Clutch removal HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 375 of 1681

Transmission Assembly

Removal (cont'dl

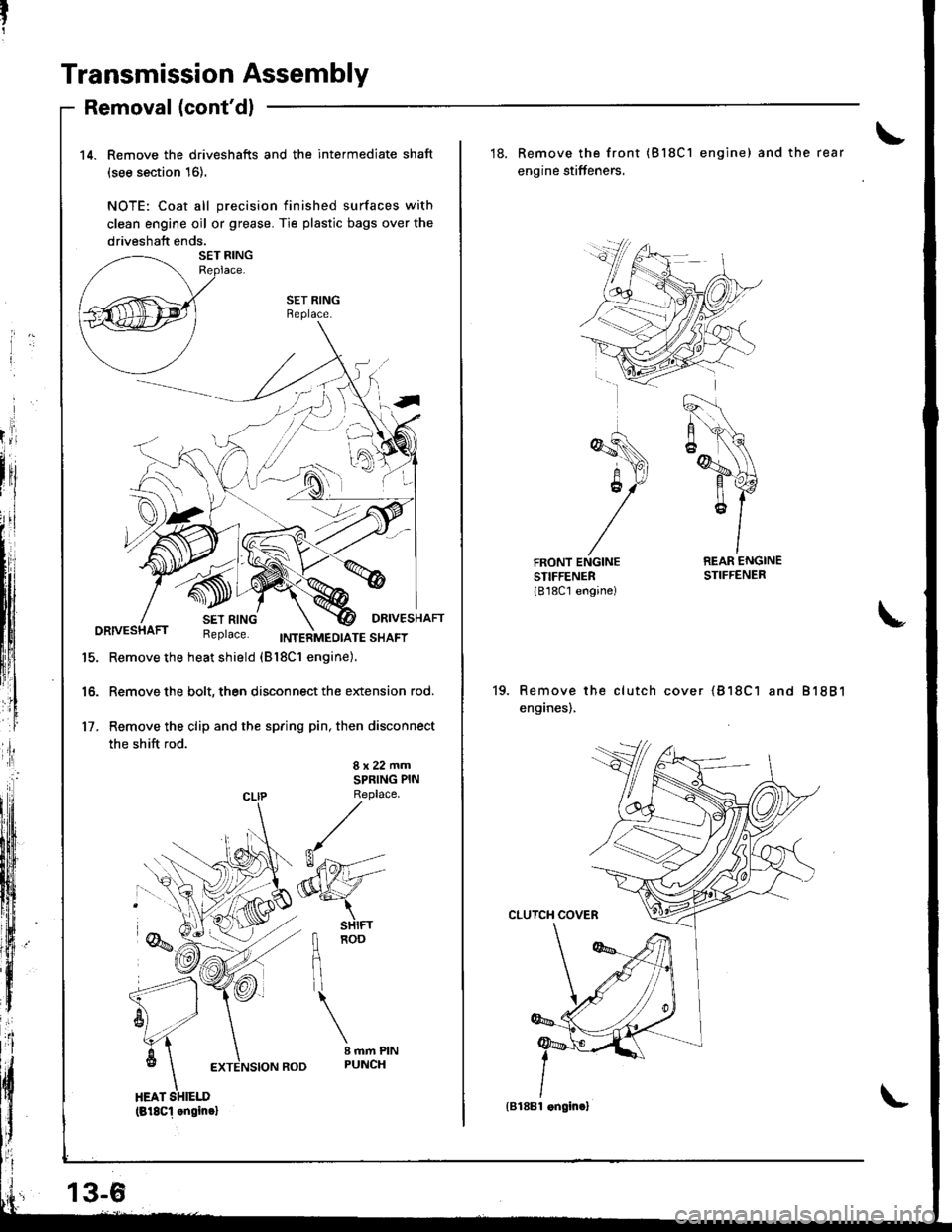

14. Remove the driveshafts and the intermediate shaft

(see section 16).

NOTE: Coat all precision finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends.

SET RINGBeplace.

DRIVESHAFTDRIVESHAFT Replace. trweinnro,ora ""ot

15. Remove the heat shield (Bl8c1 engine).

16. Remove the bolt, then disconnect the extension rod.

17. Remove the clip and the spring pin, then disconnect

the shift rod.

8x22mmSPRING PIN

CLIP Replace

fl noo

flil

\

I mm PINPUNCH

(818c1 .ngin.l

13-6

'18. Remove the front (Bl8C1 engine) and the rear

engine stiffeners,

REAR ENGINESTIFFENER

Remove the clutch cover {818C1 and 81881

enganes),

{B188l .ngin.}

Page 376 of 1681

Transmission Housing

Removal

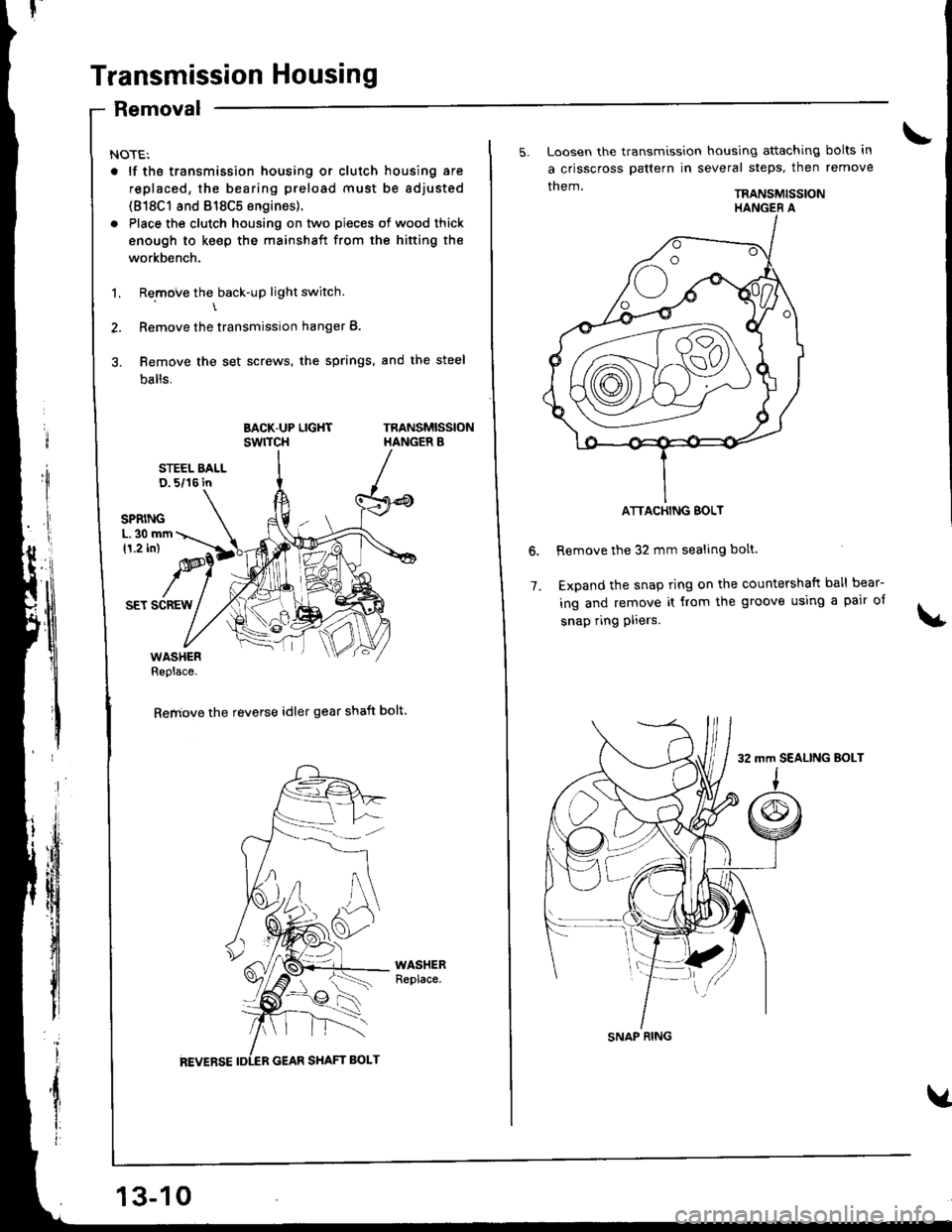

NOTE:

. lf tho transmission housing or clutch housing are

replaced, the bearing preload must be adjusted

(818C1 8nd 818C5 engines).

. Place the clutch housing on two pieces of wood thick

enough to keep the mainshaft from the hifting the

workbench.

1. Remove the back-up light switch.\

2. Remove the transmission hanger B.

3. Remove the set screws, the springs, and the steel

balls.

BACK-UP LIGHTswrTcHTRANSMISSIONHANGER B

STEEL BALLD. 5/16 in

SET SCREW

WASHERReplace.

Remove the reverse idler gear shaft bolt.

13-10

5. Loosen the transmission housing attaching bolts in

a crisscross pattern in several steps, then remove

them.TRANSMISSION

Remove the 32 mm sealing bolt.

Expand the snap ring on the countershaft ball bear-

ing and remove it from the groove using a pair of

snap ring pliers.

6.

7.

ATTACHING BOLT

SNAP RING

32 mm SEALING BoLT

Page 383 of 1681

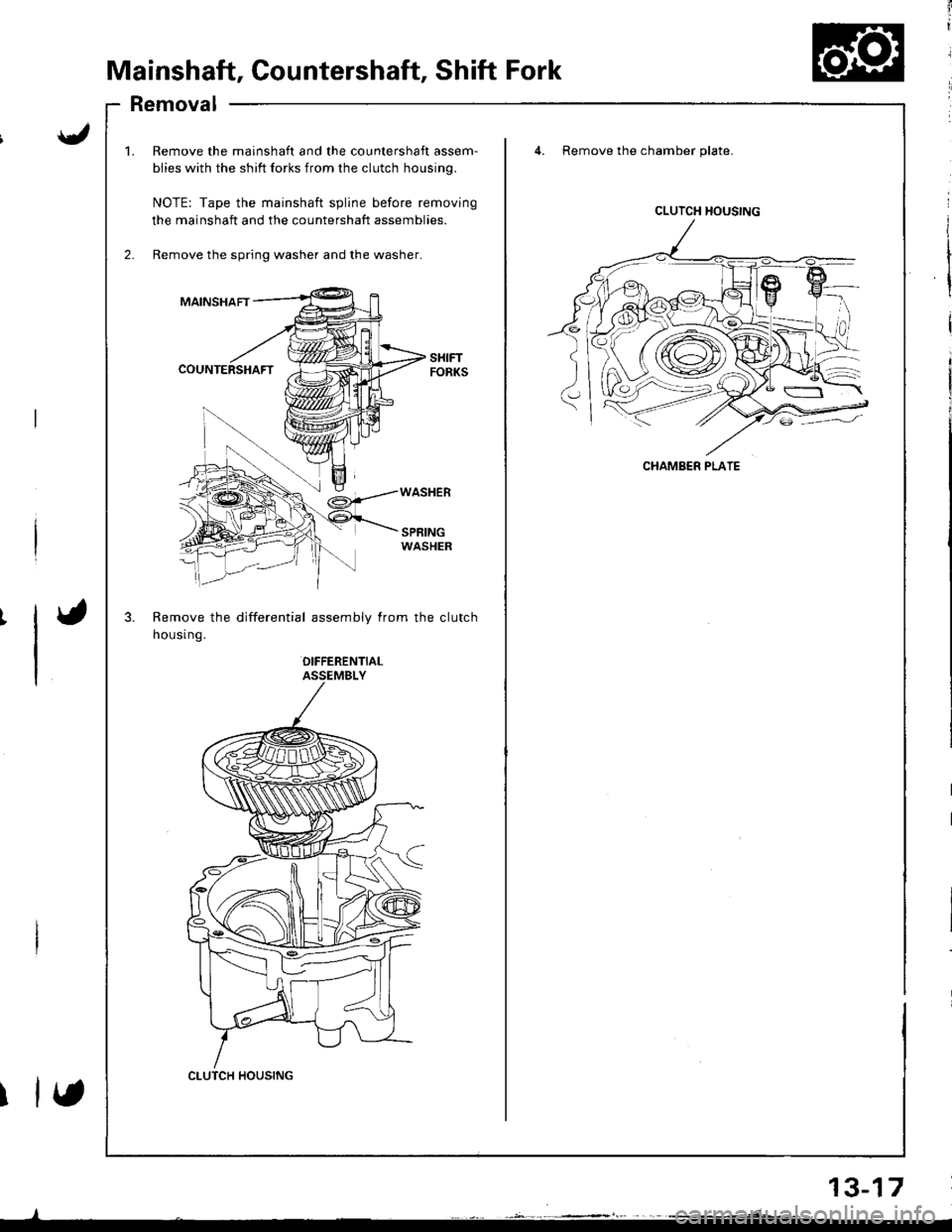

Mainshaft, Countershaft, Shift Fork

Removal

mainshaft and the countershaft assem-

? shift forks from the clutch housing.

the mainshaft spline before removing

ft and the countershaft assemblies.

spring washer and the washer.

differential assembly from the clutch

OIFFERENTIALASSEMBLY

4. Remove the chamber plate.

SPRINGWASHER

1.Remove the m€

biies with the sl

NOTE: Tape th

the mainshaft a

Remove the spr

MAINSHAFT

COUNTERSHAFT

Remove the

housr ng.

CLUTCH HOUSING

CLUTCH HOUSING

CHAMBER PLATE

etsY')

2r}5

(\cyl,//_\::iv/.

13-17

Page 418 of 1681

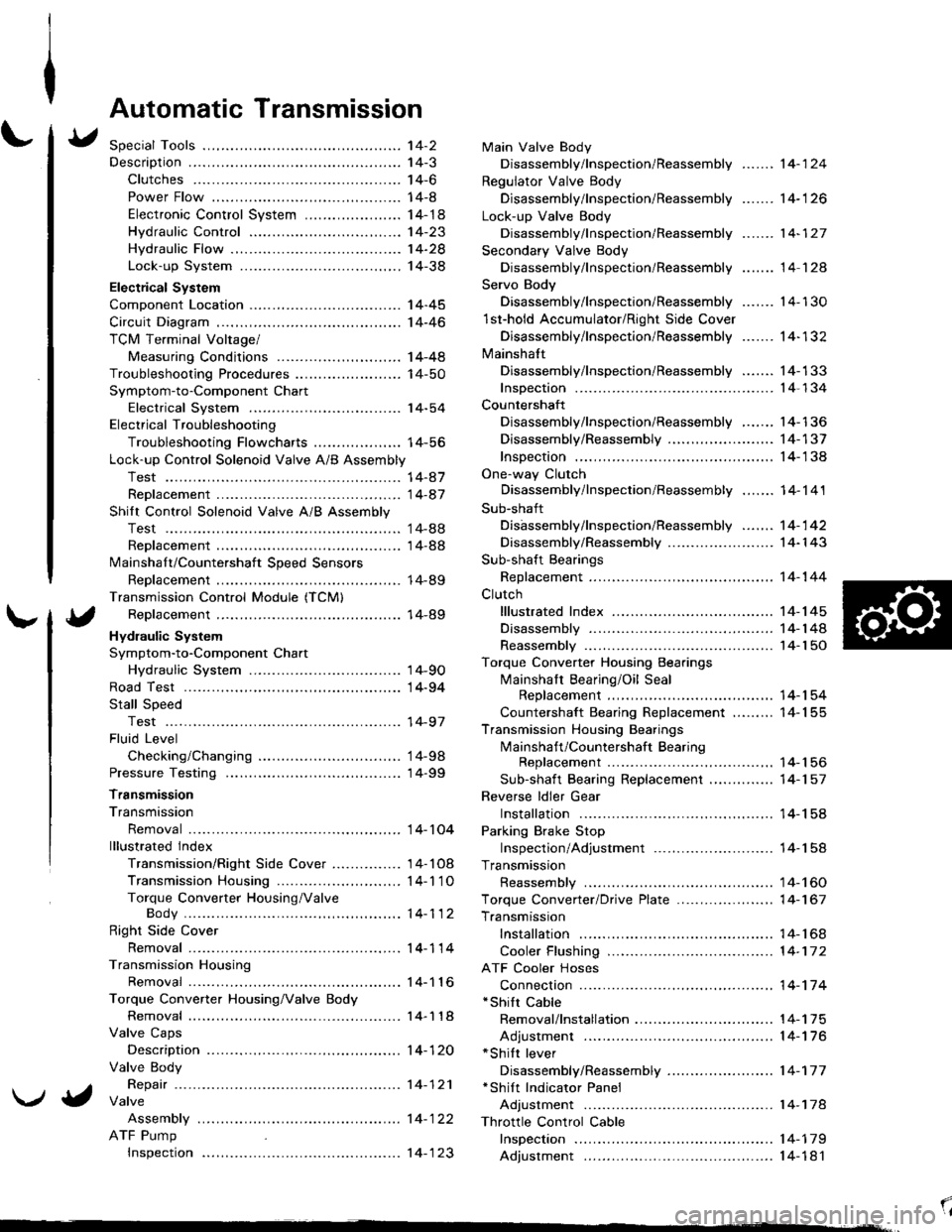

Automatic Transmission

Special Tools ................ '14-2

Descraption .................... 14-3

Clutches ............ ...... 14-6

Power Flow ..,........... 14-8

Electronic Control System ..................... 1 4-1 8

Hydraulic Control ...... 14-23

Hydraulic Flow .........- 14-28

Lock-up System ........ 14-38

Electrical System

Component Location -................................ 1 4-45

Circuit Diagram ............. 14-46

TCM Terminal Voltage/

Measuring Conditions ......,.................... 1 4-48

Troubleshooting Procedures .. . ... ........ ...... ... 14-50

Symptom-to-Component Chart

Electrical System ...... 14-54

Electrical Troubleshooting

Troubleshooting Flowcharts .......... ... ...,.. 14-56

Lock-up Control Solenoid Valve A/B Assembly

Test .................. ...... 14-A7

Replacement ............. 14-a7

Shilt Control Solenoid Valve A/B Assembly

Test .................. ...... '14-88

Replacement .,..,........ 14-88

lvlainshaf t/Countershaft Speed Sensors

Replacement ....-......,. 14-89

Transmission Control Module (TCM)

Replacement ............. 14-89

Hydraulic System

Symptom-to-Component Chart

Hydraulic System ...... 14-90

Road Test ,................... 14-94

Stall Speed

Test .................. ...... 14-97

Fluid Level

Checking/Changing .... 14-98

Pressure Testing ........... 14-99

Transmission

Transmission

Removal ............. ...... 14-10�4

lllustrated lndex

Transmission/Right Side Cover ............... 1 4-1 08

Transmission Housin9 ................,..,....... 1 4-1'1 O

Torque Converter Housing/ValveBody .................. .. 14-112

Right Side Cover

Removal ............. ...... 14-114

Transmission Housing

Removal ............. ...... 14-1 l6

Torque Converter Housing/Valve Body

Removal ............. ...... l4-1 18

Valve Caps

Description ...........-... 14-120

Valve Body

Repair ................ ...... 14-12'l

Valve

Assembly

ATF Pump

Inspeclton

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly

Secondary Valve Body

Disassembly/lnspection/Reassembly

Servo Body

....... 14-124

....... 14-126

....... 14-127

....... 14 124

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Cover

Disassembly/lnspection/Reassembly .......

Mainsha{t

14-130

14-132

Disassembly/lnspection/Reassembly ....... 14-133

Inspection ................. 14-134

Countershaft

Disassembly/lnspection/Reassembly,..,.., l4-136

Disassembly/Reassembly ..,...,..,.........,,.. 1 4-1 37

Inspection ......,...,..,... 14-138

One-way Clutch

Disassembly/lnspection/Reassembly ....,.. 14-141

Sub-shaft

Disassembly/lnspection/Reassembly ...,,..'14-142

Disassembly/Reassembly ....................... 1 4- l 43

Sub-shaft Bearings

Replacement ,..,,.,,..,.. 14-144

Clutch

lllustrated Index ................................... I 4-1 45

Disassembly ............. 14-144

Reassembly .............. 14-150

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Replacement ......... 14-154

Countershaft Bearing Replacement ......... 1 4- 1 55

Transmission Housing Bearings

Mainshaft/Countershaft BearingReplacement ......,.. 14-'156

Sub-shaft Bearing Replacement .,............ 1 4-1 57

Reverse ldler Gear

Installation .........-..... 14-158

Parking Brake Stop

Inspection/Adjustment .......................... 1 4-1 58

Transmission

Reassembly .............. 14-160

Torque Converler/Drive Plate ..............,.,,.,, 1 4-1 67

Transmission

Installation ............... 14-168

Cooler Flushing ......... 14-172

ATF Cooler Hoses

Connection ,..,,,....,,.,, '14-'174

*shift cable

Removal/lnstallation . . .. .... ... .... ... .... .. . ... .. 14-'l75

Adjustment ,..,...,,,,.,, 14-'116*Shilt lever

Disassembly/Reassembly ....................... 1 4-'17 7'Shift Indicator Panel

Adjustment .............. 14-178

\l

)g

Page 531 of 1681

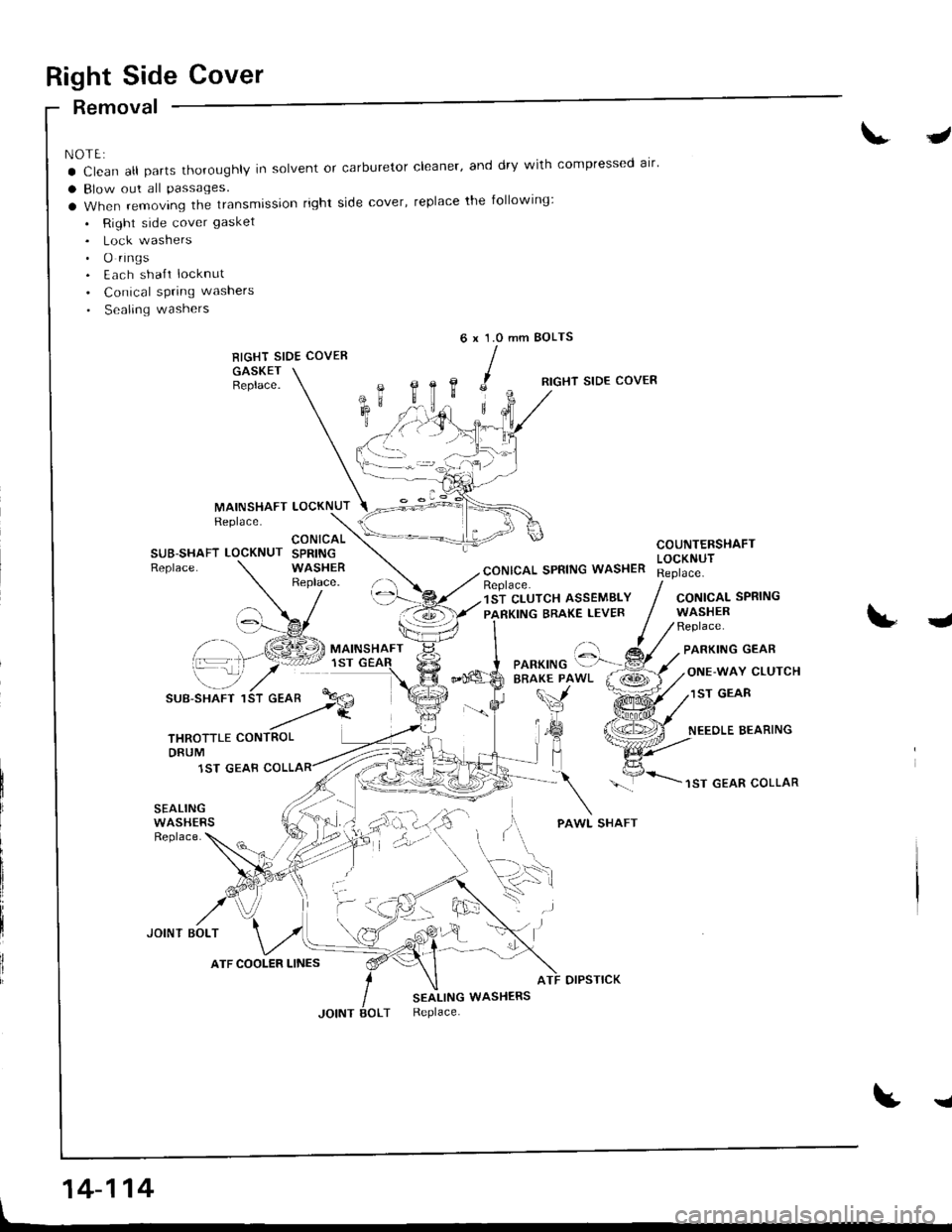

Right Side Cover

Removal

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner' and dry with compressed alr'

a Blow out all Passages.

a When removing the transmission right side cover, replace the following:

. Right side cover gasket

. Lock washers. O rings. Each sha{t locknut

. Conical spring washers

. Sealing washers

RIGHT SIDE COVER

GASKETBeplace.

J

mm BOLTS6x1.0

,c

B,

MAINSHAFTReplace.LOCKNUT

RIGHT SIDE COVER

CONICAL SPRING WASHER

COUNTERSHAFTLOCKNUTSUB-SHAFT LOCKNUTReplace.

CONICALSPRINGWASHERReplace.Replace.1ST CLUTCH ASSEMBLY

PARKING BRAKE LEVERCONICALWASHERReplace.

SPRING

J

\-_7

SUB-SHAFT 1

PARKING GEAR

ONE-WAY CLUTCH

1ST GEAR

NEEOLE BEARING

1ST GEAR COLLAR

SEALINGWASHERSReplace.

JOINT BOLT

otPsTtcK

SEALING WASHERSReplace.

t

'::-Pf.a

THROTTLE CONTROLDRUM

1ST GEAB

ATF COOLER LINES

'. .)

14-114

I

Page 603 of 1681

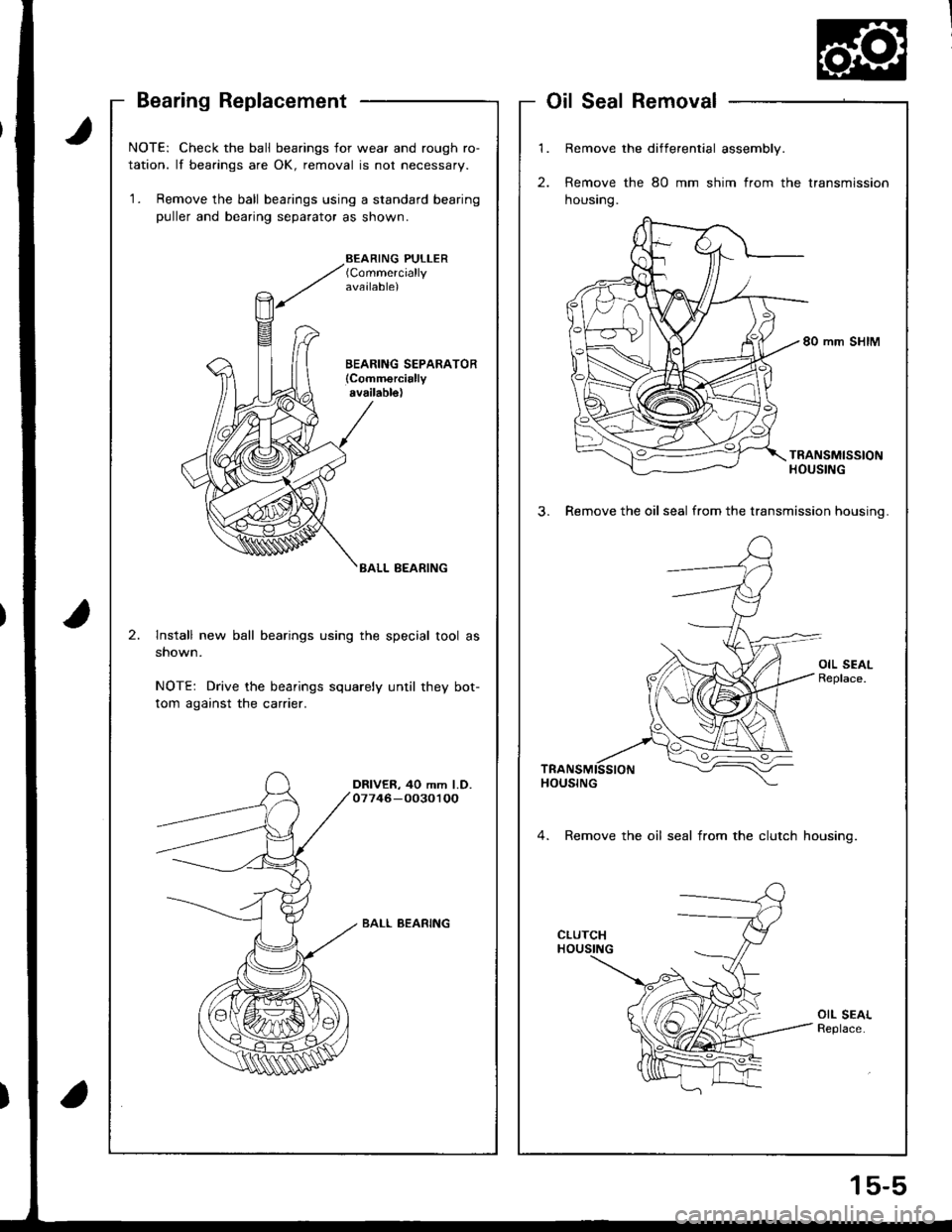

Bearing Replacement

t

a

NOTE: Check the ball bearings for wear and rough ro-

tation. lf bearings are OK, removal is not necessary.

'1. Remove the ball bearings using a standard bearing

puller and bearing separator as shown.

BEARING PULLER(Commercially

available)

BALL BEARING

2.lnstall new ball bearings using the special tool as

shown.

NOTE: Drive the bearings squarely until they bot-

tom against the carrier.

DRIVER, 40 mm l.D.07746-00301OO

BALL BEARING

't.

2.

Remove the differential assembly.

Remove the 80 mm shim from the transmission

housrng.

80 mm SHIM

TRANSMISSIONHOUSING

3. Remove the oil seal from the transmission housinq.

4. Remove the oil seal from the clutch housinq.

OIL SEALReplace.

SealRemoval

1s-5

Page 609 of 1681

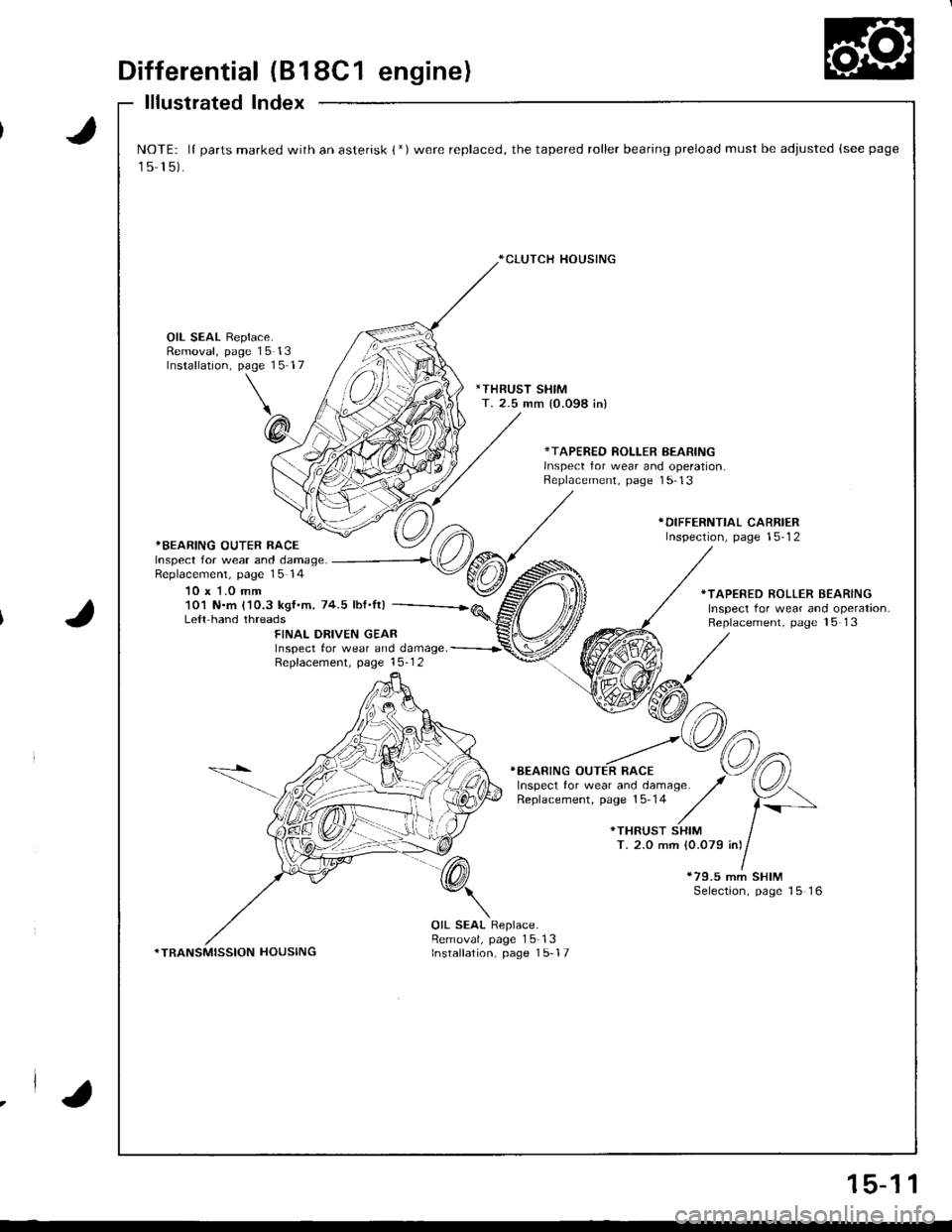

Differential (B18C1 engine)

lllustrated Index

J

J

NOTE: lI parts marked with an asterisk {*)were replaced, the tapered roller bearing preload must be adjusted (see page

15 15).

*CLUTCH HOUSING

OIL SEAL Replace.Removal, page 15 13Installation, page 15 17

*THRUST SHIMT. 2.5 mm {0.098 in)

*TAPERED ROLLER BEARINGlnsDect for wear and ooeration.Replacement, page 1 5-13

*BEARING OUTER RACEInspect for wear and damage.Replacemenl, page 15 14

10 x 1.0 mm

*DIFFERNTIAL CARRIERInspection, page 15-12

101 N.m {'10.3 kgf.m, 74.5 lbf.It)Le{t hand threads

*TAPERED ROLLER BEARINGInspect tor wear and operation.Replacement, page 15 13FINAL DRIVEN GEARInspect tor wear and damage. -----------r'

Repfacement. page 15-1 2

}BEARING OUTER RACE

*79.5 mm SHIMSelection, page 15 16

*TRANSMISSION HOUSING

OIL SEAL Replace.Removal, page 15-13Installation, page 1 5-17

.la

15-1 1

Page 611 of 1681

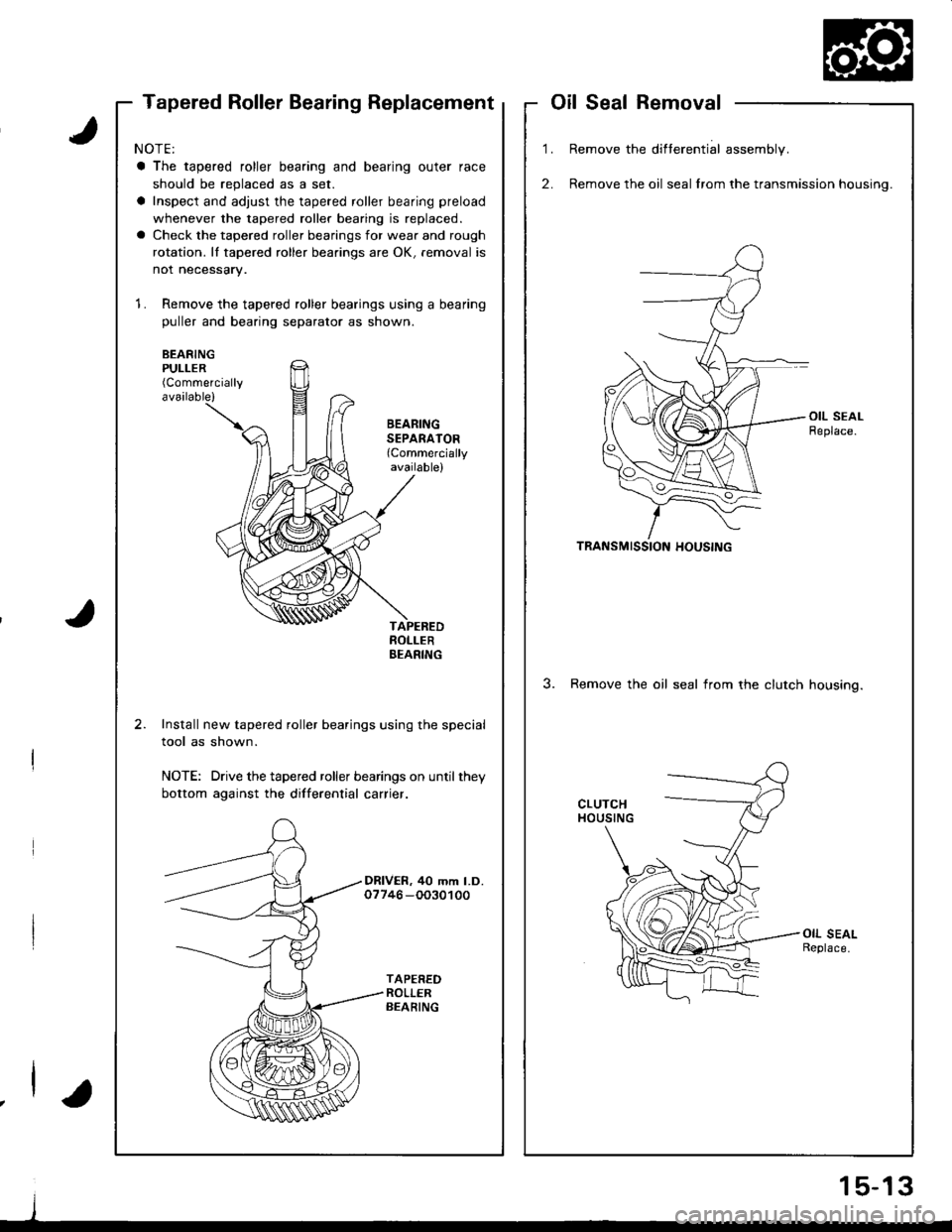

Tapered Roller Bearing ReplacementoilSealRemoval

1.

2.

Remove the difterential assembly.

Remove the oil seal lrom the transmission housing.

TRANSMISSION HOUSING

3. Remove the oil seal irom the clutch housino.

NOTE:

a The tapered roller bearing and bearing outer race

should be replaced as a set.

a Inspect and adjust the tapered roller bearing preload

whenever the tapered roller bearing is replaced.

a Check the tapered roller bearings for wear and rough

rotation. lI tapered roller bearings are OK, removal is

not necessary.

1. Remove the tapered roller bearings using a bearing

puller and bearing separator as shown.

BEARINGPULLER(Commercially

available)

BEARINGSEPARATOR(Commercially

available)

Install new tapered roller bearings using the special

tool as shown.

NOTE: Drive the tapered roller bearings on until they

bottom against the dillerential carrier.

DRIVER, 40 mm LD.07746 -OO30100

j

1 5-13

Page 1051 of 1681

J

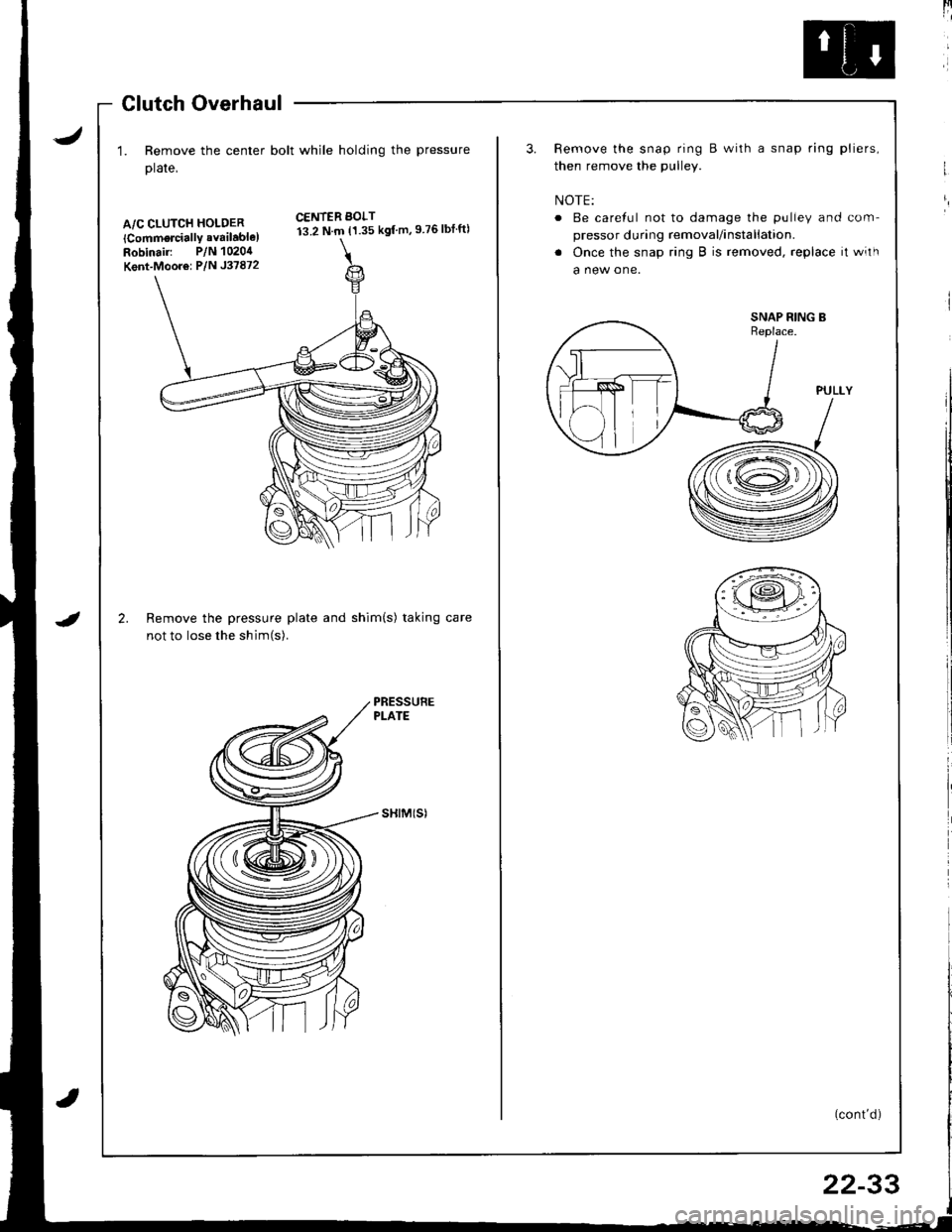

Glutch Overhaul

1. Remove the center bolt while holding the pressure

plate,

A/C CLUTCH HOLDER

lCommorcially available)Robinair: P/N 1020,1

Kent-Moor6: P/N J37872

2.

CENTER BOLT13.2 N.m {1.35 kgf m,9 76lbtft)

IRemove the pressure plate and shim(s) taking

not to lose the shim(s).

sHtM(sl

[4

3. Remove the snap ring B with a snap ring pliers,

then remove the pulley.

NOTE:

o Be careful not to damage the pulley and com-

pressor during removal/installation.

. Once the snap ring B is removed, replace it with

a new one.

(cont'd)

I

/ T-\vr= ...--.-

-ffitll---.\lr l,

\-l I .v

22-33

Page 1052 of 1681

Compressor

a

a

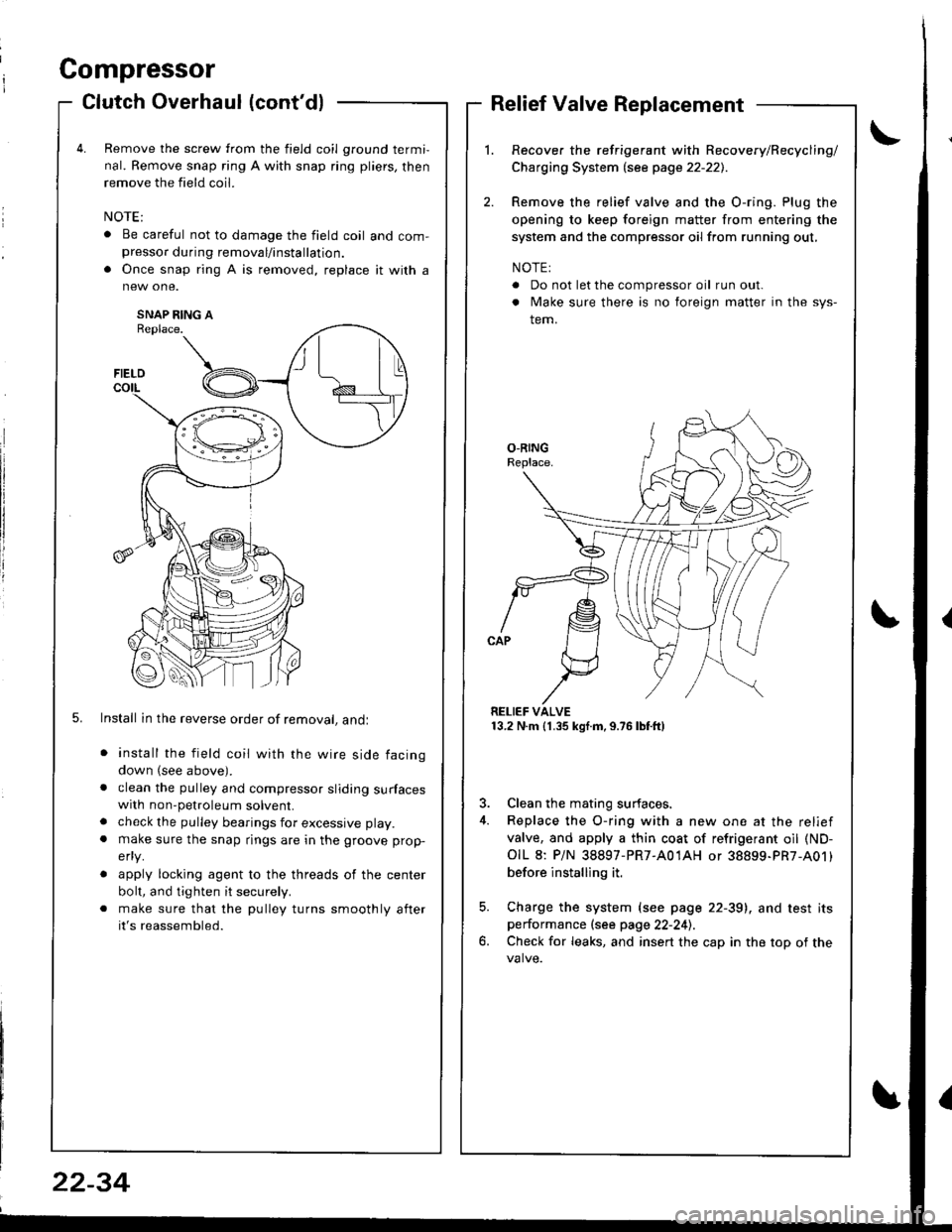

Clutch Overhaul (cont'dl

Remove the screw from the field coil ground termi,

nal. Remove snap ring A with snap ring pliers, then

remove the field coil.

. Be careful not to damage the field coil and com-presso. during removal/installation.

. Once snap ring A is removed, replace it with a

SNAP RING AReplace.

5. Install in the reverse order of removal, andl

install the field coil with the wire side facing

down (see above).

clean the pulley and compressor sliding surfaceswith non-petroleum solvent.

check the pulley bearings for excessive play.

make sure the snap rings are in the groove prop-

efly.

apply locking agent to the threads of the center

bolt, and tighten it securely.

make sure that the pulley turns smoothly after

it's reassembled.

Relief Valve Replacement

Recover the refrigerant with Recovery/Recycling/

Charging System lsee page 22-221.

Remove the relief valve and the O-ring. Plug the

opening to keep foreign matter from entering the

system and the compressor oil from running out,

NOTE:

. Do not let the compressor oil run out.

. Make sure there is no foreign matter in the sys-

tem.

RELIEF VALVE13.2 N.m (1.35 kgf.m,9.76lbtft)

3. Clean the mating surfaces.

4. Replace the O-ring with a new one at the relief

valve, and apply a thin coat of refrigerant oil (ND-

OIL 8: P/N 38897-PR7-A01AH or 38899-PR7-A01)

before installing it.

5. Charge the system (see page 22-39), and test itsperformance (see page 22-241.

6. Check for leaks, and insert the cap in the top of the

FIELD

t\I lu

B _t_:---\-lr

\,/

22-34