Idle HONDA INTEGRA 1994 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 304 of 1413

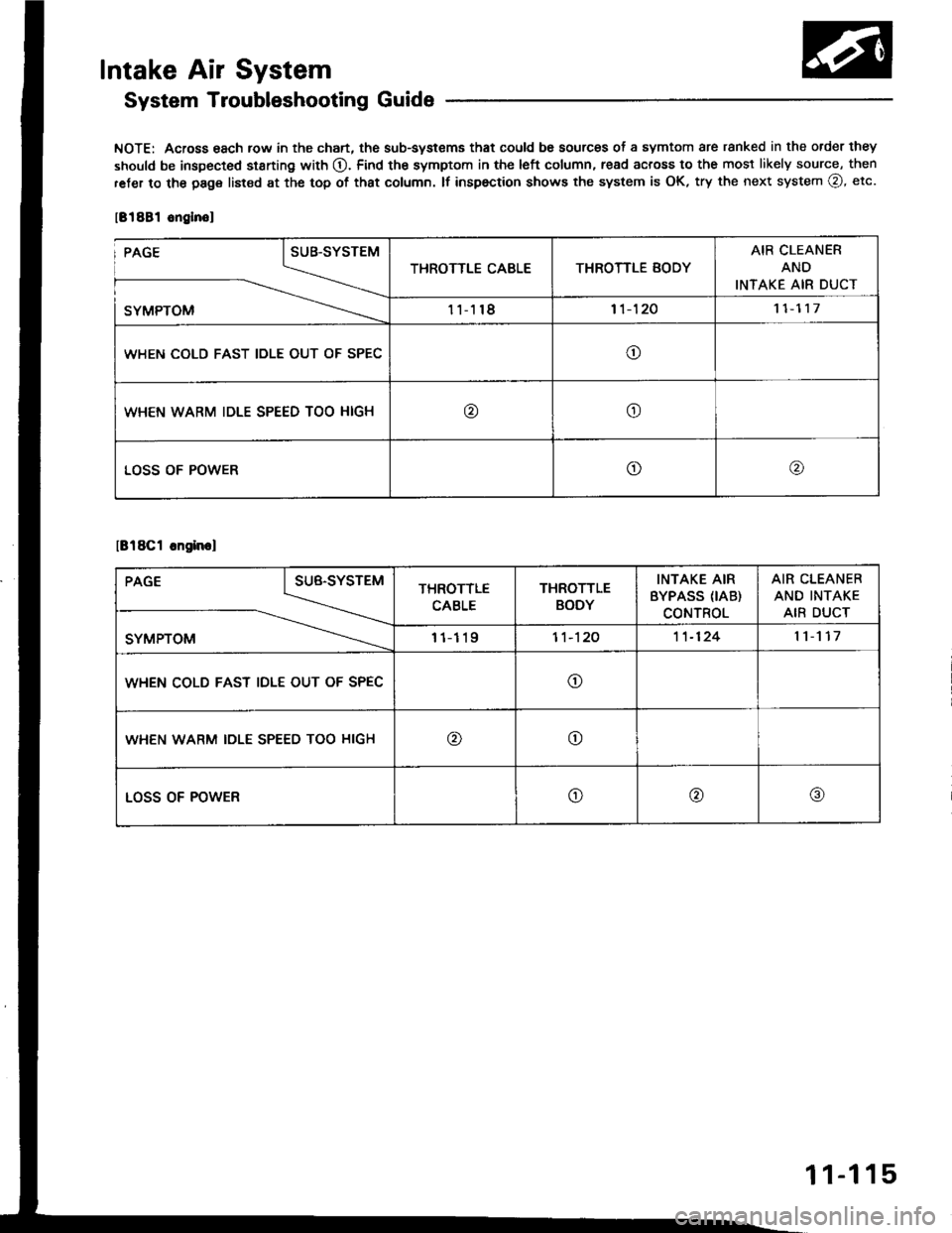

Intake Air System

System Troubleshooting Guide

NOTE: Across 6ach row in the chart, the sub-systems that could be sources of a symtom are ranked in the order they

should be inspected st8rting with O. Find the symptom in the left column, read across to the most likely source, then

ret€r to the page listod at the top of that column. tf inspection shows the system is OK, try the next system @, etc.

181881 onglnol

't 1-11711-118

WHEN COLD FAST IOLE OUT OF SPEC

WHEN WARM IDLE SPEED TOO HIGH

lB18Cl cngin.l

PAGE I sue-svsreu

_\.-..\

sYMPToM \---...-

THROTTLE

CABLE

THROTTLE

BODY

INTAKE AIR

BYPASS (IAB)

CONTROL

AIR CLEANER

AND INTAKE

AIR DUCT

111191'�t -12011-1241l117

WHEN COLD FAST IDLE OUT OF SPECo

WHEN WARM IDLE SPEED TOO HIGHoo

LOSS OF POWERo@@

11-115

Page 305 of 1413

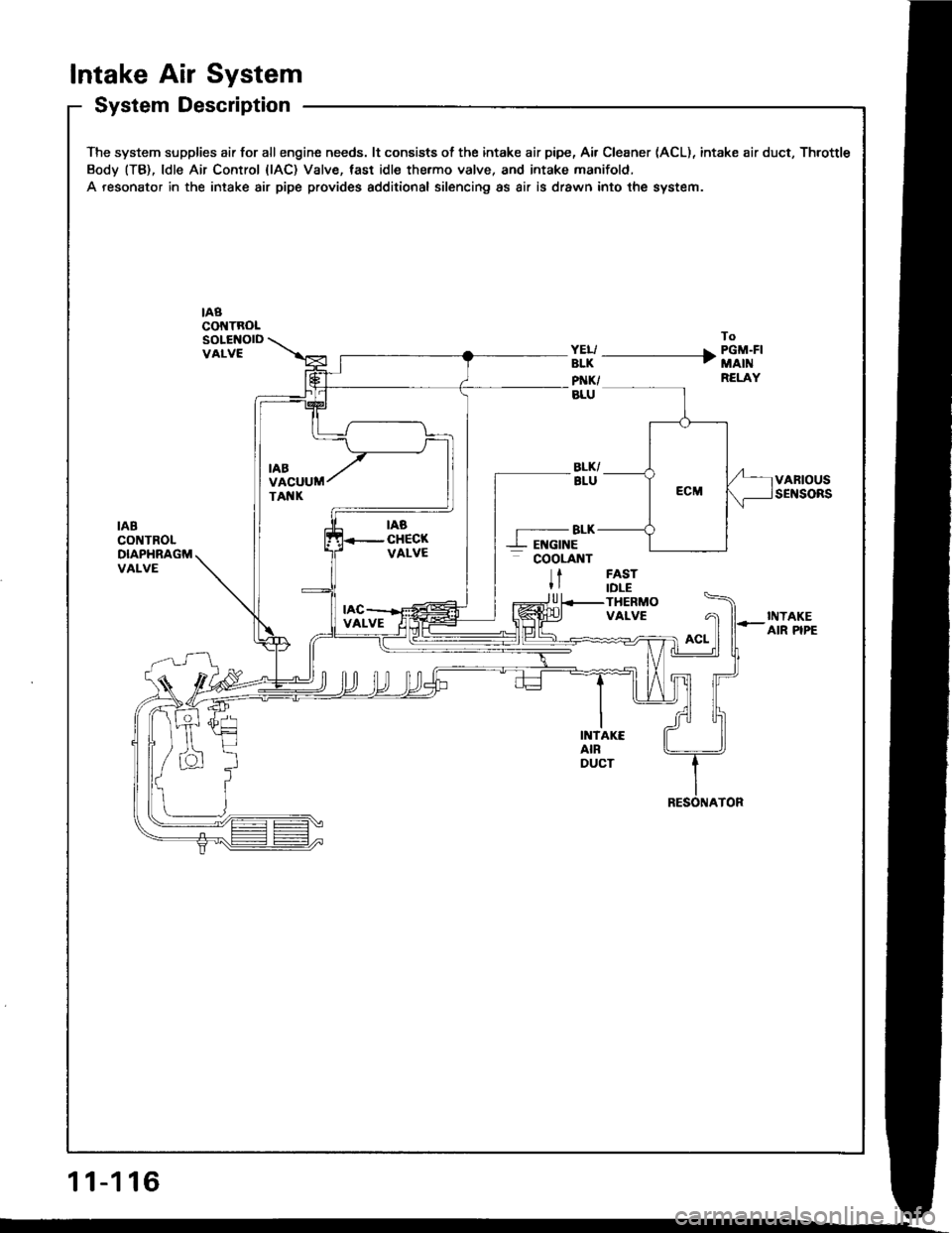

Intake Air System

System Description

The system supplies air for allengine needs. lt consists of the intake air pipe, Air Cleaner (ACL), intake air duct, Throttle

Body (TB), ldle Air Control {lAC) Valve, tast idle thermo valve, and intake manifold.

A resonator in the intake air pipe provides additional silencing as air is drawn into the system.

nacot{TRoLSOLENOIDVALVE

To

ffi -------------+ i'"ii'i''RELAY

VARIOUSSENSORS

IABCONTROLDIAPHRAGMVALVE

-BLK--L EI{GINE- cooLnnt

tFASTIDLETHERMOVALVE

U

INTAKEAIR PIPE

INTAKEAIRDUCT

11-116

Page 307 of 1413

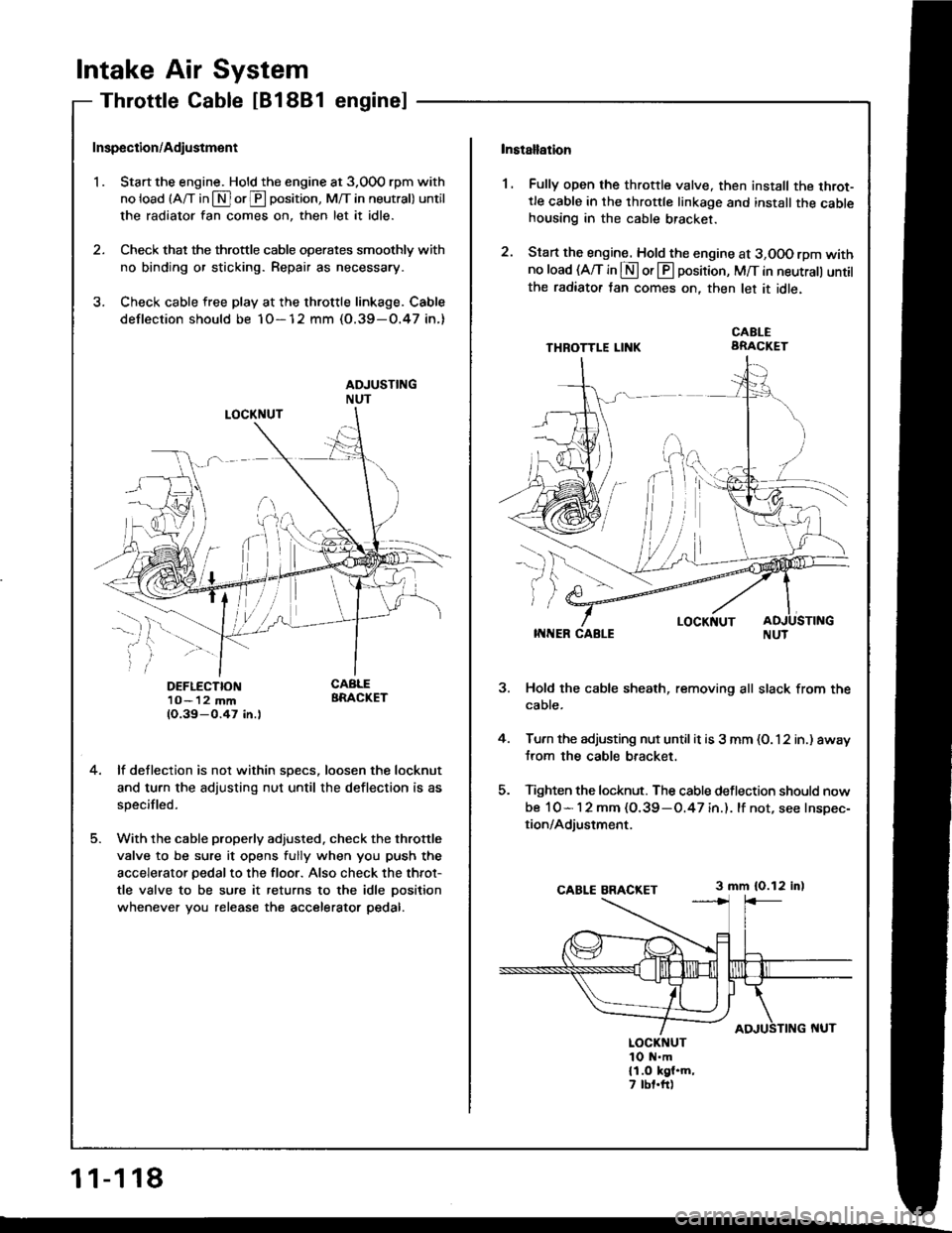

Intake Air System

Throttle cable [81881 enginel

1 1-1 18

Inspection/Adiustment

'I . Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in $ or@ oosition, M/T in neutral) until

the radiator fan comes on, then let it idle.

2. Check that the throttle cable operates smoothly with

no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 1O-12 mm (O.39-O.47 in.)

DEFLECTION1O- 12 mm1O.39-0.47 in.l

4.lf deflection is not within specs, loosen the locknut

and turn the adjusting nut until the deflection is as

specifled.

With the cable properly adjusted. check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle oosition

whenever you release the accelerator pedal.

Installation

1. Fully open the throttle valve. then install the throt-tle cable in the throttle linkage and install the cablehousing in the cable bracket.

2. Start the engine. Hold the engine at 3,OOO rpm withno load (A/T in S or @ position, M/T in neutrall untilthe radiator tan comes on, then let it idle.

THBOTTLE LII{KCABLEARACKET

i;

-l-r

,)

j

5.

LOCKNUTITINER CABLE

Hold the cable sheath, removing all slack from the

cable.

Turn the adjusting nut until it is 3 mm (O. 12 in.) away

trom the cable bracket.

Tighten the locknut. The cable deflection should now

be 10- 1 2 mm (O.39 -O.47 in.). lf not, see Inspec-

tion/Adjustment.

3 mm {0.12 in)

LOCKNUT1O N.m{1.O kgl.m,7 tbt.ft)

Page 308 of 1413

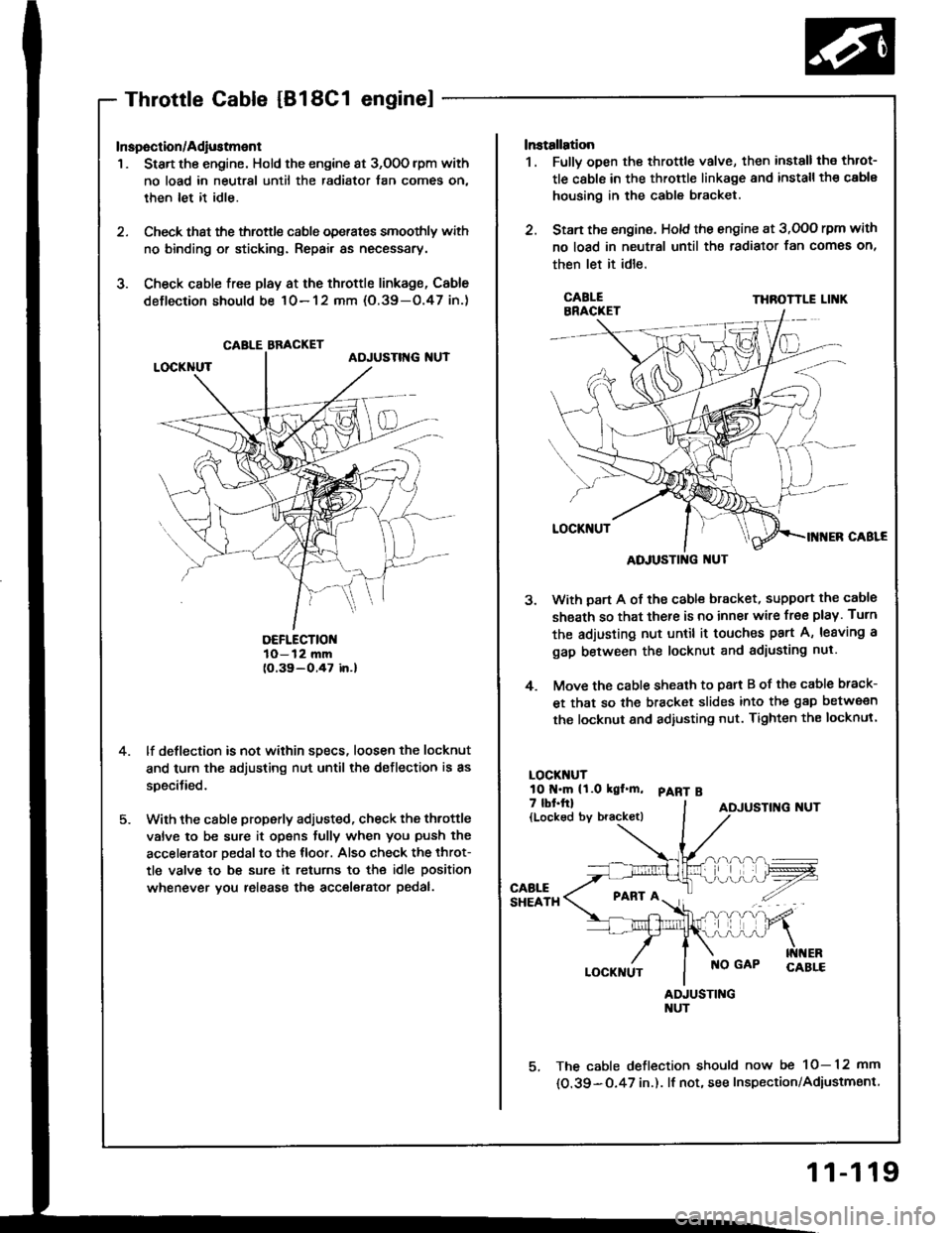

Throttle cable [B18C1 enginel

Inspection/Adiustment

1 . Start the engine. Hold the engine at 3,O0O lpm with

no load in neutral until the radiator fan comes on,

then let it idle.

2. Check that the throttl€ cable operates smoothly with

no binding or sticking. Repair as necessary.

3. Check csble free play at the throttle linkage, Cable

deflection should be 10-12 mm (O.39-O.47 in.)

DEFLECTIOI{10-12 mm(O.39-O.47 in.l

lf deflection is not within sDecs, loosen the locknut

and turn the adjusting nut until the deflection is as

specitied.

With the cable properly adjusted, check the throttle

valve to be sure it opens fully when you push the

accelerator Dedal to the tloor. Also check the throt-

tle valve to be sure it retums to the idle position

whenever vou release the accel€rator pedal.

CABLE BBACKET

ADJUSTING I{UT

lnstallation

1. Fullv open the throttle valve, then install the throt-

tle cable in the throttle linkage and install th€ cable

housing in the cable bracket.

2. Stan the engine. Hold the engine at 3,OOO rpm with

no load in neutral until the radiator fan comes on,

then let it idle.

THROTTLE LI K

With part A of the cabl€ bracket, support the cable

sheath so that there is no inner wire free play. Turn

the adjusting nut until it touches part A, leaving a

gap between the locknut and adiusting nul.

Move the cable sheath to psrt B of the cable brack-

et that so the bracket slides into the gap between

the locknut and adiusting nut. Tighten the locknul.

LOCKT{UTlO t{.m (t.O kgl.m, pART B

5.

4.

7 lbt.ftl{Locked by bracket)ADJUSTING NUT

PABT A

LOCKNUTNO GAP

AIUUSTINGNUT

5, The cable deflection should now be 10-12 mm

{O.39-O.47 in.). lf not, see Inspection/Adiustmsnt

11-119

Page 309 of 1413

lntake Air System

Throttle Body

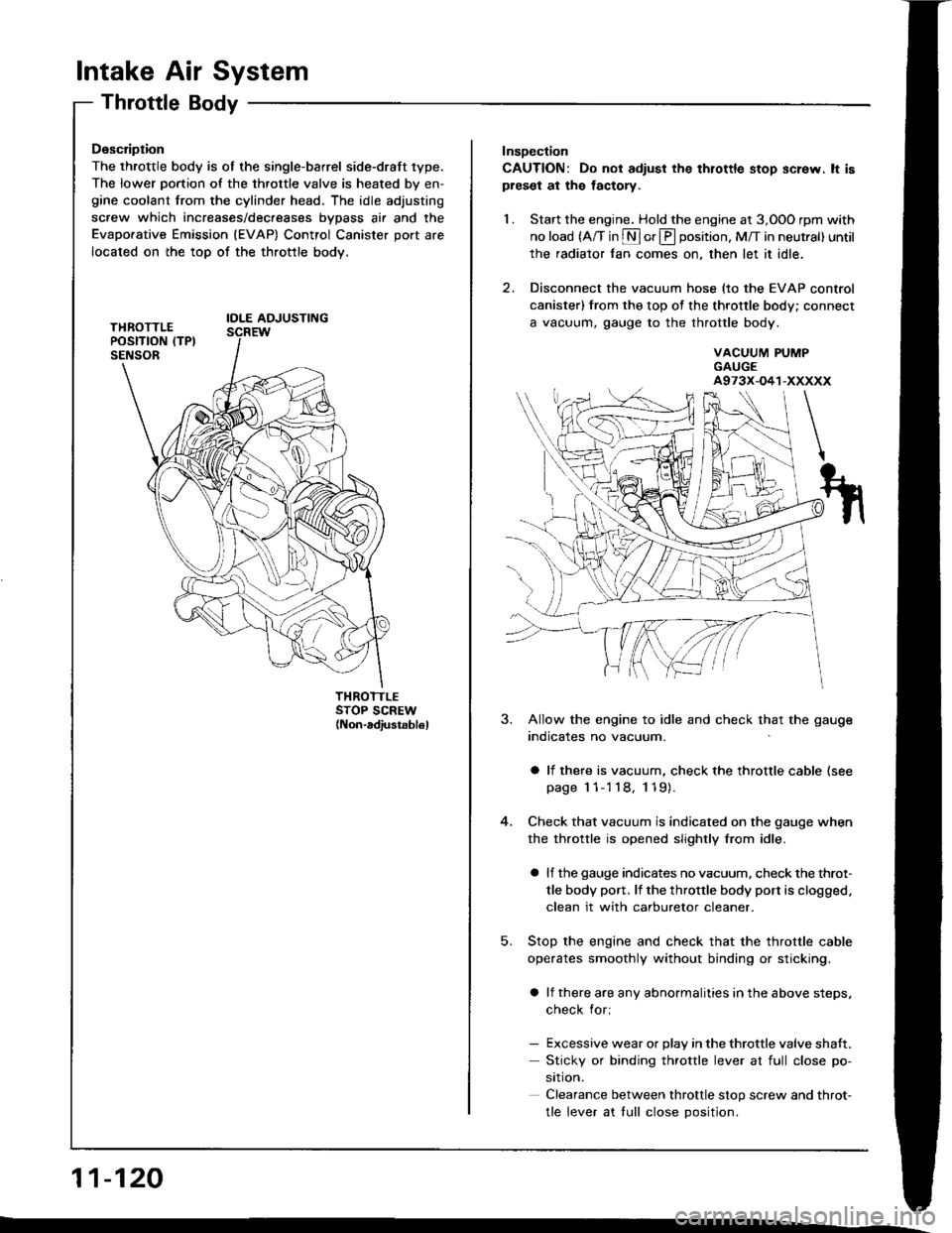

Description

The throttle body is ot the single-barrel side-draft 1ype.

The lower portion of the throttle valve is heated by en-gine coolant from the cylinder head. The idle adjusting

screw which increases/dec.eases bvDass air and the

Evaporative Emission (EVAP) Control Canister port are

located on the top of the throttle body.

IOLE AOJUSTING

THROTTLESTOP SCREW(Non-adiustsb16l

11-120

Insoection

CAUTION: Do not adiust the thlottle stop screw. lt ispreset at the lactory.

1. Start the engine. Hold the engine at 3,OOO rpm with

no load (A/T in S or E position, M/T in neutral) until

the radiator fan comes on, then let it idle.

2. Disconnect the vacuum hose (to the EVAP control

canister) from the top of the throttle body; connect

a vacuum, gauge to the throttle body.

VACUUM PUMPGAUGEA973X-O41-XXXXX

5.

3. Allow the engine to idle and check that the gauge

indicates no vacuum.

a li there is vacuum, check the throttle cable (see

page 1 1-'l 18, 119).

Check that vacuum is indicated on the gauge when

the throttle is opened slightly from idle.

a lf the gauge indicates no vacuum, check the throt-

tle body port. lf the throttle body port is clogged.

clean it with carburetor cleaner.

Stop the engine and check that the throttle cable

operates smoothly without binding or sticking.

a lf there are any abnormalities in the above steps,

check for:

- Excessive wear or Dlav in the throttle valve shaft.

Sticky or binding throttle lever at full close po-

srtron.

Clearance between throttle stop screw and throt-

tle lever at tull close Dosition.

Page 311 of 1413

Intake Air System

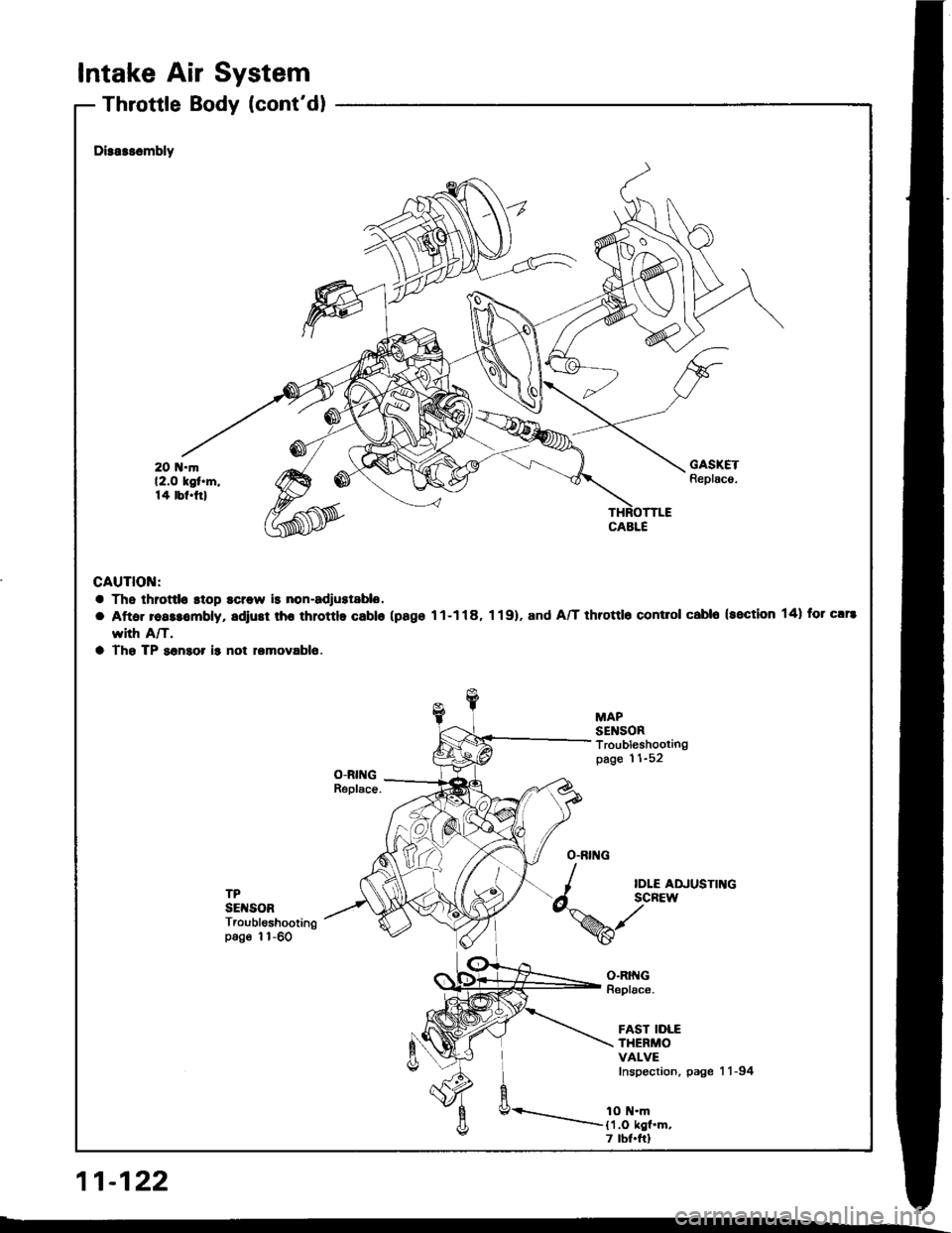

Throttle Body (cont'dl

11-122

Dirarssmbly

GAUTION:

a Ths throttlo stop scrow is non-adrustablo.

a Aftar reassombly, adiust rhr throttlo Gablo (pago 11-118, 1 19). and A/T throttlo contlol cabl6 (section 14) for c!r8

rYith A/T.

a Tho TP sonaor ir not lomovablo

MAPSENSORTroubleshootingpage 11-52

TPSETSORTroubleshootingpoge 1l-60

O.BING

I

d^'%

IDLE ADJUSTINGSCREW

o-RtftGReplace.

FAST IDLETHERMOVALVEInspection, page 11-94

1O N.m11.O kgl.m.7 tbf.ftl

Page 313 of 1413

Intake

Intake

Air

Air

System

Bypass (lAB) ControlSystem tBl8C1 enginel (cont'dl

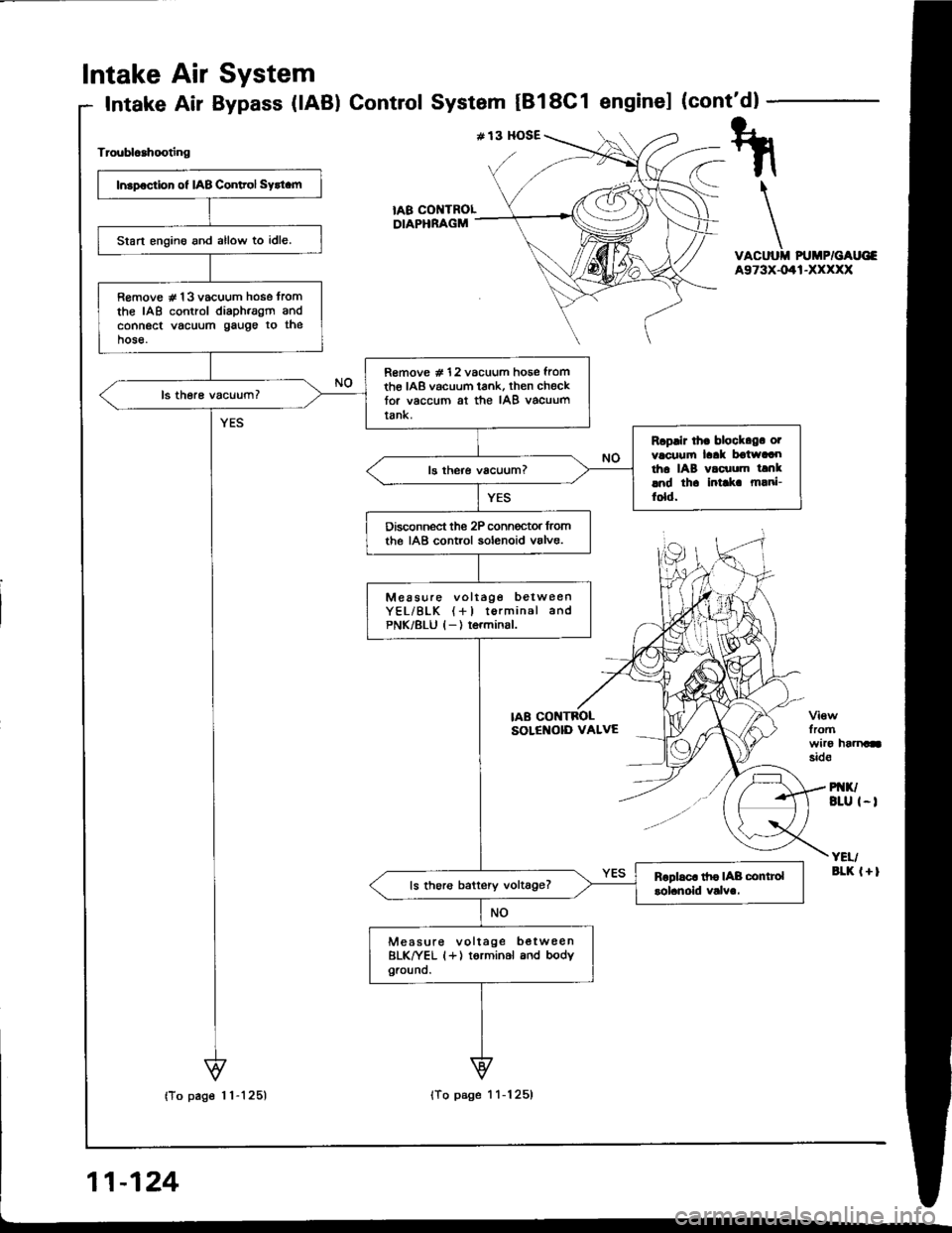

Troublcahooting

VACUUII PUMP/GAUG€A973X-041-XXXXX

fromwiro haanasid€

PI{K/BLU I-I

YEI/aLK l+l

tA8 COI{TROLDIAPHRAGM

Insp€ction of IAB Conltol Sytt.m

Start engino and allow to idle.

R€move # 13 vacuum hose tromthe IAB control diaph.agm andconnect vacuum gauge to thehose.

R€move # 12 vacuum hose fromth€ IAB vacuum tank, then checktor vaccum at the IAB vacuumtank.

Rcplir lh. block.g. otvacuufi laak boiwaaotha IAB vacuum tanklnd th. intlk m!ni-fold.

Disconnect the 2P conn€ctor lromthe IAB control solenoid valve.

Measure voltage betweenYEL/BLK (+l torminal andPNK/8LU l-) terminsl.

ls thoro battery voltage?

Measure voltage b€twee nBLK^|/EL (+) torminal and bodyground.

IAB CONTBOLSOLENOID VALVE

Page 315 of 1413

a

Intake Air System

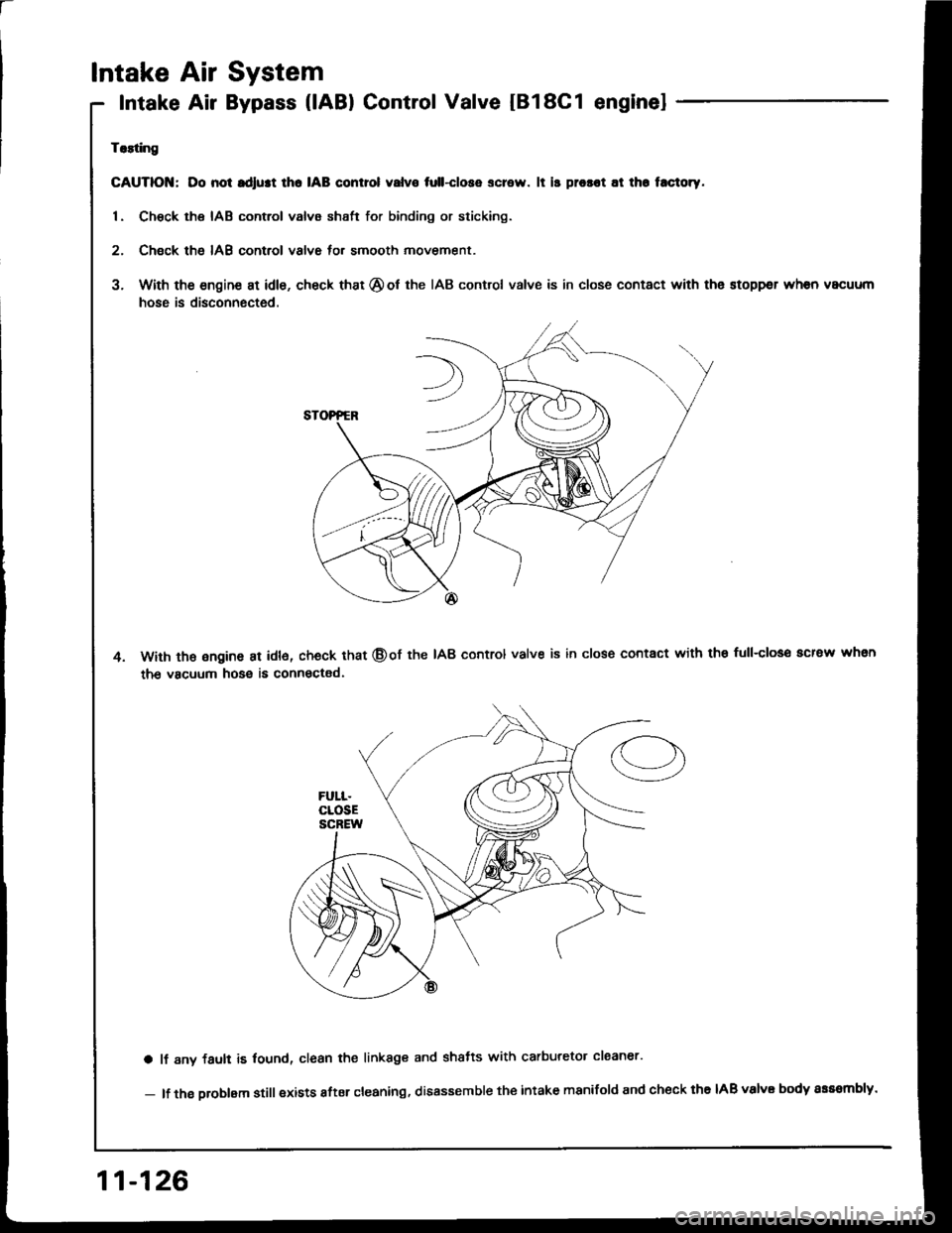

Intake Air Bypass (lABl Control Valve IB18C1 enginel

Trlting

GAUTIOI{; Do not rdlust lho IAB control valvo tull-close screw. lt is prosot at th. t.ctoty.

1. Chsck the IAB control valve shsft for binding or sticking.

2. Check th6 IAB control valve for smooth movement.

3. With the engine at idle, check that @ot the IAB control valve is in close contact with the stoppsr when vacuum

hose is disconnected.

With th€ ongine at idl6, check that @of the IAB control valve is in close contact with the full-closo acrew whsn

the vacuum hose is connectad.

a lf 8ny fault is lound, clean the linkage and shatts with carburetor claaner'

- lf the oroblam still exists after cleaning, disassemble the intake manifold and check the IAB valvE body sss8mbly.

11-126

Page 318 of 1413

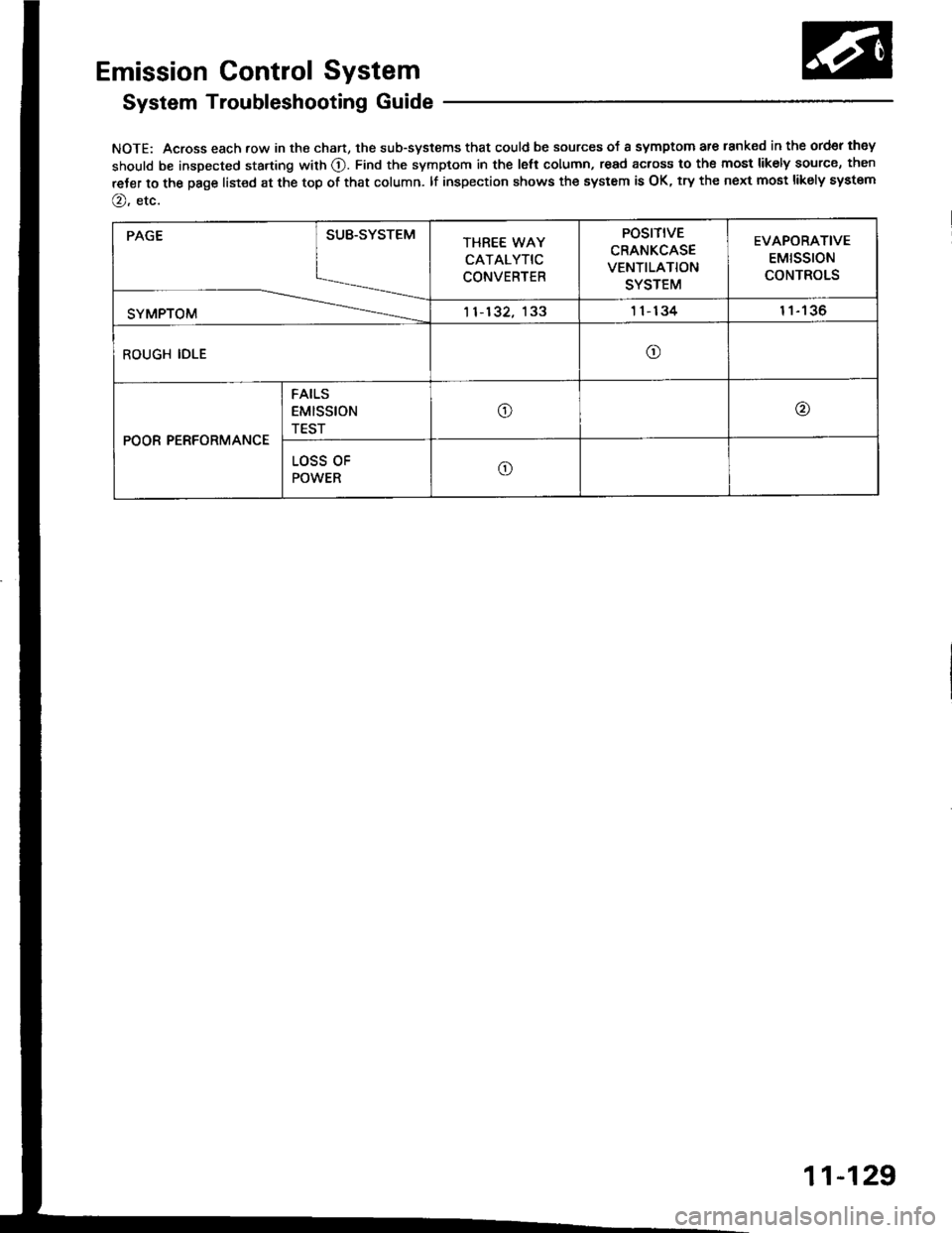

Emission Control System

System Troubleshooting Guide

NOTE: Across each row in the chart, the sub-systems that could be sources of a symptom are lanked in the ord€r they

should be inspected starting with O. Find the symptom in the lett column, read across to the most likely source, then

reJer to the page list€d at the top of that column. lf inspection shows the system is OK, try the next most likely system

@, etc.

PAGE

SYMPTOM

SUB.SYSTEMTHREE WAY

CATALYTIC

CONVERTER

POSITIVE

CRANKCASE

VENTILATION

SYSTEM

EVAPORATIVE

EMtSSTON

CONTROLS

11-132, 1331 1- 13411tJo

ROUGH IDLEo

POOR PERFORMANCE

FAILS

EMISStON

TEST

o@

LOSS OF

POWERo

11-129

Page 319 of 1413

Emission Control System

SystemDescription

The emission control system includes a Three Way Cata-

lytic Convener (TWC), Positive Crankcase Ventilation(PCV) system and Evaporstive Emission {EVAP) Contfol

syst€m. The emission control system is designed to meet

federsl and stats emission standards.

Tailpipe Emission

Inspection

f!fifil oo nor amoro ou]rng rnr! Foacqurr. ^!op

any open flame away from yout wotk atca.

Start the engine. Hold the engine at 3,OOO rpm with

no load (A/T in @ or@ position, M/T in neutral) until

the radiator fan comes on, then let it idle,

Connect a tachometer.

Check and adiust the idle speed, if necessary (sss

page 1 1-95).

Warm up and calibrate the CO meter according to

the meter manutacturer's inst.uctions.

Check idle CO with the headlights, hester blower,

rear window defogger, cooling fan, and air condition-

er otf.

NOTE: (Canada) Pull the parking br8ke lever up.

Stan the engine, then check that the headlights are

off.

CO meter should indicate 0.1 maximum.

11-130