engine coolant HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 249 of 1413

PGM-FI System

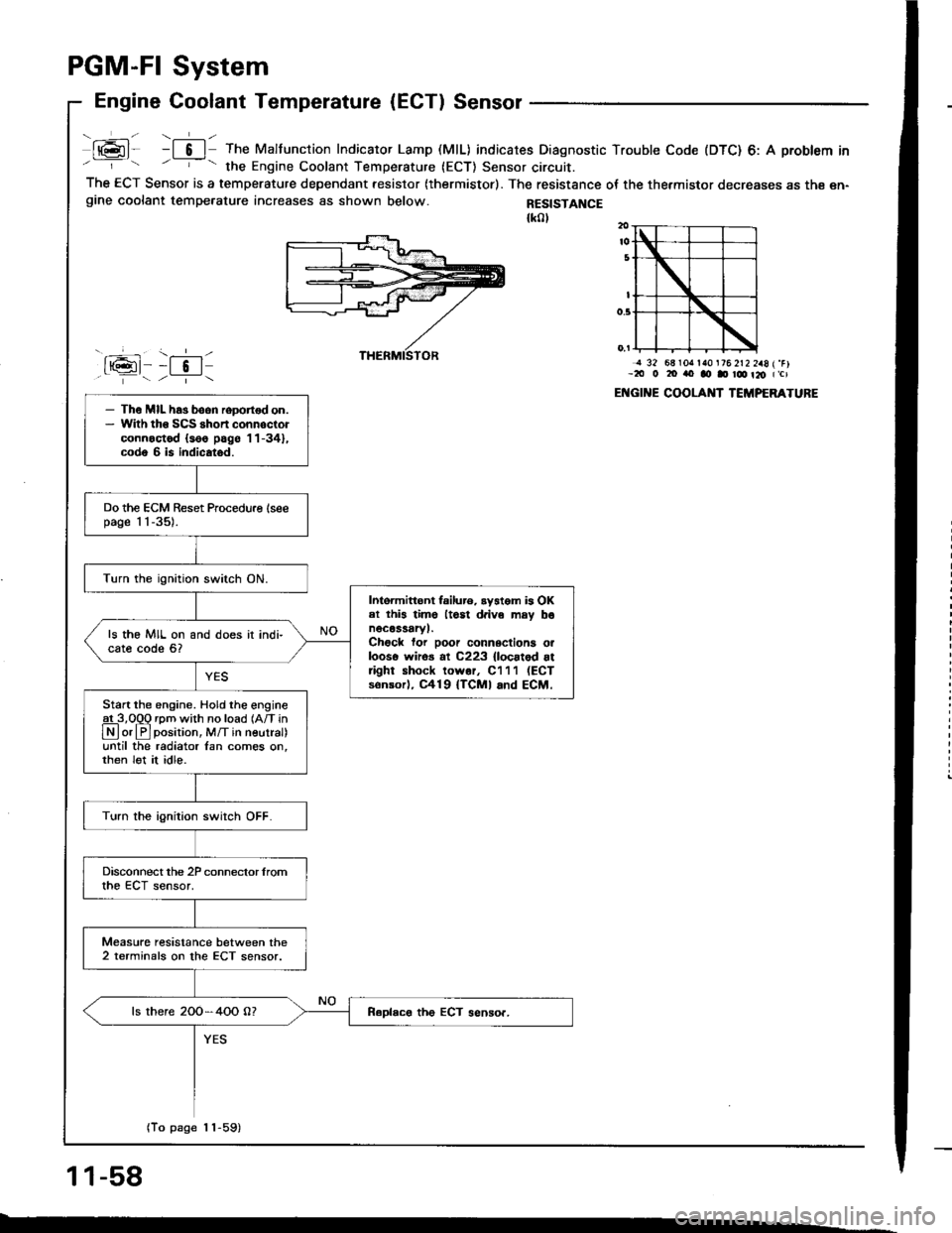

Engine Coolant Temperature (ECT) Sensor

- ,-!-- ---1- -

t@l- -l 6 | The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 6: A problem in- - the Engine Coolant Temperature (ECT) Sensor circuit.The ECT Sensor is a temperature dependant resistor (thermistor). The resistance oI the thermistor decreases as th€ en-gine coolant tempe.ature increases as shown below.

J rsG-11

RESISTANCE{k0l

- \.--r-l--t 5 | /--i- \

j 32 68lOrr la0 t76 2t2 2a8 (.Fl-2tt 0 20 rto ao D r@ t20 (,cl

ENGII{E COOLAI{T TCMPERATURE- Th€ MIL has boon roDortod on.- Wlth tho SCS shon connoctorconnoctod {s66 pag6 '11-34},

code 6 is indicatod.

Do the ECM Reset Procedu.e lseepage 1 1-35).

Turn the ignition switch ON.

Intoimittont failur6. ryatom is OKel this lime ltosl d.ive may bonocassaryl.Chock for poor connsctiona orlooso wiros al C223 {locatod attight shock lowor, C111 (ECT

sonsorl, C419 {TCMI and ECM.

ls the MIL on and does it indi-cate code 6?

Start the engine. Hold the engineat 3,O0O rom with no load {Afi in

N or lF]position, M/T in neutral)until the radiator lan comes on,then lot it idle.

Turn the ignition swirch OFF.

Disconnect the 2P conneclor lromthe ECT sensor.

Measure resistance between the2 terminals on the ECT sensor.

ls there 2OO-4OO O?

(To page 1 1-59)

11-58

--

Page 269 of 1413

ldle Control System

System Description (cont'd)

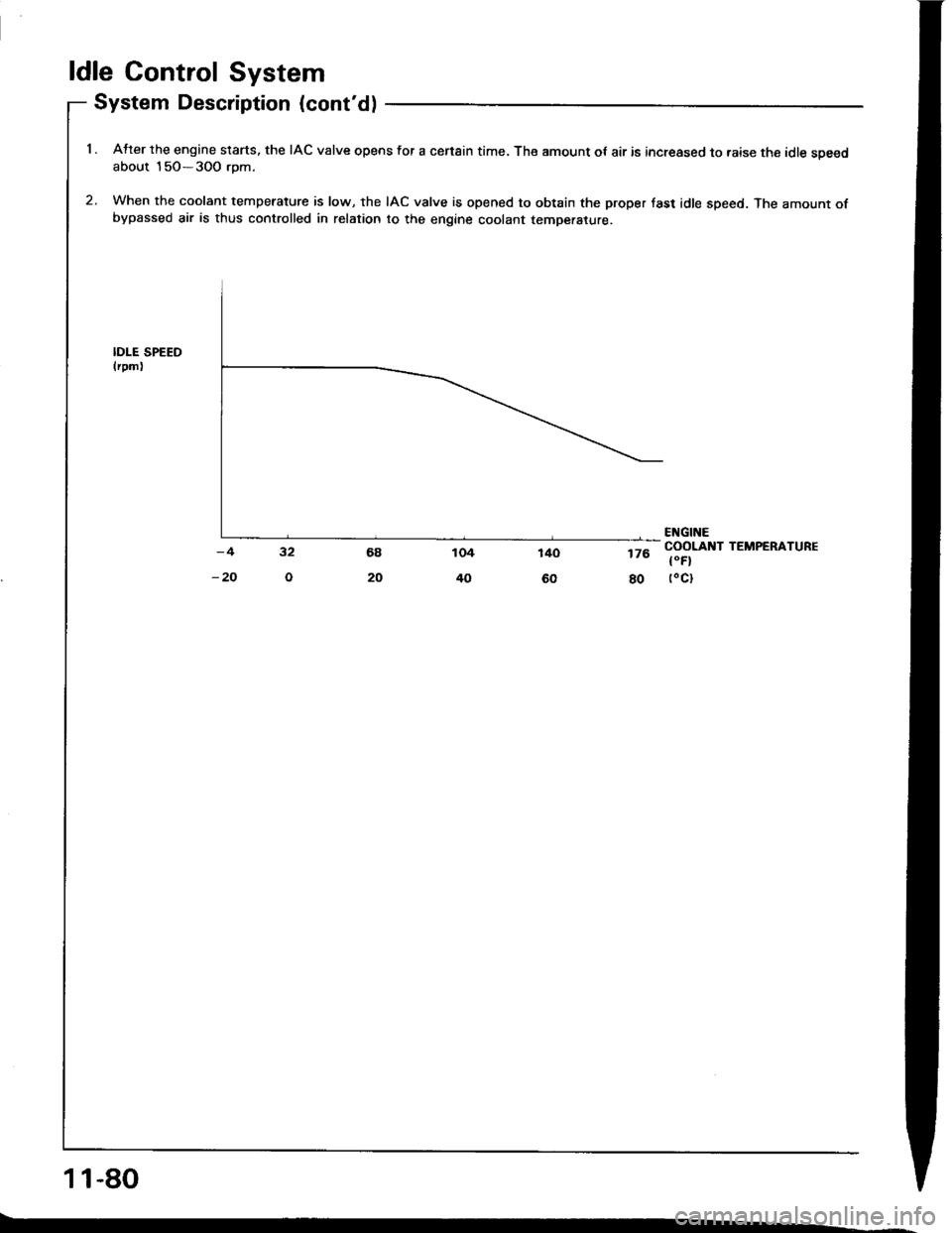

1 . Atter the engine slarts. the IAC valve opens for a censin time, The amount ot air is increased to raise the idle soeedabout 15O-3OO rom.

2. When the coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. The amount ofbypassed air is thus controlled in relation to the engine coolant temperature.

IDI-E SPEEDlrpm)

176

80

ENGINECOOLANT TEMPERATURE

t"Fl(oct

11-80

Page 283 of 1413

ldle Control System

Fast ldle Thermo Valve

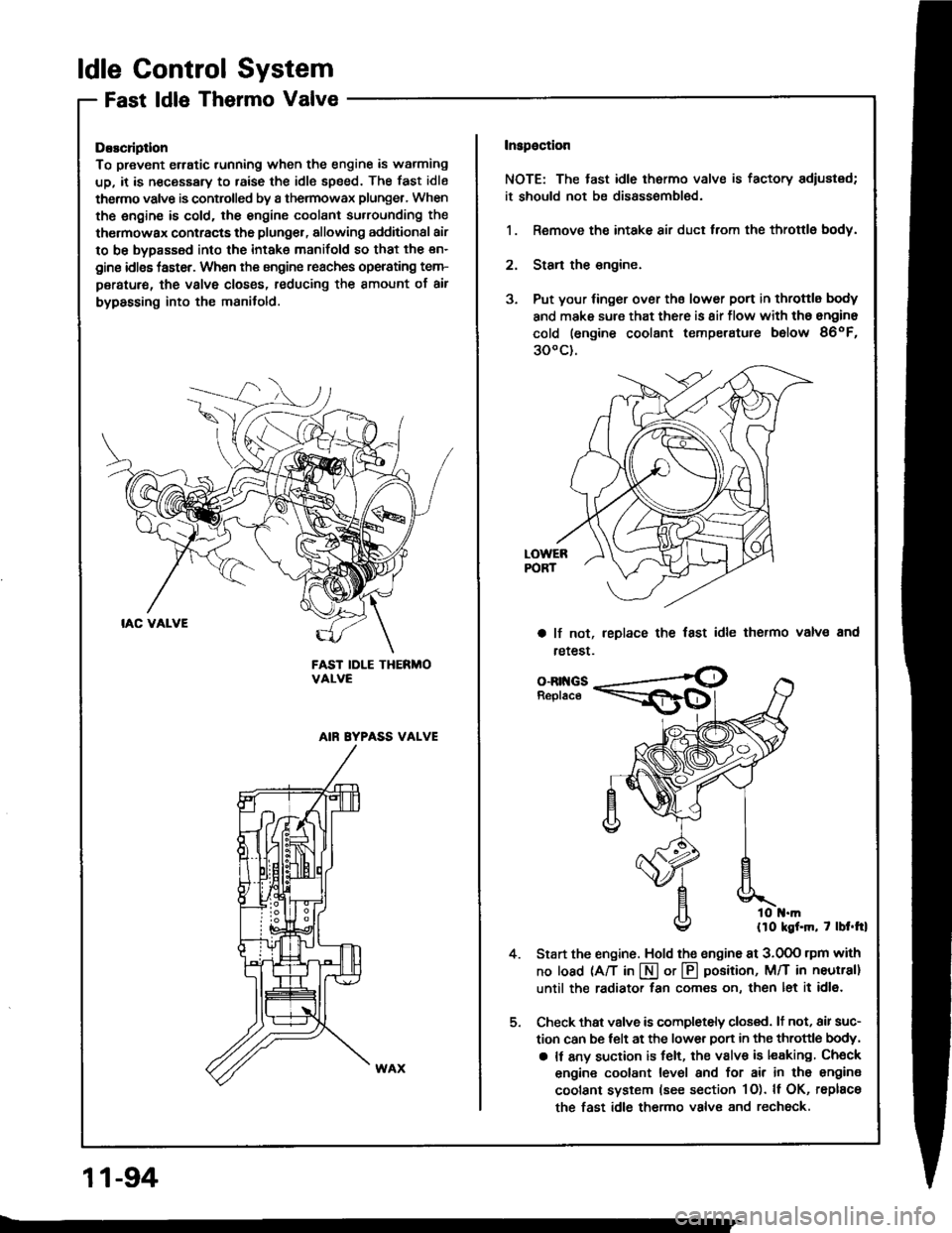

DEscliptlon

To prevent erratic running when the engine is warming

up, it is n€cessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger, When

the engine is cold. the engine coolant su.rounding the

thermowax contracts the plunger, allowing additional air

to be bypassed into the intake manifold so that the en-

gine idlss taster. When the engine reaches operating tem-

peratur€, the valve closss, reducing the amount of air

bypassing into the manifold.

FAST IDLE THERMOVALVE

AIN EYPASS VALVE

Inspaction

NOTE: The tast idle thermo valve is factory adiustsd;

it should not be disassombl€d.

1. Remove the intake air duct from the throttlg body.

2. Stan the engine.

3. Put your finger over ths lower port in throttle body

and make sure that there is 8ir flow with tho engine

cold (engine coolant temperatute below 86oF,

300c).

a lf not,

retest.

leplace the fast idle thermo valvs and

4.

o-Rr{GsReplace

llo kgf.m, 7 lbt.trl

Start the engine. Hold the sngine at 3.0OO rpm with

no load (A/T in I or @ position, M/T in neutral]

until the radiator fan comes on, then let it idl6.

Check thst valve is completely closed. lt not, air suc-

tion can be telt at the lower Don in the throttle body,

a It any suction is felt, the valve is leaking Check

engine coolant level and for air in tho engine

coolant system (see section 1O). ll OK, rsplace

the fast idle thermo valve and rechock.

11-94

Page 309 of 1413

lntake Air System

Throttle Body

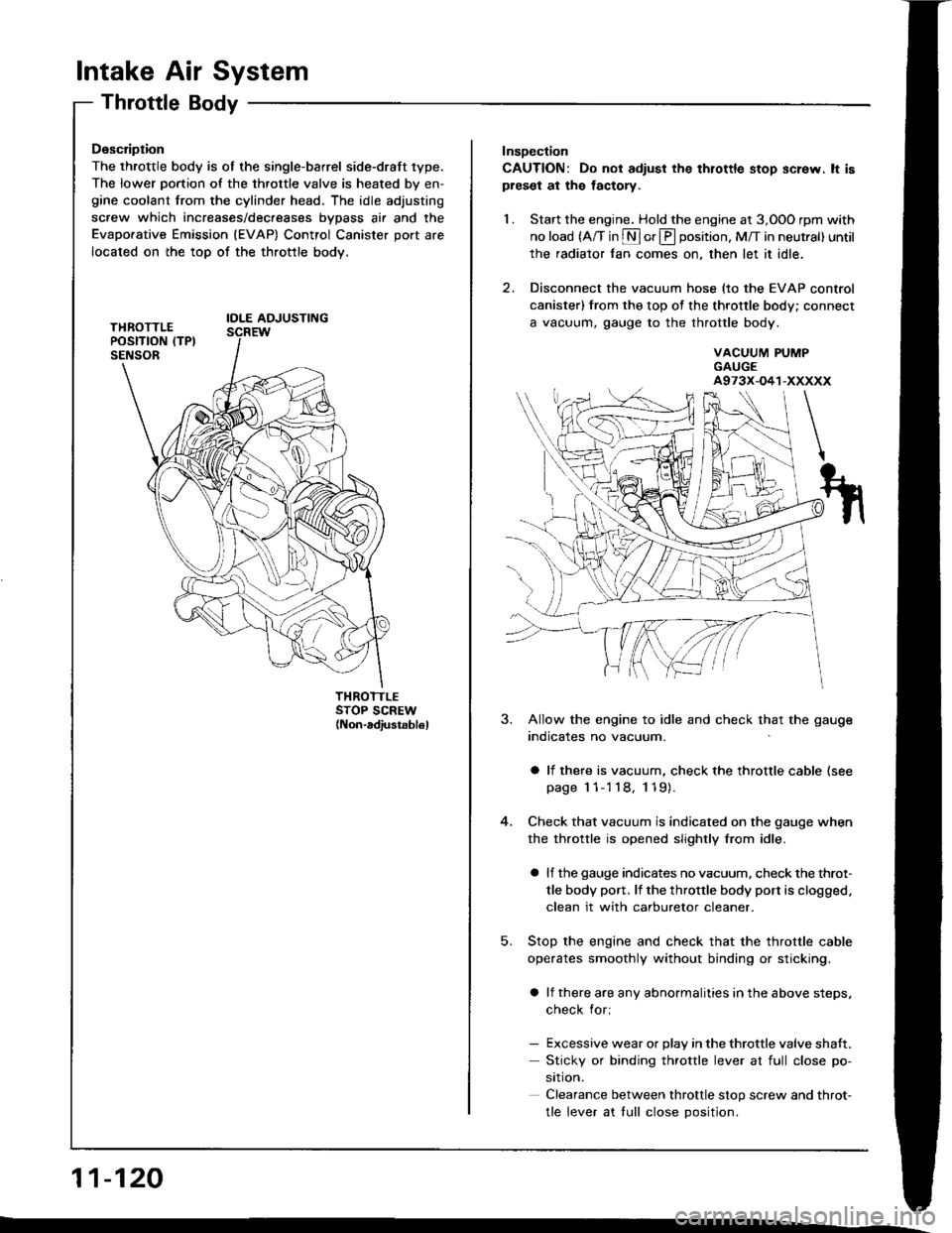

Description

The throttle body is ot the single-barrel side-draft 1ype.

The lower portion of the throttle valve is heated by en-gine coolant from the cylinder head. The idle adjusting

screw which increases/dec.eases bvDass air and the

Evaporative Emission (EVAP) Control Canister port are

located on the top of the throttle body.

IOLE AOJUSTING

THROTTLESTOP SCREW(Non-adiustsb16l

11-120

Insoection

CAUTION: Do not adiust the thlottle stop screw. lt ispreset at the lactory.

1. Start the engine. Hold the engine at 3,OOO rpm with

no load (A/T in S or E position, M/T in neutral) until

the radiator fan comes on, then let it idle.

2. Disconnect the vacuum hose (to the EVAP control

canister) from the top of the throttle body; connect

a vacuum, gauge to the throttle body.

VACUUM PUMPGAUGEA973X-O41-XXXXX

5.

3. Allow the engine to idle and check that the gauge

indicates no vacuum.

a li there is vacuum, check the throttle cable (see

page 1 1-'l 18, 119).

Check that vacuum is indicated on the gauge when

the throttle is opened slightly from idle.

a lf the gauge indicates no vacuum, check the throt-

tle body port. lf the throttle body port is clogged.

clean it with carburetor cleaner.

Stop the engine and check that the throttle cable

operates smoothly without binding or sticking.

a lf there are any abnormalities in the above steps,

check for:

- Excessive wear or Dlav in the throttle valve shaft.

Sticky or binding throttle lever at full close po-

srtron.

Clearance between throttle stop screw and throt-

tle lever at tull close Dosition.

Page 326 of 1413

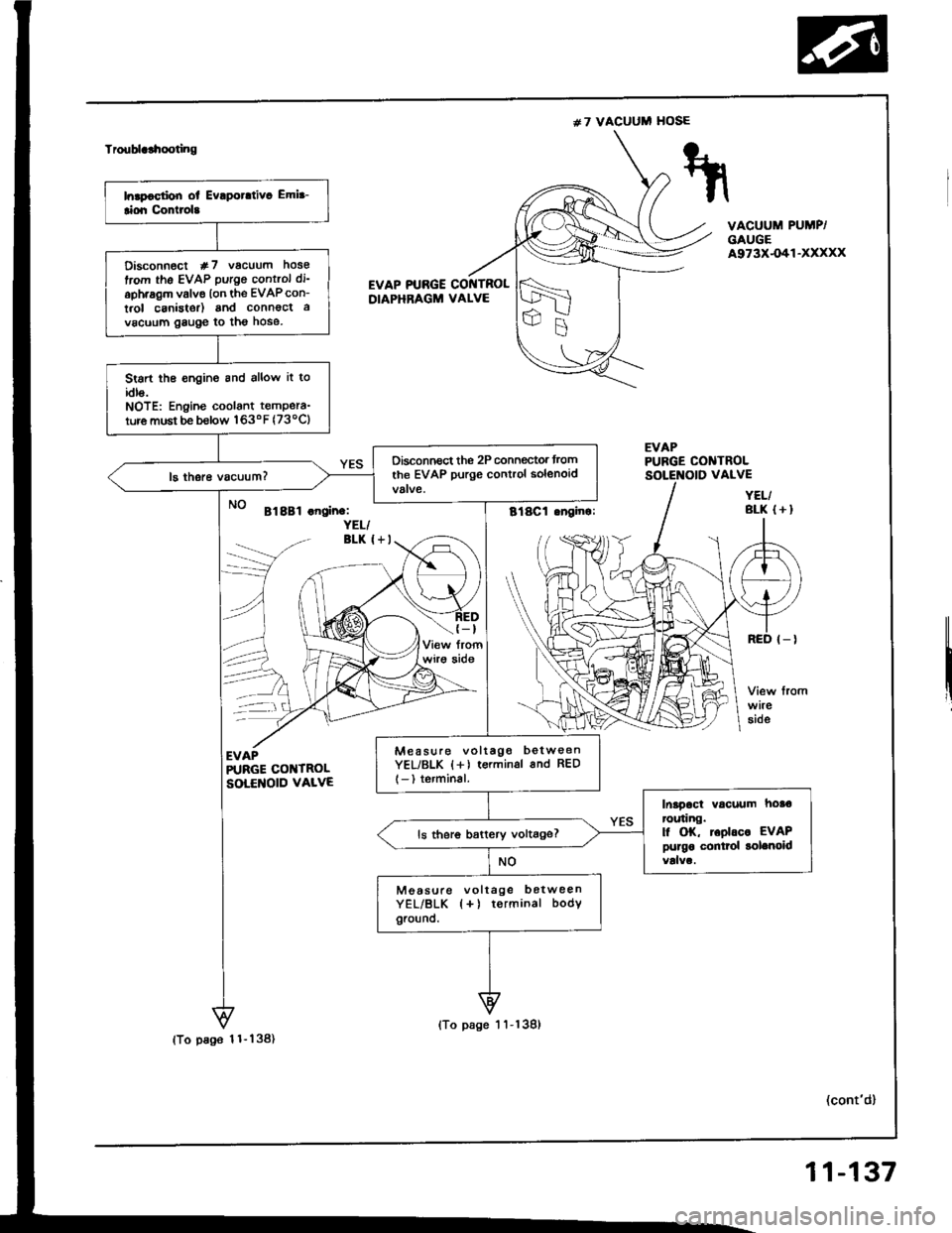

#7 VACUUM HOSE

Troublclhooting

VACUUM PUMP/GAUGEA973X-O41-XXXXX

EVAP PTJBGE COI{TROLDIAPHRAGM VALVE

EVAPPUBGE CONTROL

Bl8Bl .noin.:YEL/BLK I+I

(-t

wirg aide

--\

EVAPR'RGE COI{TROLSOLENOID VALVE

(cont'd)

VALVE

YEL/BLK (+I

Disconn€ct #7 vacuum hose

trom the EVAP putgo control di'

aph.agm valve lon the EVAPcon-

t.ol canistor) and connoct a

vacuum gauge to tho hose.

Stsrt the €ngine and allow it toidls.NOTE: Engine coolant tempera-

ture must be b€low 163oF (73ocl

Oisconnect the 2P connegtor trom

the EVAP purge control solenoid

Mea suro voltago betw€enYEL/BLK {+) terminsl 6nd RED

l-) terminal.

Inapact vacuum hoa€ror.ring.l| OK, toolrc. EVAPpurgo conttol solenoidls ther6 battery voltage?

Moasule voltage botweenYEL/BLK {+) terminal bodYground.

(To pa96 1 1- 138)

(To page 1 'l -139)

11-137

Page 412 of 1413

Description

Electronic Control System (cont'd)

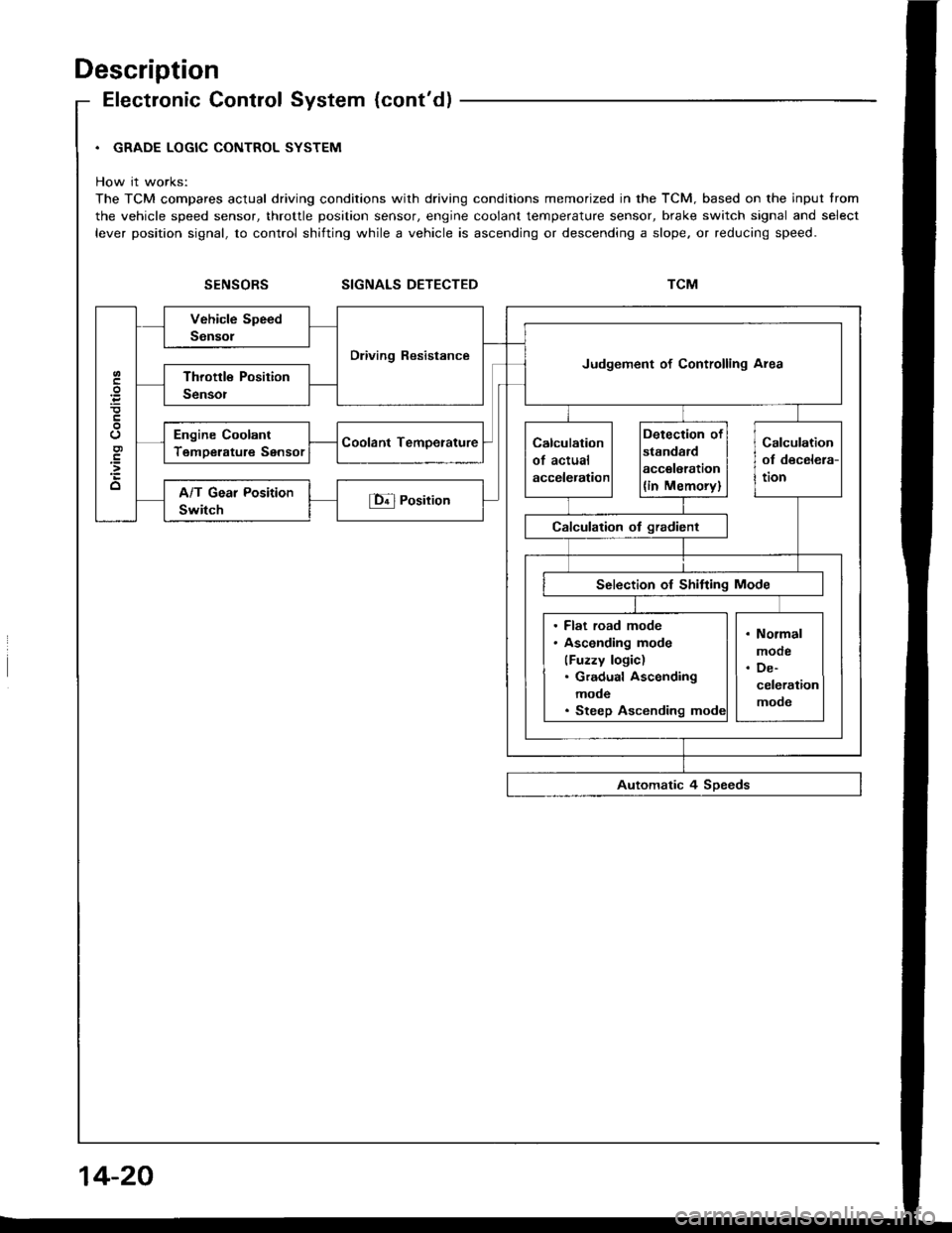

. GRADE LOGIC CONTROL SYSTEM

How it works:

The TCM compares actual driving conditions with driving conditions memorized in the TCM. based on the input trom

the vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, brake switch signal and select

lever position signal, to control shifting while a vehicle is ascending or descending a slope. or reducing speed.

SIGNALS DETECTED

Dliving ResistanceJudgement of Controlling Area

Engine Coolant

TemDerature Sensor

. Flat road mode. Asconding mode

(Fuzzy logic). Gradual Ascending

mode. Steep Ascending

14-20

Page 437 of 1413

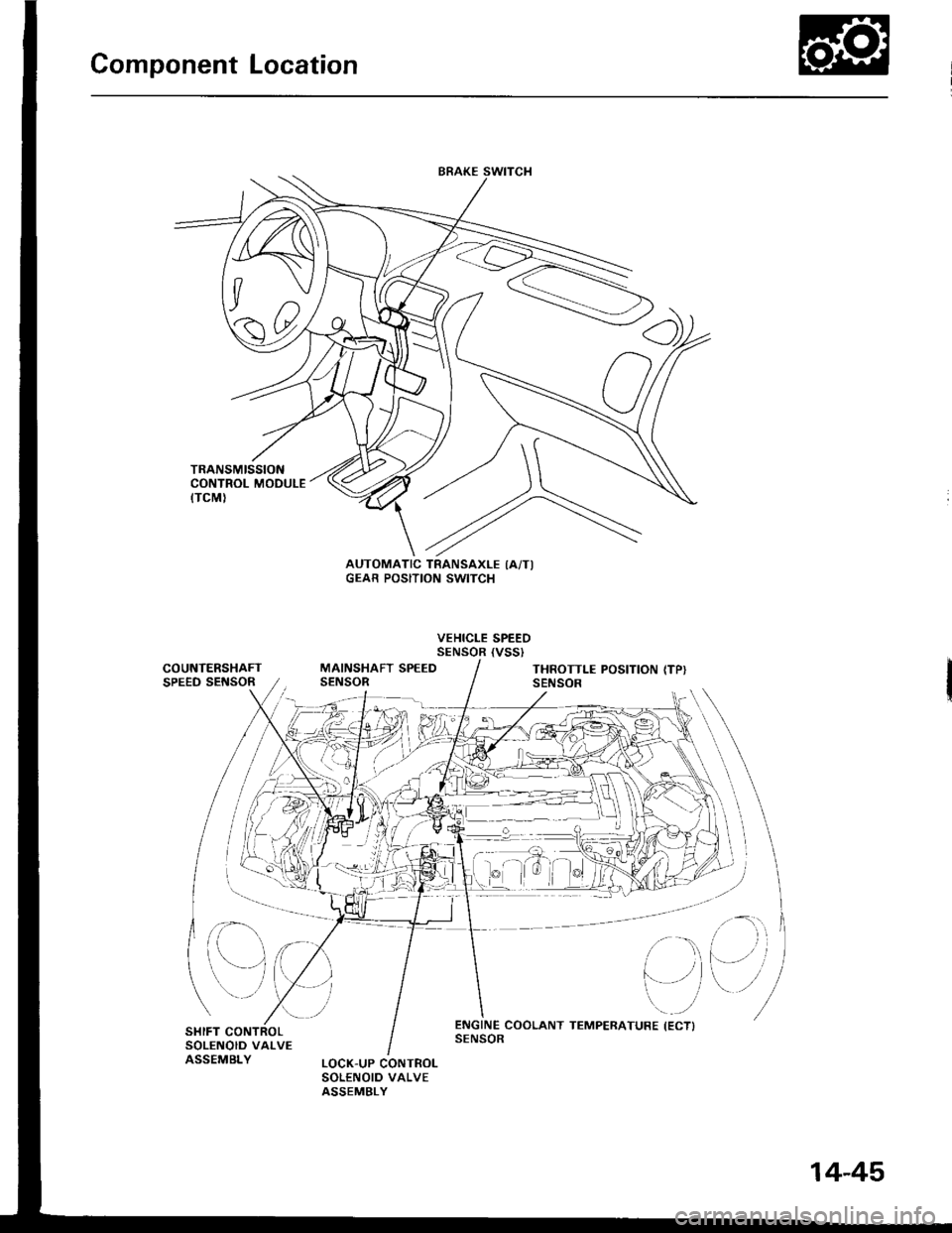

Component Location

)/

,/s\

{7v

A0t

AUTOMATIC TRANSAXLE IA/TIGEAR POSITION SWITCH

VEHICLE SPEEDSENSOR {VSSI

COUNTERSHAFTSPEED SEf{SORMAINSHAFT SPEEDSENSORTHROTTLE POSITION (TP}SENSOR

at

,

)''ENGINE COOLANT TEMPERATURE (ECTISENSOR

14-45

Page 443 of 1413

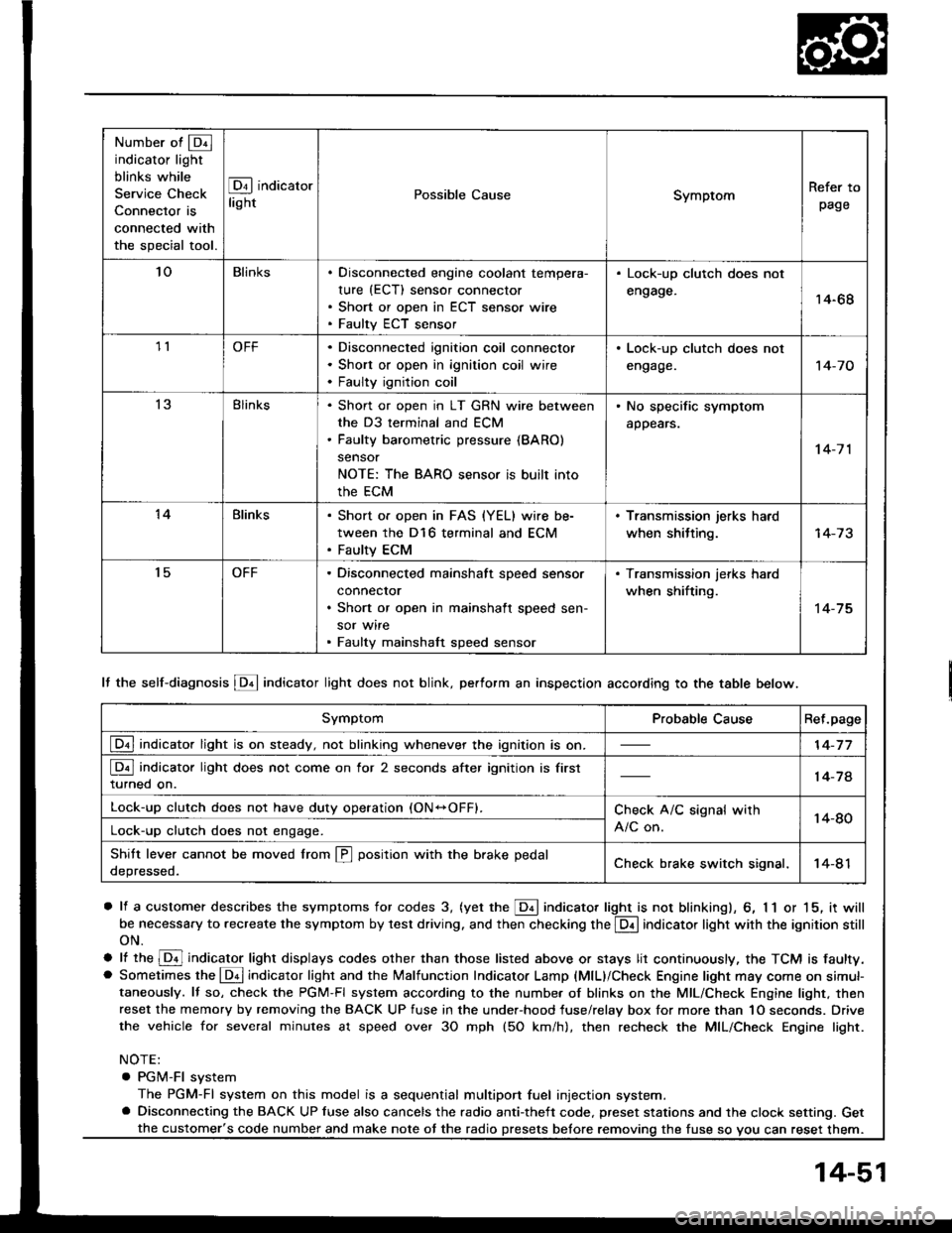

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@ indicator

lightPossible CauseSymptomRefer to

page

'loBlinksDisconnected engine coolant tempera-

rure (ECT) sensor connector

Short or open in ECT sensor wire

Faulty ECT sensor

Lock-up clutch does not

engage.14-68

1lOFFDisconnected ignition coil connector

Short or open in ignition coil wire

Faulty ignition coil

. Lock-up clutch does not

engage.'t 4-7 0

13Blinks. Shon or open in LT GRN wire between

the D3 terminal and ECM. Faulty barometric pressure {BARO)

sensor

NOTE: The BARO sensor is built into

the ECM

. No specific symptom

appears.

14-7 1

14Blinks. Short of open in FAS {YEL} wire be-

tween the D16 terminal and ECM. Faulty ECM

. Transmission jerks hard

when shitting.

't5OFFDisconnected mainshaft speed sensor

connecror

Short or open in mainshaft speed sen-

sor wire

Faulty mainshaft speed sensor

. Transmission jerks hard

when shifting.

14-75

SymptomProbable CauseRet.page

LQ! indicator light is on steady, not blinking whenever the ignition is on.14-77

[Q3] indicator light does not come on for 2 seconds after ignition is first

turned on.14-78

Lock-up clutch does not have duty operation (ON-OFFI.Check A/C signal with

A/C on.14-80Lock-up clutch does not engage.

Shitt leve. cannot be moved lrom @ position with the brake pedal

depressed.Check brake switch signal,14-41

It the self-diagnosis LQ4 indicator light does not blink, perform an inspection according to the table below.

a lf a customer describes the symptoms for codes 3, (yet the LQ! indicator light is not blinkingl, 6, 1 1 or 15, it will

be necessa.y to recreate the symptom by test driving. and then checking the @ indicator light with the ignition still

oN.

e lt ttre @ indicator light displays codes olher than those listed above or stays lit continuously, the TCM is faulty.. Sometimes the Lqd indicator light and the Malfunction Indicator Lamp (MlL)/Check Engine light may come on simul-taneously. lf so, check the PGM-Fl system according to the numbe. of blinks on the MIL/Check Engine light. thenreset the memory by removing the BACK UP fuse in the unde.-hood fuse/relay box for more than 1O seconds. Drive

the vehicle for several minutes at speed over 30 mph (5O km/h), then recheck the MIL/Check Engine light.

NOTE:

. PGM-FI system

The PGM-Fl system on this model is a sequential multiport fuel injection system.a Disconnecting the BACK UP luse also cancels the radio anti-theft code. preset stations and the clock setting. Get

the fuse so vou can reset them.the customer's code number and make note ot the radio

14-51

Page 460 of 1413

Electrical Troubleshooting

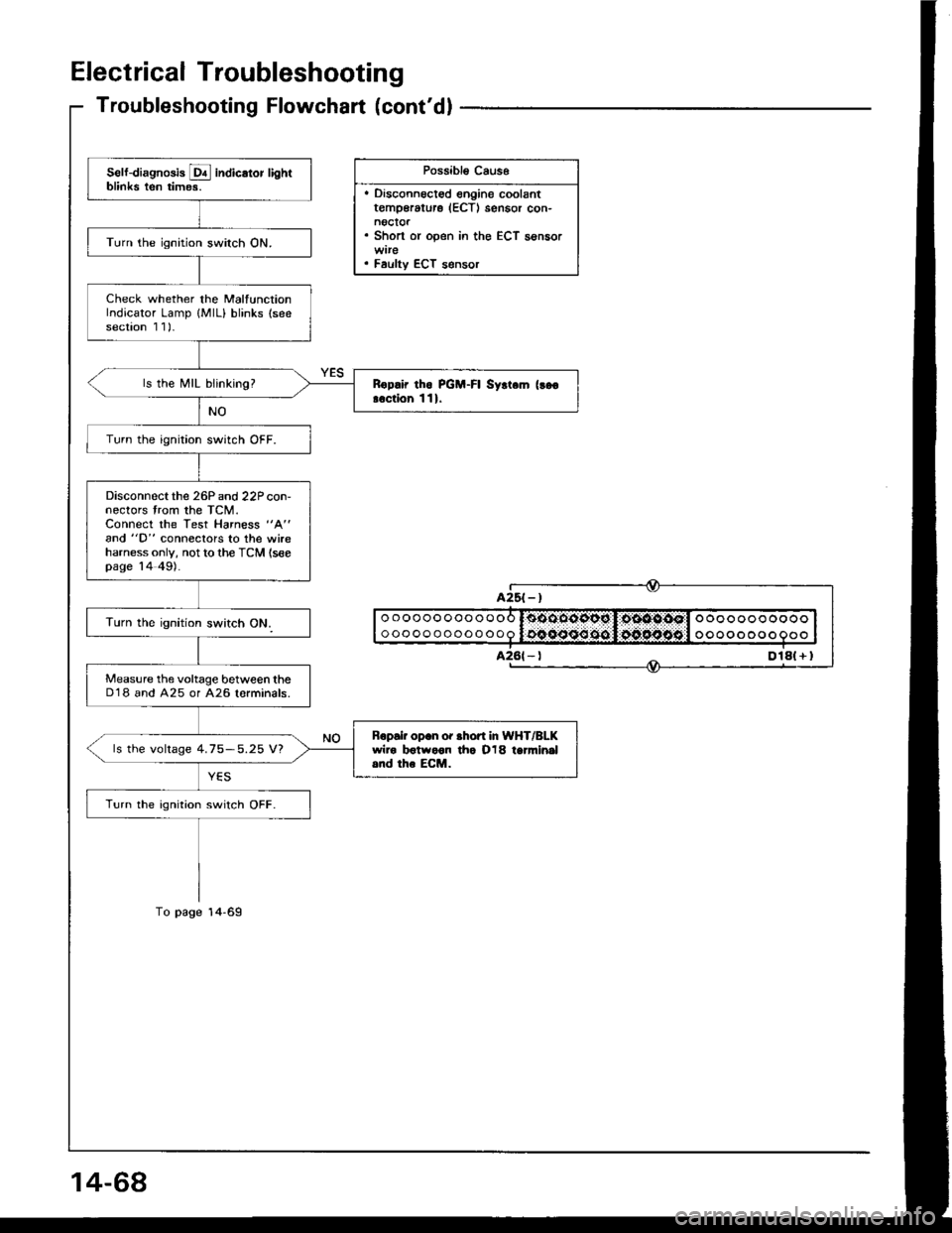

Troubleshooting Flowchart (cont'dl

Possibl€ Caus6

. Disconnoct€d engine coolantt€mp€rature (ECTI sensor con-noctor. Short or open in the ECT sensor

. Faulty ECT s€nsor

Self-diagnosis E indicator lightblinks ten times.

Turn the ignition switch ON.

Check whether the MalfunctionIndicator Lamp {MlL} blinks (seesection 1 1)-

ls the MIL blinking?Rop.ir tho PGM-FI Syrt.m (!go

!.ction 111.

Turn the ignition switch OFF.

Disconnectthe 26P and 22P con-nectors trom the TCM.Connect the Test Harness "A"

and "D" conneclors to the wireharness only, not to the TCM (seepage 14 49).

Measure the voltage between theD'18 and A25 or A26 lorminals.

Bopair op.n or .hofi In WHT/BLKwiro botwoon tho O18 tanni.|al.nd the ECM.ls the voltage 4.75-5.25 V?

Turn the ignition switch OFF.

oooooooooooo

ooooooooooooooooooooooo

oooo o oo o

Dlal + I

Page 1045 of 1413

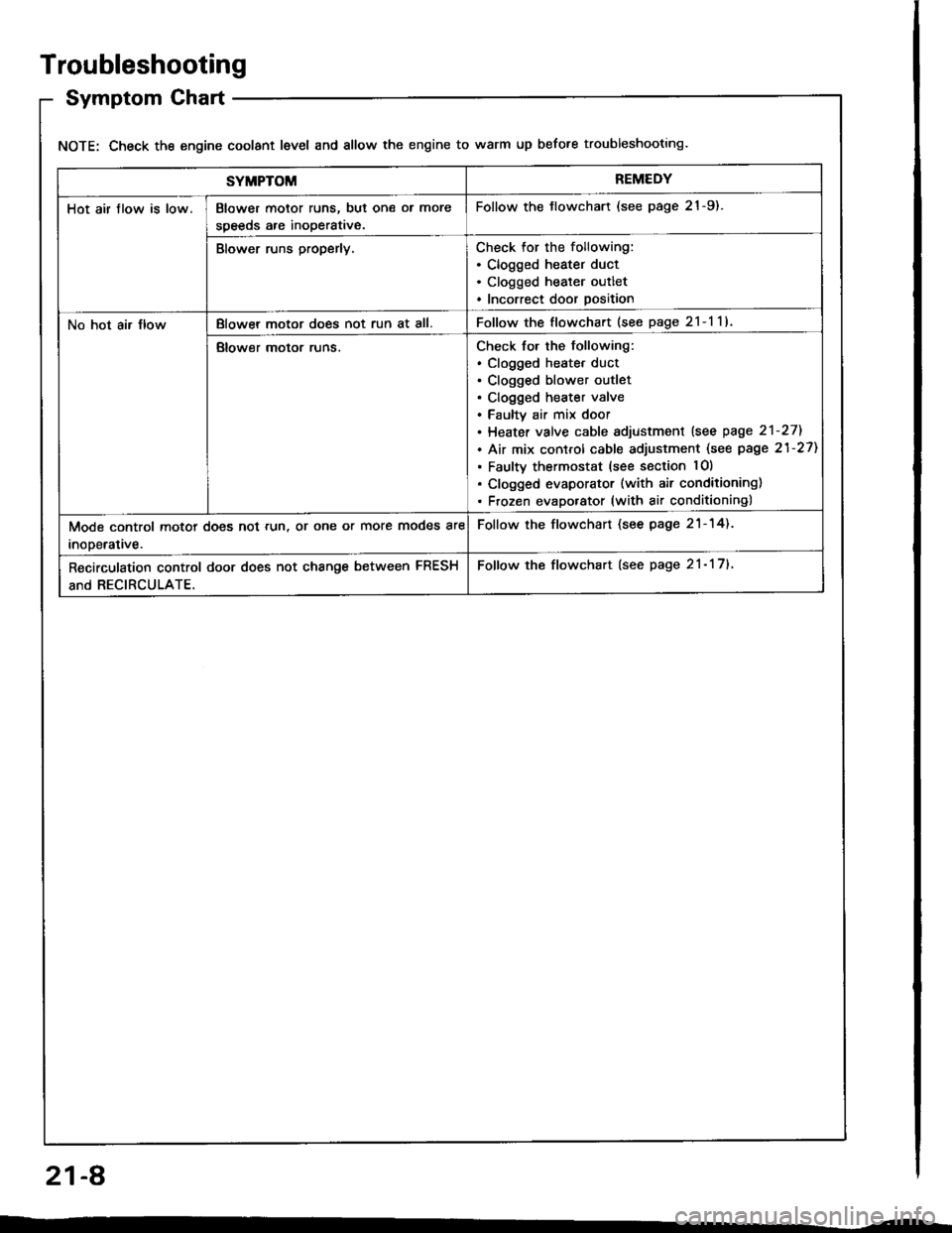

Troubleshooting

Symptom Chart

NOTE: Check the engine coolant level and allow the engine to warm up before troubleshooting.

SYMPTOMREMEDY

Hot air flow is low.Blower motor runs, but one ol more

speeds are inoperative.

Follow the tlowchart (see page 21-9).

Blower runs properly.Check for the following:. Clogged heater duct. Clogged heater outlet. Incorrect door position

No hot air JlowBlowel motor does not run at all.Follow the flowchart (see page 2l-l1l

Blower motor runs.Check for the following:. clogged heatet duct. Clogged blower outlet. Clogged heater valve. Faultv air mix door. Heater valve cable sdjustment lsee page 2'l-271

. Air mix control cable adjustment (see page 21-27)

. Faulty thermostat (see section lO)

. Clogged evaporator (with air conditioning). Frozen evaporator (with air conditioning)

Mode control motor does not run, or one or more modes are

inooerative.

Follow the flowchart (see page 21-14).

Recirculation control door does not change between FRESH

and RECIRCULATE.

Follow the flowchart (see page 21- 17).

21-A