Idle HONDA INTEGRA 1994 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 323 of 1413

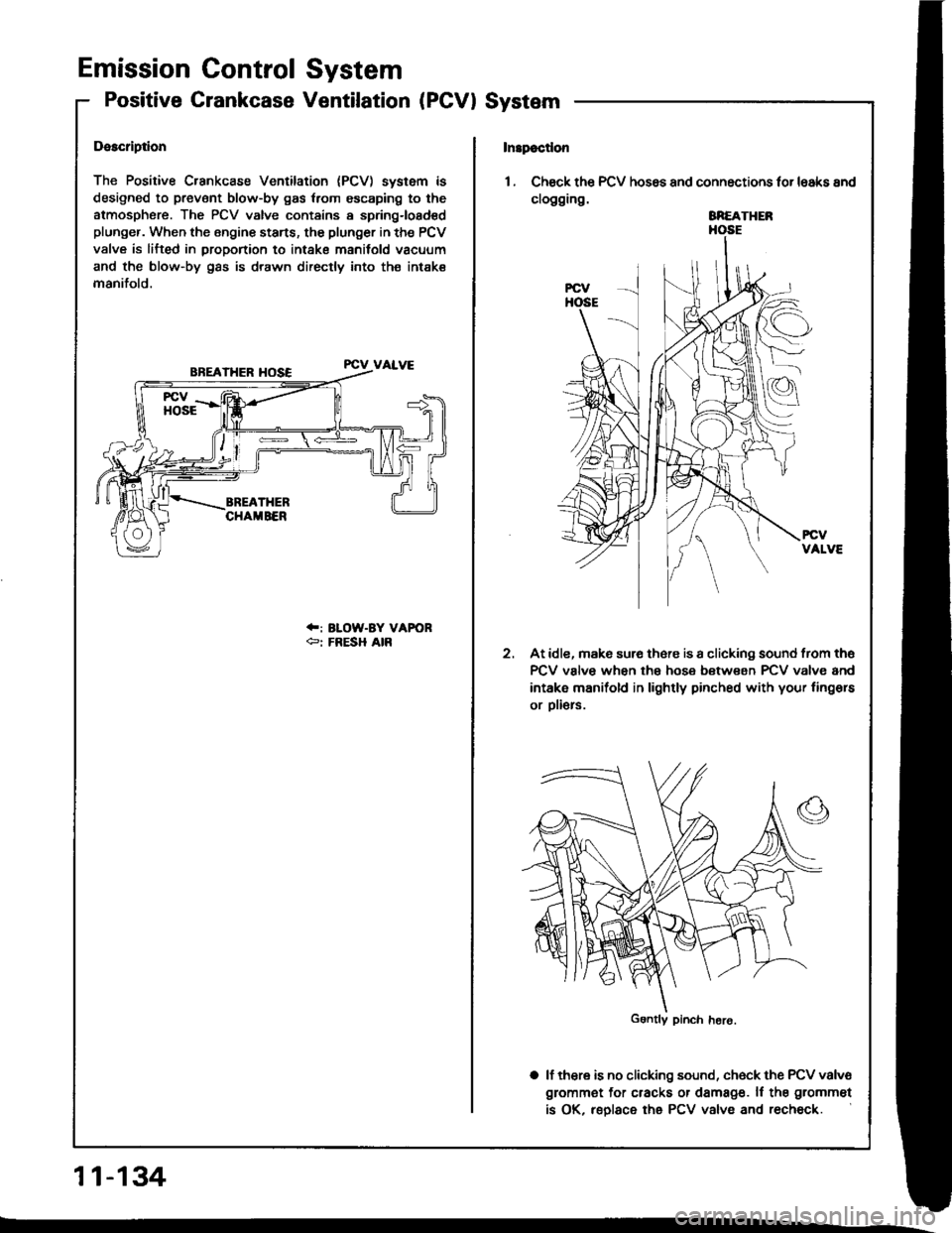

Emission Control System

Positive Crankcase Ventilation (PCVI System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas {rom escaping to the

atmosphsre. The PCV valve contains a spring-loadsd

plunger. When the Bngine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into th€ intak€

manifold.

FCV VALVE

.F: ILOW-BY VAFORer FRESH AIR

11-134

Insp€cdon

1. Check th€ PCV hos6s and connections tor lsaks and

clogging.

At idle, mak6 sur€ th6fe is a clicking sound from th6

PCV valve when the hose between rcV valve and

intake manifold in lightly pinched with your fingors

or oli€rs.

a lf thera is no clicking sound, ch6ck the PCV valve

grommet for cracks or damage. ll the grommet

is OK, reolace the PCV valve and recheck.

2.

SREATHER

Gontly pinch hero.

Page 327 of 1413

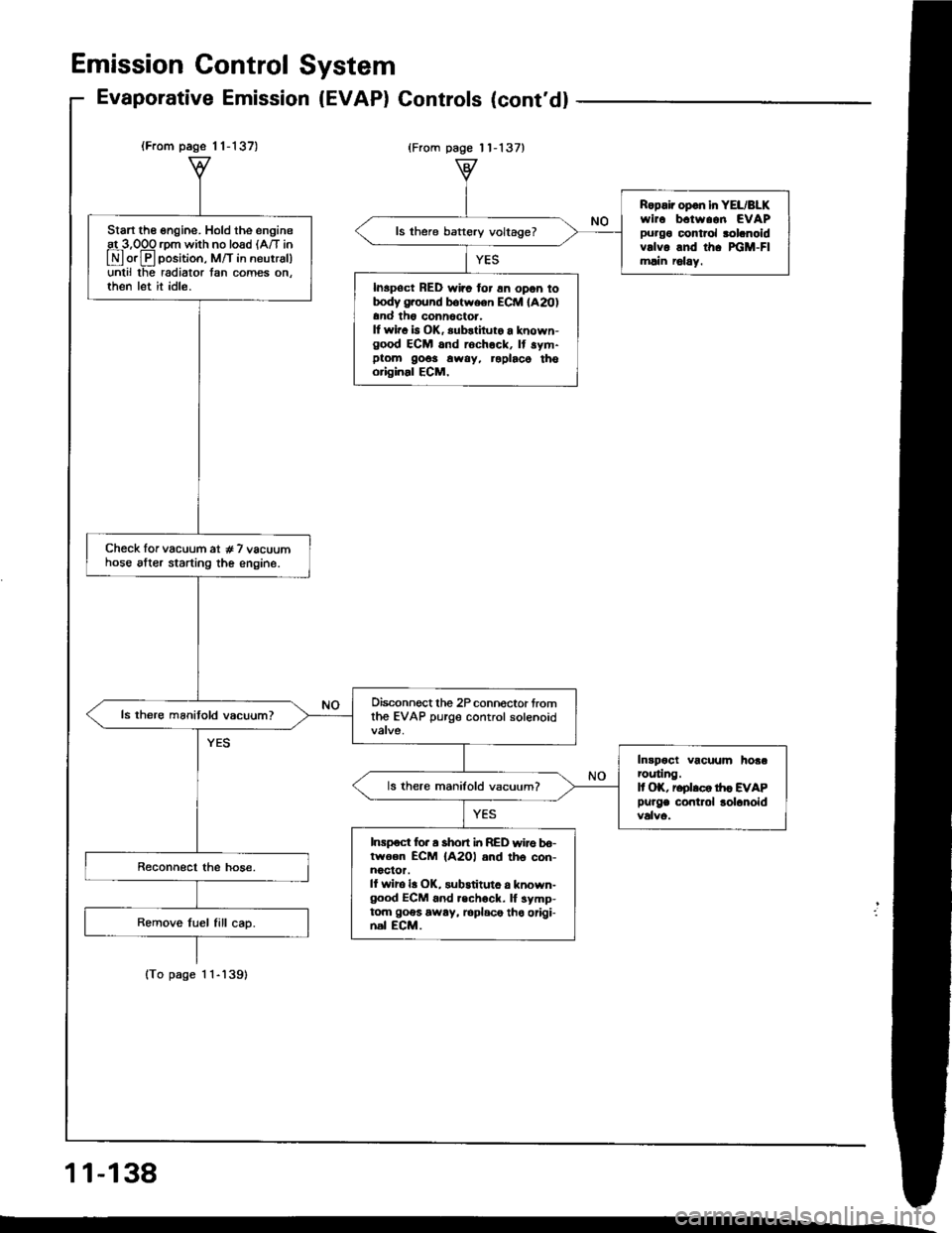

(From page 1 1-137)

lTo page 1 1-'l39)

Start the engine. Hold the engineat 3,OOO rom with no load lA/T in

E orE position, M/T in neutrsl)unlil lhe radiator tan comes on.then let it idle.

Check lor vacuum at # 7 vacuumhose alter starting the engine.

Oisconnect the 2P connoctor fromthe EVAP purge control solenoid

Intpoct vacuum hoaarcuting.It OK, reolrco tr|c EVAP

Purge contlol lolanoid

ls there manifold vacuum?

Inrpoct for a short i|t RED wire bo-lwoen ECM {A2Ol and th6 con-noclor.ll wiro la OK, substituto a known-good ECM 6nd .echock. lf symp-tom goes away, loplace tho origi-nal ECM.

Ropair opon in YEL/BLKwirc b.tw..n EVAPpurgo control rolanoidvrlvo and th. xiM-Flmlin r6lay.

ls there baftery voltage?

Inspoct RED wirc for 6n opon totrody g.ound botween ECM lA20)and th6 conn6ctor.It wir. b OK, substiluto a known-good ECM and rochock, It sym-ptom 9o6s away, roplaco thooriginal ECM,

Emission Gontrol System

Evaporative Emission (EVAP) Gontrols (cont'd)

{From page 11-137}

11-138

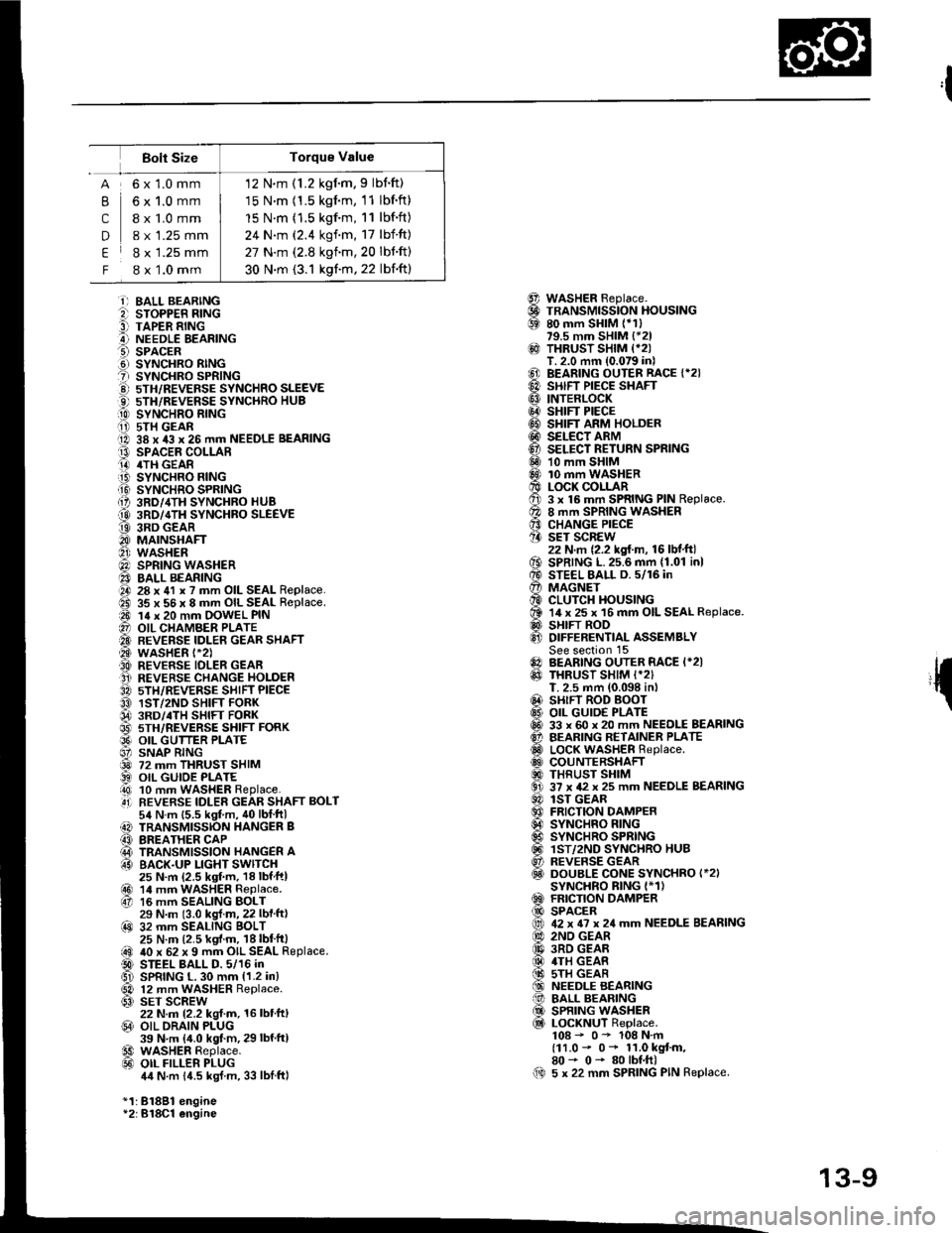

Page 351 of 1413

12 N.m (1.2 kgim,9 lbnft)

15 N.m (1.5 kgnm, 11 lbf.ft)

15 N.m (1.5 kgf.m, 11 lbf.ft)

24 N.m (2.4 kgf.m, 17 lbf'ft)

27 N.m (2.8 kgnm,20 lbnft)

30 N.m (3.1 kgf.m, 22 lbf'ft)

Bolt Size

,l

{

@@69

@

@@@@@@@@6Dq0

o€xv0@

@0!@@@@al

61@

B

c

D

E

F

6x1.0mm

6x1.0mm

I x 1.0 mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.0 mm

i) BALL BEARINGe sroPPER R|NG9 TAPER RINGA NEEDLE EEARINGO SPACER.d SYNCHRO RINGt sYNcHRo SPR|NG!) 5TH/REVEFSE sYNcHRo SLEEVEO 5TH/REVERSE SYNCHRO HUB[0 sYrucxao nlrucii i) 5TH GEARO 38 x 43 x 26 mm NEEDLE BEARINGt3 SPACEE COLLARO 4TH GEAR.iB SYNCHRO FING.Ii9 SYNCHRO SPRING{, 3RD/,ITH SYNCHRO HUB

@ 3RD/4TH SYNCHBO SLEEVEt9 3RD GEARO MAINSHAFTO wasHER@) SPRING WASHER40 BALL BEARINGO 28 x 41 x ? mm OIL SEAL Replace.ad 35 x 56 x 8 mm OIL SEAL Replace.a0 14 x 20 mm OOWEL PIN@ OIL CHAMBER PLATE'A BEVERSE IDLEN GEAR SHAFT@ wasHER t-2).A REVERSE IDLER GEAFO REVERSE CHANGE HOLDER3A sTH/REVERSE SHIFT PIECEO 1ST/2ND SHIFT FORK04 3RD/.TH sHlFr FoRK@ 5TH/REVERSE SHIFT FORKO9' OIL GUTTER PLATE6' SNAP RING@ 72 mm THRUST SHIM) OIL GUIOE PLATEi!0 10 mm WASHER Replace..4i] REVERSE IDLER GEAR SHAFT BOLT54 N.m {5.5 kgt m, 40lblftl) TRANSMISSION HANGER B(3 BREATHER CAP@ TRANSMISSION HANGER A63 BACK.UP LIGHT SWITCH25 N.m (2.5 ksf.m, 18lbfftl@r 14 mrn waSHER Replace.67 16 mm SEALING BOLT29 N.m (3.0 kgl.m, 22 lbf ft)@ 32 mm SEALING BOLT25 N.m (2.5 kgf.m. 18lbt'ft|@ 40 x 62 x 9 mm OIL SEAL Replace.D STEEL BALL D. 5/16 inGl SPRING L. 30 mm {1.2 in}

@ 12 mm WASHER Replace.63) SET SCREW22 N.m 12.2 kgl.m, 16 lbt'ft,@ OIL ORAIN PLUG39 N.m {4.0 kgt.m, 29 lbf'ftl€9 WASHER Replace.@ oIL FILLER PLUG4,1N.m 14.5 kgJ m, 33 lblftl

*1:81881 engine*2:B18Cl engine

WASHER Beplace.TRANSMISSION HOUSING80 mm SHIM (*1)79.5 mm SHIM {*21THRUST SHIM {*2IT. 2.0 mm (0.079 in)BEARING OUTER RACE {*2}SHIFT PIECE SHAFTINTERLOCKSHIFT PIECESHIFT ARM HOLDERSELECT ARMSELECT RETURN SPRING10 mm SHIM10 mm WASHERLOCK COLLAR3 x 16 mm SPRING PIN Replace.8 mm SPRING WASHERCHANGE PIECESET SCREW22 N.m {2.2 kgf.m, 16 lbf.ft}SPRING L.25.6 mm {1.01 inlSTEEL BALL D. 5/16 inMAGNETCLUTCH HOUSING14 x 25 x 16 mm OIL SEAL Replace.SHIFT RODDIFFERENTIAL ASSEMBLYSee section 15BEARING OUTER RACE I*2ITHRUST SHIM I*2)T. 2.5 mm (0.098 in,SHIFT ROD BOOTOIL GUID€ PLATE33 x 60 x 20 mm NEEDLE BEARINGBEARING RETAINER PLATELOCK WASHER Replace.COUNTERSHAFTTHRUST SHIM37 x 42 x 25 mm NEEDLE BEARINGlST GEARFRICTION DAMPERSYNCHRO RINGSYNCHRO SPRINGlST/2ND SYNCHRO HUBREVERSE GEARDOUBLE CONE SYNCHRO I*2ISYNCHRO BING I*1)FRICTION DAMPERSPACER42 x 6? x 24 mm NEEDLE BEARING2ND GEAR3RD GEAR4TH GEAS5TH GEARNEEDLE BEARINGBALL BEARINGSPRING WASHERLOCKNUT Replace.108 - 0- 108 N.m(11.0 - 0* 11.0 kgt m,80- 0- 80lbf.ft)5 x 22 mm SPRING PIN Replace.00

13-9

Page 352 of 1413

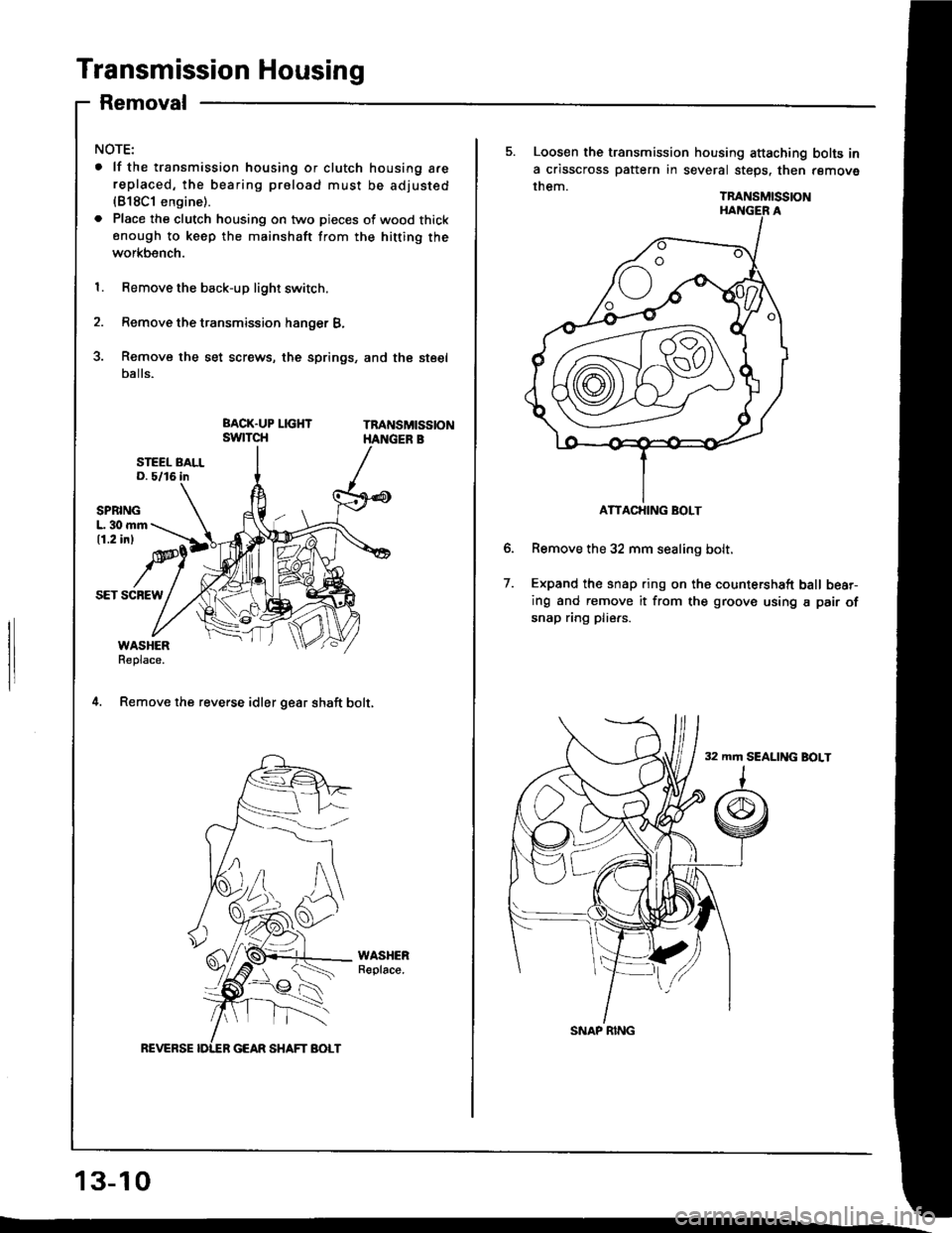

Transmission Housing

Removal

NOTE:

. lf the transmission housing or clutch housing a.ereplaced, the bearing proload must be adjusted(818C1 engine).

. Place the clutch housing on two pieces of wood thickenough to keep the mainshaft from the hitting the

workbench.

1. Remove the back-up light switch.

2. Remove the transmission hanger B,

3. Remove the set screws, the springs, and the steel

balls.

Tna sMtsstoN

SPBINGL. 30 mm11.2 inl

SET SCBEW

WASHERReplace.

4. Remov€ the reverse idler gear shaft bolt,

WASHERReplace.

REVERSE

L

13-10

ATTACHING BOLT

5. Loosen the transmission housing attaching bolts in

a crisscross pattern in several steps. then remove

them.TRANSMISSION

Remove the 32 mm sealing bolt.

Expand the snap ring on ths countershaft ball bear-

ing and remove it from the groove using a pair of

snap ring pliers.

32 mm SEALING BOLT

7.

SNAP RING

Page 354 of 1413

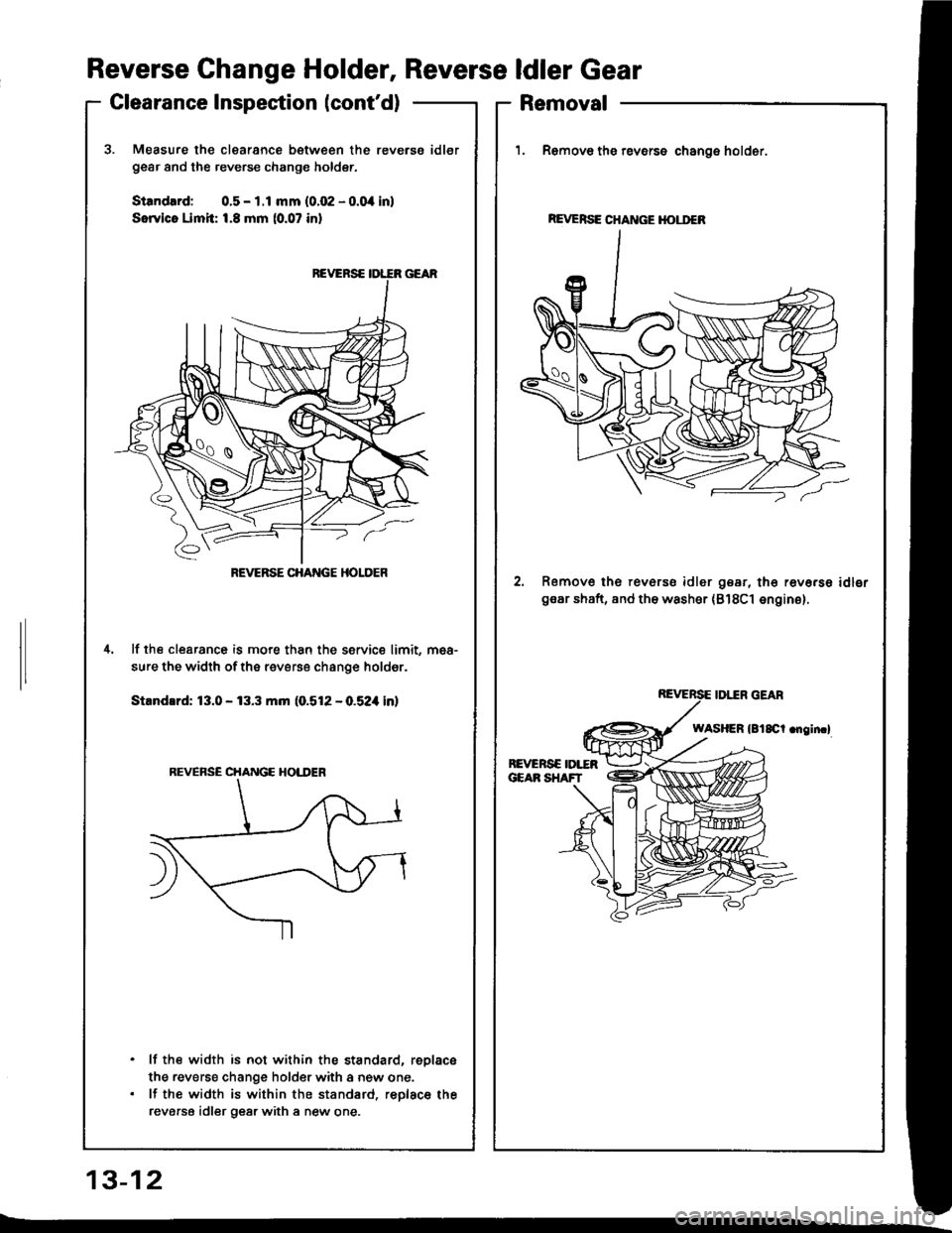

Measure the clearance between the reverss idler

gear and the reverse change holder.

Standard: 0.5 - 1.1 mm (0.02 - 0.04 inl

Sorvico Limit: 1.8 mm (0.07 inl

4.lf the clearance is more than the service limit, mea-

sure the width ofthe reverse change hold6r.

St.ndrrd: 13.0 - 13.3 mm (0.512 - 0.52/t inl

lf the width is not within the standard, replace

the reverse change holder with a new one.

lf the width is within the standard, reolaco the

reversa idler gear with a new one.

REVERSE CHA'{GE HOLDER

REVERSE CHANGE HOTI'ER

Reverse Change Holder, Reverse ldler Gear

Clearance Inspection lcont'd)Removal

1. Removo the reverse change holder.

2. Remove the revorss idler g€ar, th€ rev6rs6 idlsrgear shaft, and the washor {B18Cl engine}.

REVERSE IDI.TRGEAF SHAFT

13-12

REVERSE CHAMiE HOII'ER

Page 384 of 1413

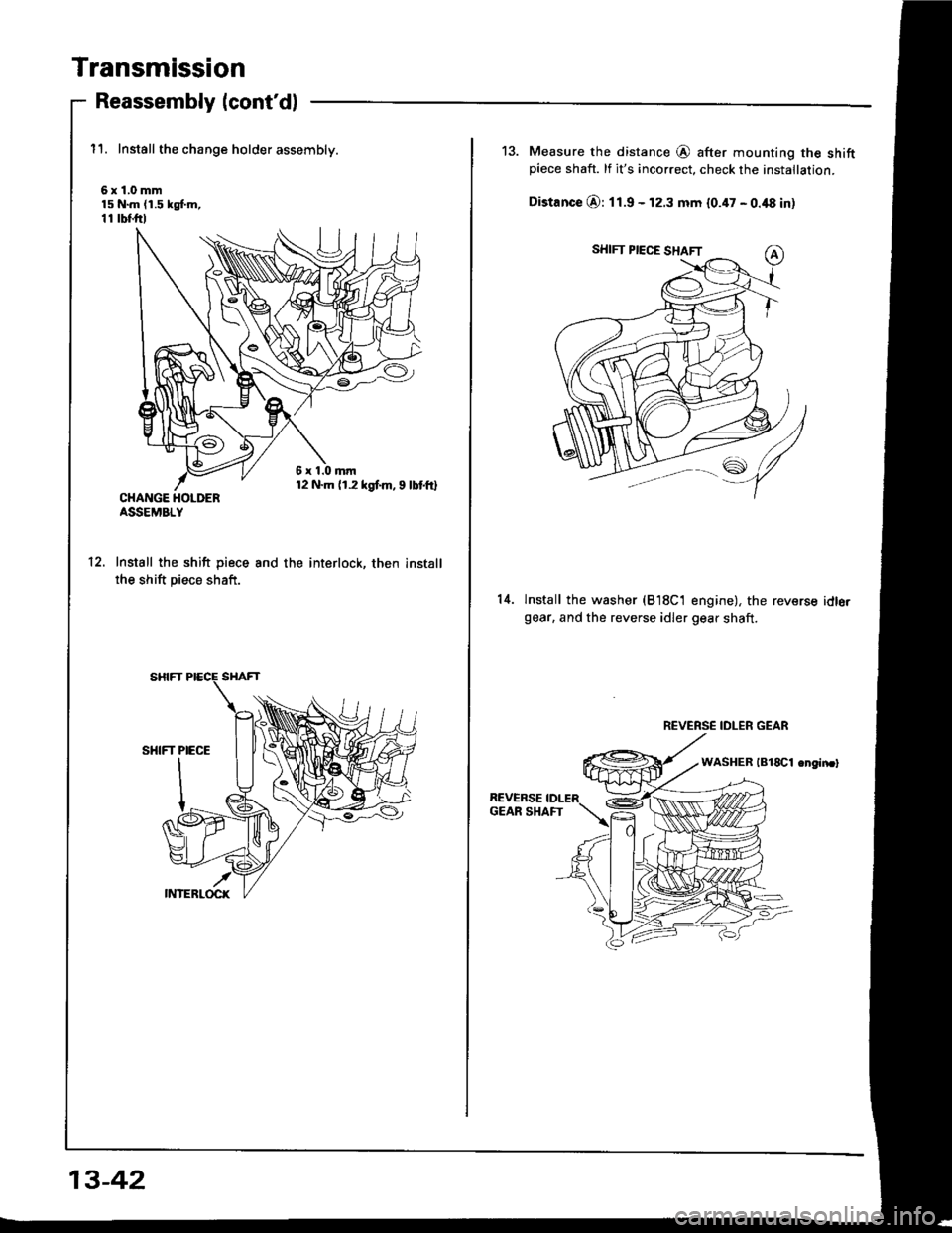

Transmission

Reassembly (cont'd)

11. Install the change holder assembly.

6x1.0mm15 N.m (1.5 kgf.m,11 tbf.ftl

CHANGE HOLDERASSEMBLY

Install the shift piece

the shift piece shaft.

and the interlock, then install12.

13-42

13. Measure the distance @ after mounting the shiftpiece shaft. lf it's incorrect, check the installation.

Distance O: 11.9 - 12.3 mm 10.47 - 0.48 in)

14.lnstall the washer (B18C1 engine), the reversegear. and the reverse idler gear shaft.

idlo.

REVERSE IDLER GEAR

Page 387 of 1413

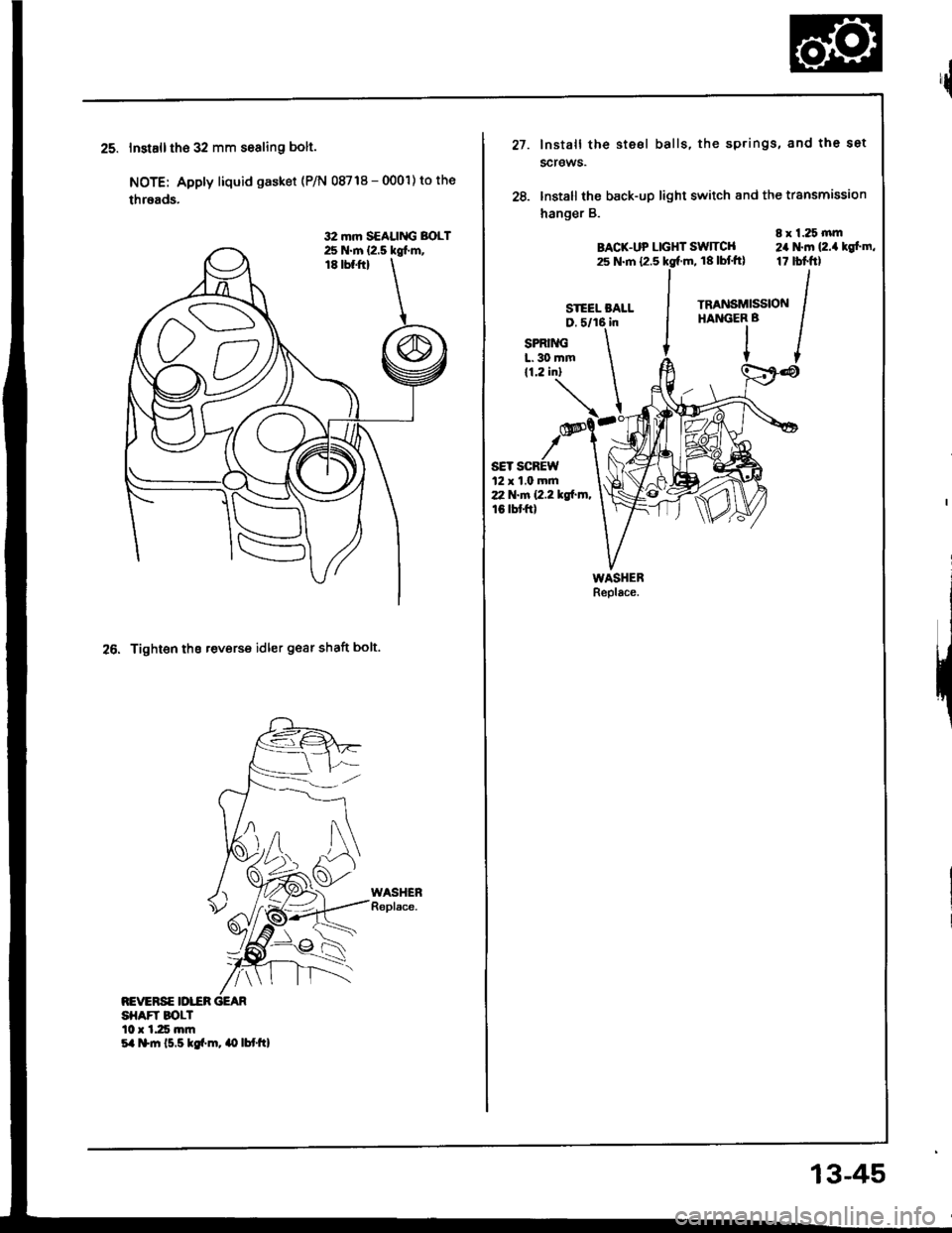

32 mm SEALING BOLT25 N.m {2.5 kgl'm,

24.Installth€ 32 mm sesling bolt.

NOTE: Apply liquid gasket (P/N 08718 - 0001) to the

threads.

26. Tight€n ths teverse idler gear shaft bolt.

REVERSE IDI.^CRSHAFT IOLTl0 r 1.25 rnm5a t$m 15.5 kg{.m. (} lbtftl

13-45

{

27.

28.

Install the stesl balls, the sp.ings, and the set

screws.

lnstall the back-up light switch and the transmission

hanger B.

8 x 1.25 mmBAC|(-UP LTGHT SWITCH 24 N.m (2.4 kgfm,2s N.m {2.5 kg{.m, 18lbtft) 17 lbtftl

,*"""."'" /HAiIGER B I

l/SPRIMiL. 30 mm

{1,2 in}

12 x 1.0 mm22 N.m (2.2 kgi.m.10 tbtft)

Page 409 of 1413

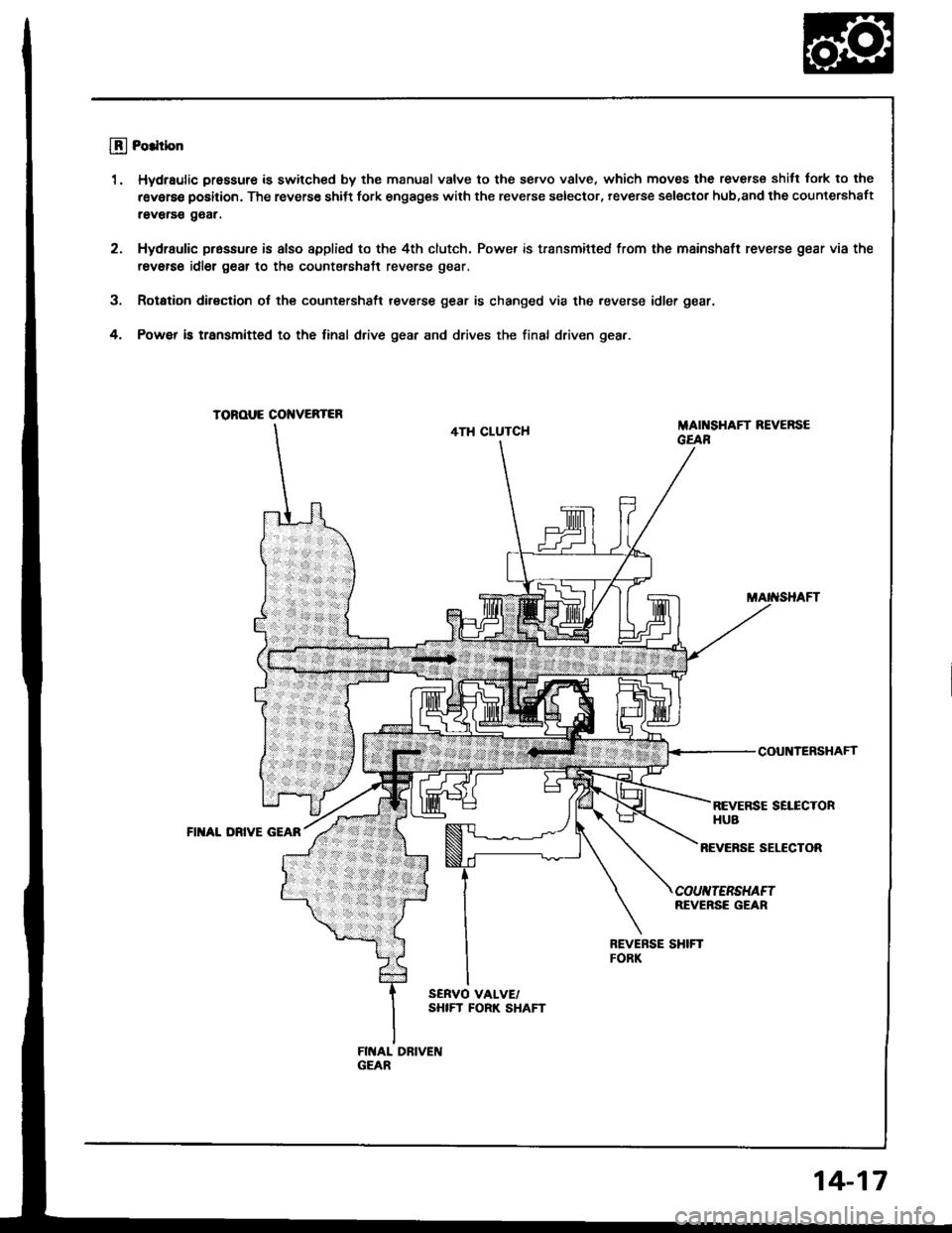

llj Po.ltbn

1. Hydraulic pressure is swilched by the manual valve to the se.vo v8lve, which moves the reverse shilt tork to the

r€verse position. The reverse shiJt fork engages with the reverse selector, reverse selsctor hub,and the countershaft

raverss g€ar.

2. Hydraulic pr6ssure is also appli€d to the 4th clutch. Power is transmifted from the mainshaft reverse gear via the

revetse idler g6ar to the countershaft reverse gear.

3. Rotation dirsction ol the countershsft reverse gear is changed via the .everse idler gear.

4. Powef b transmitted to the linal drive gear and drives the final driven gear.

TOROUE CONVEBTER

4TH CLUTCHMAI SHAFT REVERSEGEAR

COUNTERSHAFf

REVERSE SELECTORHUBFII{AL DRIVE GEAR

REVEFSE SELECTOR

COUIITERSHAFTREVERSE GEAR

14-17

Page 442 of 1413

![HONDA INTEGRA 1994 4.G Service Manual Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

Bl HONDA INTEGRA 1994 4.G Service Manual Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

Bl](/img/13/6067/w960_6067-441.png)

Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

BlinksDisconnected lock-up control solenoidvalve A connector

Short or open in lock-up control sole-noid valve A wire

Faulty lock-up control solenoid valve A

Lock-up clutch does not

engage.

Lock-up clutch does not

disengage.

Unstable idle speed.

14-52

BlinksDisconnected lock-up control solenoidvalve B connector

Short or open in lock-up control sole-noid valve B wire

Faulty lock-up cont.ol solenoid valve B

. Lock-up clutch does not

enga9e.

14-54

Blinks or

OFF

Disconnected throttle position (Tp)

sensor connector

Short or open in TP sensor wireFaully TP sensor

. Lock-up clutch does not

engage.14-56

4BlinksDisconnected vehicle speed sensor(VSS) connector

Short or open in VSS wire

Faulty VSS

. Lock-up clutch does not

engage.'t 4-57

Blinks. Short in A/T gear position switch wire. Faulty A/T gear position switch

. Fails to shift other than

2nde4th gears.. Lock-up clutch does not

engage.

14-58

OFFDisconnected A/T gear position switch

connector

Open in A/T gear position switch wireFaulty A/T gear position switch

Fails to shift other than

2nd-4th gears.

Lock-up clutch does not

en98ge.

Lock-up clutch engages

and disengages alter-

nately.

14-60

7BlinksDisconnected shift control solenoidvalve A connector

Short or open in shitt control solenoidvalve A wire

Faulty shift control solenoid valve A

. Fails to shift (between

1st-4th, 2nd-4th or

2nd-3rd gears only).. Fails to shift (stuck in

4th gear).

14-62

8BlinksDisconnected shitt control solenoid

valve B connector

Shon or open in shift control solenoidvalve B wi.e

Faulty shift control solenoid valve B

. Fails to shiJt (stuck in

lst or 4th gears).'t 4-64

aBlinksDisconnected countershatt speed sen-sor connector

Short or open in the countershaft

speed sensor wire

Faulty countershaft speed sensor

. Lock-up clutch does not

engage_

14-50

Page 478 of 1413

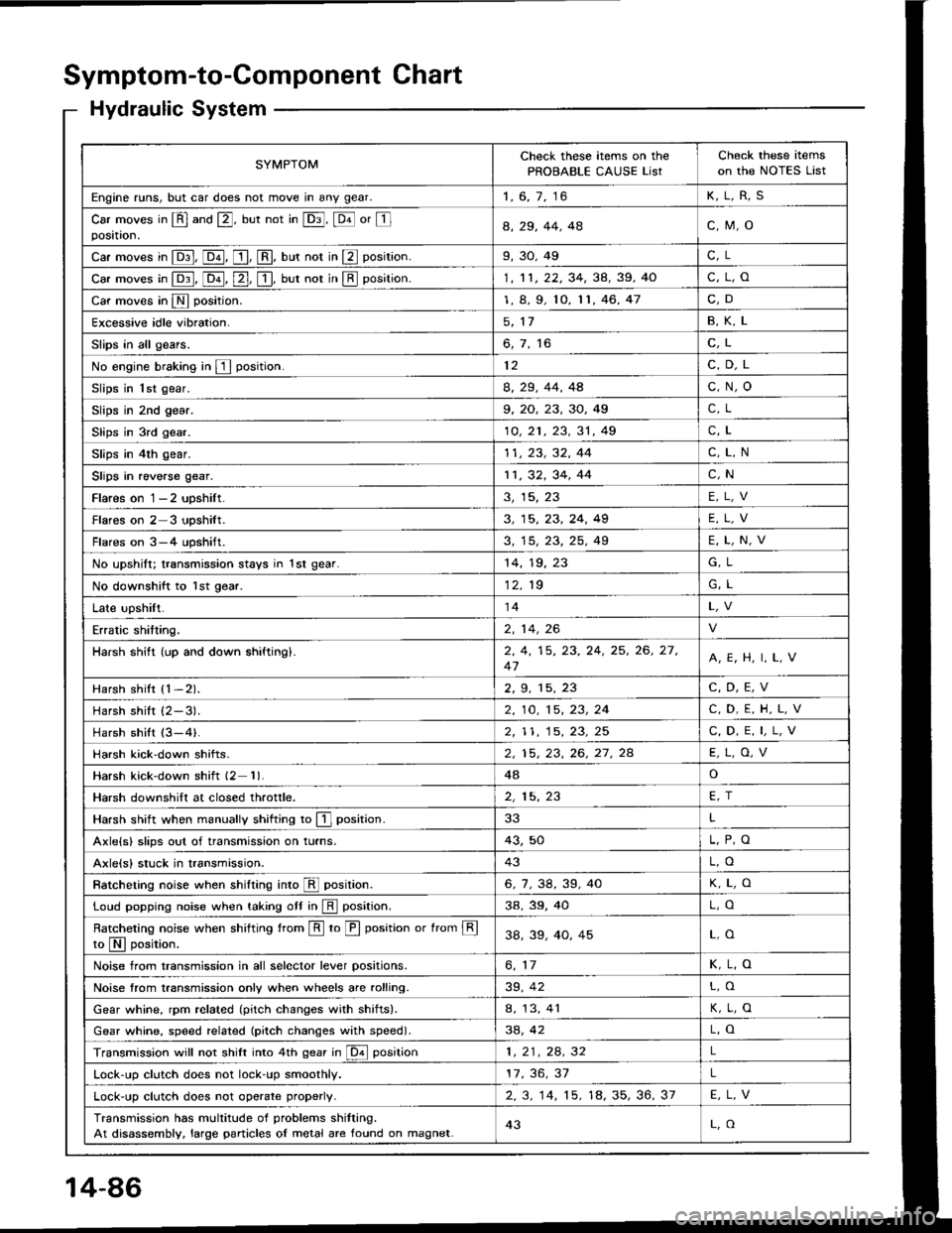

Symptom-to-Component Chart

Hydraulic System

SYMPTOMCheck these items on the

PROBABLE CAUSE ListCheck these items

on the NOTES List

Engine runs, but car does not move in any gear.1, 6, 7, 16K,L,R,S

Car moves in @ and @, but not in @, @ or Iposataon.a, 29, 44. 4ac,M,o

Car moves in E, @, [, @, uut not in E position.9,30,49C, L

car moves in p:1, [o-il, [2-], [!, uut not in E position.1, 11, 22, 34, 38, 39, 40c,L,o

Car moves in N position.1, 8, 9, 10, 11,46,47C,D

Excessive idle vibration.5, 1'1B,K,L

Slips in all gears.6, 7, 16C,L

No engine braking in E position.12C,D,L

Slips in 1st gear.8, 29, 44, 4Ac,N,o

Slips in 2nd gear.9, 20, 23, 30, 49C, L

Slips in 3rd gear.10, 21 , 23, 31 , 49C,L

Slips in 4th gear.11, 23, 32, 44C,L,N

Slips in reverse gear.11,32,34,44C,N

Flares on 1-2 upshilt.3, 15, 23E,L,V

Flareson2 3 upshilt.3, 15, 23, 24, 49E,L,V

Flares on 3-4 upshift.3, 15, 23, 25, 49E,L,N,V

No upshift; transmission stays in 1st gear.14,19,G, L

No downshift to lst gear.12. 19G, L

Late upshift.14

Erratic shitting.2, 14,26

Harsh shift (up and down shiftingl.2, 4, 15, 23, 24, 25, 26, 27,

47A,E, H, I, L,V

Harsh shitt {1-2).2, 9. 15, 23C,D,E,V

Harshshilt (2-3).2, 10, 15, 23, 24C,D,E,H,L,V

Harsh shift (3-4).2,| 1, 15, 23, 25C, D, E, I,L,V

Harsh kick'down shifts.2, 15, 23, 26, 27. 2AE,L,O,V

Harsh kick-down shift 12 1)48o

Harsh downshift at closed throttle.2, 15, 23FT

Harsh shift when manually shifting to E] position.33L

Axle{s} slips out of transmission on turns.43,50

Axlels) stuck in transmission.43L,O

Ratcheting noise when shifting inro E position.6,7,38,39,40K,L,O

Loud popping noise when taking ott in E position.3a,39,40L,O

Ratcheting noise when shifting from E to E position or from Eto N I oosition.38,33,40,45L,O

Noise from transmission in all selector lever positions.6, 11K,L,O

Noise trom transmission only when wheels are rolling.39, 42L,O

Gear whine, rpm related (pitch changes with shitts).a, 13, 41K,L,O

Gear whine, speed rel6ted (pitch changes with speed).38, 42L,O

Transmission will not shift into 4th gear in @ position1,21,24.32L

Lock-up clutch does not lock-up smoothly.17, 36, 37L

Lock-up clutch does not operate properlV.2.3. 14, 15. 18, 35, 36, 37E,L,V

Transmission has multitude of problems shitting.

At disassembly, large particles oI metal are found on magnet.43L,O

14-86