Wiring HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 4 of 1413

,,

SUPPLEMENTAL RESTRAINT SYSTEM (SRS}

The Integra SRS includes a driver's airbag, located in the steering wheel hub. ln addition, all mod€ls excepi tna

Rs model for canada have a front passenger's airbsg located in the dashboard above the glove box, InformaUon

necessary to safely service the SRS is included in this servica Manual. ltems marked with an sstorisk (r) on thr

contents page include, or are located near, SRS components. Servicing. disassembling or roplacing thea6 ltems

will require special precautions and tools, and should thoreiore be done by an authorhed Acura dealer.

' To avoid rondering ths sRS inoporativo, which could lard to porronll Injury or darth In thc cvant ot. r.yr.

trontal collision, all sRs sorvico work must be pcrformcd by !n ruthorizcd Acu.! daerrr,

' lmpTopor 3orvica proceduroa, including inco.roct r.movd r d Installation of tha SRS, could Lld to pc[onc Inlu-

ry caussd by unintsntional activation ot tho airbags.

' All sRs oloctrical wiring harnoa$! aro coverod with yallow In3ulatlon, Rcbtcd componcnts arc bcrtad In tha

stoering Golumn, front console, dsrhboa.d, and darhboard lowor plnol, lnd in thc d$hbolrd abovc tha gaov!

bor. Do not uas oloctdcal te$ oquipmont on thaaa citcuhs.

NoTE: The original radio has a coded thett protection circuit. Be sure to get the customer's code numb6r b€lore* disconnecting the battery.

- removing the No. 32 (7.S A) fuse Jrom the undsr-hood fuse/relay box.

- removing the radio.

After service, reconnect power to the radio and turn it on. When the word ,,CODE,, is displayed, enter the cus_

tomer's 5-digit code to restore radio oDerauon.

Page 11 of 1413

J: GLOVE BOX INFORMATIOf{

AIBBAG INFORMANO

SUPPLEMENTAL RESTiAINT SYSTEM (SRS)

. THE SRS MUST BE INSPECTED TEN YEARS AFTER IT

IS INSTALLED. TI{E DATE OF INSTALLATION IS SHOWN

ON THE CERTTFICATION PLATE, LOCATED ON THE

DRIVER'S DOOR JAMB.

. DIAGNOSTIC CHECKS AND REPLACEMENT OF SNS

COMPONENTS MUST BE DONE BY AN AUTHORIZED

DEALER

. SEE YOUR OWNER'S MANUAL FOR AODITIONAL SRS

INFORMATION.

K: FRONT SEAT PASSENGER INFLATOR WARNING TAG

A WARNING

ACCIDENTAL AIRBAG DEPLOYMENT CAN SERIOUSLY

HURT OR KILL YOU.

INSTALL THE RED SERVICE CONNECTOR WHEN THE IN-

FLATOR HARNESS IS DISCONNECTED

L: FRONT SEAT PASSENGER MODULE DANGER

A DANGER

EXPLOSIVE/FLAMMABLE

CONTACT WITH ACID, WATER OR HEAVY METALS SUCH

AS COPPER. LEAD OR MERCURY MAY PRODUCE HARM'

FUL AND IRRITATING GASES OR EXPLOSIVE COM.

POUNDS.

STORGE TEMPERATURES MUST NOT EXCEED 2OOOF

tlOO"CI. FOB PROPER HANDLIING, STORAG€ AND DIS-

POSAL PROCEDURES REF€B TO THE SERVICE MANUAL,

SBS SUPPLEMENT.

POTSON

CONTAI'\'S POISONOUS SODIUM AZIOE AND POTASSIUM

NITRATE.

FIRST AID

IF CONTENTS ARE SWALLOWED, INDUCE VOMITING.

FOR EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES.

IF GASES (FROM ACID OR WATER CONTACT) ARE IN.

HALED, SEEK FRESH AIR. IN EVERY CASE. GET PROMPT

MEDICAL ATTENTION.

KEEP OUT OF REACI.I OF CHILDREN.

A' WARNING

THE AIRBAG INFLATOR IS EXPLOSIVE AND. IF ACCIDEN-

TALLY DEPLOYEO, CAN SERIOUSLY HURT OR KILL YOU.

. DO NOT USE ELECTRICAL TEST EOUIPMENT OR PROB.

ING DEVICES.

THEY CAN CAUSE ACCIOENTAL DEPLOYMENT.

. NO SERVICEAALE PABTS INSIDE. OO NOT OISAS-

SEMBLE.

. PLACE AIRBAG UPFIGHT WHEN REMOVED.

. FOLLOW SERVICE MANUAL INSTRUCTIONS

CAREFULLY.

fi{lHfiFe*% _

1-7

M: AIRBAG LABEL

AIRBAG

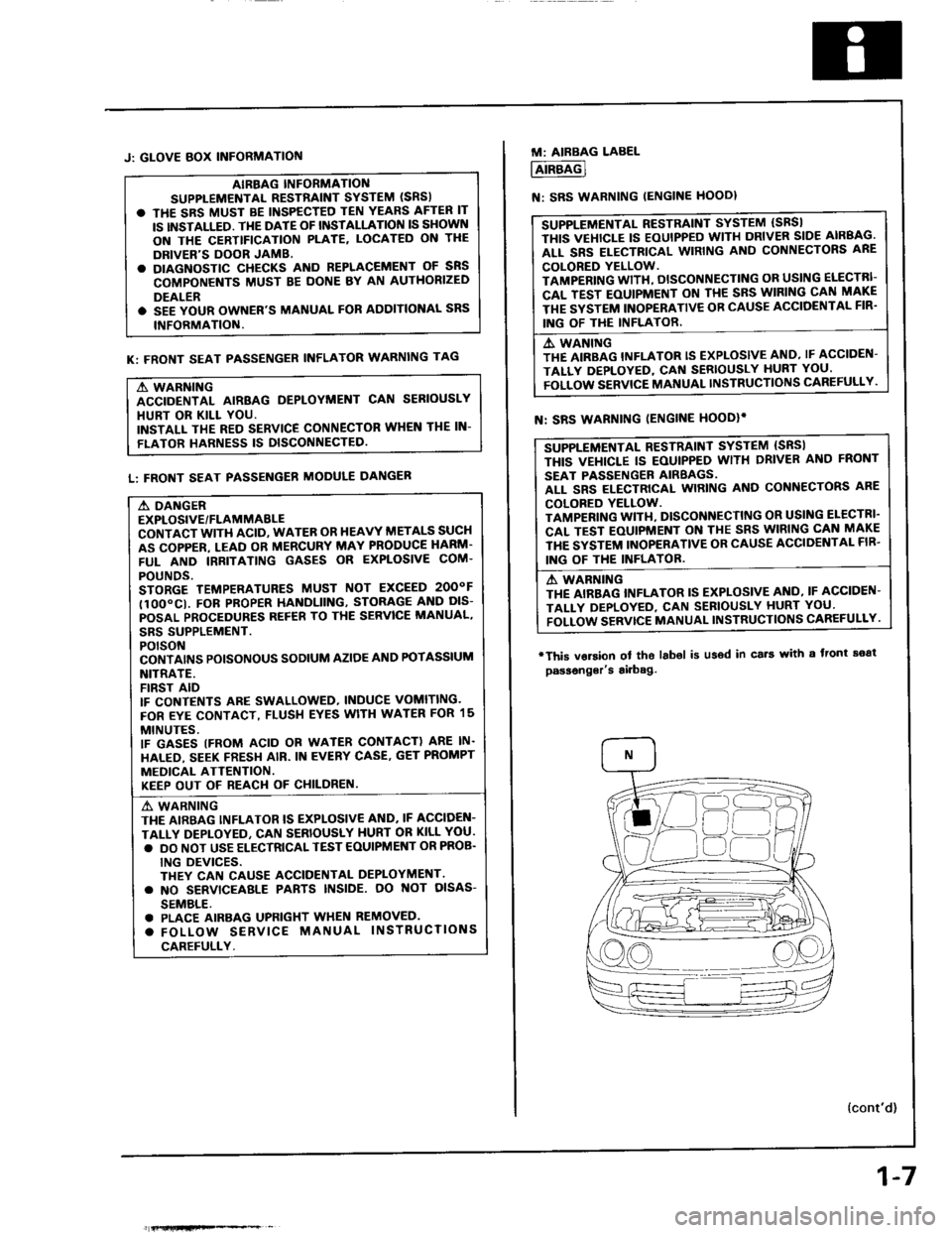

N: SRS WARNING IENGINE HOODI

SUPPLEMENTAL RESTRAINT SYSTEM (SBSI

THIS VEHICLE IS EOUIPPED WITH DRIVER SIDE AIRBAG.

ALL SRS ELECTRICAL WIRING AND CONNECTORS ARE

COLORED YELLOW.

TAMPERING WITH, DISCONNECTING OR USING ELECTRI-

CAL TEST EOUIPMENT ON TI{E SRS WIRING CAN MAKE

THE SYSTEM INOPERATIVE OB CAUSE ACCIOENTAL FIR'

ING OF THE INFLATOR.

A. WANING

THE AIRBAG INFLATOR IS EXPLOSIVE AND, IF ACCIDEN-

TALLY DEPLOYED, CAf{ SERIOUSLY HURT YOU'

FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.

SUPPLEMENTAL RESTRAINT SYSTEM {SRSI

THIS VEI{ICLE IS EOUIPPED WITH DRIVER ANO FRONT

SEAT PASSENGER AIRBAGS.

ALL SRS ELECTRICAL WIRING AND CONNECTORS ARE

COLORED YELLOW.

TAMPENING WITI{, DISCONNECTING OR USI G ELECTRI'

CAL TEST EOUIPMENT ON THE SRS WIRING CAN MAKE

THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTAL FIB'

ING OF THE INFLATOB.

A WABNING

THE AIRBAG INFLATOR IS EXPLOSIVE AI{O, IF ACCIDEN-

TALI-Y DEPLOYED, CAN SEBIOUSLY HURT YOU'

FOLLOW SERVTCE MANUAL INSTRUCTIONS CAREFULLY.

N: SRS WARNING IENGINE HOODIi

'This vorsion

passonger's

ol tho labol is u36d in cs.t with a front soat

airbag.

{cont'd)

Page 48 of 1413

Engine Removal/lnstallation

@a Make sure jacks and safety stands aro placed ploper-

ly and hoisl brackots arg attachod to the correct po-

sitions on tho engine (se€ ssction 1).

a Mak€ sure tho car willnot roll off stands and tallwhile

you are wotking under it'

CAUTION:

a Use fendet covals to avoid damaging painted

sudaces.

r Unspecified itsms alo common

a Unplug tho widng connectots carefully while holding

the couplor and tha connector portion to avoid

oamage.

a Mark all wiring and hoses to avoid misconnection.

Also, be sulo that thsy do not contact other wiring

or hoses, or interfere with oth€l parts.

NOTE: Anti-theft radios have a coded theft ptotection

circuit. Be sure to get the customer's code number beJore

- Disconnecting the batterY.

- Removing the No. 32 (7.5 A) fuse from the under-

hood tuse/relay box.- Removing the radio

Atter service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operataon.

1. Remove the hood (see section 2O).

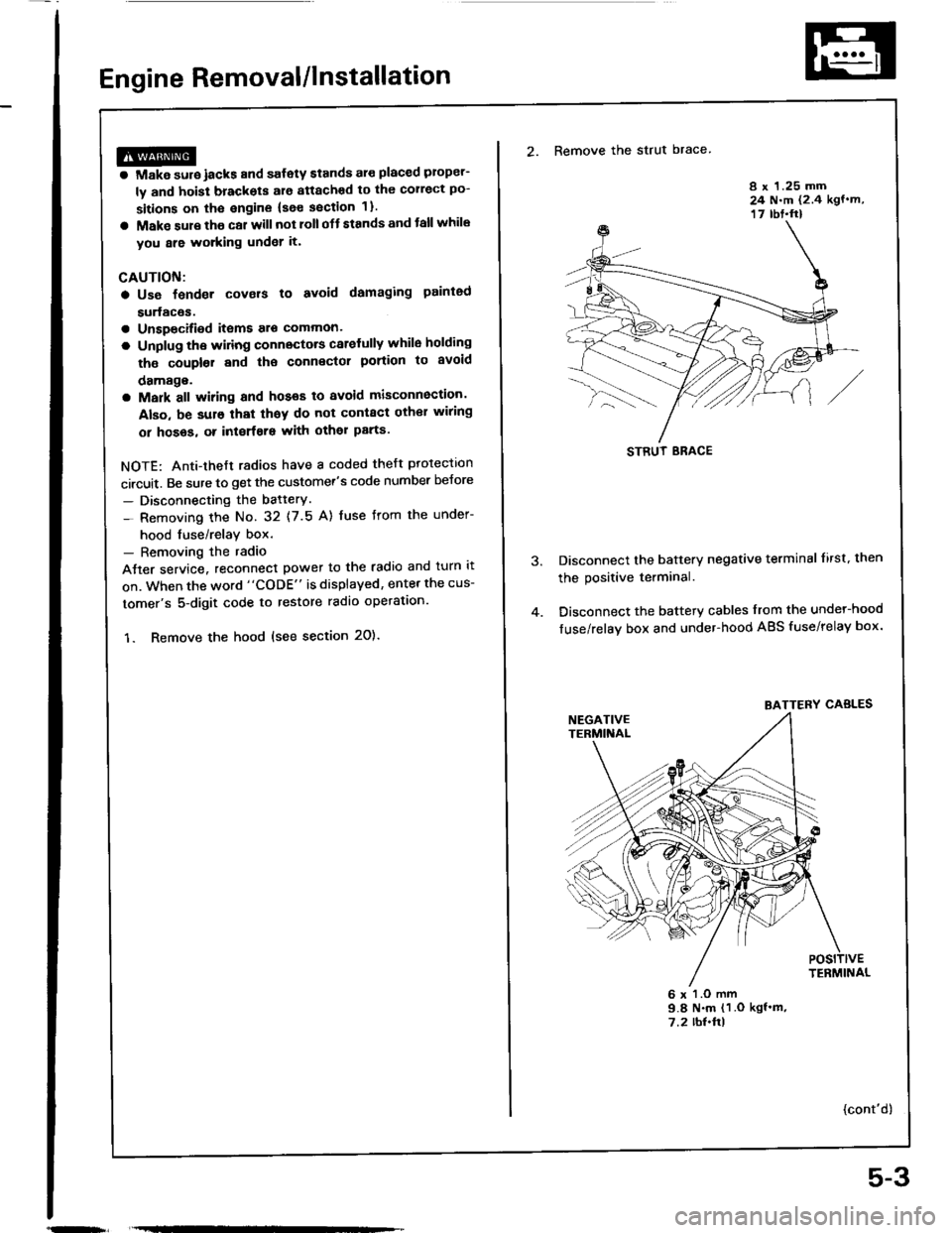

2. Remove the strut brace

8 x 1.25 mm24 N.m (2.4 kgf.m,17 rbt.ft)

Disconnect the battery negative terminal lirst. then

the positive terminal.

Disconnect the battery cables from the undel-hood

fuse/relay box and under-hood ABS fuse/relay box.

6 x l.O mm9.8 N.m (1 .O kgf'm,7.2 rbl.ftl

{cont'd)

STRUT ERACE

BATTERY CABLES

5-3

Page 237 of 1413

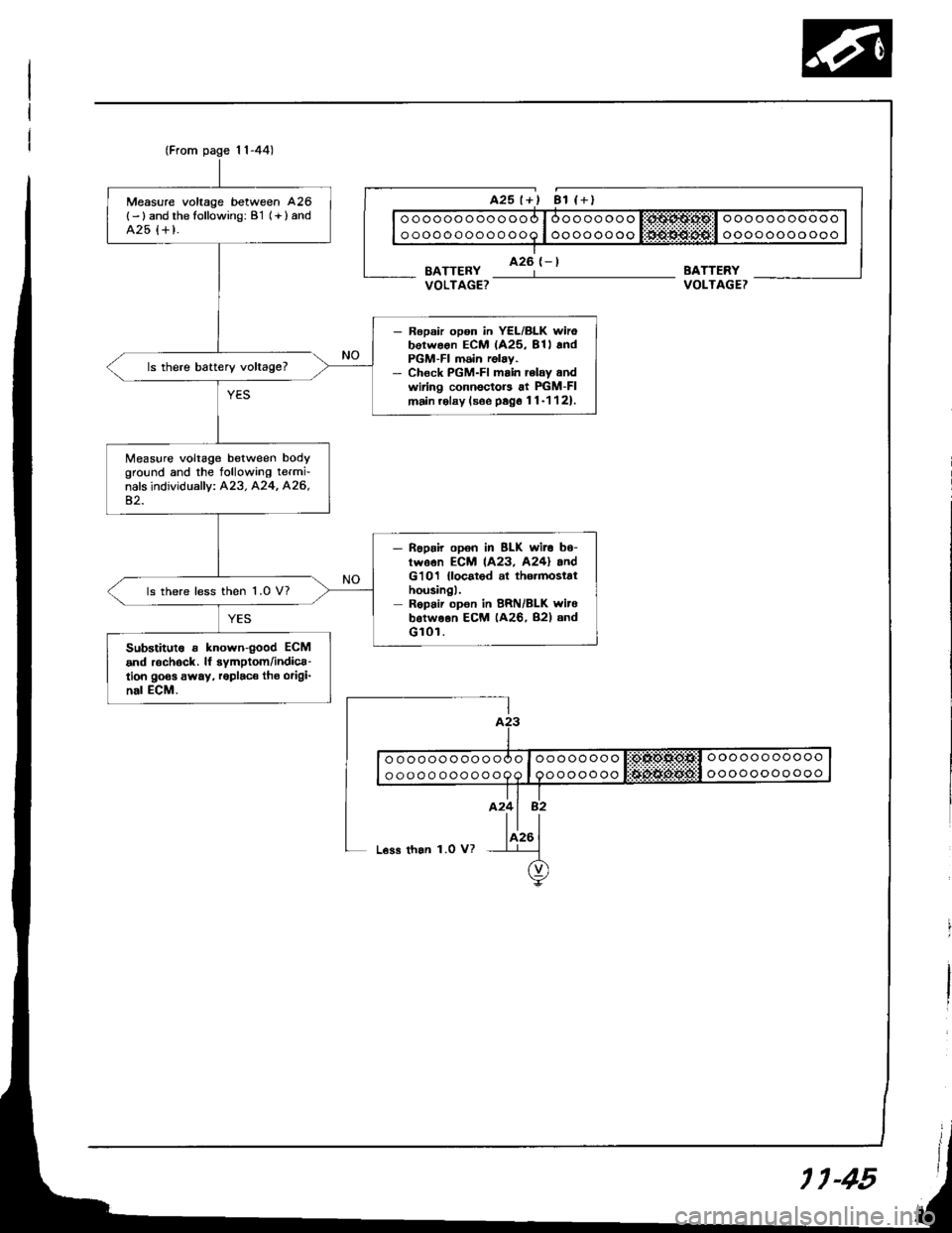

(From page 1l-44)

Measure voltage between 426

{- ) and the following: B'1 (+ } andA25 {+ t.

- Ropsir opon in YEL/BLK wirobotwoon ECM (425, 81l andPGM-FI m6in relay.- Chock PGM-FI main rclay andwiring connectors at PIGM-FImain.olay (soe psg6 11-1121.

ls there battery voltage?

Measure voltage between bodyground and the tollowing termi-nals individually: A23. A24, A26,42.

- noprir opon in BLK wit. b6-twson ECM 1A23, A24l andG'101 {locatod al th6.mostathousingl.Repair opon in BRN/BLK witebotweon ECM (A26, B2l andGl0r.

ls there less then 1.0 V?

Substitut6 r known{ood ECM

and r6chock. lf symptom/indica-tion goos away, roplaco tho origi-nal ECM.

BATTERYVOLTAGET

ooooooooooo

oooooooooooooooooooooo

ooooooooooo

oooooooo

ooooooo

L€ss than 1.0 V?

11-45

Page 441 of 1413

CAUTIOI{:

a All SRS eloctdcal wiring harna$os are covcred whh

yollow lnaulation.

a Sofora disconnecting any pan ot tho SRS wirc har'

n6ss, connoct the short connoctots (s€6 pago 23-701.

a Roplacs tho entiro aff.ct d SRS ham6t. rssombly it

ii has an opon circuil or damagcd wlrlng.

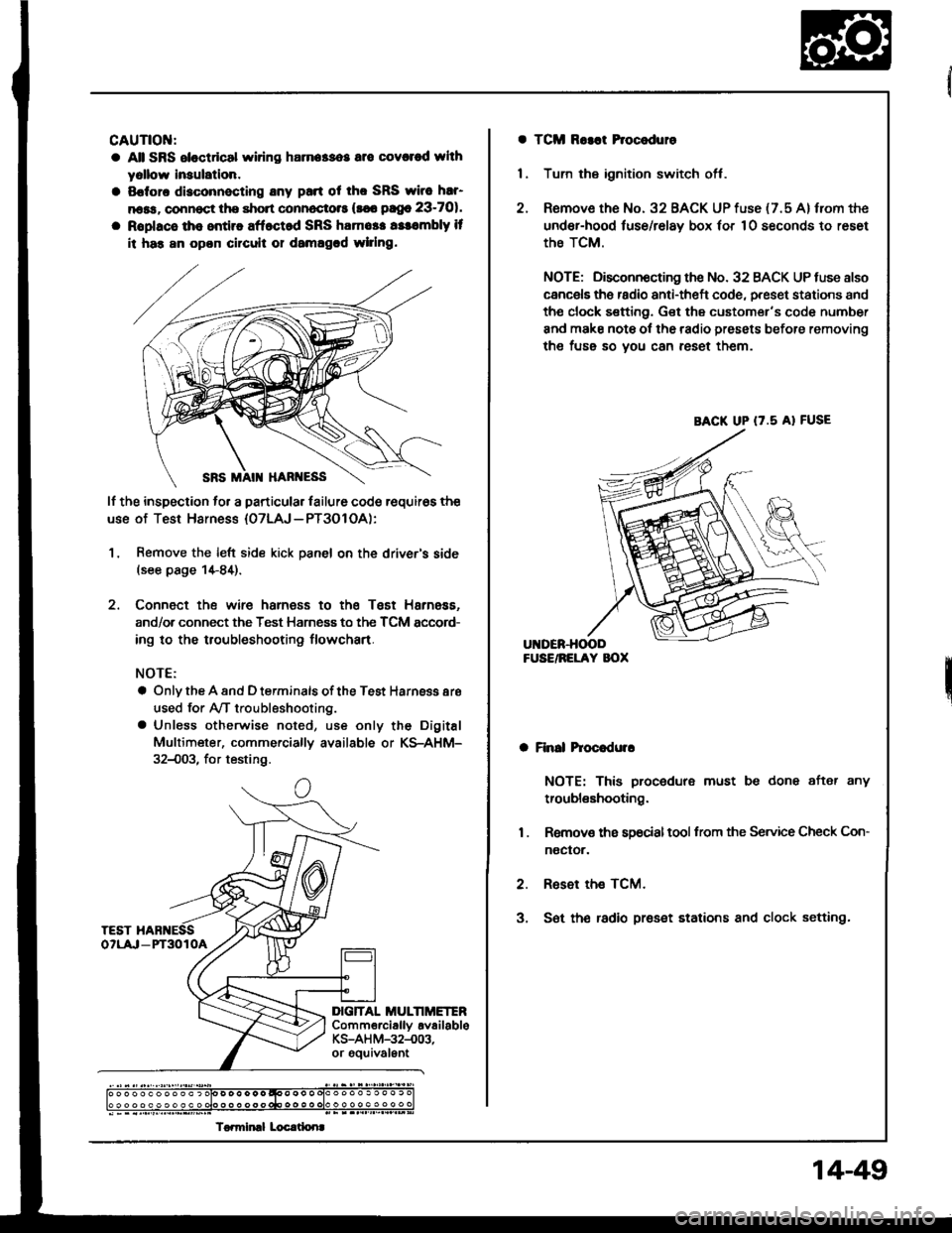

lf the inspection to. a particular lailure code requir6s the

use of Test Harness {07LAJ - PT3O1 OA):

1, Remove the left side kick panel on the driver's side(see page 1+84).

2. Connect the wire harness to the Tsst Harness.

and/or connect the Test Harness to the TCM sccord-

ing to the troubleshooting flowchart.

NOTE:

a Only the A and D terminals of the Test Harnsss aro

used for Ay'T troubleshooting.

a Unless otherwise noted, use only the Digital

Multimeter, commerciallv available or KS-AHM-

32{)03, for testing.

c

DIG]TAL MULTIMETERComm€rciallv availableKS-AH M-32-.003,or gouivalEnt

) o o o o o o o o o o ) olo D o o o o o qoo o o o olo o o o o . o o o . c

To.miml Locrtlonr

a TCM Ro3at Procoduro

1 . Tum the ignition switch off.

2. Remove the No. 32 BACK UP fuse {7.5 A} from the

under-hood luse/relay box 'or 10 seconds to reset

the TCM.

NOTE; Disconnocting the No. 32 BACK UP tuse also

cancels ths radio anti-theft code, preset stations and

tho clock sefting. Get the customer's code number

and make note ol the radio presets before removing

the fuss so you can reset them.

a Finll hoc.dulr

NOTE: This procedure must be done after any

troubleshooting.

1 . Removs ths s9ocialtool from the Service Check Con-

noctor.

2. Reset the TCM.

3, S6t th€ radio preset stations and clock setting.

BACK UP (7.5 A} FUSE

14-49

Page 476 of 1413

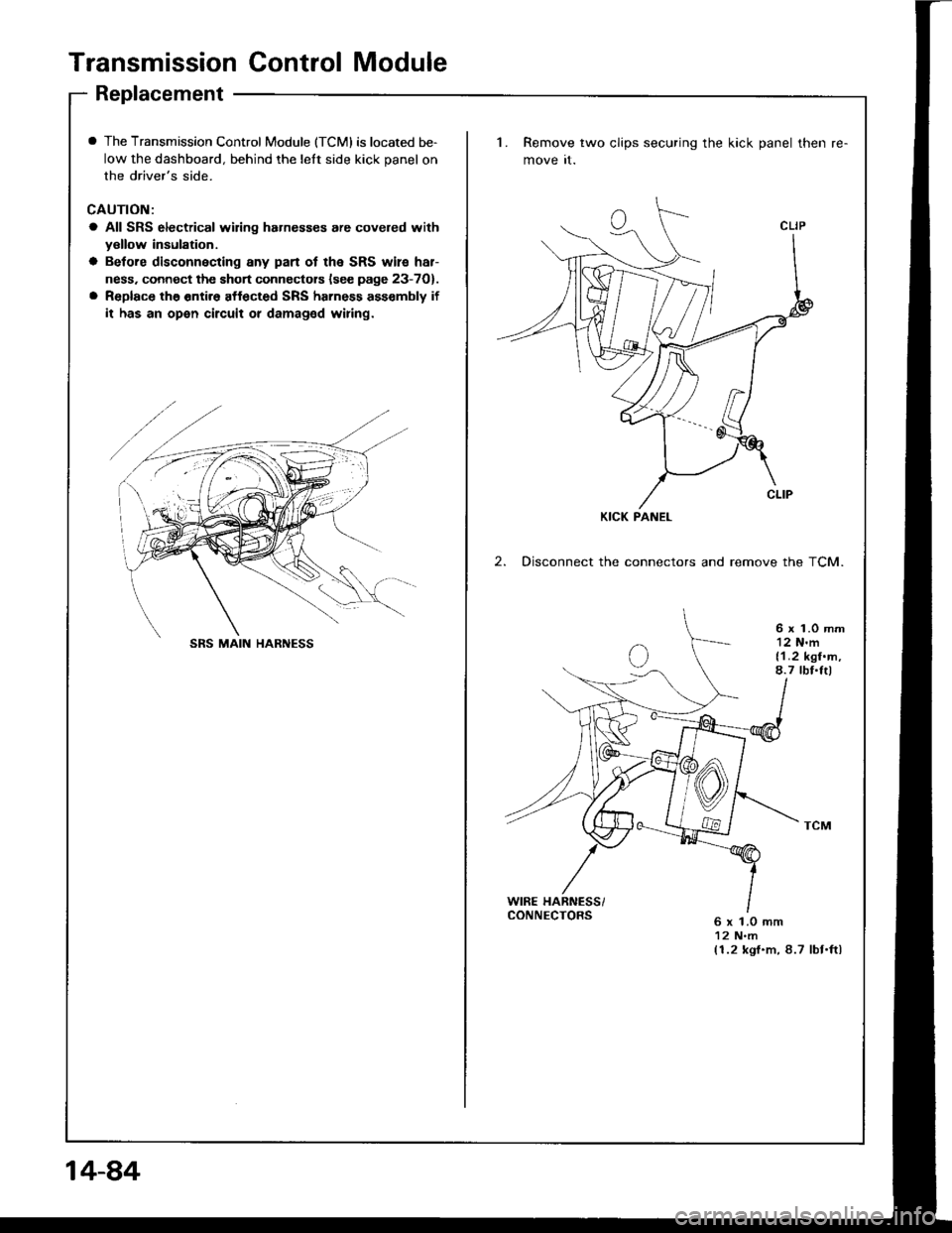

Transmission Control Module

Replacement

I The Transmission Control Module (TCMI is located be-

low the dashboard, behind the lelt side kick panel on

the driver's side.

CAUTION:

a All SRS electrical wiring hahesses are covered withyellow insulation.

a Betore disconnecting any pan ot the SRS wile har-

ness. connect the short connectors lsee page 23-7O).

a Replace the entir6 affected SRS harness ass€mbly if

it has an open circuit or damaged wiring.

1. Remove two clips securing the kick panel then

move it.

2. Disconnect the connectors and remove the TCM.

6 x 1.0 mm12 N'm{1.2 kgf.m,8.7 tbf.Itl

WIRE HARNESS/CONNECTORS6 x 1.0 mm12 N.m(1.2 kgf.m, 8.7 lbt.ftl

KICK PANEL

SRS MAIN HARNESS

14-84

Page 560 of 1413

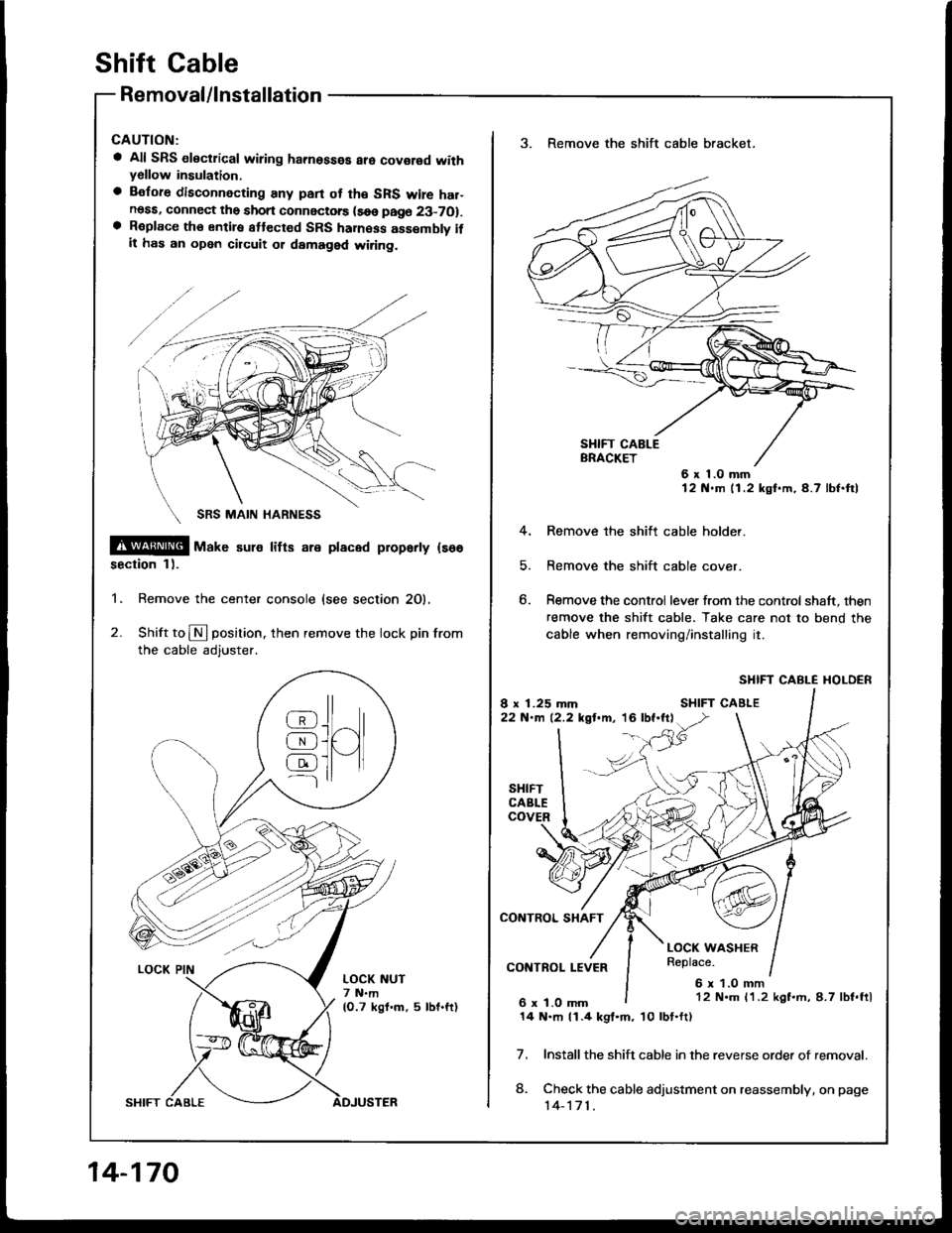

shift cable

Removal/lnstallation

a All SRS electrical wiring hamosses are covor€d withyellow insulation.

a Before disconnecting any pan ot th€ SRS wire har-noss, connect the short connectorc (soe page 23-7O1.a Roplace th€ entiro attect€d SRS haness assembly itit has an open circuit ot damaged wi.ing.

@@[ uar" sul€ litts are placed proparty {so6

section 1).

1. Remove the center console {see section 20).

2. Shift to N position. then remove the lock pin from

the cable adjuster.

@J^ll

AJUI[qJ ]l tl---l

LOCK NUT7 N.m(O.7 kgf.m, 5 lbf.ft)

14-170

3. Remove the shift cable bracket.

6x1.0mm12 N.m 11.2 kgf.m,4.7 lbf.ftl

4. Remove the shitt cable holder.

5. Remove the shift cable cover.

6. Remove the control lever from the control shaft, then

remove the shift cable. Take care not to bend the

cable when removing/installing it.

SHIFT CABLE I{OLDER

Install the shift cable in the reverse orde. of removal.

Check the cable adjustment on reassembly, on page

14-171.

7.

8.

12 N.m 11.2 kgf.rh, 8.7 lbf.ftl

14 N.m 11.4 kgl.m, 10lbt.ft)

Page 561 of 1413

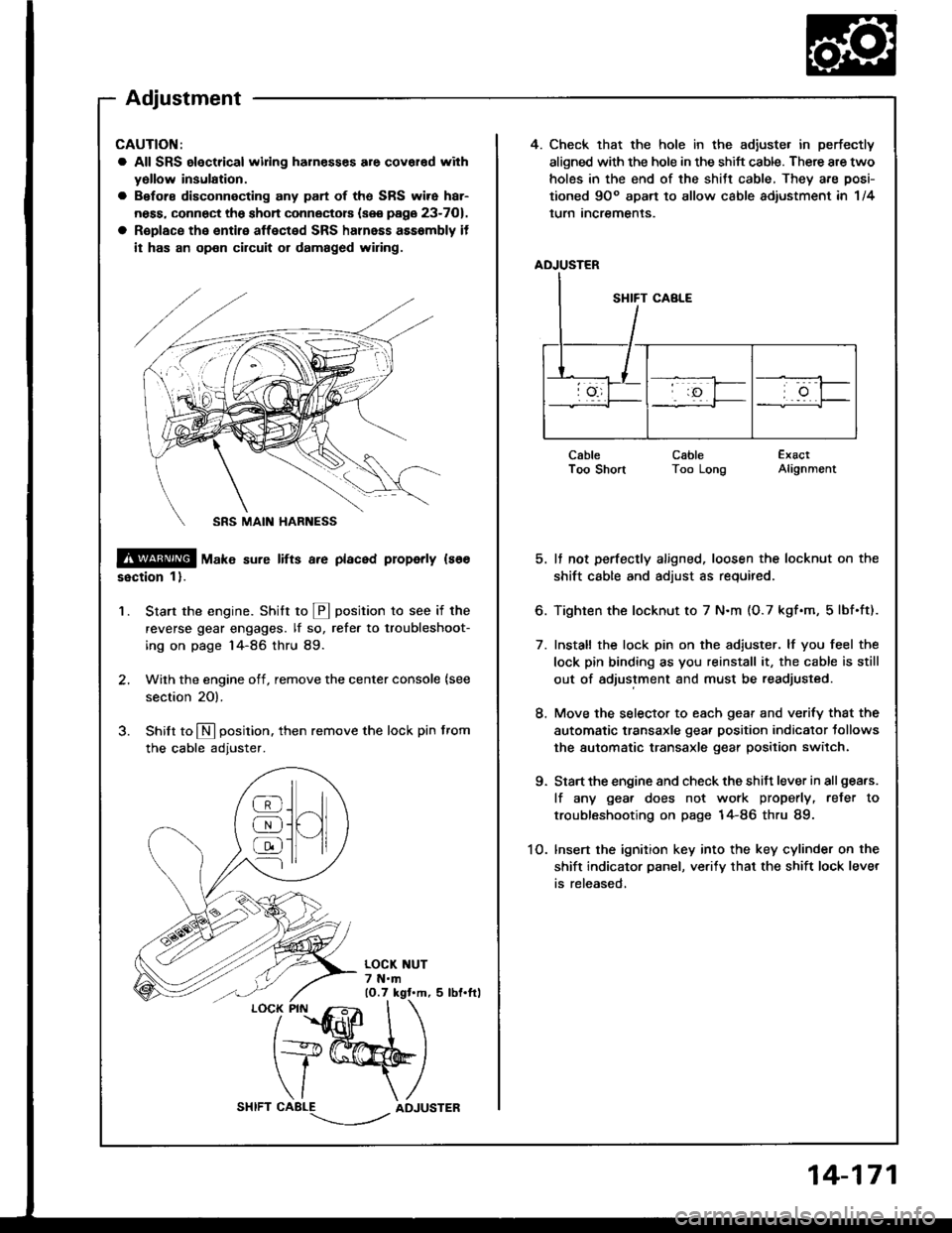

4. Check that the hole in the adiuste. in perfectly

aligned with the hole in the shift cable. There are two

holes in the end of the shitt cable, They are posi-

tioned 9Oo apart to allow cable adiustment in 1/4

lurn Incremenls.

ADJUSTER

CableI oo snonCableToo LongExactAlignment

5. It not perfectly aligned, loosen the locknut on the

shift cable and adjust as required.

6. Tighten the locknut to 7 N.m (O.7 kgf.m, 5lbf.ft).

7. Install the lock pin on the adiuster. lf you feel the

lock pin binding as you reinstall it, the cable is still

out of adjustment and must be readjusted.

8. Move the selector to each gear and verify that the

automatic transaxle gear position indicator tollows

the automatic transaxle gear position switch.

9. Start the engine and check the shift lever in all gea.s.

lf any gea. does not work properly, refer to

troubleshooting on page 14-86 thru 89.

1O. lnsert the ignition key into the key cylinder on the

shift indicator panel, ve.ify that the shift lock lever

is released,

CAUTION:

a All SRS electrical widng harn€sses are covar€d with

yollow insulation.

a Before disconnecting any part of ths SRS wire har-

ness, connect the shon connectors (see page 23-701.

a R€place the entire affected SRS halnass asssmbly it

it has an op€n circuit or damaged wiring.

@ tu"t" sure lifts a.e placed properly ls66

ssction 1).

Start the engine. Stritt to @ position to see if the

reverse gear engages. lf so, refer to troubleshoot-

ing on page 14-86 thru 89.

Wilh the engine off, remove the center console {see

section 20).

Shilt to N position. then remove the lock pin from

the cable adjuster.

'1.

/

''fidlfr

I

t+@

\/ \

CABLE-.'.-_--l../ADJUSTER

]H

@

@

@

Adjustment

14-171

Page 562 of 1413

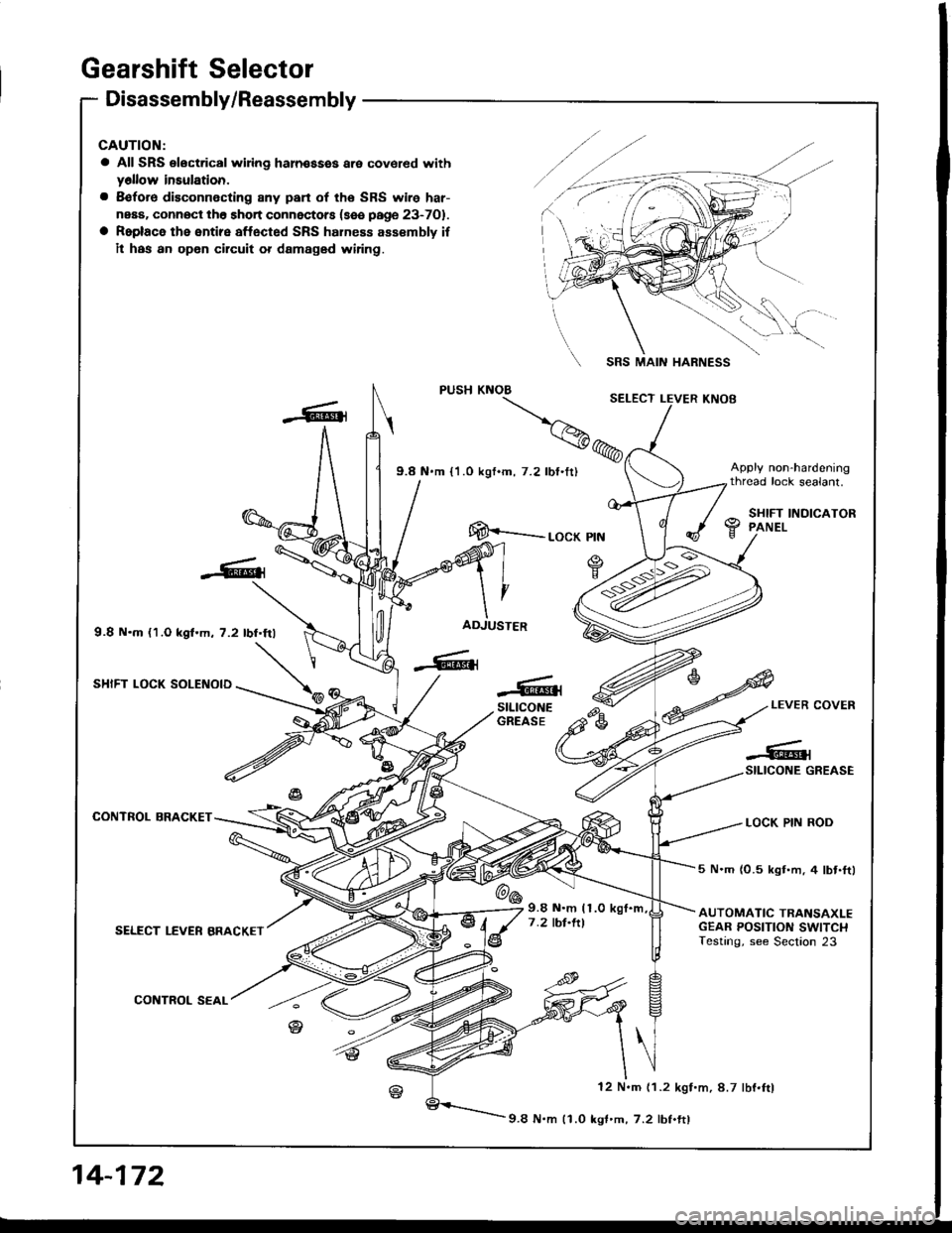

Gearshift Selector

Disassembly/Reassembly

CAUTION:

a All SRS electrical wiing haln€ssss are covered withy6llow insulation.

a 8€fore disconnecting 8ny pan of the SRS wire har-

neaa. connOct th6 short connectors (sse page 23-701.

a Roplace the entire affected SRS hahess assembly if

il has an opon circuit or damaged wiring.

9.8 N.m {1.O kgf.m, 7.2 lbf.frl

SHIFT LOCK SOLENOID

CONTROL BRACKET

SELECT LEVER BRACKET

CONTROL SEAL

SRS MAIN HARNESS

[E--__ rocK ptN

ADJUSTER

-6{stLtcoNEGREASEe-LEVER COVER

LOCK PIN ROD

-#qSILICONE GREASE

@6

5 N.m (0.5 kgt.m, 4 lbt.ftl

AUTOMATIC TRANSAXLEGEAR POSITION SWITCHTesting, see Section 23

9.8 N.m (1.0

7 .2 tbt.ltl

12 N.m (1.2 kgf.m, 8.7 lbf.ftl

9.8 N.m 11.0 kgf'm,7.2 lbf.ftl

14-172

Page 563 of 1413

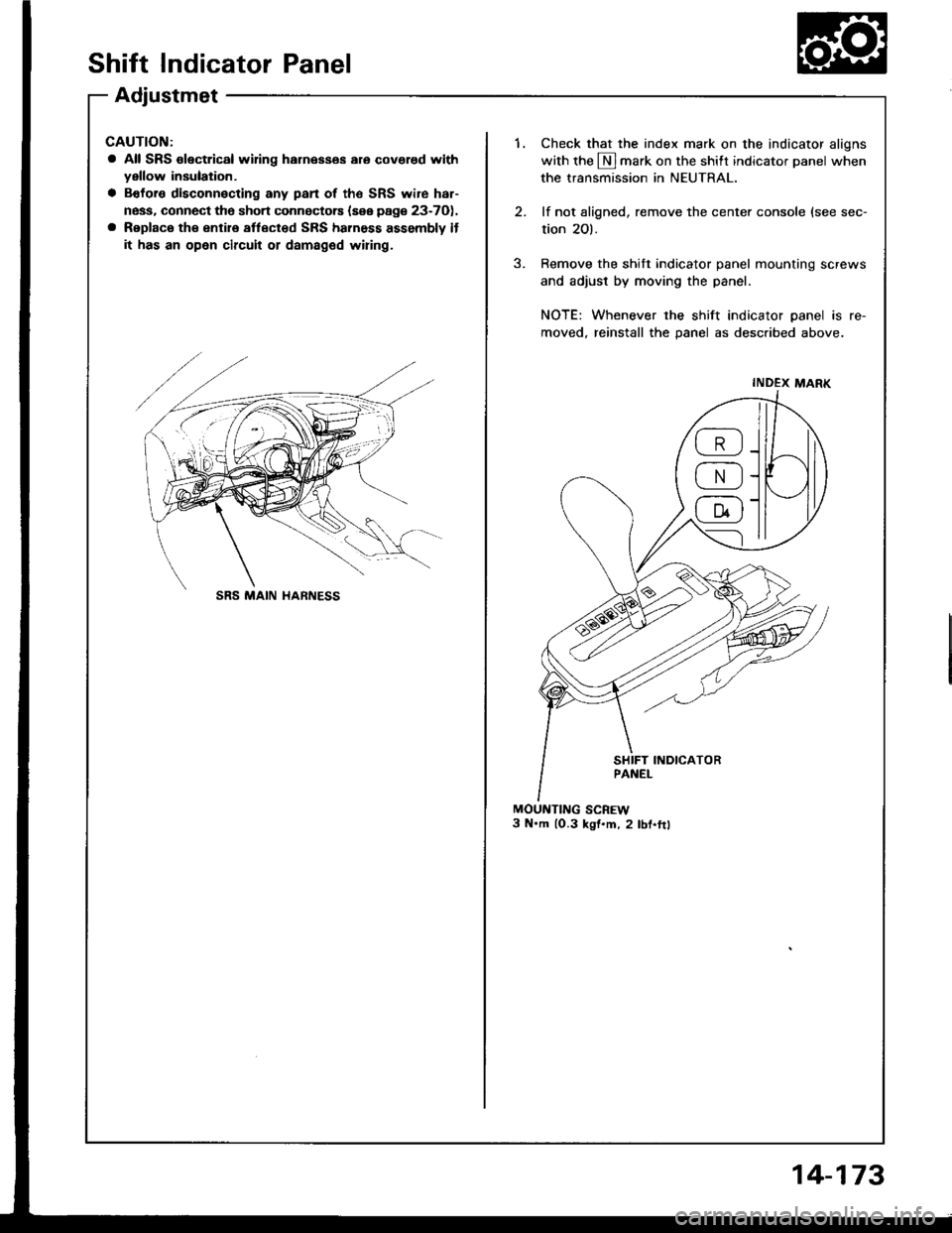

Shift Indicator Panel

Adjustmet

CAUTION:

a All SRS olectrical wifng harnesses aro covered withyellow insulation.

a Bofors disconnecting any pan of the SRS wire har-

ness, connect tho sho.t connectors {sse page 23-7O),

a Replace the entire aflect€d SRS harness assembly if

it has an open circuit or damaged wiring,

1.Check that the index mark on the indicator aligns

with the N]mark on the shift indicator panel when

the transmission in NEUTRAL.

lf not aligned, remove the center console (see sec-

tion 2O).

Remove the shift indicator panel mountinq screws

and adjust by moving the panel.

NOTE: Whenever the shift indicator panel is re-

moved, reinstall the panel as described above.

MOUNTING SCREW3 N'm lO.3 kst.m, 2 lbf.ftt

INDEX MARK

@

@

@

SRS MAIN HARNESS

14-173