brake HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 3 of 1413

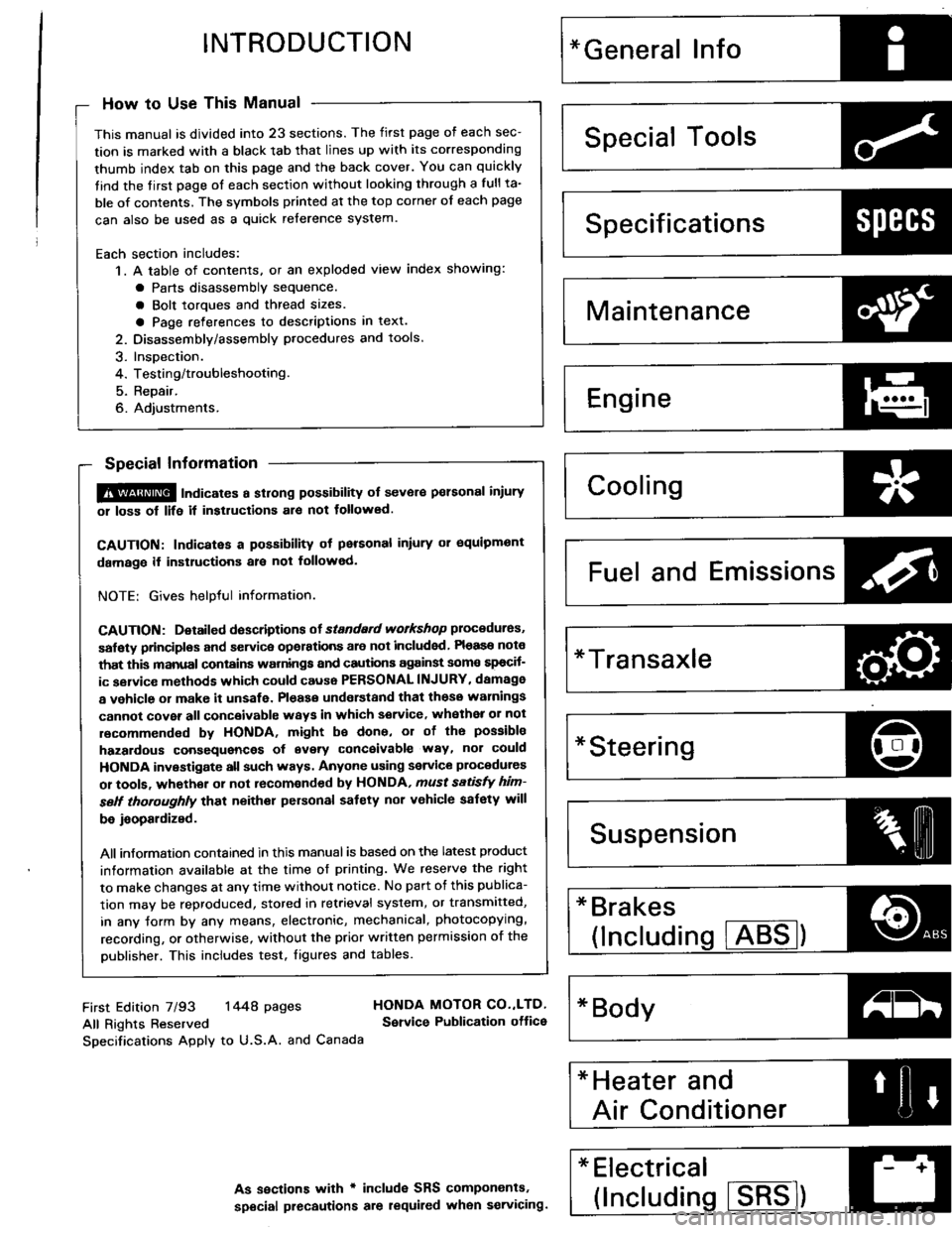

INTRODUCTION

How to Use This Manual

This manual is divided into 23 sections. The first page of each sec-

tion is marked with a black tab that lines up with its corresponding

thumb index tab on this page and the back cover. You can quickly

tind the tirst page of each section without looking through a full ta-

ble of contents. The svmbols printed at the top corner of each page

can also be used as a quick reference system.

Each section includes:

1. A table of contents. or an exploded view index showing:

a Parts disassemblv sequence.

a Bolt toroues and thread sizes.

a Page references to descriptions in text.

2. Disassemblv/assembly procedures and tools.

3. InsDection.

4. Testing/troubleshooting.

5. Repair.

6. Adiustments.

Special Information

@ lnai""tes a strong possibility of sevor€ pelsonal iniury

01 loss of life it instructions al€ not tollowed.

CAUTION: Indicates a possibility ot personal inlury or oquipmont

damage if instructions ale not followed.

NOTE: Gives helpful information.

CAUTfON: Detaifed doscriptions ot standad workshop procedures,

salety principlos and servica opelations are not included Pleaso note

that this manual conlains warnings and cautions against somo spocif-

ic sgrvice methods which could cause PERSONAL INJURY, damage

a vehicle or make it unsafe. Pleaso understand that those warnings

cannot cover all conceivablc waYs in which service, whethea or not

recommended bv HONDA, might be done, or of the possibla

hazardous consequences of svery conceivable way, nor could

HONDA investigate all such ways. Anyone using seryice plocedures

or toofa, whethor 01 not recomonded by HONDA, ,nust sttisfY him-

sett thoroughly that neither personal saf€ty nor v€hicle safety will

be jaopaldized.

All information contained in this manual is based on the latest product

information available at the time of printing. We reserve the right

to make changes at any time without notice. No part of this publica-

tion mav be reproduced, stored in retrieval system, or transmitted,

in any Jorm by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of the

publisher. This includes test. figures and tables.

Specificationstrtl:{lt'

Maintenance4Pi

Engine

H

I-""

Fuel and Emissions Za

*Transaxle

*Steeringr-\

lDl\.t/

* Brakes

(lncludins !TEg)o

*Electrical J--*

(lncludins ISBE)

First Edition 7/93 1448 pages

All Rights Reserved

Specifications Apply to U.S.A. and Canada

HONDA MOTOR CO.,LTD,

Service Publication ottice

As sections with r includ€ SRS components.

special precautions are lequiled when servicing.

Page 14 of 1413

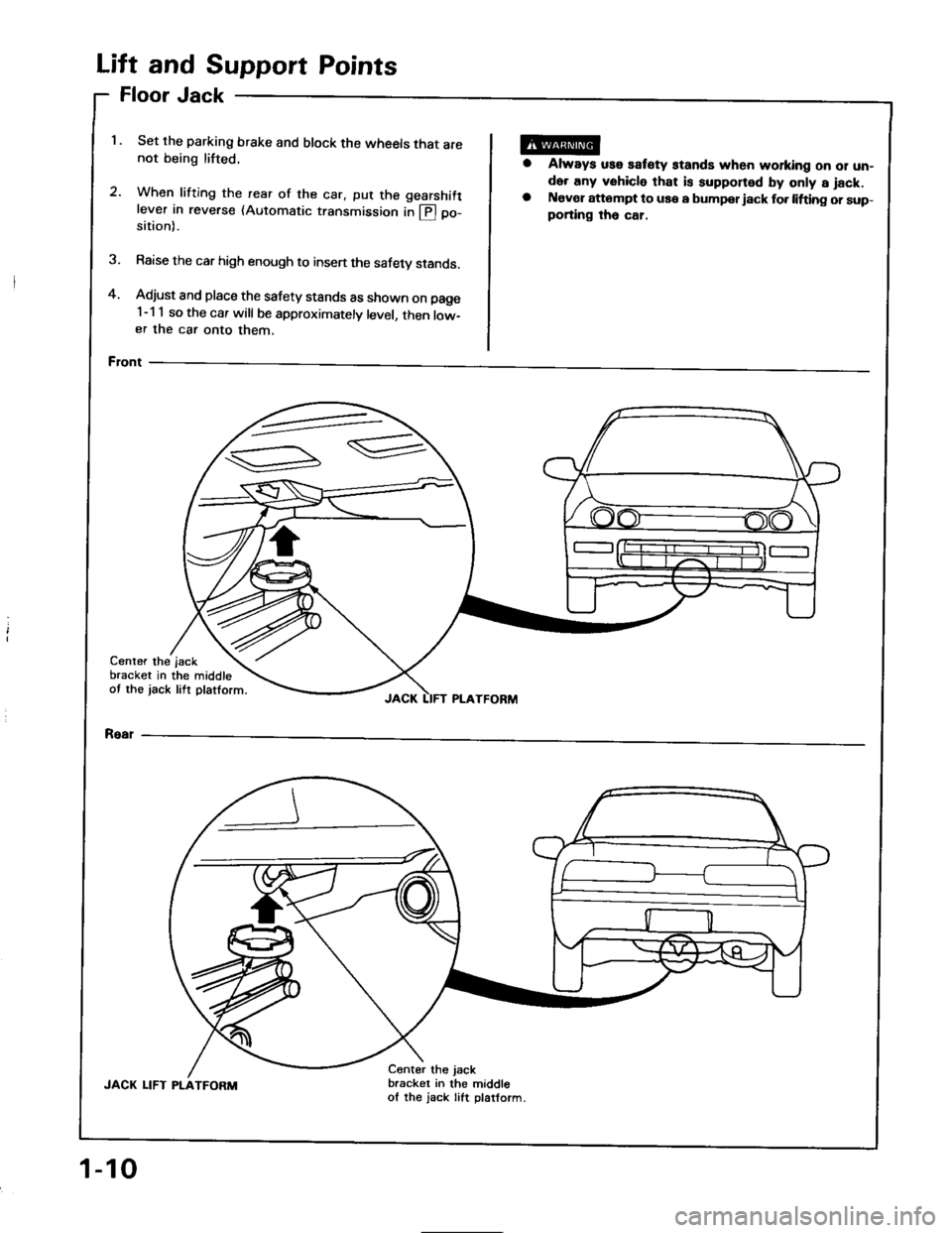

and Support Points

Jack

Set the parking brake and block the wheels that are

not being lifted.

2.When lifting the rearwhen tritrng the rear of the car, put the gearshift

lever in reverse (Automatic transmission in @ po-

of

sition).

Raise the car high enough to insen the safety stands.

Adjust and place the safety stands as shown on page

1-1 1 so the car will be approximately level, then low-

er the car onto them.

Front

oor

ft

FI

Li

4.

1.

a

Always uss satety stands when working oo 01 un-

der any vehicle that is supponed by only a jack.

Naver attompt to use a bumpor iack fo. lifting or sup-

porting tho car,

3.

Center the

bracket in

ot the jack

the middle

lift platform.

jsck

JACK LIFT PLATFORM

Rear

JACK LIFT PLATFORM

Center the jack

bracket in the middle

of the jack Iift platform.

1-10

Page 16 of 1413

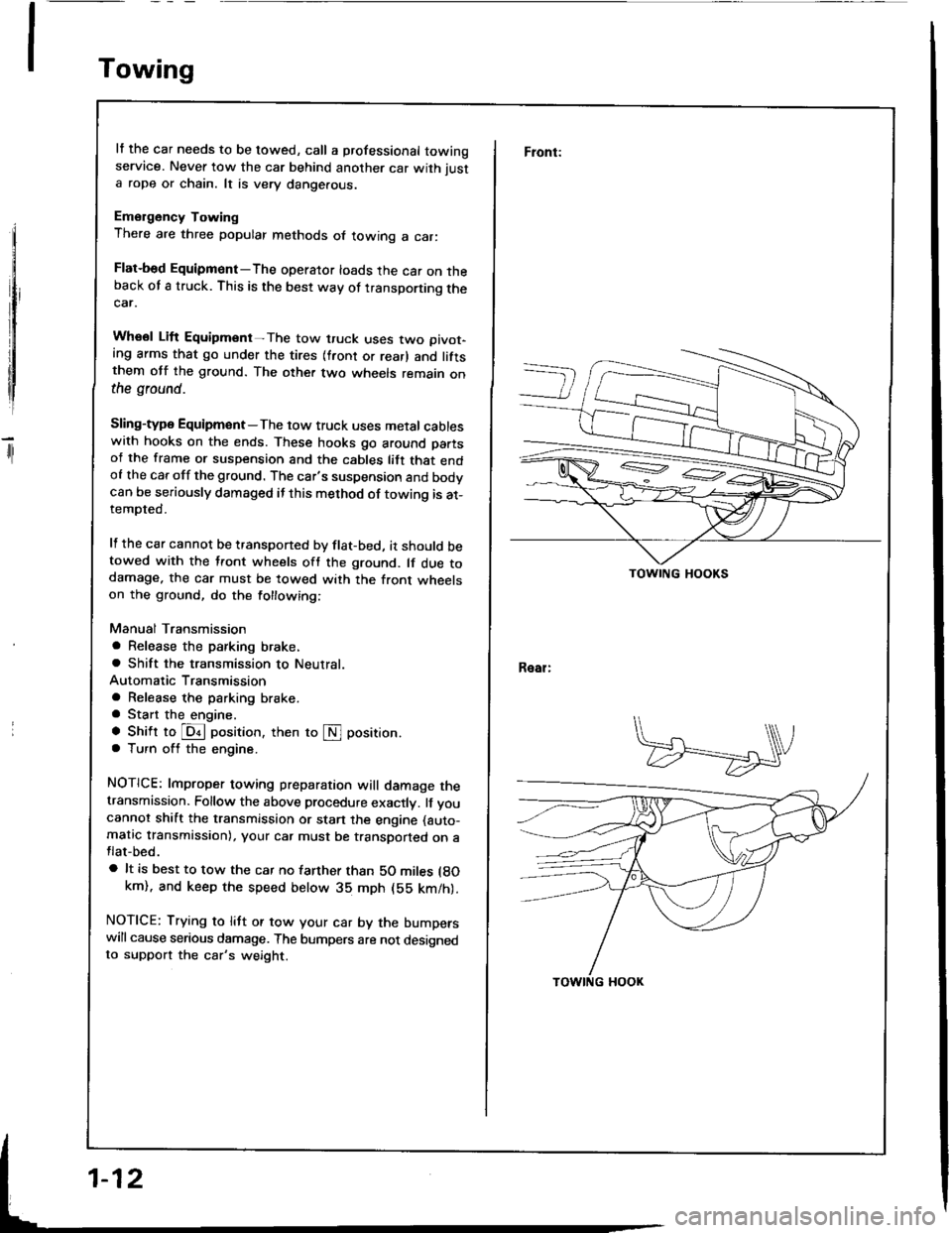

Towing

rl

It the car needs to be towed, call a professional towingservice. Never tow the car behind another car with just

a rope or chain. lt is very dange.ous.

Emergency Towing

There are three popular methods of towing a car:

Flat-bed Equipmont-The operator loads the car on theback of a truck. This is the best way of transporting thecar.

Whsol Lift Equipment-The tow truck uses two oivot-ing arms that go under the tires (front or rear) and liftsthem otf the ground. The other two wheels remain onthe ground.

Sling-type Equipmont-The tow truck uses metal cableswith hooks on the ends. These hooks go around partsof the frame or suspension and the cables lift that endof the car off the ground. The car's suspension and bodvcan be seriously damaged if this method of towing is at-tempted.

It the car cannot be transponed by flat-bed, it should betowed with the tfont wheels oft the ground. lf due todamage. the car must be towed with the front wheelson the ground, do the tollowing:

Manual Transmission

a Release the parking brake,a Shift the transmission to Neutral.

Automatic Transmission

a Release the parking brake.a Start the engine.

a Shift to @ oosition, then to S position.

a Turn off the engine.

NOTICE: lmproper towing preparation will damage thetransmission. Follow the above procedure exactly. lf you

cannot shift the transmission or stan the engine (auto-

matic transmission), your car must be transDorted on aflat-bed.

a lt is best to tow the car no tarther than SO miles lgokm). and keep the speed below 3b mph (bE km/h).

NOTICE: Trying to litt or tow your car by the bumperswill cause serious damage. The bumpers are not designedto support the car's weight.

Front:

Real:

TOWING HOOKS

Page 29 of 1413

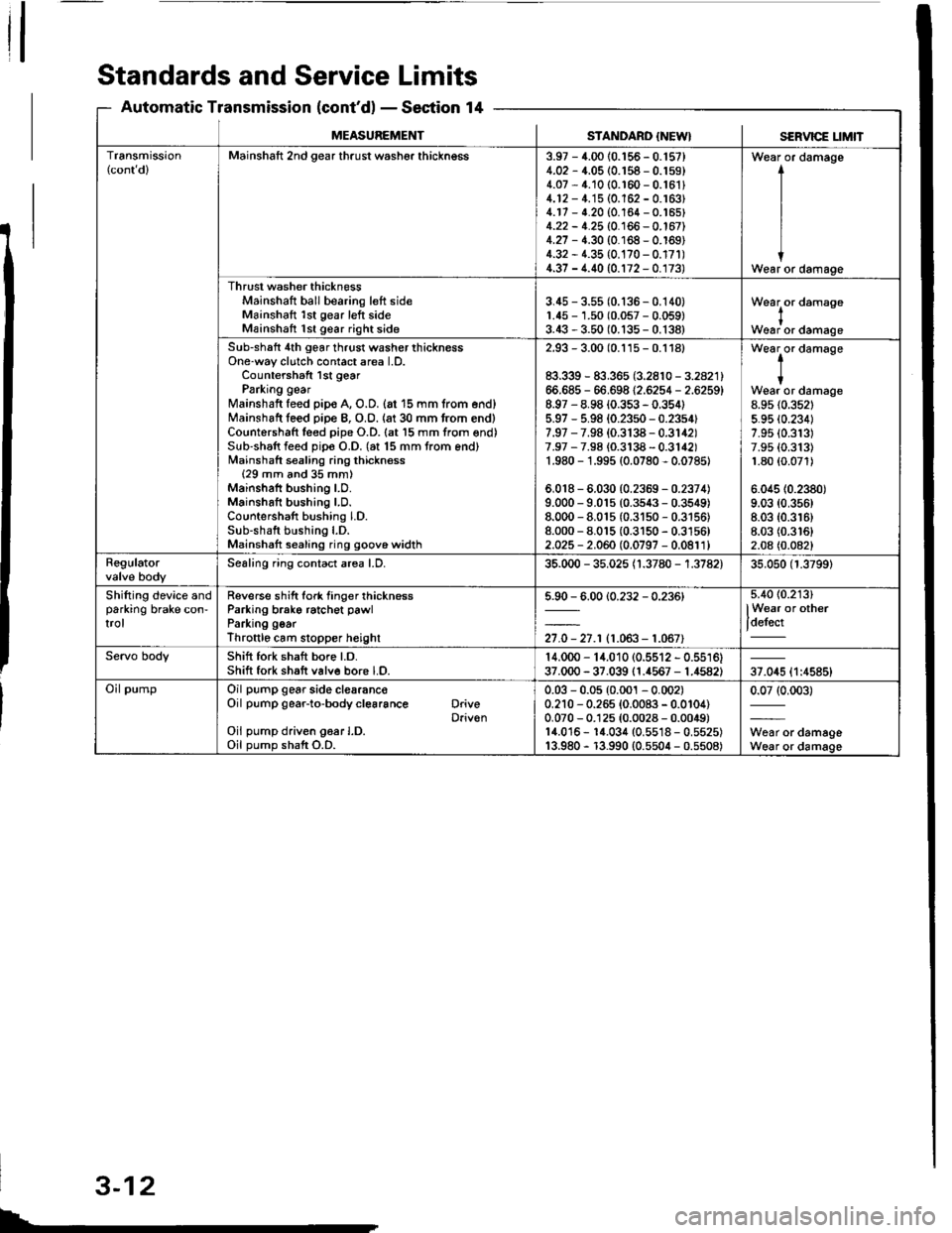

Standards and Service Limits

Automatic Transmission (cont'dl - Section 14

SERVICE t_tMtTMEASUREMENTSTANDARD {NEW}

Transmission(cont dlMainshaft 2nd gear thrust washer thickngss3.97 - 4.00 {0.156 - 0.'t57}4.02 - 4.05 (0.158 - 0.159)4.07 - 4.10 (0.r60 - 0.16114.12 - 4.'15 (0.162 - 0.163)4.17 - 4.20 (0.164 - 0.'�t65)4.22 - 4.25 (0.166 - 0.167)4.27 - 4.30 {0.168 - 0.169)4.32 - 1.35 {0.170 - 0.17r)4.37 - 4.40 (0.172 - 0.173)

Wear or damage

I

I

IWear or damage

Thrust washer thicknessMainshaft ball bearing left sideMainshaft 1st gear left sideMainshatt 1st gear right side

3.45 - 3.55 (0.136 - 0.140)1.45 - 1.50 (0.057 - 0.059)3.43 - 3.50 (0.135 - 0.138)

Wearlor damase

Woar or damage

Sub-shaft 4th gear thrust washer thicknessOne-way clutch contact area l.D.Countershaft lst gearParking gearMainshaft feed pip€ A, O.D. {at 15 mm trom end}Mainshaft leed piDe B, O.O. {at 30 mm from end)Countershaft leed pipe O.D. (at l5 mm from end)Sub-shaft feed pip€ O.D. (at 15 mm trom end)Mainshaft sealing ring thickness{29 mm and 35 mm)Mainshaft bushing LO.Mainshaft bushing LD.Countershaft bushing LD.Sub-shaft bushing l.D.Mainshatt sealing ring goove widlh

2.93 - 3.00 (0.115 - 0.1181

83.339 - 83.365 (3.2810 - 3.2821)66.685 - 66.698 12.6254 - 2.6259)8.97 - 8.98 {0.353 - 0.354)5.97 - 5.98 (0.23s0 - 0.2354f7.97 - 7.98 (0.3138 - 0.3142)7.97 - 7.98 {0.3138 - 0.3142)1.980 - 1.995 (0.0780 - 0.07851

6,018 - 6.030 (0.2359 - 0.2374)9.000 - 9.015 (0.3s43 - 0.3549)8.000 - 8.01s (0.31s0 - 0.3156)8.000 - 8.015 (0.3150 - 0.3156)2.025 - 2.060 (0.0797 - 0.0811)

t-

tWear or damage8.95 {0.352t5.95 (0.2341

7.95 (0.313)

7.9s (0.313)

1.80 {0.071)

6.045 (0.2380)

9.03 (0.356)

8.03 (0.3r6)

8.03 (0.3161

2.08 (0.0821

RegulatorSealing ring contact area LD.35.000 - 35.025 {1.3780 - 1.3782)35.050 (1.3799)

Shifting device andparking brake con-trol

Reverse shift fork tinger thicknessParking brako ratchet pawlParking goarThroftlo cam slopper heighl

5.90 - 6.00 {0.232 - 0.236)

27.0 - 27.r (1.063- 1.067)

5.4O {0.213)

lWear or other

t_'--'

Servo bodyShift fork shaft bore Lo.Shift fork shaft v6lve bore LO.14.000 - 14.010 (0.5512 - 0.5516)37.000 - 37.039 (1.{567 - 1.4582)37.045 {1:4585}

Oil pumpOil pump gear side clearanc€Oil pump gear-to-body cl€6rance DriveDriv€nOil pump driven g6ar I.D.Oil pump shaft O.D.

0.03 - 0.05 (0.001 - 0.002)0.210 - 0.265 {0.0083 - 0.0104)0.070 - 0.125 (0.0028 - 0.0049)14.016 - 1{.034 (0.5518 - 0.5525)13.980 - r3.990 {0.5504 - 0.5508)

0.07 (0.003)

W6ar or damageWear or damage

L

3-12

Page 32 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual MEASUFEMENTSTANDARD I]{EWI

a gnmentCamber FrontRgarCaster FrontTotaltoe FrontRearFront whe€lturning angle Inward whe€lOutwsrd wh€el

-0. 10 1 1.-0 15 l$igl1. 10�r t"0i2(010.081rN 3:i (0.121ff HONDA INTEGRA 1994 4.G Workshop Manual MEASUFEMENTSTANDARD I]{EWI

a gnmentCamber FrontRgarCaster FrontTotaltoe FrontRearFront whe€lturning angle Inward whe€lOutwsrd wh€el

-0. 10 1 1.-0 15 l$igl1. 10�r t"0i2(010.081rN 3:i (0.121ff](/img/13/6067/w960_6067-31.png)

MEASUFEMENTSTANDARD I]{EWI

a gnmentCamber FrontRgarCaster FrontTotaltoe FrontRearFront whe€lturning angle Inward whe€lOutwsrd wh€el

-0. 10' 1 1.-0' 15' l$igl1. 10'�r t"0i2(010.081rN 3:i (0.121ff)36' 0o' r 2'30. 30'

A1lc€lbearingEnd playFrontRoaa0 - 0.05 (0 - 0.002)0 - 0.05 {0 - 0.002}

Rim runout (Aluminum wheel) AxialRadialRim runout isteelwhgel) AxialRadisl

STANDARD INEWISEBVICE UMIT

0 - 0.7 {0 - 0.03)0 - 0.7 (0 - 0.03)0 - 1.0 {0 - 0.0{)0 - 1.0 (0 - 0.04)

2.0 (0.08)

1.5 (0.06)

2.0 (0.081

r.5 (0.061

SuspensionSestion 18

BrakeSection 19

Air ConditioningScction 22

.1: When using a new bek, adjust dellection or tension to new values. Run the engine tor 5 minules ihen turn it ott.

Readiust detlection or tension to lsed beh values.'2: 81881 engine'3: 818C1 engine

Unit of length: mm {in)

MEASUREMENTSTANDARD {NEWI

trrling brakePlay in strok€ at 200 N {20 kgf, 44 lbt)lever lorceTo b€ lockod when pulled 6 -10

nolchsa

; oot brake,adalPedal heighl lwith floor mat removod)

Free play

M/T160 (6.30)

155 (6.50)

1-5(0.04-0.20)

Vaster cylinderPiston-to-oushrod clearance0 - 0.4 (0 - 0.2)

f,,s4 brakeOisc thickness FrontRe6rDisc runout FrontR6arDisc parallolism Front and rear

Pad lhickness FrontRoar

STANDARD INEWISERVICE LIM]T

20.9 - 21.1 t0.82 - 0.83t8.9 - 9.1 {0.35 - 0.36)

9.5 - 10.5 {0.37 - 0.41}7.0- 8.0 {0.27 - 0.31)

19.0 (0.75)

8.0 (0.31)

0.10 (0.004)

0.r0 (0.00a)

0.015 (0.0006t

r.6 (0.06)

1.6 (0.06)

MEASUREMENTSTANDABO IT{EWI

Ar conditioningLubricant capacity mf (ll oz) Cond€nserEvaporatorLine or hoseReceiverLubricant type: NO-OlL8 {P/N 38899 - PR7 - A0l)

25 (5/6)

40 t1 1/3)10 (lBt

10 (1/31

CompressorLubricant capacity m{ (ll oz}Lubricant tvge: ND-O|L8 (P/N 38899 - PR7 - A01)Stator coil resistance at 68'F (20'C) 0Pulley-to-pressure plate clearance

140';u (4-23';")

3.4- 3.80.5 r 0.15 {0.02 r 0.006)

Compressorb€h'rDetlection with 98 N (10 kgf, 22 lbf)betlveen pulleys

7.5 - 9.5 {0.30 - 0.37)with used b€lt*'�8.5 - 10.5 {0.33 - 0.41}with t/sod belt'35.0 - 7.0 {0.20 - 0.28) with new belt

Belt t€nsion N (kgf, lbl)Measured with belt lension gauge390 - 540 {r0 - 55, 88 - 120} with used beh*'�340 - 490 {35 - 50, 77 - 110} with used belt*3740 - 880 {75 - 90, 170 - 200) with new belt

3-15

Page 36 of 1413

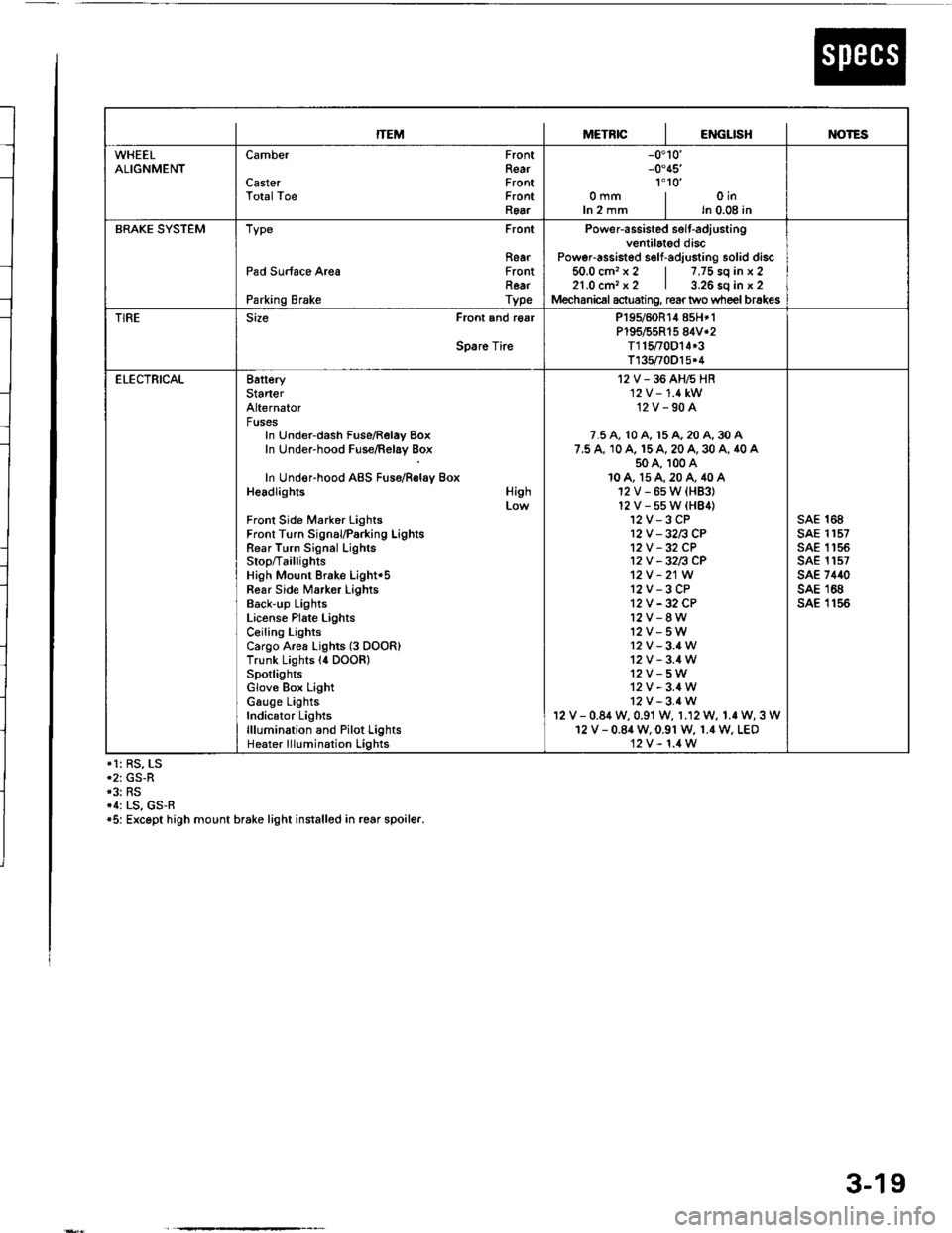

ITEMMETRICIENGLISHIM)TES

WHEELALIGNMENTCamber

CasterTotalToe

FrontRearFrontFrontRear

-0.10'-0.45'�

1'1o'�omm | oinIn 2 mm I ln 0.08 in

BRAKE SYSTEMType Front

RearPad Surface Area FrontRearParking Brake Type

Power-assisted selt-adiustingventilated discPoweFassisted self-adjusting solid discio.u cm. x z | /,/5 so tn x z21.0 cm, x2 | 3.26 sq in x 2Mechanical actuating, rear two wheel brakes

TIRESize Front and r€ar

Spare Tire

P195/60R14 858*1P195/55R15 84V*2T115t0D14*3T135/70O15.4

ELECTRICAL8atteryStarterAlternatorFusesIn Under-dash Fuse/Relay BoxIn Under-hood Fuse/Relay Box

In Under-hood ABS Fuso/Rolay BoxHeadlights

Front Side Marker LightsFront Turn SignauParking LightsRear Turn Signal LighlsStop/Ta illig htsHigh Mount Brake Light'5Fear Side Marker LightsBack-up LightsLiconse Plate LightsCeiling LightsCargo Area Lights (3 DOOR)Trunk Lights l4 DOOR)SpotlightsGlove Box LightGauge LightsIndicator Lightslllumination and Pilot LightsHeater lllumination Lights

High

I2V-36AH6HR'12 V -'1.4 kW12V-90A

7.5 A, 10 A, 15 A, 20 A, 30 A7.5 A, 10 A. 15 A, 20 A, 30 A, 40 A50 A, 100 A10A, 15A,20A,40A12V-6sW{HB3}12V-55W(HB4)12V-3CP12V -32n CP12V -32 CP12V -32n CP12V -21W

12V-3CP12V -32 CP12V-8W12V-5W12v-3.4W12V-3.4W12V-5W12V-3.4W12V-3.4Wv - 0.84 w, 0.91 w, 1.12 W, 1.r W, 3 W12 V - 0.84 W. 0.91 W, 1.4 W. LEO12V-1.4W

sAE 168sAE 1157sAE 1 '�t 55sAE 1157sAE 7440sAE 168sA€ 1156

*1: RS, LS*2: GS-R*3: RS*1: LS, GS-R*5: Except high mount brake light installed in rcar spoiler.

3-19

Page 40 of 1413

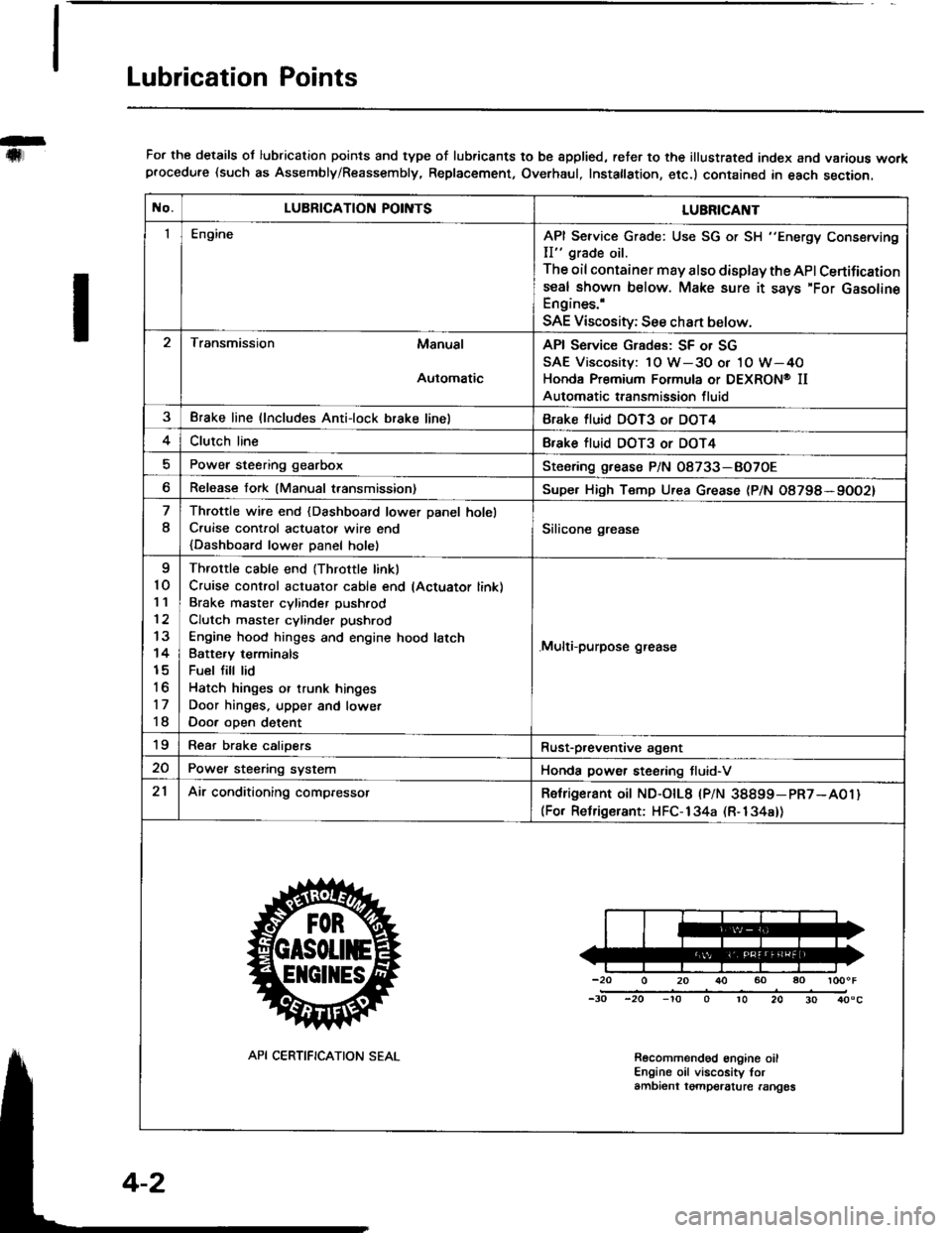

Lubrication Points

For the details ol lubrication points and type of lubricants to be spplied, reter to the illustrated index and various workprocedure (such as Assembly/Reassembly, Replacement, Overhaul, Instatlation, etc.) contained in each section.

No.LUBRICATION POII\ITSLUBRICAI\IT

IEngineAPI Service Grade: Use SG or SH "Energy Conserving

II" grade oil.

The oil container may also display the API Certifications€al shown below. Make sure it says'For GasolineEngines.'

SAE Viscosity; See chan below.

Transmission Manual

Automatic

API Service Grades: SF or SG

SAE Viscosity: 1O W-3O or 1O W-4O

Honda Premium Formula or DEXRON@ II

Automatic transmission fluid

3Brake line (lncludes Anti-lock brake linelBrake fluid DOT3 or DOT4

4Clutch lineBfake tluid DOT3 or DOT4

Power steering gearboxSteoring grease P/N 08733-BO7OE

Release fork (Manual transmission)Supe. High Temp Urea Grease (P/N O8798*9OO2)

8

Throttle wire end {Dashboard lower Danel holel

C.uise cont.ol actuatot wire end

{Dashboard lower Danel holel

Silicone grease

I

10'I '�l

12

13

14

15

to

17

18

Throttle cable end (Throttle linkl

Cruise control actuator cable end lActuator link)

Brake master cvlinder Dushrod

Clutch master cylinder pushrod

Engine hood hinges and engine hood latch

Batte.v terminals

Fuel fill lid

Hatch hinges or trunk hinges

Door hinges. upper and lowet

Door oDen detent

.Multi-purpose grease

19Rear brake calioersRust-p,eventive agant

20Power steering systemHonda power steering tluid-V

21Air conditioning compressorRetrigerant oit ND-otL8 |PlN 38899-pR7-A01)(For Relrigerant: HFC-134a (R-134a))

-20 0 20 r}() 60 ao loooF

-30 -20 -'to o 10 20 30 40"c

Recolnmendod engine oilEngine oil viscosity torambient tgmpelalure rangos

API CERTIFICATION SEAL

Page 50 of 1413

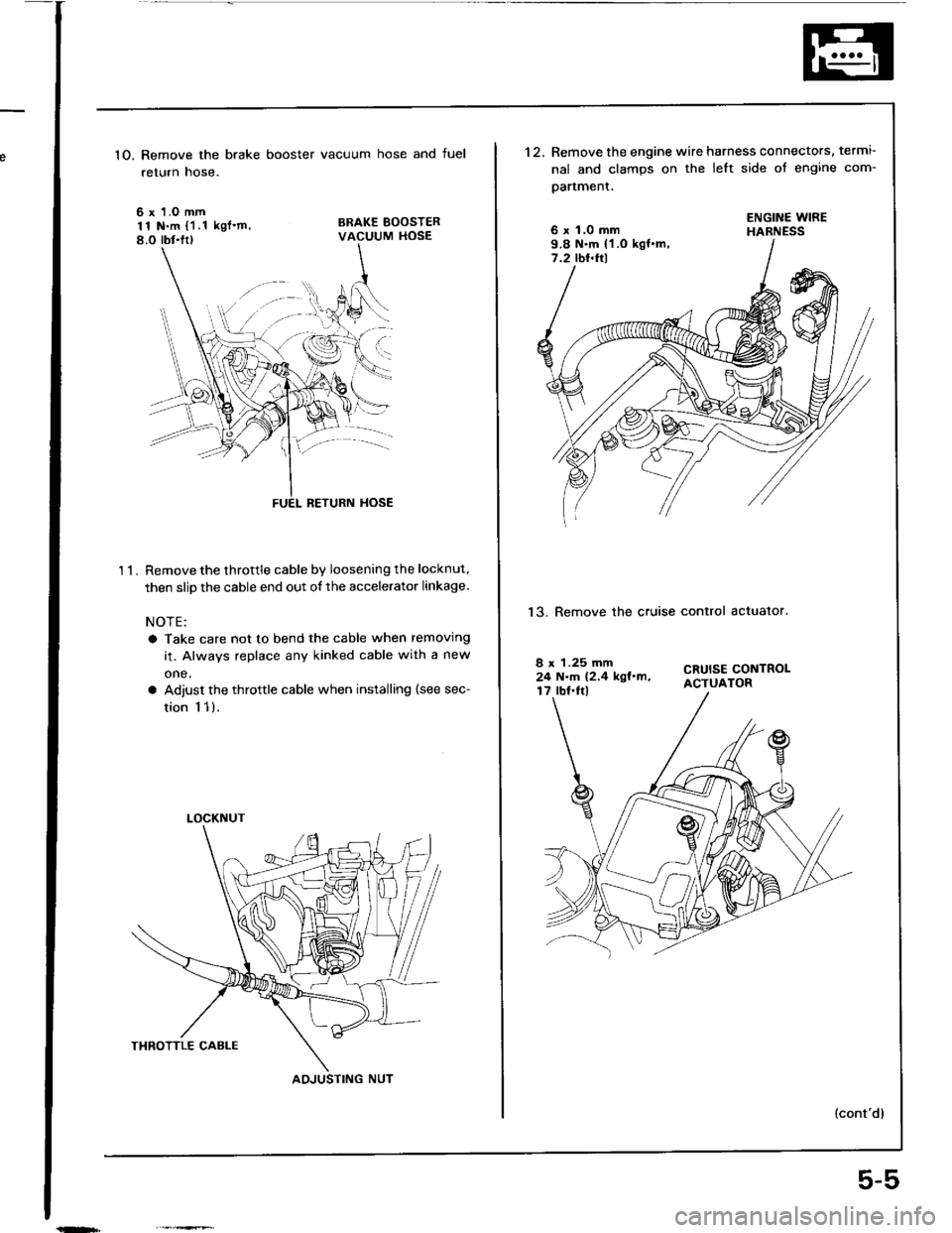

1O. Remove the brake booster vacuum hose and fuel

return hose.

6 x 1.O mm11 N.m {1.1 kgl'm,8.O rbt.ltl

BRAKE BOOSTERVACUUM HOSE

't 1.

BETURN HOSE

Remove the throttle cable by loosening the locknut.

then slip the cable end out of the accelerator linkage.

NOTE:

a Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one,

a Adjust the throttle cable when installing (see sec-

tion 1 1).

LOCKNUT

AOJUSTING NUT

5-5

't2.Remove the engine wire harness connectors, termi-

nal and clamps on the left side ot engine com-

oartment.

6 x 1.0 mm9.8 N.m {1 .O kgf.m,7.2 tbt.ftl

ENGINE WIREHABNESS

13. Remove the cruise control actualor.

CRUISE CONTROLACTUATOR

8 x 1.25 mm24 N.m (2,4 kgl.m,17 lbf.Irl

Page 79 of 1413

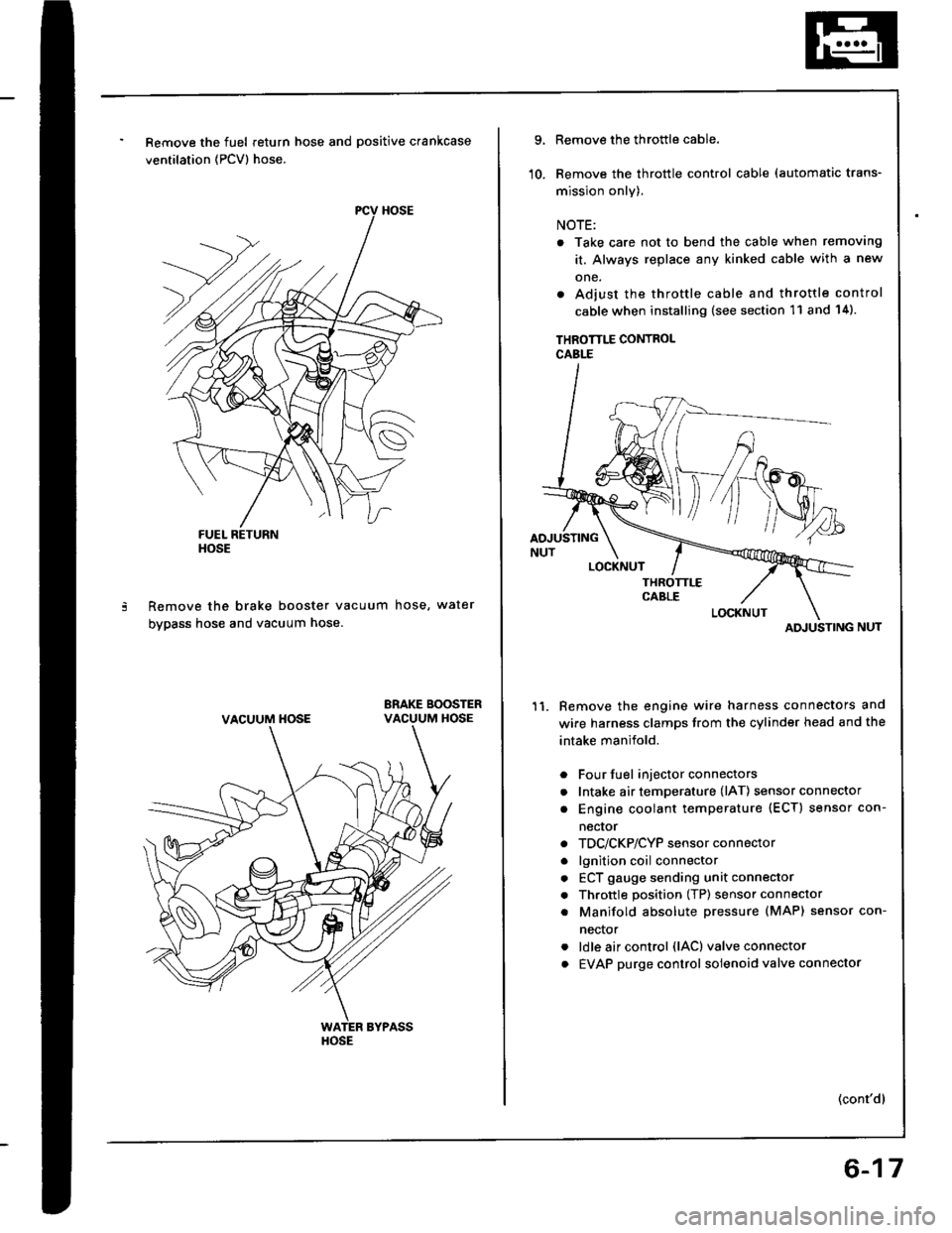

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 117 of 1413

Cylinder Head

Removal (cont'd)

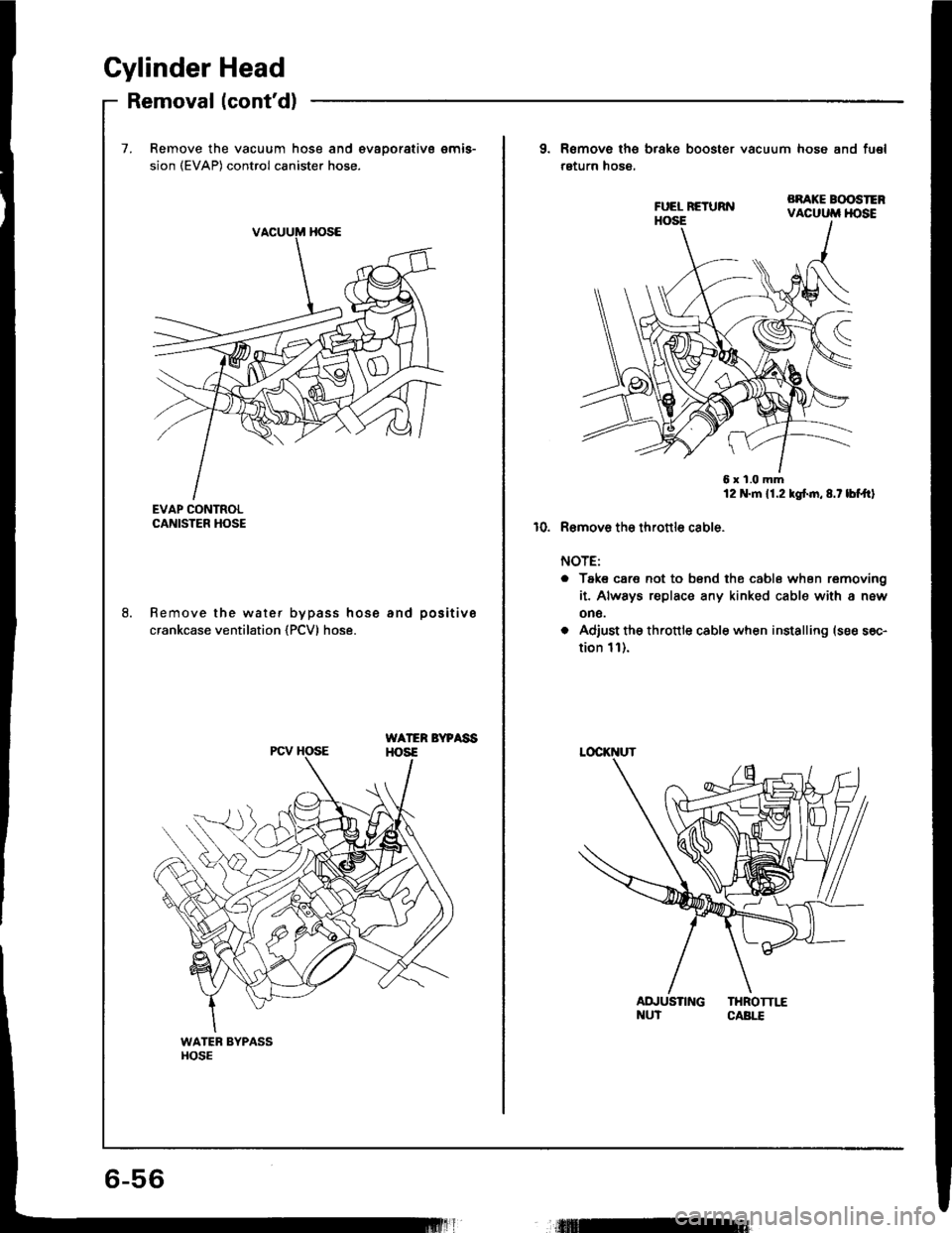

7. Remove the vacuum hose and €vaoorativs emis-

sion (EVAP) control canister hose.

EVAP CONTROLCANISTER HOSE

Remove the water bypass hose and positive

crankcase ventilation {PCV) hose.

WATER BYPAssHOS€PCV HOSE

9. Remove ths brake booster vacuum hose and fu€l

return hose,

BRAKE BOOSTERVACUUM HOSE

6x1.0mm12 N.m 11.2 kgf.n,8.t lbf.trl

10. R€mov6 tho thronlo cable.

NOTE:

o Taks care not to bsnd the cabl6 when removing

it. Always replace any kinked cable with a new

on6.

o Adiust the th.ottle cable when installing (see s6c-

tion 1l).

AD.'USTING THROTTI,"ENUT CABI.T