service HONDA INTEGRA 1994 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 172 of 1413

Englne Oil

Replacement {cont'd)

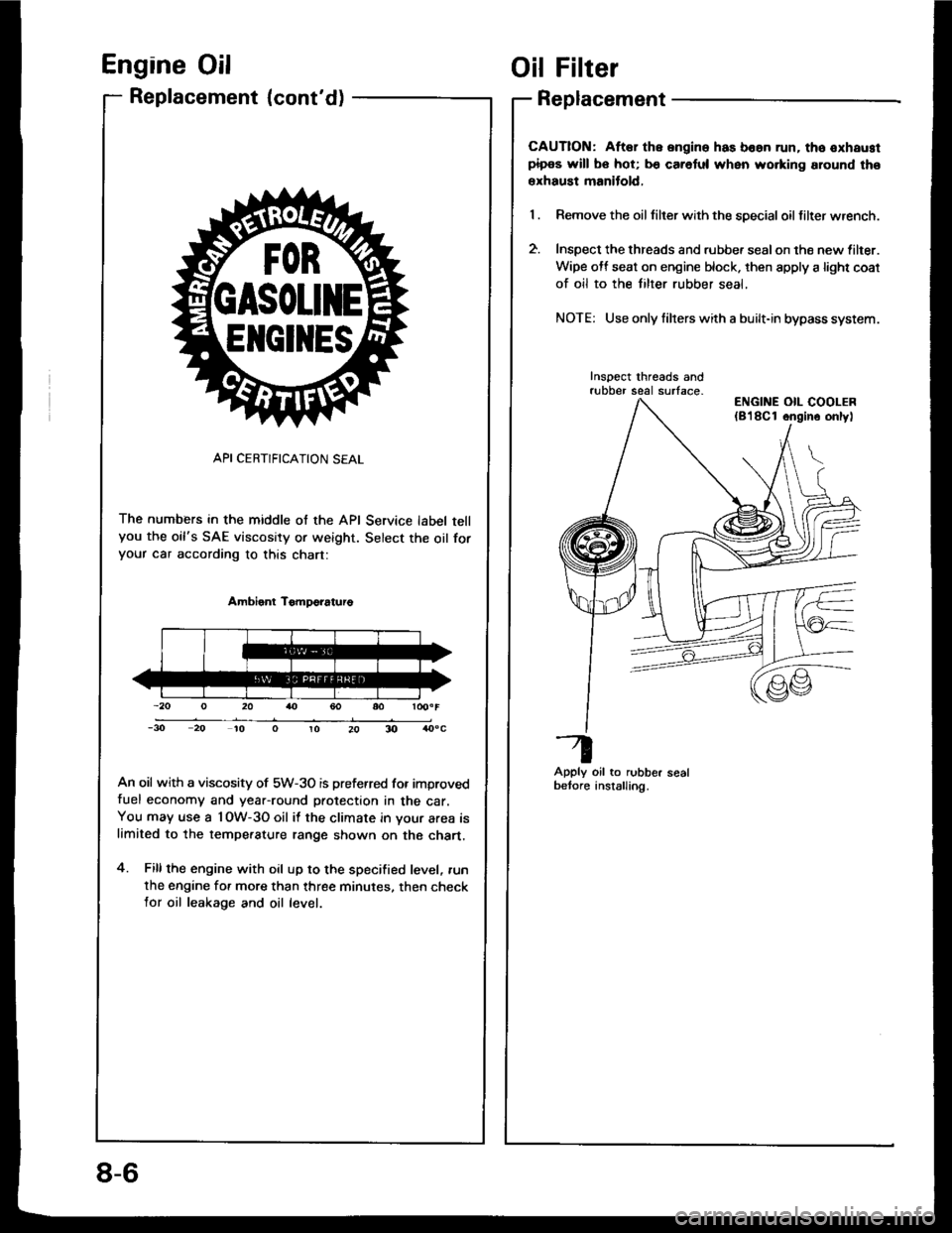

API CERTIFICATION SEAL

The numbers in the middle of the API Service label tellyou the oil's SAE viscosity or weight. Select the oil foryour car according to this chart:

Ambient TomDo?aturo

An oil with a viscosity of 5W-3O is preferred for improvedfuel economy and year-round protection in the car.You may use a l OW-3O oil it the climate in your area islimited to the tempe.ature range shown on the chart.

4. Fillthe engine with oil up to the specified level, .un

the engine for more than three minutes. then checklor oil leakage and oil level.

ElrclltEs

Oil Filter

Replacement

CAUTION: Aftar the ongine has boan run. tho oxhaustpipos will bo hot; b€ caretul when wo.king around tho

erhaust manitold,

Remove the oil tilter with the special oil filter wrench.

Inspect the threads and rubbe. sealon the new lilter.

Wipe off seat on engine block. then apply a light coat

of oil to the tilter rubber seal,

NOTE: Use only filrers with a built-in bypass system.

Inspect threads andrubber seal surface-

Apply oil to rubber sealbetore anstalling.

ENGINE OIL COOLER(8'l8Cl ongino onlyl

8-6

Page 176 of 1413

Oil Pump

5.

4.

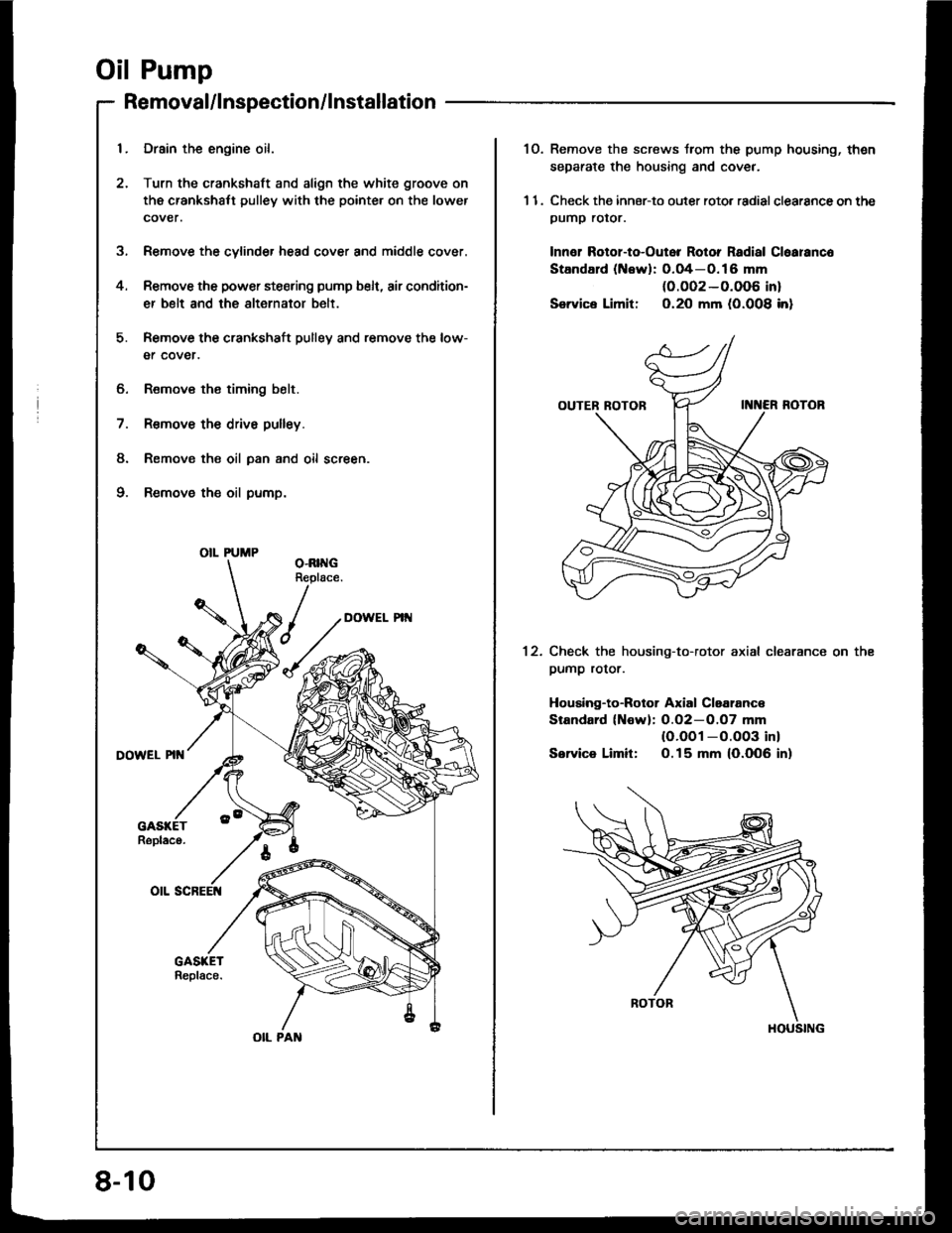

Removal/lnspection/lnstallation

6. Remov€ the timing belt.

7. R€move the drive pulley.

8. Remov€ the oil pan and oil screen.

9. Remove the oil pump.

Drain the engine oil.

Turn the crankshatt and align the white groove on

the crankshalt pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condition-

er belt and the alternator belt.

Remove the crankshaft pulley and remove the low-

er cover.

OIL PUMP

OIL PAN

8-10

1O. Remove the screws trom the pump housing, thsn

separate the housing and coveJ.

1 1. Check the inner-to outer roto. radial clearance on thepumP rotor.

Innor Rotol-to-Outor Rotor Radial Cloaranco

StandErd (Newl: O.O4-O.16 mm(0.O02-0.006 in)

Service Limit: O.2O mm (0.008 inl

Check the housing-to-rotor axial clearance

pump rotor.

Housing-to-Botor Axial Claalanc€

Standard (Nowl: O.O2-O.O7 mm(O.OO1 -O.OO3 inl

Service Limit: O.15 mm (0.006 in)

on the12.

HOUSING

Page 198 of 1413

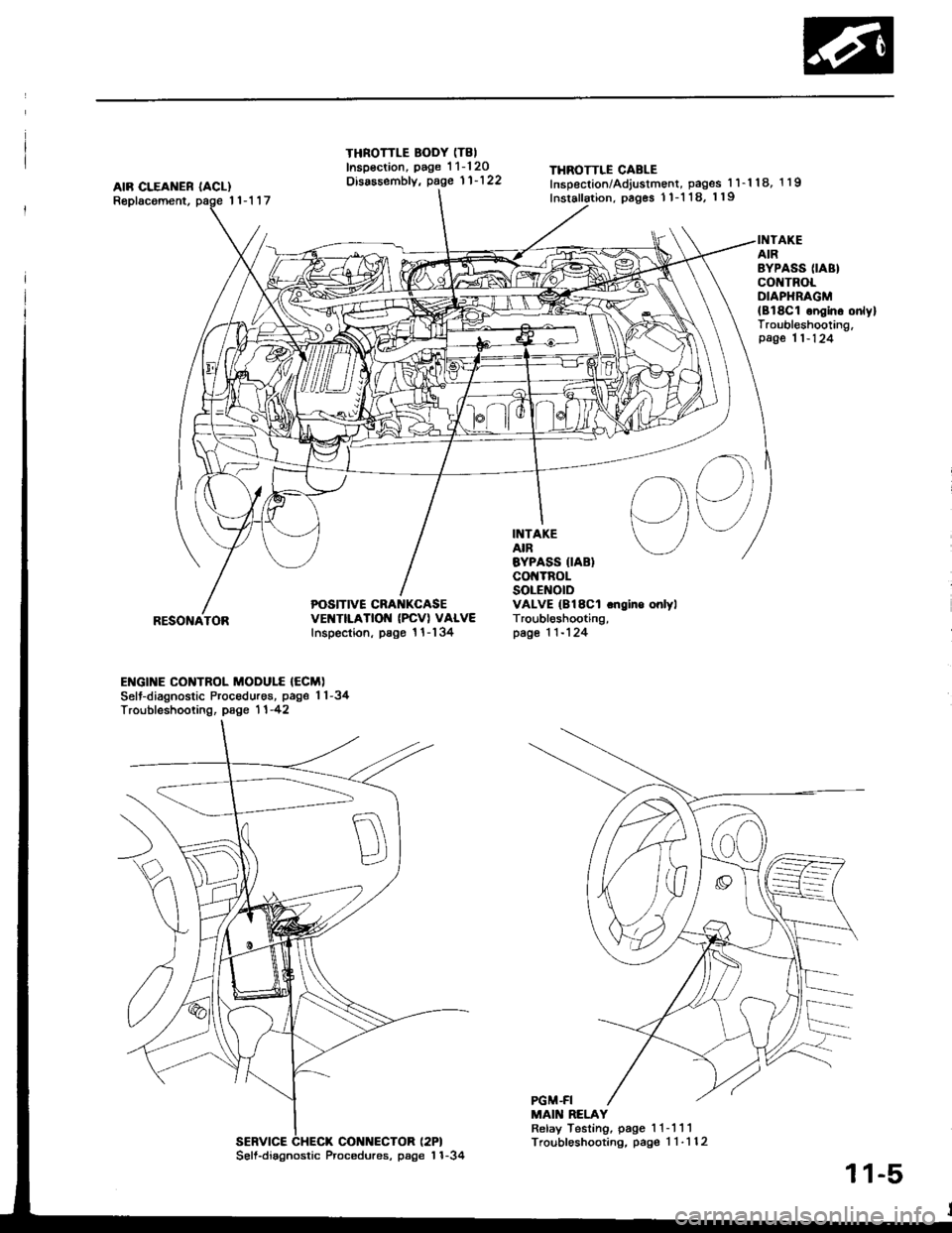

AIR CLEAI{ER IACL)Replacoment,11-117

THROTTLE BODY (T8I

Inspsction, page 1 1-120Disassembfy, page 11'122THROTTLE CABLEInsDection/Adjustment, pages 1 l-'l 18, 1 19

Inslallation, pages 1 1-1 18, 119

POSITIVE CRA KCASEvEt{TtLATtOt{ (PcVl VALVEInspection, psgo 1 l-134

INTAKEAIREYPASS IIABIco TnoLSOLENOIDVALVE (B18Cl .ngino onlylTroubl6shooting,page 1 1-124

INTAKEAIRBYPASS (IABI

co TROLOIAPHRAGM{Bl8C1 ongino onlylTroubleshooting,page 11-124

I

RESONATOR

ENGI]TE CONTROL MODULE {ECM)Selt-diagnostic Procedures, page 1 1-34Troubfeshooting, page 1 1 -42

MAIN RELAYRelay Testing, page 1 1- 111Troubleshooting, pag€ 1 1-112SERVICE CHECX CONNECTOR (2PI

56ll.diagnostic Procedures, page'l 1-34

11-5

Page 208 of 1413

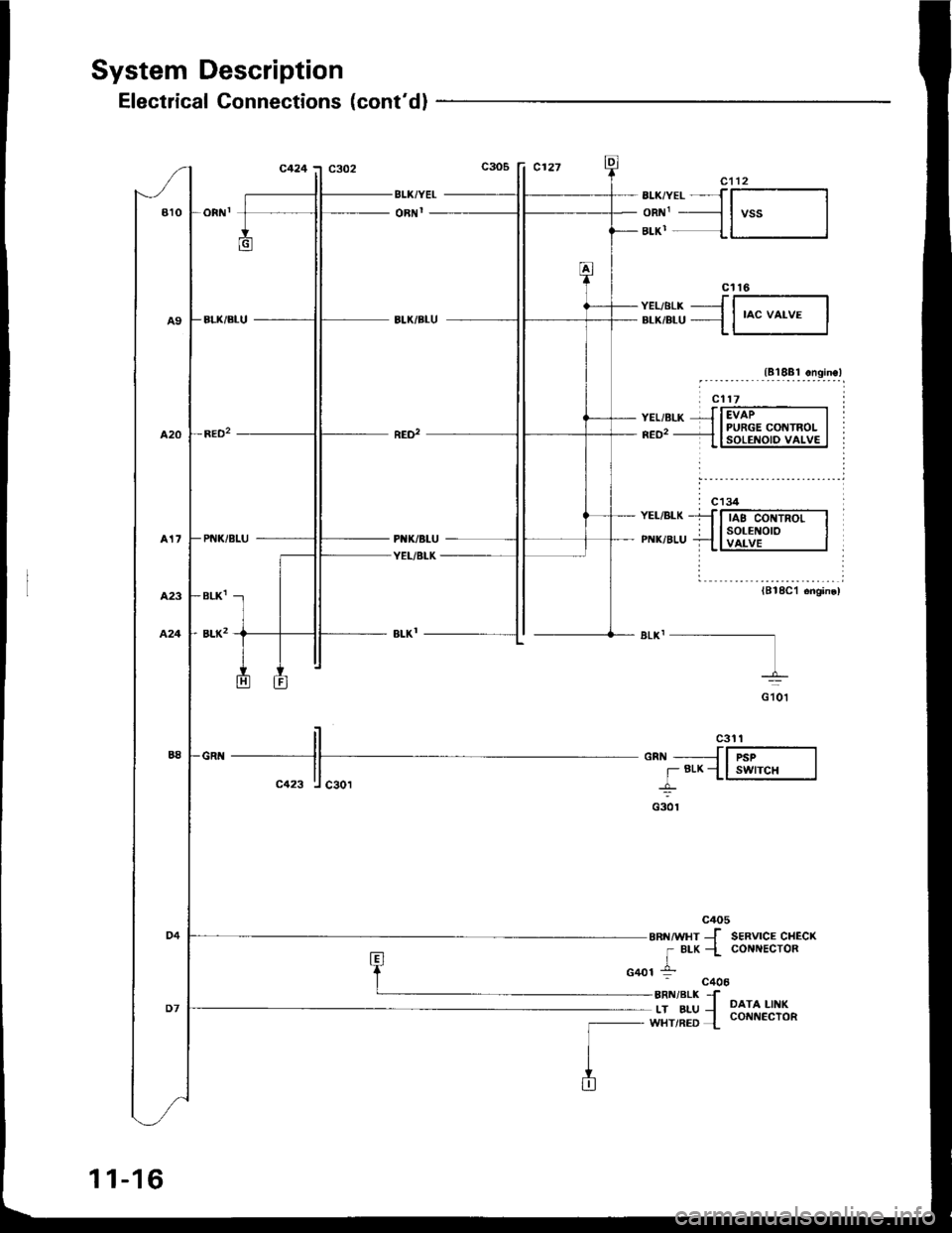

System Description

Electrical Connections (cont'dl

BLI(/YEL

oRI{r

il ".t ttlenn __JlF-----l

ll r Brx_Ll swrcH Ic423 ! caor -L

e s-ot

c405

eaurvxr Jr BLK -l

1-G401 :-

SERVICE CHECKCOIIIIECTOR

DATA LINKcorrttIEcToR

- c40aBRN/BLK fLT BLU IWHT/RED {

BTKiYEL-JT---l

oR 1 ----l I vss IBLK' {l I

c't 16

v:r-,sr-* -J l-----]".*,".u {l

'o" uo.u. I

lA18a1 ongine,

lB18C1 6ngin€)

11-16

Page 220 of 1413

System Description

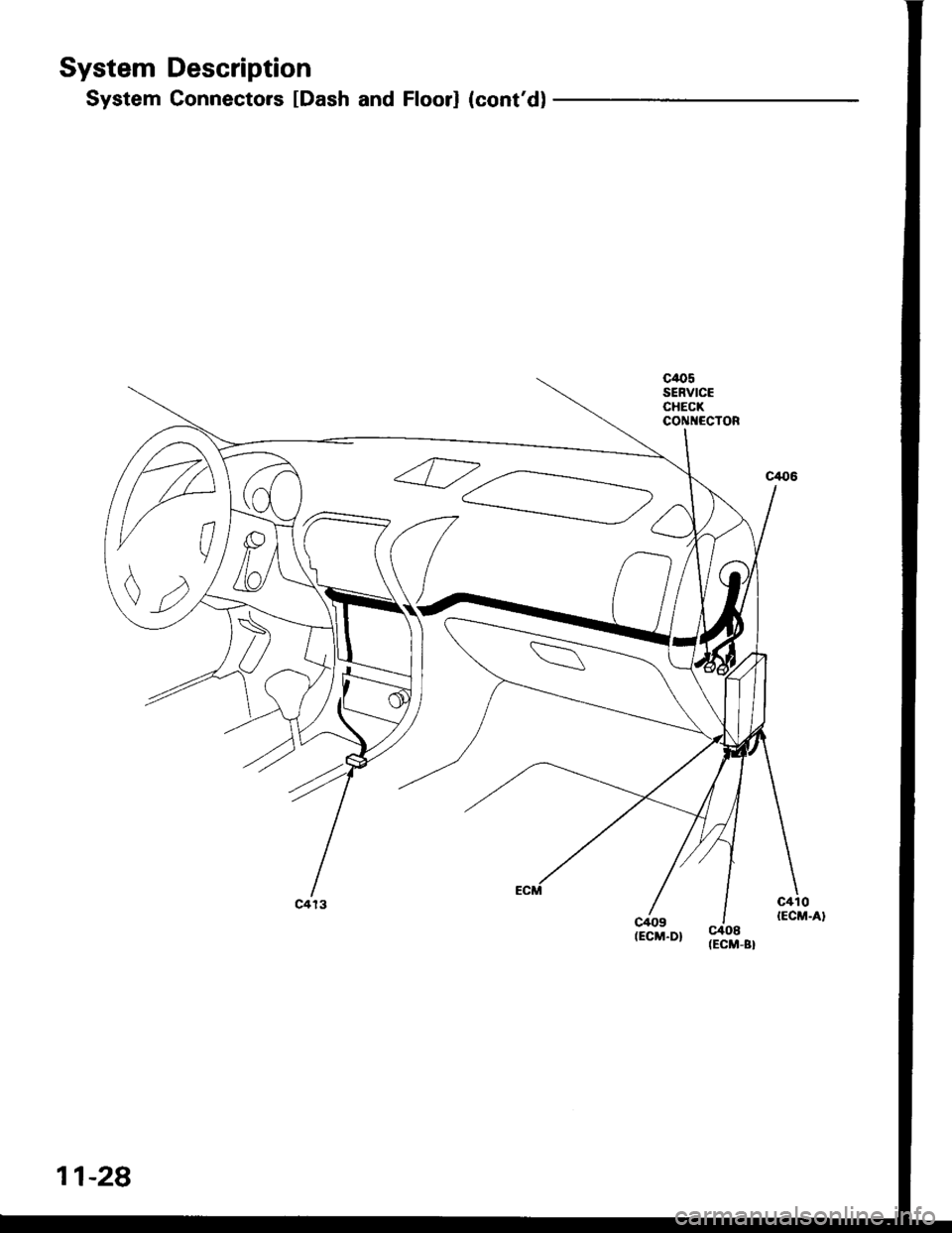

System Connectors [Dash and Floorl (cont'd)

c/ro5SERVICECHECKCONI{ECTOR

11-28

Page 224 of 1413

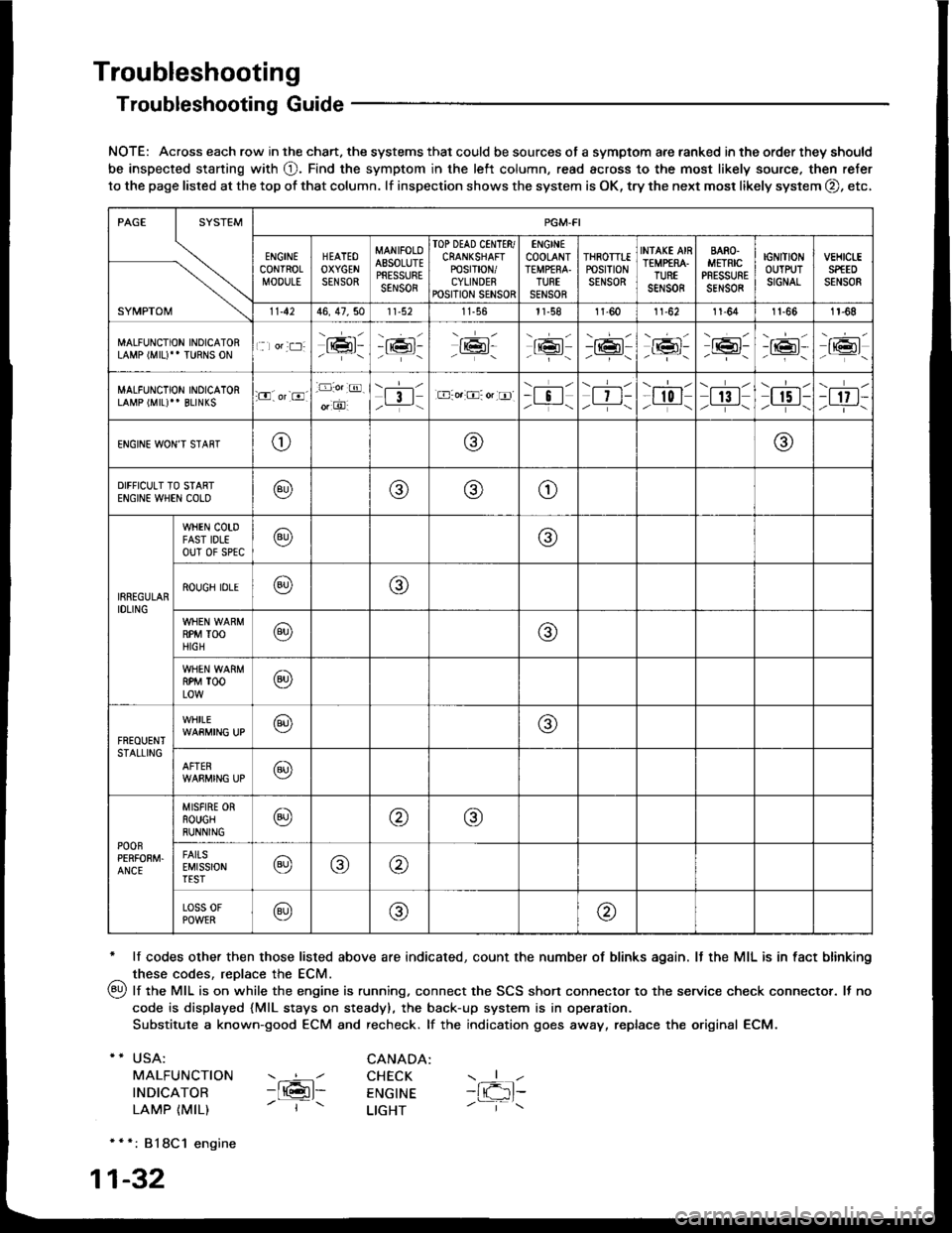

Troubleshooting

Troubleshooting Guide

NOTE: Across each row in the chart. the systems that could be sources of a symptom are ranked in the order they should

be inspected staning with O. Find the symptom in the left column, read across to the most likely source. then refer

to the page listed at the top of that column. lf inspection shows the system is OK, try the next mosr likely system O, etc,

* lf codes other then those listed above are indicated, count the number of blinks again. It the MIL is in fact blinking

^ these codes, replace the ECM.

qy, lf the MIL is on while the engine is running. connect the SCS shon connector to the service check connector. It no

code is displayed {MlL stays on steady), the back-up system is in operation.

Substitute a known-good ECM and recheck. lf the indication goes away, replace the original ECM.

USA:

MALFUNCTION

INDICATOR

LAMP {MIL)

CANADA: ----l CHECK-ltGl- ENGTNE- | - LTGHT

- { -1t-

* * *: 818C1 engine

1-32

SYMPTOM

PGM.FI

ENGINECONTROLMOOULE

HEATEOOXYGENSENSOR

MANIFOLOAESOLUTEPRESSURESENSOR

TOP DEAD CINTTR/CRANKSHAFTPOSTT|ON/CYLINDERPOSITION SENSOR

ENGINECOOLANTTEMPfRA.TURTSENSOR

THROTTTEPOStTtONSENSOR

INfAKE AIRTEMP€RA.TUREsar,rs0R

BARO.METRICPRESSURESENSOR

IGNITIONOUTPUTSIGNAL

vEHtct-ESPfEDSENSOR

11.4246, 47,5011-56l1-581l-6011-6211-641t-661r-68

MALFUNCTION INOICATORLAMP (MIU" TURNS ON1 lor:t:]:lrmr:- i;:i'-tK3t-16l-16l'-\-16l/-----\

-r:+r-

-{"Pr:-o_-16l-.z-\r6t/_-\

MALFUNCTION INOICATORLAMP (MIL)'' BLINKS:O. or-8.-D:o.:@.

o, O'l3l/__-\.E-o.:O: or tr]--i !l/ -i-\| 7 t-/__-\

--l-l-l r0 I/----\| 13 |z_---\

\.--r--l

I r5 t-/.---\-t 17 t-/-]-\

ENGINE WON'T STAffTo@@

DIFFICULT TO STARTENGIN€ WHEN COLO@@(9)o

IRREGULARIDLING

WHEN COTDFAST IDLEouT 0f sPtc@@

ROUGH IDLE@o

RPM TOOHIGH@@

RPM TOOLOW@

FREOUENTSTALLING

WHILE@@

AFTER@

POOnPERFOEM.ANCE

MISFIRE ORROUGHRUNNING@@@

FAITSEMISSIONTEST@@@

Loss 0FPOWER@@@

Page 226 of 1413

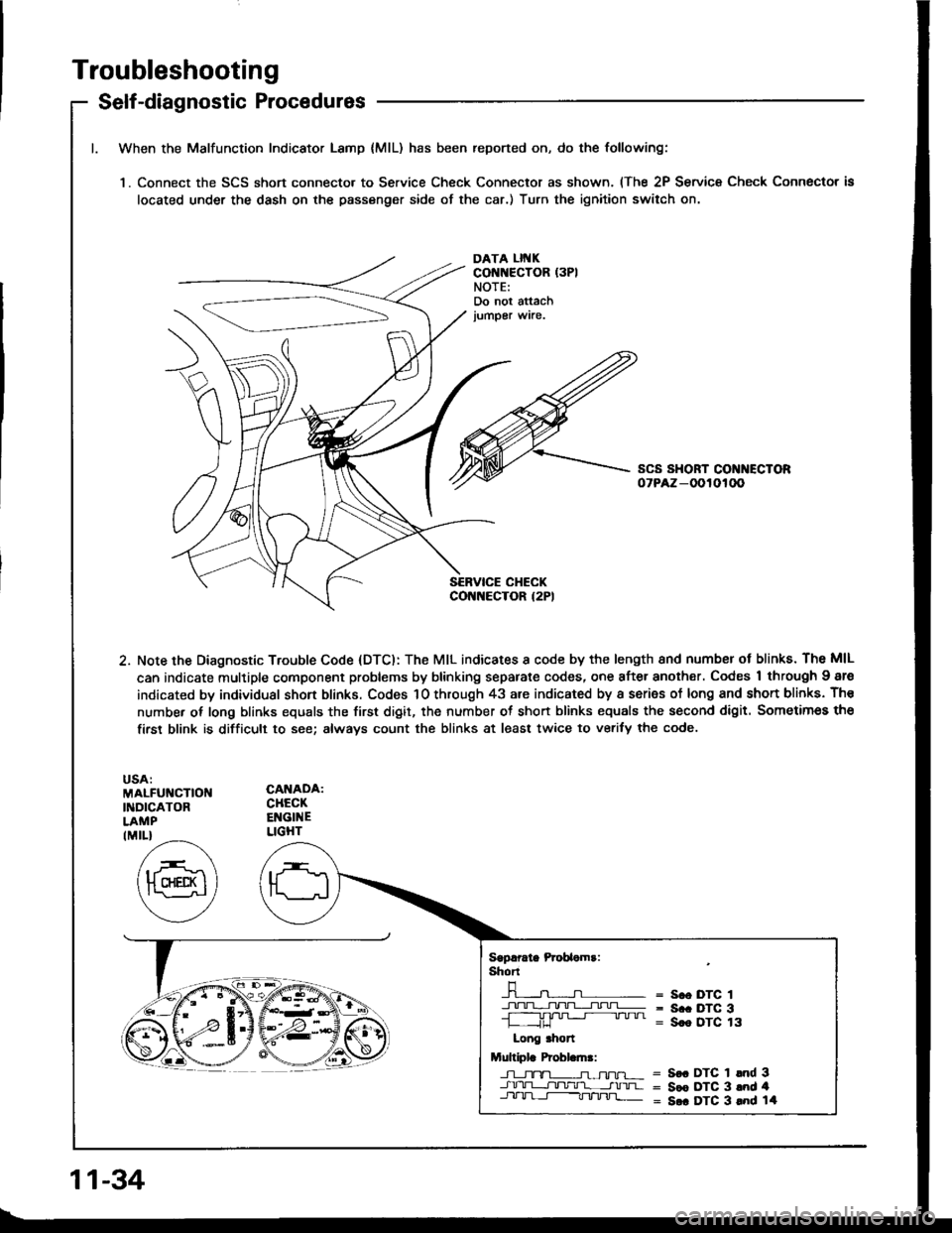

Troubleshooting

Self-diagnostic Procedures

When the Malfunction Indicator Lamp {MlL) has been reported on, do the following:

'1. Connect the SCS short connecto. to Service Check Connector as shown. (The 2P Service Check Connector is

located under the dash on the passenger side of the car.) Turn the ignition switch on.

DATA LII{KCONNECTOR (3PI

NOTE:Do not attachjumper wire.

2. Note the Diagnostic Trouble Code (DTC): The MIL indicates I code by the length 8nd numbsr ot blinks. The MIL

can indicate multiple component problems by blinking separate codes, one after another. Codes 1 through Igre

indicated by individual shon blinks. Codes 1O through 43 are indicated by a series of long and shon blinks. Th€

number of long blinks equals the first digit, the number ot short blinks equals the second digit. Sometimes the

firsr blink is difficult to see; always count the blinks at least twice to verify the code.

MALFUNCTIOI{INDICATORLAMP

CANADA:CHECKENGINELIGHTIMIL}

Sgprrate Prcbaomr:shT

-n-----n- =n- = s.o DTc 1

+!+1].TL;I!!=- = s.. Drc 3-L ,JU '" " " = Sce DTC 13

Long .hon

Multiplr Probl.ln.:

J-l_tx-TL-n-ffu-r- = S€. DTC 1 lnd 3-J.rrU-L-r]tltlr'l- __-tnrua = Sce DTC 3 and 4Jll-lrl-t-----Tt/'tnj]_ = S.. DTC 3 lnd 14

11-34

Page 228 of 1413

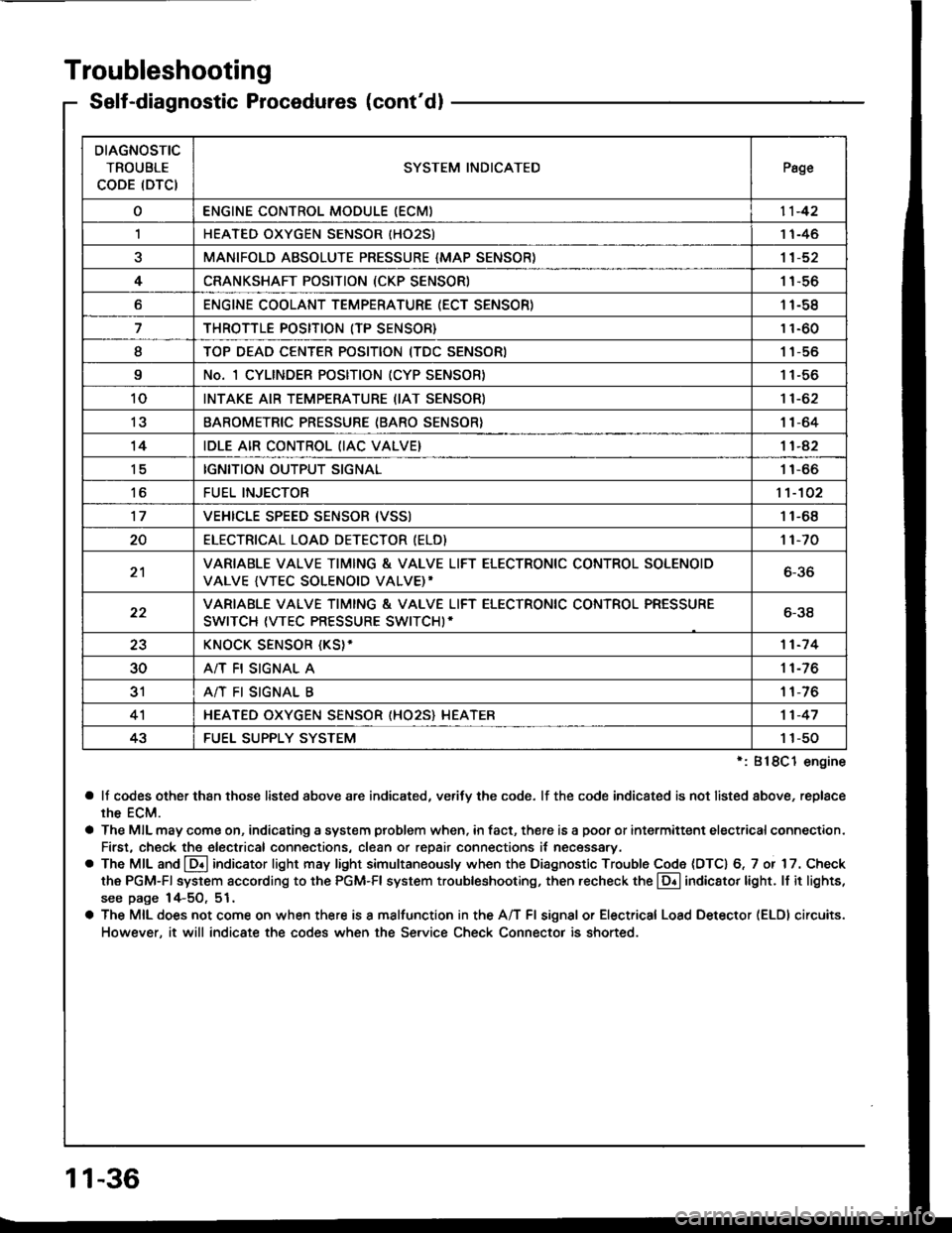

Troubleshooting

Self-diagnostic Procedures (cont'dl

':818C1 engine

a lf codes other than those listed above are indicated, verifv the code. lf the code indicated is not listed above, replace

rhe ECM.

a The MIL may come on, indicating a system problem when, in fact, there is a poor or intermittent electricalconnection.

First, check the electrical connections, clean or repair connections it necessary.

o The MIL and @ indicator light may light simultaneously when the Diagnostic Trouble Code (DTC) 6, 7 or 17. Check

the PGM-Fl system according to the PGM-Fl system troubleshooting, then recheck the l!! indicator light. ll it lights,

see page 14-5O, 51.

a The MIL does not come on when there is a malfunction in the A/T Fl signal or Electrical Load Detector (ELDI circuits.

However, it will indicate the codes when the Service Check Connector is shorted.

DIAGNOSTIC

TROUBLE

CODE (DTCISYSTEM INDICATEDPsge

oENGINE CONTROL MODULE IECM)11-42

,lHEATED OXYGEN SENSOR IHO25)1 1-46

aMANIFOLD ABSOLUTE PRESSURE {MAP SENSOR)11-52

4CRANKSHAFT POSITION (CKP SENSOR)1 1-56

oENGINE COOLANT TEMPERATURE (ECT SENSOR)11-58

THROTTLE POSITION (TP SENSOR}11-60

ITOP DEAD CENTER POSITION (TDC SENSORI1 1-56

9No. 1 CYLINDER POSITION (CYP SENSOR)1 1-56

10INTAKE AIR TEMPERATURE (IAT SENSOR)11-62

13BAROMETRIC PRESSURE (BARO SENSOR}1|-64

14IDLE AIR CONTROL (IAC VALVE}11-42

tcIGNITION OUTPUT SIGNAL11-66

toFUEL INJECTOR1't-102

17VEHICLE SPEED SENSOR {VSSI11-68

20ELECTRICAT LOAD DETECTOR (ELD)'t 1-70

21VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL SOLENOID

VALVE {VTEC SOLENOID VALVE)'6-36

22VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL PRESSURE

SWITCH (VTEC PRESSURE SWITCHI-6-38

23KNOCK SENSOR {KS}-11-7 4

30A/T FI SIGNAL A11-76

3'rA/T FI SIGNAL B1 1-76

4'lHEATED OXYGEN SENSOR (HO25} HEATER11-47

43FUEL SUPPLY SYSTEM1 1-50

11-36

Page 233 of 1413

3. Fuel Cut-oft Control

a During deceleration with the throttle valve closed, current to the {uel injectors is cut otJ to improve fuel economy

at speeds over tollowing rpm:

. 8188l engine: 91O tpm (Canada model: 1,O50 rpm)

. 818C1 engine: 95O tpm (Canada model: l,O5O rpm)

a Fuel cut-olf action also takes place when engine speed exceeds, 7,O0O rpm {81 8B1 engine), 8,1O0 rpm (B 18Cl

engine), regardless oI the position of the throttle valve, to protect the engine from ovet-revving.

A/C Compressor Clutch Relay

When the ECM receives a domand for cooling trom the air conditioning system, it del8ys the compressor from being

enetgized, and enriches the mixture to assure smooth transition to the A/C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant tempersture is below 163oF {73"C), the ECM supplies a ground to the EVAP pu.ge control

solenoid valve which cuts vacuum to the EVAP purge control diaphragm valve.

Intake Air Bypsss (lAB) Control Sol€noid Valve

When the engine rpm is below 5,750 rpm, the IAB control solenoid valve is activated by a signal from the ECM,

intske air flows through the long intake path, then high torque is delivered. At spaeds highe. than 5,750 rpm, the

solenoid valve is deactivated by the ECM, and intake air flows through the short intake path in order to reduce the

resistance in airflow.

ECM fail-safe/bEck-up Functions

1. Fail-sate Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-progtammed

value tor that sensor that allows the engine to continue to run.

Back-uD Function

When an abnormalitv occurs in the ECM itself, the fuel iniectors are controlled by a back-up citcuit independent of

the system in order to permit minimal driving.

Self-diagnosis Function IMaltunction Indicator Lamp {MlL)1

Wh6n an abnormality occurs in a signal from a sensor, the ECM supplies ground for the MIL and stores the code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground tor the MIL tor two seconds

to check the MIL bulb condition.

Two Trio Detection Method

To prevent tals€ indications, th€ Two Trip Dstection Method is used for the HO2S and fuel metering-related self-

diagnostic tunctions. When an abnormslity occurs, the ECM stores it in its memo.y. Wh€n the ssme sbnormality

recurs alter the ignition switch is turned OFF and ON ag8in, the ECM informs the driver by lighting the MlL.

However, to ease troubleshooting, this function is canc€ll€d when you short the service check connector. The MIL

will then blink immedistelv when an abnormality occurs.

4.

6.

2

4.

11-41

Page 235 of 1413

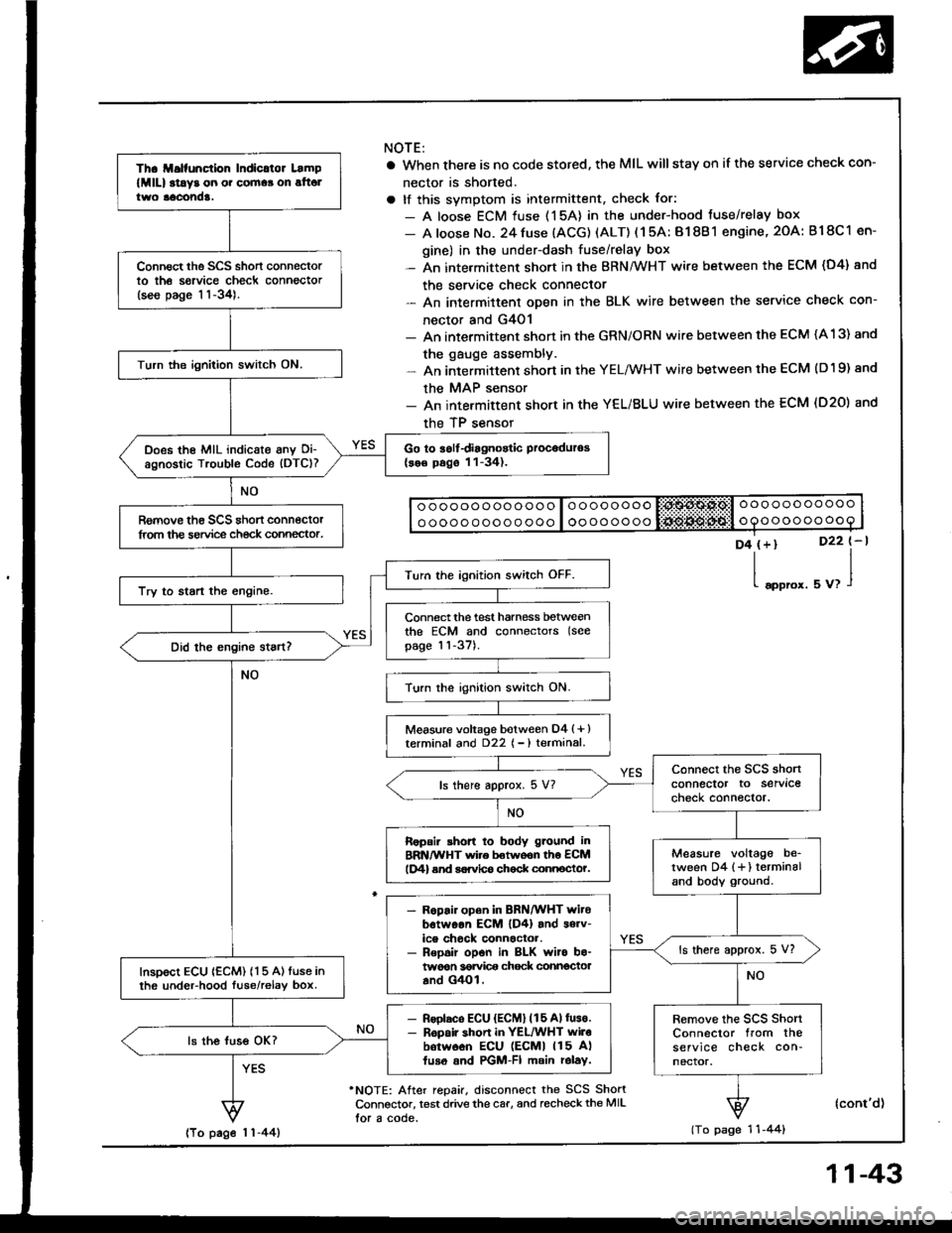

Th. ll.lfunction Indicltor Lamp

lMlll at!y3 on o. cornaa on alt6ltwo aacond!.

Connect the SCS short connectorto th6 sorvice check connector(see page 11-34).

Turn the ignition switch ON.

Go to iolfdiagnostic Proceduros(se€ pago 11-34).Does the MIL indicate anv Oi-agnostic Trouble Code (DTC)?

Romove th€ SCS shon connectorlrom the service ch€ck connector.

Turn the ignition switch OFF.

Try to start the engine.

Connect the test harness betweenthe ECM and connectors (see

page 11-37).

Turn the ignition switch ON.

Measure voltage botween D4 (+ )terminal and D22 { - ) terminal.

connect the SCS shonconnector to servlcecheck connector.ls there approx. 5 V?

Ropair shon to body g.ound inBRN/WHT wire betwoon th6 ECMlD4) end sorvlco chock connocto?.Measure voltage be_tween D4 {+} terminaland body ground.

- R6pair open in BRN/WHT witobotwoon EcM lD4) and s6rv-ice chock connactor.- Repoir opon in BLK wiro bo-twoon 36rvi@ chock connectoaand G4Ol.

ls there approx. 5 V?

InsDoct ECU {ECM) 115 A) tuse inth6 undeFhood luse/relav box.

- Rsolaco ECU {ECM} (15 Allus€.- R6pair shon in YEL/WHT wilobotw6on ECU lEcMl 115 A)fuso and PGM-FI main rolay.

Remove the scs shortConnector from theservice check con-nector.

ls the luss OK?

NOTE:

a When there is no code stored, the MIL willstay on if the service check con-

nector is shorted.

a tf this svmotom is intermittent, check for:

- A loose ECM fuse (15A) in the under-hood tuse/relay box

- A loose No. 24 fuse (ACG) (ALT) ( 1 5A: B1 8B 1 engine, 2OA: B18C 1 en-

gine) in the under-dash fuse/relay box- An intermittent short in the BRN/WHT wire between the ECM (D4) and

the service check connector- An intermittent oDen in the BLK wire between the service check con-

nector and G4O1- An intermittent shon in the GRN/ORN wire between the ECM (A 13) and

the gauge assembly.- An intermittent short in the YELMHT wire between the ECM (D19) and

the MAP sensor- An intermittent short in the YEL/BLU wire between the ECM (D20) and

the TP sensor

o ooooo ooo ooo o loooooooo liii:$A$.Ps,l o oo ooo ooooo

o oooo ooo o o ooo I oooooooooooooooooo

D4 (+)

l"oo,o'.

D22 t-l

uu,l

'NOTE: After repair, disconnect the SCS ShortConnsctor, test drive the car, and recheckthe MIL

lor a code.

(cont'd)

(To page 1 'l -44)lTo page 1 1-44)

11-43