Block HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 145 of 1413

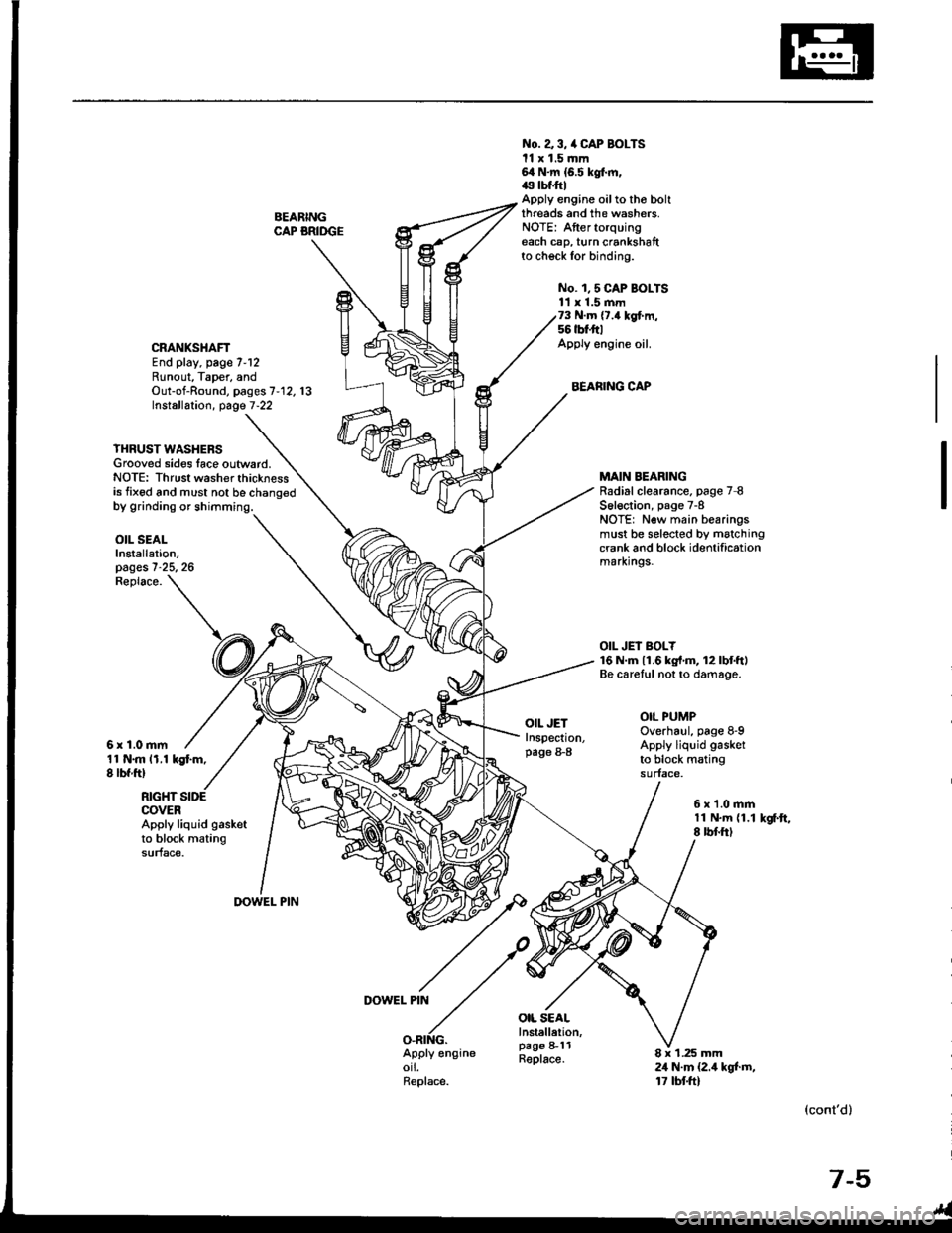

BEARINGCAP BRIDGE

No. a 3, /a CAP BOLTSll x 1.5 mm64 N.m {6.5 kgt m,49 tbf.ftlApply engine oilto tho boltthreads and the washers.NOTE: Aftertorquingeach cap, turn crankshaftto check for binding.

No. 1,5 CAP BOI-TS11 x 1.5 mm73 N.m {7.4 kgf.m,56 tbt'ft|Apply engine oil.

BEARING CAP

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7'12. 13Installation, page 7-22

YHRUST WASHERSGrooved sides lace outward.NOTE: Thrust washer thicknessis fixed and must not be chano€d

MAIN BEARINGRadial clearance. page 7 8S6l€ction, page 7-8NOTE: New main bearingsmust be selected by matchingcrank and block identificationmarxrngs.

OIL JEI BOLY16 N.m 11.6 kg{'m, 12lbtftlBe caretul not to damage.

OIL PUMPOverhaul, page 8-9Apply liquid gasket

to block matingsurface.

OIL SEALInstallation,pages 7-25, 26

11 N.m 11.1 kgt m,8 lbf ftl

Replace.

6r1.0mm

OIL JETInspection,page 8-8

OIL SEALInstellelion,page 8-11Replace.

RIGHT SIDECOVERApply liquid gasketto block matingsurface.

6x1.0mm11 N.m {1.18 rbf.ftlkSf.ft,

DOWEL PIN

DOWEL PIN

O.RING.Apply engineorl.Replace.

8 x 1.25 mm24 N.m {2.4 kgt m,17 tbtft)

(cont'd)

7-5

Page 147 of 1413

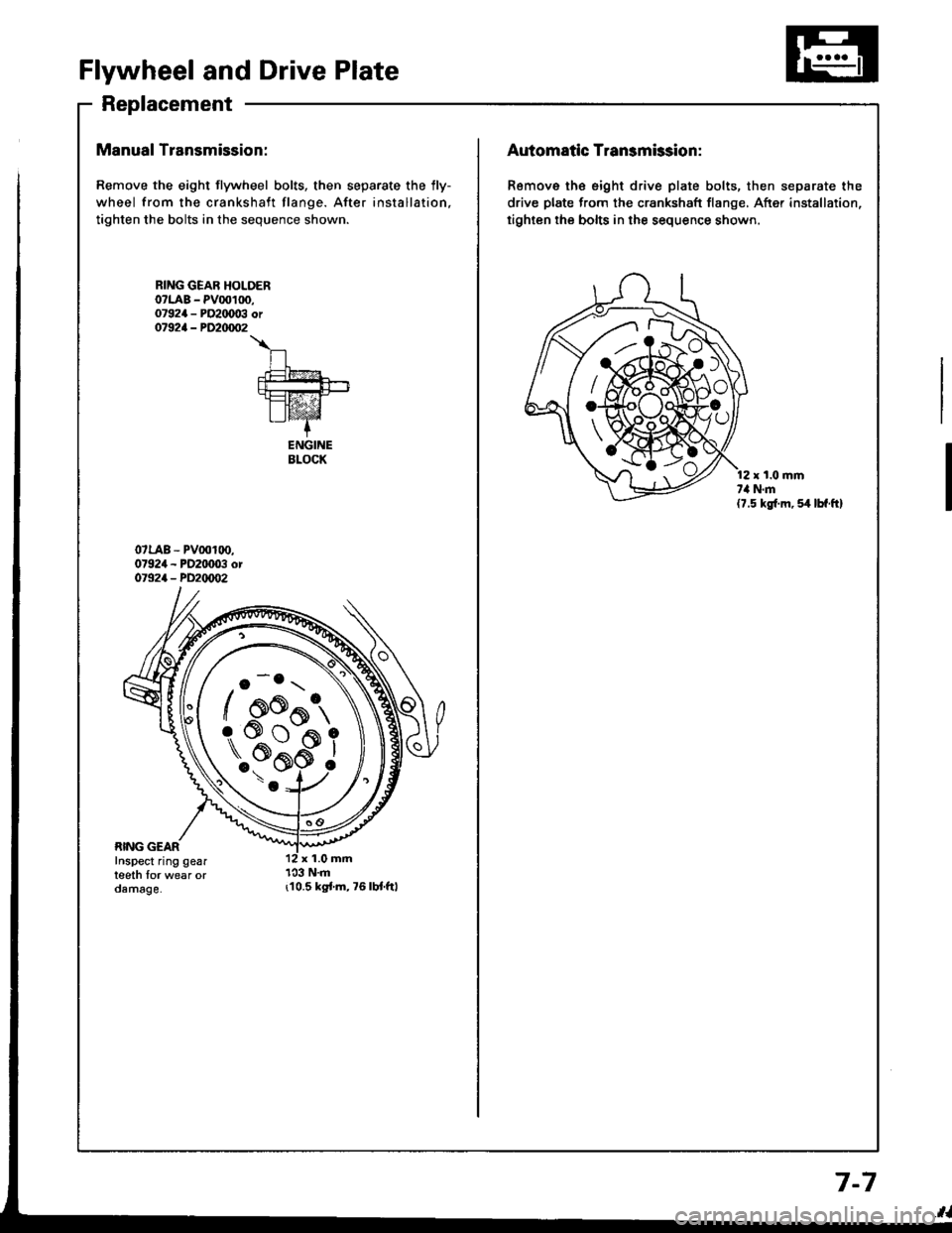

Flywheel and Drive Plate

Replacement

Manual Transmission:

Remove the eight flywheel bolts, then separate the lly-

wheel from the crankshaft flange. After installation,

tighten the bolts in the sequence shown.

r10.5 kgi.m,76lbt.ftl

RING GEAR HOLOERo?LAB - PV00100,07924 - PO2IX)03 or07924 - PD20/m�2

\

n.t=?4

fut!!-+-rt=tz-21I lvaz'Z-+

ENGINEBLOCK

o -o.r \

/ oo^t,

\..?bi

/ AK{:{AAo

rs#*ffi_9

Automatic Transmission:

Remove th€ eight drive plate bolts, then separate the

drive plate from the crankshaft flange, After installation,

tighten the bolts in the sequence shown.

r t.0 mmt,l N.m(7.5 kg{.m, 54 lbf.ft}

7-7

Page 148 of 1413

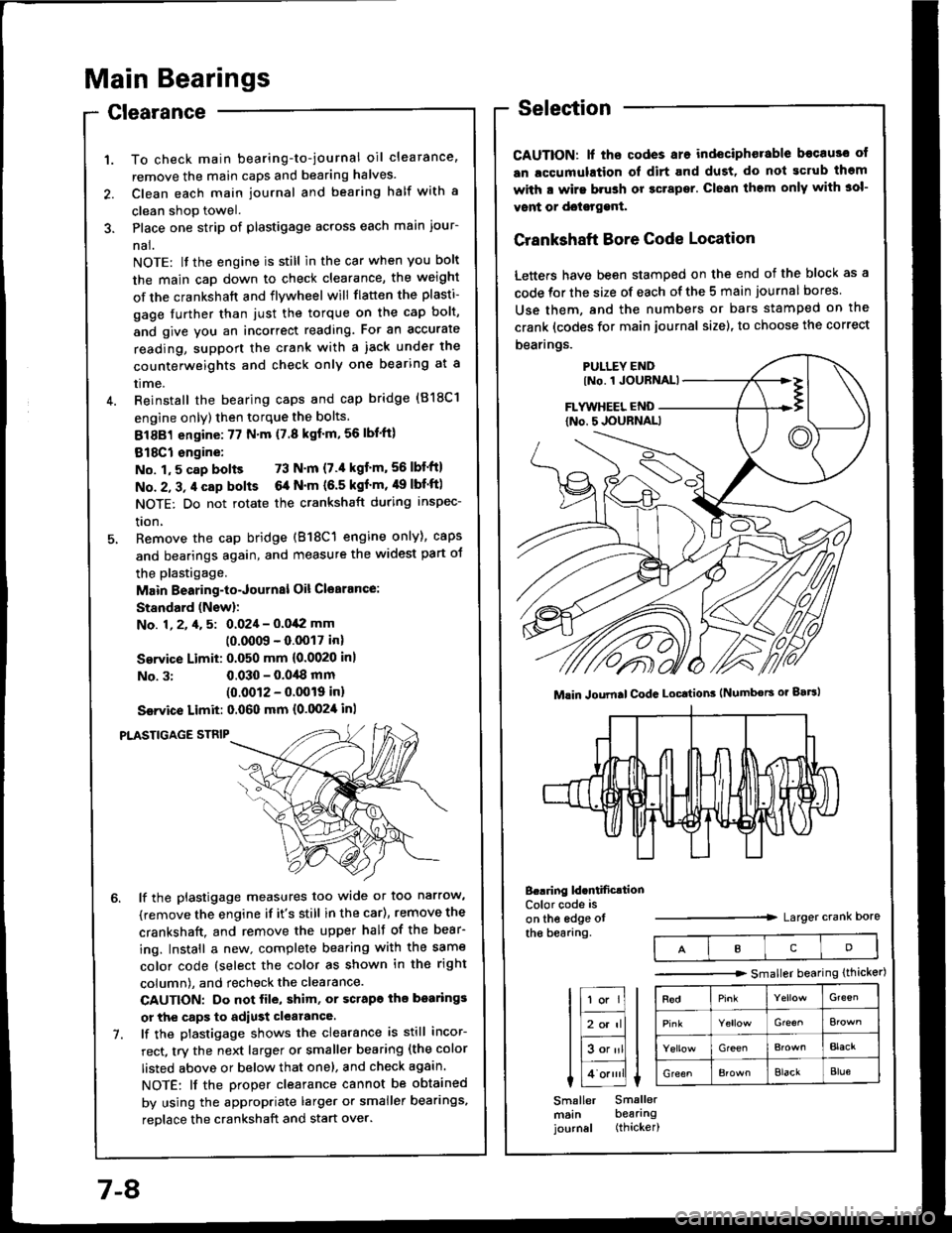

Main Bearings

Clearance

To check main bearing-to-journal oil clearance,

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

Place one strip of plastigage across each main iour-

nal.

NOTE: lf the engine is still in the car when you bolt

the main caD down to check clearance, the weight

of the crankshaft and flywheel will flatten the plasti-

gage further than just the torque on the cap bolt,

and give you an incorrect reading. Fot an accurate

reading, support the crank with a iack under the

counterweights and check only one bearing at a

trme.

Reinstall the bearing caps and cap bridge (818C1

engine only) then torque the bolts.

81881 engine:77 N'm (7.8 kgf'm,56lbl'ft)

818C1 engine:

No. 1,5 cap bolts 73 N'm (7.'l kgt'm,56lbf'ftl

No. 2, 3, 4 cap bolts 6a N'm (6.5 kgf'm, 49 lbf'ftl

NOTE: Do not rotate the crankshaft during inspec-

tron,

Remove the cap bridge (818C1 engine only), caps

and bearings again, and measure the widest part oJ

the plastigage.

Main Bearing-to-Journal Oil Cl€arance:

Standard (Newl:

No. 1, 2, 4, 5: 0.024 - 0.042 mm

10.0009 - 0.0017 inl

Service Limit: 0.050 mm {0.0020 inl

No. 3:0.030 - 0.0,18 mm(0.0012 - 0.0019 inl

Ssrvice Limit: 0.060 mm {0.0024 inl

PLASTIGAGE STNIP

lf the plastigage measures too wide or too narrow,

(remove the engine if it's still in the car), remove the

crankshaft. and remove the upper half of the bear-

ing. Install a new. complete bearing with the same

color code (select the color as shown in the right

column), and recheck the clearance.

CAUTION: Do not file, shim, or scrapo ihe bo.rings

or the caps to adiust clearance.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again.

NOTE: lf the Droper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

reolace the crankshaft and start over.

Selection

CAUTION: lf ths codes are indeciphorable becau3o ot

an lccumulation ol dirt and dust, do not gcrub thgm

with a wirs brush or gcrapsr. Clean them only with 3ol-

vont or doisrggnt.

Crankshaft Bore Code Location

Letters have been stamped on the end of the block as a

code for the size of each of the 5 main journal bores

Use them, and the numbers or bars stamped on the

crank (codes for main journal size), to choose the correct

bearings.

B..ring ld.ntificrtionColor code is

on the edge otthe bearang.Larger crank Dore

Mlin Joumal CodG Locttion3 (Numbors or gaBl

IcD

tr;;lIl

Itr-tl

lE;tl I tlHlt

I Lo.""li L

Smaller Smallermsin bearingjournal (thicker)

-------.r> smaller bearing (thicker)

G'een

Gre€^

GreenBlacr

GreenElackBlue

7-8

Page 153 of 1413

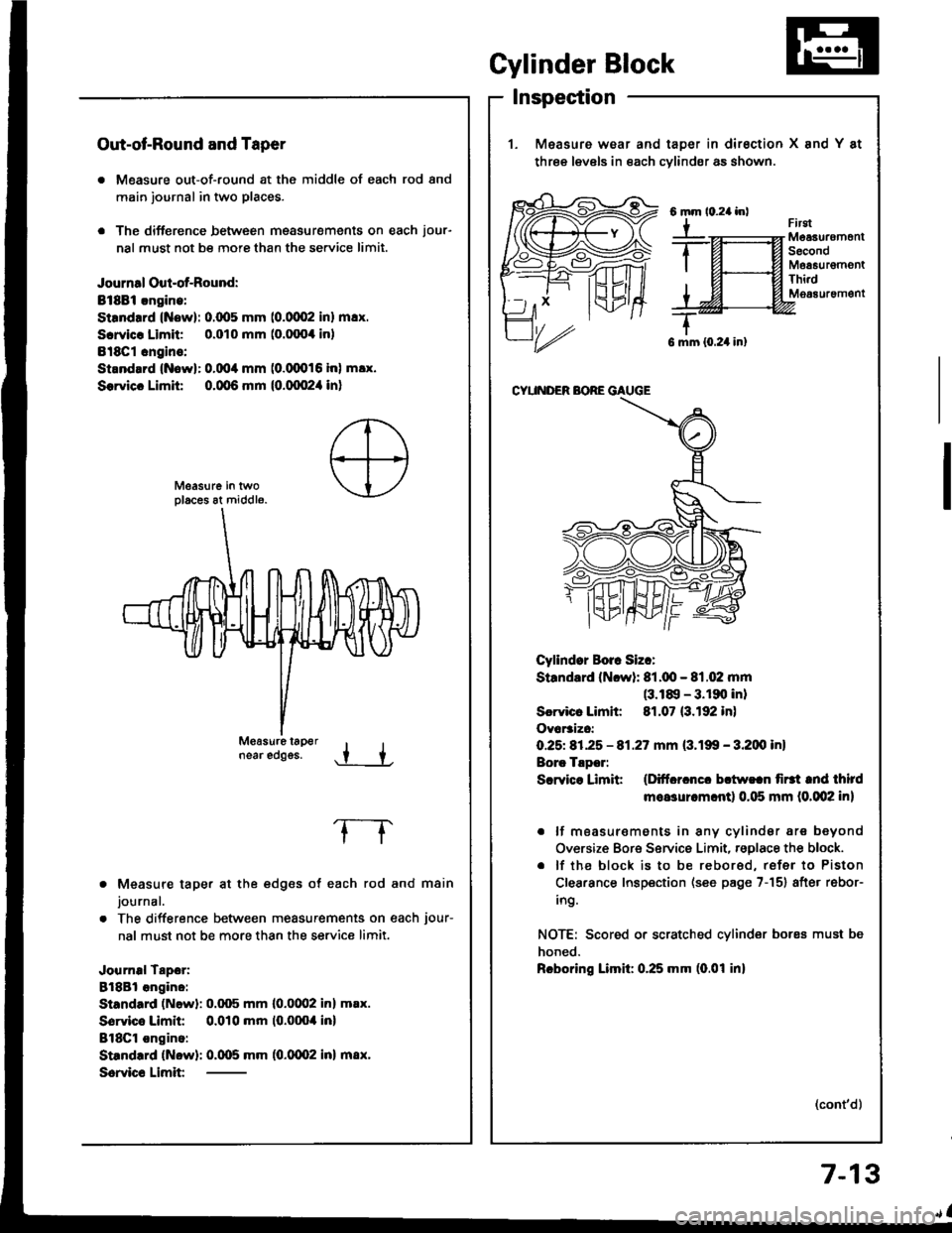

Out-ot-Round and Taper

. Measure out-of-round at the middle of each rod and

main journal in two places.

. The difference between msasurements on each jour-

nal must not be more than the se.vice limit.

Journal Oul-of-Round:

Bt8Bi.ngine:

Strndrrd (Now): 0.(x15 mm (0.0002 inl m!x.

Scrvicr Limit 0.010 mm (o.fixx inl

Bl8Cl cngins:

Strnd.rd {Nowl: 0.004 mm (0.(XD16 inl m!x.

Sorvicc Limit 0.qt6 mm {0.qx!2,1 in}

near edggs..t +

Measure taper at the edges of each rod and main

journal.

The difference between measurements on each jour-

nal must not be more than the service limit.

Journal Tapor:

8l8Bl angino:

Standard (Newl: 0.q)5 mm l0.0(Xl2 inl m.x.

Sorvico Limit 0.010 mm (0.0004 inl

BlSCl ongino:

Standrrd (Now): 0.005 mm (0.0002 inl m8x.

Scrvic€ Limit

frrgtMeaauremonlSecondMoa6urgmontThi.dM063uremgnt

G mm {0.24 in}

CYUNDER BORE GAUGE

Cyllndor Borr Siz.:

Standard (Ncwl: 81.q!- 81.02 mm(3.18, - 3.190 inl

Scrvicr Limh: 81.07 (3.192 in)

Ovar3izc:

O.25t 81.25 - 81.27 mm (3.199 - 3.200 inl

Borc Tlpor:

Scrvice Limit (Ditfcrcncc bctw!.n firtt tnd third

moasurcm.ntl 0.115 mm (0.002 in)

. lf moasur€ments in any cylindsr are beyond

Oversize Bore Service Limit, rsglace the block.

. lf the block is to be rebored, refer to Piston

Clearance Inspection (see page 7-151 after rebor-

ing.

NOTE: Scored or scratched cylinder bores must be

honed.

Rcboring Limil: 0.25 mm (0.01 inl

(cont'd)

Gylinder Block

Inspection

1. Measure wear and taDer in dirsction X and Y at

three levels in each cvlindsr as shown.

6mm

Y

7-13

Page 154 of 1413

Cylinder Block

Inspection (cont'dl

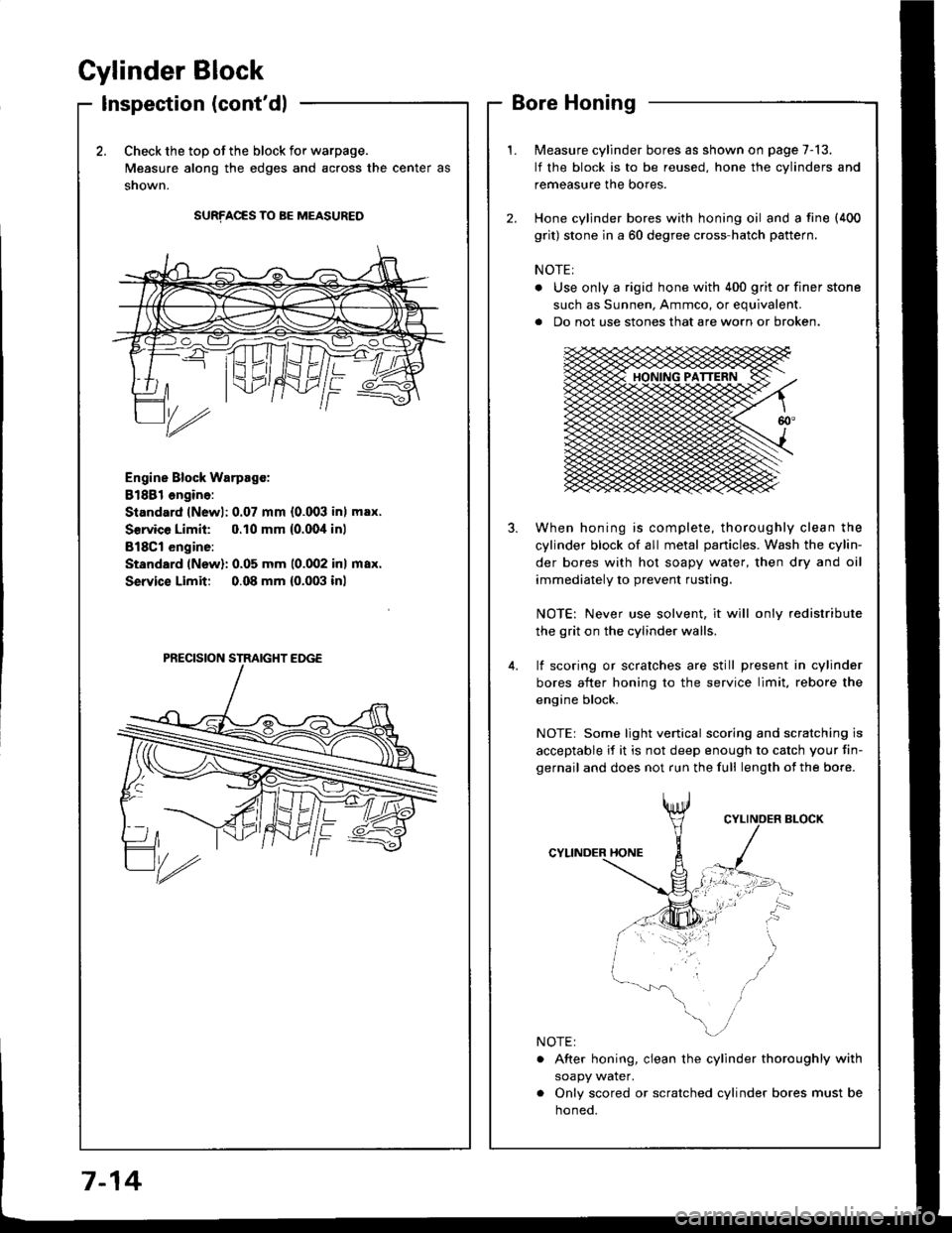

2.Check the top of the block for warpage.

Measure along the edges and across the center as

snown.

SURFACES TO BE MEASURED

Engine Block Warpsgc:

81881 ongine:

Standard lNewl: 0.07 mm {0.003 inl max.

Service Limil: 0.10 mm {0.00,1inl

B18Cl engine:

Standard (New): 0.05 mm 10.002 inl max.

Service Limit 0.08 mm {0.003 inl

Measure cylinder bores as shown on page 7-13.

lf the block is to be reused, hone the cylinders and

remeasure the bores.

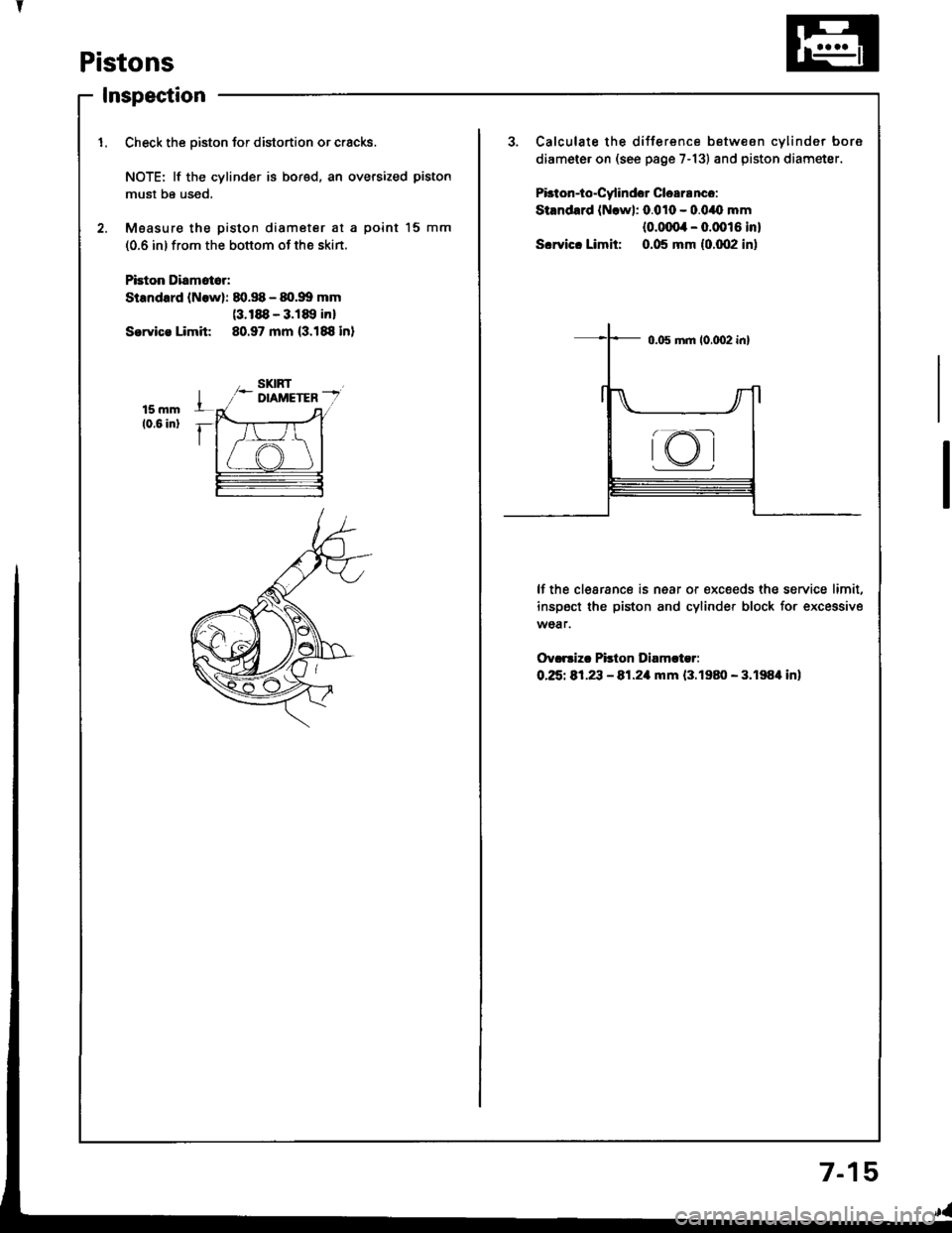

Hone cylinder bores with honing oil and a fine (400

grit) stone in a 60 degree cross-hatch pattern.

NOTE:

. Use only a rigid hone with 400 grit or finer stone

such as Sunnen, Ammco, or equivalent.

a Do not use stones that are worn or broken.

When honing is complete, thoroughly clean the

cylinder block of all metal panicles. Wash the cylin-

der bores with hot soapy water, then dry and oil

immediately to prevent rusting.

NOTE: Never use solvent, it will only redistribute

the grit on the cylinder walls.

lf scoring or scralches are still present in cylinder

bores after honing to the service limit, rebore the

engine block.

NOTEr Some light venical scoring and scratching is

acceptable if it is not deep enough to catch your fin-

gernail and does not run the full length of the bore.

CYLINDER HONE

. After honing, clean the cylinder thoroughly with

soapy water.

. Only scored or scratched cylinder bores must be

noneo.

7-14

Page 155 of 1413

Pistons

Inspection

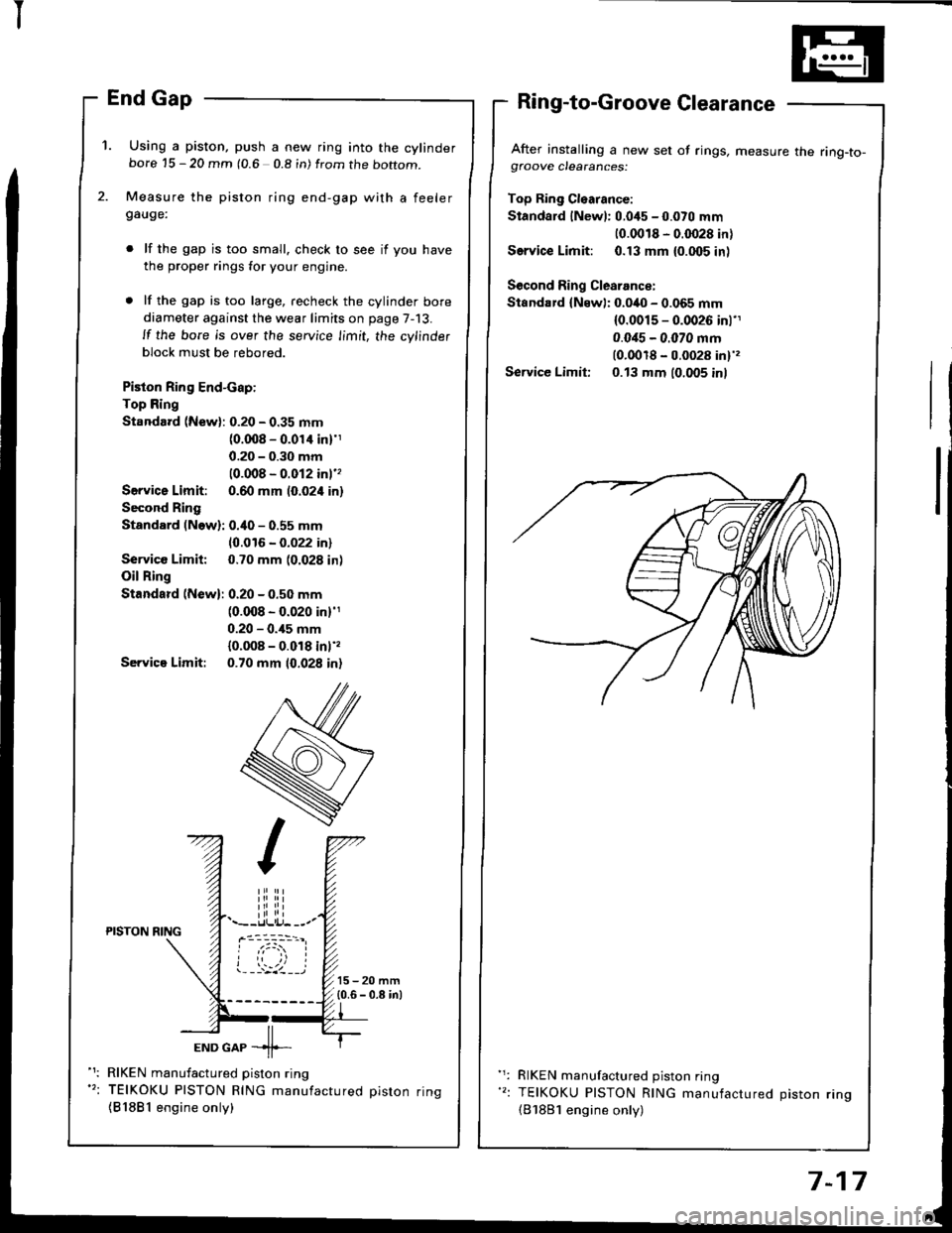

1. Check the oiston for distortion or cracks.3, Calculate the difference betw€on cvlinder bore

diameter on (see page 7-13) and piston diametsr.

Pbton-io"Cy'indor Clea18nco:

Stsndard (Nrwl: 0.010 - 0.0/O mm

{o.ofira - 0.0016 in}

S.rvic. Limit: 0.05 mm {0.002 in)

NOTE: lf the cylinder is bored, an oversized piston

must be used,

2. Moasur€ the piston diameter at a point l5 mm

(0.6 in) from the bottom of the skin.

Pbion Diamat6r:

Standard lNowl: 80.S - 80.99 mm(3.188 - 3.189 inl

Sorvica Limit 80.97 mm (3.188 in)

lf the clearance is near or €xc€eds the service limit,

inspect the piston and cylinder block for excessive

wear.

Ov.rsizc Pilton Diamcter:

O.25t 81,23 - 81.21|rnm {3.1980 - 3.198'l in)

rKI

7-1

Page 157 of 1413

I

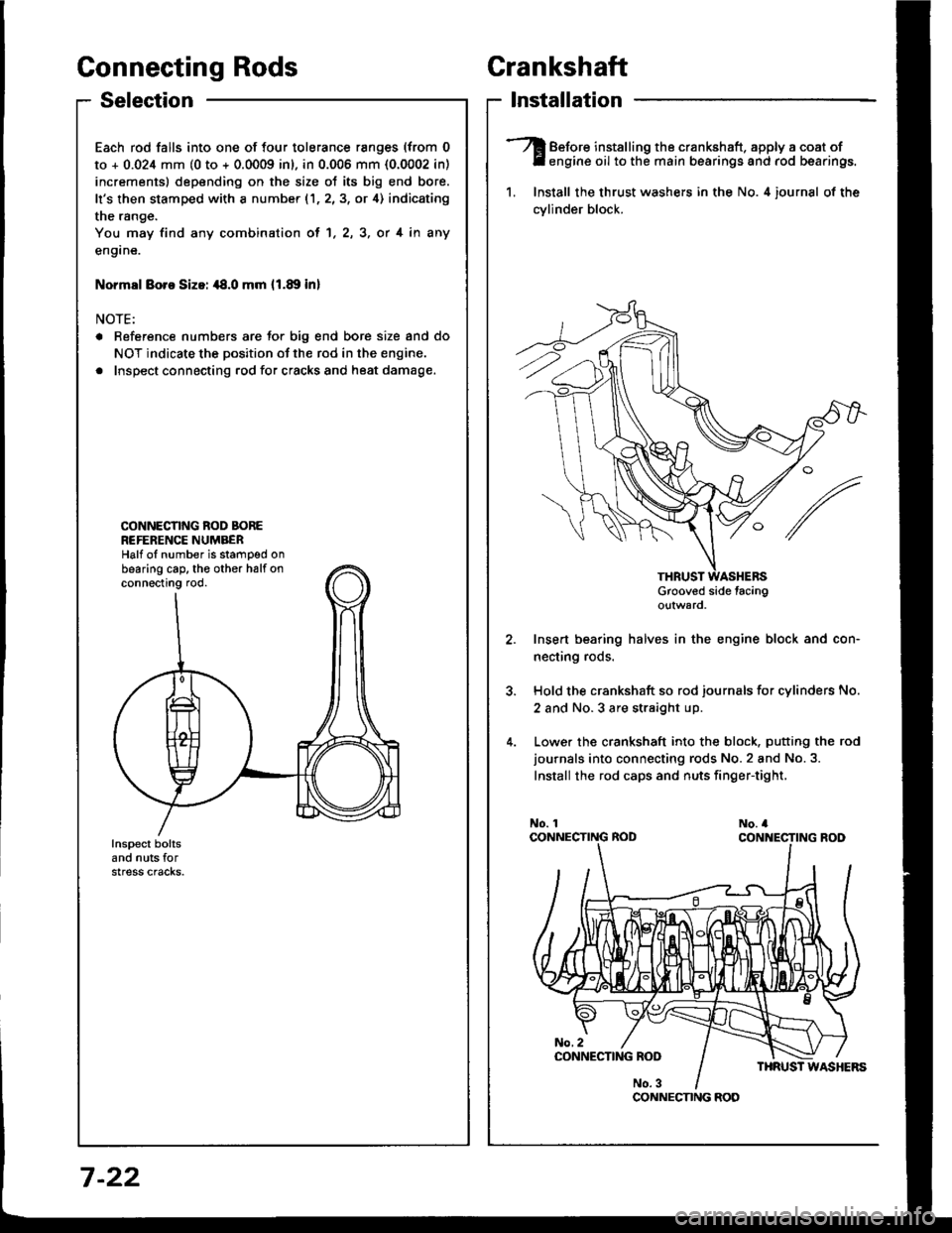

'1. Using a piston, push a new ring into the cylinderbore 15 - 20 mm (0.6 0.8 in) from the boftom.

Measure the piston ring end-gap with a feelergauge:

lf the gap is too small. check to see if you have

the proper rings for your engine.

lf the gap is too large, recheck the cylinder bore

diameter against the wear limits on page 7-13.

ll the bore is over the service limit, the cylinder

block must be rebored.

Piston Ring End-cap:

Top Ring

Standard (New): 0.20 - 0.35 mm(0.008 - 0.01'l inl'1

0.20 - 0.30 mm

10.008 - 0.012 inl''

Servica Limit: 0.60 mm (0.024 in)

Second Ring

Standard (Now): 0.40 - 0.55 mm

10.016 - 0.022 in)

Service Limit: 0.70 mm (0.028 in)

Oil Ring

Standard (New): 0.20 - 0.50 mm(0.008 - 0.020 in)'1

0.20 - 0.,15 mm

{0.008 - 0.018 inl',

Servica Limit: 0.70 mm 10.028 in)

After installing a new set of rings, measure the ring-to-gfoove clearances:

Top Ring Cl€arance:

Standard lNewl: 0.045 - 0.070 mm

10.0018 - 0.0028 in)

Service Limit: 0.13 mm {0.005 inl

Second Ring Clearance:

Standard {Newl: 0.040 - 0.065 mm(0.0015 - 0.0026 inl'1

0.0i15 - 0.070 mm(0.0018 - 0.0028 in)',

Service Limit: 0.13 mm (0.005 inl

iliiii.--r.llli.j- --.-PISTON NING

ioi

---'z llEND GAP -11--

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured oiston rinq

{81881 engine only)

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured Diston rino(B'1881 engine only)

7-17

Page 162 of 1413

Connecting Rods

Selection

Each rod falls into one of four tolerance ranges (from 0

to + 0.024 mm (0 to + 0.0009 inl, in 0.006 mm {0.0002 in)

increments) depending on the size ot its big end bore.

It's then stamped with a number (1,2,3, or 4) indicating

the range.

You may find any combination ol 1, 2, 3, or 4 in any

engane.

Normsl Boro Sizoi ,18.0 mm 11.89 inl

NOTE:

a Reference numbers are Jor big end bore size and do

NOT indicate the position of the rod in the engine.

. Inspect connecting rod for cracks and heat damage.

CONNECNNG ROD BOREREFERENCE NUMBERHalf oI number is stamped onbearing cap. th€ other halfonconnecting rod.

Crankshaft

lnstallation

Before installing the crankshaft. apply a coat ofengine oil to the main bearings and rod bearings.

1. Install the thrust washers in the No. 4 iournsl of the

cvlinder block.

Grooved side tacingo!tward

Insert bearing halves in the engine block and con-

necting rods.

Hold the crankshaft so rod journals for cylinders No.

2 and No.3 are straight up.

Lower the crankshaft into the block. putting the rod

journals into connecting rods No.2 and No.3.

Install the rod caps and nuts finger-tight,

CONNECNNG ROD

7 -22

Page 164 of 1413

Grankshaft

Installation (cont'd)

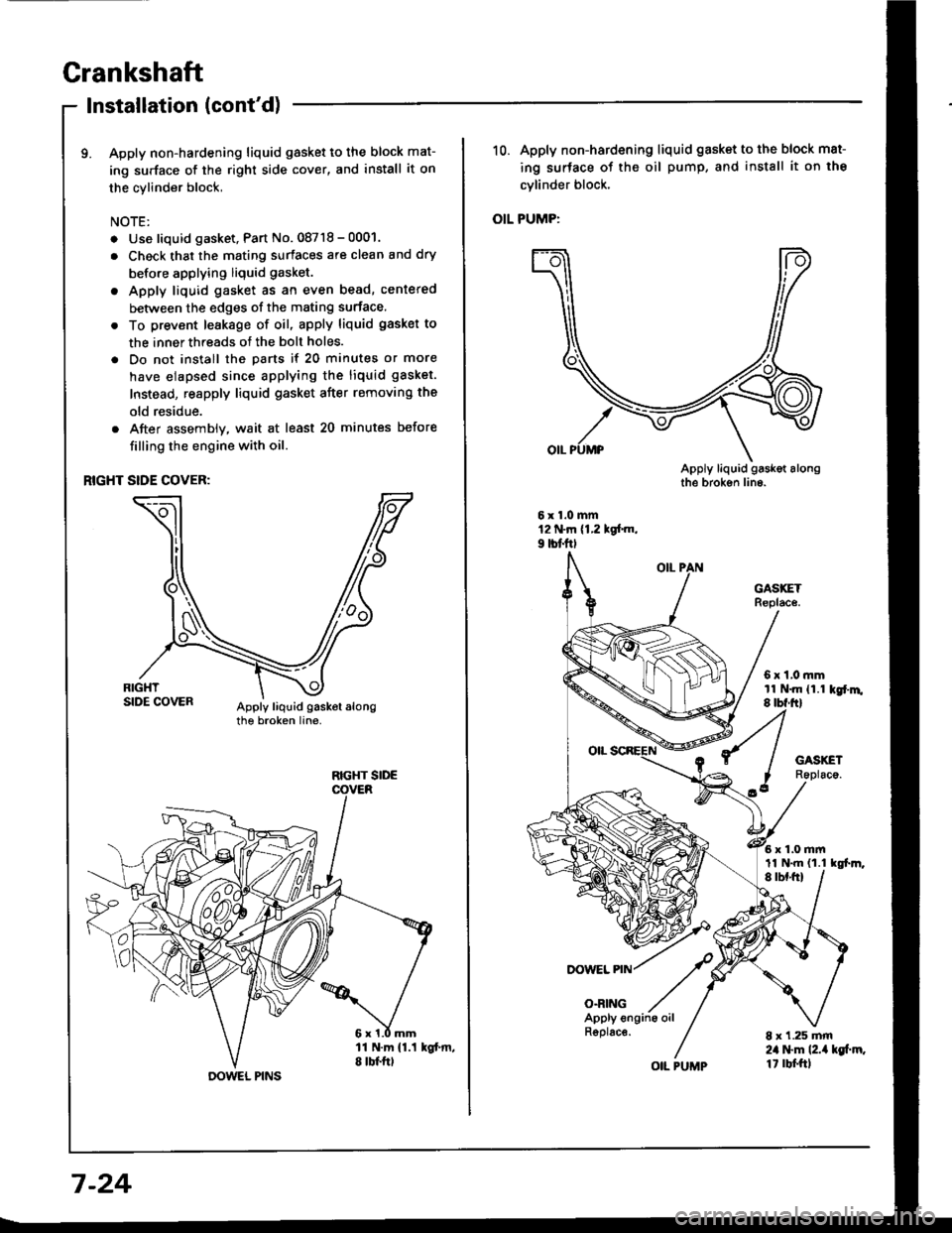

9. Apply non-hardening liquid gasket to the block mat-

ing surface of the right side cover, and install it on

the cylinder block,

NOTE:

. Use liquid gasket, Part No. 08718 - 0001.

. Check that the mating surfaces are clean and dry

before applying liquid gasket.

. Apply liquid gasket as an even bead, centered

between the edges of the mating surface.

. To prevent leakage of oil, apply liquid gasket to

the inner threads of the bolt holes.

. Do not install the parts if 20 minutes or more

have elapsed since applying the liquid gasket.

Instead, reapply liquid gasket after removing the

old residue.

. After assembly, wait at least 20 minutes before

filling the engine with oil.

RIGHT SIDE COVER:

RIGHT SIDE

DOWEL PINS

7-24

R6plac€.

OIL PUMP

10. Apply non-hardening liquid gasket to the block mat-

ing surface of the oil pump, and install it on the

cvlinder block.

OIL PUMP:

DOWEL PIN

O.RING

6x1,0mmtl N.m {1.1 kgr'm.8 tbf.ftl

6x1.0mm

8 x 1.25 mm2il l$m l2.ia kg[.m.1t rbf.ftl

11 N.m {1.1 tgl.m,

Page 165 of 1413

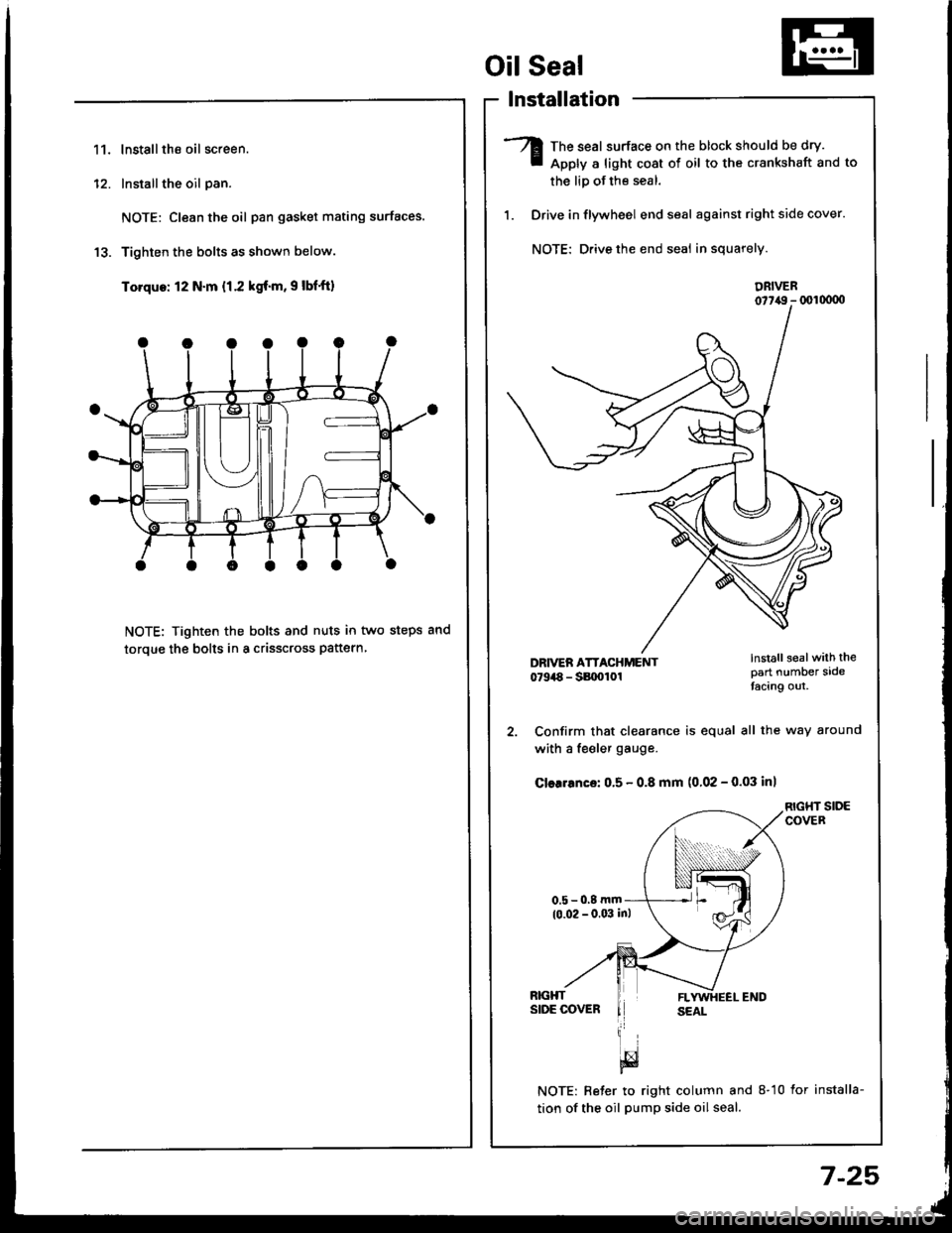

11.lnstallthe oil screen.

Installthe oil pan.

NOTE: Clean the oil pan gasket mating surfaces.

Tighten the bolts as shown below.

Torque: 12 N.m {1.2 kgf.m, 9 lbf'ft)

NOTE: Tighten the bolts and nuts in two steps and

toroue the bolts in a crisscross pattern

1'�I

Oil Seal

lnstallation

The seal surface on the block should be dry.

Apply a light cost of oil to the crankshaft and to

the liD of the seal.

Drive in flywheel end seal against right side cover.

NOTE: Drive the end seal in squarely.

DRIVER07t,49 - (xll(xtoo

2. Confirm that clearance is equal all the way around

with a fe€ler gauge.

Cler.6nce: 0.5 - 0.8 mm (0.02 - 0.03 inl

RIGHT SIDECOVER

NOTE: Reter to right column and 8-10 lor installa-

tion of the oil pump side oil seal.

lnstall sealwith thepart number sidetacing out.

7-25