tow HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 999 of 1413

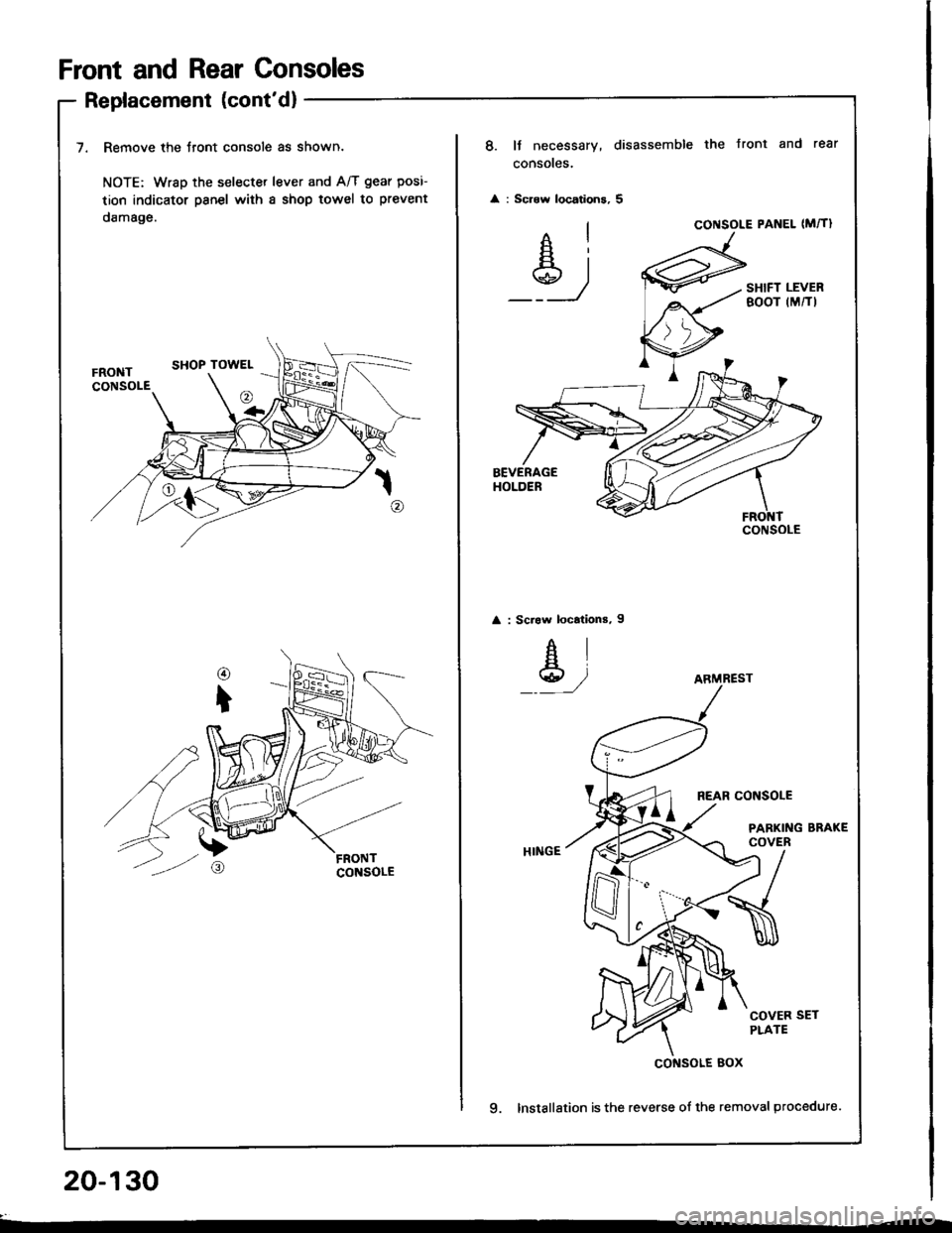

Front and Rear Consoles

Replacement (cont'd)

7. Remove the Jront console as shown.

NOTE: Wrsp the selecter lever and A/T gear posi-

tion indicator psnel with a shop towel to prevent

damage.

20-130

8. It necessary, disassemble the Jront and rear

consoles.

: Scrow locations, 5

Ai

_Y_)

CONSOLE PANEL (M�TI

SHIFT LEVERBOOT (M/TI

: Scraw locations, I

AI

Y,/

REAR CONSOLE

PARKING BRAKECOVER

COVER SETPLATE

9. Installation is the reverse of the removal procedure.

CONSOLE

ARMREST

cof{solE Box

Page 1006 of 1413

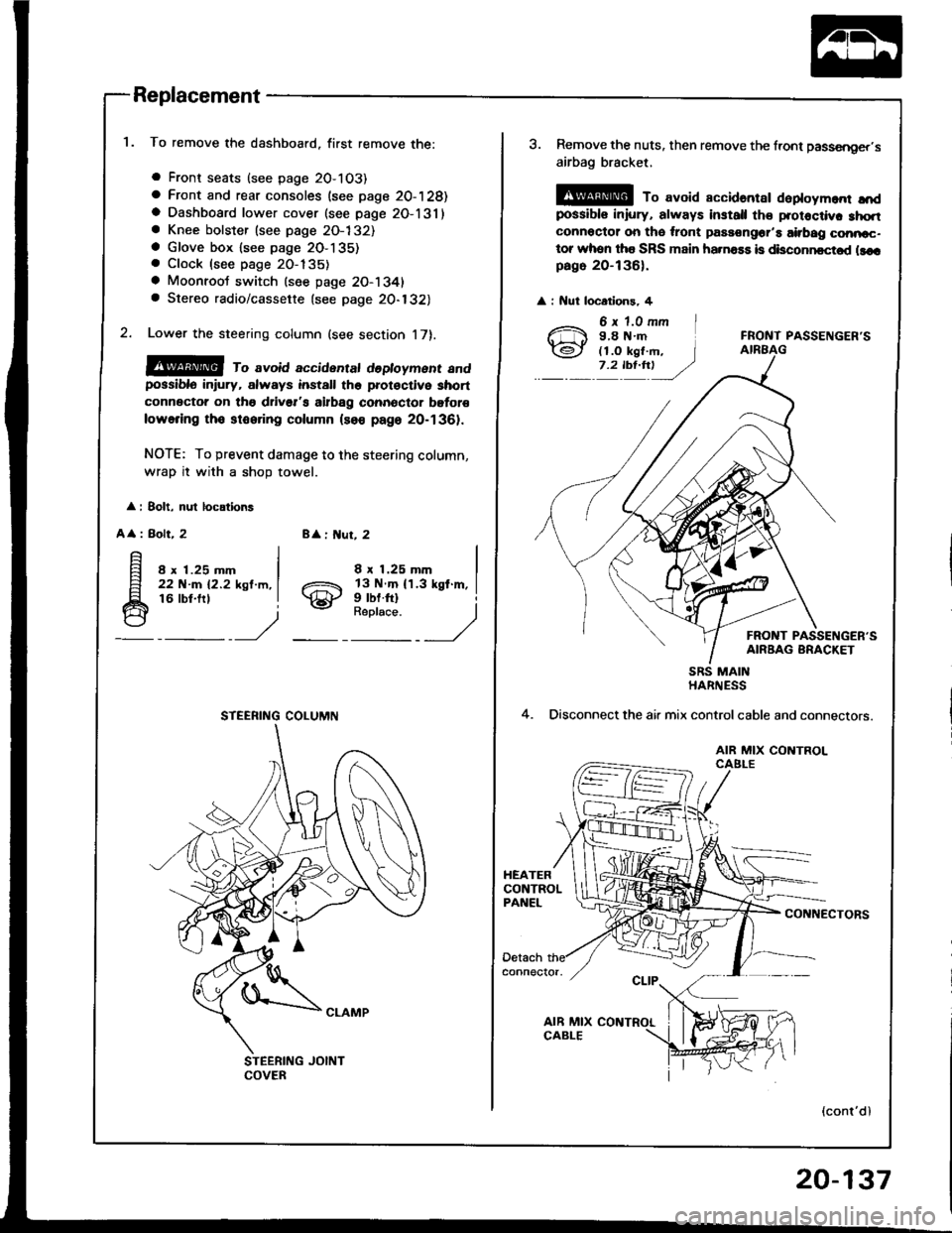

Replacement

To remove the dashboard, first remove the:

a Front seats (see page 2O-103)

a Front and rear consoles (see page 20-128)a Dashboard lower cover (see page 2O-131)a Knee bolster (see page 2O-132)a Glove box lsee page 2O-135). Clock (see page 20-135)

a Moonroot switch (see page 20-1341a Stereo radio/cassette {see page 20-132)

Lower the steering column (see section 17).

@@ ro avoid accidentat dedoyment andpossiblo in ury, always install the prot€ctive short

connector on tho drivsr's airbag connector bgtor€

lowering tho stooring column (so€ page 20-1361.

NOTE: To prevent damage to the steering column,

wrap it with a shoD towel.

: 8olt, nul locations

A

: Bolt, 28 : ut, 2

8 x 1.25 mm22 N-m 12.2 ksl.m,16 lbt.frl

8 x 1.25 mm

gill$"'l

STEERING COLUMN

3. Remove the nuts, then remove the front passsnger,s

airbag bracket,

@ To avoid accidantar daploym.nr ",'dpossibls iniury, always install th€ protoctiv. 3hqtconnoctor on tho ,ront passongor'a airbag conncc-tor whon tha SRS main ha.na$ is disconncctod llcrpago 20-136).

: Nut locatlons, 4

FRONT PASSENGER'S

FRONT PASSENGER'SAIRBAG BRACKET

4.

SRS MAINHARNESS

Disconnect the air mix controlcable and connectors.

AIR MIX CONTROLCAELE

CONNECTORS

(cont'dl

20-137

Page 1007 of 1413

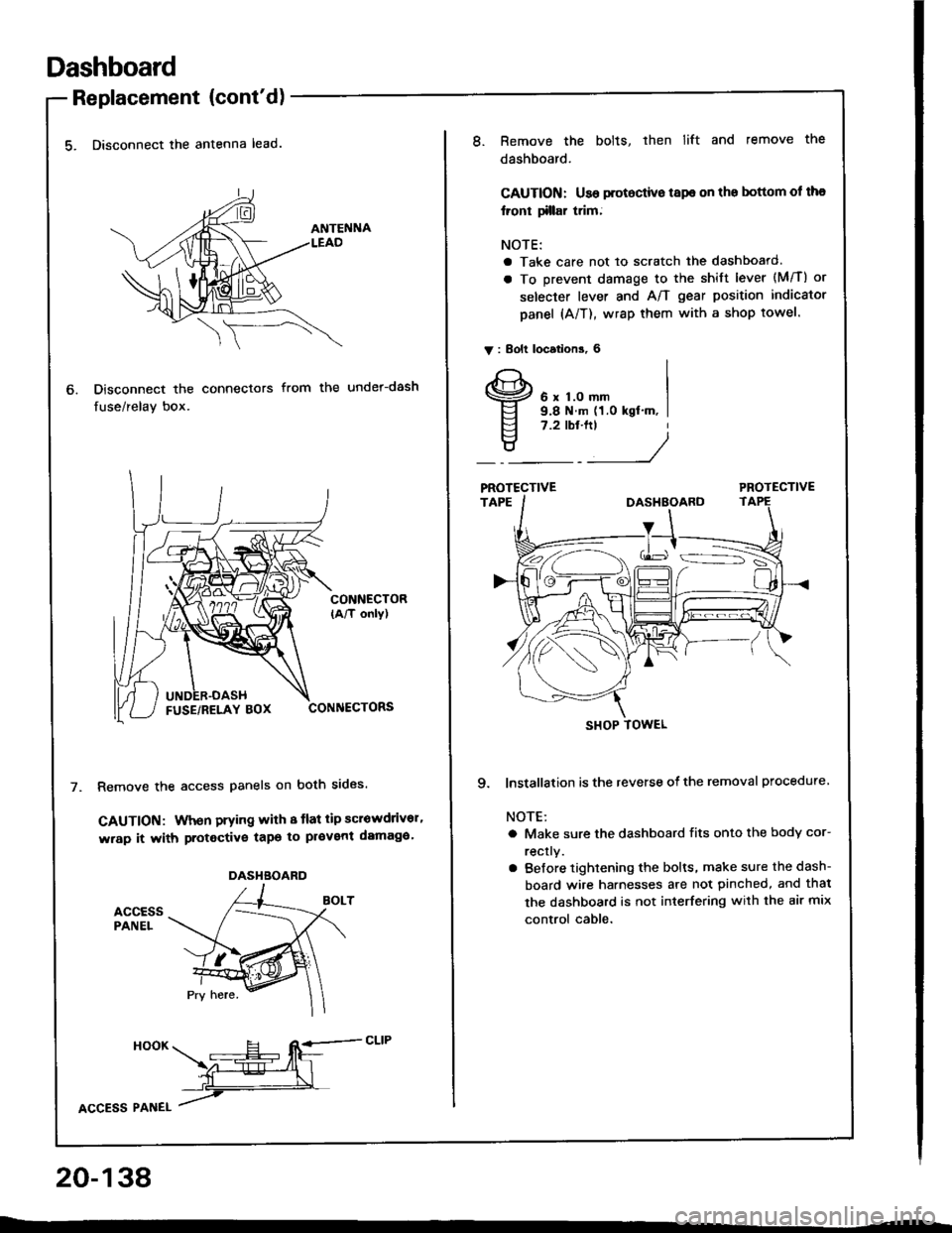

Dashboard

Replacement (cont'd)

5. Disconnect the antenna lead.

Disconnect the connectors

fuse/relay box.

from the under-dash

CONNECTOR(A/T only)

CONNECTORS

Remove the access panels on both sides.

GAUTION: When prying with 8 tlat tip scrowdrivor'

wrap it with protective tapo to pl€vent damaga'

accEssPANEL

6.

DASHBOARD

HooK ___E-- RE=-cLrP

ffiL

lcCesS Plnel /

20-138

8.Remove the bolts, then lift and remove the

dashboard.

CAUTION: Use protoctive tspe on the bottom ol tha

lront tillar trim;

NOTE:

a Take care not to scratch the dashboard.

a To prevent damage to the shift lever (M/T) or

selecter lever and A/T gear position indicator

panel (A/T), wrap them with a shop towel.

V : Bolt locations, 6

6 x 1.0 mm9.8 N.m (1.0 kgt'm, I7.2 tbt.ftt

____/

PROTECTIVE

9. lnstallation is the reverse of the removal procedure

NOTE:

a Make sure the dashboard fits onto the body cor-

rectly.

a Before tightening the bolts, make sure the dash-

board wire harnesses are not pinched, and thal

the dashboard is not interfering with the air mix

control cable.

SHOP TOWEL

Page 1027 of 1413

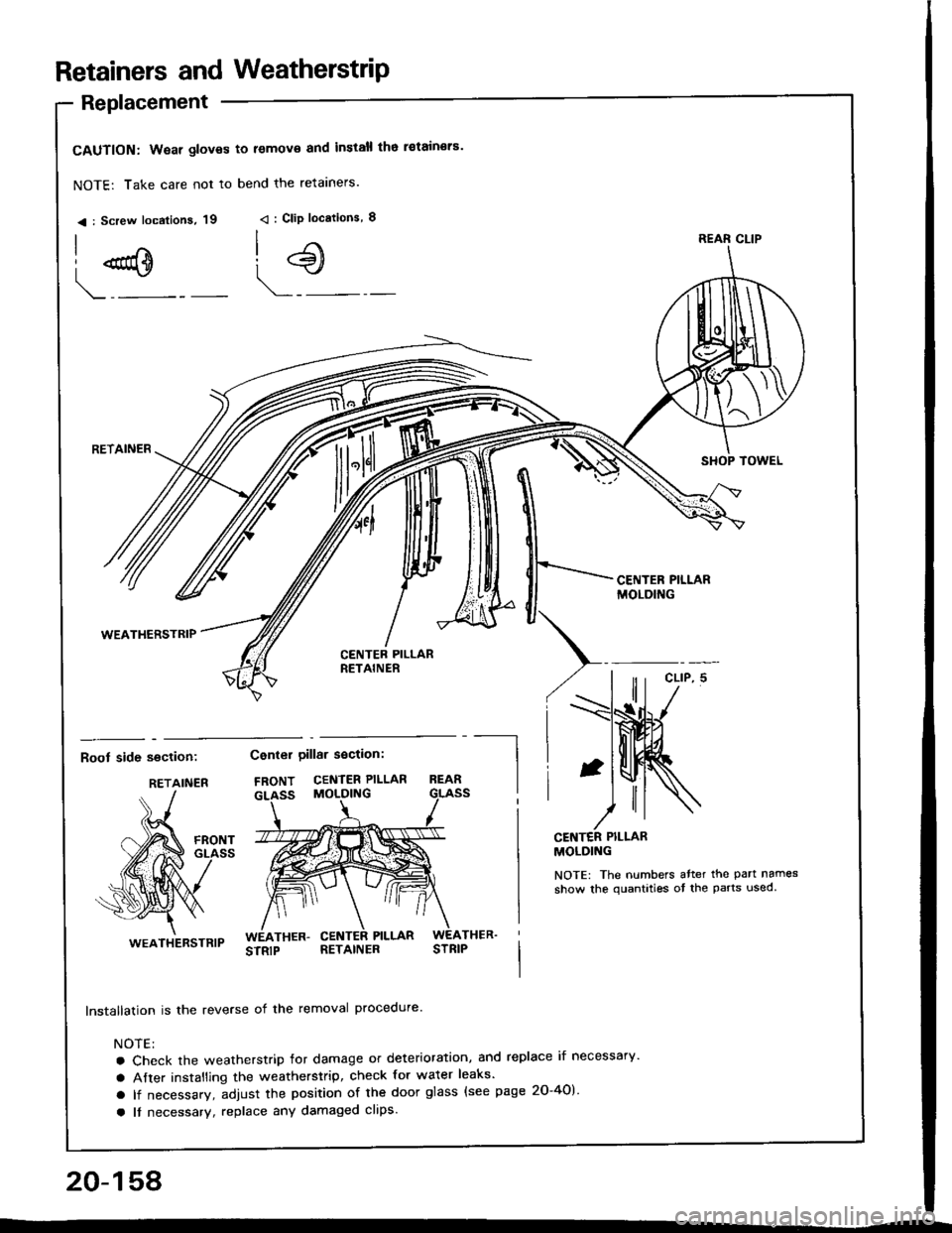

Retainers and WeatherstriP

Replacement

CAUTION: Wear gloves to lemov€ and install tho i€tain€rs'

NOTE: Take care not to bend the retarners.

< : Screw localions, 19 < : Clip locations, I

| .€\

!:

l{SHOP TOWELq

CENTER PILLARMOLDING

Boot side section:

I

RETAINER

lnstallation is the reverse of the removal procedure.

NOTE:

a Check the weatherstrip lor damage or deterioration, and replace if necessary'

a After installing the weatherstrip, check for water leaks'

a lf necessary, adjust the position of the door glass (see page 20-40)

a It necessarv, replace any damaged clips.

Center oillar section:

FRONT CENTER PILLAR

CENTER PILI-ARMOLDING

NOTE: The numbers atter the part names

show the quantities ot the parts used

!9

RETAINER

WEATHERSTRIP

REAR CLIP

RETAINER

WEATHERSTRIP

20-158

Page 1047 of 1413

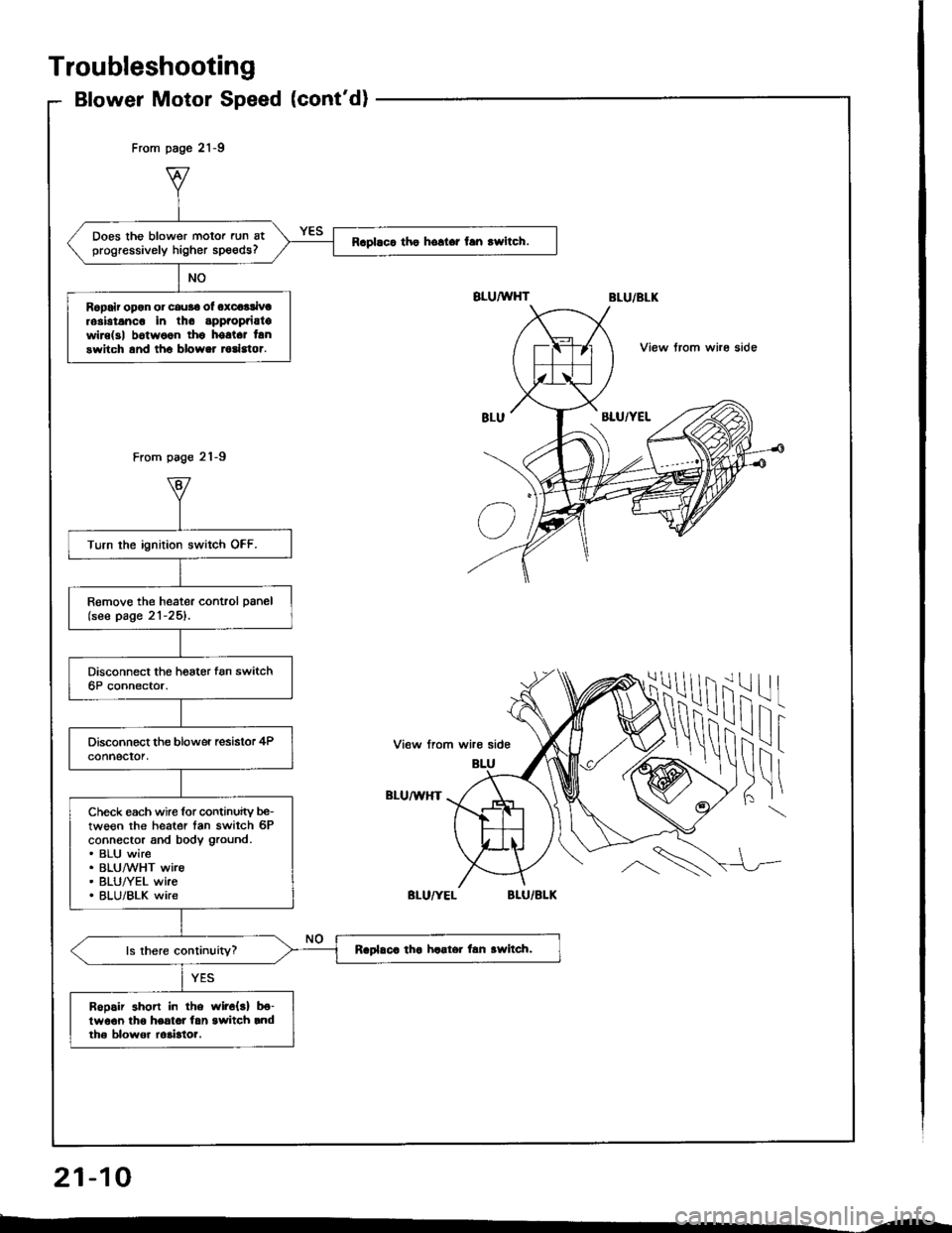

Does the blower motor run atprogressively higher speeds?Raplaca tho hollar fan rwitch.

Ropair opon or cau36 ol oxcoalivtrosbtanco in tho appaopaiatowire(3| b6twoon thg hostct lanswitch and tho blower todstor.

Turn the ignition switch OFF.

Remove the heater control panel(see page 21-25).

Check each wire for continuity be-tween the heater tan switch 6Pconnector and body ground.. BLU wire. BLUMHT wire. BLU/YEL wke. BLU/BLK wire

Raplaca tha haater lan awltch.

Bopair shon in the wir6{s} b€-lwo€n lho heatot lan switch rndth6 blowor ro3bto?.

From page 21-9

From page 21-9

View trom whe side

ilil

!\i

-l

I

View from wire side

BLU/U,HT

Troubleshooting

Blower Motor Speed (cont'd)

21-10

--

Page 1091 of 1413

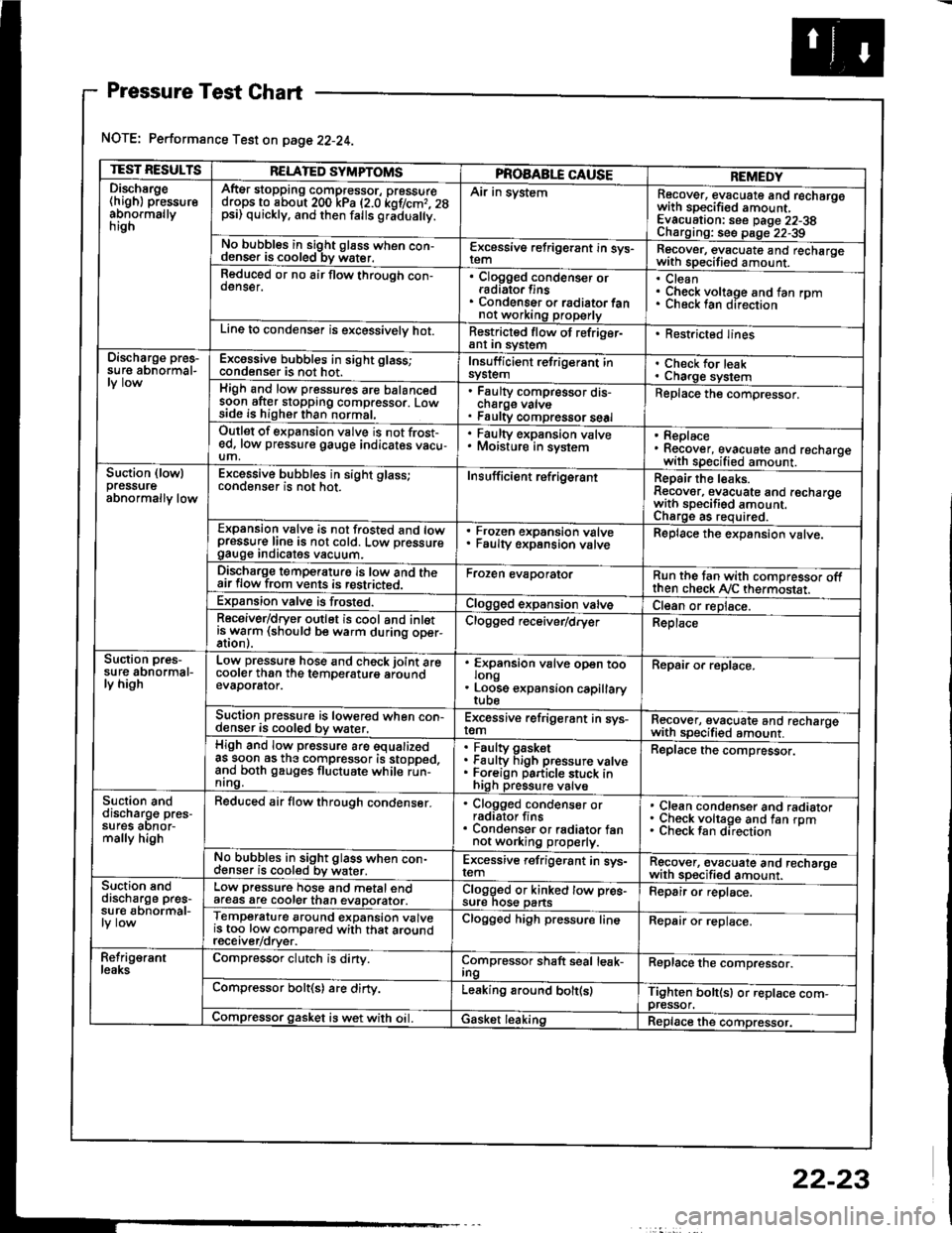

Pressure Test Chart

NOTE: Performance Test on page 22-24.

TEST RESULTSRELATED SYMPTOMSPROAABLE CAUSEREMEDYDischsrge(high) pressureabnormallynrgn

AftEr stopping compressor, pressuredrops to about 200 kPa (2.0 kof/cmr. 28psi) quickly, and then falls gr;dua y.

Air in systemRecover, evacuate and recharqowith sDecified amount. -

Evacuation: see Daqe 22-38Charoino: se6 D;op--2?-?qNo bubbles in sight g16ss when con-denser is cooled bv water.E-\cessive refrigerant in sys-Recover, evacuate and recharqewith specitied amount. -

Reduced or no air flow through con-oenser.Clogged condenser orradiato. finsCondenser o. radiator fannot working properly

CleanCheck voltage and fan rpmunecK lan ofeclton

Line to condenser is excessivelv hot.Restricted flow of refriger-ant In syslem. Restricted lines

Discharge pres-su re abnormal-Excossive bubbles in sight glass;condenser is not hot.Insuff icient refrigerant insyslemCheck for leakCharge systemHigh and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal,

Faulty compressor dis-cnarge vaNsFaulty compressor seal

Replace the compressor.

Outlet of expansion vslve is not frost-ed, low pressure gauge indicates vacu-um,

. Faulty expansion valve. Moisture in sysiem. Replace. Recover, evacuate and recharoewith specified amount. -

Suction (lowlpressureabnormally low

Excessive bubbles in sight glass;conqenser rs not hot_Insuff icient ref rigerantReoair the leaks.Reaover, evacuate and recharoewith sDecifisd amount. -

Charqe as required.Expansion valve is not trosted and lowpressur€ line is not cold. Low pressuregauge Inorcates vacuum.

Frozen expansion valveFaulty expansion valveReplace the expansion valve.

Discharge temperaturg is low and theair flow from vents is restricted.Froren evaporatorRun the tan with comoressor oftthen check Ay'C thermostat.Expansion valve is frost€d.Clogged expansion valveCl€an or replace.Receiver/dryer outlet is cool and inletisrryarm (should be warm during oper-Clogged r€ceiver/dry€rReplace

Suction pres-su re abnormal-ly high

Low pressure hose and check joint arecooler than the temDeraturo aroundevaDorator.

'

ffin"nsion u"lu" oD"n too

. Loose expansion capillary

Repair or replace.

Suction pressure is lowered when con-denser is cooled by water,Excessive refrigerant in sys-remRecover, evacuate and recharqewith sDecifi€d amount. -

High and low pressure are equalizedas soon as the compressor is stopped,and both gauges fluctuate while run-nrng.

Faultv oasketFaulty Figh pressure valveForeign particle stuck inhigh pressure valve

Replace the compressor.

Suction anddischarg€ pres-sufes aonor-mally high

Reduced air flow through condenser.. Clogged condenser orradiator fins. Condenser or radiator fannot working properly.

Clean condenser and radiatorCheck voltage and fan rpmCheck fan direcrion

No bubbles in sight glass when con-cl€nser is cooled bv water.Excessive refrigerant in sys-remRgcover, €vacuate and recharoewith sp€cified amount.Suction snddischarge pres-su r€ abnormal-

Low pressure hose and metal endafeas are cooler than evaDorator.Clogged or kinked tow pre€-sure nos€ pansFepair or replace.

Temperature around expansion valveis too low compared with that aroundrecerver/orver.

Clogged high pressure lineRepair or replace.

Refrig€rantleaksCompressor clutch is dirty.Compressor shaft seal leak-IngReplace the comDressor.

Compressor bolt(s) are dirty.Leaking around bolt(s)Tighten bolt(sl or replace com-pressor.Compressor gasket is wet with oil. IGasket leakingReplace the compressor.

22-23

Page 1104 of 1413

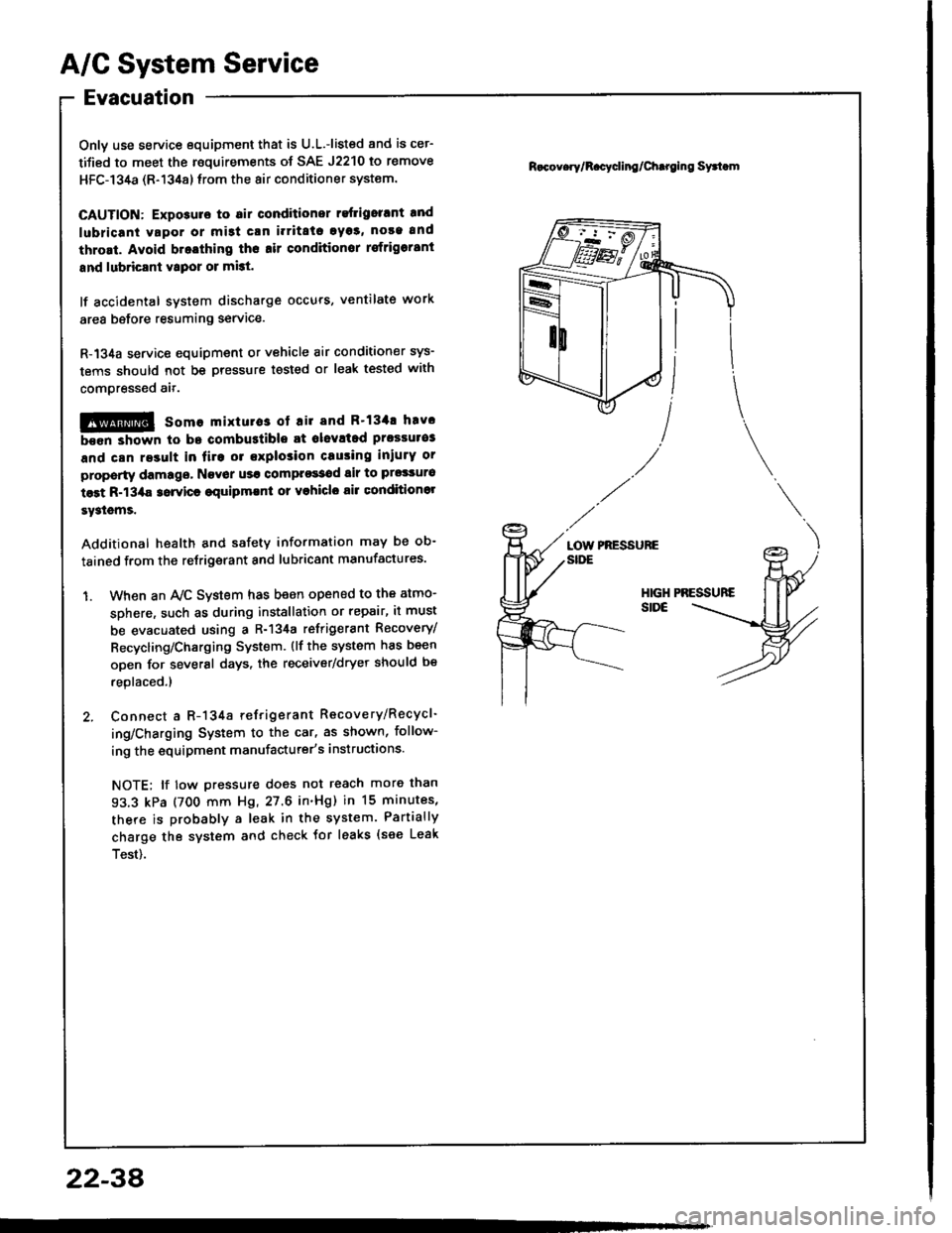

A/G System Service

Evacuation

Only use service equipment that is U.L.-listed and is cer-

tified to meet the roquirements of SAE J2210 to remove

HFC-134a (R-134a) lrom the 8ir conditioner system.

CAUTION: Exposulo to 6ir conditioner refligorrnt and

lubricani vapor or mi3t crn i.ritato 9y33, noaa and

thrort. Avoid bratthing ths .ir conditionor rsfrigorrnt

snd lubricsnt vtpor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle 8ir conditioner sys-

tems should not be pressure tested or leak tested with

compressed ait.

!@ somo mixtuto3 ot ril and R'134! hav.

been shown to bo combustible at olevltad prossulo3

and can re3ult in fire or explosion crusing inlurY or

property damago, Navor us! comprossod air to prgsauro

test R-13/aa 3orvicr €quipmlnl or vohiclo air conditionol

sy3lems.

Additional health and safety information may be ob-

tained from the retrigerant and lubricant manufactures.

1. When an Ay'C System has been opened to the atmo-

sDhere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant Recovery/

Recycling/Charging System. {lf the system has been

open for several days, the receiver/dryer should be

replaced.l

2. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the car, as shown, follow-

ing the equipment manufacturer's instructions.

NOTE; lf tow pressure does not reach more than

93.3 kPa (700 mm Hg, 27.6 in'Hg) in 15 minutes,

there is probably a leak in the system. Partially

charge the system and check tor leaks {see Leak

Test).

R.cov.ry/R.cycling/Chtroing Syttom

PRESSUREaotnSIDE

2234

Page 1120 of 1413

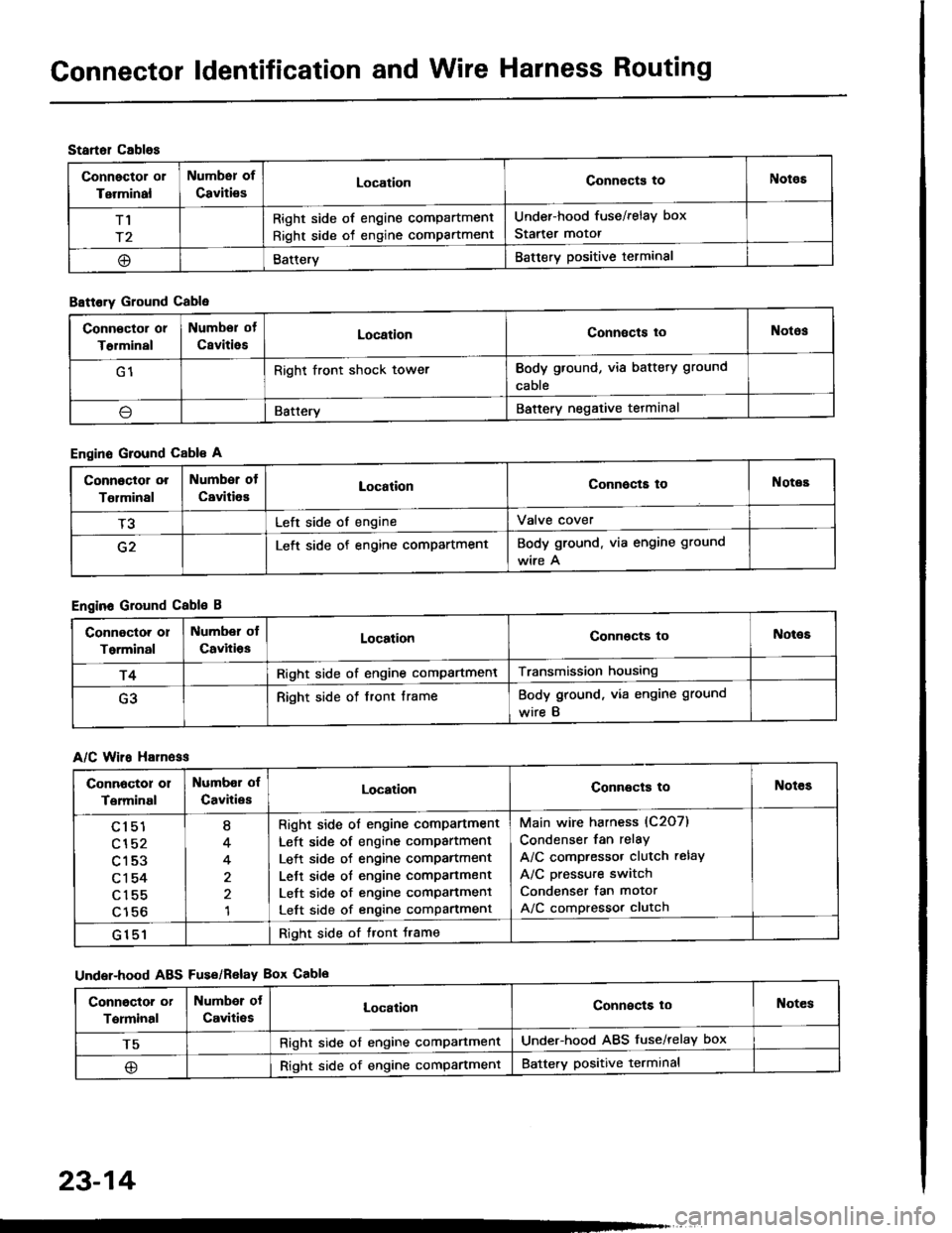

Gonnector ldentification and Wire Harness Routing

Startol cablos

Connector or

Terminal

Numbsr of

CavitiesLocationConnects toNotos

T1

r2

Right side of engine compartment

Right side of engine compartment

Under-hood fuse/relay box

Starter motor

@BatteryBattery positive terminal

B8ttory Ground Cable

Engine Ground Cable A

Engine Ground Cable B

A/C Wiro H81n6ss

Under-hood ABS Fus€/Relav Box Cablo

Conn€ctor or

T€rminal

Numbor of

CsvitiesLocationConnects toNotos

G1Right front shock towerBody ground, via battery ground

cable

\lBatteryBattery negative tetminal

Connoctor or

Tolminal

Number of

CavitiesLocationConnocta toNotes

T3Left side of engineValve cover

G2Left side of engine compartmentBody ground. via engine ground

wire A

Connoctor or

Torminal

Number ol

CavitiosLocationConnocts toNot€s

r4Right side of engine compartmentTransmission housing

G3Right side of front frameBody ground, via engine ground

wire B

Connoctor 01

Terminal

Numbor of

CavitiesLocationConnects toNotes

cl51

cl52

c153

c1 54

c155

c156

I

4

4

1

Right side ol engine comPartment

Left side of engine compartment

Left side of engine comPartment

Lett side ot engine compartment

Left side of engine comPanment

Left side of engine compartment

Main wire harness (C2O7)

Condenser fan relay

A/C compressor clutch relay

A/C pressure switch

Condenser fan motor

A/C compressor clutch

G151Right side of tront Jrame

Conngctor or

Terminal

Numbor ot

Caviti€sLocalionConnects loNotes

T5Right side of engine comPartmentUnder-hood ABS fuse/relay box

@Right side of engine compartmentBattery positive terminal

23-14

Page 1161 of 1413

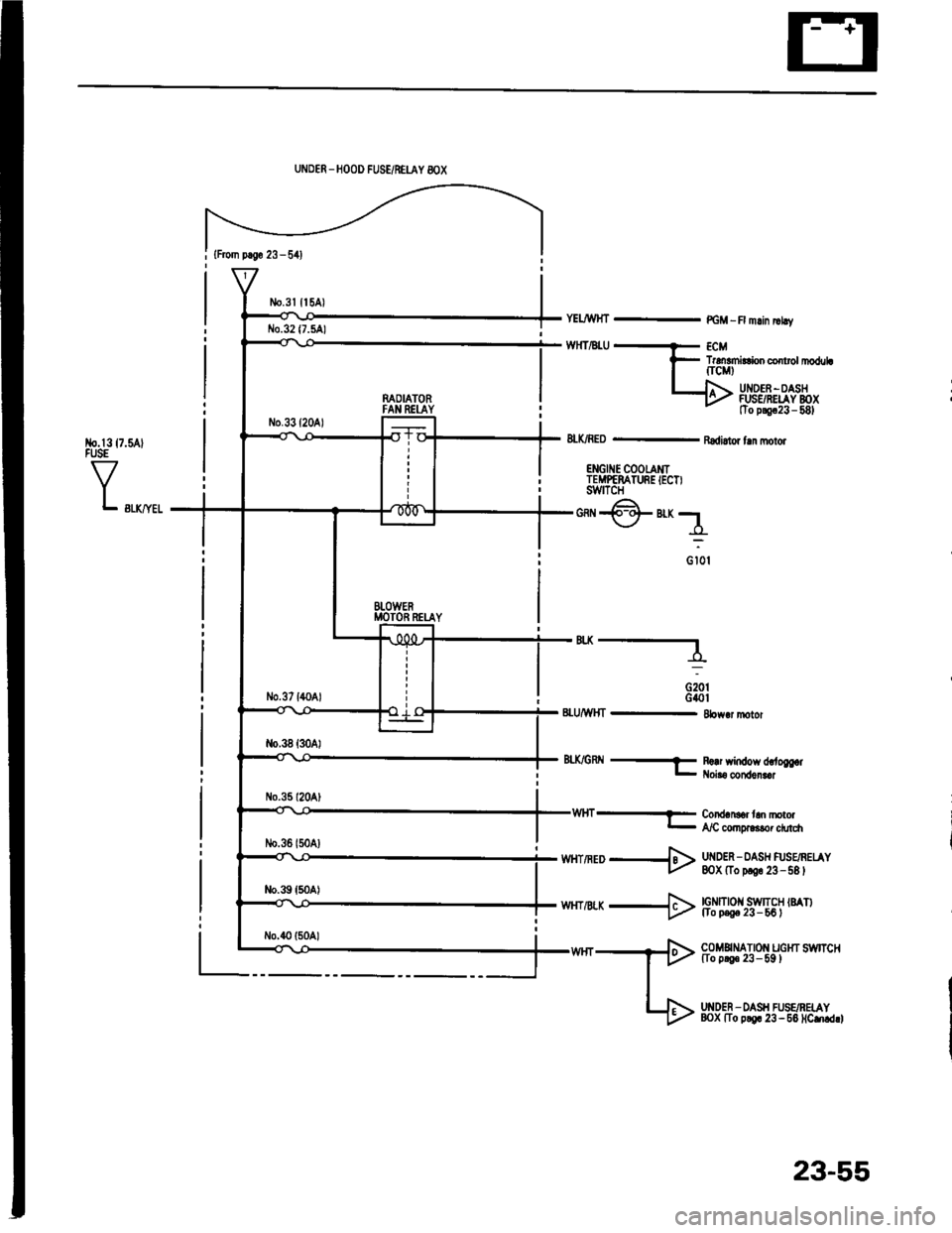

{From p.So 23 - 541

No.l317.5AlFUSE

VL swyel

UNDER _HOOD FUSE/NEUY 8OX

n^OIATORFAN REI-AY

BTOWERMOTOR RETAY

YELJWHT - PGM -R mlin |rhv

TrdEmirConco rolrl|oduLfrcMt

UI{DEF -OASHFUSSRELAY BOXtTo p!9c23 - 581

8LK/RED - Radi.tor fln molor

ENGII{E COOTAMITEMPEMTURE IECT)swtTcH

*@"r;1

o iot

'"----

G20tG40t8LU/WHT - 8bw.r motor

8tX/GRtl -f R!!r window d,.to

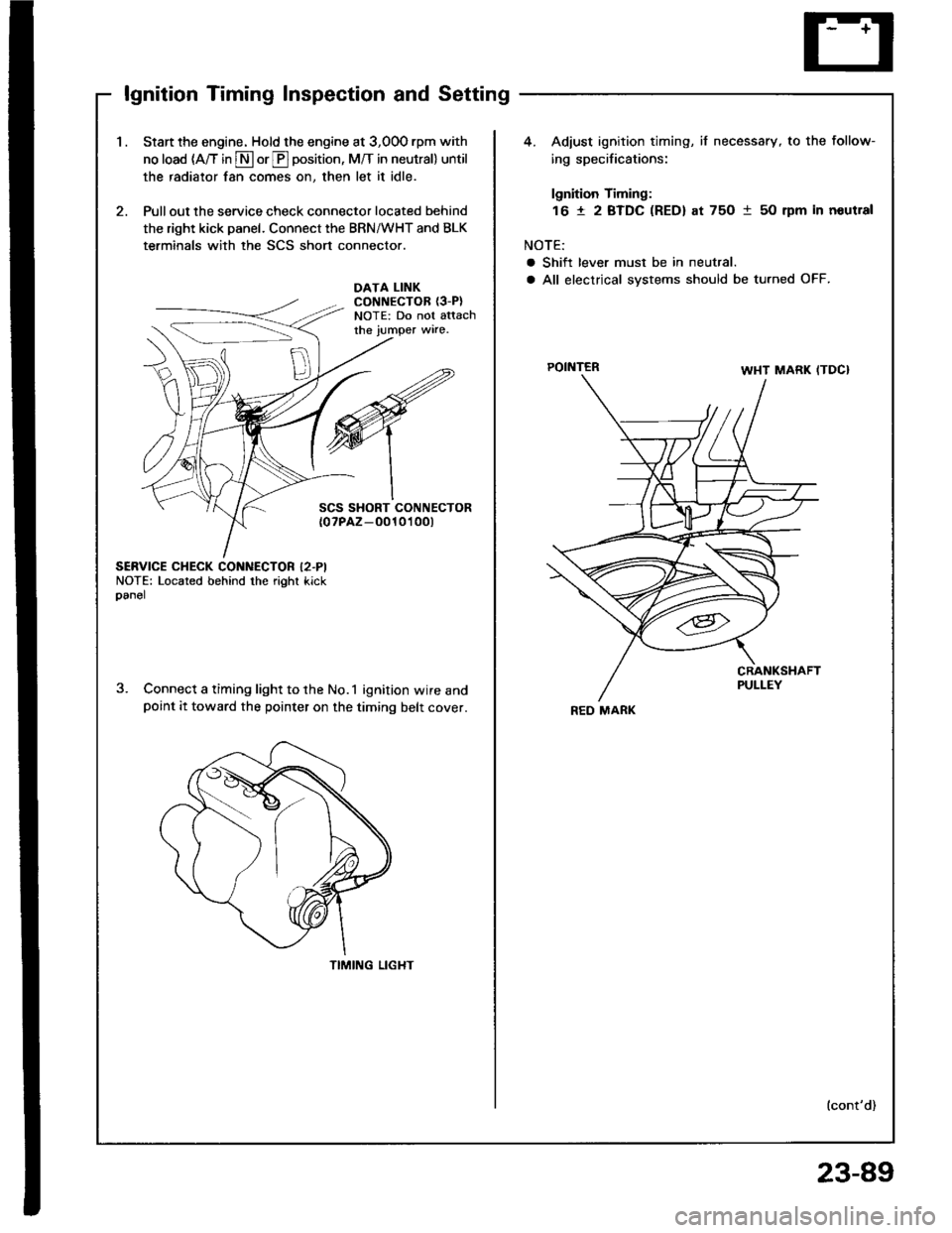

lgnition Timing Inspection and Setting

1.Start the engine. Hold the engine at 3,00O rpm with

no load (A/T in S or E position, M/T in neutral) until

the radiator fan comes on, then let it idle.

Pull out the service check connector located behind

the right kick panel. Connect the BRN/WHT and BLK

terminals with the SCS short connector.

4. Adiust ignition timing, if necessary, to the follow-

ing specifications:

lgnition Timing:

16 t 2 BTDC (RED) at 75O 1 50 rpm in noutral

NOTE:

a Shift lever must be in neutral.

a All electrical systems should be turned OFF.DATA LINKCONNECTOR {3-P}NOTE: Do not attachthe jumper wire.

POINTER

SCS SHORT CONNECTOR{0?PAZ-O010't 00t

SERVICE CHECK CONNECTOR I2.PINOTE: Located behind the right kickoanel

Connect a timing light to the No.1 ignition wire andpoint it toward the pointer on the timing belt cover.

TIMING LIGHT

lcont'd)

REO MARK

23-89