Block HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1088 of 1413

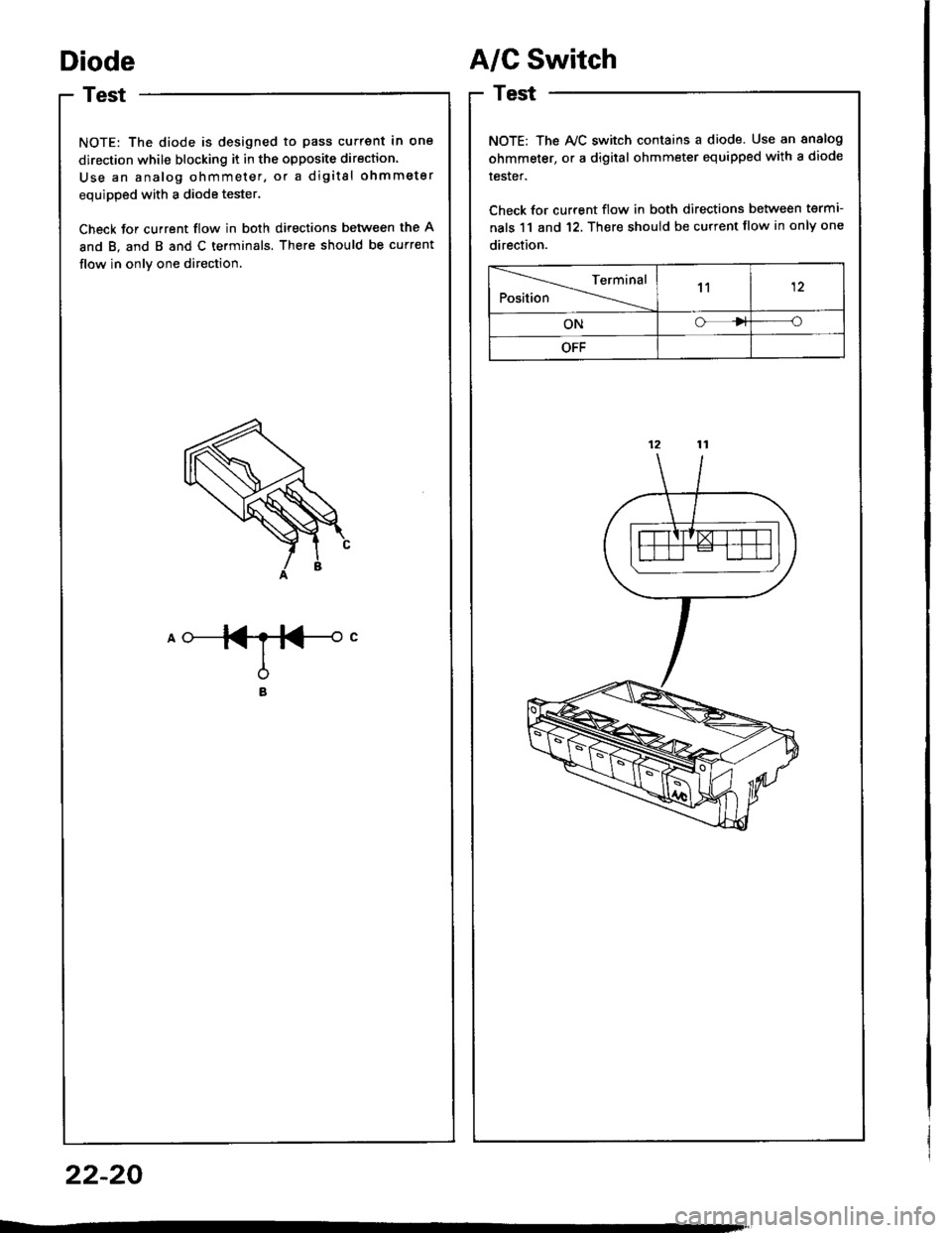

Diode

Test

NOTE: The diode is designed to pass current in one

direction while blocking it in the opposite direction.

Use an analog ohmmeter, or a digital ohmmeter

equipped with a diode tester.

Check for current flow in both directions between the A

and B. and B and C terminals. There should be current

flow in onlv one direction.

A/C Switch

Test

NOTE: The Ay'C switch contains a diode. Use an analog

ohmmeter, or a digital ohmmeter equipped with a diode

tester.

Check for current flow in both directions between termi

nals 11 and 12. There should be current flow in only one

direction.

Terminal

Position11

ONo

OFF

22-20

Page 1154 of 1413

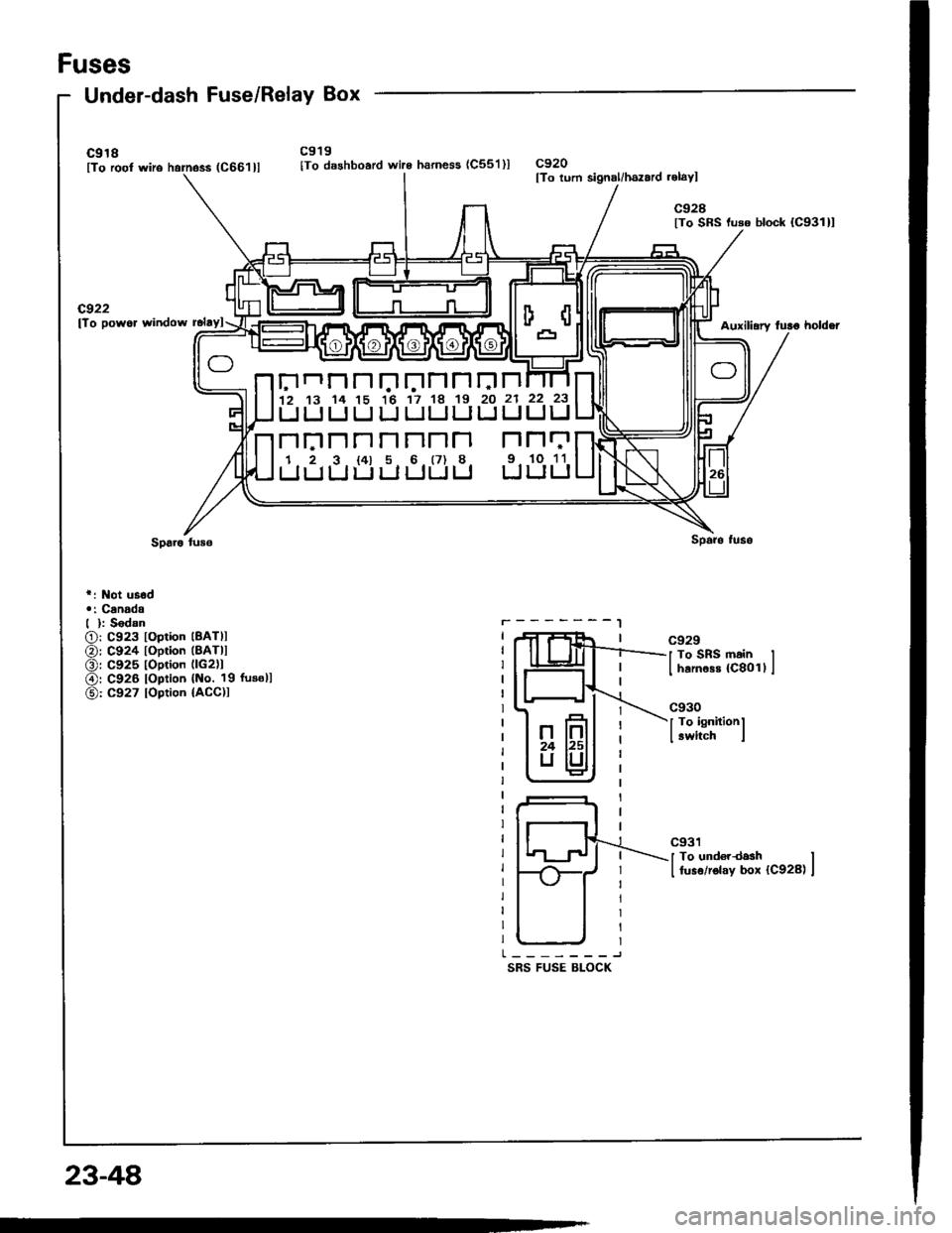

Fuses

Under-dash Fuse/Relay Box

c918lTo root wiro harness (C661llc919

lTo dashboard wire harness (C55'l )lc920lTo lurn signal/hszard .elayl

c928lTo SRS luso block {C931}l

cg22lTo powor window rclaylAuxili.ry fulo holdei

r: Not usod.: Canadd| ): S6dan

O: C923 loplion lBATll

@: C924 toption (BATll

O: C925 toption llc2)1

@r C926 loption {No. 19 fusoll

@: C927 loption {ACC)I

r.-------l

SRS FUSE BLOCK

c929

J To SRS main II harnass {C8011 I

c930

I To ignitionl

I switch i

c931

I To und€rdash II fuso/rolay box {C928) I

Elnnnr.'trJnnrJn12 13 14 15 16 17 18 19 20 21

UUIJUIJULJLILIIJ

n|:]nnnnnn r''l

1 2 3 t4l 5 6 (7) 8 9.

LIIJLIULJUUU U

22 23

UIJ

N11

10 11

LILI

23-48

Page 1212 of 1413

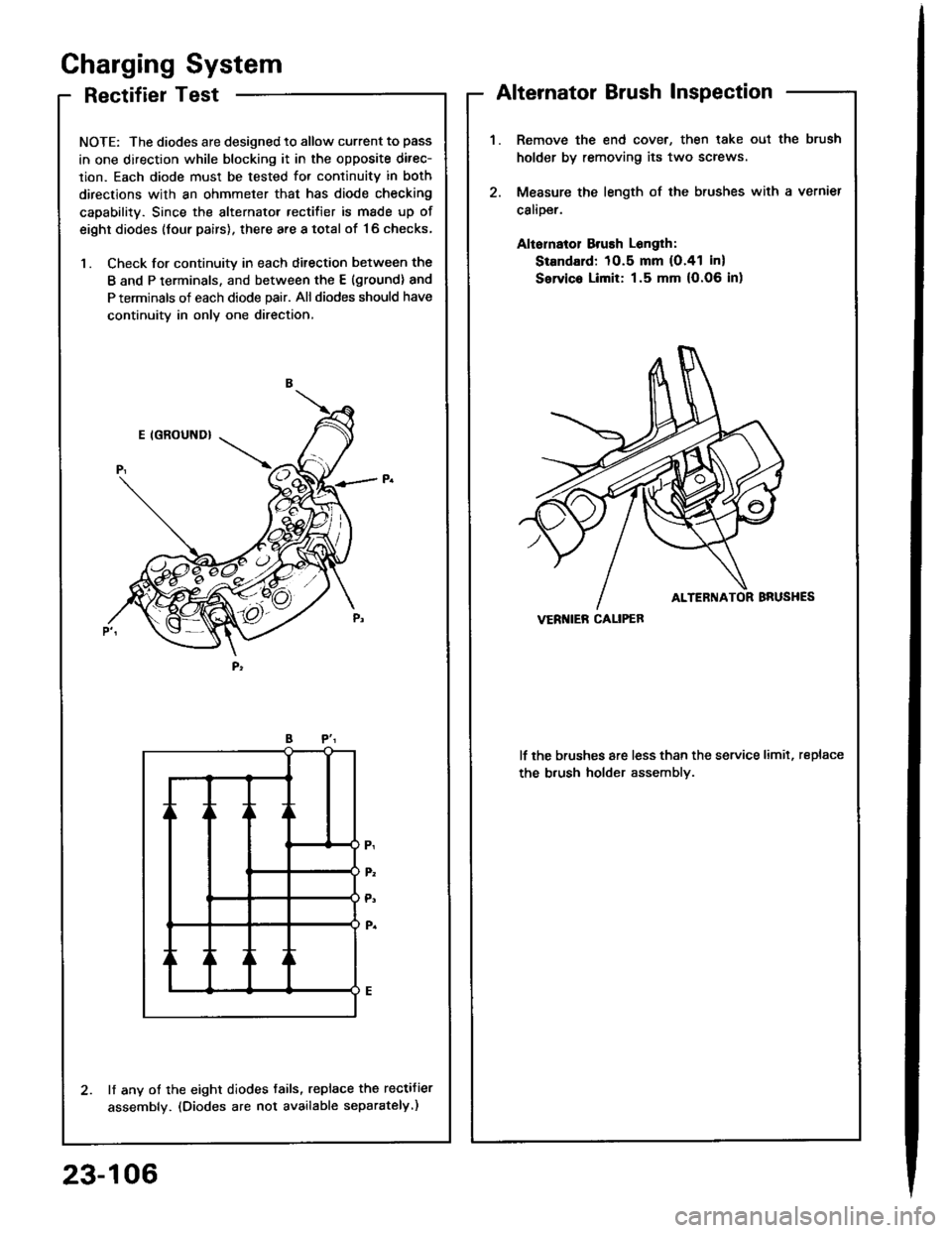

RectifierTest

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc-

lion. Each diode must be tested for continuitv in both

directions with an ohmmeter that has diode checking

capability. Since the alternator rectifier is made up of

eight diodes (four pairs), there are a total of '16 checks,

1. Check for continuity in each ditection between the

B and P terminals, and between the E (ground) and

P terminals of each diode pair. All diodes should have

continuity in only one direction,

lf any of the eight diodes tails, replace the rectifier

assembly. (Diodes are not available separately.)

Gharging System

Alternator Brush Inspection

Remove the end cover, then lake oul the brush

holder by removing its two screws

Measure the length of the brushes with a vernier

calioer.

Aliornatol Brush Longlh:

Standard: 10.5 mm (O.41 in)

Servic. Limit: 1.5 mm (O.06 in)

lf the brushes are less than the service limit, replace

the b.ush holder assemblv.

VERI{IEB CALIPEB

23-106

Page 1227 of 1413

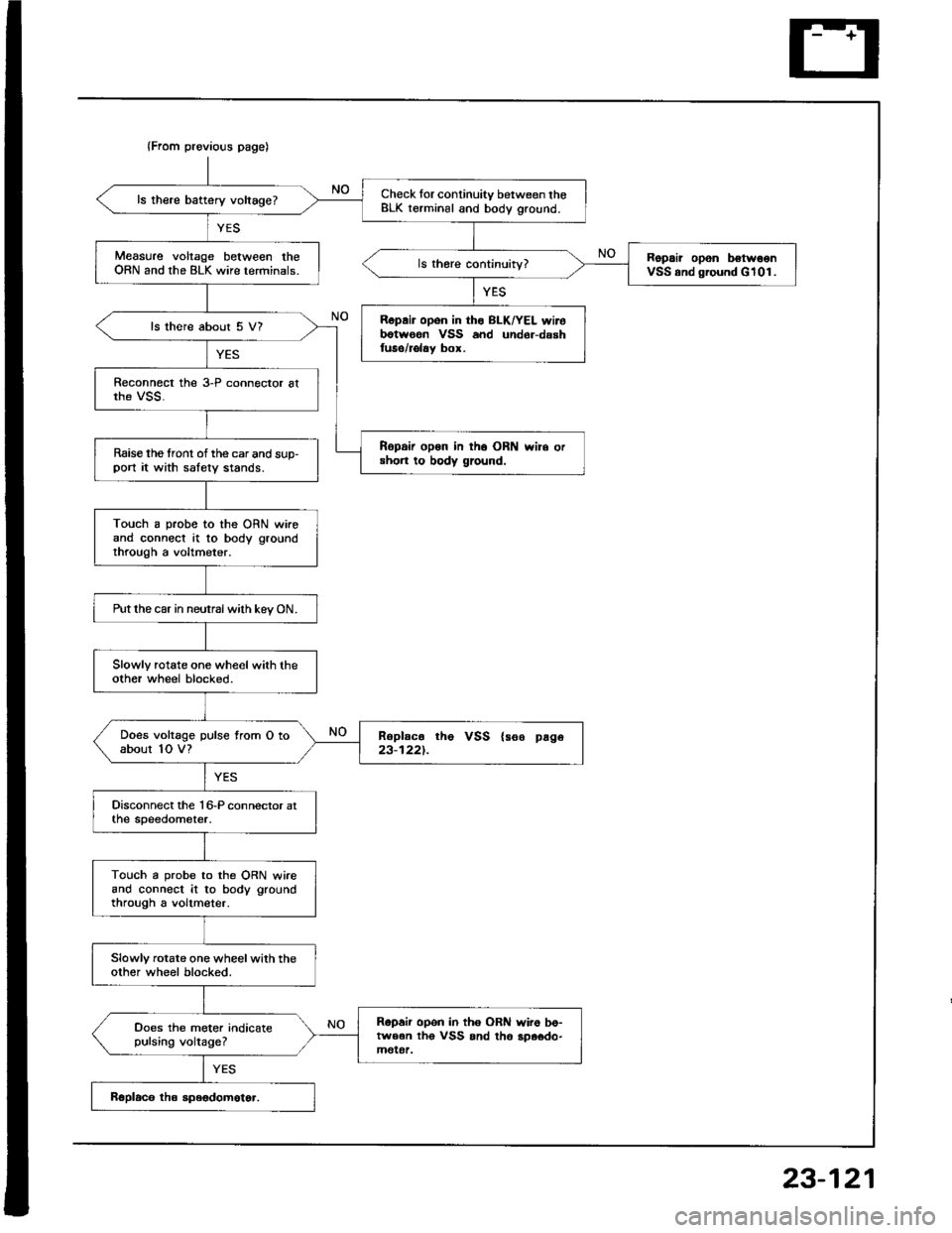

{From previous page)

Check tor continuity between theBLK terminal and body ground.ls there battery voltage?

Measure voltage between theORN and the BLK wire terminals.Ropair opon belw€onVSS and ground G101.

Ropair opon in tho BLKrYEL wirobotwoen VSS and undor-dsshluse/rolay box.

ls there about 5 V?

Ropair op6n in th6 ORN wire orshon to body ground.Raise the tront of the car and sup-port it with salety stands.

Touch a probe to the ORN wireand connect at to body groundthrough a voltmeter.

Putthe car in neutralwith kev ON.

Slowly rotate one wheel with theother wheel blocked.

Does voltage pulse from O toabout 1O V?Roplac. tho VSS {see page23-1221.

Touch a probe to the ORN wireand connect it to body groundthrough a voltmeter.

Slowly rotate one wheelwith theother wheel blocked.

Ropair opon in th6 OBil wire bo-tween tho VSS and th6 3p.odo-molgt.

Ooes the meter indicatepulsing voltage?

23-121

Page 1237 of 1413

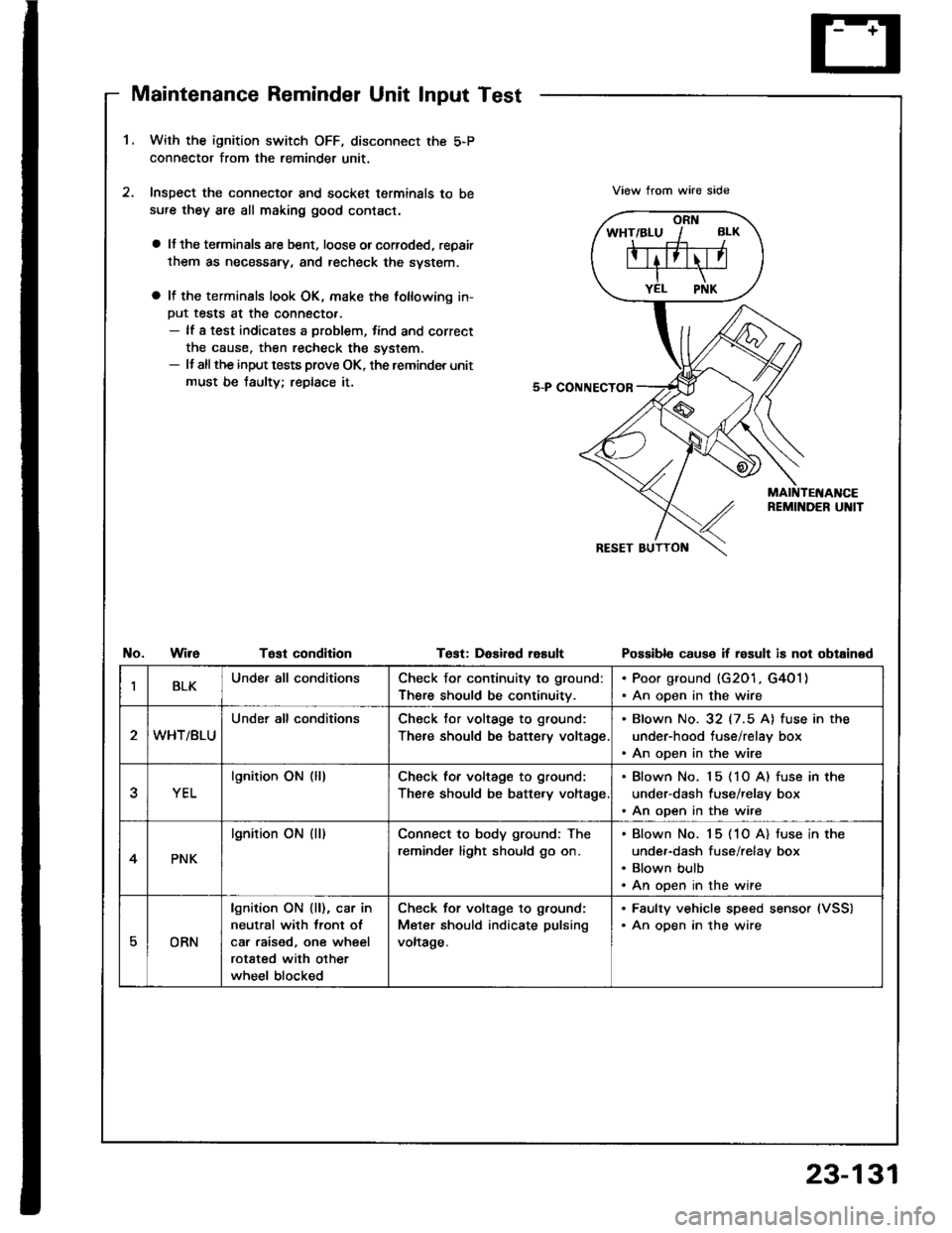

Maintenance Reminder Unit Input Test

1.With the ignition switch OFF, disconnect the 5-P

connector from the reminder unit,

Inspect the connector and socket terminals to be

sufe they are all making good contact.

a lJ the terminals are bent, loose orcorroded, repair

them as necessary, and recheck the svstem.

a It the terminals look OK, make the following in-

Put tests at the connecto..- lf a test indicates a problem, tind and correct

the cause, then recheck the system.- It allthe input tests prove OK, the reminder unit

must be taulty; replace it.

View trom wire side

No.WireTost condltionTest: DaEired rasultPossibl€ cause if result is not obtained

IBLKUnde. all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G201, G4O1). An open in the wire

WHT/BLU

Under all conditionsCheck tor voltage to ground:

There should be battery voltage

. Blown No. 32 (7.5 A) fuse in the

under-hood tuse/relay box. An open in the wire

YEL

lgnition ON (lllCheck for voltage to ground:

There should be batte.y voltage

. Blown No. 15 (1O A) fuse in the

under-dash fuse/relay box. An open in the wire

4PNK

lgnition ON (ll)Connect to body ground; The

reminder light should go on.

Blown No. 15 (1O A) tuse in the

under-dash fuse/relay box

Blown bulb

An open in the wire

EORN

lgnition ON {ll), car in

neutral with lront ol

car raised, one wheel

rotated with other

wheel blocked

Check for voltage to g.ound:

Meter should indicate pulsing

voltage.

. Faulty vehicle speed sensor (VSS)

. An oDen in the wire

23-131

Page 1249 of 1413

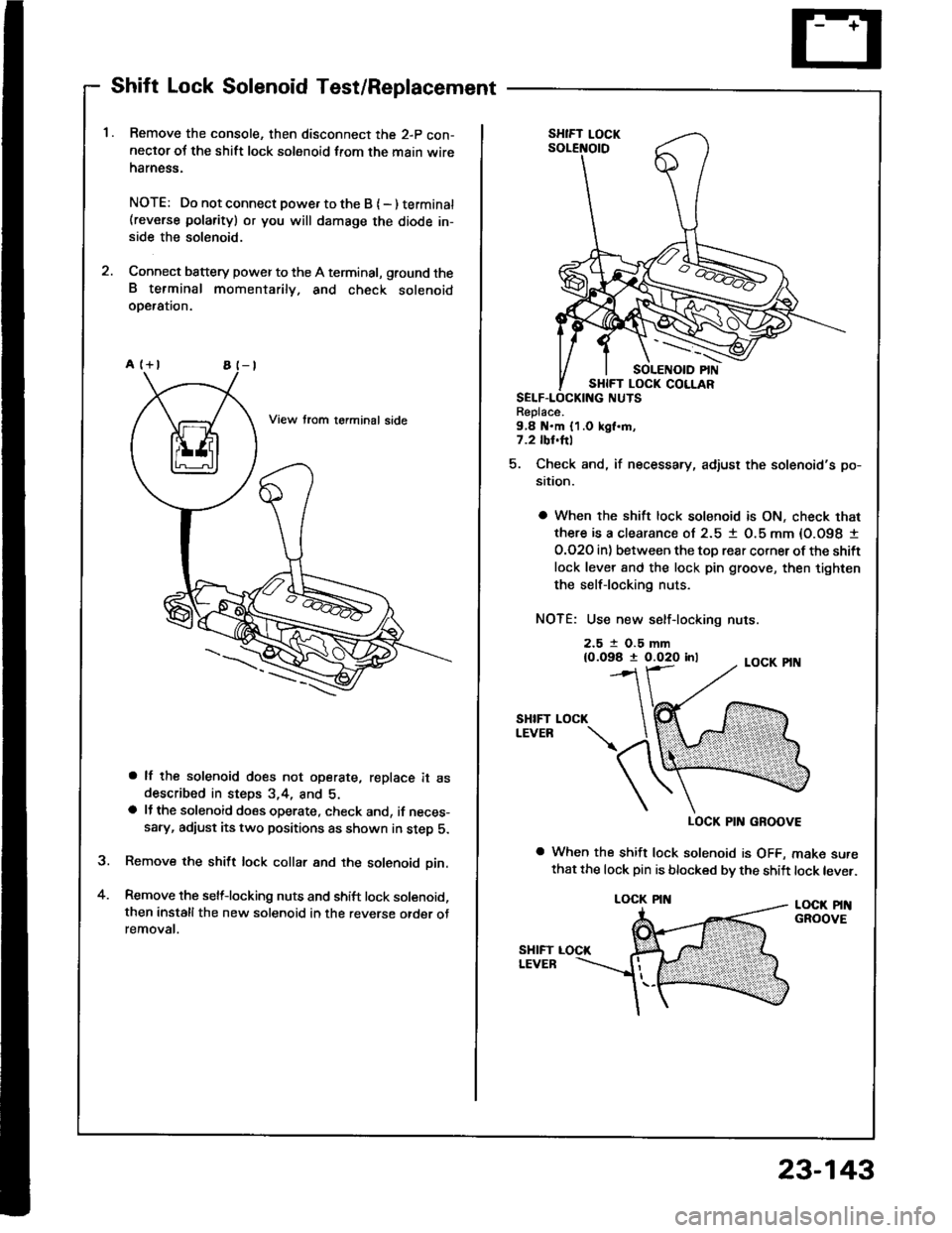

Shift Lock Solenoid Test/Replacement

Remove the console, then disconnect the 2-p con-neclor oJ the shift lock solenoid from the main wireharness.

NOTE: Do not connect powe. to the B { - ) terminat(reverse polarity) or you will damsge the diode in-side the solenoid.

Connect battery power to the A terminal, ground theB terminal momentarily. and check solenoidoDeralron.

a lf the solenoid does not operate, replace it asdescribed in steps 3,4, and 5.a lJ the solenoid does operate, check and, if neces-sary, adiust its two positions as shown in step 5.

Remove the shift lock collar and the solenoid pin.

Remove the selflocking nuts and shift lock solenoid,then installthe new solenoid in the reverse otder otremovat.

a

Replace.9,8 N.m {1.0 kgl.m,7.2 tbl.hl

5. Check and, if necessary, adjust the solenoid's po-

sition.

a When the shift lock solenoid is ON, check that

there is a clearance ol 2.5 1 O.5 mm {O.O98 I

O.O2O in) between the toD rear corner ot the shift

lock lever 8nd the lock pin groove, then tighten

the selflocking nuts.

NOTE: Use new self-locking nuts.

2.5 t O.5 mm{0.098 t 0.020 inl

SHIFTLEVEB

LOCK PIN GROOVE

a When the shift lock solenoid is OFF, make surethat the lock pin is blocked bv the shift lock lever.

LOCK PINGROOVE

LOCK

LOCK PIN

23-143

Page 1369 of 1413

l.

2.

1.

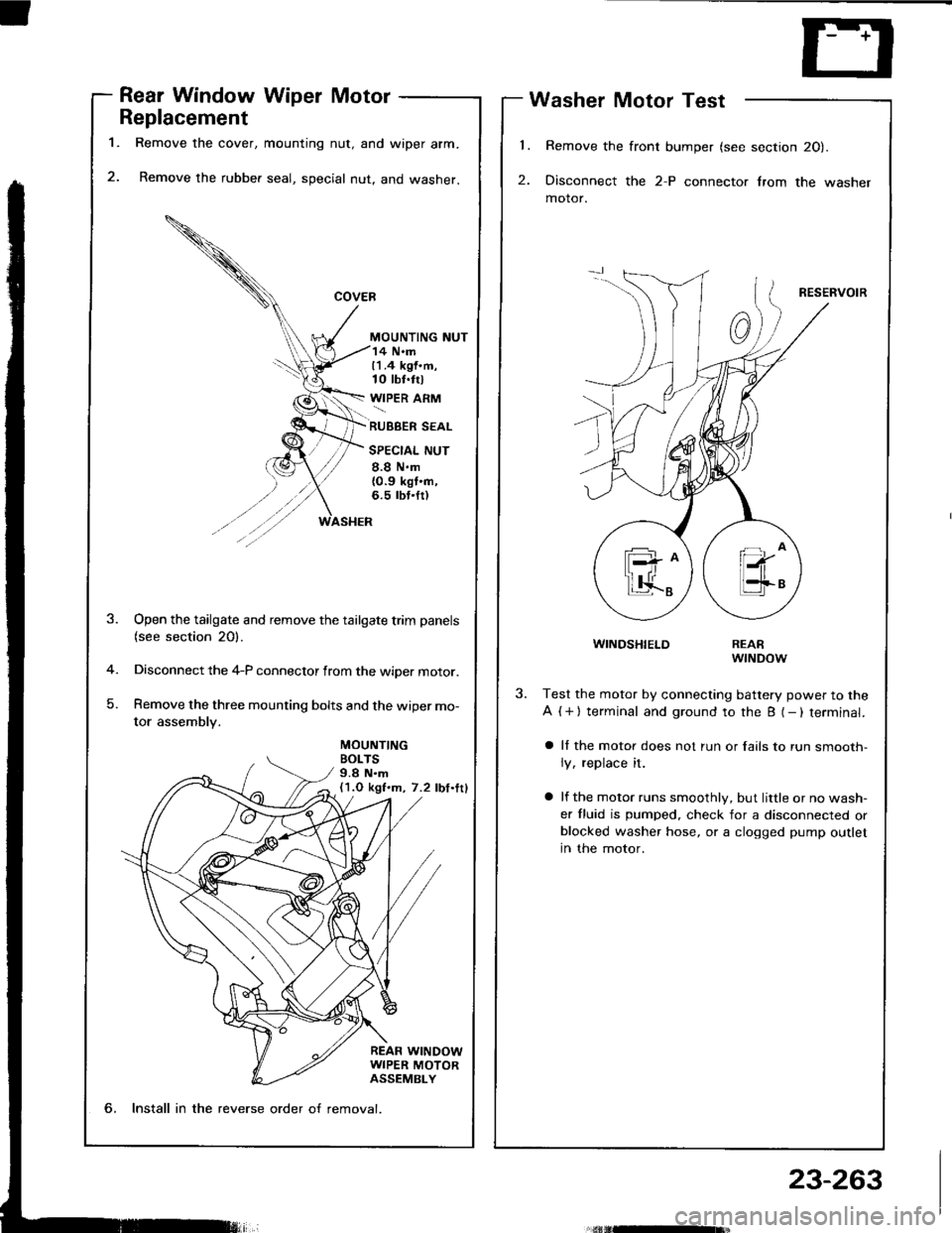

Rear Window Wiper Motor

Replacement

Remove the cover, mounting nut, and wiper arm.

Remove the rubber seal, special nut, and washer.

MOUNTING NUT

Washer Motor Test

Remove the front bumper (see section 20).

Disconnect the 2-P connector lrom the washer

motor.

RESERVOIR

WINDSHIELD

14 N.m11.4 kgf.m,10 tbt.trl

WIPER ARM

RUBBER SEAL

SPECIAL NUT

8.8 N.m{0.9 kgt'n,6.5 rbt.fr)

MOUNTINGBOLTS9.8 N.m(1.O kgf.m, 7.2 lbf.ttl

-4

)

Open the tailgate and remove the tailgate trim panels(see section 20).

Disconnect the 4-P connector from the wiper motor.

Remove the three mounting bolts and the wiper mo-

tor assembly.

REARwrNDow

Test the motor by connecting battery power to the

A ( + ) terminal and ground to the B (- ) terminal.

a ll the motor does not run or fails to run smooth-

ly, replace it.

a lf the motor runs smoothly, but little or no wash-

er fluid is pumped. check for a disconnected orblocked washer hose, or a clogged pump outlet

in the motor.

6, Install in the reverse order o{ removal.

23-263