main relay HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 289 of 1413

The fusl supply system consists ot a fuel tank, in-tank

high presssure fu6l pump, PGM-FI main relay, fuel filter,

tuel pressure regulatot, fuel inioctors, fusl pulsation

damper and fuol delivery and return linss. This system

delivers pressure-regulatored fu6l to the fu6l injectors and

cuts the fuel delivory wh6n the engine is not running.

Fuel Supply System

System DescriptionFuel Pressure

a Do not smok6 while working on the fuol syst6m,

Keep open flames or spalks away tlom your work

aroa.

a 8e sure to raliavo fuol p.essur6 while th6 6n9in6 is off.

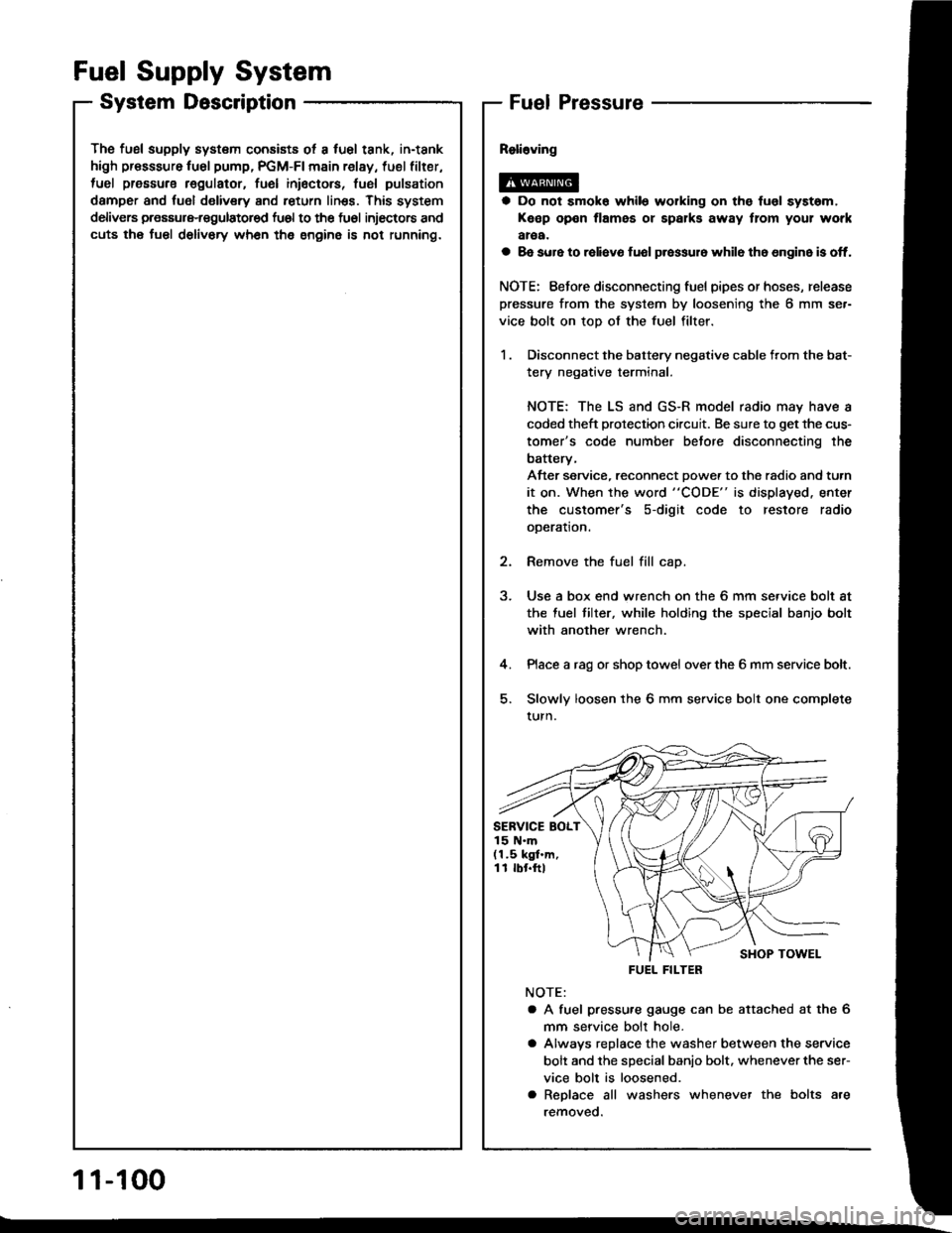

NOTE: Eefore disconnecting fuel pipes or hoses, release

pressure from the system by loosening the 6 mm se.-

vice bolt on top of the fuel filter.

1 . Disconnect the battery negative cable from the bat-

tery negative terminal.

NOTE: The LS and GS-R model radio may have a

coded theft protection circuit. Be sure to get the cus-

tomer's code number betore disconnecting the

batterv,

After service, reconnect Dowe. to the radio and turn

it on. When the word "CODE" is displayed. enter

the customer's s-digit code to restore radio

ooeration.

2. Remove the fuel fill cap.

3. Use a box end wrench on the 6 mm service bolt at

the fuel tilter, while holding the special banjo bolt

with another wrench.

4. Place a rag or shop towel over the 6 mm service bolt.

5. Slowly loosen the 6 mm service bolt one complete

turn.

NOTE:

a A fuel pressu.e gauge can be attached at the 6

mm seryice bolt hole.

a Alwavs replace the washer between the service

bolt and the special banio bolt. whenever the ser-

vice bolt is loosened.

a Replace all washers whenever the bolts are

removeo.

SERVICE BOLT15 N.m(1.5 kgf.m,11 rbr.ftl

FUEL FILTER

1 1-100

Page 298 of 1413

[":::,::-'

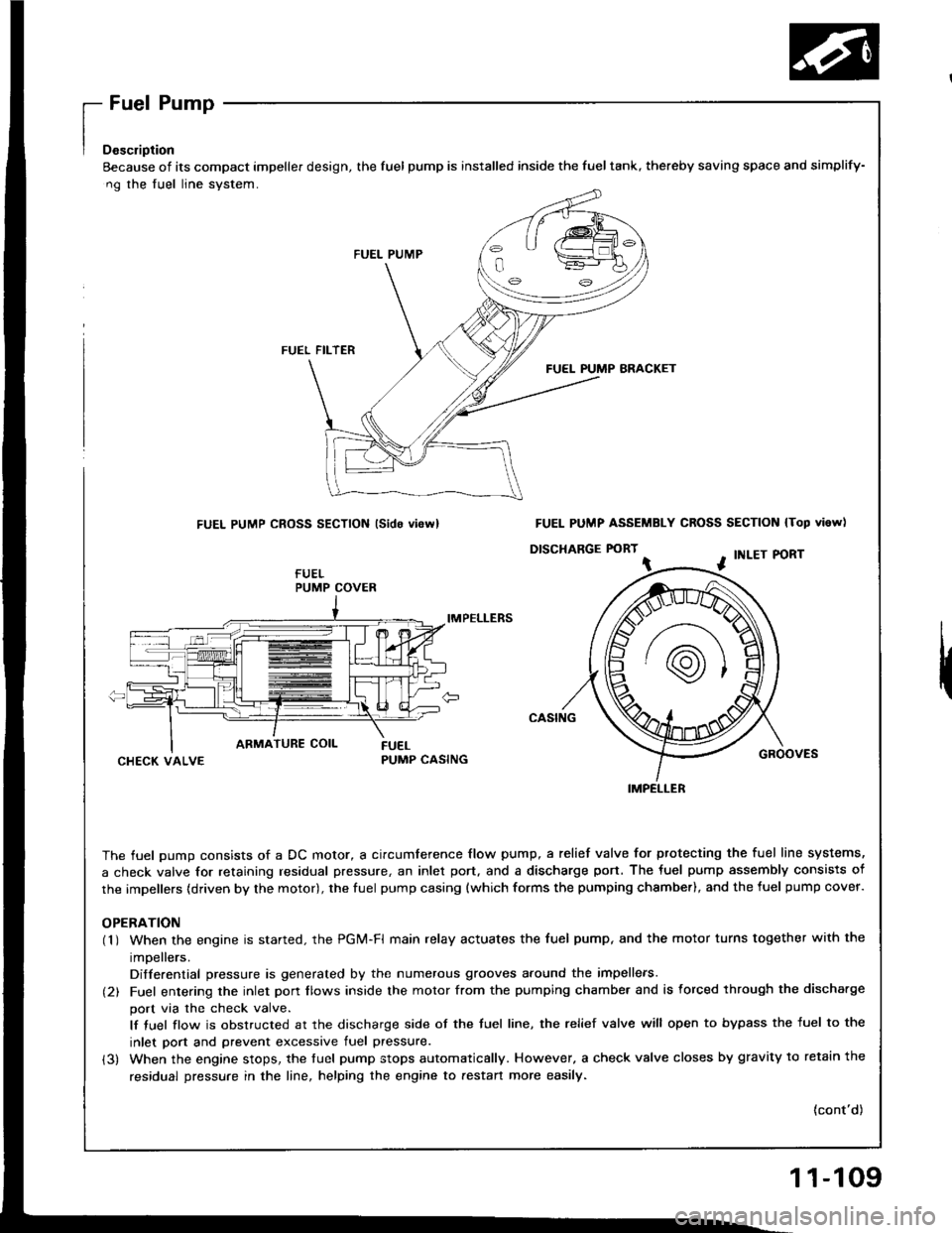

Eecause of its compact impeller design, the fuel pump is installed inside the fueltank, thereby saving space

ng the fuel line system.

FUEL PUMP

FUEL FILTER

FUEL PUMP BRACKET

FUEL PUMP CROSS SECTION lsido vi6rvl

IMPELLERS

CHECK VALVEPUMP CASING

The fuel oumo consists of a DC motor, a circumference flow pump, a relief valve for ptotecting the fuel lir

a check valve for retaining residual pressure, an inlet port, and a discharge port. The fuel pump assembly

the impellers (driven by the motor), the fuel pump casing {which forms the pumping chsmber), and the fuel p

OPERATION(1 ) When the engine is started. the PGi/t-Fl main relay actuates the fuel pump, and the motor turns togeth

impellers.

Differential pressure is generated by the numerous grooves around the impellers.

(2) Fuel entering the inlet porr flows inside the motor from the pumping chambe. and is forced through th

port via the check valve.

lf tuel flow is obstructed at the discharge side of the tuel line, the relief valve will open to bypass the

inlet port and prevent excessive fuel pressure.

(3) When the engine stops, the tuel pump stops automatically. However, a check valve closes by gravity t

residual pressure in the line, helping the engine to aestan more easily.

and simplify-

N lTop vi6w)

PORT

GROOVES

fuel line systems,

embly consists of

fuel pump cover.

together with the

rgh the discha.ge

ss the fuel to the

avitv to retain the

(cont'd)

PUMP COVER

FUEL PUMP ASSEMBLY CROSS SECTION

D|SCHARGE FORT ^ . tNLEr P

IMPELLER

11-109

Page 299 of 1413

Fuel Supply System

Fuel Pump (cont'dl

Tc.ting

@E o" not smoko during tho tesr. Koop openflrmo away fiom your work area.

lf you susp€ct a problem with the tuel pump, check thatthe lusl pump actually runs; when it is ON, you will hearsome noise if you hold your ear to the luel lill oon withthe fuel fill cap remov6d. The fuel pumD should run fortwo seconds, when ignition switch is first turned on. llthe fuel pump does not make noiss, check as tollows;

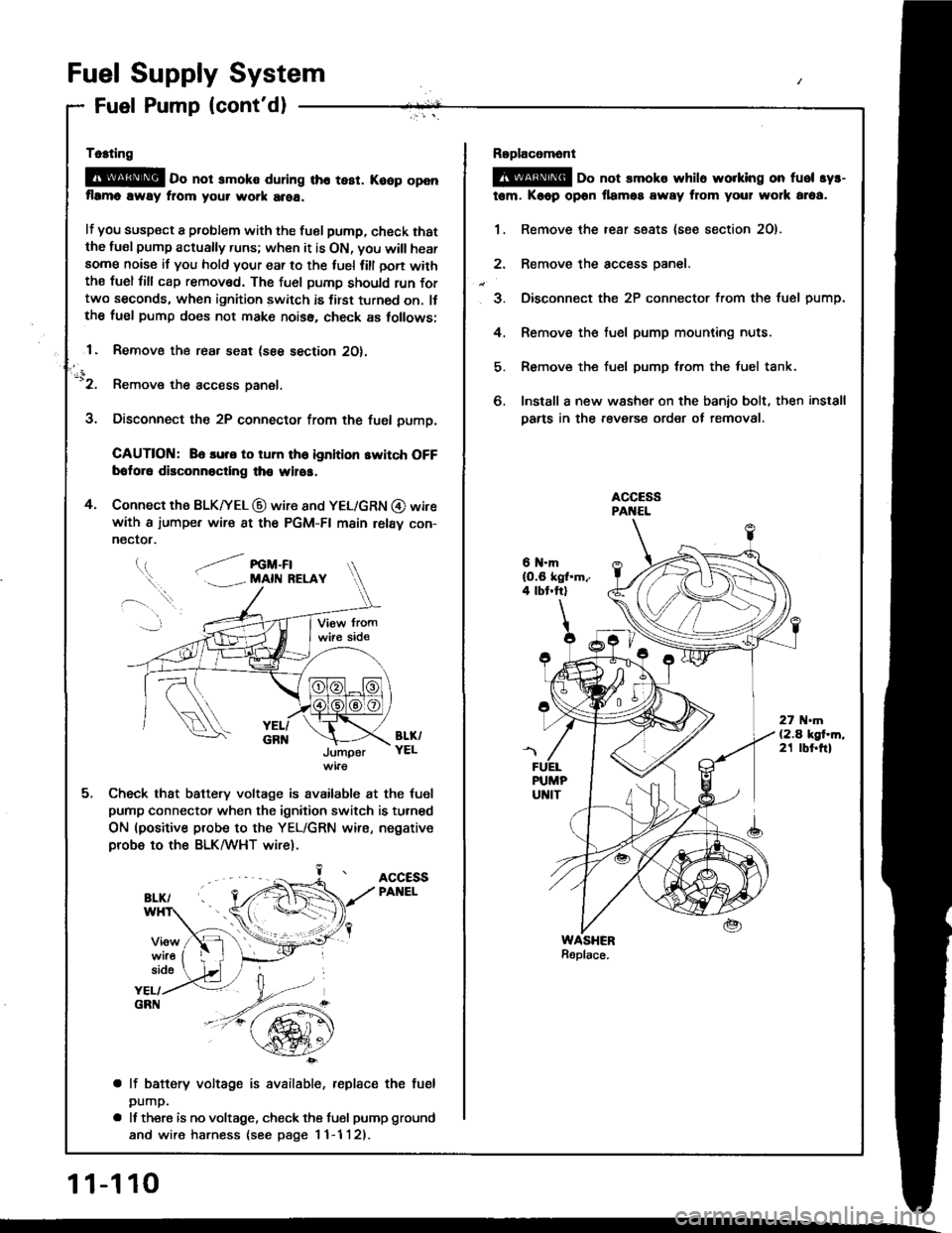

1. Removo the rear seat (see section 2O).

-'2. Remove the access panel.

3. Disconnect the 2P connector from the fuel pump.

CAUTION: 86 lure to tum th6 ignition switch OFFbotor6 disconnoctlng th€ wilos,

4. Connect the BLK|yEL @ wire 8nd YEL/GRN @ wirewith a iumpe. wire 8t the PGM-FI main relav con-

nectot.

l.t, .--/ re -Fl. . MAll{ RELAY

BL&YELJumper

Check that battery voltage is available at the tuel

pump connector when the ignition switch is turned

ON (positive probe to the YEL/GRN wire, negativeprobe to ths BLK/WHT wire).

ACCESSPANEL

side

YEL/GRN

a lf battery voltage is available, replace the fuel

pump.

a It there is no voltage, check the tusl pump ground

and wire harness {see page I 1-1 l2).

11-110

Roplacomont

@ oo not smoks whilo worklng on fuel syr-

tem. Kaop opon llamos away from your wolk araa.

1. Remove the rear ssats {soe section 2O).

2. Remove the access oanel.

3. Disconnect the 2P connector from the fuel pump.

4. Remove the fuel pump mounting nuts.

5. Remove the fuel pump trom the luel tank.

6. Install a new washer on the banio bolt, then install

Darts in the revers€ order of removal.

6 N.mlO.6 kgl.m,.4 tbt.ftl

27 .m(2.4 kgt.m,21 tbt.ftl

Page 300 of 1413

PGM-Fl Main Relay

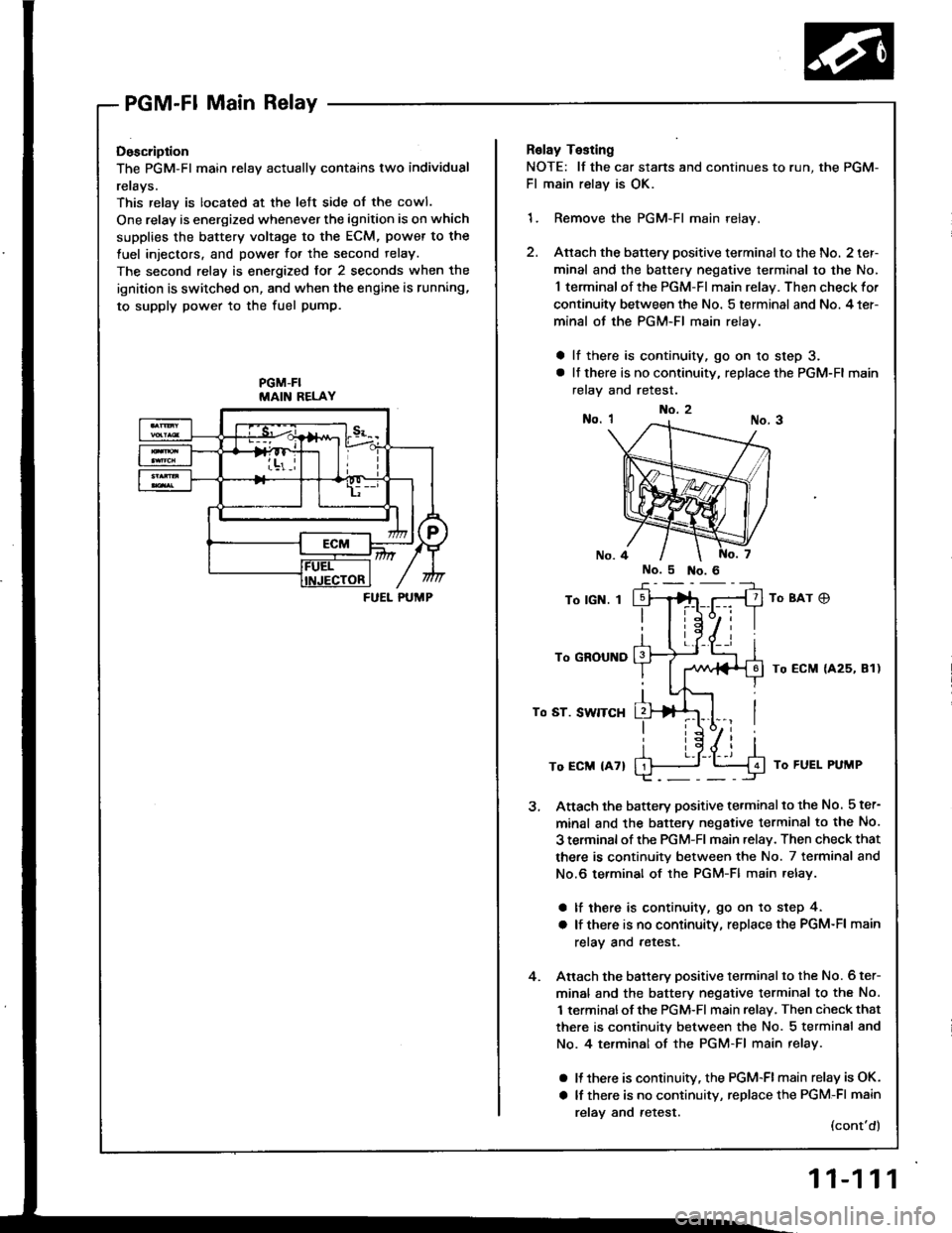

Doscription

The PGM-Fl main relav actuallv contains two individual

rerays.

This relay is located at the lett side of the cowl.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

fuel injectors, and power for the second relay.

The second relay is energized for 2 seconds when the

ignition is switched on, and when the engine is running,

to supply power to the fuel pump.

PGM-FIMAIN RELAY

FUEL PUMP

Relay Testing

NOTE: lf the car stans and continues to r

Fl main relay is OK.

1. Remove the PGM-Fl main relay.

2. Attach the battery positive terminalto

minal and the battery negative termir

1 terminal of the PGM-FI main relay. T

continuity between the No. 5 terminal

minal of the PGM-FI main relay.

a lf there is continuity, go on 10 ste

a lt there is no continuity, replace the

relay and retest.

To lGN. I

To GROUND

To ST. SWITCH

To ECM {47}

Attach the battery positive terminalto

minal and the battery negative termil

3 terminal of rhe PGM-Fl main .elav. Tl

there is continuity between the No. ;

No.6 terminal of the PGM-Fl main re

a lf there is continuity, go on to st€

a lf there is no continuity, replace th€

relay and retest.

Anach the battery positive terminalto

minal and the battery negative termil

1 terminalof the PGM-Fl main relay, Tl

there is continuity between the No. :

No. 4 te.minal of the PGM-Fl main r

a It there is continuitv, the PGM-FI mi

a lf there is no continuity, replace th(

relav and retest.

No.2

run, the PGM-

nalto the No. 2 ter-

terminal to the No.

lay. Then check for

minal and No. 4 ter-

to step 3.

ce the PGM-Fl main

8Ar C)

ECM {425, 81)

J To FUEL PUMP

inalto the No. 5 ter-

terminsl to the No.

ay. Then check that

No. 7 terminal and

ain relay.

to step 4.

ce the PGM-Fl main

inal to the No. 6 ter-

terminal to the No.

ay, Then check that

No. 5 terminal and

nain relay.

-Flmain relay is OK.

ce the PGM-Fl main

(cont'd)

11-111

Page 301 of 1413

![HONDA INTEGRA 1994 4.G User Guide Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng HONDA INTEGRA 1994 4.G User Guide Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng](/img/13/6067/w960_6067-300.png)

Fuel Supply System

PGM-Fl Main Relay (cont'dl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Engino will not sran.- Inspection oI PGM-FI main re-lay and rolay ha.n6!a.

Check lor continuitv between BLKterminal @ and body ground.

Rapair open in BLK wire botwoonPGM-FI main.el6y and GIO'l llo-catod at thormostot housingl.

Measure the voltage betweenYELMHT terminal @ and bodyground.- Roplaco th. ECU IECMI(15 Allus6 in tho under-hood fu!o/r6-lay box.- Ropair opan or short in theYEL/WHT wil6 botwosn thePGM-FI main rolay and the ECU

{EcMl 115 A} luso.

ls there battery voltage?

Turn the ignition switch ON.

Measure the voltage betweenBLK/YEL terminal @ and bodyground.- Reolac. ths No. 24 ACG {ALT}{lcl {15 A:81881 6ngino, 20A: Bl8Cl engin6) tuse in thoundor-dash fuso/rolaY box.- Ropaii op6n or rhon in thoBLK/YEL wiro botwoen thoPGM-FI main ielay and th€ No.24 ACG {ALT) flG} {'�15 A:818Bi ongine, 20 A: 818Cionginol fuso.Turn the ignition switch to theSTART position.

Measure the voltage betweenBLUMHT terminsl @ and bodyground.

- Replaco the l\lo. 18 STARTERSIGNAL {7.5 A} fuso in thoundor-dash fuaa/rolay box.- R6pai. open or short in thoBLU/WHT wire botweon thsPGM-FI main relay and tho No.1A STARTER SIGNAL I7.5 AIluse.

11-112

Page 302 of 1413

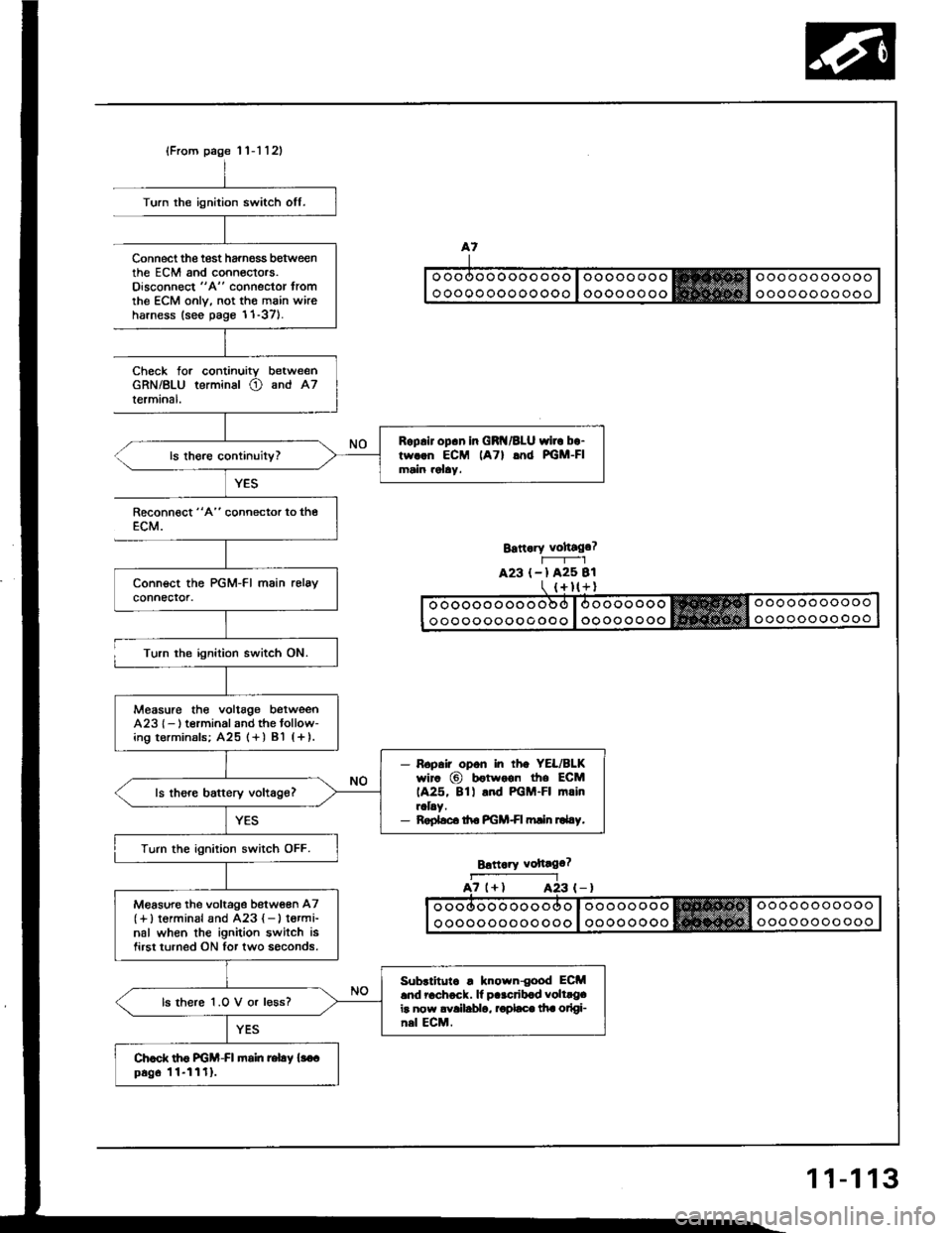

(From page 'l'l-1121

Roplir op.n in GRI{/BLU wirc bo-tw..n ECM lATl lnd PGM-FImain rolay.

Measure the voltag€ betweenA23l- ) t€rminal and the tollow-ing t€rminals; A25 (+ ) Bl (+ ).

- Ropair opon in rh. YEL/BLKwir. @ b€twoon the ECM1A25, 8tl .nd PGM-FI mrinraLy.- Roplsc. ttro PGM+I min ru4.y.

Turn the ignition switch OFF.

M€asure the voltage betw€en A7(+)torminal and A23 { - } t€rmi-nal when the ignition switch isfirst turned ON for two soconds.

Subrlitutc . known{ood ECM.nd 6chock. lf p..crib.d volt.g.ir now avallablo, rodaco lha otlgi-nsl ECM.

ls there 1.O V or l€ss?

Chod. th6 FGM-FI fioin relay {3o.p6g6 11-1111.

Turn the ignition switch off.

Connect the test harnoss b€tweenthe EcM and conneclors.Oisconnect "A" connector tromthe ECM onlv. not the main wireharness (see page 1'1-37).

Check forGRN/BLUlermrnal.

continuity betweenterminal O and A7

YES

Reconn€ct "4" connector to theECM.

Turn the ignition switch ON.

Bstt.ry vohago?r-----r_-lA23 (-l A25 Bl

Brttaiy voftago?

a7 (+l A23A23 (-)

11-113

Page 312 of 1413

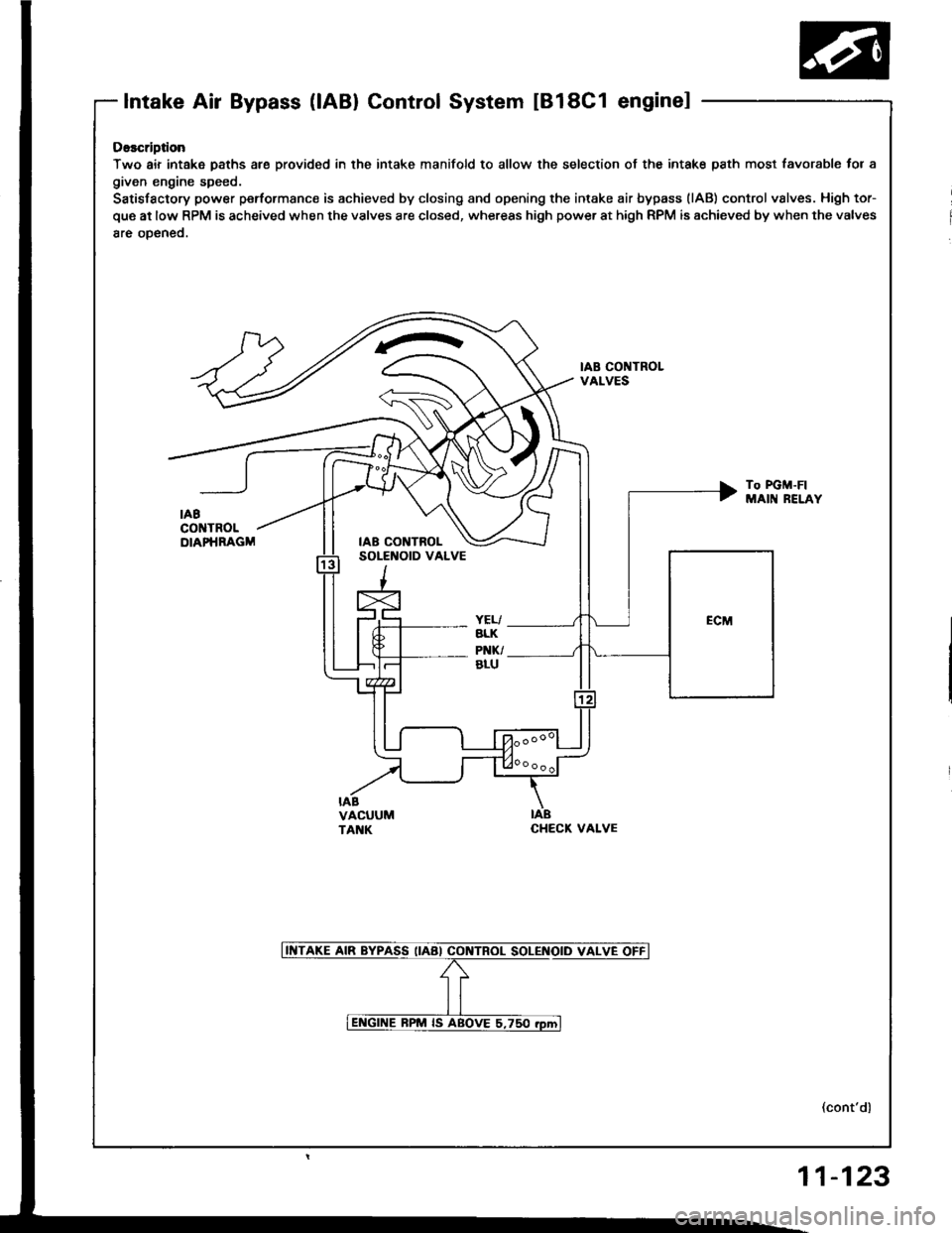

Intake Air Bypass (lABl Control System tBl8C1 enginel

Osscription

Two air intake paths are provided in the intake manifold to allow the selection of the intak€ path most favc

given engine speed.

Satisfactory power peformanc€ is achieved by closing and opening the intake air bypass (lAB) control valve!

que at low RPM is acheived when the valves are closed, whereas high power at high RPM is achieved by when

8re oDeneo.

IAB CONTROLVALVES

To PGM-FIMAIN RELi

IABCHECK VALVE

t favorabl€ for a

vslves. High tor-

when the valves

RELAY

(cont'dl

11-123

Page 314 of 1413

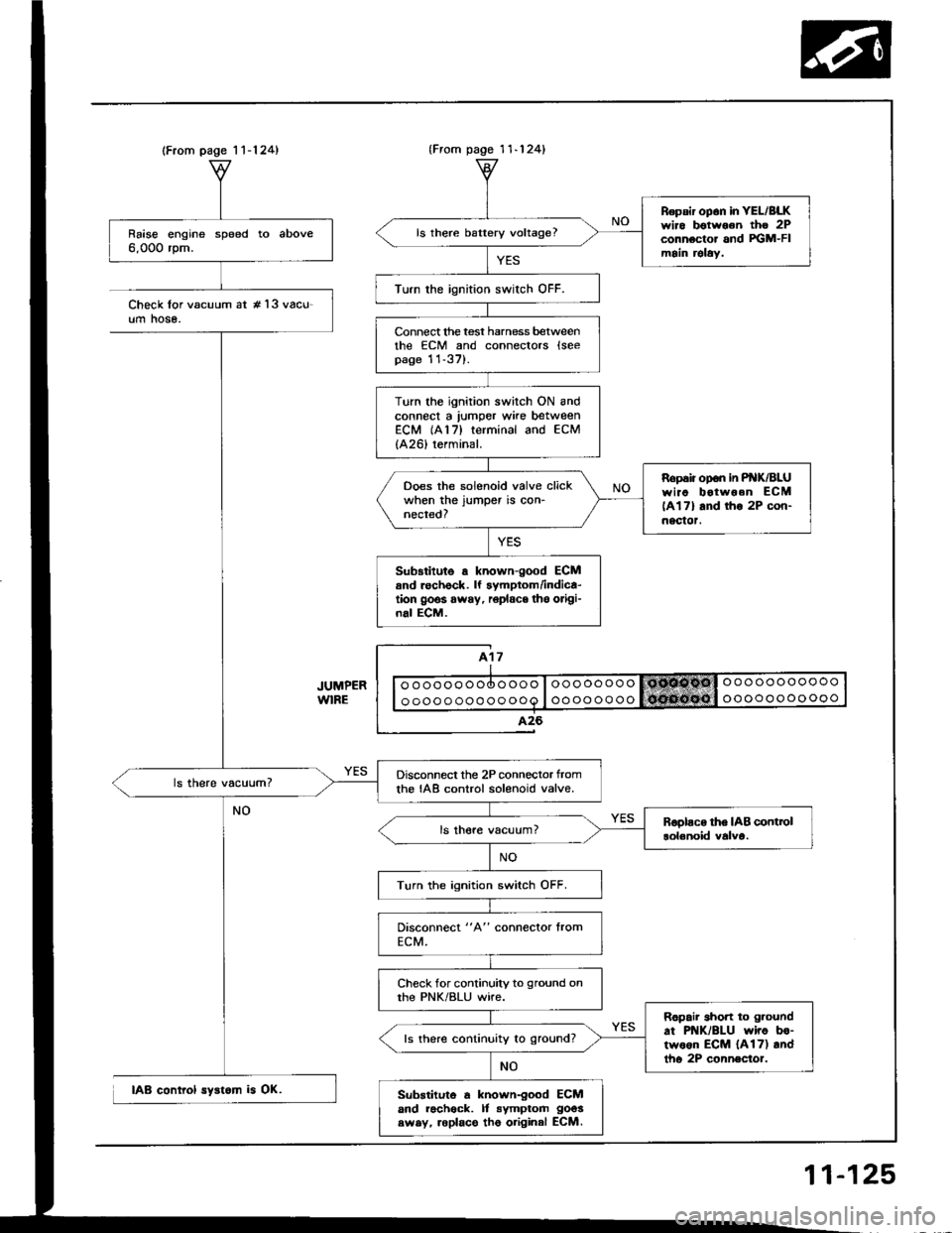

(From page 1 1-124)

Raise engine speed to above6,000 rpm.

Disconnect the 2P connector tromthe IAB control solenoid valve.

Turn the ignition switch OFF.

Check for continuity to ground onthe PNK/BLU wire.

Ropair short to g.ound

at PNK/BLU wiro bo-two6n ECM {A17) andtho 2P connector.

ls there continuity to ground?

Substituto a known-good ECMand racheck. It symptom goos

swsy, roplace tho original ECM.

{From pago 1 1-124}

Repsir op6n in YEL/BLKwiro botwoon tho 2Pconnector and FGM-FImain relaY.

ls there battery voltage?

Turn the ignition swirch OFF.

Connect lhe test harness betweenthe ECM and connectors lseepage 11-37).

Turn the ignition switch ON andconnect a lumper wke betweenECM (A17) terminal and ECM

{A26) terminal.

Ropaiiopon inP K/BLUwiao botwoen ECM

lAl7l and tho 2P con-nectot.

Ooes the solenoid valve clickwhen the jumper is con-nected?

Sub3titute a known-good ECMand rechock. lf symptom/indica-tion goos away, r6place tho origi-nal ECM.

Check lor vacuum at #'l3 vacu-um hose.

IAB control syst6m is OK.

11-125

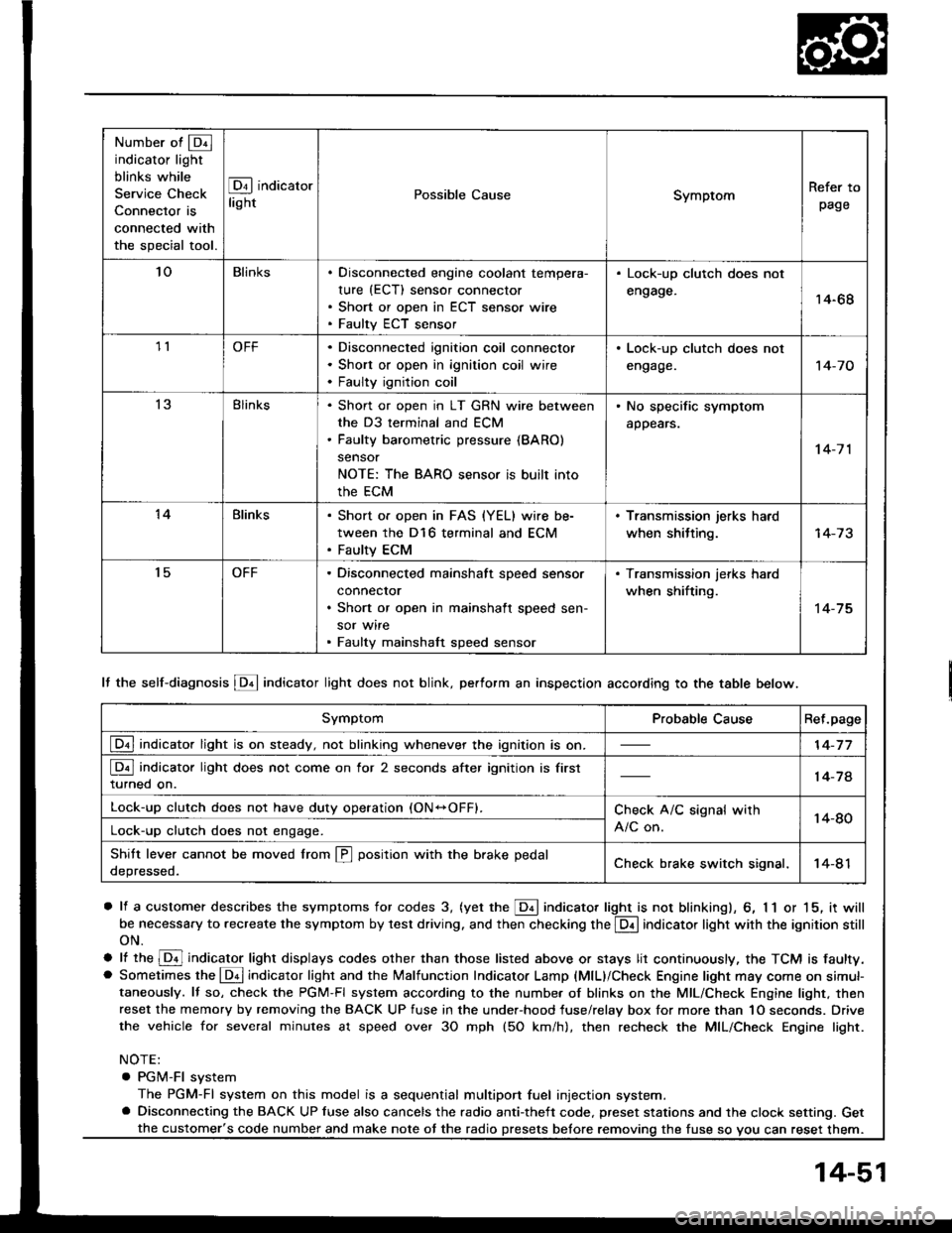

Page 443 of 1413

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@ indicator

lightPossible CauseSymptomRefer to

page

'loBlinksDisconnected engine coolant tempera-

rure (ECT) sensor connector

Short or open in ECT sensor wire

Faulty ECT sensor

Lock-up clutch does not

engage.14-68

1lOFFDisconnected ignition coil connector

Short or open in ignition coil wire

Faulty ignition coil

. Lock-up clutch does not

engage.'t 4-7 0

13Blinks. Shon or open in LT GRN wire between

the D3 terminal and ECM. Faulty barometric pressure {BARO)

sensor

NOTE: The BARO sensor is built into

the ECM

. No specific symptom

appears.

14-7 1

14Blinks. Short of open in FAS {YEL} wire be-

tween the D16 terminal and ECM. Faulty ECM

. Transmission jerks hard

when shitting.

't5OFFDisconnected mainshaft speed sensor

connecror

Short or open in mainshaft speed sen-

sor wire

Faulty mainshaft speed sensor

. Transmission jerks hard

when shifting.

14-75

SymptomProbable CauseRet.page

LQ! indicator light is on steady, not blinking whenever the ignition is on.14-77

[Q3] indicator light does not come on for 2 seconds after ignition is first

turned on.14-78

Lock-up clutch does not have duty operation (ON-OFFI.Check A/C signal with

A/C on.14-80Lock-up clutch does not engage.

Shitt leve. cannot be moved lrom @ position with the brake pedal

depressed.Check brake switch signal,14-41

It the self-diagnosis LQ4 indicator light does not blink, perform an inspection according to the table below.

a lf a customer describes the symptoms for codes 3, (yet the LQ! indicator light is not blinkingl, 6, 1 1 or 15, it will

be necessa.y to recreate the symptom by test driving. and then checking the @ indicator light with the ignition still

oN.

e lt ttre @ indicator light displays codes olher than those listed above or stays lit continuously, the TCM is faulty.. Sometimes the Lqd indicator light and the Malfunction Indicator Lamp (MlL)/Check Engine light may come on simul-taneously. lf so, check the PGM-Fl system according to the numbe. of blinks on the MIL/Check Engine light. thenreset the memory by removing the BACK UP fuse in the unde.-hood fuse/relay box for more than 1O seconds. Drive

the vehicle for several minutes at speed over 30 mph (5O km/h), then recheck the MIL/Check Engine light.

NOTE:

. PGM-FI system

The PGM-Fl system on this model is a sequential multiport fuel injection system.a Disconnecting the BACK UP luse also cancels the radio anti-theft code. preset stations and the clock setting. Get

the fuse so vou can reset them.the customer's code number and make note ot the radio

14-51

Page 1005 of 1413

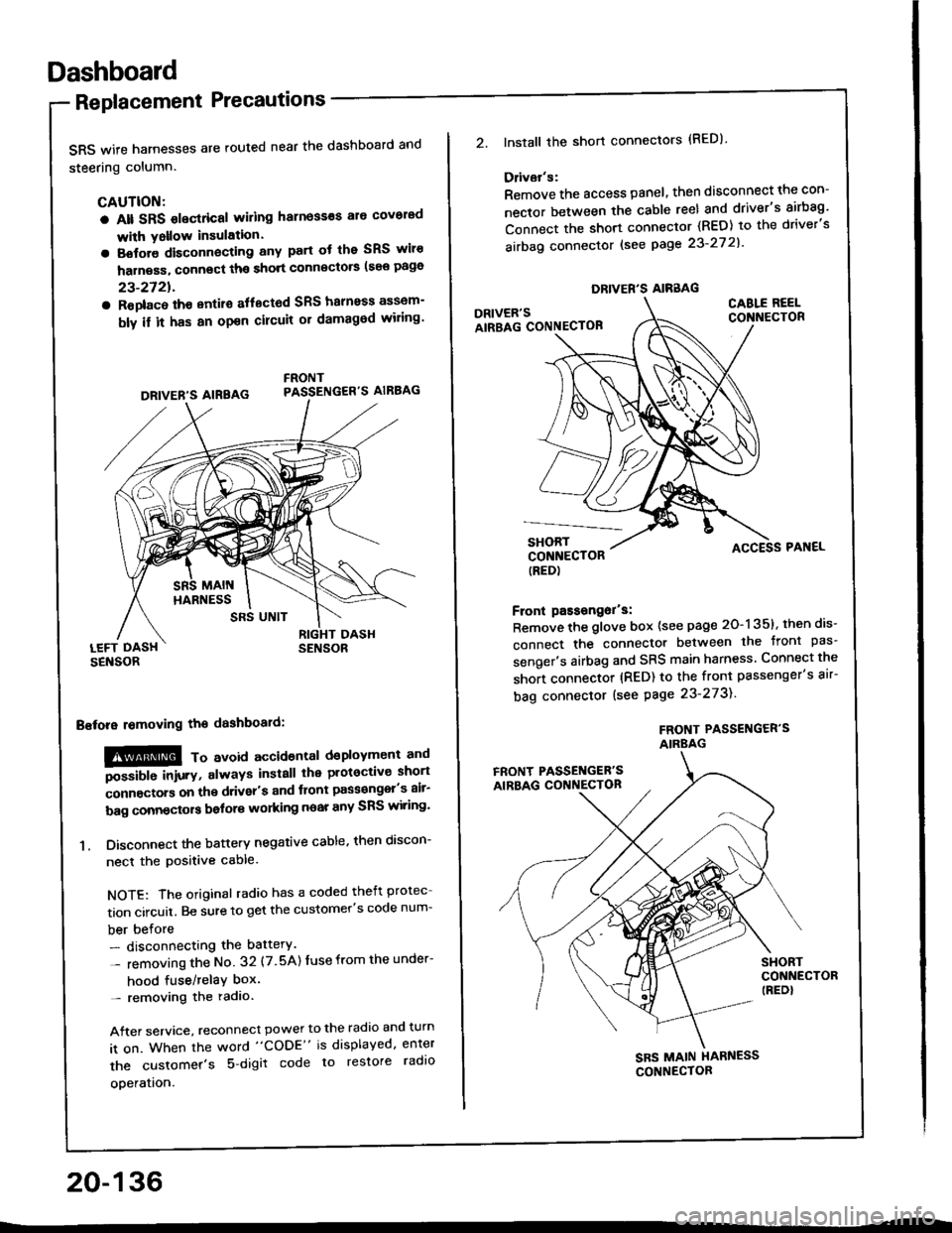

Dashboard

Replacement Precautions

SRS wife harnesses are routed near the dashboard and

steering column.

CAUTION:

a Alt SRS olectrical wiling harness€s ale covorad

with Yollow insulation.

a Botore disconnecting any part ot the SRS wiro

harness, connect ths short connscto6 (see page

23-2721.

a Roplac6 ih€ entiro aflectod SRS halnoss assem-

bly il it has an opon cilcuit or damagod wiling'

LEFT DASHSENSOR

Bstora lomoving the dashboaid:

!@@ To avord accioenlal dsployment and

""iUU inir.v, always install the plotoctive short

;onnectors on the driver's and tlont pass€ngel's air-

bag connectors bolors working near any SRS wiring'

1. Disconnect the battery negative cable, then discon-

necl the positive cable.

NOTE: The original radio has a coded theft protec

tion circuit. Be sure to get the customer's code num-

ber before- disconnecting the battery.

- removing the No 32 (7.5A) Iuse from the under-

hood fuse/relaY box'- removing the radio.

After service, reconnect power to the radio and turn

it on. When the word "CODE" is displayed, enter

the customer's 5 digit code to restore radlo

ooeration.

DRIVER'S AIREAG

SRS UNIT

20-136

DRIVER'S AIRBAG

2.lnstall the short connectors (RED)

Ddvar's:

Remove the access panel, then disconnect the con-

nector between the cable reel and driver's airbag'

Connect the short connector (RED) to the driver's

airbag connector lsee page 23-27 2l'

DRIVER'SAIRBAG CONNECTOB

CABLE REELCONNECTOR

SHORTCONNECTOR(RED)

Front passongor's:

Remove the glove box {see page 20-135}, then dis-

connect the connector between the tront pas'

senger's airbag and SRS main harness Connect the

short connector (RED) to the front passenger's air-

bag connector (see Page 23-273).

FROf{T PASSENGER'SAIRBAG

ACCESS PAI{EL

FRONT PASSET{GER'SAIRBAG CONNECTON

SHORTCONNECTOR(REDI

SBS MAIN HARNESS

CONNECTOR