tow HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 247 of 1413

![HONDA INTEGRA 1994 4.G Owners Manual PGM-FI System

TDC/CKP/CYP Sensor

_f=l_ fi_l The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 4: A problem int:- the Crankshaft Position (CKP) Sensor circuir.

l6]- ftl - T HONDA INTEGRA 1994 4.G Owners Manual PGM-FI System

TDC/CKP/CYP Sensor

_f=l_ fi_l The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 4: A problem int:- the Crankshaft Position (CKP) Sensor circuir.

l6]- ftl - T](/img/13/6067/w960_6067-246.png)

PGM-FI System

TDC/CKP/CYP Sensor

_f'=l_ fi_l The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 4: A problem int:- the Crankshaft Position (CKP) Sensor circuir.

l'6]- ftl - The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 8: A problem in-i- the ToD Dead Center ITDC) Sensor circuit.

-flG]l- ft-] The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 9: A problem in- , - the Cvlinder Position ICYP) Sensor circuit.

The CKP Sensor determines timing tor fuel injection and ignition of each cylinder and also detects engine speed. TheTDC Sensor determines ignition timing at start-up (cranking) and when crank angle is abnormal. The CYP Sensor detects

the position of No. 1 cylinder tor sequential fudl injection to each cylinder.

- \.--r-l - -__l_-

tPJ:;LlJ:lEl--;l ?,:

- Tho MIL hos beon roponod on.- With rho SCS short connoctorconneclod lsso pago I l-341,code 4, 8 and/or 9 ar6 in-dicated.

Do the ECM Reset procedure (seepage 11-35).

Intohittent failuro, syst€m is OKat thia tima {t6st drivo may benoceaSaayr.Chock for poo. connections orlooss wires at C222 (located atright shock towerl, C110(TOC/CKP/CYP Sonsorl and ECM.

ls the MiL on and does it in-dicate code 4, 8 and/or 9?

Turn the ignition switch OFF.

Disconnect the 8P connector fromthe TDC/CKP/CYP sensor.

{To page 1 1-57)

11-56

Page 251 of 1413

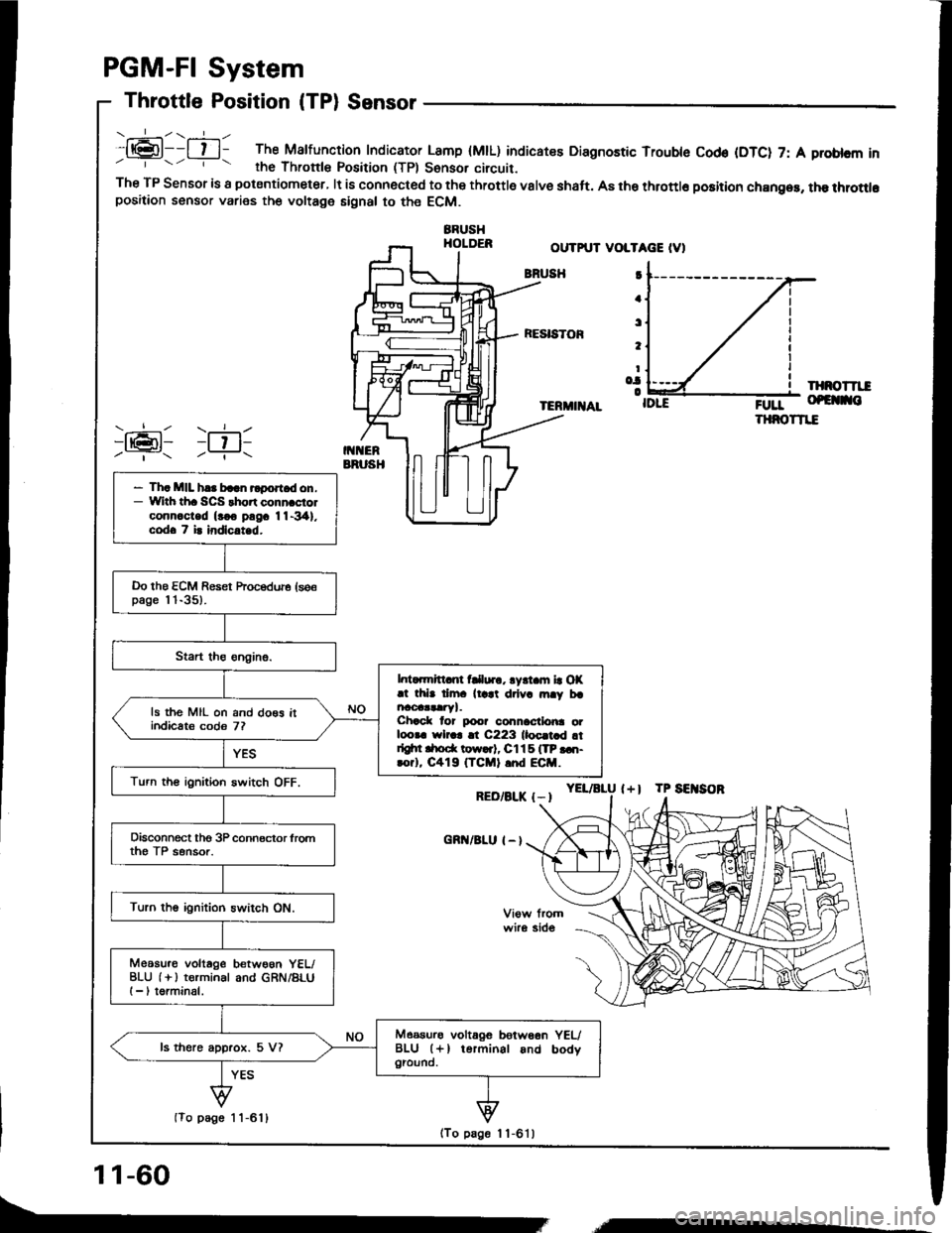

.:-\.-----ll@l--l t l- The Malfunction Indicator Lamp (MtL) indicatee Diagnostic Trouble Cod€ (DTC) 7: A problcm inrhe Thronle Position (TPl Sonsor circuit.The TP Sensor is a potsntiometer, lt is connected to the throttle valve shaft. A8 the throttlo position chan96, the throttlopositaon sensor varies the voltage signal to the ECM.

BBUSHHOLDER

PGM-FI System

Throttle Position (TPl Sensor

OUTPUT VOLTAGE IV)

BNUSH

RESISTOF

IXNOTTII

TERMIIIAL;0rr- of€ no

THNOTTIE

YEL/aLU l+l TP SEITSOR

I

a

t

t

Io.|o

RED/BLK {-I

cnn/BLu I - l

)ran1 )ril-Y- -?..

- Th. MIL h.. baln rlport d on.- With th. SCS thort conn.ciolconn.c-ted (rco pngc 11-341.codo 7 i. indlc.t d.

Do the ECM Reset hocedure (se€page l 'l-35).

l. ..mrtt nt fClur., lyrt m la OX.t thb dm. ll.at drlv. rn.y brncoaataryl.Chack lor poo? connactlo|ra otloora wlr.r !t C223 lloc.t d !tdgtn drod( tow..t, Cl15 ITP ...t-rorl, C419 (TCMI .nd ECM.

ls the MIL on and do€s itindicats codo 7?

Turn th€ ignition switch OFF.

Disconnect tho 3P connector lromth€ TP sensor.

Turn the ignition switch ON.

Meosu.o voltage betwoon YEL/BLU (i ) terminal and GRN/BLUI -, torminal.

Measurs voltagG betw66n YEUBLU (+l terminal and bodygiound.ls there approx. 5 V?

(To page 1 1-611

11-60

(To page 1 1-6'l )

,,,----

Page 253 of 1413

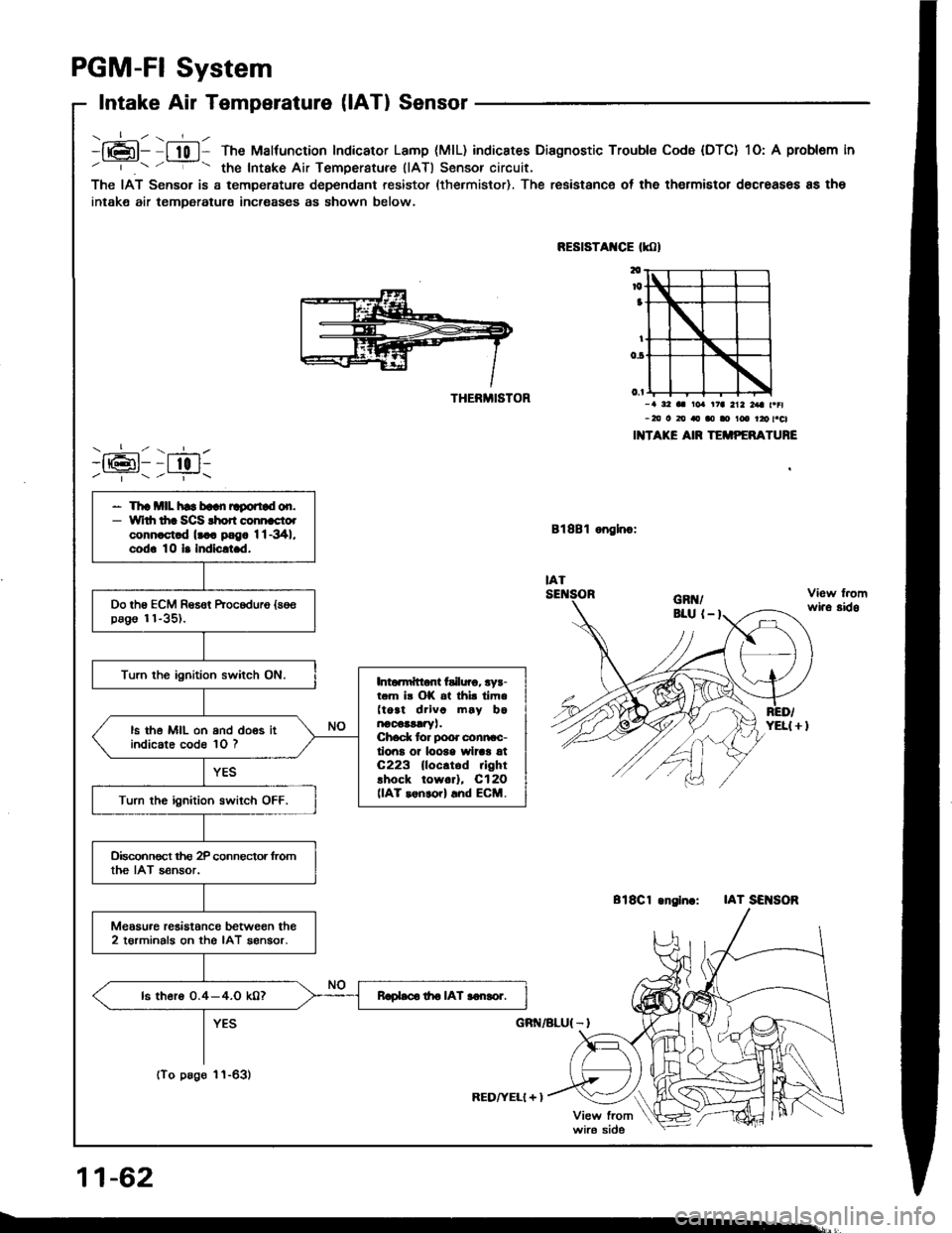

PGM-FI System

Intake Air Temperature (lAT) Sensor

----:-- z ---L /-h6l- I t0 l- The Malfunction Indicator Lamp (MlL) indicstes Diagnostic Trouble Cod6 (DTC) 1O: A problem in/ | / - the Intake Air TemDerature (lAT) Sensor circuit,

The IAT Sensor is a temperature dependant resistor (the.mistor). The resistanc€ of the thermistor d6creases 8s the

intake air temDeratura incroases as shown below.

)1611:till/ ---l- z ---i-\

THERMISTOR

RED/YELI + )

RESTSTAXCE tmt

Bl8Bl onglnc:

-a a2 aa roa .t7a 212 a t |l-20 o 20 rto ao I t6 rro t.cl

I TAKE AIR TEiiIPTFATURE

818C1 .nglnc:IAT SEI{SOR

11-62

wi.a sido

- Th! *llL hs b!!n Egortad on.- \|

rdr dra SCS rhon connrcto.conn.ct.d lt . psg. 1l-341.cod. 10 l. hdlclt.d.

Do the ECM Resot kocoduro {se€pago 11-35).

Turn the ignition switch ON.Into.n{tlont failuro. rys-r.m ir OK .t thi. iim.(toat drlvc m6y b6arooa!!1ryt.Ched( tor poor clnncc-lioiE or loote wlrar 6tC223 lloc.tod rightlhock toworl, C12O(lAT renrcrl and ECM.

ls the MIL on and doos itindicate code 10 ?

Turn the ignition swiich OFF.

Oisconnoct tho 2P connector fromthe IAT sensor.

Meosu.e resistonc€ between the2 torminals on the IAT aengor.

ls thero 0.4-4.0 k0?Rlobco tho IAT aonsor.

(To pago 1'l-63)

Page 256 of 1413

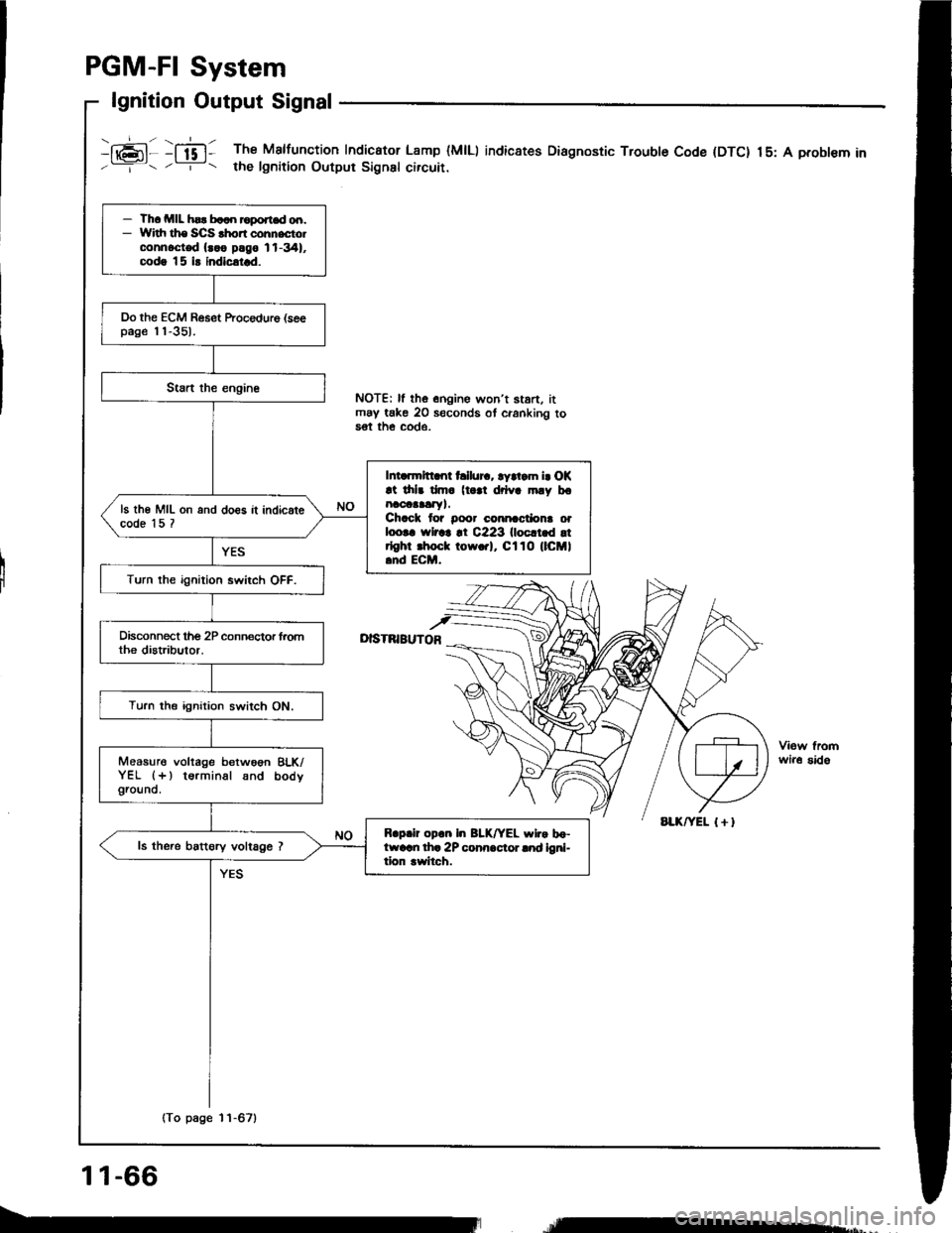

PGM-FI System

lgnition Output Signal

i16;11 :ffi1 The Malfunction Indicator Lamp (MlLl indic8tes Diagnostic Trouble Code (DTC) 15: A probl€m in'--=-- . -r- t the lgnition Output Signsl circuir.

I

NOTE| ll the onoine won't stan. itmay take 20 seconds ot cranking to5€t th€ COde.

D|STNIBUTOB

wir6 sido

- Th. MIL hsr b..n roport.d od.- Widr ths SCS .hon cohnecto.connoct€d {..o plgo 11-341,codg |5 i! indicatrd.

Do the ECM Reset ftocedure (seepage 'l'l-351.

Intarmltt nt hllur.. ryltam i. OK!t drlr dm. (t |l drlva mly bonaoaaalry).Chack tor Door cmnactiona orloo|. rYlrar !t C223 llocltld !trlghr .hoct tow.rl, Cl10 (lCMl.nd ECM.

ls th€ MIL on and do€s it indicatecode 15 ?

Turn the ignition swirch OFF.

Turn the ignition switch ON.

Measure voltage betwoon BLK/YEL (+) terminal snd bodygrouno.

R.p.ir op.n In BLK/YEL wlr. bo-ftvarn th. 2P conn.cior lnd ioni-tion rwitch.

ls the.e battory voltage ?

(To page 11-67)

11-66

re*,

Page 263 of 1413

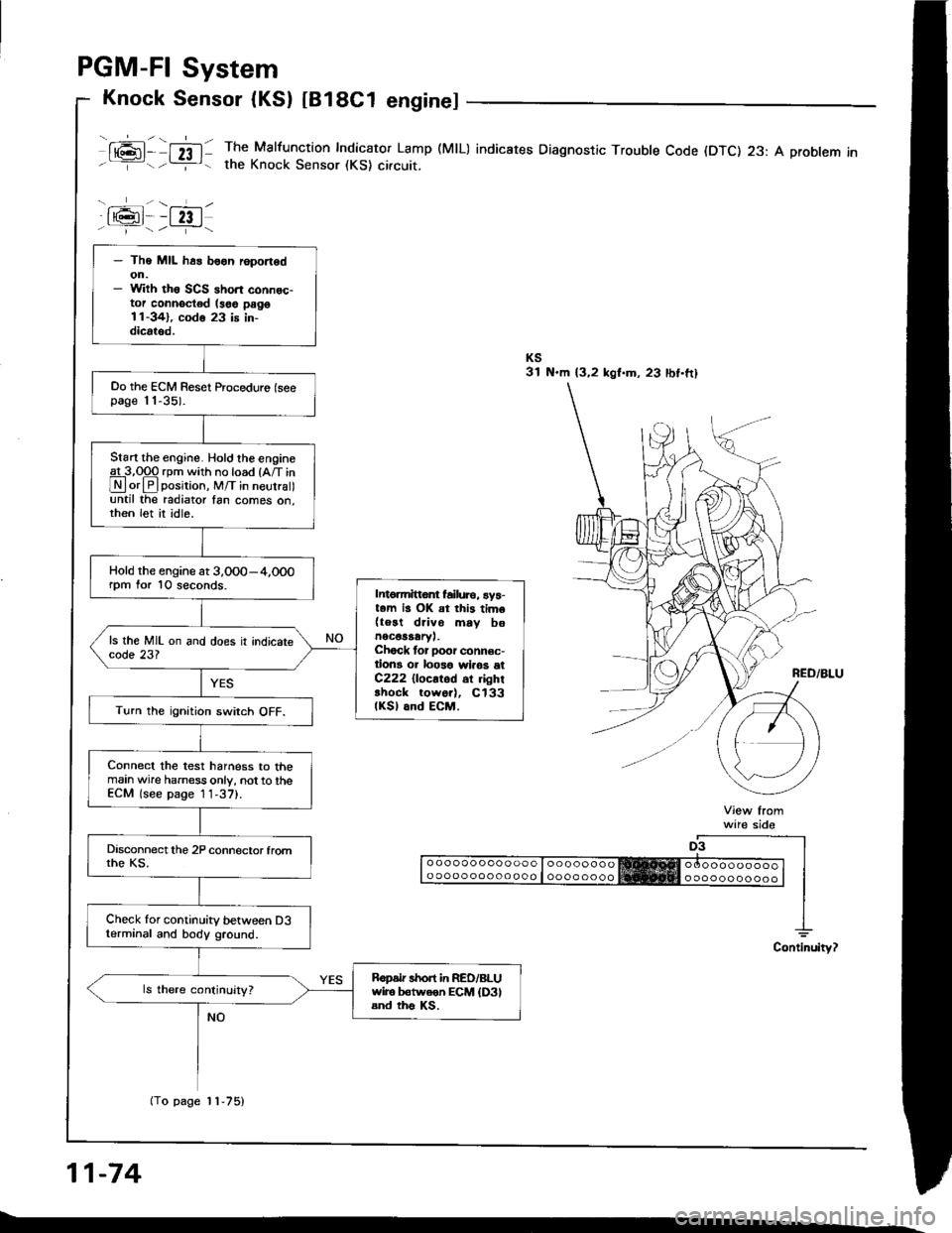

PGM-FI System

Knock Sensor (KS) tB18C1 enginel

ml- nl: The Malfunction Indicator Lamp (MlL) indicates Diagnostic Troubte Code (DTC) 23: A probtem inthe Knock Sensor (KS) circuit.

a6l--fzt.i--1/.---r+\

ware sido

o ooooo ooo ooo o looooooooo oooo ooo oo ooo I oooo oooo

11-74

- The MIL h6s boon r6port6don.- With th6 SCS ahort connec-tor connoctod (soe pago11-341, codo 23 is in-dicrtod.

Oo the ECM Reset Proceduro (seepage 11-35).

Start the engine. Hold the engineg!-3,Opq rpm with no load {A/T in

Lryl orlPlposirion, M/T in neurra until the radiator fan comes on,then let it idle.

Hold the engine at 3,0O0-4,000rpm for 10 seconds.Intomittor failure, ay5-t.m is OK at this tim6(teat drivo mav bonec€saary,.Chock tor Door connec-tion3 or loo3o wlaos etC222 {locatod 6r ghrshock tow6r), Cl33(KSl and ECM.Turn the ignition swirch OFF.

Connect the test harness to themain wire harness only, not to theECM (see page 1 1-37).

Check for continuity between D3terminal and body ground.

Ropdr short in RED/BLUwiro b€tweon ECM {D3land ths Ks.

(To page 11-75)

Page 271 of 1413

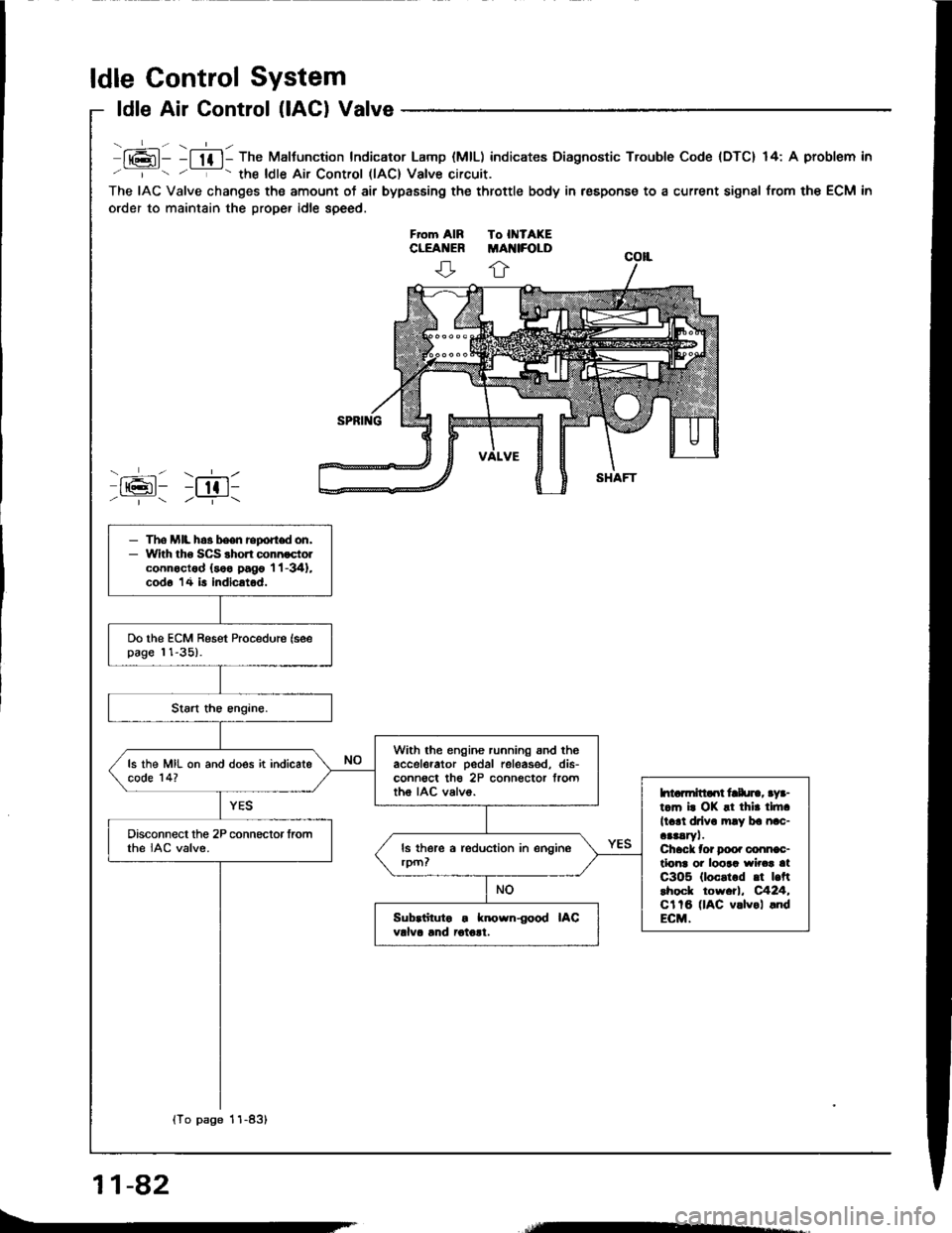

ldle Control System

ldle Air Control (lACl Valve

lt6l- -l lf l- The Maltunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code {DTC} 14: A problem in

' '- the ldle Air Control llAC) Valve circuit.

The IAC Valve changes the amount of air bypasEing the throttle body in respons€ to a current signal from the ECM in

order to maintain the proper idle speed.

ffi: r;611/ | /--T-\

- The MIL h.3 been report don,- With tho SCS shon connoctolconnoctod (soo pago 'l 'l -341,

cod6 14 is indicatod.

Do the ECM Reset Procedure (seepage 11-35).

With the engine running snd theaccelerator pedal releas€d, dis-conn€ct th€ 2P connector frorttho IAC valvo.

ls the MIL on and does it indicatecode 14?

htarmitlaot frlu]., aya-t.m i. OK !t thir tlft.

ll.rl drlv. mly ba nac-aaaaryl.Chack tor Doo. conn€c-tlonr oi loora wirca atC3O5 (loc.t.d .t |.ftlhock tow.tl, C424,Cl tB (lAC v.lvol .ndECM.

Disconnect the 2P connector fromthe IAC valve.

Sub.iituto . known{ood IACvdva lnd iotolt.

{To page 11-83}

11-82

Page 289 of 1413

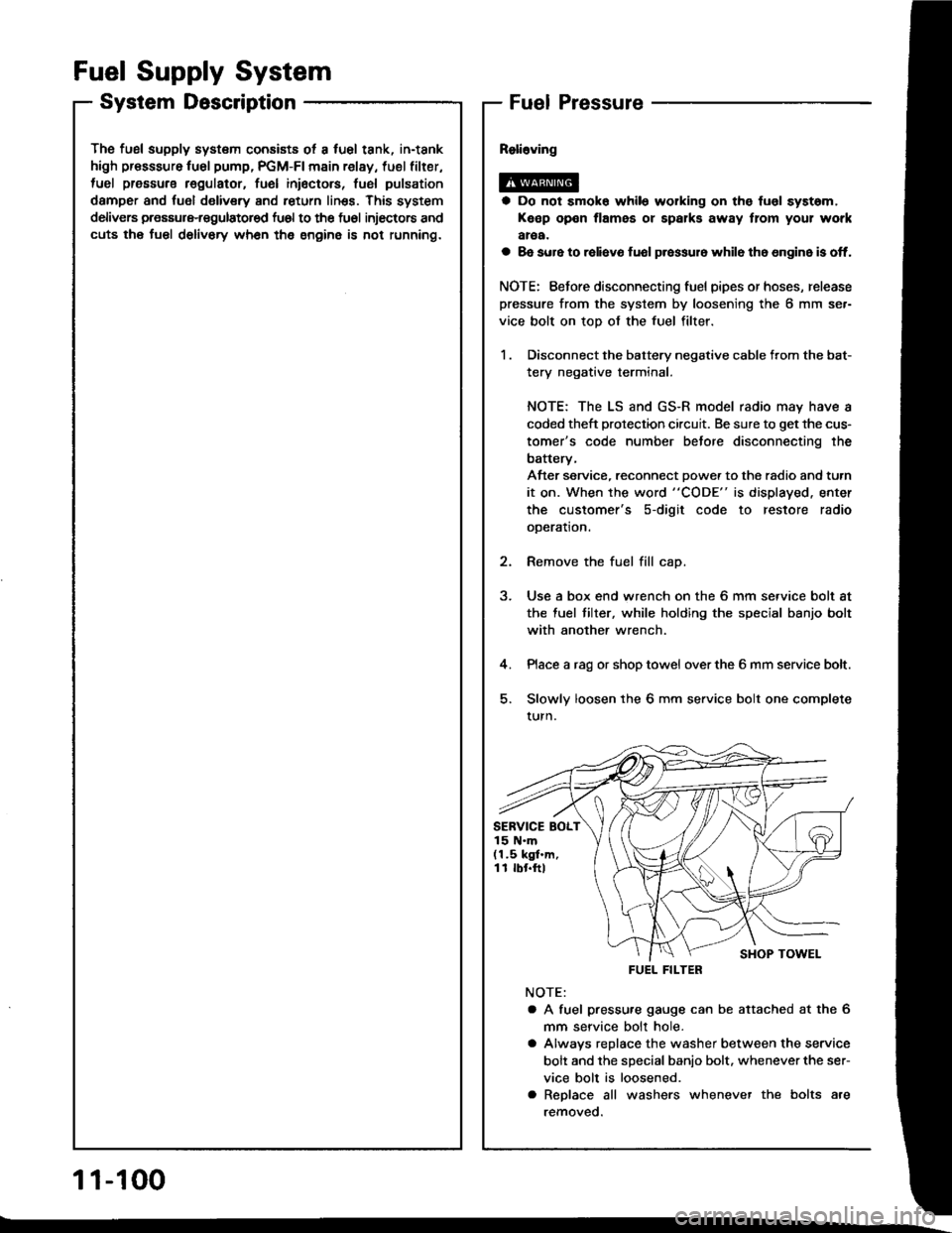

The fusl supply system consists ot a fuel tank, in-tank

high presssure fu6l pump, PGM-FI main relay, fuel filter,

tuel pressure regulatot, fuel inioctors, fusl pulsation

damper and fuol delivery and return linss. This system

delivers pressure-regulatored fu6l to the fu6l injectors and

cuts the fuel delivory wh6n the engine is not running.

Fuel Supply System

System DescriptionFuel Pressure

a Do not smok6 while working on the fuol syst6m,

Keep open flames or spalks away tlom your work

aroa.

a 8e sure to raliavo fuol p.essur6 while th6 6n9in6 is off.

NOTE: Eefore disconnecting fuel pipes or hoses, release

pressure from the system by loosening the 6 mm se.-

vice bolt on top of the fuel filter.

1 . Disconnect the battery negative cable from the bat-

tery negative terminal.

NOTE: The LS and GS-R model radio may have a

coded theft protection circuit. Be sure to get the cus-

tomer's code number betore disconnecting the

batterv,

After service, reconnect Dowe. to the radio and turn

it on. When the word "CODE" is displayed. enter

the customer's s-digit code to restore radio

ooeration.

2. Remove the fuel fill cap.

3. Use a box end wrench on the 6 mm service bolt at

the fuel tilter, while holding the special banjo bolt

with another wrench.

4. Place a rag or shop towel over the 6 mm service bolt.

5. Slowly loosen the 6 mm service bolt one complete

turn.

NOTE:

a A fuel pressu.e gauge can be attached at the 6

mm seryice bolt hole.

a Alwavs replace the washer between the service

bolt and the special banio bolt. whenever the ser-

vice bolt is loosened.

a Replace all washers whenever the bolts are

removeo.

SERVICE BOLT15 N.m(1.5 kgf.m,11 rbr.ftl

FUEL FILTER

1 1-100

Page 294 of 1413

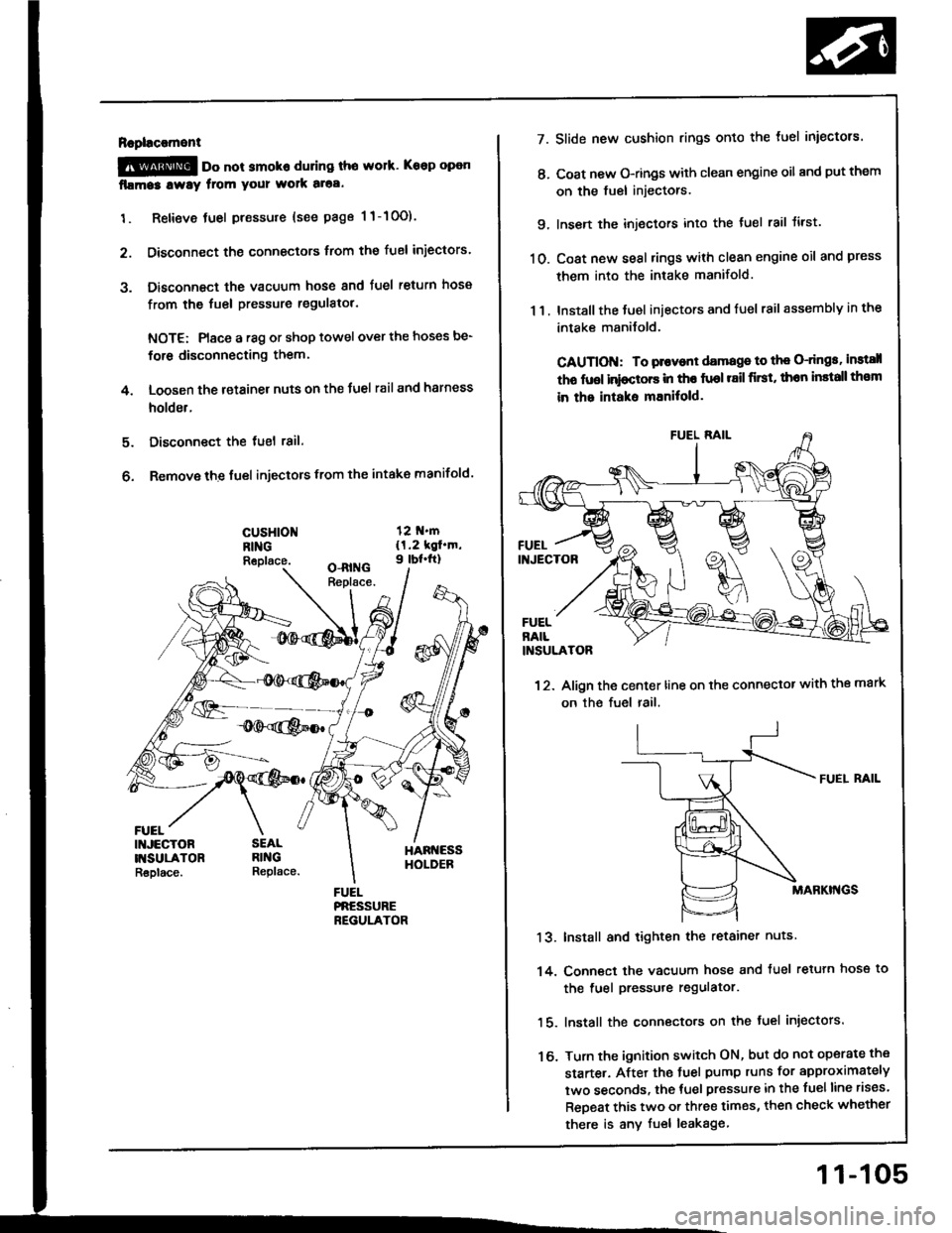

Rapl!c!ment

@ oo not smoko during tho work. Keep open

fllma3 lway from your wolk aloa.

1. Retieve tuel pressure {see page 1 1-10O).

2. Disconnect the connectors trom the fuel iniectors.

3. Disconnect the vacuum hose and fuel return hosa

from the fuel pressure regulatol.

NOTE: Place a r8g or shop towel over the hoses be-

for6 disconnecting them.

4. Loosen the retainer nuts on the Juel rail and harness

holder.

Disconnect the tuel 18il.

Remove the fuel injectors from the intake manifold.

5.

6.

cusHloNRINGReplace.

FUEL

7.

t'.

9.

10.

13.

14.

16.

11.

Slide new cushion rings onto the luel iniectors.

Coat new O-rings with clean engine oil and put them

on the fuel injectors.

Insen the injectors into the tuel rail tirst.

Coat new seal rings with clean engine oil and press

them into the intake manifold.

Install the Juel iniectors and fuel rail assembly in the

intake manilold.

CAUTION: To plovont damage to th€ O-dngs, instsll

tho fuol inioctors in tho fuol r8il first, thon install th€m

in the intaks mEnitold.

12. Align the center line on the connector with the mark

on the fuel rail.

FUEI. RAIL

MABKI'{GS

Install and tighten the retainer nuts

Conn€ct the vacuum hose and tuel retuln hose to

the fuel pressure regulator.

lnstall the connecto.s on the fuel injectors.

Turn the ignition switch ON, but do not operate the

starte.. After the tuel pump runs for approximately

two seconds, the tuel pressure in the fuelline rises.

ReDeat this two or three times, then check whether

there is any fuel leakage

11-105

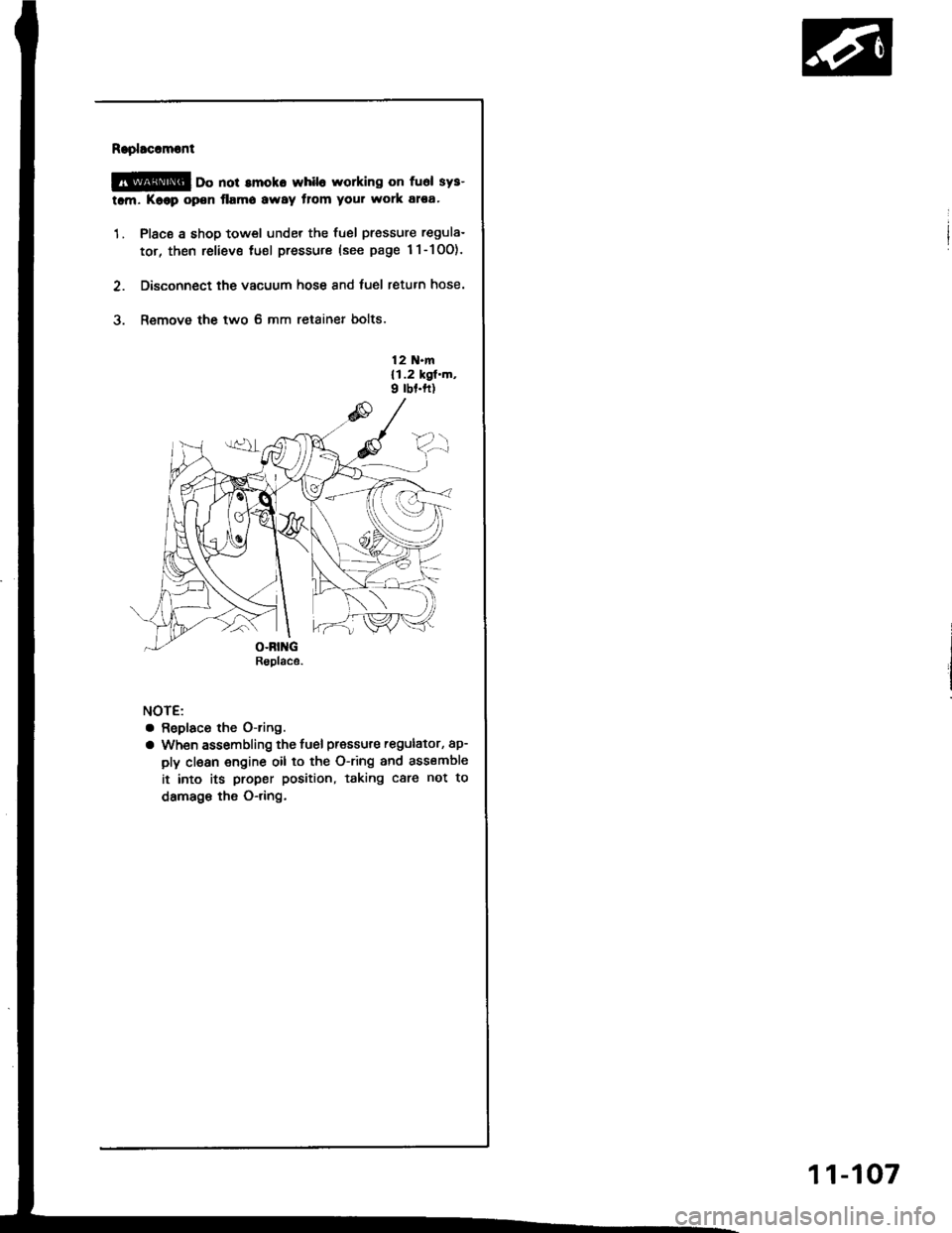

Page 296 of 1413

Raplacoment

@ oo not amoko whil6 working on fuel sys-

tam. Koop open flamo away tlom your work atea'

1. Place a shop towel under the fuel pressure regula-

tor, then reliev€ tuel pressure (see page 1l-10O).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts.

12 N.m{1.2 kgl.m,9 rbf.ft)

NOTE:

a Replaco the O-ring.

a When assembling the fuel pressure regulator, ap-

ply clean engine oil to the O-ring and assemble

it into its proper position, taking care not to

damage the O-dng.

Rsplace.

11-107

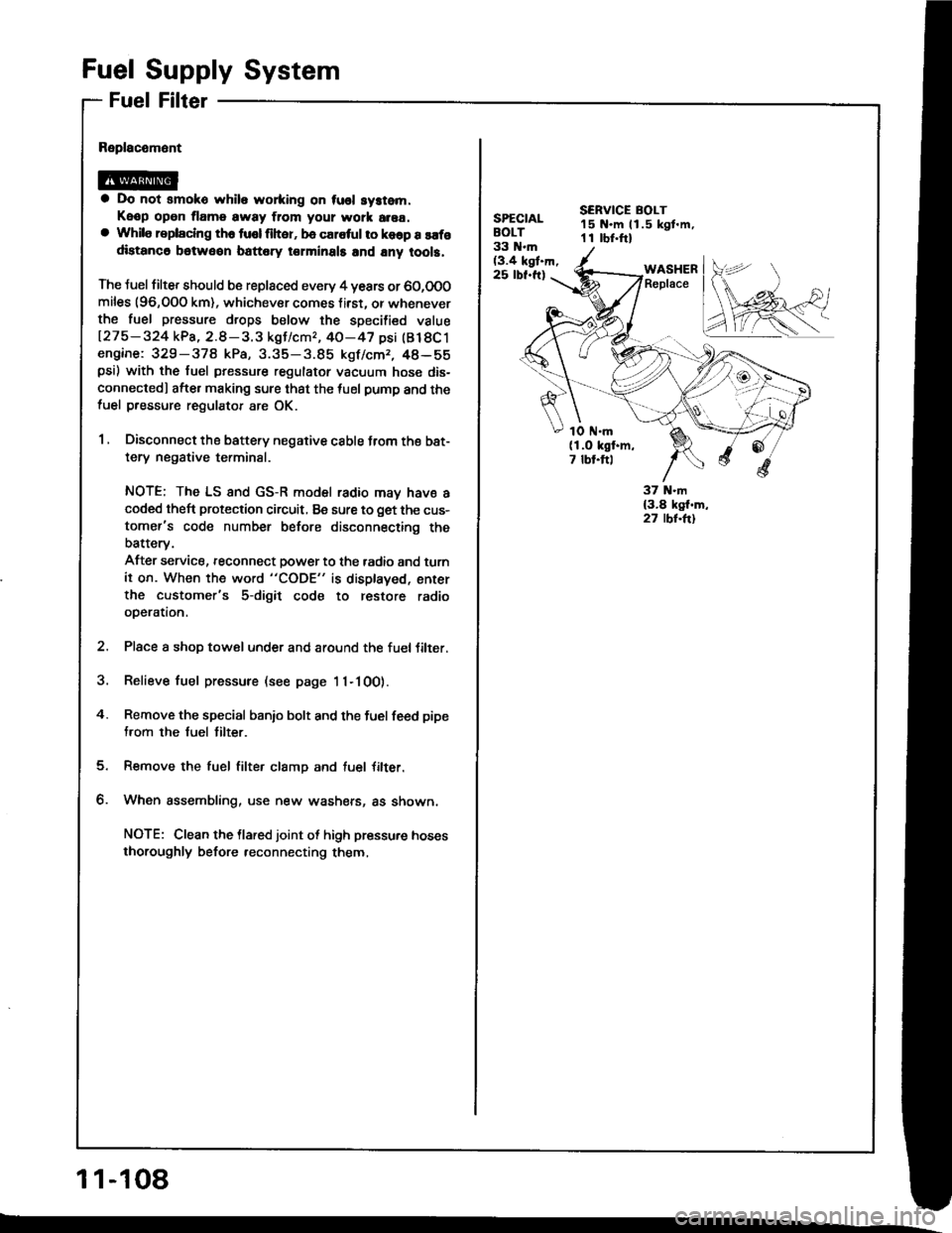

Page 297 of 1413

Filter

Fuel Supply System

Fuel

a Do not smoko while wo*ing on tusl system.

Keop open tlame away ftom your wotk area.a While replaclng th6 tusl liher, be caletul to koop a safodistanc6 betweon battery torminals and any tool3.

The Juel filter should b€ replaced every 4 years or 60,0O0miles (96,OOO km), whichever comes f irst. or wheneverthe fuel pressure drops below the specilied value

127 5 - 324 kPa, 2.8 - 3. 3 kgJ/cmr, 40-47 psi (Bl 8C 1engine: 329-378 kPa, 3.35-3.85 kgf/cmr, 48-55psi) with the fuel pressure regulator vacuum hose dis-

connectedl afte. making sure that the tuel pump and thefuel pressure regulator are OK.

1 , Disconnect the battery negative cable trom the bat-

tery negative terminal.

NOTE; The LS and GS-R model radio may have acoded theft protection circuit, Be sure to get the cus-

tomer's code number before disconnecting the

batterv.

After service, reconnect power to the tadio and turn

it on. When the word "CODE" is displaved, enter

the customer's 5-digit code to restore radio

operation.

2. Place a shop towel under and around the fueltilter.

3. Relieve fuel pressure (see page 11-100).

4. Remove the special banio bolt and the fuel feed pipe

from the fuel tilter.

Remove the fuel filter clamp and tuel Jilter.

When assembling, use new washers, as shown,

NOTE: Clean the llared joint ot high pressure hoses

thoroughly before reconnecting them,

1 1-108

SPECIALBOLT33 N.m(3.4 kgt.h,25 rbf.ft)

SERVICE BOLT15 N.m ll.5 kgt.m,1 I rbr.ftl

WASHERReplace

1O ttl.m(1.O kgf.m,7 tbt.ftl