light HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 602 of 1413

Driveshafts

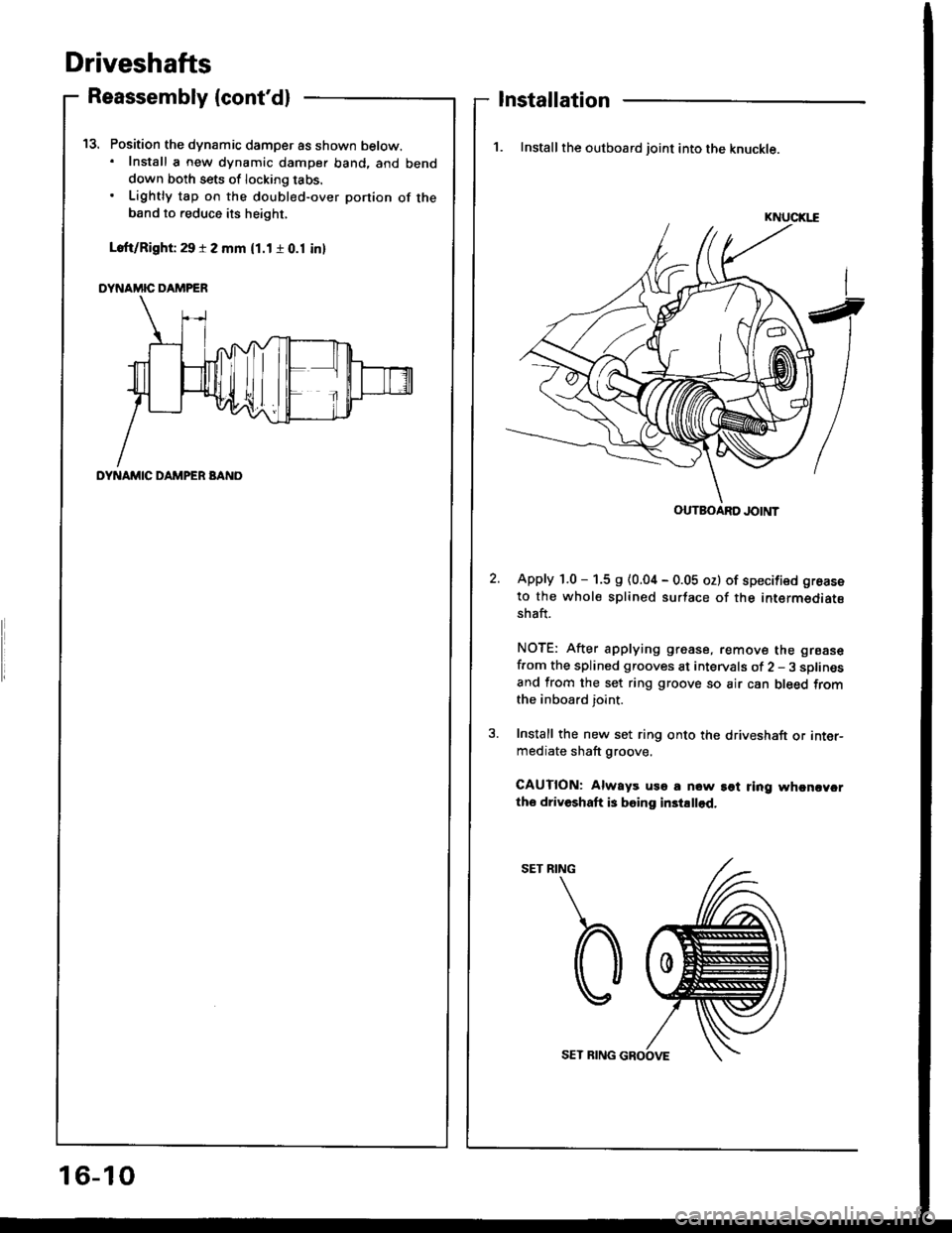

Position the dynamic damper as shown below.. Install a new dynamic damper band. and benddown both sets of locking tabs.

Lightly tap on the doubl€d-over ponion of theband to reduce its height,

Loft/Right 29 r 2 mm (1.1 r 0.1 inl

DYNAMIC DAMPER

t5.

Reassembly (cont'dl

DYNAMIC DAMPER BANO

Installation

1. Install the outboard joint into the knuckle.

KNUCIGE

Apply 1.0 - 1.5 s (0.04 - 0.05 oz) of specified groase

to the whole splined surtace of the intermediatsshaft.

NOTE: After applying grease, remove the grsase

f.om the splined grooves at intervals of 2 - 3 sDlinesand from the set ring groove so air can bleed fromthe inboard joint.

Install the new set ring onto the driveshaft or inter-mediate shaft groove.

CAUTION: Always uso a now sot ring whcncycrtho driveshaft is boing in3tallod.

RING

b

OUTBOARD JOINT

16-10

SET RING GROOVE

Page 616 of 1413

Pressure Control

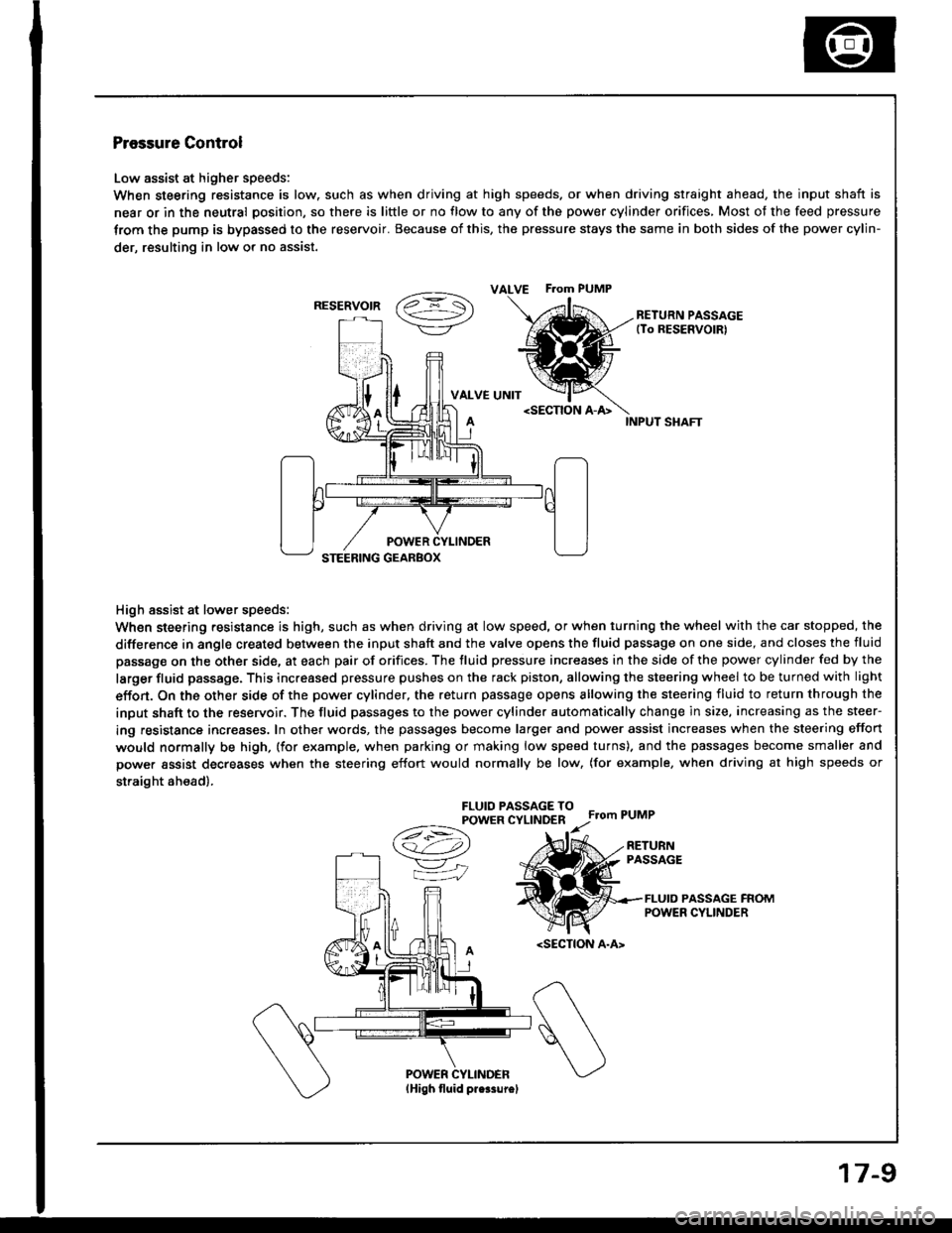

Low assist at higher speeds:

When steering resistance is low. such as when driving at high speeds. or when driving straight ahead, the input shaft is

near or in the neutral position, so there is little or no flow to any of the power cylinder orifices, Most of the feed pressure

trom the pump is bypassed to the reservoir. Because of this, the pressure stays the same in both sides of the power cylin-

der, resulting in low or no assist.

vaz =- S\->/-\7/RETURN PASSAGE(To RESERVOIRI

VALVE UNIT

High assist at lower speeds:

When steering resistance is high, such as when driving at low speed, or when turning the wheel with the car stopped, the

difference in angle created between the input shaft and the valve opens the fluid passage on one side, and closes the fluid

passage on the other side, at each pair of orifices. The fluid pressure increases in the side of the power cylinder fed by the

larger fluid passage. This increased pressure pushes on the rack piston, allowing the steering wheel to be turned with light

effon. On the other side of the power cylinder, the return passage opens allowing the steering fluid to return through the

input shaft to the reservoir. The fluid passages to the power cylinder automatically change in size, increasing as the steer-

ing resistance increases. In other words, the passages become larger and power assist increases when the steering effort

would normally be high, (for example. when parking or making low speed turns). and the passages become smaller and

power assist decreases when the steering effort would normally be low, (for example, when driving at high speeds or

straight ah€ad).

FLUIO PASSAGE TOPOWER CYLINDERFrom PUMP

A

/t-:\

v"

=iJ

RETURNPASSAGE

FLUID PASSAGE FROMPOWER CYLINDER

ALVE F.om PUMP

RESERVOIR

17-9

Page 619 of 1413

Troubleshooting

General Troubleshooting {cont'd}

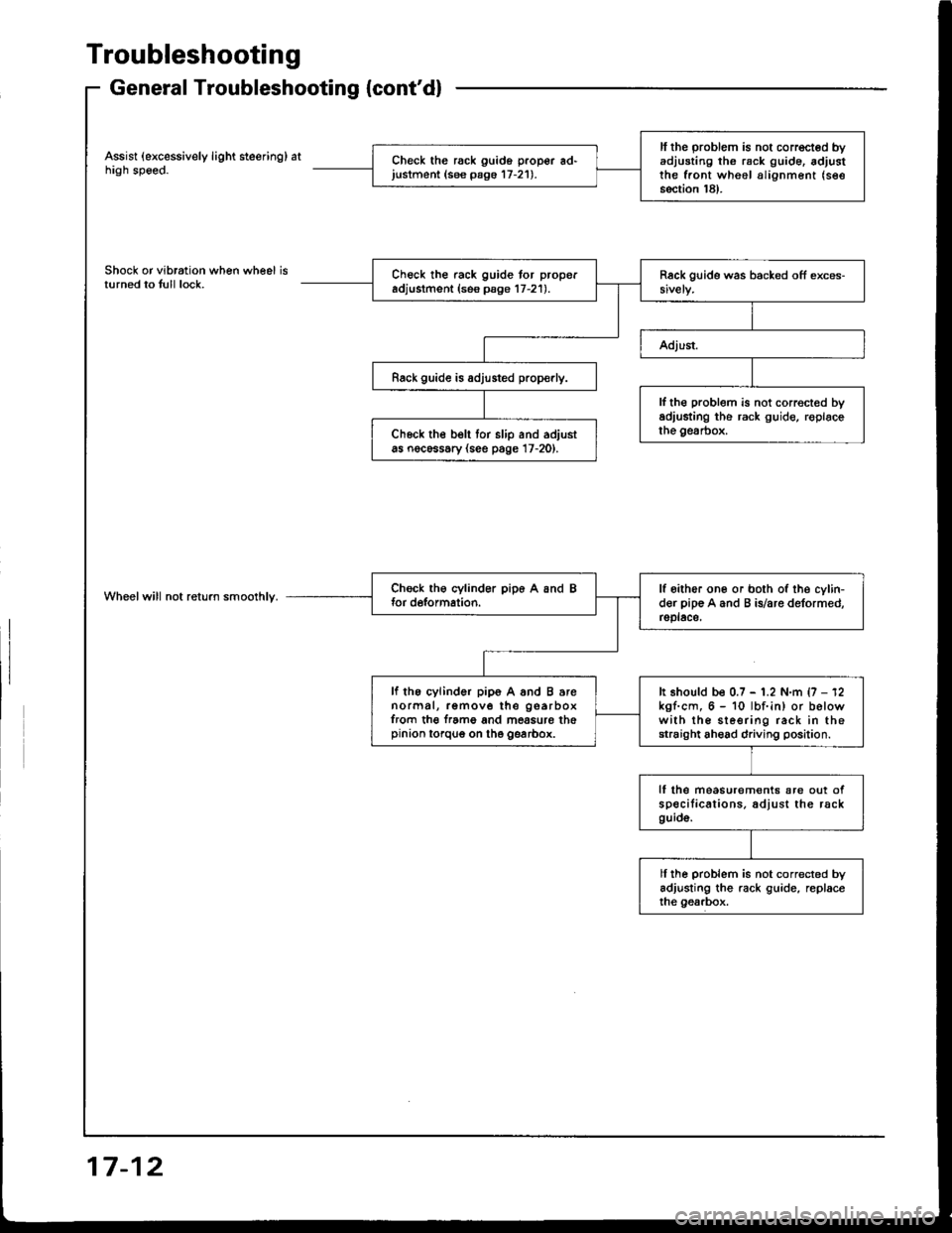

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to tull lock.

Wheelwill not return smoolhly.

ll the problem is not corrected byadjusting th6 rack g!ide. adjustthe front wheel alignment (see

section 18).

Check the rack guido proper ad'justment (see pago 17-21).

Check the rack guide tor properadjustment (ses psge 17-21).

Rack guide is adjusted prop€rly.

lf th€ problem is not correct€d byadiusting the rack guide, roplacethe gesrbox.Ch6ck the belt tor slip and adjustas nocessary (see page 17-20).

lf oither one or both of the cylin-der pip€ A and B is/are deformed,rsplace,

lf the cylinder pip6 A and B arenormal, remove the gearboxfrom th€ f.ame and mossure thepinion torqug on the gearbox.

It should be 0.7 - 1.2 N.m {7 - 12kgf.cm, 6 - 10 lbf.in) or belowwith the sleering rack in thestraight ahead driving position.

lf lhe measurem€nts are out ofspecilications. adjust the rackguid6.

ll ihe problem is not corrected byadjusting the rack guide, replaceihe gearbox.

17-12

Page 632 of 1413

Removal

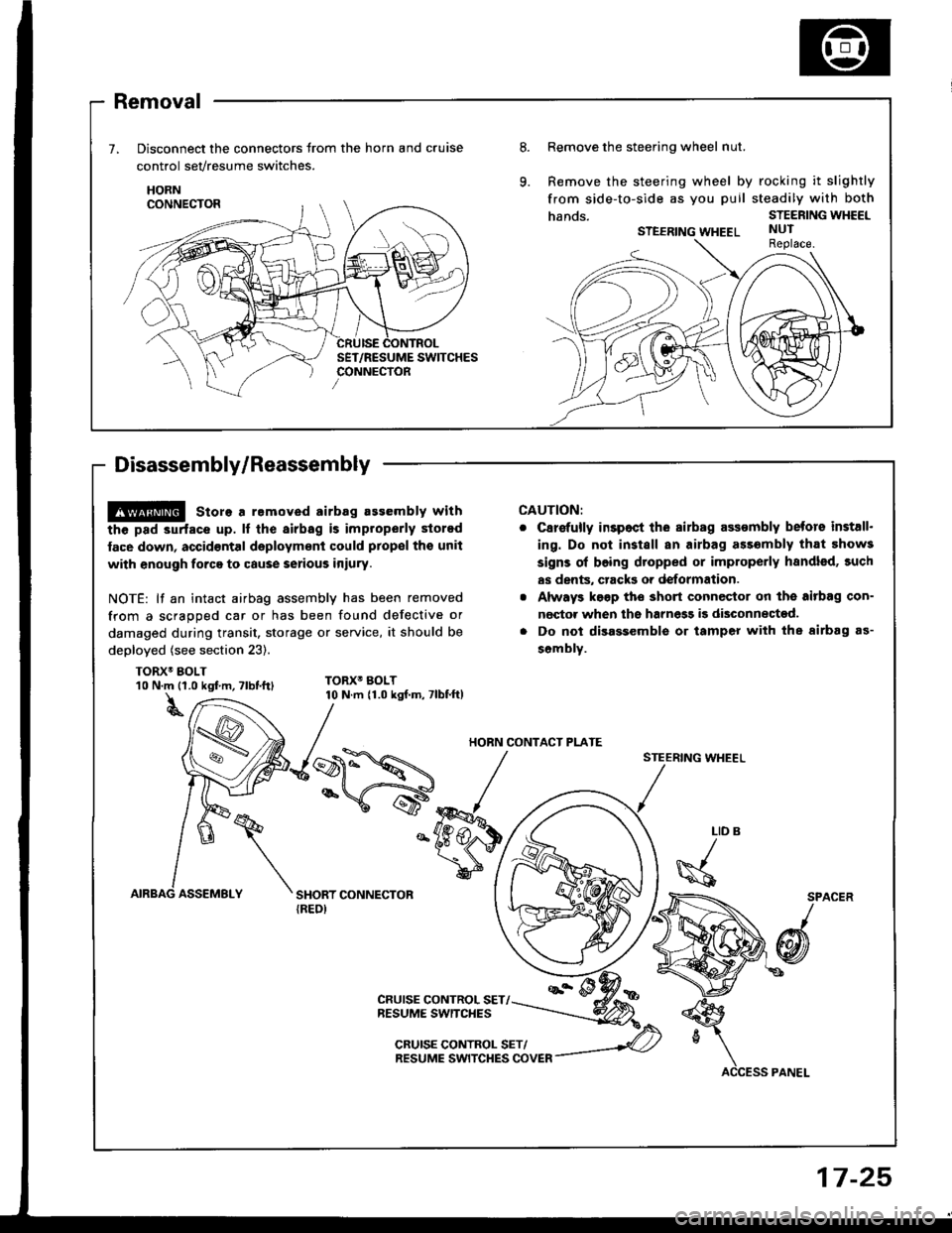

Disconnect the connectors trom the horn and cruise

control sevresume switches.

HORN

Disassembly/Reassembly

8.Remove the steering wheel nut.

Remove the steering wheel by rocking it slightly

from side-to-side as you puil steadily with both

hands.STEERING WHEEL

STEERING WHEELNUTReplace.

@ store a removed airbag assembly with

the pad 3urfacs up. lf the airbag is improperly stored

face down, accid€ntal daployment could prop€l tho unit

with enough forca to cause serious iniury.

NOTE: lf an intact airbag assembly has been removed

from a scragoed car or has been found defective or

damaged during transit. storage or service, it should be

deployed (see section 23).

TORX6 BOLT

CAUTION:

C8r€{ully inspoct ihe sirbag assombly betors install.

ing. Do not install an airbag ass6mbly that 5how3

signs ol boing dtopped or improperly handled, such

as dents, crack3 or deformation.

Always k€gp tho short connector on the aitbag con-

nector when ths harnegg i9 disconnected.

Do not disassemble or tamper with the airbag as-

sombly.

STEERING WHEEL

10 N.m {1.0 kgf m, Tlbt.ttl

t

TORX6 BOLT10 N.m {1.0 kgf.m, 7lbf.ft)

LID

\s

SPACER

/

@

CRUISE CONTROL SET/NESUME SWITCHES

CRUISE CONTROL SET/RESUME SWITCHES COVER

HORN CONTACT PI-ATE

17-25

Page 634 of 1413

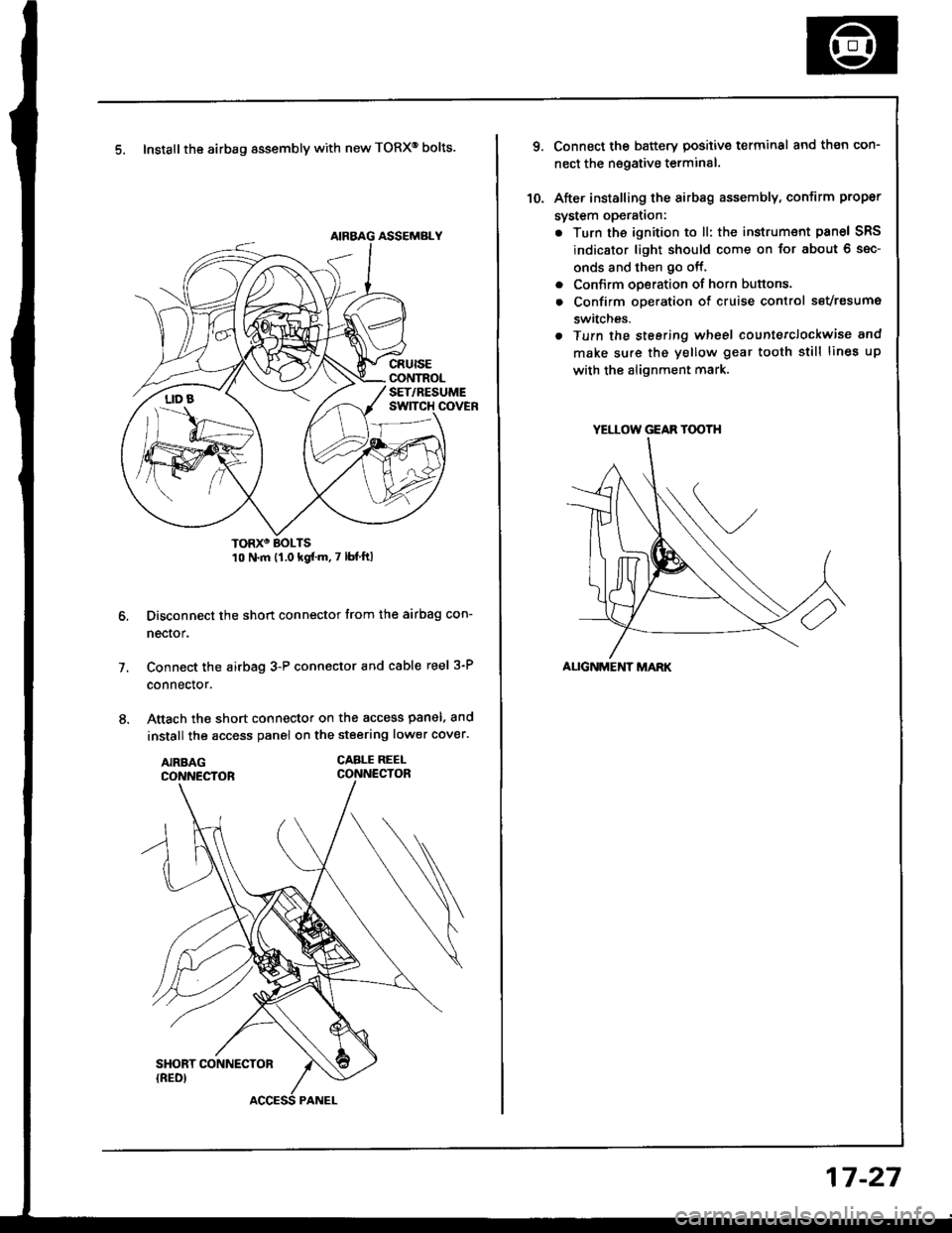

5. Install the airbag assembly with new TORXo bolts.

TORXO BOLTS10 N.m {1.0 kgf'm.7 lbf ftl

Disconnect the short connector trom the airbag con-

nector.

Connect the airbag 3-P connector and cable reel 3-P

connector.

Attach the short connector on the access panel. and

install the access panel on the steering lower cover.

CABLE REEI-CONNECTOR

7.

YELLOW GEAR TOOTH

ALIGNMENT MARK

10.

Connect the battery positive terminal and th€n con-

nect the nsgative terminal.

After installing the sirbag assembly, confirm proper

system opera(on:

. Turn the ignition to ll: the instrum€nt pan6l SRS

indicator light should come on for about 6 sec-

onds and then go off,

. Confirm operation of horn buttons.

. Confirm oDeration of cruise control sevresume

switches.

a Turn the steering wheel countetclockwise and

make su.e the yellow gear tooth still lines up

with the alignment mark.

17-27

Page 669 of 1413

Steering Gearbox

Reassembly (cont'dl

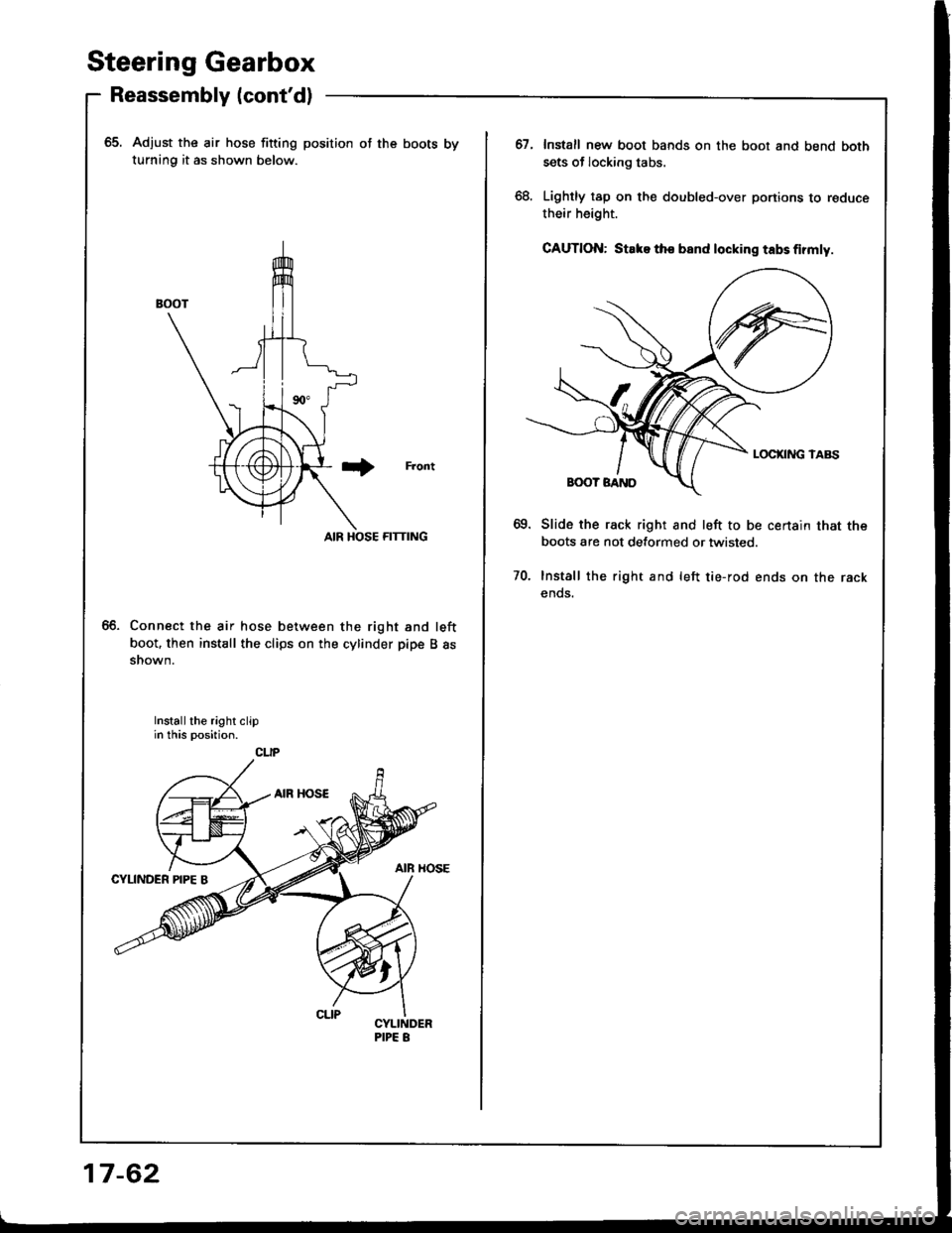

65. Adjust the air hose fitting position of the boots by

turning it as shown below.

Front

AIR HOSE FITTING

Connect the air hose between the right and left

boot. then install the clips on the cylinder pipe B assnown.

Install the right clipin this position.

CLIP

17-62

67.Install new boot bands on the boot and bend both

sets of locking tabs.

Lightly tap on the doubled-over portions to reduce

their height.

GAUTION: Stake tho band locking tabs firmly.

Slide the rack right and left to be certain that the

boots are not detormed or twisted.

Install the right and left tie-rod ends on the rack

ends.

70.

Page 915 of 1413

Doors

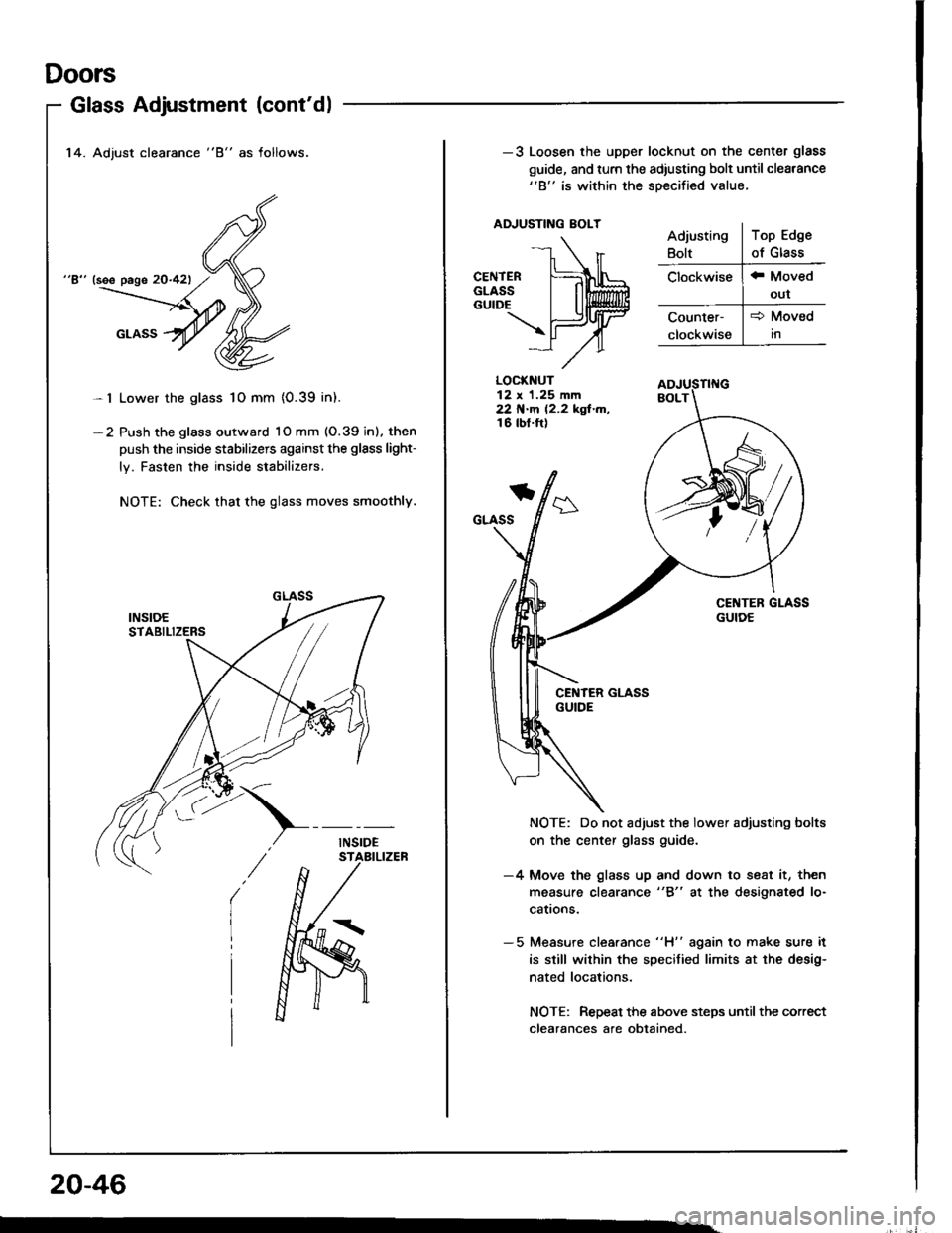

14. Adjust clearance "8" as follows.

"8" (see page 20-421

Lower the glass 1O mm {0.39 in).

Push the glass outward 1O mm (O.39 inl. then

push the inside stabilizers against the glsss light-

ly. Fasten the inside stabilizers.

NOTE: Check that the glass moves smoothly.

Glass Adjustment (cont'dl

-l

-2

20-46

-3 Loosen the upper locknut on the center glass

guide, and turn the adiusting bolt until cleatance"B" is within the soecified value.

ADJUSTING EOLT

LOCKNUT12 x 1.25 mm22 N.m 12.2 kgf.m,16 tbt.ft)

*

GLASS

NOTE: Do not adjust the lower adjusting bolts

on the center glass guide.

-4 Move the glass up and down to seat it, then

measure clearance "8" at the designated lo-

cattons.

- 5 Measure clea.ance "H" again to make sure it

is still wilhin the specified limits at the desig-

nated locations.

NOTE: Repeat the above steps until the correct

clearances afe obtained.

Page 917 of 1413

Doors

Position Adjustment

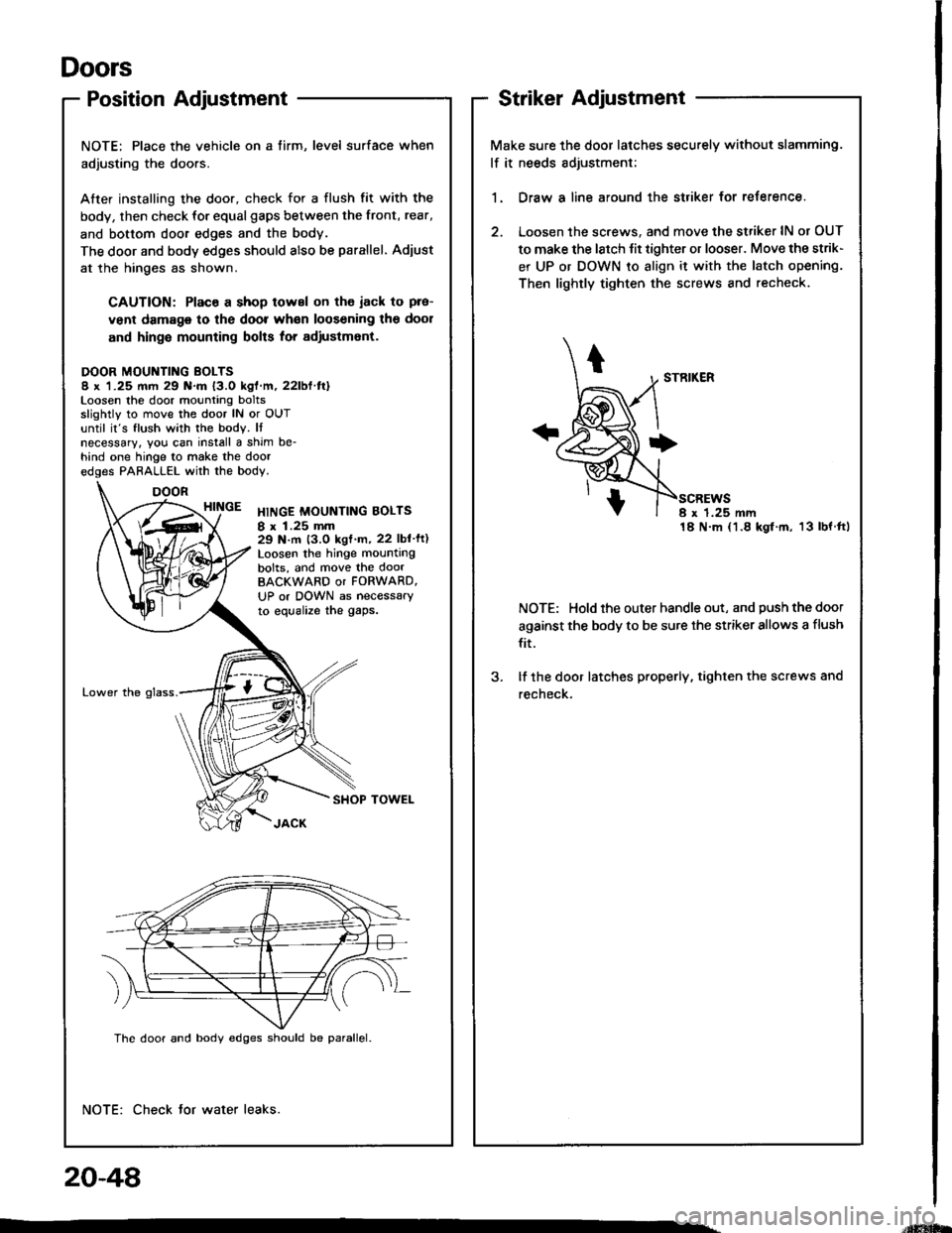

NOTE: Place the vehicle on a tirm, level surface when

adjusting the doors.

After installing the door, check for a flush fit with the

body, then check for equalgaps between the front, rear,

and bottom door edges and the body.

The door and body edges should also be parallel. Adiust

at the hinges as shown.

CAUTION: Plac€ a shop towsl on tho jack to pre-

vent damage to the door when loosening the dool

and hingo mounting bolts for adjustmont.

DOOR MOUNTING BOLTS8 x 1.25 mm 29 N.m l3.O kgl m, 22lbf trlLoosen lhe door mo!nting boltsslightly to move the door lN or OUTuntil ir's flush wath the body. Itnecessary, you can install a shim be-hind one hinge to make the door

edges PAFALLEL with the body.

HIIGE xrruce MouNTTNG BoLTs

I x 1.25 mm29 N.m l3.O kgt'm,22 lbl'ft)Loosen the hinge mounting

bolts, and move the doorBACKWARD oI FORWARD,

UP or DOWN as necessaryto equalize the gaps.

Lower the glass,

SHOP TOWEL

NOTE: Check tor water leaks.

DOOR

The door and body edges should be parallel.

Striker Adjustment

Make sure the door latches securely without slamming.

lf it needs adjustment;

1.Draw a line around the st.iker for reJerence.

Loosen the screws, and move the striker lN or OUT

to make the latch tit tighter or looser. Move the strik-

er UP or DOWN to align it with the latch opening.

Then liqhtly tighten the screws and recheck.

scREwsI x 1.25 mm18 N.m ('1.8 kgt.m, 13lbf.ttl

NOTE: Hold rhe outer handle out, and push the door

against the body to be sure the striker allows a flush

fit.

lf the door latches properly, tighten the screws and

recheck.

20-48

;dlHffi

Page 927 of 1413

Windshield

Installation (cont'd)

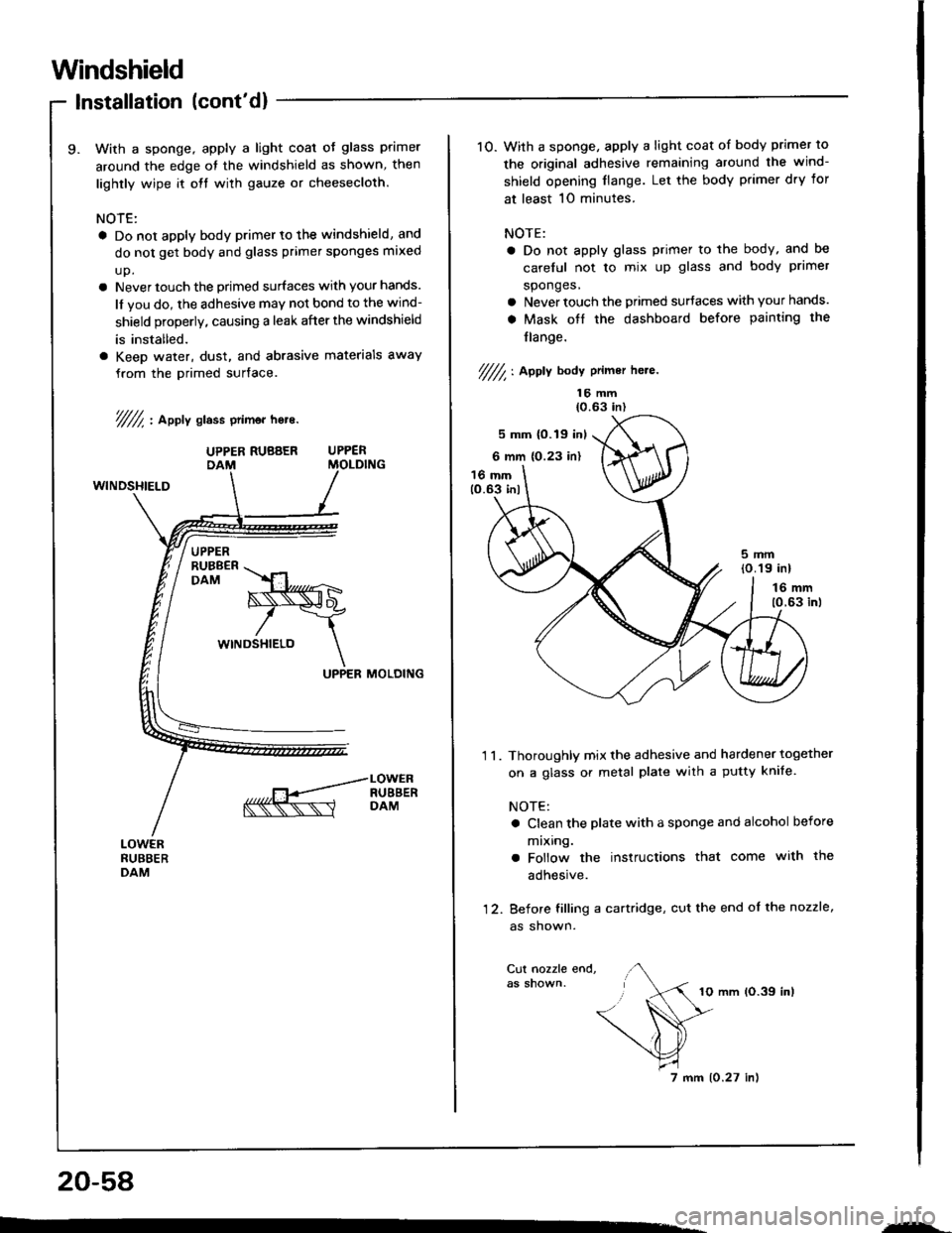

With a sponge. apply a light coal oJ glass primer

around the edge ot the windshield as shown, then

lightly wipe it olt with gauze or cheesecloth.

NOTE:

a Do not apply body primer to the windshield, and

do not get body and glass primer sponges mlxed

up.

a Never touch the primed surfaces with your hands.

ll you do, the adhesive may not bond to the wind-

shield properly, causing a leak afterthe windshield

is installed.

o Keep water, dust, and abrasive materials awaY

from the primed surface.

V//f, : apptv stass ptimer hors.

WINDSHIELD

RUBBER -DAM .YJ * o

>\ast,

/\WINDSHIELD

\UPPER MOLOING

UPPER RUBBER UPPER

10. With a sponge, apply a light coat of body primer to

the original adhesive remaining around the wind-

shield opening flange. Let the bodY primer dry tor

at least 1O minutes.

NOTE:

a Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges,

a Never touch the primed surfaces with your hands.

a Mask otl the dashboard before painting the

flange.

//////, I Aeely bodv Primer h6te.

16 mm{0.63 in)

5 mm {0.19 inl

6 mm (0.23 in)

16 mm1O.63 inl

5mm(O.19 inl

16 mm

10.63 inl

1 1 . Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

a Clean the plate with a sponge and alcohol before

mixlng.

a Follow the instructions that come with the

adhesive.

12. Before filling a cartridge, cut the end ol the nozzle,

as shown.

Cut nozzle end,

10 mm (O.39 inl

20-58

7 mm 10.27 in)

,*-

Page 928 of 1413

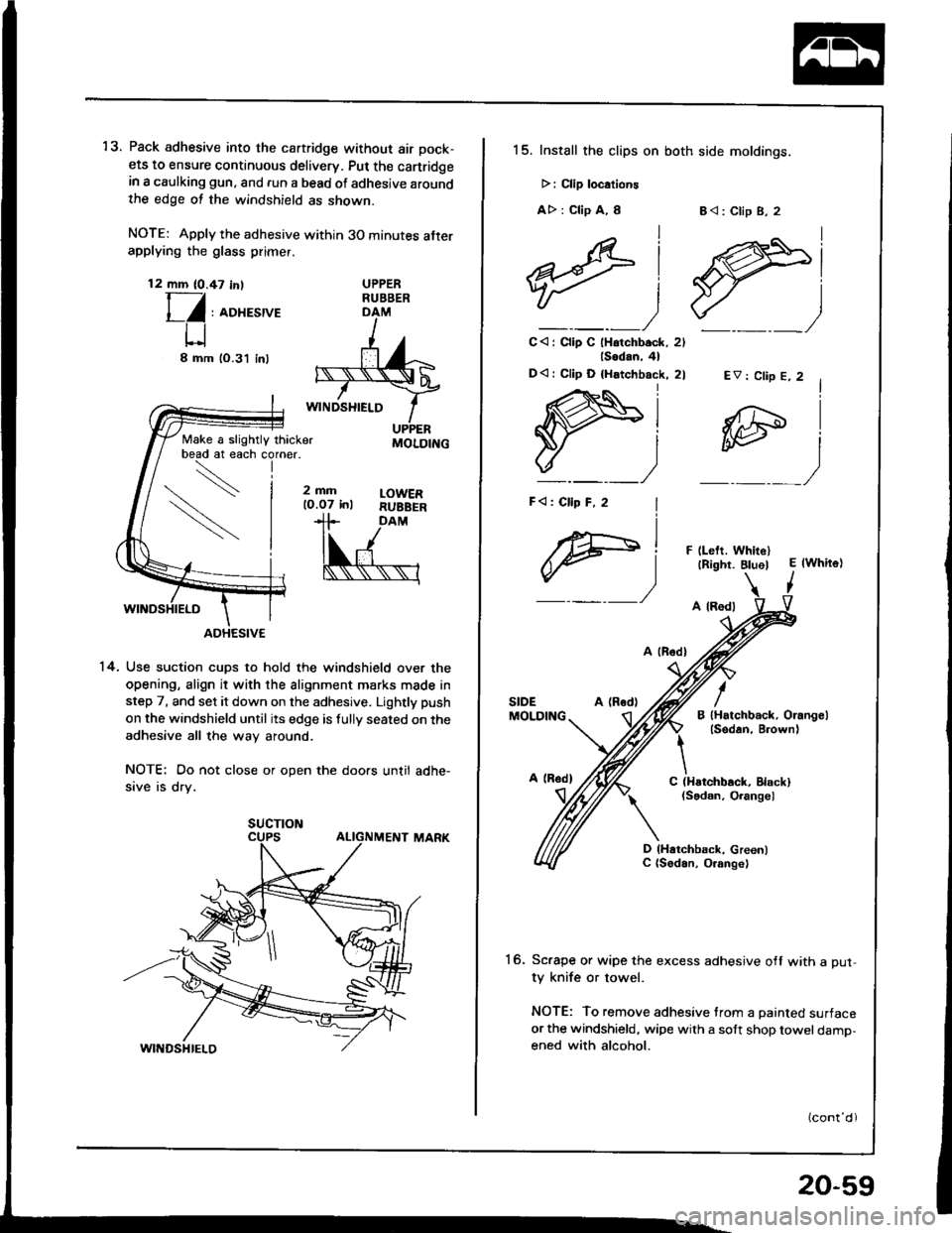

13. Pack adhesive into the cartridge without air pock-

ets to ensure continuous delivery. Put the canridgein a caulking gun, and run a bead ot adhesive aroundthe edge ot the windshield as shown.

NOTE: Apply the adhesive within 30 minutes afterapplying the glass primer.

12 mm (0.47 in,T-/

l_/ : roxesrve

U8mm

Make a slightly thicker

DAM

'14. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly push

on the windshield until its edge is fully seated on the

adhesive all the way around.

NOTE: Do not close or open the doors until adhe-

sive is dry.

UPPERRUBBER

lO.3'l inl

2mfilO.O7 inlLOWERRUBBEB

MOLDING

SUCTION

15. Install the clips on both side moldings.

>: Clip localione

A> : Clip A, I

lsodan,4l

D<: Cllp D {Hatchback, 2l

I

F)

B<: Clip B, 2

lAi

ffil"___)

C<: Clip C lHatchback, 2l_)

EV: Clip E, 2

F llelt. WhitellRight. BluelE lwhite)

I

A (Rod)

A lRodl

B lHatchback, Orangellsedan, B.own)

/SIDEMOLDING

It\C (Hstchback, Elack)(Sodan, Orangel

D lHatchback, Green)C (Sodan, O.ange)

16. Sc.ape or wipe the excess adhesive off with a Dut-ty knife or towel.

NOTE: To remove adhesive trom a painted surface

or the windshield, wipe with a solt shop towel damp-ened with alcohol.

20-59