Block HONDA INTEGRA 1994 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 258 of 1413

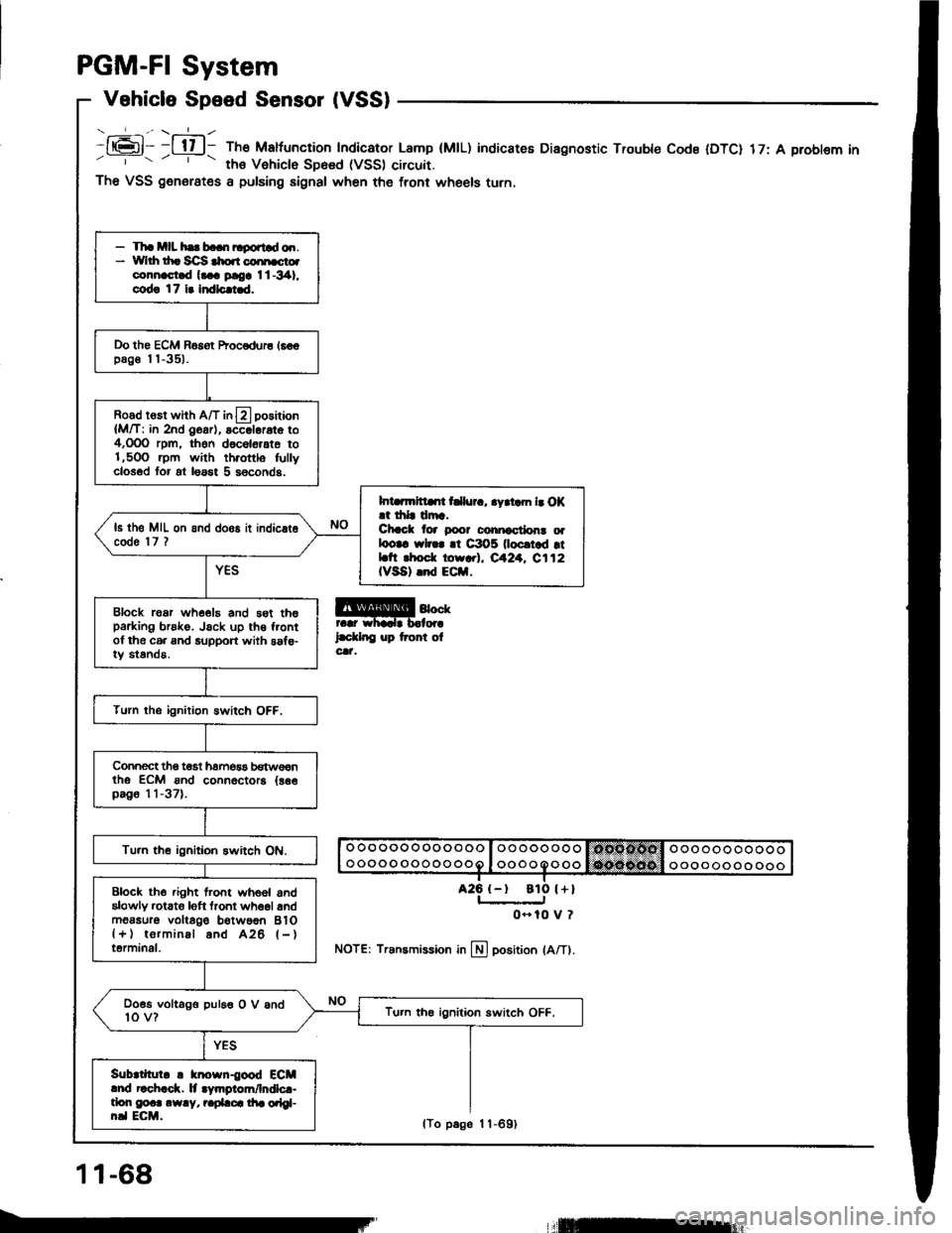

PGM-FI System

Vehicle Speed Sensor (VSS)

- _-_f_-., \-=1_ -

It6l- -l tl l- The Maltuncrion Indicator Lamp (MtL)' ths Vehiclo SD6sd (VSS) circuit.

indicateE Diagnostic Trouble Code IDTC) 17: A problem in

a25 {-t

The VSS generates a pulsing signal when the front wheels turn.

@4""rr.r whadr b.lor.

l.d.lnC up tront olcat,

NOTE: Transmission in llj position lA/Tl.

- Tha mll hs b..n ltgortld o.r.* Yvlrh th. Sc]S $o.r coi[cto.connast.d l... ploa I l -341,

cod! 17 i. Indlc.i.d.

Do the ECM Basot Procodur6 16€€pag€ I I -351.

Road rosr whh A/T in13 positaon

{M/T: in 2nd O6ar), accol6rat6 to4,OOO rpm, thon d6c6l6,ate to1,5OO .pm with th.ottlo fullyclosod tor at loast 5 s6conds.

Int rmltllrt t llur., .yrtam b O|(.t drlr drr.Chcct lor poor conicctlon! oalootc wl... !t C3O5 0ocrtad rtLtt rhod. torr.l, eA24. C112IVSA) .nd ECil.

ls th6 MIL on and doos it indic.t6code 'l7 ?

Block roar whe€19 and 5st th6parking brsko. Jsck up th€ f.ontof the c6. and support with saf€-iy standa.

Turn the ignition Bwitch OFF.

Connect tho t€st hamos3 b€tw€€ntho ECM ond connoctora {as€pag6 11-37).

Tu.n th€ ignitioh switch ON.

Block the .ight lront whoel andalowly rctato loft tront wh6ol andm6asur6 voltago b€twoon BlO{+) torminal and A26 l-}terminal.

Doss voltago puleo O V and10 v?Tu.n th€ ignition switch OFF.

Sub|tllul. ! knosn{ood ECMlnd r!ch.ck. lt .Vmgiom/lndlc.-tlon g@.. .w.y, r.pLca di. orlgl-n.l ECM.

ato l+l

0- 10 V ?

11-68

lTo p6ge 1 1-691

llEur

Page 259 of 1413

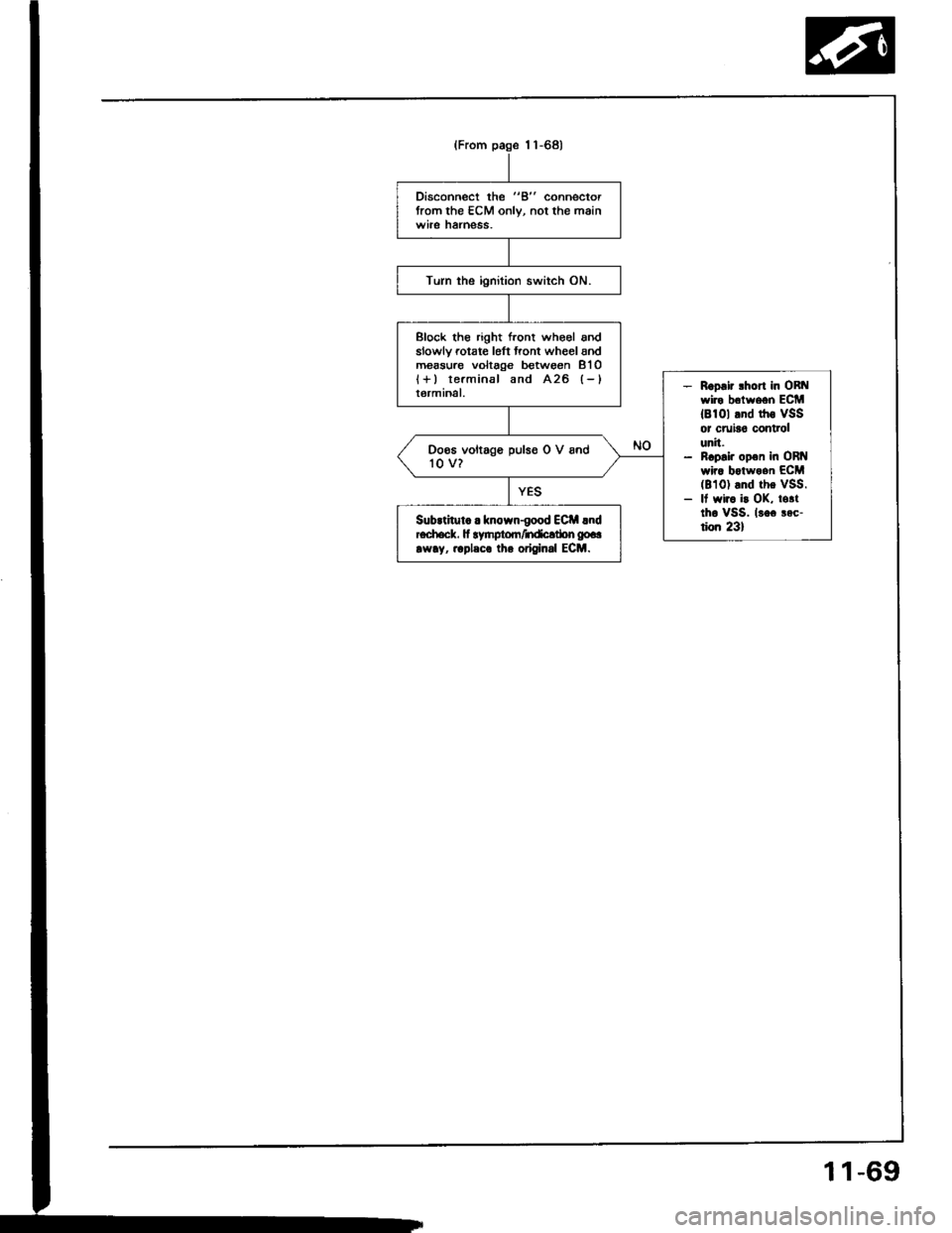

Disconnect the "B" connectorfrom the ECM only, not the mainwile hatness.

Turn the ignition switch ON.

Block tho right front who€l andslowlv rotate l6ft front wheel andm€asure voltage between 8'l Ol+) terminal and A26 (-)

terminal.- Roo.ir lhort in ORt{wire belween ECM18101 tnd rhs VSSor cruia6 controlunit.- ncp.i. op€n in ORI{wira botwoan ECM(8101 and the vSS.- It wir. i! OK, totttho vSS. lsoc aec-tion 231

Doos voltage pulso O V and'to v?

SubrtituL . known-good ECil lndEch.ck. fi lynptom/ndcltbn gp..

rw!y, .rpleco lh. original ECM.

(From page 1 1-68)

1 1-69

Page 313 of 1413

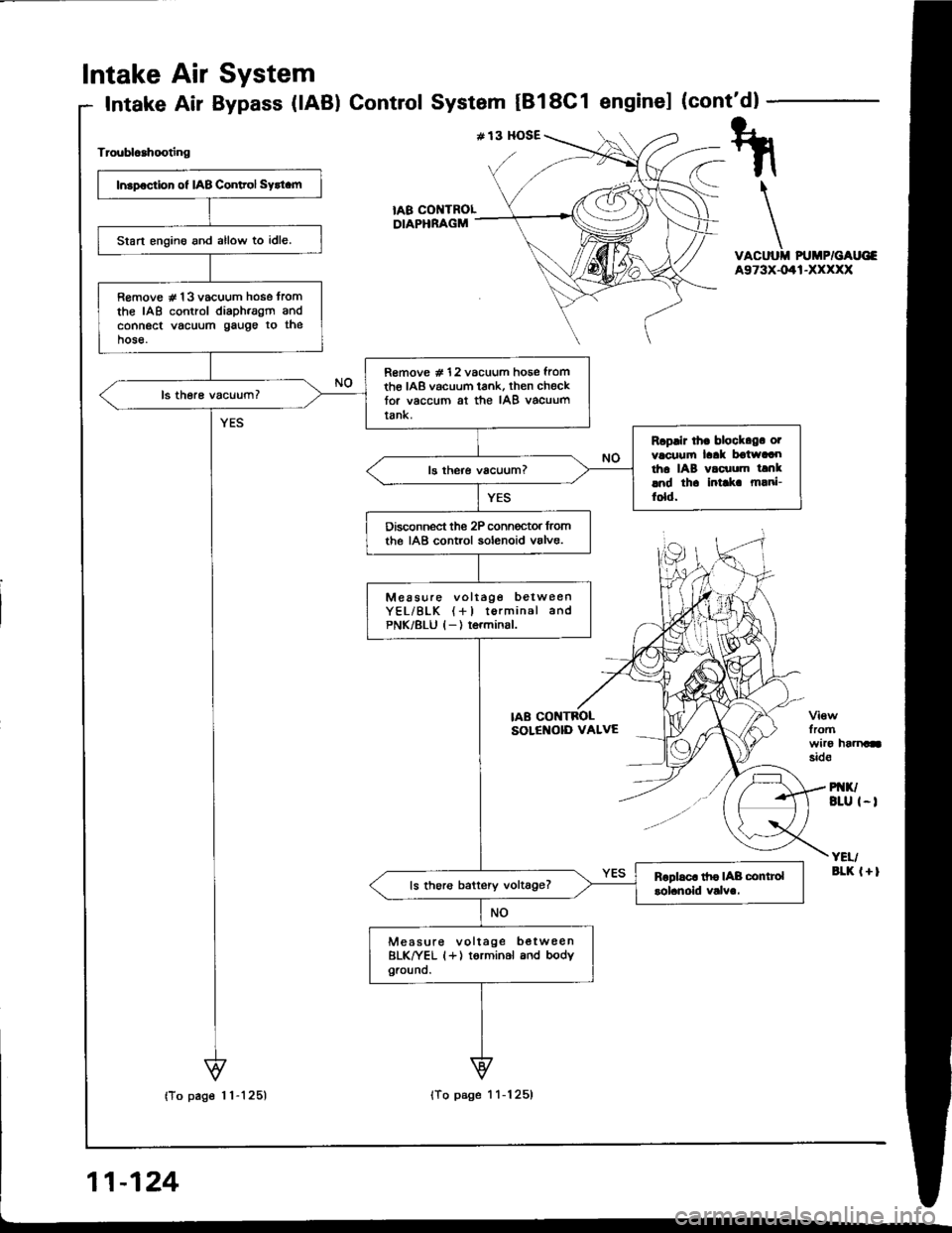

Intake

Intake

Air

Air

System

Bypass (lAB) ControlSystem tBl8C1 enginel (cont'dl

Troublcahooting

VACUUII PUMP/GAUG€A973X-041-XXXXX

fromwiro haanasid€

PI{K/BLU I-I

YEI/aLK l+l

tA8 COI{TROLDIAPHRAGM

Insp€ction of IAB Conltol Sytt.m

Start engino and allow to idle.

R€move # 13 vacuum hose tromthe IAB control diaph.agm andconnect vacuum gauge to thehose.

R€move # 12 vacuum hose fromth€ IAB vacuum tank, then checktor vaccum at the IAB vacuumtank.

Rcplir lh. block.g. otvacuufi laak boiwaaotha IAB vacuum tanklnd th. intlk m!ni-fold.

Disconnect the 2P conn€ctor lromthe IAB control solenoid valve.

Measure voltage betweenYEL/BLK (+l torminal andPNK/8LU l-) terminsl.

ls thoro battery voltage?

Measure voltage b€twee nBLK^|/EL (+) torminal and bodyground.

IAB CONTBOLSOLENOID VALVE

Page 328 of 1413

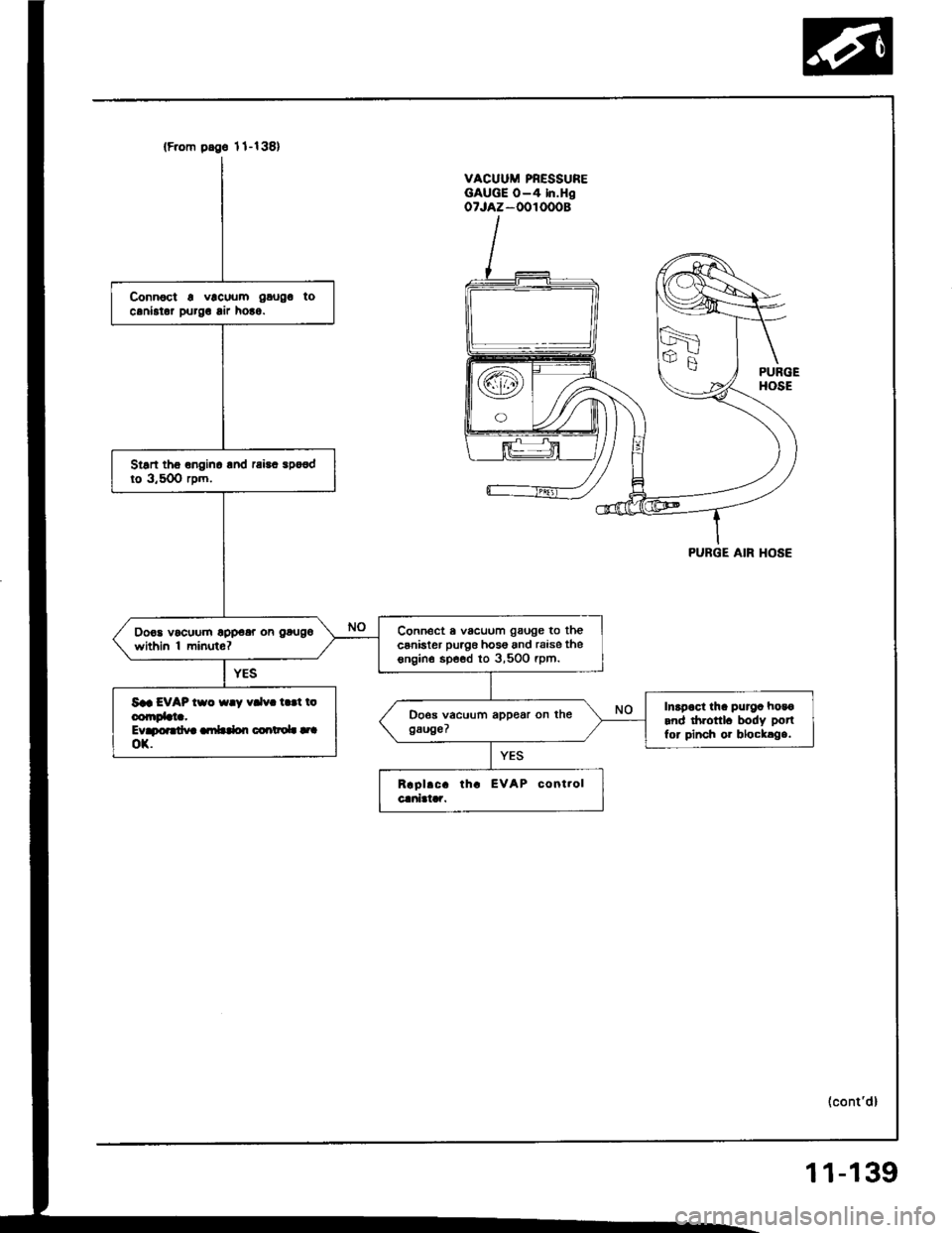

(F.om pdge 1l-138)

Connoct a vlcuum gaugo tocaniator purg! lir ho!o.

Stsn tho onginc lnd rai!. spo€dto 3,50O rpm.

Connect a vacuum gauge to thecsnister puag6 hos6 and raise thesngin€ spe€d to 3,500 rpm.

Do€a vocuum opp€ar on gougo

within 'l minuto?

Saa EVAP tso {ay vdv. t.!t ioconrDbta.Evapoardva ambdon coartaoL |.|ox.

Inapoct tha purga hosoand drronl. body potl

for pinch or blocklga.

VACUUM PRESSUREGAUGE O-4 In.HgoTJAZ-OOIOOOB

PURGE AIR HOSE

(cont'd)

11-139

Page 346 of 1413

Transmission Assembly

Removal

Mskc aurs iack! and safoty Etands aro placod proper-

ly lsl8 saqtion 1|.

Apply parking brake tnd block rear whccl! to car

will not roll ofl stand3 and f.ll on you while wotking

undrr it.

CAUTION: Use tondcr coyar3. to avoid drmlging

plintsd 3qrfaca3,

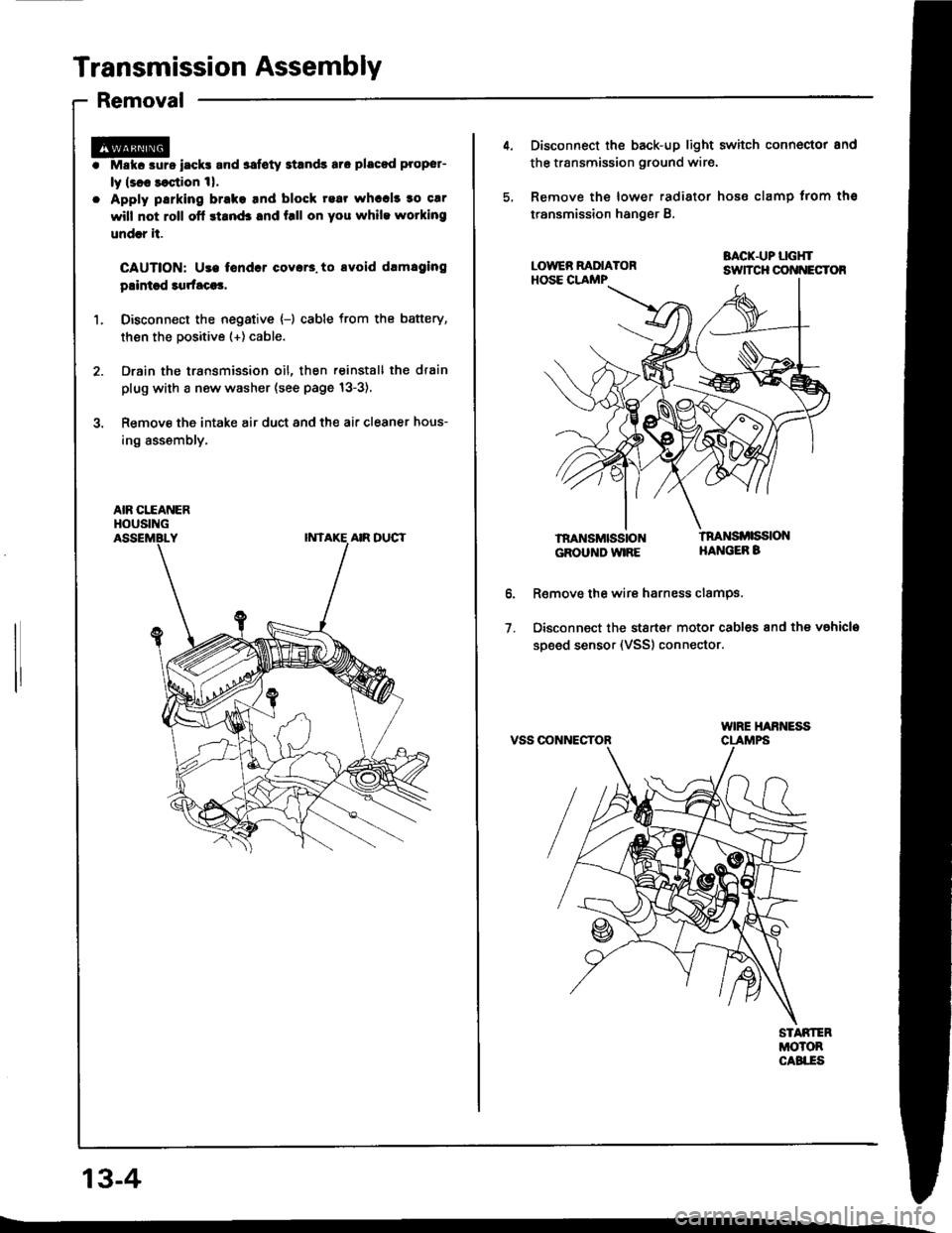

Disconn€ct the negative {-) cable from the battery,

then the positive (+) cable.

Drain the transmission oil, then reinstall the drain

plug with a new washer (see page 13-3),

Remove the intake air duct and the air cleaner hous-

ing assembly,

AIR CITANERHOUSING

13-4

4. Disconnect the back-up light switch connoctor and

the transmission ground wir€.

5, Remove the lower radiator hose clamp trom ths

transmission hanger B.

BACK.UP LGHTsuTcH cot{t{EcToR

lnaNsMttistoNGROUND WIRE

tnaNsi ssloNHANGEB B

o.

1.

R€move the wire harness clamPs.

Disconnect the stsrt€r motor cables and the vahicla

soeed sensor (VSS) connector.

VSS OONNECTOR

Page 367 of 1413

- Disassembly

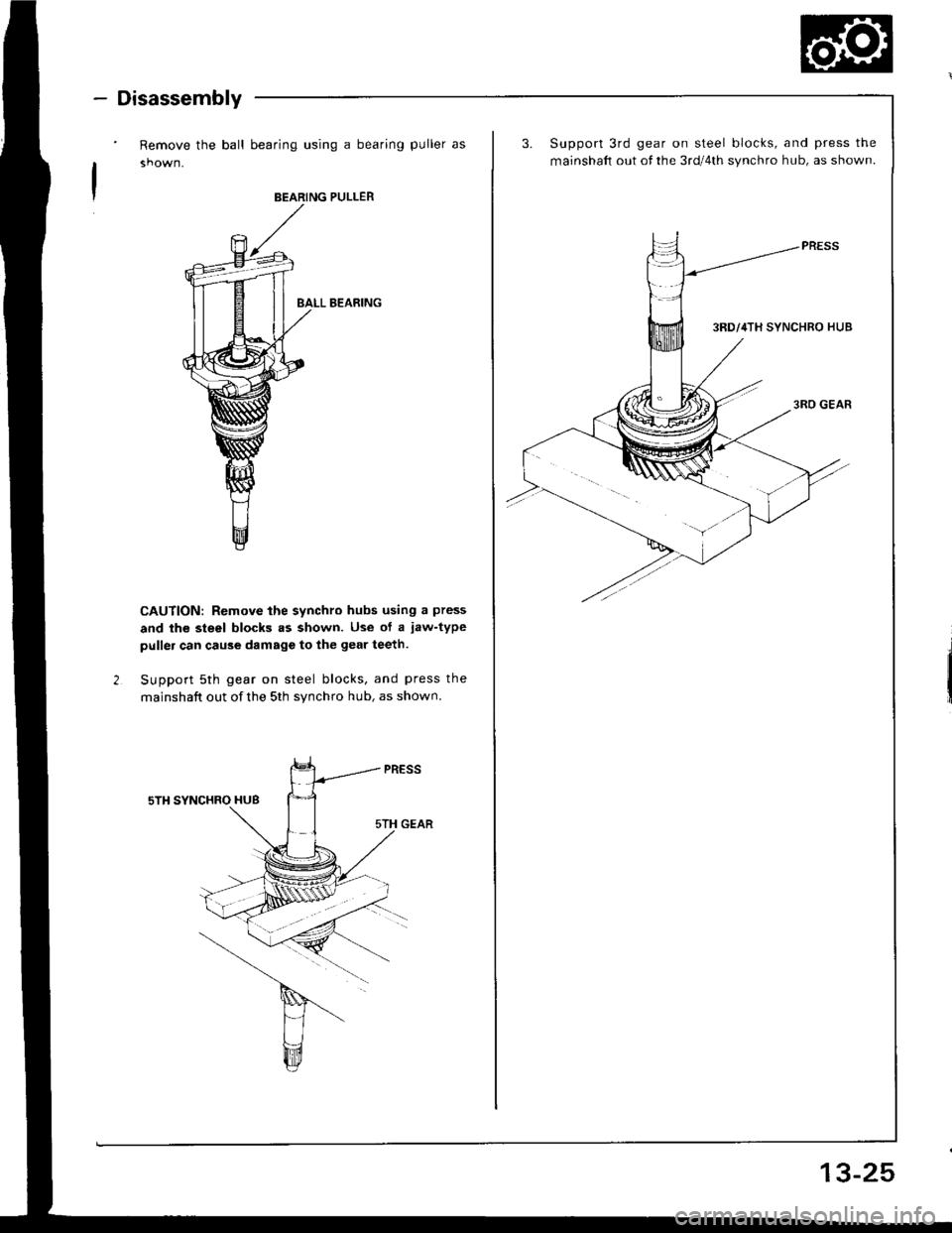

Remove the ball bearing using a bearing puller as

BEARING PULLER

BALL B€ARING

CAUTION: Remove the synchro hubs using a press

and the steel blocks .s shown. Use of a jaw-type

puller can cau3e damags to the gear teeth.

Support 5th gear on steel blocks, and press the

mainshaft out of the 5th synchro hub, as shown.

3.Support 3rd gear on steel blocks, and press the

mainshaft out of the 3rd/4th synchro hub, as shown.

13-25

Page 369 of 1413

1_

ReassemblV

ATTACHMENT,35 mm LD.07746 - 0o30/rc0

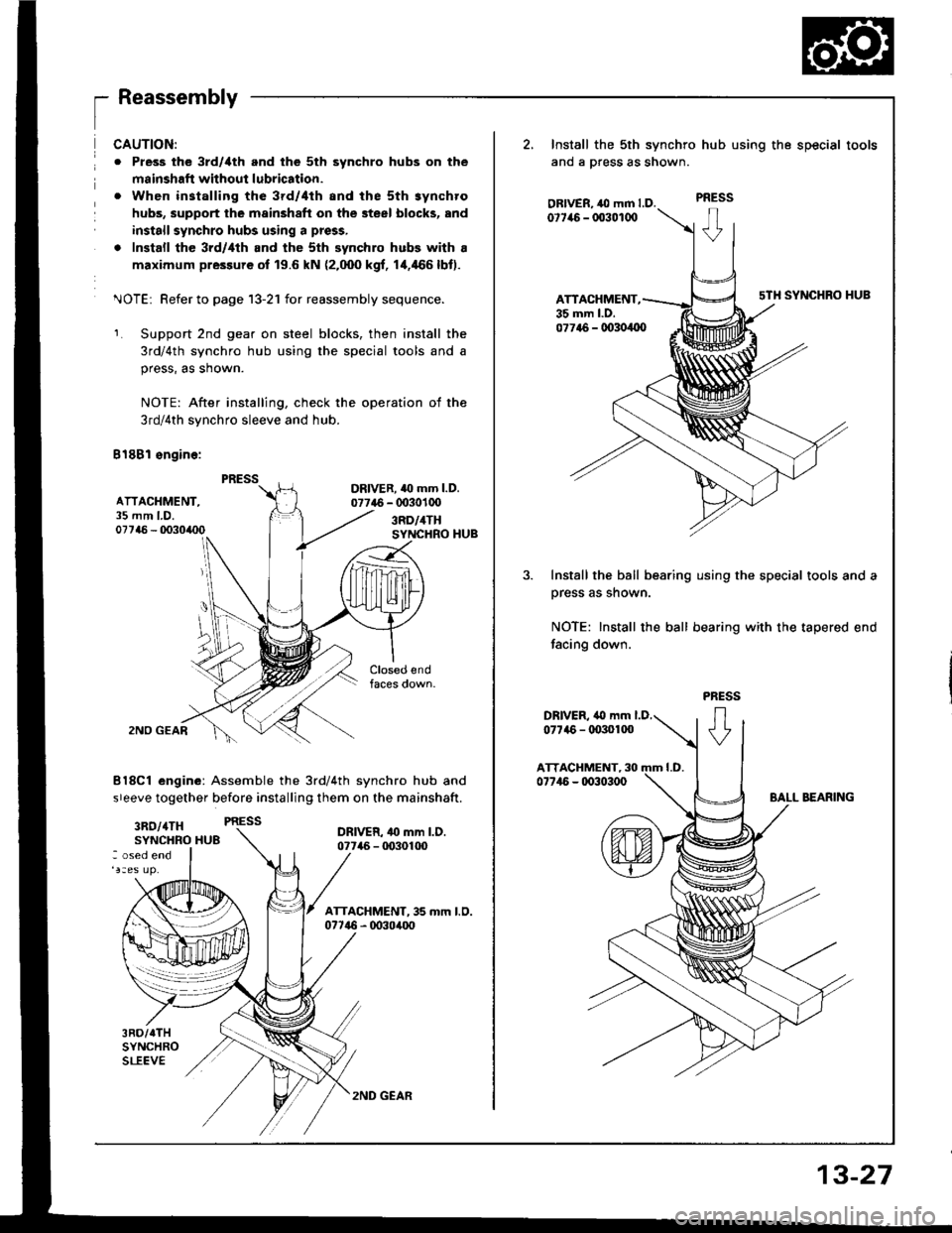

CAUTION:

o Pless the 3rd/ilth and the 5th synchro hubs on the

msinshafi without lubrication.

. When installing the 3rd/4th and the sth synchro

hubs, support the mainshaft on the steel blocks, and

install synchro hubs using a press,

. Install the 3rd/,lth and the sth synchro hubs with a

maximum pressure of 19.6 kN (2.000 kgf, 1+466lbt).

^JOTEi Refer to page 13-21 for reassembly sequence.

Support 2nd gear on steel blocks, then install the

3rd/4th synchro hub using the special tools and a

press, as shown.

NOTE: After installing, check the operation of the

3rd/4th synchro sleeve and hub.

B18Bl sngine:

DRIVER. 40 mm l.D.07746 - 0030100

3RD/4THSYNCHRO HUB

2NO GEAR

8l8Cl engine: Assemble the 3rd/4th synchro hub and

sreeve together before installing them on the mainshaft.

3RO/4TH PRESS

SYNCHRO HU8DRIVER- 4o mm l.D.07746 - tD30100: osed end

3RD/TTHSYNCHROSLEEVE

2, Install the sth synchro

ano a press as snown.

OBIVER, ,O mm LD.0t7it6 - 003010O

ATTACHMENT,35 mm l.D.

hub using the special tools

PRESS

sTH SYNCHRO HUB

077t6 - 00304{x)

Install the ball bearing using the special tools and a

prsss as shown.

NOTE: Install the ball bearing with the tapered end

facing down.

2ND GEAR

13-27

Page 372 of 1413

Countershaft Assembly

Disassembly

13-30

't.Securely clamp the countershaft assembly in a

bench vise with wood blocks.

Raise the locknut tab from the groove in the coun-

tershaft, then remove the locknut and the spring

washer.

4,Remove the bearing outer .ace, then remove the

needle bearing using a bearing puller as shown.

2.

BEARING PULLER

BEARING

Remove the ball bearing using a bearing puller as

shown.

CAUTION: Romove the gclrs using a pross and tho

steol blocks rs shown. U3a of a l.w.typo pullor can

cau36 damagg to tho gsar iocth.

Support 4th gear on steel blocks. and press the

countershaft out of sth and 4th gears, as shown.

PULlTR

\-Y

Page 374 of 1413

Countershaft Assembly

Reassembly

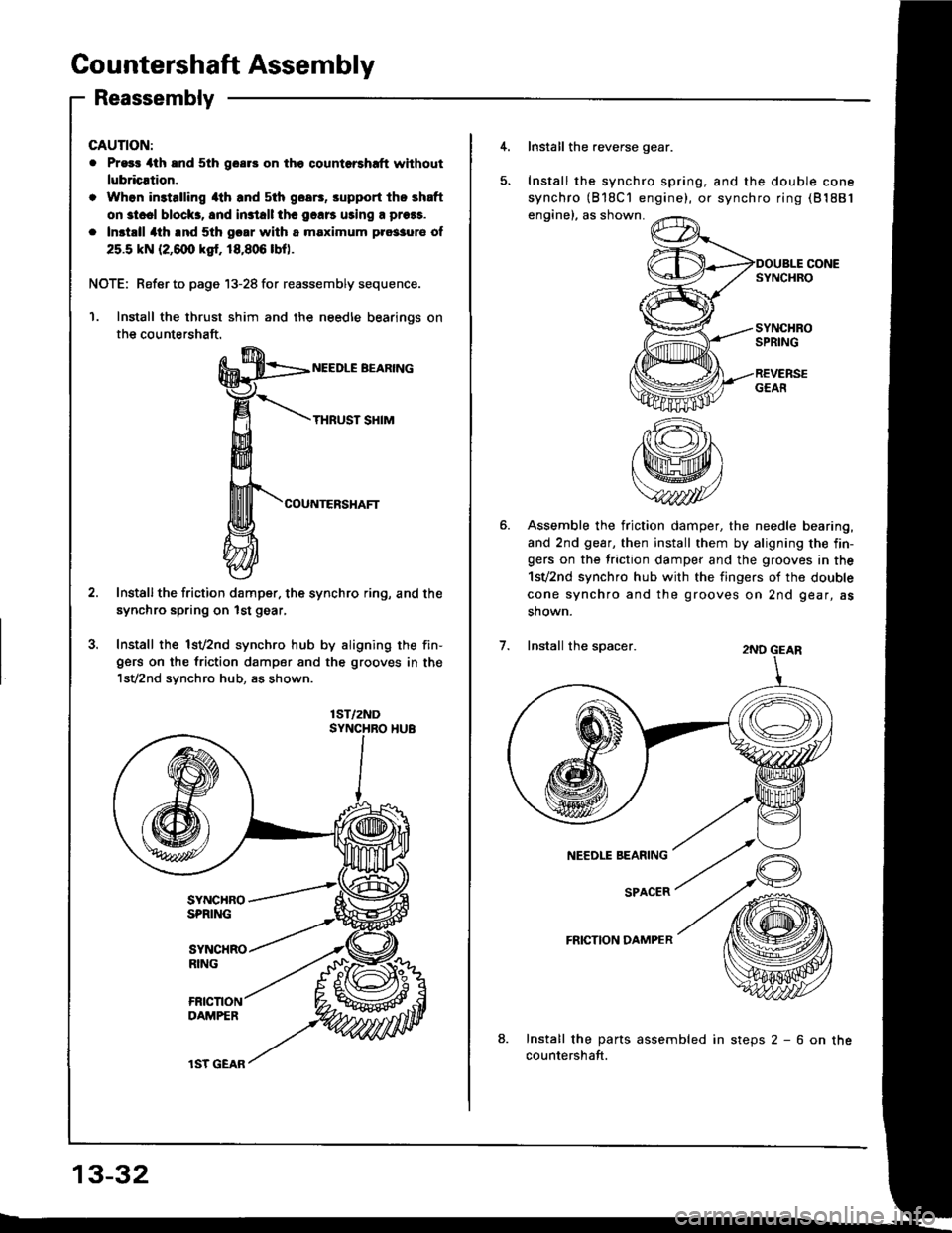

GAUTION:

. Pr93r 4th and 5th goar3 on the qountorshrft without

lubricrtion.

. Whon in3talling 4th and sth goa6, srpport the shaft

on st..l block3, 8nd in3tall thc 9.116 uring a prors.

. Inst.ll 4th lnd 5th gcar with a maximum pro33ur€ of

25.5 kN (2,6@ ksr. 18,806 lbo.

NOTE: Refer to page 13-28 for reassembly sequence.

Install the thrust shim and the needle bearinos on

the countershaft.

NEEDLE BEARING

THRUST SHIM

COUNTERSHAFT

Installthe friction damper. the synchro ring, and the

synchro spring on lst gear,

Install the lsv2nd synchro hub by aligning the fin-gers on the friction damper and the grooves in the'lsV2nd synchro hub, as shown.

1ST/2ND

13-32

lST GEAR

4. Install the reverse gear.

Install the synchro spring, and the double cone

synchro (818C'l engine), or synchro ring (81881

engine), as shown.

SYNCHROSPRING

REVERSEGEAfi

Assemble the friction damper, the needle bearing,

and 2nd gear, then install them by aligning the fin-gers on the friction damper and the grooves in the

1sv2nd synchro hub with the fingers of the double

cone synchro and the grooves on 2nd gear, as

shown.

2ND GEAR

NEEDLE BEARING

SPACER

FRICTION DAMPER

8.Install the parts assembled in steps 2 - 6 on the

countershaft.

Install the spacer.

Page 375 of 1413

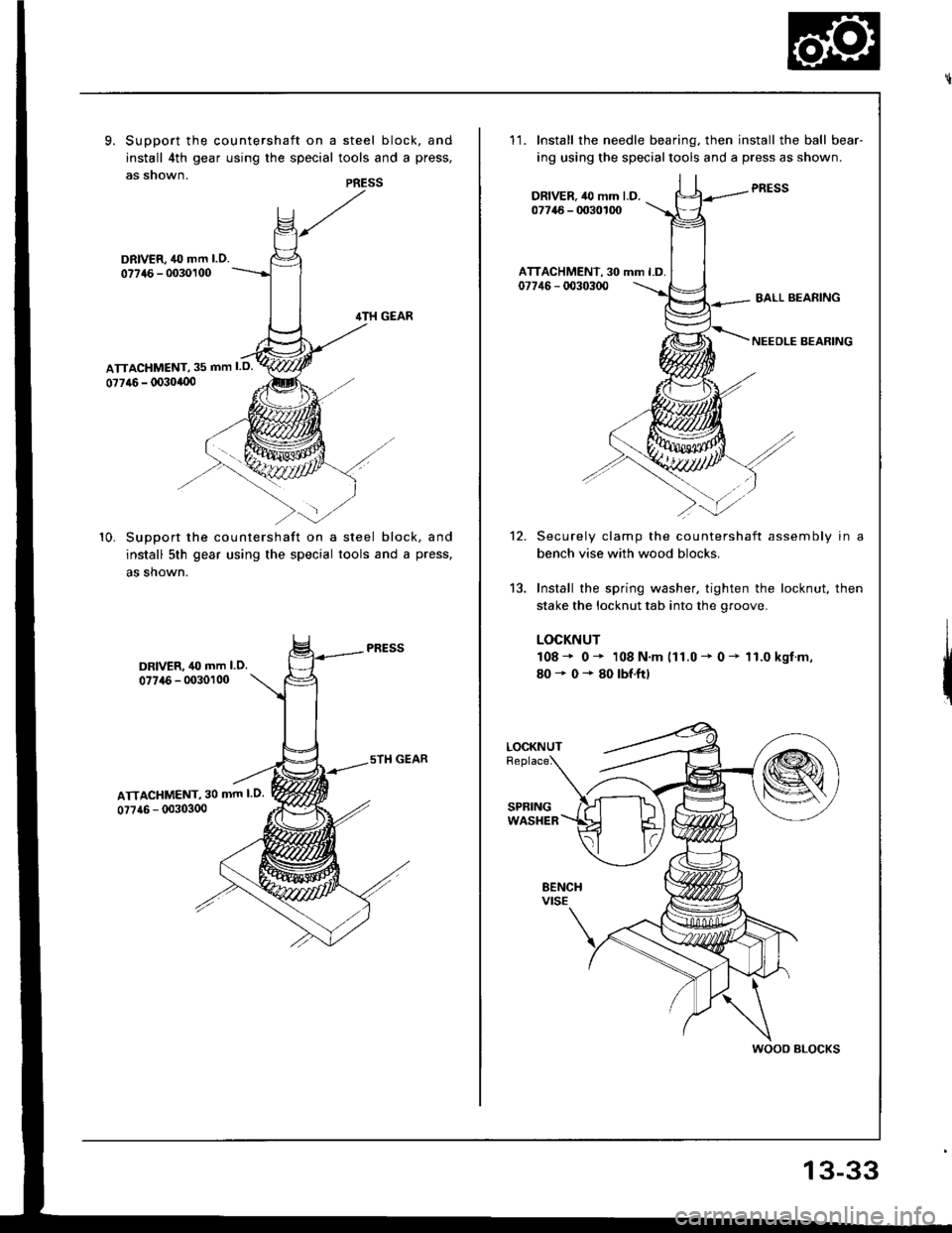

9. Support the countershaft on a steel block, and

install 4th gear using the special tools and a press,

as snown.PRESS

DRIVER, 40 mm l.O.

077{6 - 0030100

10. SuDDort the countershaft on a steel block, and

install 5th gear using the special tools and a press,

as shown.

DRIVER, 40 mm l.O.07746 - 0030100

ATTACHMENT, 30 mm l.O.

0?7a6 - (X)303(x)

11.Install the needle bearing. then install the ball bear-

ing using the specialtools and a press as shown.

PRESSDRIVER.,l0 mm l.D.07746 - 0030100

ATTACHMENT, 30 mm l.D.07746 - d)30300BALL BEARING

NEEDLE BEARING

12.

13.

Securely clamp the countershaft assembly in a

bench vise with wood blocks.

Install the spring washer. tighten the locknut, then

stake the locknut tab into the groove.

LOCKNUT

108* 0* 108 N.m (11.0 - 0 - 11.0 kgf.m,

80+0*80lbf.ftl

LOCKNUT

wooo BLocKs

13-33