Transmission removal HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 521 of 1681

Transmission

Removal

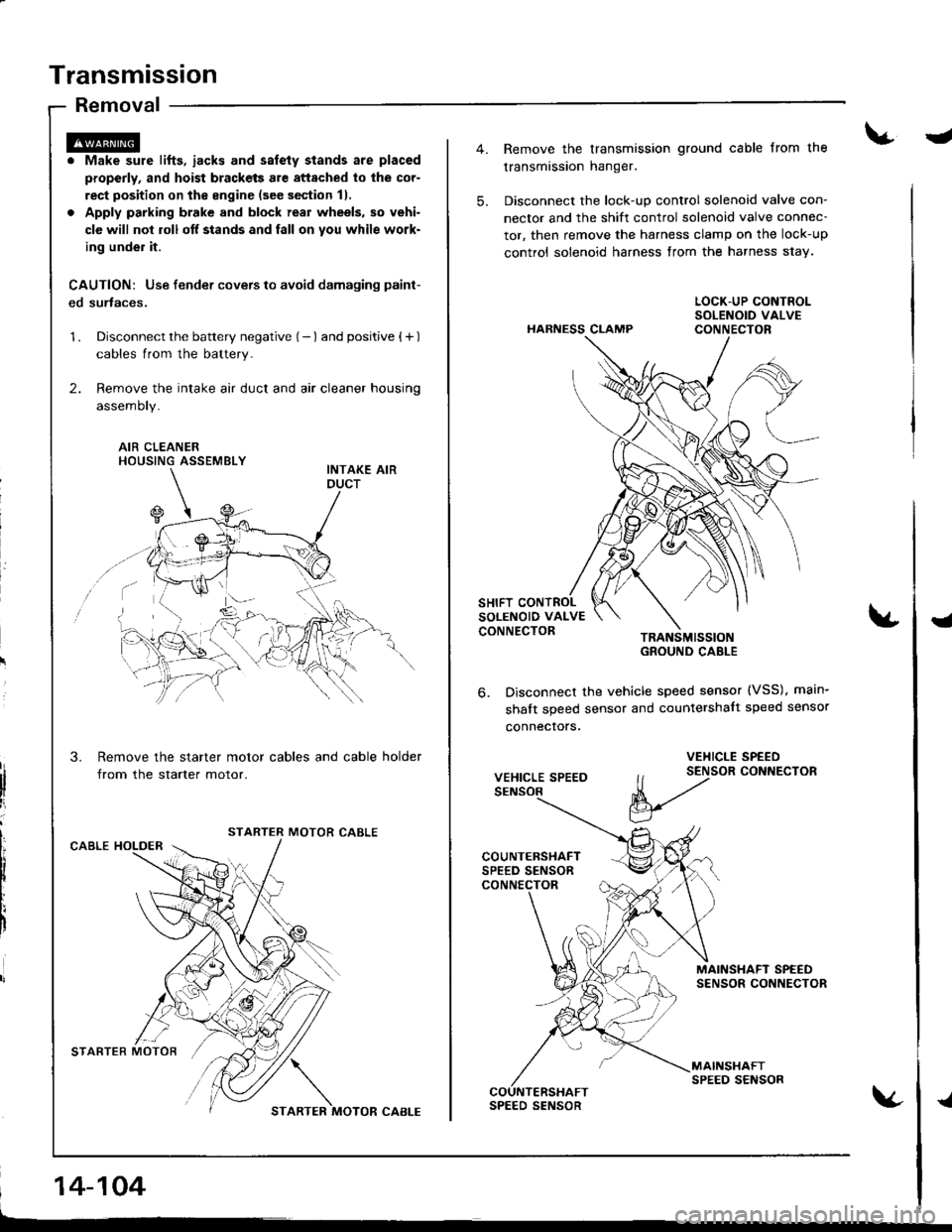

. Make sure lifts, iacks and salety stands are placed

properly, and hoist brackets are attached to lhe cor-

rect position on the engine (see section 11.

. Apply parking brake and block real wheels, so vehi-

cle will nol roll off stands and fall on you while work-

ing under it.

CAUTION: Use fender covers to avoid damaging paint-

ed surtaces.

1 . Disconnect the battery negative (- ) and positive { + )

cables from the battery.

2. Remove the intake air duct and air cleaner housing

assemoty.

AIR CLEANERHOUSING ASSEMBLY

Remove the starter motor cables and cable holder

from the starter motor.

MOTOR CABLECABLE HOLDER

STARTER MOTOR'/,/ \

STARTER MOTOR CABI-E

14-104

-

5.

Remove the transmission ground cable from the

transmission hanger.

Disconnect the lock-up control solenoid valve con-

nector and the shift control solenoid valve connec-

tor, then remove the harness clamp on the lock-up

control solenoid harness from the harness s1ay.

HARNESS CLAMP

TRANSMISSIOIGROUND CABLE

Disconnect the vehicle speed sensor (VSS), main-

shalt speed sensor and countershalt speed sensor

connecrors.

{

6.

VEHICLE SPEED

VEHICLE SPEED

ll t2tor coNNEcroR

V

MAINSHAFT SPEEDSENSOR CONNECTOR

MAINSHAFTSPEED SENSORCOUNTERSHAFTSPEED SENSOR{

Page 523 of 1681

Transmission

Removal (cont'd)

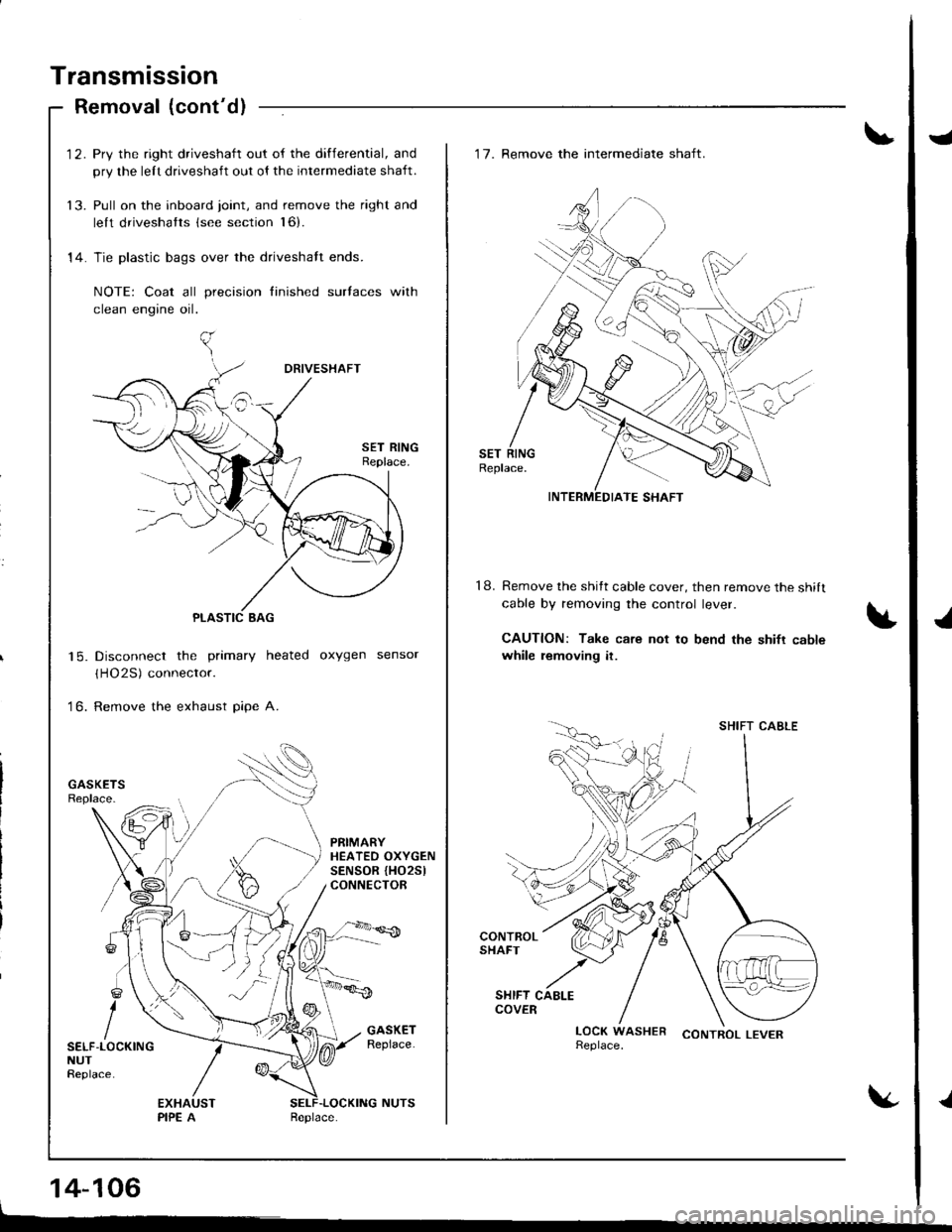

'12. Pry the right driveshaft out of the differential, and

pry the lelt driveshaft out ol the intermediate shaft.

13. Pull on the inboard joint, and remove the right and

lelt driveshatts (see section l6).

14. Tie plastic bags over the driveshalt ends.

NOTE: Coat all precision finished surlaces with

clean engine oil.

Disconnect the primary heated oxygen sensor

(HO2S) connector.

Remove the exhaust pipe A.

| 5.

to.

PRIMARYHEATEO OXYGENSENSOR {HO25lCONNECTOR

SELF-LOCKINGNUTReplace.

14-106

J

J

.l

18.

'17. Remove the intermediate shaft.

Remove the shitt cable cover, then remove the shilt

cable by removing the control lever.

CAUTION: Take care not to bend the shifr cablewhile removing it.

CONTROL LEVER

INTERMEDIATE SHAFT

SHIFT CABLE

Page 531 of 1681

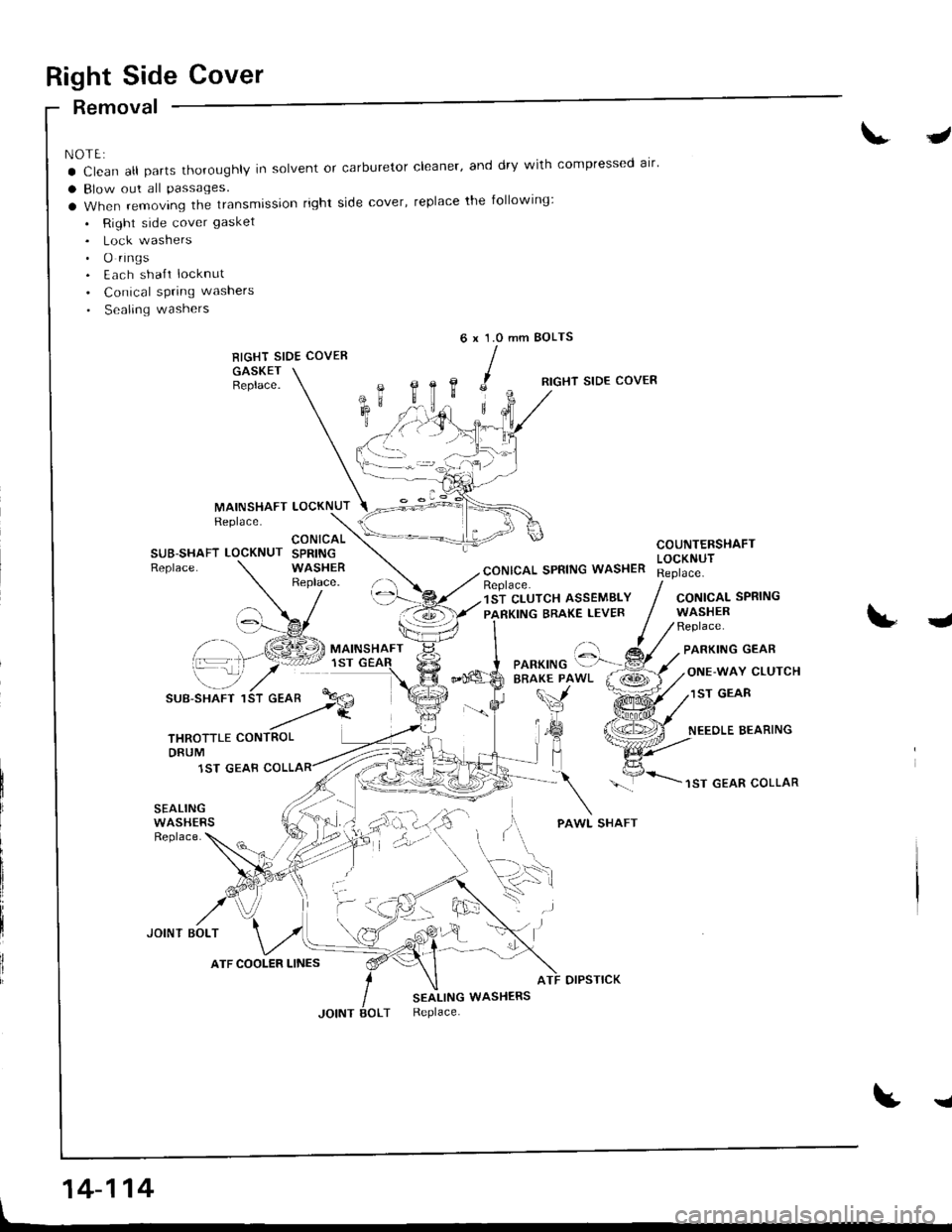

Right Side Cover

Removal

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner' and dry with compressed alr'

a Blow out all Passages.

a When removing the transmission right side cover, replace the following:

. Right side cover gasket

. Lock washers. O rings. Each sha{t locknut

. Conical spring washers

. Sealing washers

RIGHT SIDE COVER

GASKETBeplace.

J

mm BOLTS6x1.0

,c

B,

MAINSHAFTReplace.LOCKNUT

RIGHT SIDE COVER

CONICAL SPRING WASHER

COUNTERSHAFTLOCKNUTSUB-SHAFT LOCKNUTReplace.

CONICALSPRINGWASHERReplace.Replace.1ST CLUTCH ASSEMBLY

PARKING BRAKE LEVERCONICALWASHERReplace.

SPRING

J

\-_7

SUB-SHAFT 1

PARKING GEAR

ONE-WAY CLUTCH

1ST GEAR

NEEOLE BEARING

1ST GEAR COLLAR

SEALINGWASHERSReplace.

JOINT BOLT

otPsTtcK

SEALING WASHERSReplace.

t

'::-Pf.a

THROTTLE CONTROLDRUM

1ST GEAB

ATF COOLER LINES

'. .)

14-114

I

Page 533 of 1681

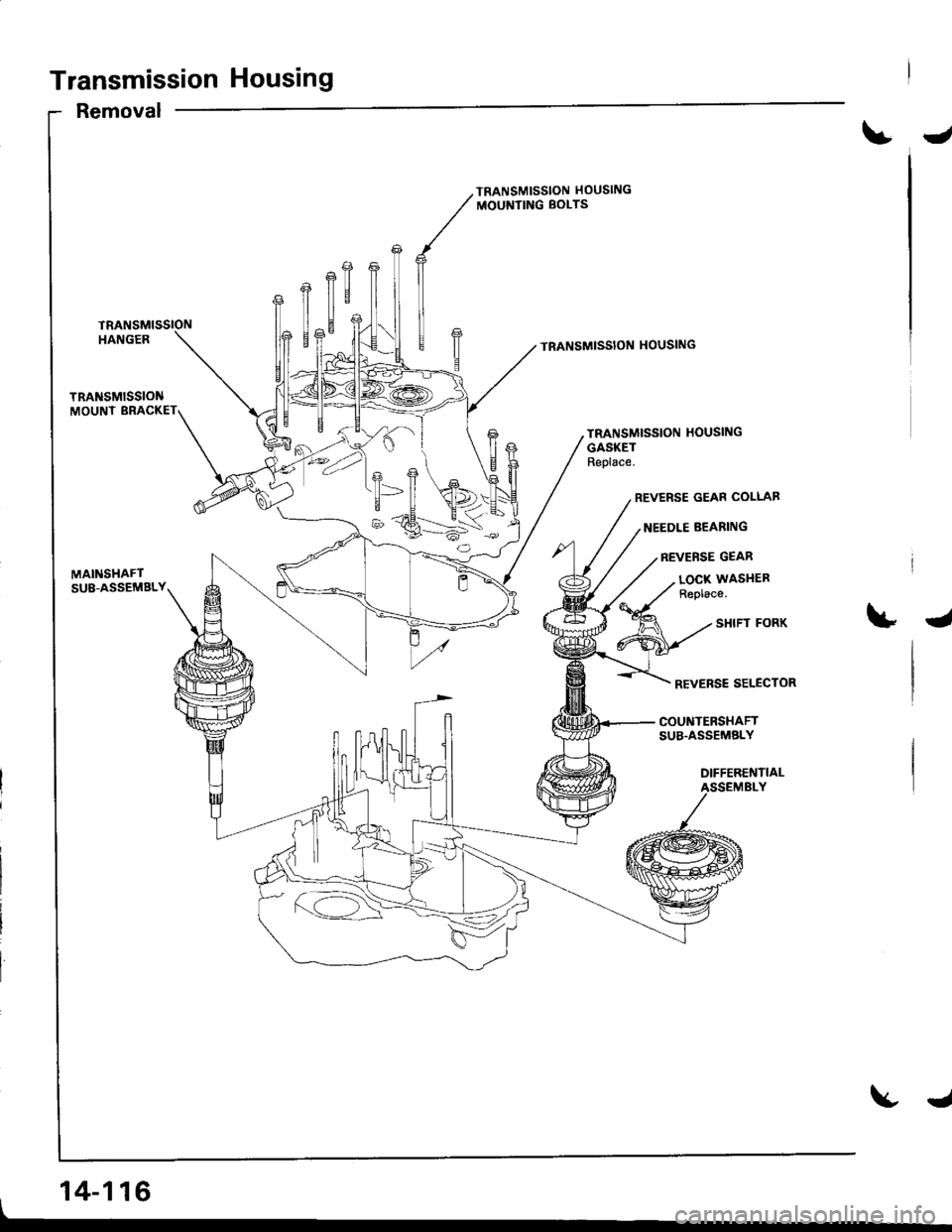

Transmission Housing

Removal

J

TRANSMISSION HOUSING

MOUNTING BOLTS

TRANSMISSION HOUSING

TRANSMISSION HOUSING

GASKETReplace.

REVERSE GEAR COLLAB

NEEDLE BEARING

REVERSE GEAR

MAINSHAFTSU8-ASSEMBLY

, 14-116

LOCX WASITEFReplace.

4

REVERSE SELECTOR

COUNTERSHAFTSUB.ASSEMELY

DIFFERENTIALASSEMBLY

J

Page 573 of 1681

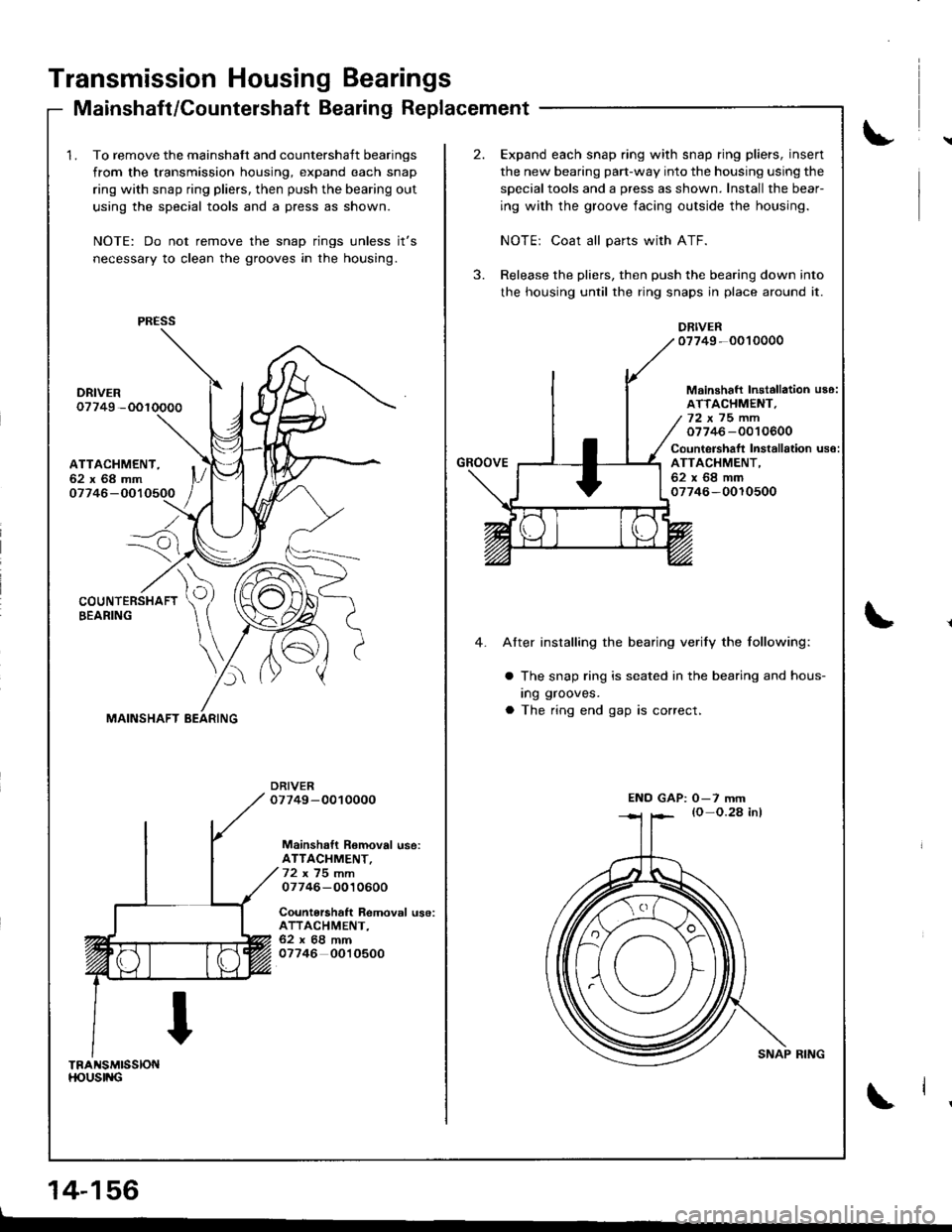

Transmission Housing Bearings

Mainshaft/Countershaft Bearing Replacement

1, To remove the mainshaft and countershaft bearings

from the transmission housing, expand each snap

ring with snap ring pliers, then push the bearing out

using the special tools and a press as shown.

NOTE: Do not remove the snap rings unless it's

necessary to clean the grooves in the housing.

DRIVER07749 -OOrOO00

ATTACHMENT,62x68mm

I07746-OO1

--_-e;

)

Mainshaft Romoval use:ATTACHMENT,

07746-0010600

Countarshaft Removal use:ATTACHMENT,62x68mm07746 0010500

TFAr{SMTSSIONT|oUSING

,,',zs>.\

/qnH

\1b22

PRESS

MAINSHAFT BEARING

2.Expand each snap ring with snap ring pliers, insert

the new bearing part-way into the housing using the

soecialtools and a oress as shown. Install the bear

ing with the groove facing outside the housing.

NOTE: Coat all parts with ATF.

Release the pliers, then push the bearing down into

the housing until the ring snaps in place around it.

DRIVER07749-0010000

Mainshafl Installation u86:ATTACHM€NT.72x75mm07746 -0010600

Countershaft Installation use:ATTACHMENT,62x68mm07746-0010500

GROOVE

4. After installing the bearing verify the following:

a The snap ring is seated in the bearing and hous-

Ing grooves.

a The ring end gap is correct.

SNAP RING

END GAP: O-7 mm

L

14-156

Page 603 of 1681

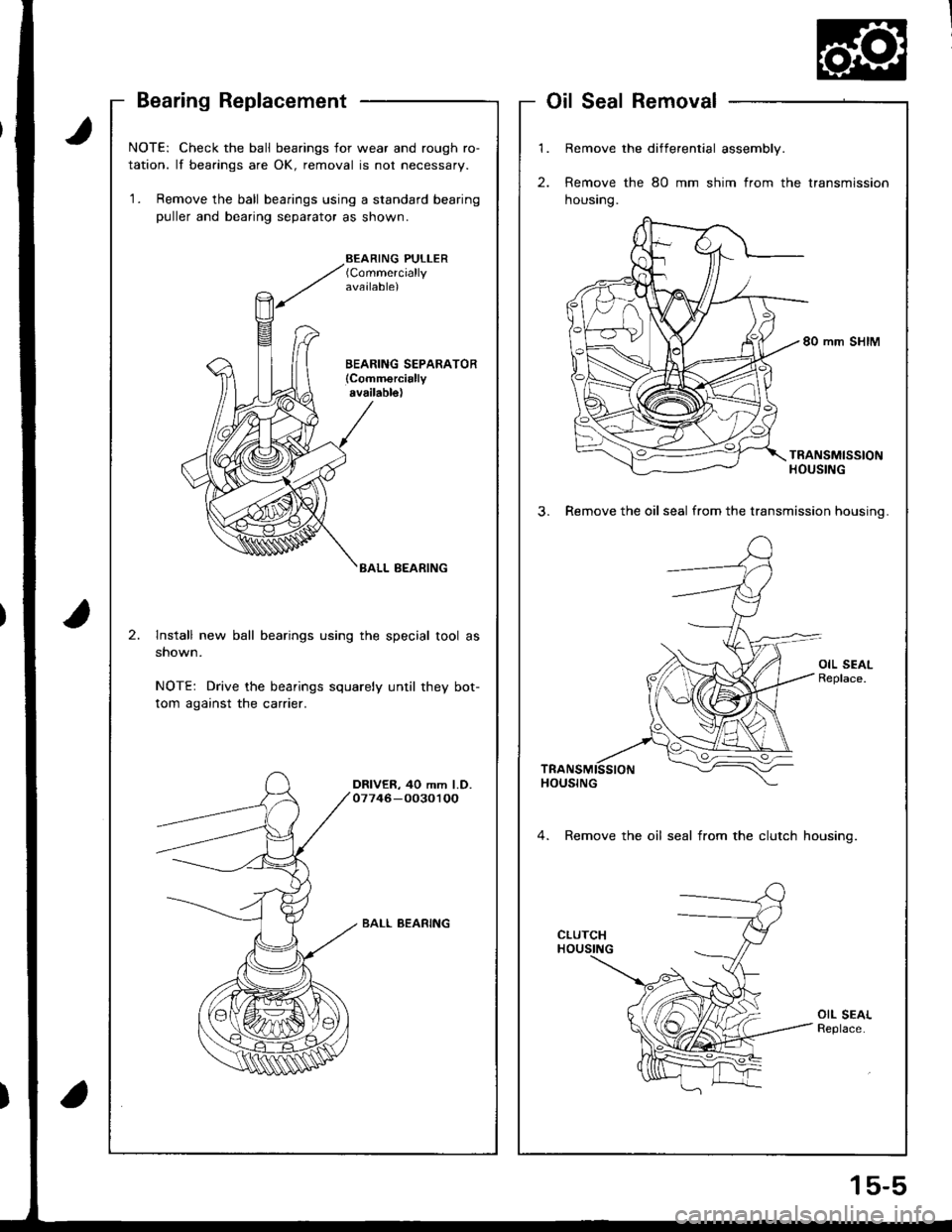

Bearing Replacement

t

a

NOTE: Check the ball bearings for wear and rough ro-

tation. lf bearings are OK, removal is not necessary.

'1. Remove the ball bearings using a standard bearing

puller and bearing separator as shown.

BEARING PULLER(Commercially

available)

BALL BEARING

2.lnstall new ball bearings using the special tool as

shown.

NOTE: Drive the bearings squarely until they bot-

tom against the carrier.

DRIVER, 40 mm l.D.07746-00301OO

BALL BEARING

't.

2.

Remove the differential assembly.

Remove the 80 mm shim from the transmission

housrng.

80 mm SHIM

TRANSMISSIONHOUSING

3. Remove the oil seal from the transmission housinq.

4. Remove the oil seal from the clutch housinq.

OIL SEALReplace.

SealRemoval

1s-5

Page 609 of 1681

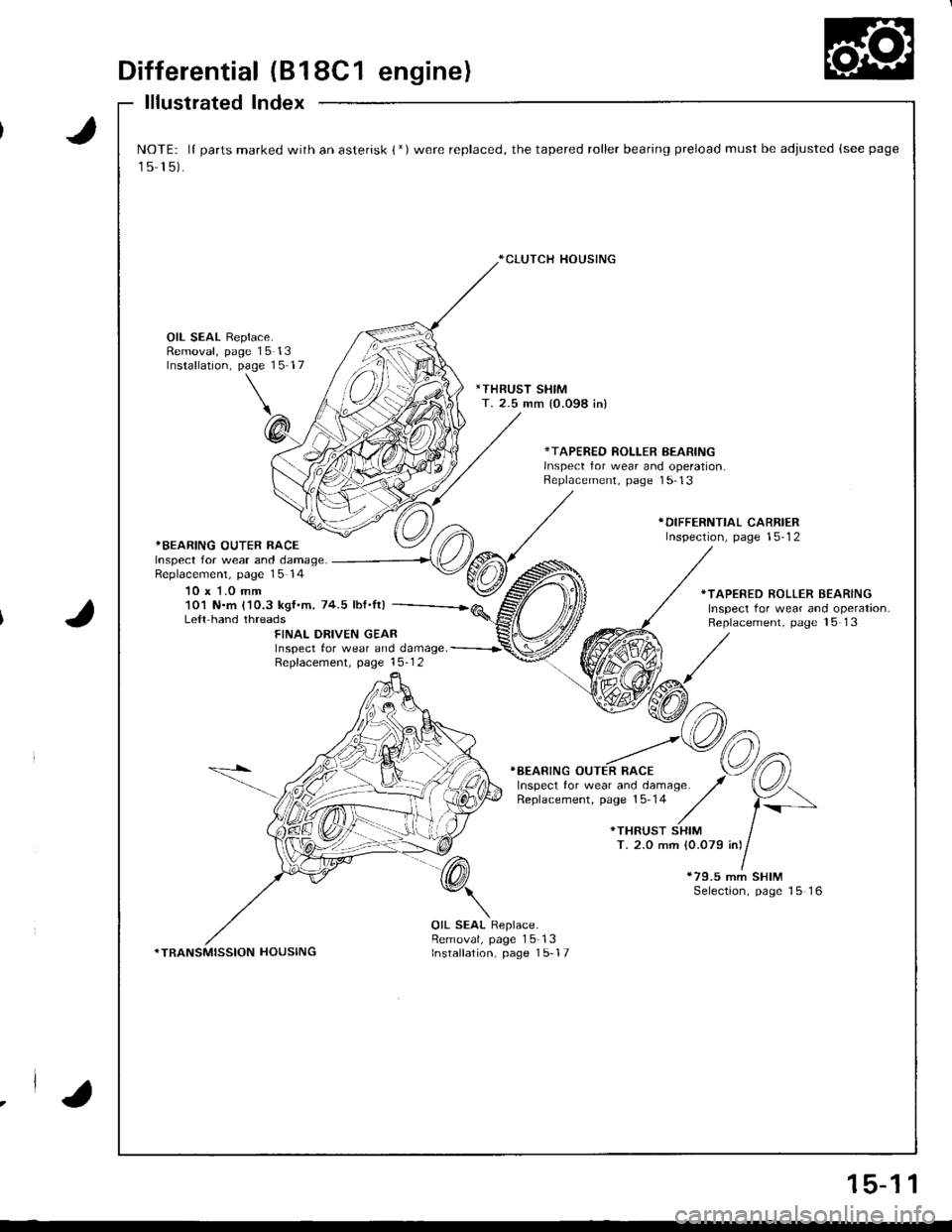

Differential (B18C1 engine)

lllustrated Index

J

J

NOTE: lI parts marked with an asterisk {*)were replaced, the tapered roller bearing preload must be adjusted (see page

15 15).

*CLUTCH HOUSING

OIL SEAL Replace.Removal, page 15 13Installation, page 15 17

*THRUST SHIMT. 2.5 mm {0.098 in)

*TAPERED ROLLER BEARINGlnsDect for wear and ooeration.Replacement, page 1 5-13

*BEARING OUTER RACEInspect for wear and damage.Replacemenl, page 15 14

10 x 1.0 mm

*DIFFERNTIAL CARRIERInspection, page 15-12

101 N.m {'10.3 kgf.m, 74.5 lbf.It)Le{t hand threads

*TAPERED ROLLER BEARINGInspect tor wear and operation.Replacement, page 15 13FINAL DRIVEN GEARInspect tor wear and damage. -----------r'

Repfacement. page 15-1 2

}BEARING OUTER RACE

*79.5 mm SHIMSelection, page 15 16

*TRANSMISSION HOUSING

OIL SEAL Replace.Removal, page 15-13Installation, page 1 5-17

.la

15-1 1

Page 611 of 1681

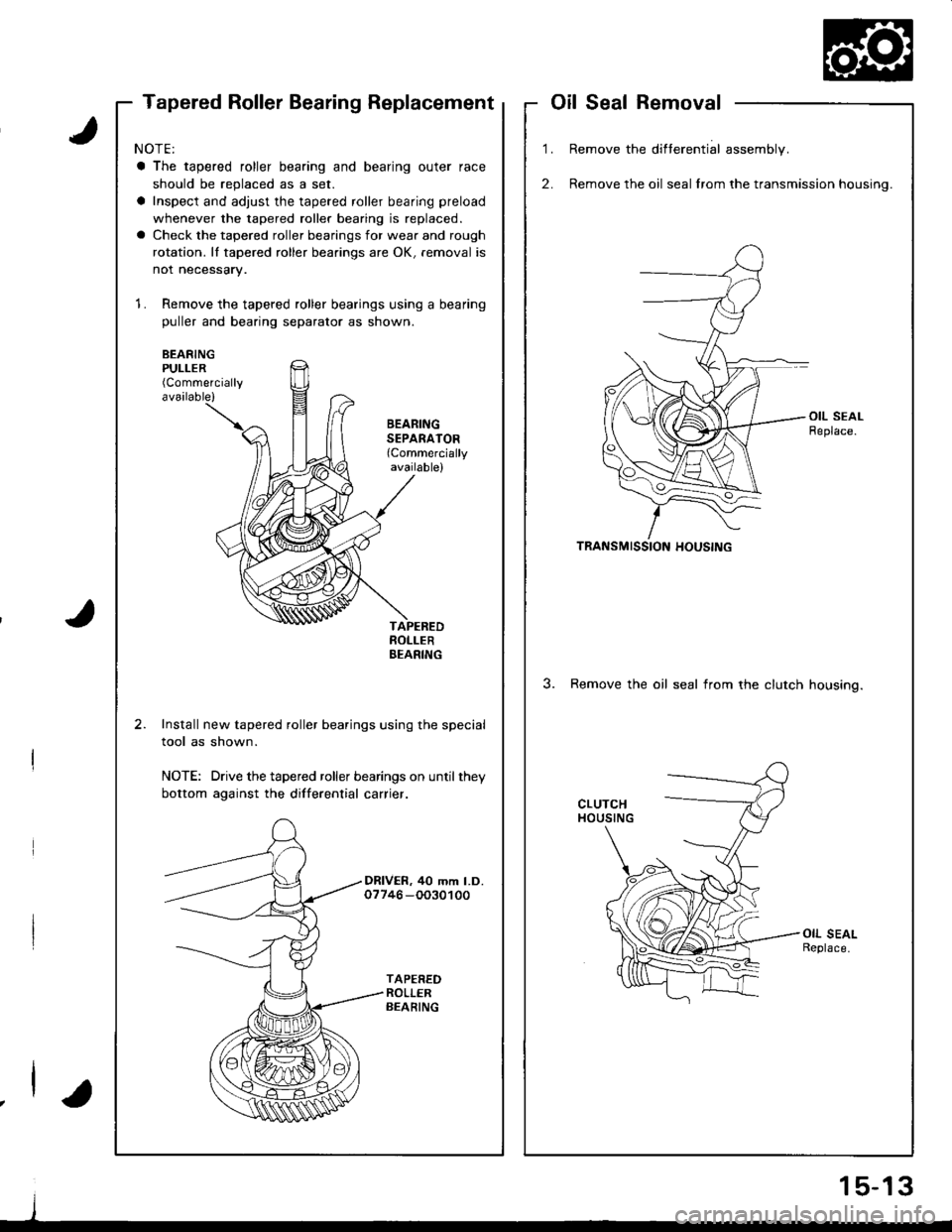

Tapered Roller Bearing ReplacementoilSealRemoval

1.

2.

Remove the difterential assembly.

Remove the oil seal lrom the transmission housing.

TRANSMISSION HOUSING

3. Remove the oil seal irom the clutch housino.

NOTE:

a The tapered roller bearing and bearing outer race

should be replaced as a set.

a Inspect and adjust the tapered roller bearing preload

whenever the tapered roller bearing is replaced.

a Check the tapered roller bearings for wear and rough

rotation. lI tapered roller bearings are OK, removal is

not necessary.

1. Remove the tapered roller bearings using a bearing

puller and bearing separator as shown.

BEARINGPULLER(Commercially

available)

BEARINGSEPARATOR(Commercially

available)

Install new tapered roller bearings using the special

tool as shown.

NOTE: Drive the tapered roller bearings on until they

bottom against the dillerential carrier.

DRIVER, 40 mm LD.07746 -OO30100

j

1 5-13

Page 624 of 1681

Differential (Automatic Transmission)

Speciaf Tools ........... ..........15-2A

Differential (Automatic Transmissionl

lllustrated Index .......... .. 15-29

Backlash Inspection ...... 15-30

Bearing Rep|acement ......................... I 5-30

Differential Carrier Replacement ...... l5-31

Oil SealRemoval ........... 15-32

Oil Seal Installation/

Side G|earance ................................. 1 5-32

Page 627 of 1681

Differential (Automatic Transmissionl

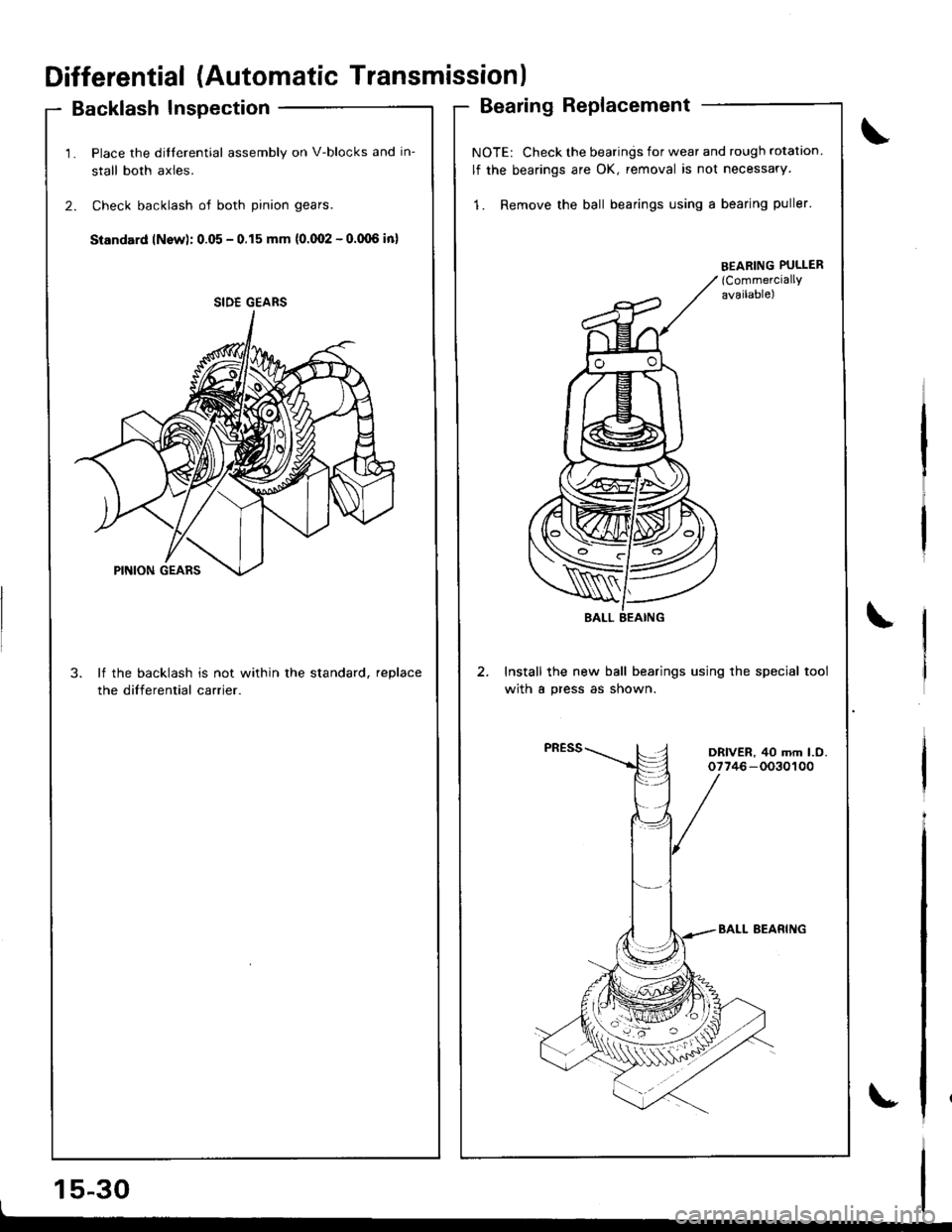

Backlash Inspection

1. Place the dilferential assembly on V-blocks and in-

stall both axles.

2. Check backlash of both pinion gears.

Standard lNsw): 0.05 - 0.15 mm {0.(Xt2 - o.(Xl6 in)

3. lf the backlash is not within the standard, reDlace

the differential carrier.

15-30I

Bearing Replacement

NOTE: Check the bearings for wear and rough rotation

lf the bearings are OK, removal is not necessary.

1. Remove the ball bearings using a bearing puller'

Install the new ball bearings using the special tool

with a press as shown.

SIDE GEARS

EEABING PULLER(CommerciallY

available)

\

DRIVER, 40 mm l.O.07746-0030100