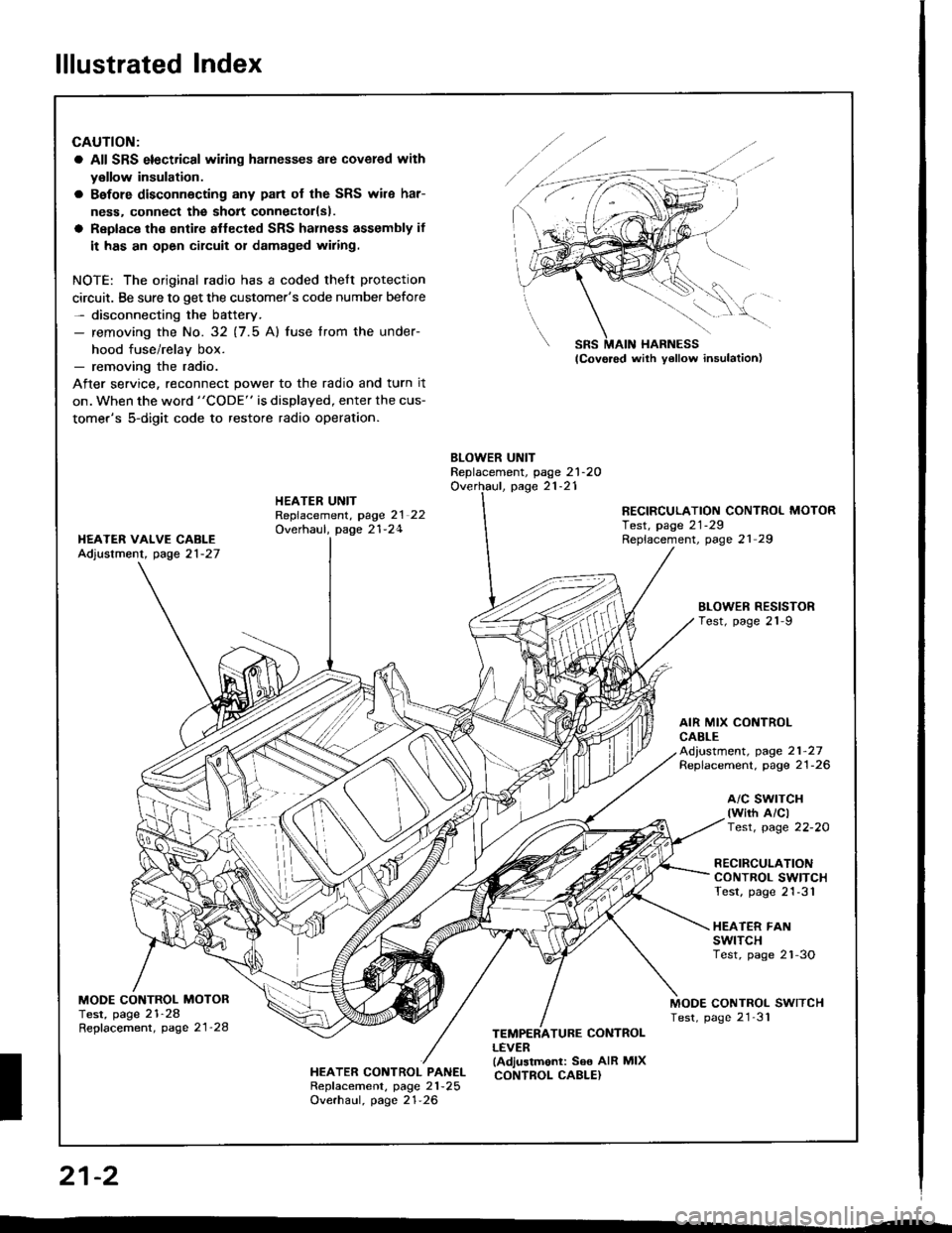

lllustrated Index

CAUTION:

a All SRS electrical wiling harnesses are covered with

y€llow insulation.

a Bafore disconnecting any pan of the SRS wile har-

ness. connect the sholt connectorlsl.

a Replace the sntire aflected SRS halness assembly if

it has an open circuit or damaged wiring.

NOTE: The original radio has a coded thelt protection

circuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 32 (7.5 Al fuse lrom the under-

hood fuse/relav box.- removing the radio.

After service, reconnect power to the radio and turn it

on. when the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

BLOWER UNITReplacement, page 21-2OOverhaul, page 21-21HEATER UNITRepfacement, page 2l 22Overhaul, page 21-24

RECIRCULATION CONTROL MOTORTest, page 21-29Replacement, page 21 29I{EATER VAIVE CABLEAdjustment, page 21-27

BLOWEN RESISTORTest, page 21-9

AIR MIX CONTROLCABLEAd,ustment, page 21-27Replacement. page 21-26

a/c swrTcH(wirh A/clTest, page 22-20

RECIRCULATIONCONTROL SWITCHTest, page 21-31

HEATER FANswtTcHTest, page 2'l-3O

MODE CONTROL MOTORTest, page 21-28Repfacement, page 21'28

MODE CONTROL SWITCHTest, page 21'31

HEATER CONTROL PANELRepf acement, page 21 -25

Overhaul, page 21-26

TEMPERATURE CONTROLLEVER(Adjustmonl: See AIR MIXCONTROL CABLE}

SRS MAIN HARNESS

W,

21-2

I

Page 1059 of 1413

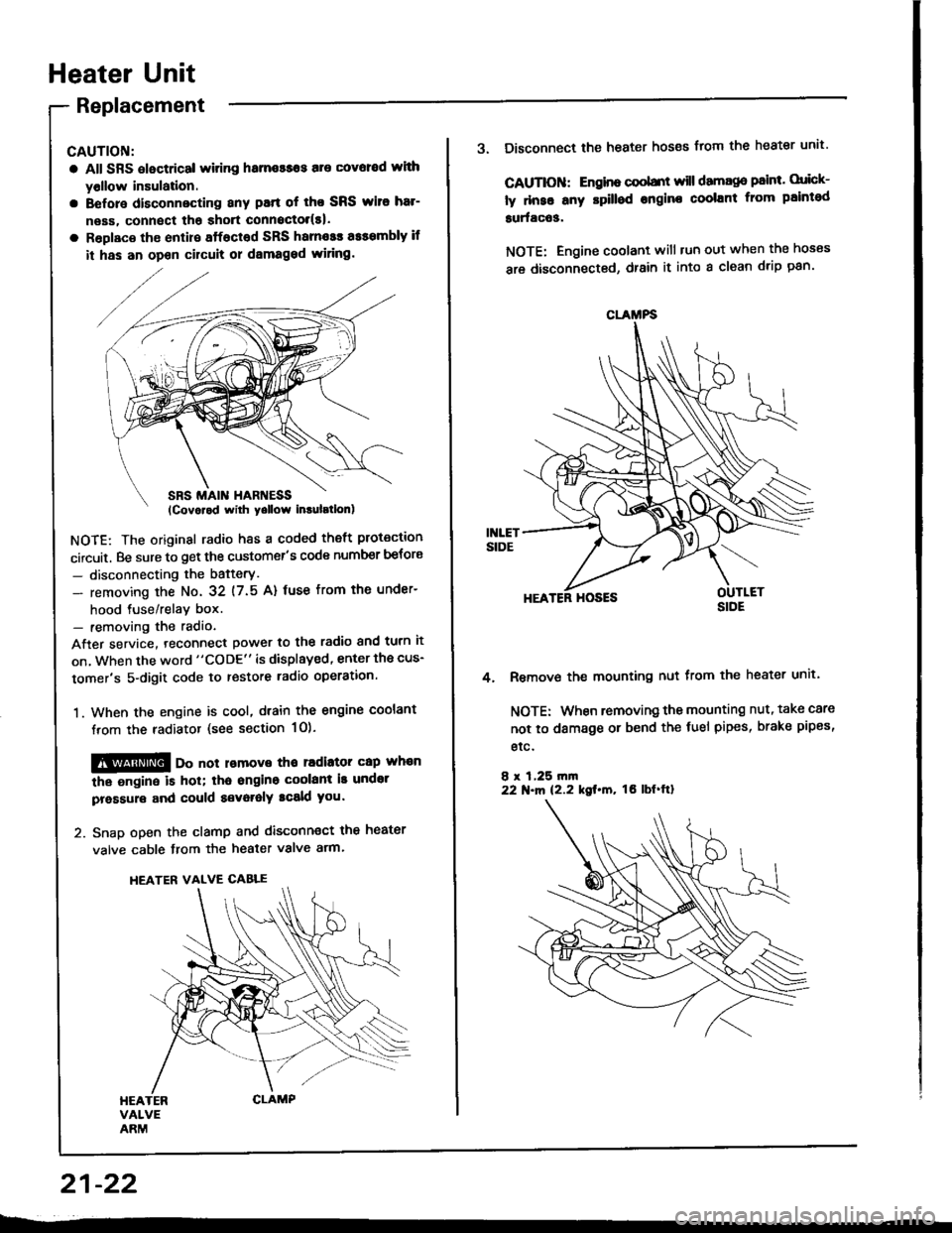

Heater Unit

Replacement

CAUTION:

a All SRS electrical witing hame$os are covoed wlth

yollow insulation.

a Before disconnecting any patt of tho SRS wito har-

neas, connect tha shott connoctol(s|.

a Roplaco th€ enlire sffacted SRS harnosr a$smbly if

it has an opon cilcult or dsmaged wiring.

NOTE: The original radio h8s a coded theft protection

circuit. Be sure to get the customer's code number betors

- disconnecting the bafterY.

- removing the No. 32 (7.5 A) fuse from th€ under-

hood tuse/relav box.- removing the radio

After service. teconnect power to the radio and turn it

on, when the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

1. When the engine is cool, dtain the engine coolant

from the radiator (see section 1O).

@@ oo not lomove tho radiator cap whan

the ongine is hol; tha ongino coolant is undot

pressure and could a€voralY tcald you.

2. Snap open the clamp and disconnect the heater

valve cable from the heater valve arm.

HEATER VALVE CABLE

21-22

CLAMFS

3. Disconnect the heater hoses from the heater unit'

CAUTIOII: Engino coobnt will damago paint. orick-

ly dnse any rpilled engine coolant from paintod

surfac63.

NOTE: Engine coolant will tun out when the hoses

are disconnected, drain it into a clean drip pan'

HEATER HOSES

Remove the mounting nut from the heater unit.

NOTE: When removing the mounting nut, take care

not to damage or bend the fuel pipes, brake pipes,

etc.

8 r 1,25 rn|n22 N.m 12.2 kgt.m, tO lbf'ftl

4.

Page 1071 of 1413

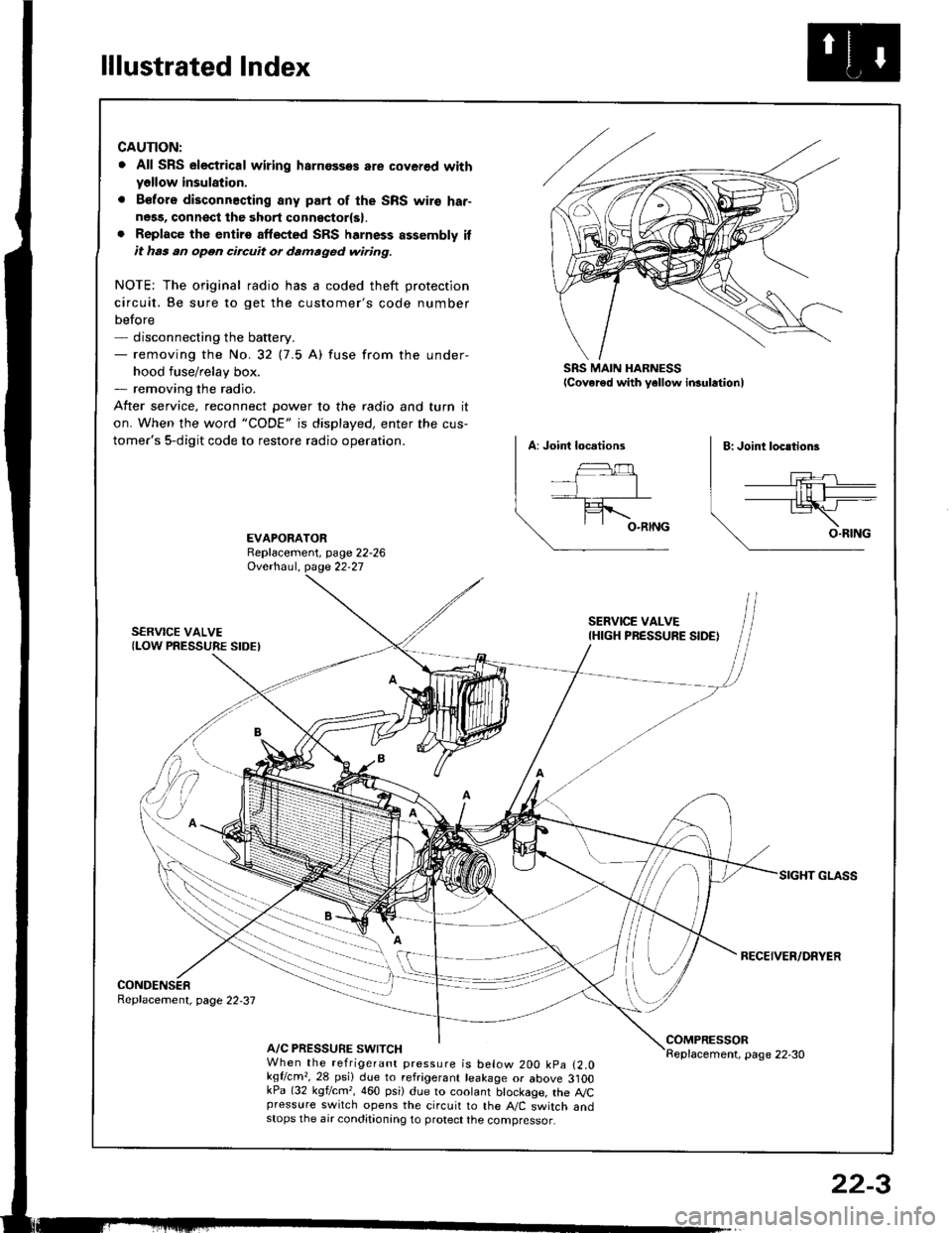

lllustrated Index

CAUTION:

. All SRS electrical wiring harnossos are cover€d withyellow insulation.

. B€fors disconnacting any part of the SRS wire har-ness, connsct the 3hort connsctor(s).. Replace the entirs affscted SRS harness assembly itit has an open circuit or damaged wiring.

NOTE; The original radio has a coded theft protection

circuit. Be sure to get the customer's code number

before- disconnecting the battery.- removing the No.32 (7.5 A) fuse from the under-

hood fuse/relay box.- removing the radio.

After service, reconnect Dower to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

SRS MAIN HARNESSlcover€d with yellow insulationl

EVAPORATORReplacement, page 22-26Ovethaul. Oase 22.27

SERVICE VALVE(LOW PRESSURE SIDEI

SERVICE VALVEIHIGH PRESSURE SIDE)

RECEIVER/DRYER

CONDENSERReplacement, page 22,37

A/C PRESSURE SWITCHCOMPRESSORReplacement, page 22-30When the refrigerant pressure is below 200 kpa (2.0kqflcm,,28 psi) due to refrigerant leakage or above 3]OOkPa (32 kgf/cm,, 460 psi) due to coolant btockage, the A,/Cpressure switch opens the circuit to the A"/C switch andstops the air conditionang to protect the compressor.

22-3

Page 1092 of 1413

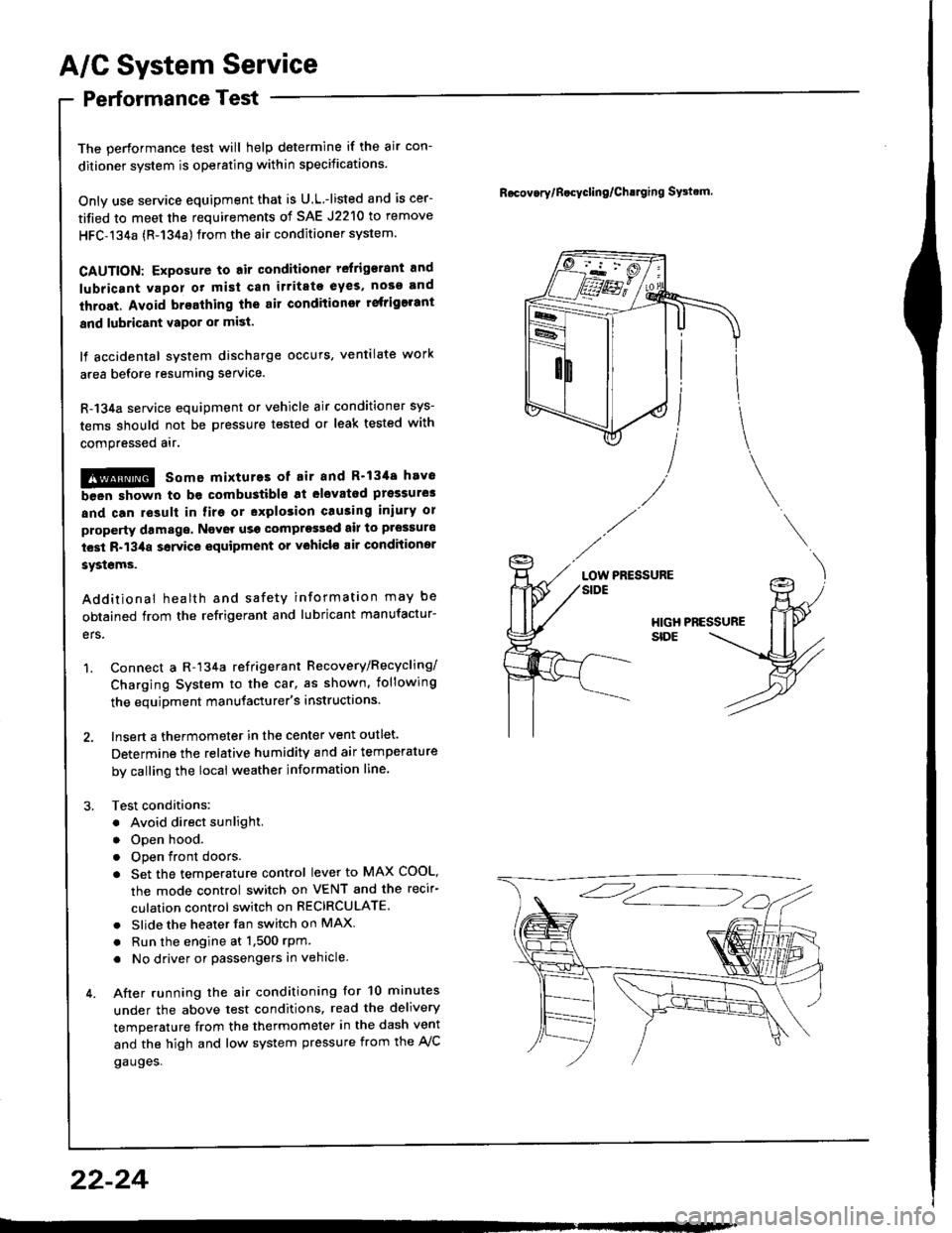

A/G System Service

Performance Test

The performance test will help determine if the air con-

ditioner system is operating within specitications.

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a {R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner relrig€rant and

lubricant vapor ot mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner rstrigerant

and lubricant vapor or mi3t.

It accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comPressed atr.

!@ some mixtures ot air and R'1344 hrv6

been shown to be combustibls at elovatod prsssurel

and can result in firg or explosion causing iniury 01

property damage. Ngvor usg compregsed ail to prossuro

t€st R-134a ssrvice equipment or vohicl€ air conditioner

syst€ms.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufactur-

ers.

1. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the car, as shown, iollowing

the equipment manufacturer's instructions.

2. Insert a thermometer in the center vent outlet.

Determine the relative humidity and air temperature

by calling the local weather information line,

3. Test conditions:

. Avoid direct sunlight.

. Open hood.

. Open front doors

. Set the temperature control lever to MAX COOL,

the mode control switch on VENT and the recir-

culation control switch on RECIRCULATE.

. Slide the heater fan switch on MAX

. Run the engine at 1,500 rPm

. No driver or passengers in vehicle.

4. After running the air conditioning for 10 minutes

under the above test conditions. read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A,/C

gauges.

Rocov.rylB.cycling/Ch!lging SFtrm.

PRESSURELOW

22-24

Page 1178 of 1413

lgnition Switch

Steering Lock Replacement

CAUTION:

a All SRS electrical wiring harnesses ale covsred with

yellow insulation.

a Belore disconnecting any parl ot the SRS wir€ hal-

ness, connecl the short connector{s).

a Replace the entire alfected SRS harness a$6mbly il

it has an open circuit or damaged wiring.

NOTE: The original radio has a coded thett protection

circuit. Be sure to get the customer's code number betore

- disconnecting the batterY.

- removing the No. 32 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

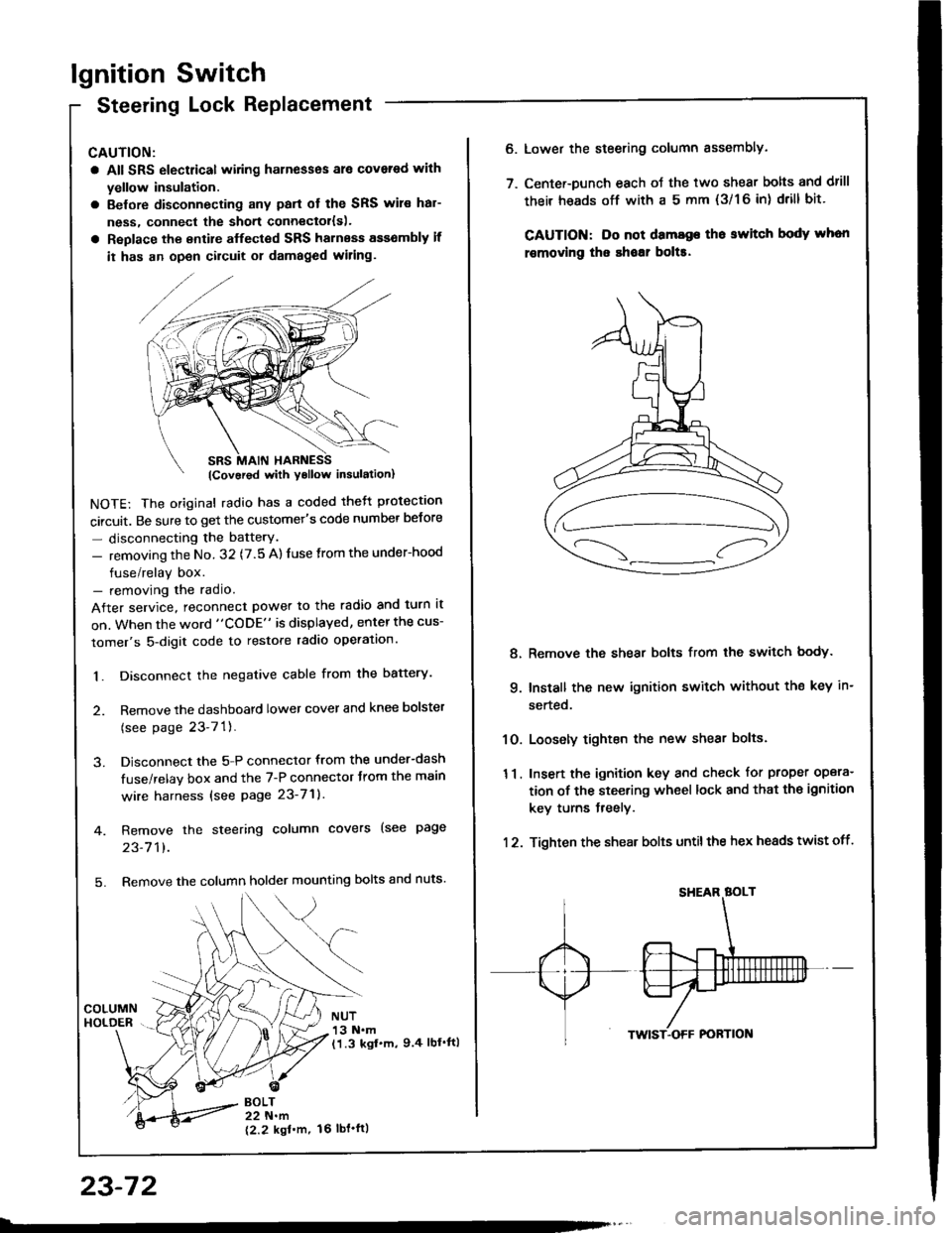

1. Disconnect the negative cable from the battery.

2. Remove the dashboald lower cover and knee bolster

(see page 23-7'l ).

3. Disconnect the 5-P connector from the under-dash

fuse/relay box and the 7-P connector trom the main

wire harness {see page 23-71).

4. Remove the steering column covers (see page

23-711.

5. Remove the column holder mounting bolts and nuts'

BOLT22 N.m

12.2 kgl'm.

NUT13 N.m(1.3 kgf.m, 9.4 lbl'ftl

23-72

16 tbt.ftl

6. Lower the steering column sssembly.

7. Center-Dunch each oJ the two shear bolts and drill

their heads off with a 5 mm {3/1 6 in) drill bit'

CAUTION: Do not dama96 tho switch body whon

r€movlng the shoar bol$.

Remove the shear bolts from the switch body.

Install the new ignition switch without the key in-

serted.

Loosely tighten the new shear bolts.

Insert the ignition key and check for proper opera-

tion of the steering wheel lock and that th€ ignition

key turns freely.

Tighten the shear bolts untilthe hex heads twist off.

8.

q

10.

11.

12.

Page 1183 of 1413

5. Check lor 8n op€n in the BLKMHT wire circuit be-

tween the staner and ignition switch, and con-

nectors.

6. Check the ignition switch (see page 23-70).

7, On cars with automatic transmission, check the A/Tgear position switch (neutral position switchl and

connector. On cars with manualtransmission, check

the staner cut relay, clutch interlock switch, and

connectors.

NOTE: Check the No. 39 (5O A) fuse in the under-hood

fuse/relay box for the starter cut relay.

Check tor Woar and Damago:

The starter should crank the engine smoothly and stead-

ily. lf th€ startsr engages, but cranks the engine errati-

cally, remove it. Inspect the starter, drive gear, and

flywheel ring gesr for damage.

a Check the drive gear overunning clutch for binding

or slipping when the armature is rotated with the drivegear held. Replace the gesrs if damaged.

Check Cranking Voltago 8nd Current Draw:

Cranking voltage should be no less than 8.O volts.

Current draw should be no more than 360 amperes.

lf cranking voltag€ is too low, or current draw too high,

check for:

a Fully charged battery

a Open circuit in starter armature commutatot segments

a Starter armature dragging

a Shoned armature winding

a Excessive drag in engine

Chack Cranking rpm:

Engine spsod during cranking should be above 1O0 rpm.

lf spe6d is too low, ch€ck for:

a Loose battsry or starter teminals

a Excessively worn starter brushes

a Open circuit in commutator segments

a Dirty or damaged helical spline or drive gear

a Defective drive gear overrunning clutch

Chock StErtor Disongagomoni:

Press the clutch pedal allth€ way in (M/T), turn the ioni-

tion switch to "lll" and rolease to "11".

The starter drive gear should disengage from the tlywheel

ring gear. When you rolease the key.

lf the drive gear hangs up on th€ flywheel ring gear, check

for:

a Solenoid plunger and switch malfunction

a Dirty drive gear assembly or damaged overrunning

clutch

23-77

Page 1237 of 1413

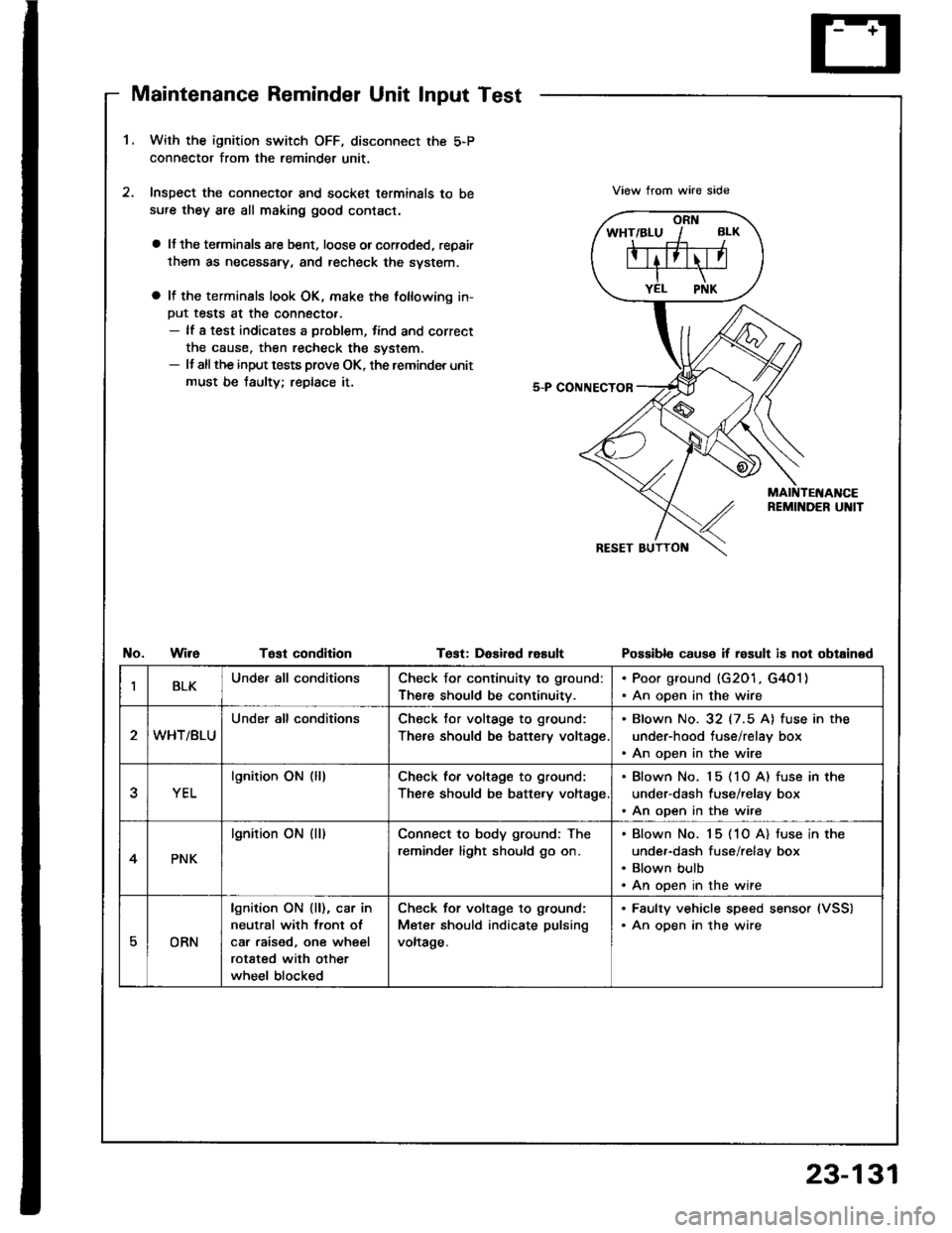

Maintenance Reminder Unit Input Test

1.With the ignition switch OFF, disconnect the 5-P

connector from the reminder unit,

Inspect the connector and socket terminals to be

sufe they are all making good contact.

a lJ the terminals are bent, loose orcorroded, repair

them as necessary, and recheck the svstem.

a It the terminals look OK, make the following in-

Put tests at the connecto..- lf a test indicates a problem, tind and correct

the cause, then recheck the system.- It allthe input tests prove OK, the reminder unit

must be taulty; replace it.

View trom wire side

No.WireTost condltionTest: DaEired rasultPossibl€ cause if result is not obtained

IBLKUnde. all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G201, G4O1). An open in the wire

WHT/BLU

Under all conditionsCheck tor voltage to ground:

There should be battery voltage

. Blown No. 32 (7.5 A) fuse in the

under-hood tuse/relay box. An open in the wire

YEL

lgnition ON (lllCheck for voltage to ground:

There should be batte.y voltage

. Blown No. 15 (1O A) fuse in the

under-dash fuse/relay box. An open in the wire

4PNK

lgnition ON (ll)Connect to body ground; The

reminder light should go on.

Blown No. 15 (1O A) tuse in the

under-dash fuse/relay box

Blown bulb

An open in the wire

EORN

lgnition ON {ll), car in

neutral with lront ol

car raised, one wheel

rotated with other

wheel blocked

Check for voltage to g.ound:

Meter should indicate pulsing

voltage.

. Faulty vehicle speed sensor (VSS)

. An oDen in the wire

23-131

Page 1263 of 1413

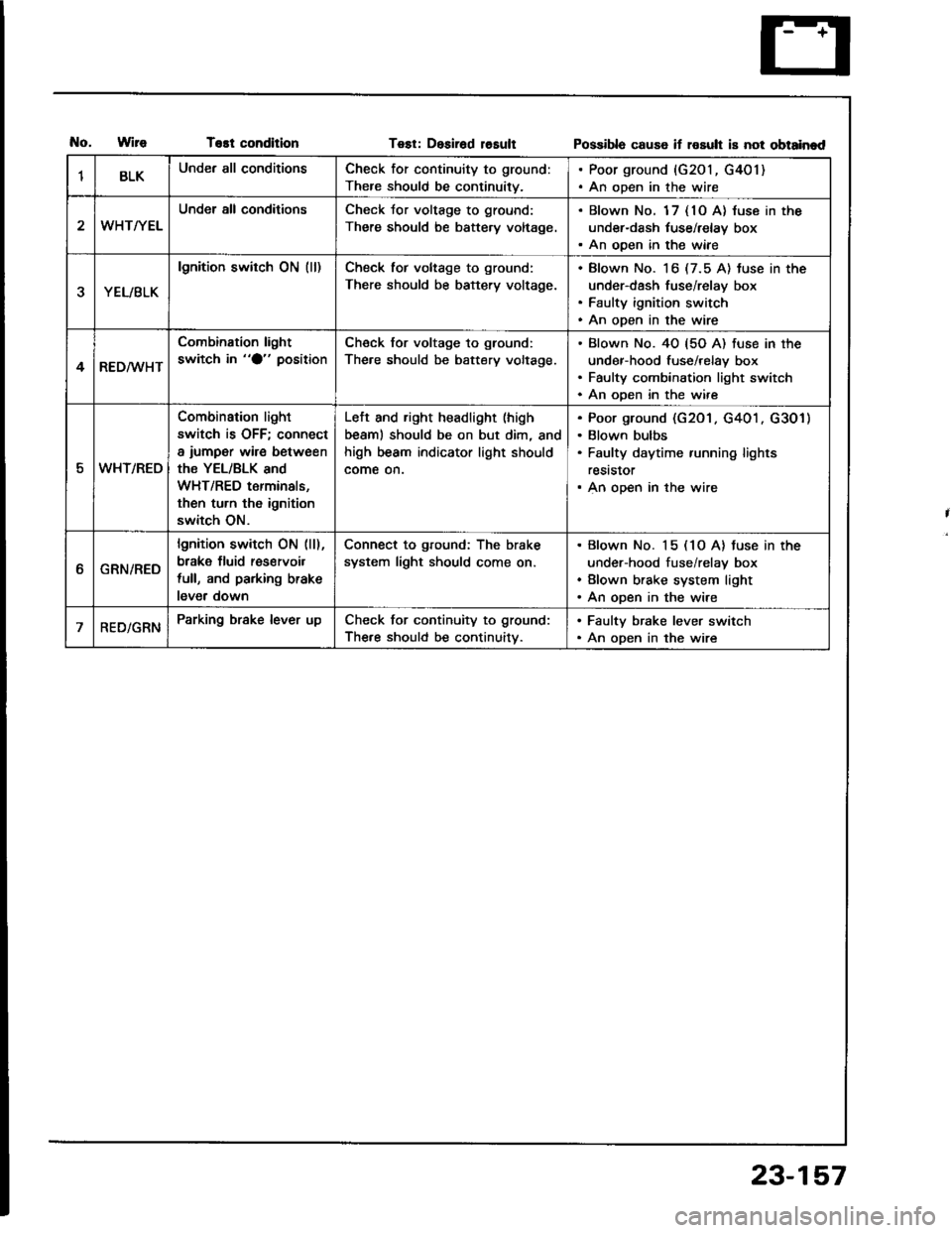

T€st conditionTest: Desirad losultPossibla cause if rosult is not obtainad

1BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground {G201, G401). An open in the wire

WHT/YEL

Under all conditionsCheck Jor voltage to ground:

There should be battery voltage.

. Blown No. 1 7 { 10 A} luse in the

under-dash tuse/relay box. An ooen in the wiae

YEL/BLK

lgnition switch ON (ll)Check tor voltage to ground:

There should be battery voltage.

Blown No. 16 (7.5 A) tuse in the

under-dash fuse/relay box

Faulty ignition switch

An open in the wire

4RED/WHT

Combination light

switch in "O" positionCheck for voltage to ground:

The.e should be battery voltage.

Blown No. 40 {5O A) fuse in the

under-hood fuse/relay box

Faulty combination light switch

An ooen in the wire

5WHT/REO

Combination light

switch is OFF; connect

a iumper wire between

the YEL/BLK and

WHT/RED terminals,

then turn th6 ignition

switch ON.

Left and right headlight (high

beaml should be on but dim, and

high beam indicator light should

come on.

Poor ground (G201 . G401 . G301)

Blown bulbs

Faulty daytime running lights

reststor

An open in the wire

ttGRN/RED

lgnition switch ON (ll),

brake fluid res€rvoil

full, and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No. 15 (1O A) tuse in the

under-hood fuse/relay box

Blown brake system light

An open in the wire

RED/GRNParking brake lever upCheck for continuity to ground:

The.e should be continuitv.

. Faulty brake lever switch. An open in the wire

23-157

Page 1268 of 1413

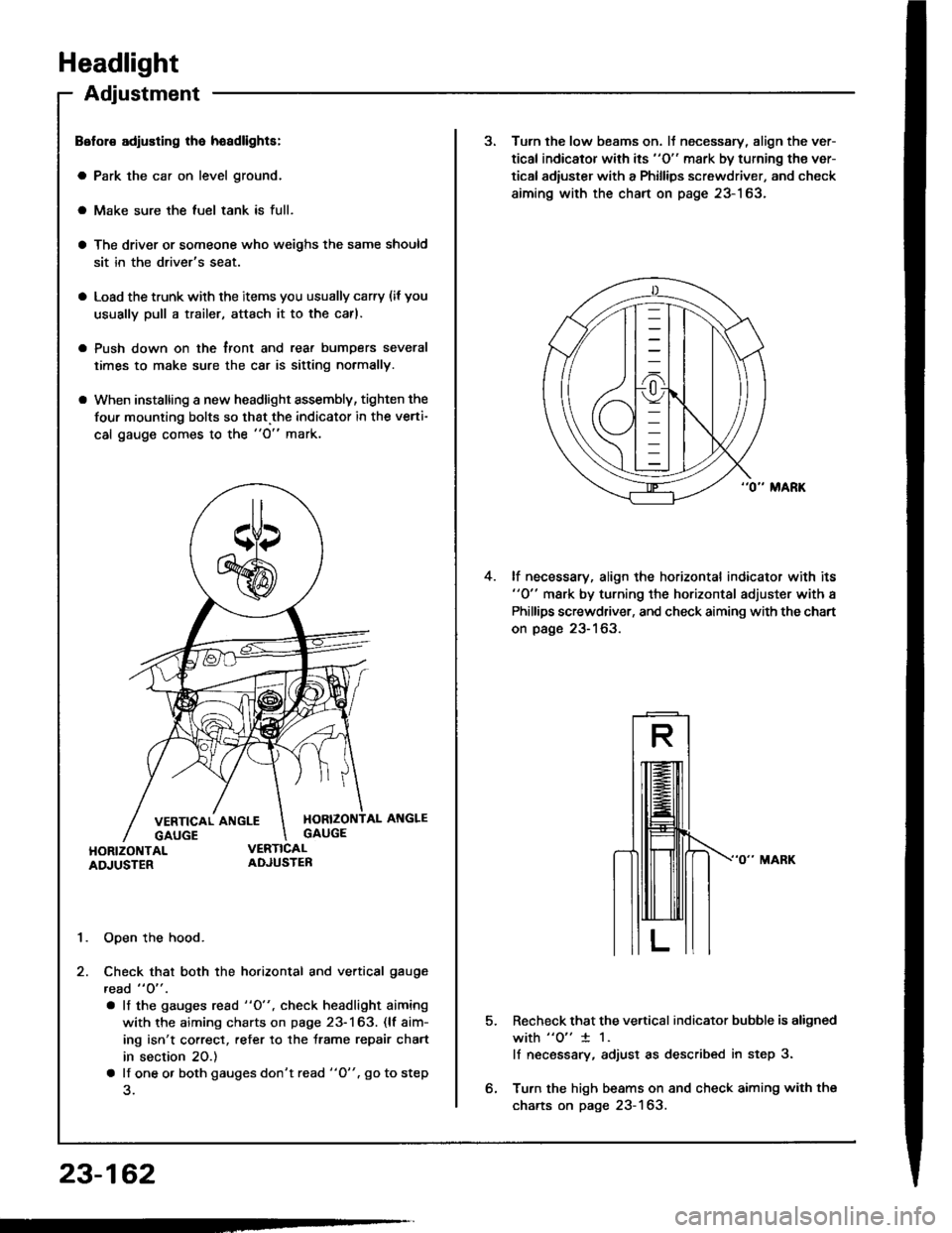

Headlight

Adjustment

Belol€ adiusting lha hoadlights:

a Park the car on level ground.

a Make sure the luel tank is full.

a The driver or someone who weighs the same should

sit in the driver's seat.

a Load the trunk with the items you usually carry (if you

usually pull a trailer, attach it to the carl.

a Push down on the tront and rear bumDers several

times to make sure the car is sitting normally.

a When installing a new headlight assembly, tighten the

four mounting bolts so that.the indicator in the verti-

cal gauge comes to the "O" mark.

1. Open the hood.

2. Check that both the horizontal and vertical gauge

read " O" .

. lf the gauges rcad "O", check headlight aiming

with the aiming charts on page 23-163. (lf aim-

ing isn't correct, refer to the trame repair chart

in section 20.)

a lf one o. both gauges don't read "O". go to step

23-162

3. Turn the low beams on. lJ necessary, align the ver-

tical indicator with its "O" mark by turning the ver-

tical adiuster with a Phillips screwdriver, and check

aiming with the chart on page 23-163.

lf necessary, align the horizontal indicator with its"0" mark by turning the horizontal adjuster with a

Phillips screwdriver, and check aiming with the chart

on page 23-163.

4.

5.Recheck that the vertical indicator bubble is aligned

with "o" 1 1.

lf necsssary, adjust as described in step 3.

Turn the high beams on and check aiming with the

charts on page 23-163.

Page 1292 of 1413

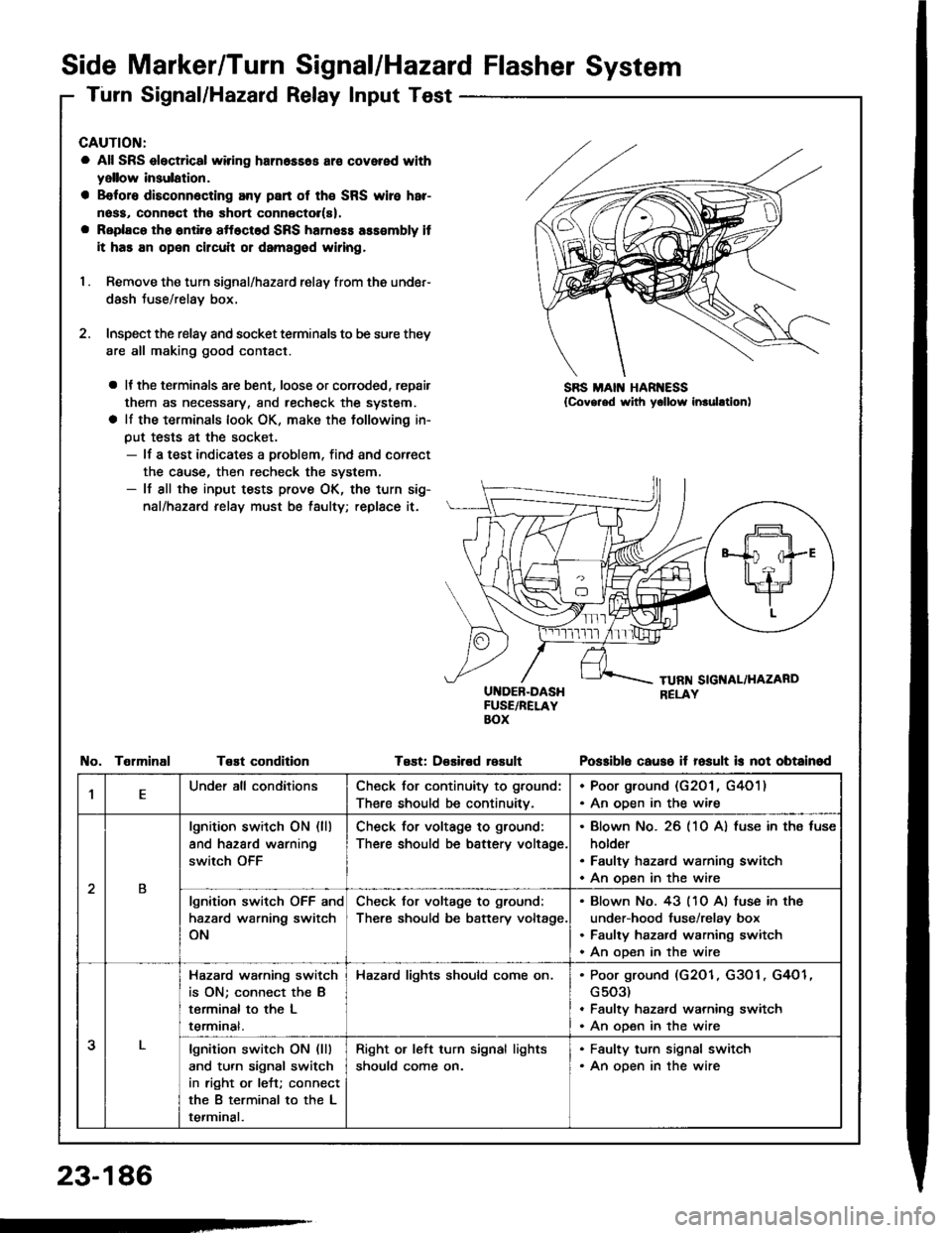

Side Marker/Turn Signal/Hazard Flasher System

Turn Signal/Hazard Relay Input Test

CAUTION:

a All SRS electrical wiring harn6ss6s ar€ covered with

yellow insulation.

a B€foro disconn6cting any part of th€ SRS wire har-

noss, connoct tho short connector(s).

a Replaco tho ontiro sftoctod SRS harness ass€mbly it

it has an open circuit or damagod wiring,

I . Remove the turn signal/hazard relay from ths under-

dash Juse/relay box.

2. Inspect the relay and socket terminals to be sure they

are all making good contact.

a It the terminals are bent, loose or coroded, repair

them as necessary, and recheck the system.

a lf the terminals look OK, make the tollowing in-

put tests at the socket.- lf a test indicates a problem, find and correct

the cause, then recheck the system.- lf all the input tests prove OK, the turn sig-

nal/hazard relay must be taulty; replace it.

UI{DEB-DASHFUSE/RELAYBOX

Test: D€sired rosult

SBS MAIN HAR ESS{Covg.ed with yollow inrulltion)

TelminalTeEt conditionPo$iblo causo it fosult is not obtainod

,lEUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G201 , G4O1). An oDen in the wire

2B

lgnition switch ON (ll)

and hazard warning

switch OFF

Check for voltage to ground:

There should be battery voltage.

Blown No. 26 (10 A) fuse in ths fuse

holder

Faulty hazard warning switch

An open in the wire

lgnition switch OFF and

hazard warning switch

ON

Check for voltage to ground:

There should be battery voltage.

Blown No. 43 (10 Al fuse in the

under-hood fuse/relay box

Faulty hazard warning switch

An ooen in the wire

3

Hazard wa.ning switch

is ON; connect the B

terminal to the L

termrnat.

Hazard lights should come on.Poor ground (G2O1, G3O1, G4O1

G503)

Faulty hazard warning switch

An open in the wire

lgnition switch ON (lll

and turn signal switch

in right or left; connect

the B terminal to the L

terminal.

Right or left turn signal lights

should come on.

. Faulty turn signal switch. An open in the wire

23-186

-